Self-pressurized device with high pressure chamber and low pressure chamber of closed air loop air suspension system

An air suspension, high and low pressure technology, used in suspension, elastic suspension, transportation and packaging, etc., can solve problems such as power consumption and energy waste, and achieve the effect of improving compression efficiency, avoiding energy loss and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

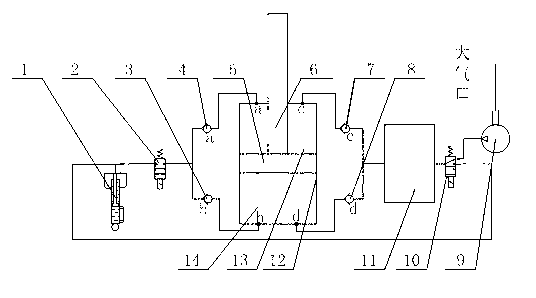

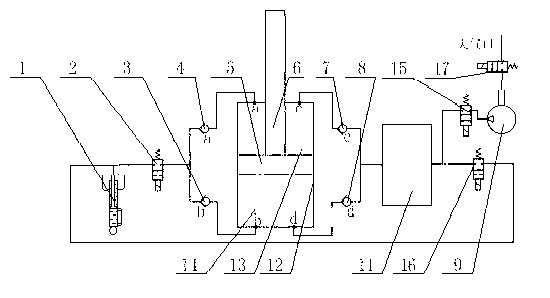

[0020] As shown in the figure, the pressurization device of the closed-loop air circuit air suspension system of the high and low pressure chamber includes a cylindrical low pressure chamber 12, the low pressure chamber 12 is equipped with a piston 5 and a piston rod 6, one end of the piston 5 and the piston rod 6 is fixedly connected, and the piston The other end of the rod 6 is connected to the external excitation suspension; the piston 5 divides the low-pressure chamber 12 into the upper working chamber 13 and the lower working chamber 14; the air outlet c of the upper working chamber 13 and the air outlet d of the lower working chamber 14 respectively pass through the one-way valve C7 and one-way valve d8 are connected in parallel to one end of the high-pressure chamber 11; the other end of the high-pressure chamber 11 is respectively connected to the air pump 9 and the air spring 1 through the two-position three-way solenoid valve 10; the other end of the air pump 9 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com