Program-controlled coal discharging device for raw coal bunker

A technology of bunker program control and raw coal bunker, which is applied in the field of coal equipment under program control of raw coal bunker, can solve problems such as affecting production and unsmooth feeding of raw coal, and achieves the effects of convenient installation, high degree of coal injection automation and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

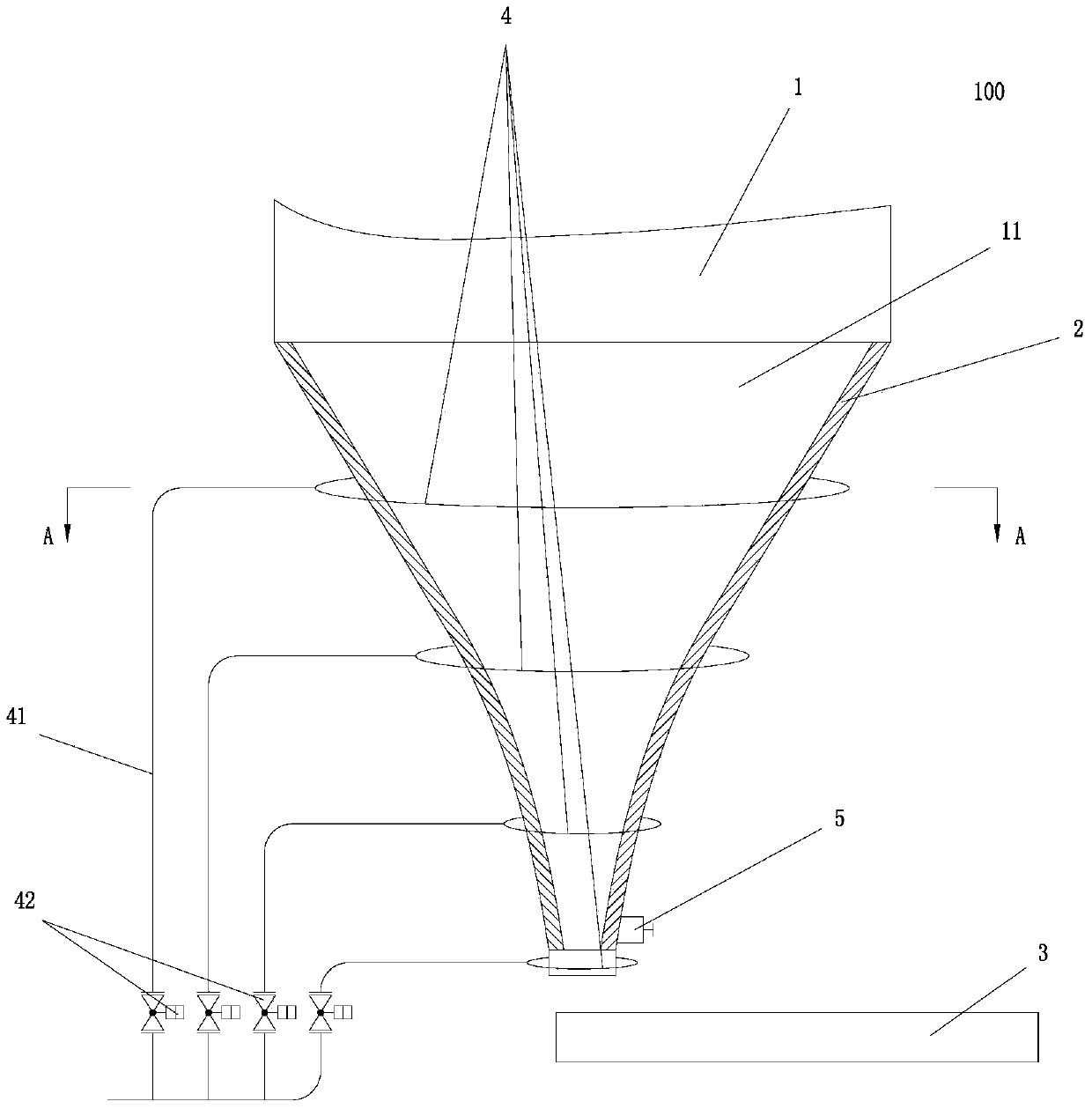

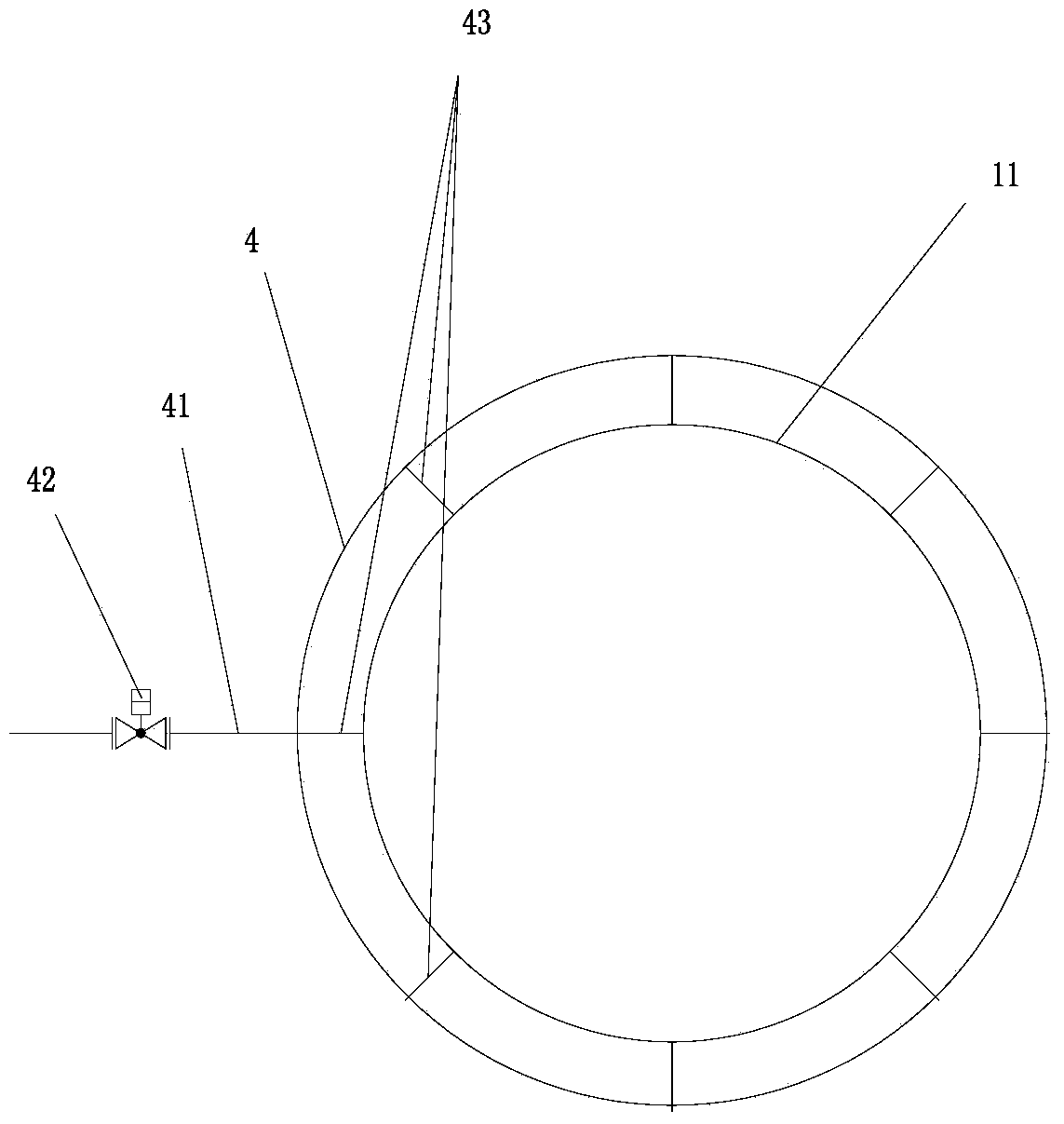

[0021] Such as figure 1 , figure 2 As shown, the present invention proposes a program-controlled coal lowering device 100 for raw coal bunkers. The raw coal bunker program-controlled coal lowering device 100 includes a raw coal bunker 1 with a tapered section 11 at the bottom, and a smooth liner is laid on the inner wall of the tapered section 11. 2. A coal feeder 3 is correspondingly provided below the discharge port at the bottom of the conical section 11; a plurality of hot nitrogen purging pipes 4 are provided on the outer wall of the conical section 11 from top to bottom, and each of the hot nitrogen The nitrogen purge pipeline 4 is welded on the outer wall of the tapered section 11 through angle steel; each hot nitrogen purge pipeline 4 is connected to the coal injection station by the corresponding first pipeline 41 and the first control valve 42 provided in the first pipeline 41. Hot nitrogen output piping (not shown), such as figure 2 As shown, each hot nitrogen p...

