Patents

Literature

84results about How to "Free from oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

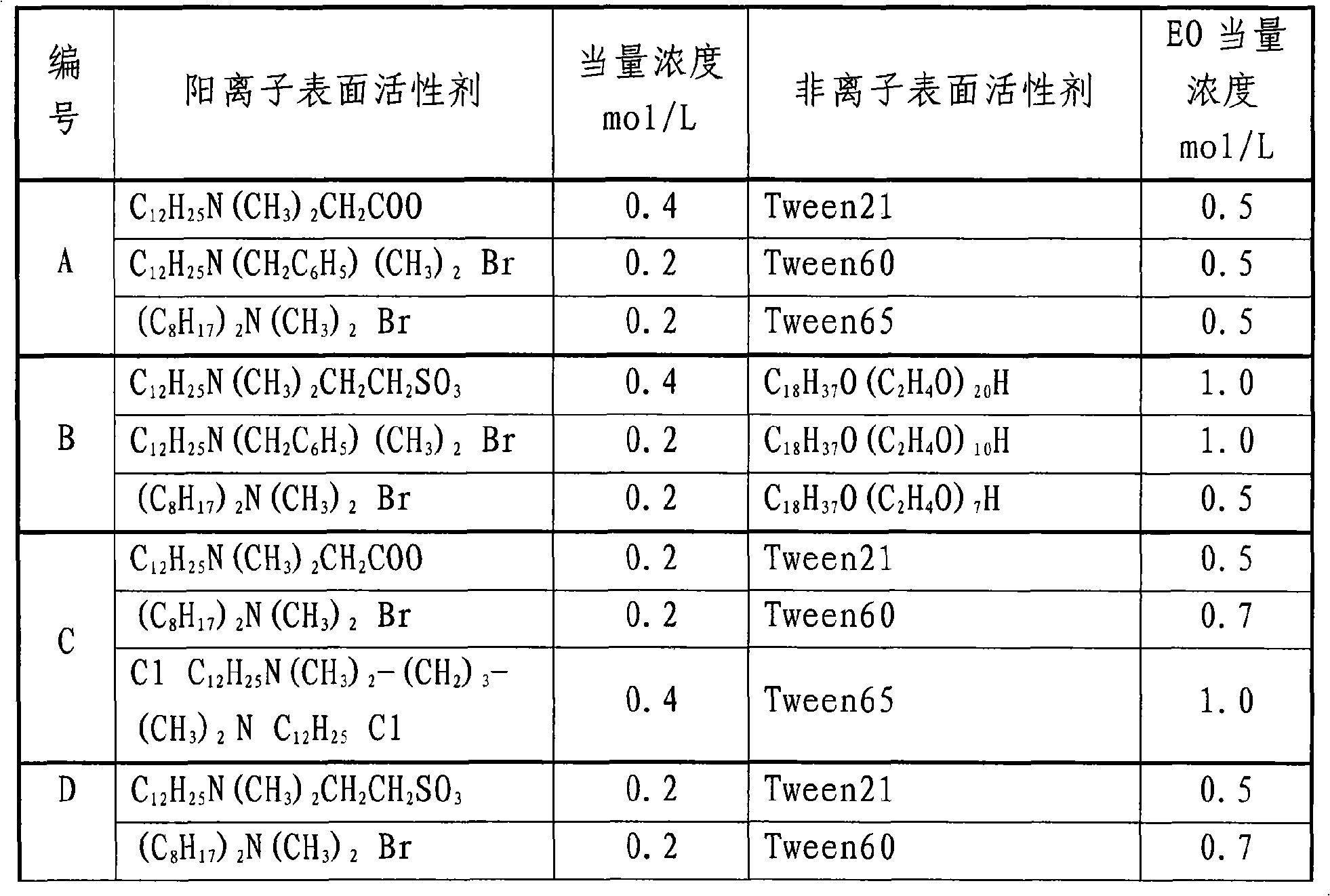

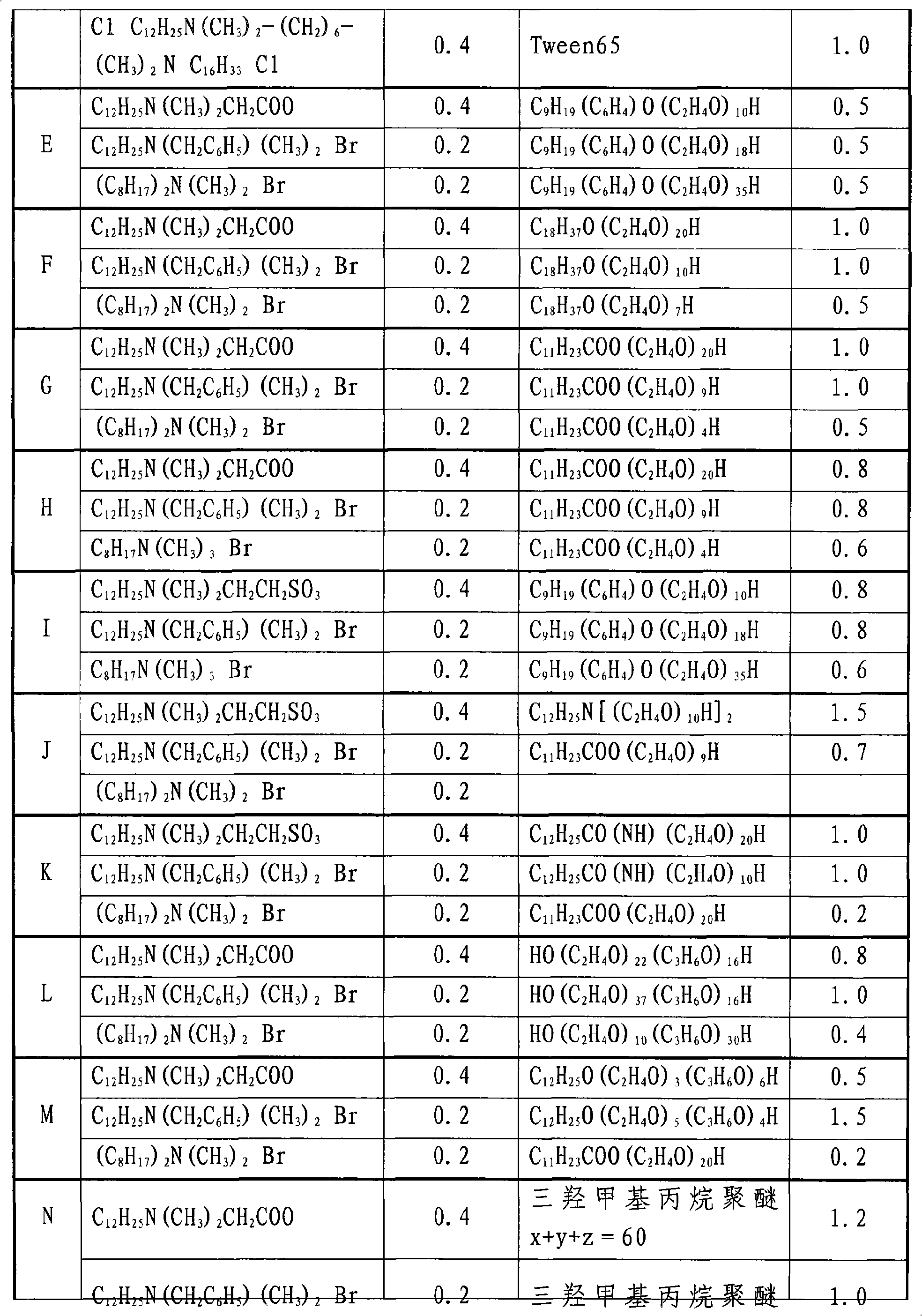

Multifunctional assistant plating additive for hot dip plating process, preparation and use method thereof

ActiveCN101328568AReduce lossImprove stabilityHot-dipping/immersion processesDissolutionLiquid metal

