Booster cavity and high-pressure cavity integrated type closed-loop gas path air suspension system

A technology of air suspension and high-pressure chamber, which is applied in the direction of suspension, elastic suspension, transportation and packaging, etc., which can solve the problems of energy waste, increase the complexity of layout space, and consume power, so as to improve compression efficiency and avoid energy loss , the effect of saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

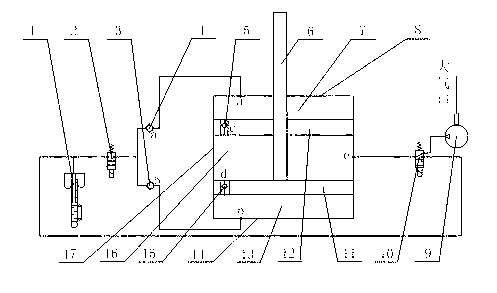

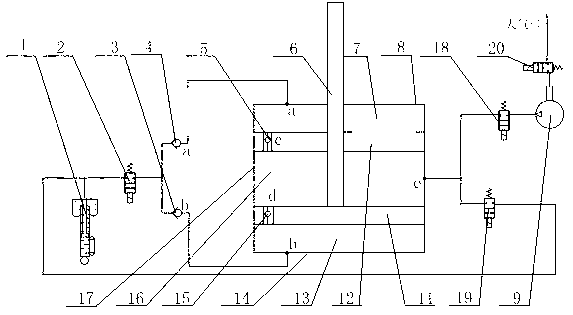

[0021] The internal structure of the self-pressurizing mechanism as shown in the figure is a cylindrical cavity 17 . Cavity 17 is equipped with upper piston 12, lower piston 11 and piston rod 6, one end of lower piston 11 and piston rod 6 is fixedly connected, the other end of piston rod 6 is connected with external excitation suspension, upper piston 12 and piston rod 6 A certain point is fixedly connected, the distance between the upper piston 12 and the lower piston 11 remains unchanged, and the space between the two pistons acts as a high-pressure chamber 16; Valve d15; the upper piston 12 and the lower piston 11 divide the cavity 17 into an upper working cavity 7, a lower working cavity 13 and a high-pressure cavity 16; a hole e is opened in the middle of the high-pressure cavity 16 to connect one end of the two-position three-way solenoid valve 10, two The other end of the three-way solenoid valve 10 is respectively connected to the air pump 9 and the air spring 1; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com