Automatic and quantitative gluing plate jointing device of short and small battens and gluing plate jointing method

A gluing device and slat technology, which is applied in the jointing of wooden veneers, wood processing equipment, manufacturing tools, etc., can solve the problem of increasing the secondary processing cost of the board, affecting the life of the pressing plate of the hot press, and uncontrollable glue amount and other problems, to achieve the effect of preventing glue from polluting the board surface, simple structure, smooth and no glue mark pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

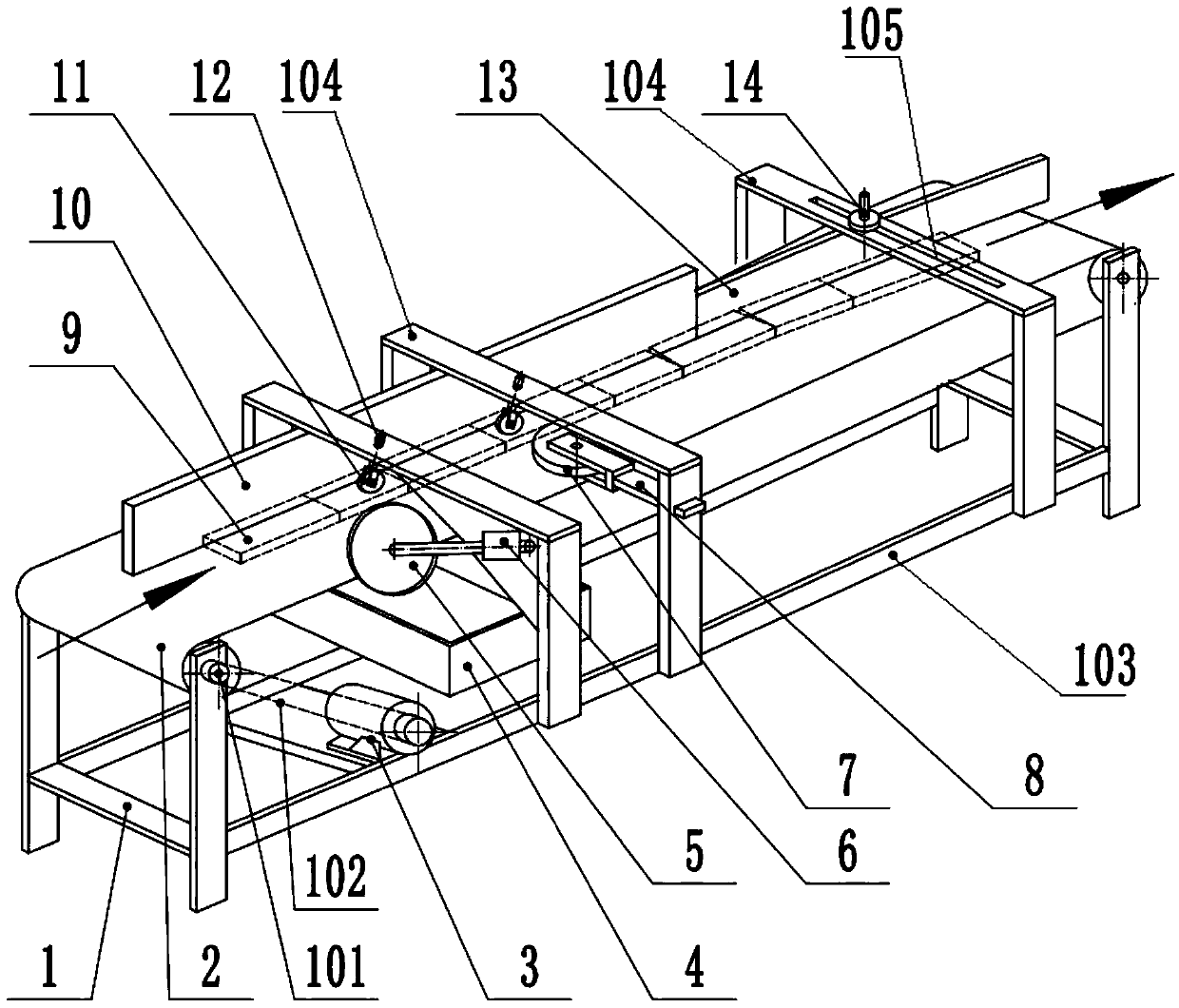

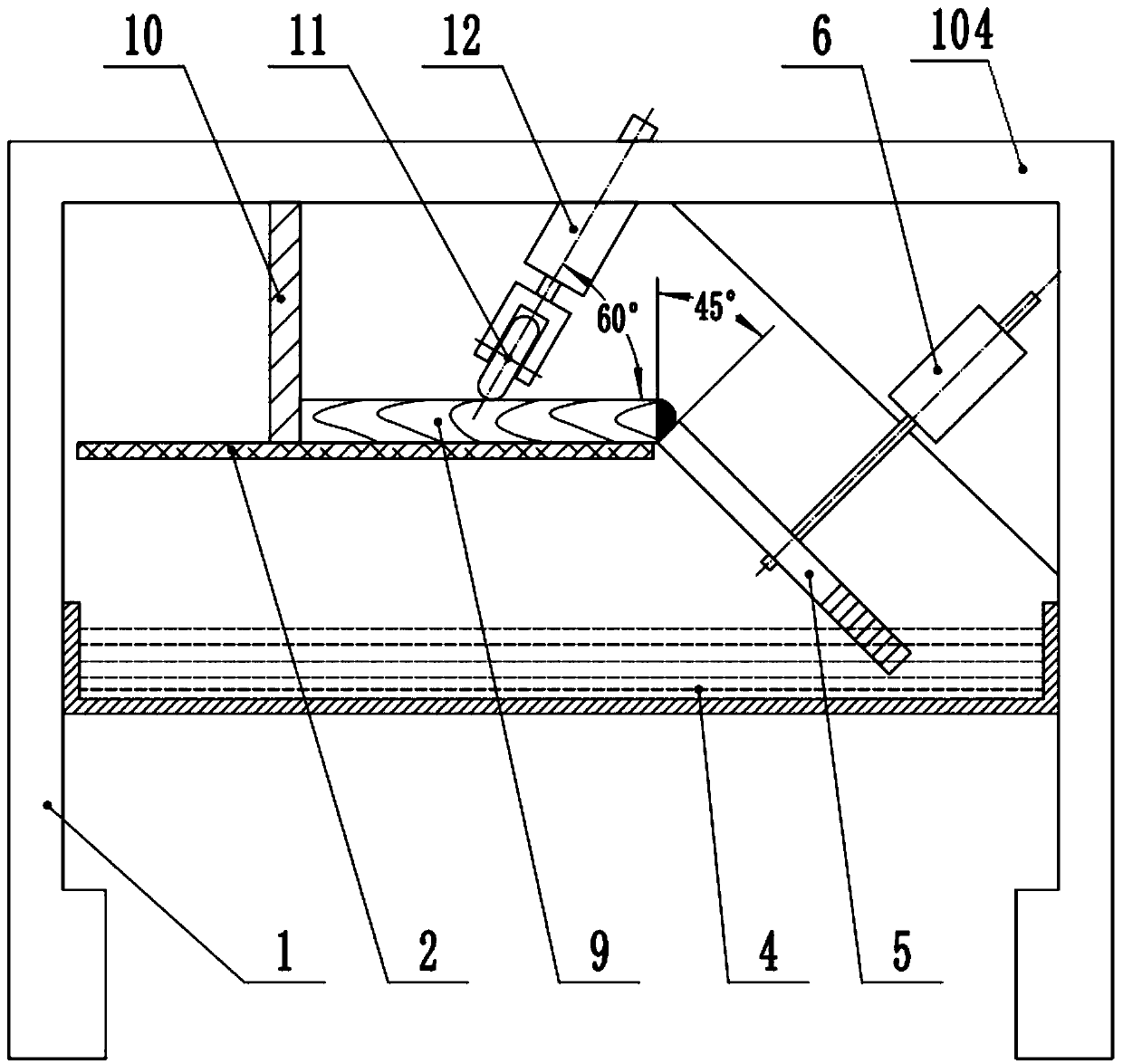

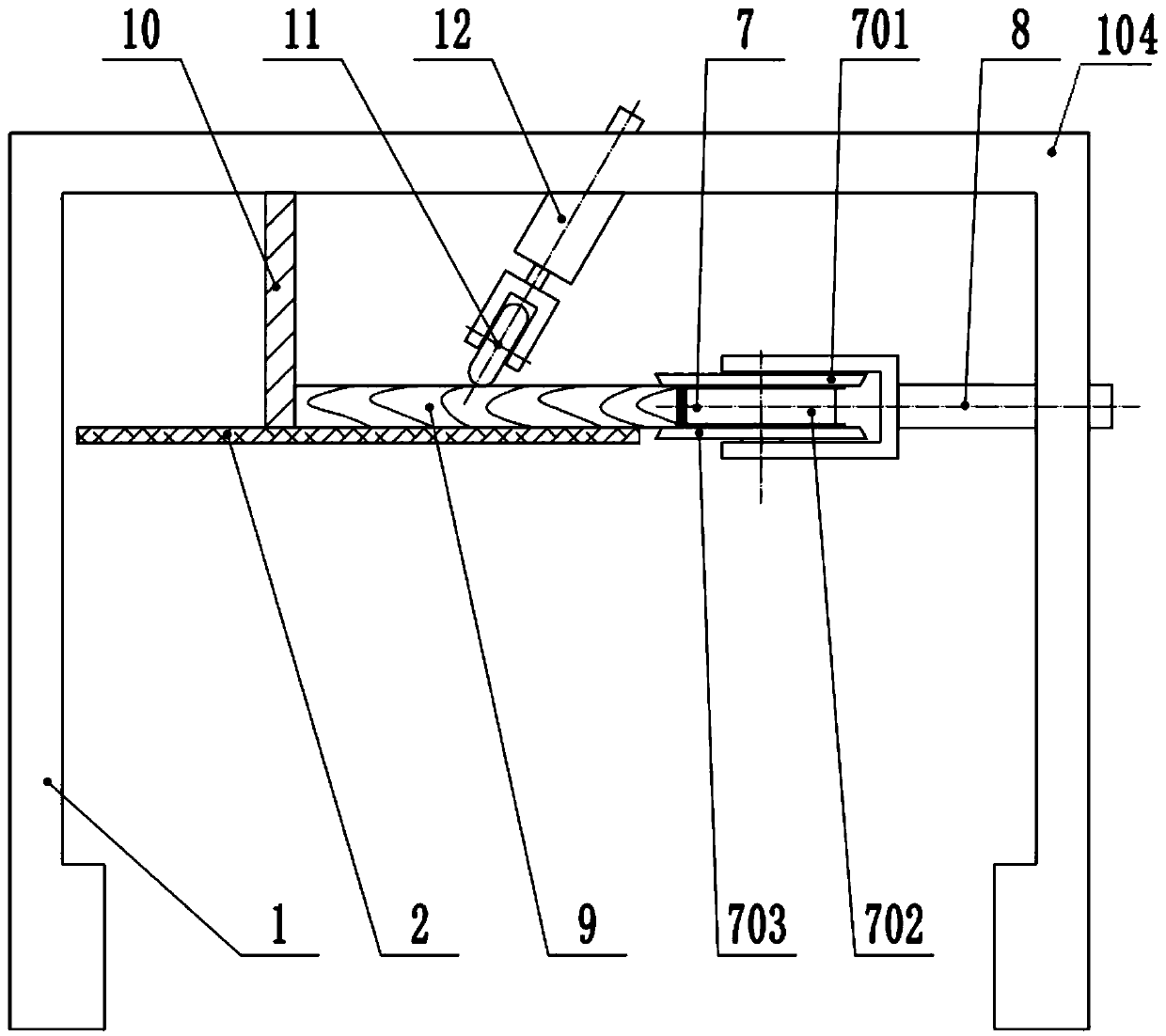

[0043] The following is based on Figure 1 to Figure 5 The specific embodiment of the present invention is further described:

[0044] This embodiment provides an automatic quantitative gluing and splicing device for short and small slats, including a side automatic quantitative gluing device and a fixed-length and width-assembling blank assembly pre-pressing device.

[0045] see figure 1 , wherein the side automatic quantitative gluing device includes a gluing frame 1, a conveyor belt 2, an adhesive box 4, a sizing toothed roller 5, a sizing toothed roller support 6, a U-shaped squeegee roller 7, and a U-shaped squeegee roller support 8 , Backer 10, flexible guide plate 13 and guide plate lateral adjustment mechanism 14. The transmission belt 2 is installed on the gluing frame 1 and is used to convey the short slats 9 under the driving of the driving device. 10 is used for limiting the lateral movement of short lath 9. The other side direction of the conveyor belt 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com