Embodiment 2

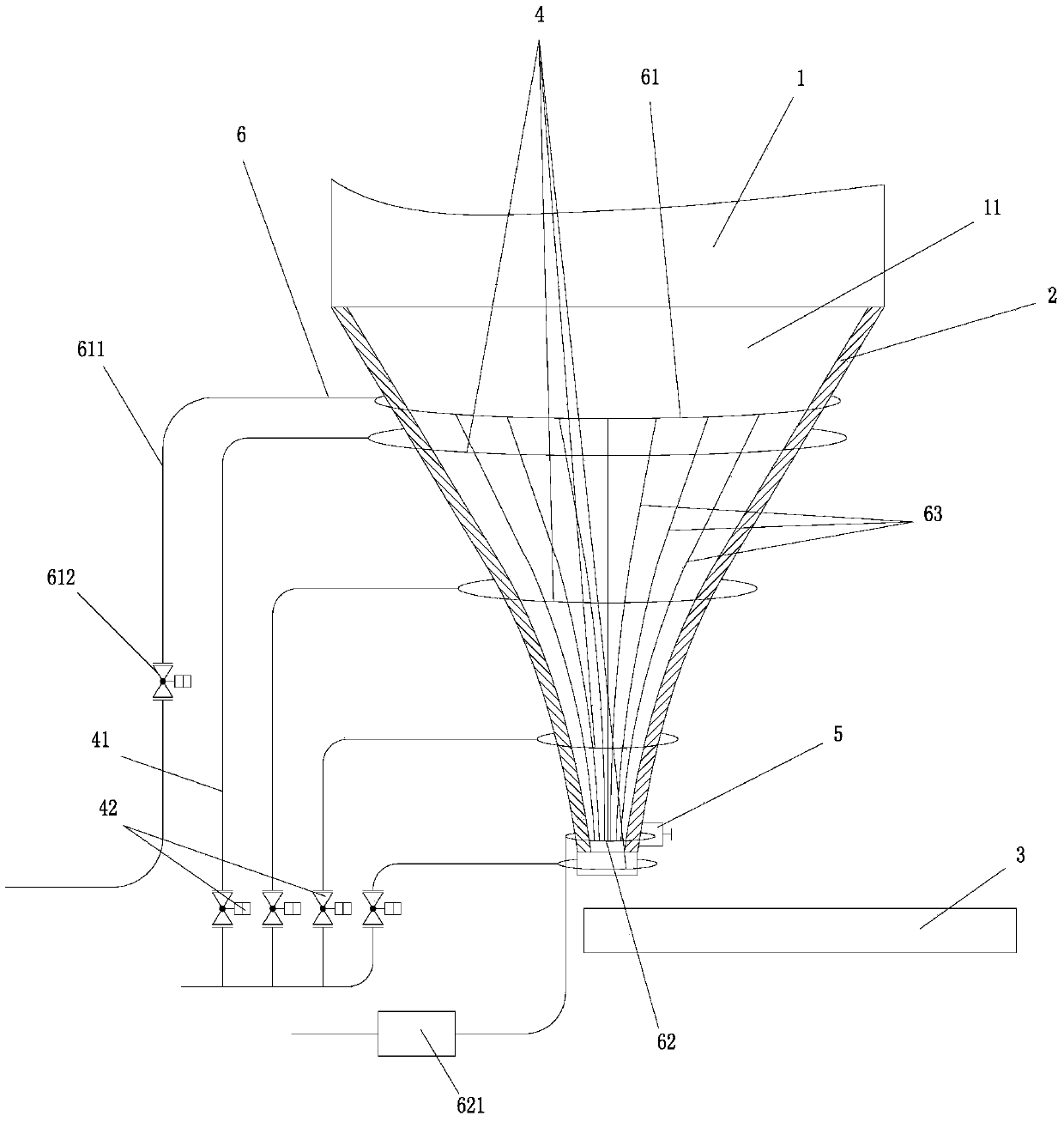

[0025] The structure and principle of this embodiment and the first embodiment are basically the same, and the difference between it and the first embodiment is that, as image 3 As shown, a steam tracing pipe 6 is arranged between the outer wall of the tapered section 11 and a plurality of hot nitrogen purge pipes 4, and the steam tracing pipe 6 is arranged close to the outer wall of the tapered section 11; The hot pipe 6 includes an upper annular duct 61 arranged at the upper end of the conical section 11 and a lower annular duct 62 arranged at the outlet of the tapered section, between the upper annular duct 61 and the lower annular duct 62 and around the The outer wall of the tapered section 11 is longitudinally spaced with a plurality of connecting pipes 63, and the two ends of each connecting pipe 63 are connected to the upper annular pipe 61 and the lower annular pipe 62 respectively; the upper annular pipe 61 is formed by the second pipeline 611 and the second control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com