Nanometer novel metal processing oil and preparation method thereof

A metalworking oil, nanotechnology, used in the petroleum industry, base materials, lubricating compositions, etc., to improve surface quality and tolerance, improve finish, and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

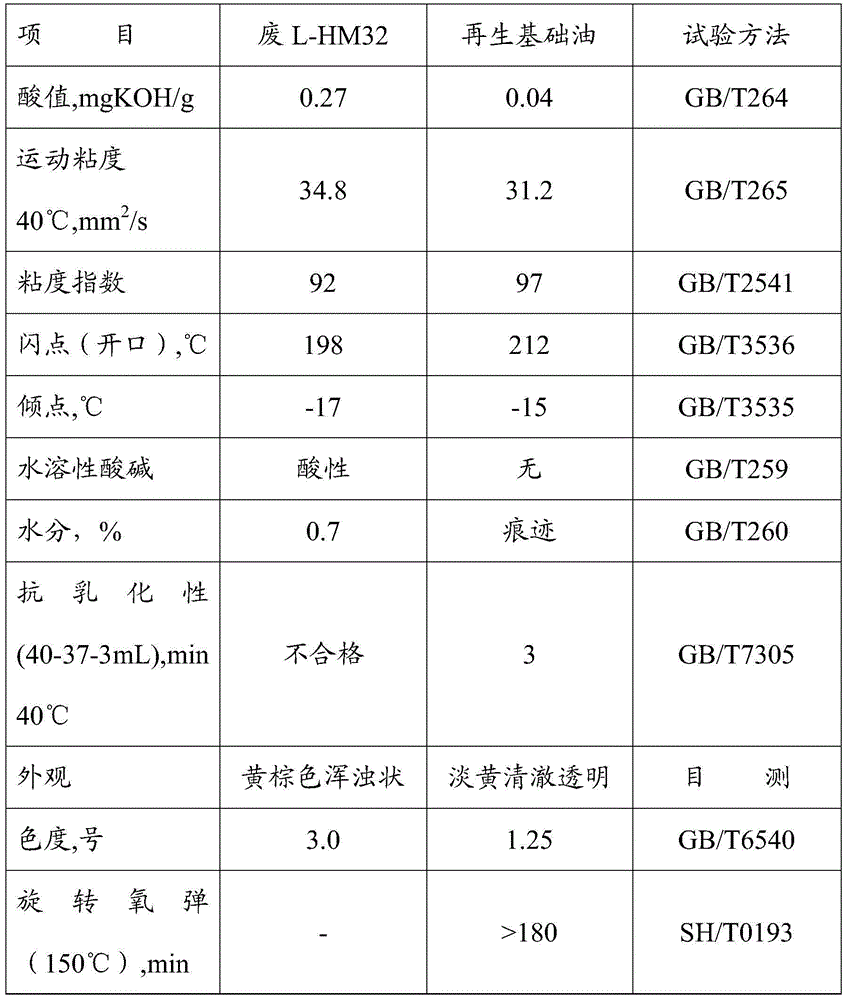

[0030] Example 1: Utilizing waste lubricating oil to prepare regenerated base oil

[0031] The first waste No. 32 anti-wear hydraulic oil (L-HM32) has a yellowish-brown color, becomes turbid with water, and has obvious sour odor after oxidation. Treated by the following process:

[0032] Step A, preparation of chemical solution: preparation containing NaOH mass concentration is 3%, NaOH 2 SO 3 Mass concentration 5%, CH 3 CH 2 OH mass concentration of 5% aqueous solution.

[0033] Step B, after the waste lubricating oil to be treated is adsorbed and filtered through a mineral fiber filter, material a is obtained;

[0034] Step C, pumping the material a into a refining tank, stirring, and heating the material a at the same time;

[0035] Step D, fully reacting the material a and the chemical solution in the refining tank; the specific steps of the reaction include: ① When the temperature of the refining tank rises to 60-70 ° C, the chemical solution prepared in the step A T...

