Method and apparatus for converting rotary motion into reciprocating impact motion

A technology of percussive motion and rotary motion, applied in drilling equipment, percussive drilling, drilling equipment and methods, etc., can solve problems such as breakage damage, increase equipment failure rate, increase manufacturing difficulty and cumbersome installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

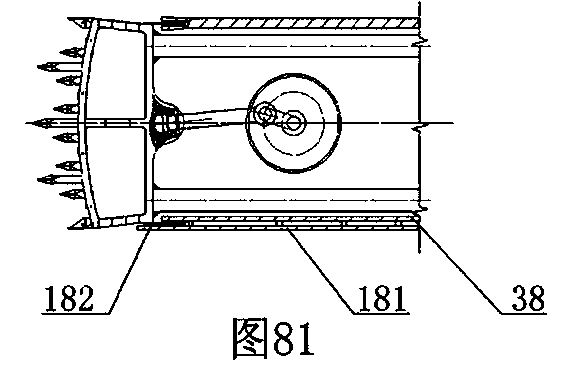

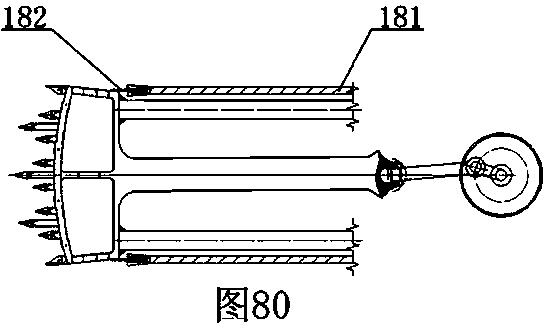

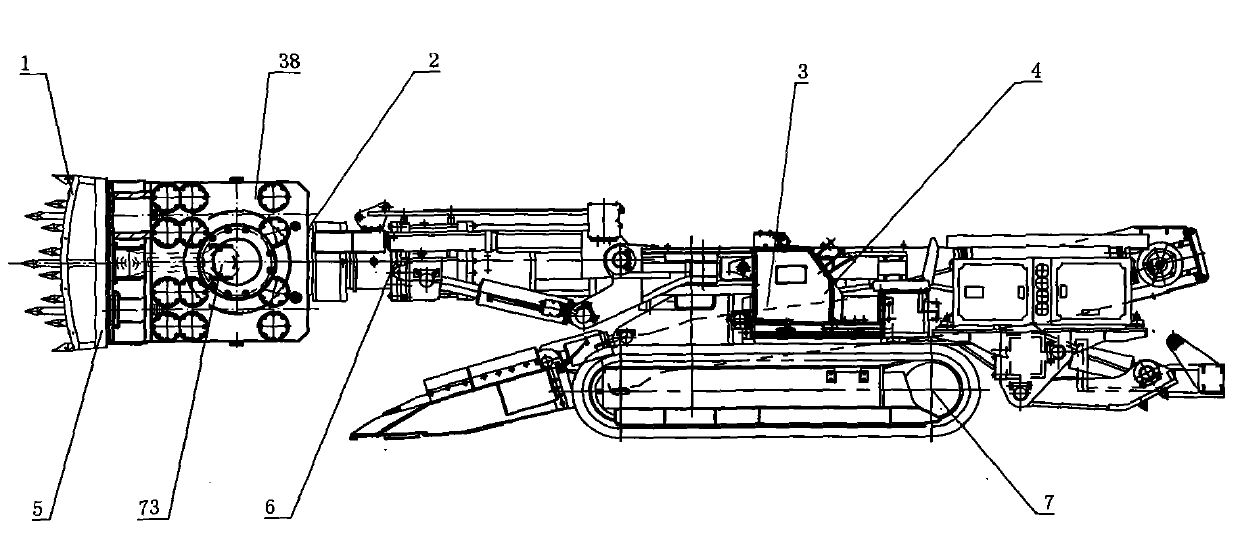

[0478] figure 1 , figure 2As shown, a rotary motion is transformed into a reciprocating impact motion device, including a fuselage 4, a walking part 7, a reciprocating impact part 5, etc., and the reciprocating impact part 5 includes an impact drive mechanism 2, a rocker arm 6, an impact head 1, etc., and the impact drive Mechanism 2 includes an impact power source 11, a transmission component, a crankshaft, etc., the impact power source 11 is arranged perpendicular to the rocker arm 6, the impact power source 11 is a motor, the motor includes a power output shaft 14, and the transmission component includes a gear transmission component, the gear Transmission part comprises power gear 13, transmission gear 12, and impact power source part 11 comprises power output shaft 14, and power gear 13 is installed on the power output shaft 14, and transmission gear 12 drives crankshaft, and transmission part comprises transmission shaft, and power output shaft 14 is perpendicular to T...

Embodiment 2

[0483] image 3 As shown, a rotary motion is converted into a reciprocating impact motion device. The rocker arm 6 includes a fixed seat 9, a movable arm 8, etc., the fixed seat 9 and the rocker arm 6 are separately arranged, and the impact drive mechanism 2 is arranged on the movable arm 8. The arm 8 is arranged on the fixed seat 9, and the fixed seat 9 is hinged with the movable arm 8, so that the telescopic movement of the impact drive mechanism 2 can be realized.

[0484] The fixed seat 9 can be integrated with the rocker arm 6, and then the fixed seat 9 is fixedly connected with the movable arm 8.

[0485] Others are with embodiment 1.

Embodiment 3

[0487] Figure 4 As shown, a rotary motion is converted into a reciprocating impact motion device. The rocker arm 6 includes a rotating device 15, a fixed seat 9, a movable arm 8, etc., the fixed seat 9 includes a fixed arm and / or a bracket, and the fixed seat 9 and the movable arm 8 are movable. Connecting, one end of the rotating device 15 is arranged on the fixed seat 9 , the other end of the rotating device 15 is connected with the movable arm 8 , and the rotating device 15 drives the movable arm 8 to rotate relative to the fixed seat 9 .

[0488] The rotating device 15 can be arranged on the movable arm 8 or on the fixed base 9 and the movable arm 8 .

[0489] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com