Lock bead type vibration isolation bumper without harmonic peaks in three directions

A technology without resonance and buffer, applied in the direction of shock absorber, friction shock absorber, shock absorber, etc., can solve the problems of unsatisfactory, easy to wear high frequency vibration isolation effect, etc., to achieve easy adjustment, improve high frequency Resonant peak vibration isolation ability, the effect of realizing buffer requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

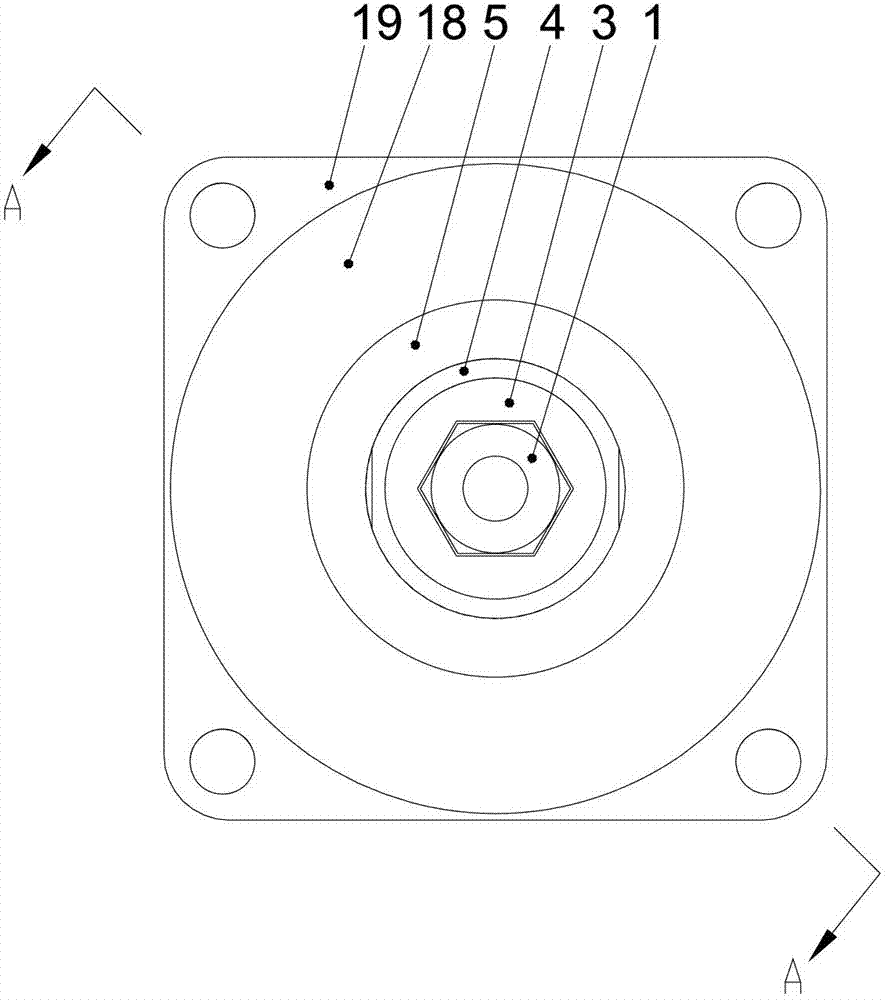

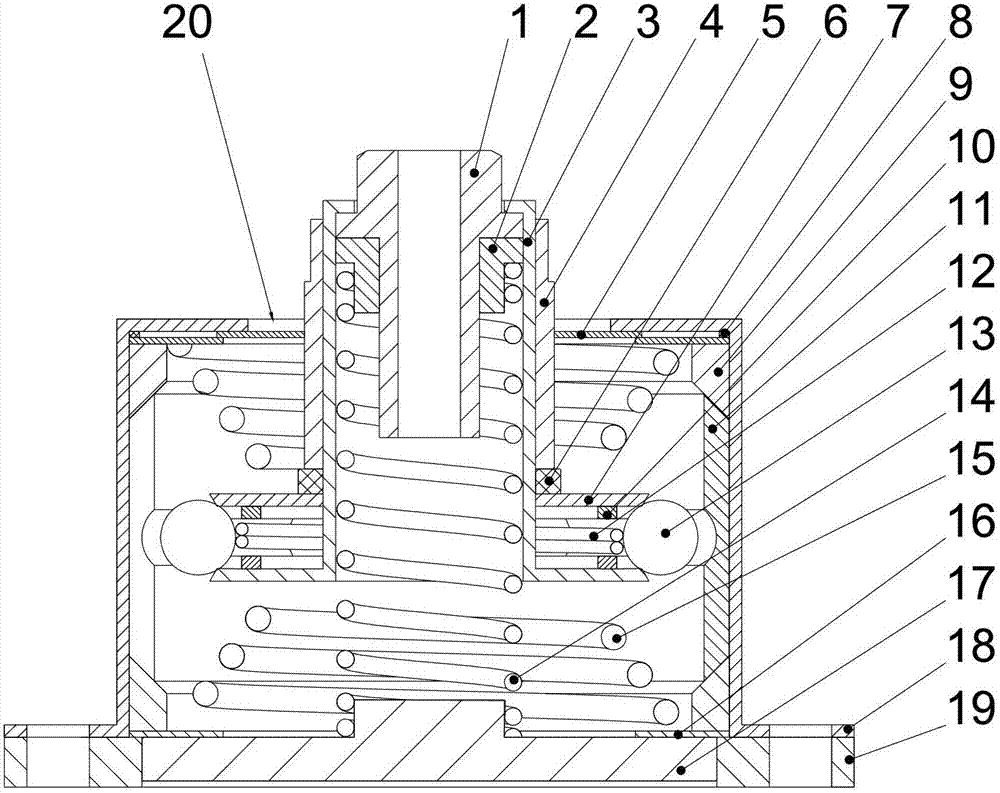

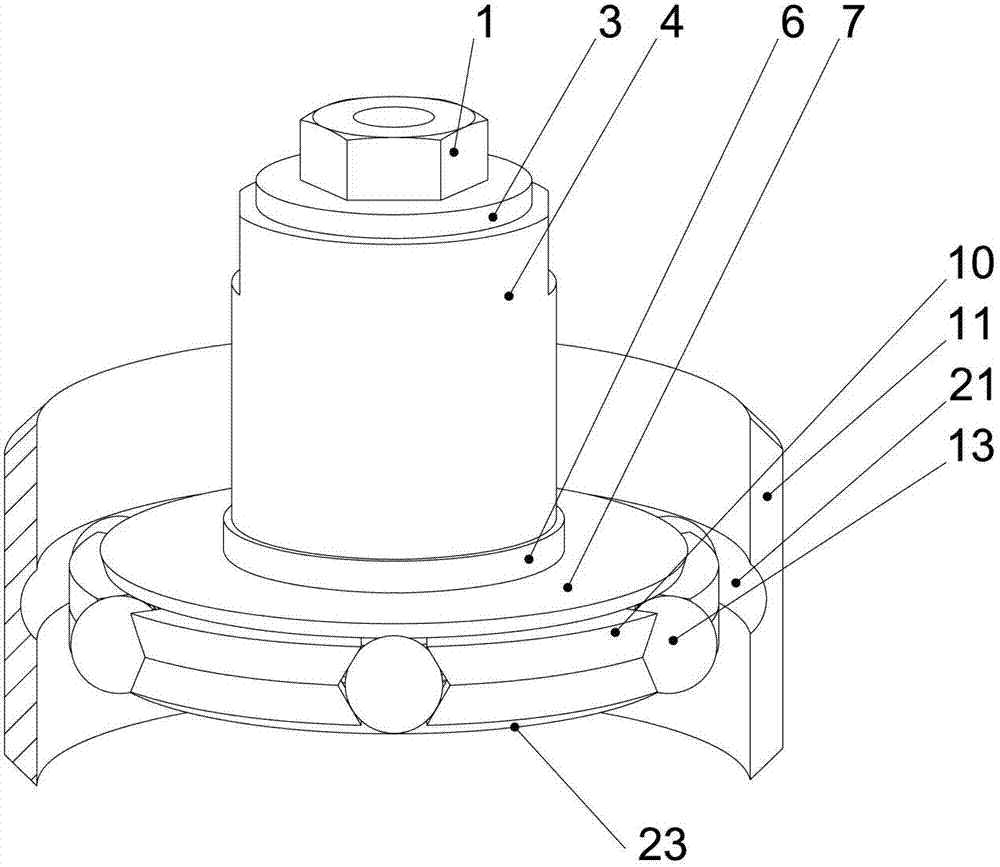

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings, such as Figures 1 to 11 Shown: the ball-locking three-way non-resonant peak vibration isolation buffer of the present invention includes a casing 18, a top cap 3, a spring nut 2 and a vibration isolation spring 14 connected between the bottom of the casing 18 and the spring nut 2. The said The bottom of the housing 18 is provided with a base 19 for connecting with the vibration source, the middle of the base 19 is screwed with a bottom plate 17, the middle of the bottom plate 17 is provided with a cylindrical boss, and the two ends of the vibration isolation spring 14 are respectively sleeved. A vibration isolation assembly is formed on the cylindrical boss and the spring nut 2, and one end of the vibration isolation spring 14 is sleeved on the cylindrical boss to prevent the vibration isolation spring 14 from sliding radially; the top of the casing 18 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com