Automatic power generating and power supply system by using vehicular dive flap or deceleration strip

An automatic power generation and power supply system technology, applied in the direction of machines/engines, mechanical power generating mechanisms, mechanical equipment, etc., can solve the problems of energy waste, vehicle deceleration, etc., and achieve the effect of increasing comfort and firm and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

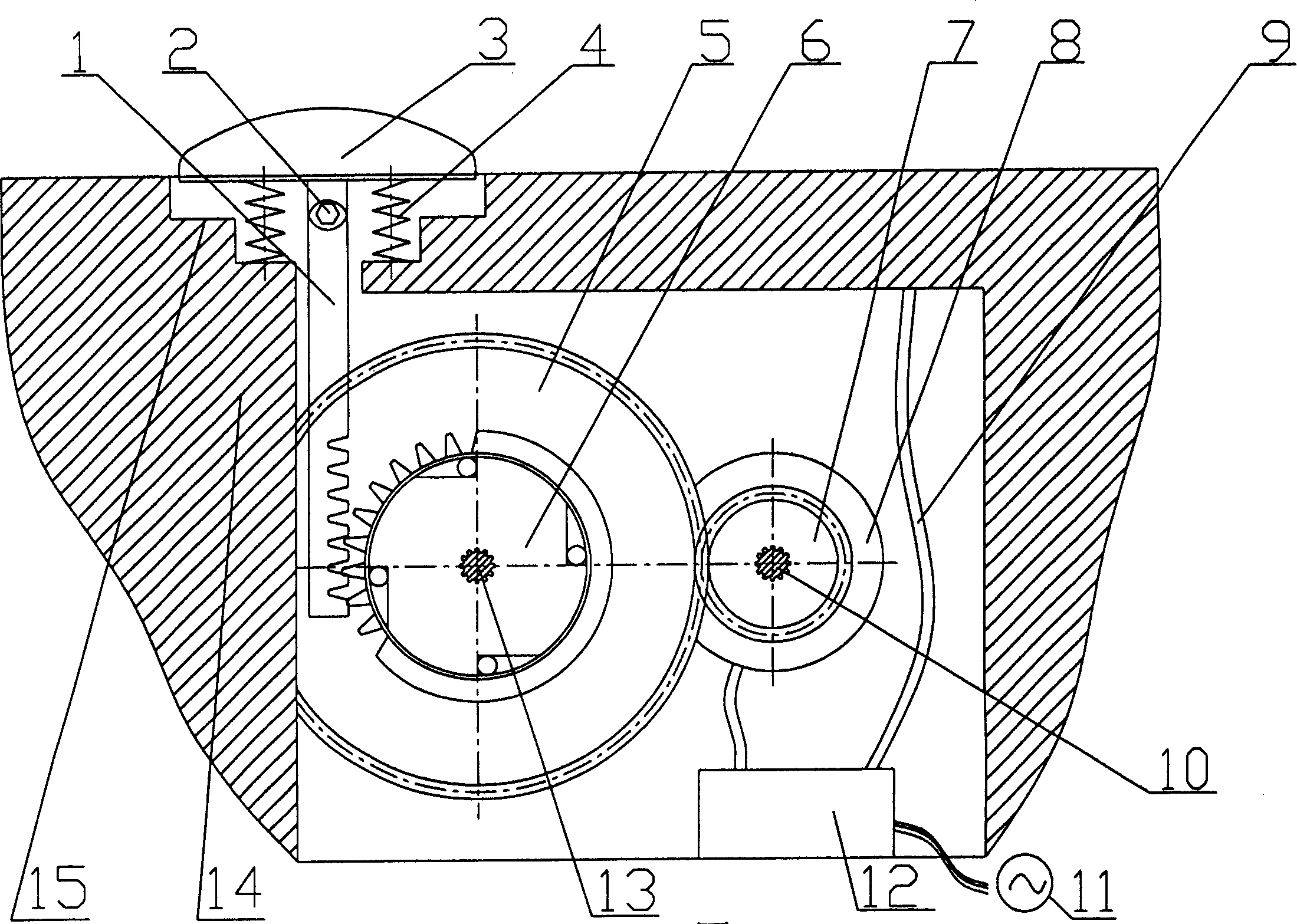

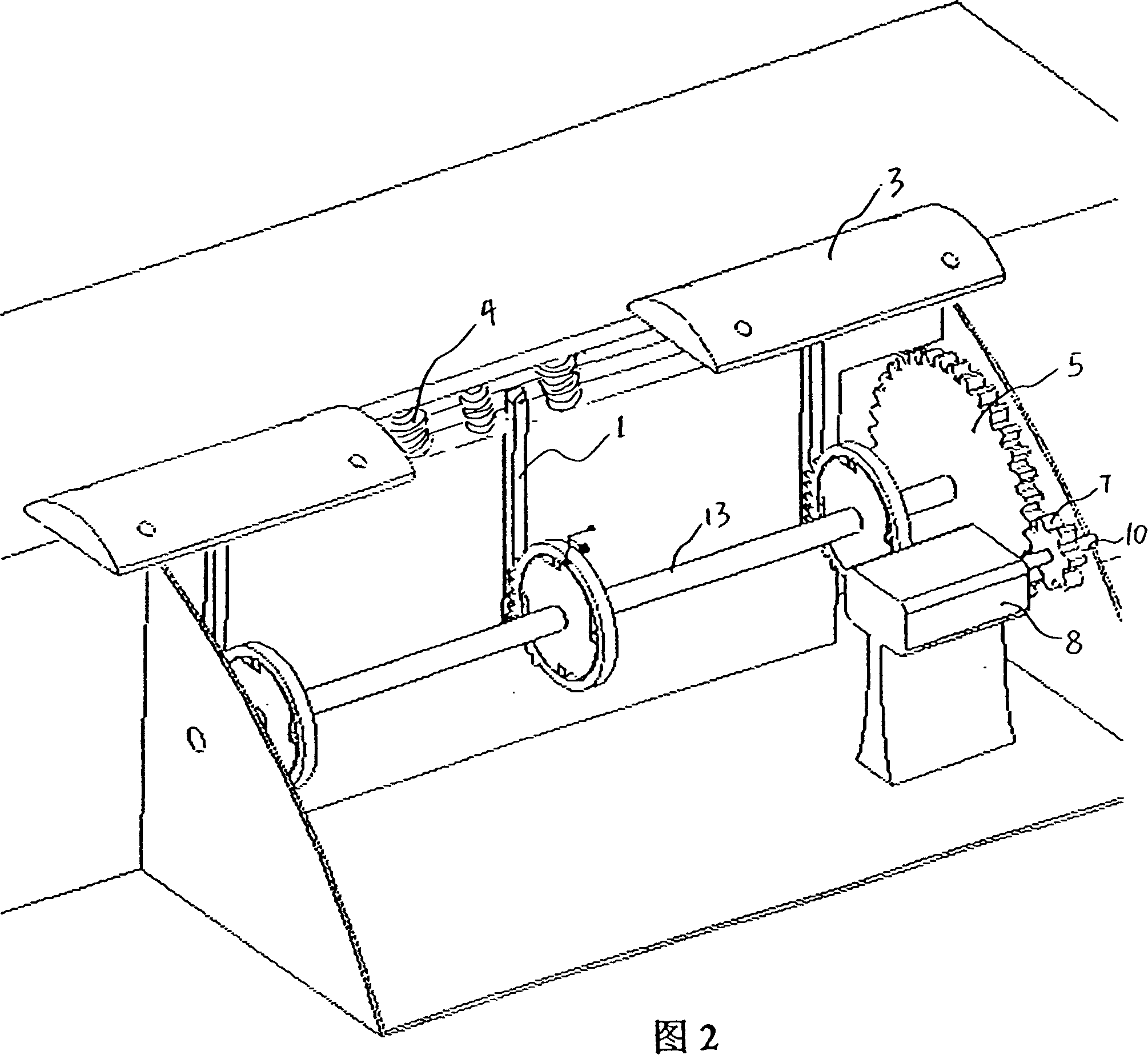

[0020] The specific structure and implementation mode of the present invention can refer to accompanying drawing. figure 1 Middle: 1 is gear rod, 2 is hinge, 3 is deceleration plate or deceleration belt, 4 is nonlinear spring, 5 is large gear, 6 is ratchet, 7 is pinion, 8 is generator, 9 is power supply output end, 10 Is the motor shaft, 11 is the terminal connected to the mains network, 12 is the controller and the storage battery, 13 is the fixed shaft of the ratchet and the large gear, 14 is the housing, and 15 is the limit boss. The speed brake or speed bump 3 is embedded in the upper chamber of the housing 14, and the upper chamber has a structure of limiting boss 15, so that the speed brake or speed bump 3 is limited downwards at the boss. The lower end surface of the fixed spring 4 is lower than the boss. The upper end of gear rod 1 is connected with the bottom end of deceleration plate or deceleration belt 3 through hinge 2. A toothed rack or transmission gear sector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com