Embodiment 2

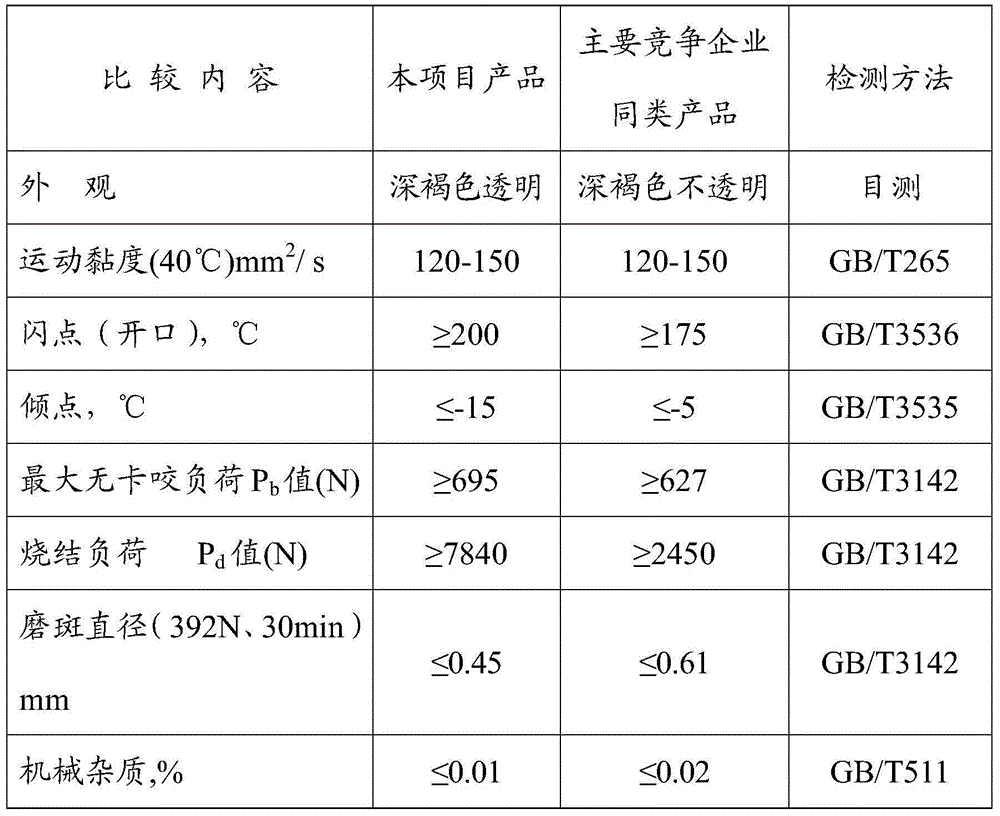

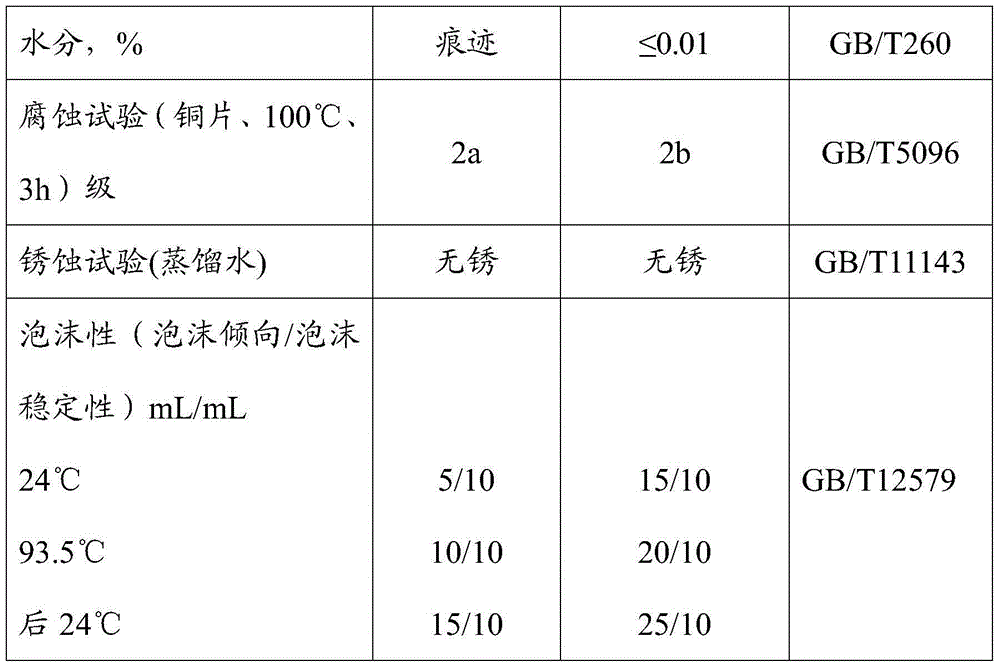

[0045] Example 2 Preparation of nano new metal processing oil

[0046] Step 1, pump the regenerated base oil prepared in Example 1 into a vacuum air conditioner and kettle, start stirring, start the vacuum system, and heat the regenerated base oil at the same time;

[0047] Step 2: Fully mix the regenerated base oil with the nano-extreme pressure anti-wear agent, and disperse evenly; the specific reaction steps include: ①Heating the regenerated base oil in the vacuum reactor at a stirring speed of 90 rpm to 60- Dehydration, degassing, deodorization and deodorization at 70°C and vacuum degree ≥ 0.09Mpa for about 0.5 hours; Pump in the required nano-extreme pressure anti-wear agent; ③Keep the oil temperature in the vacuum reactor at 60-70°C, the stirring speed at 90 rpm, and the vacuum degree ≥ 0.09Mpa for 1 hour to obtain the crude product of nano-new metal processing oil ;

[0048] Step 3: After the crude product of the nano new metal processing oil obtained in the above ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com