The invention relates to a multifunctional plating assisting additive for a hot dipping metallization process and a preparation and application method thereof, and belongs to the metal material anticorrosive technical field for providing multiple plating assisting efficacy. The technical proposal of the invention comprises that: a plurality of cations or an amphoteric surfactant ( an equivalent concentration of a quaternary ammonium group is between 0.1 and 2 mol / L) and nonionics (an equivalent concentration of a polyoxyethylene group is between 0.5 and 5 mol / L) are dissolved in deionized water. The method can improve the wetting quality between a liquid-state metal and a workpiece, and the adhesive uniformity and continuity of the plating assisting additive, reduces the drying time, prevents the liquid-state metal from falling and splashing, shortens the dipping and plating time, saves raw materials, improves a residue form, reduces an ash content, increases an ash discharge speed, isolates air, stops oxidation, disperses residual dirt and is suitable for a plurality of processes of hot galvanizing, hot plating zinc-aluminum alloy, hot plating aluminum, etc. The preparation steps comprise dissolution, cubage determination, cooling, keeping stand and filling; when the multifunctional plating assisting additive is used, the multifunctional plating assisting additive is directly added into a plating assisting additive solution and is evenly stirred.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

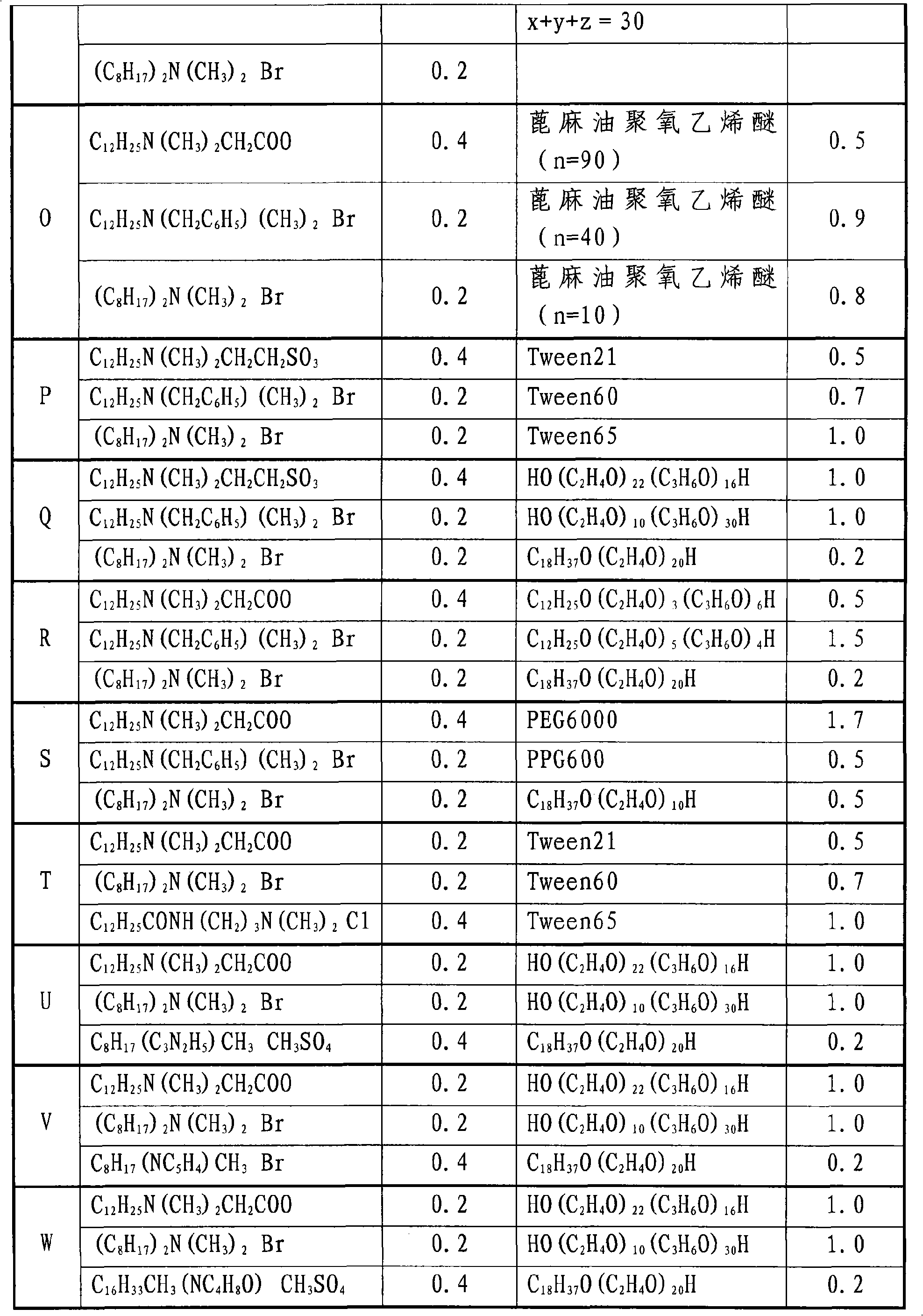

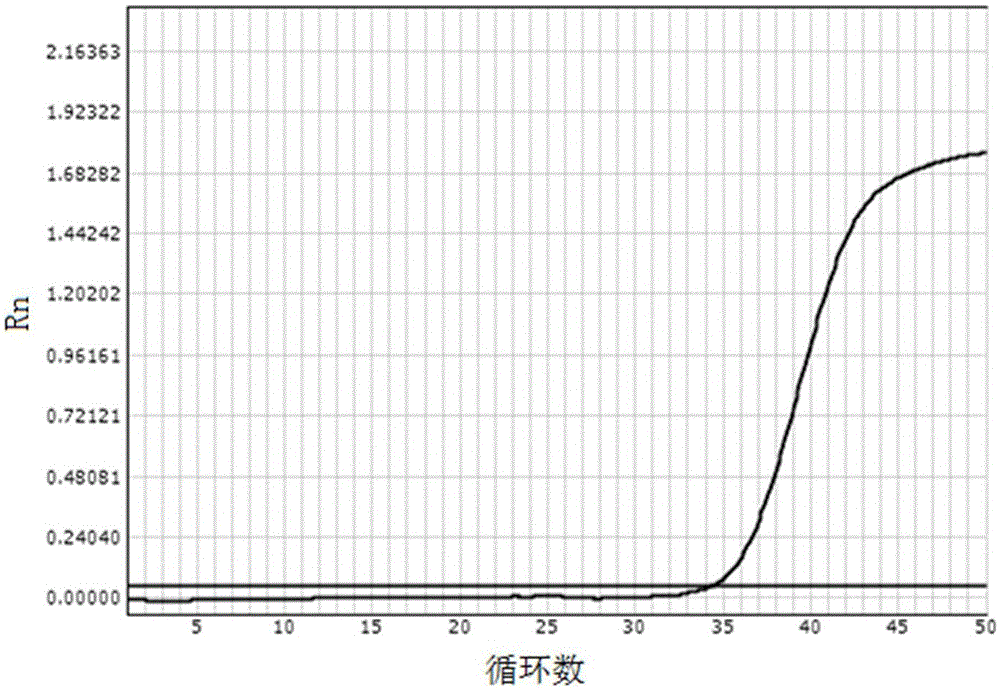

Lysis solution for extracting nucleic acid through magnetic bead method

The invention provides a lysis solution for extracting nucleic acid through a magnetic bead method. The lysis solution is prepared from 0.2-0.4 N sodium hydroxide, 0.3-0.6 M potassium chloride, 0.01-0.05% sodium n-lauroyl sarcosinate, 5mM EDTA, 0.3-0.6 M Tris-HCL and 1-2% triton X-100. The lysis solution for extracting nucleic acid through the magnetic bead method can fully and effectively lyse cells to accelerate the lysis progress and also can protect nucleic acid against oxidation to prevent formation of DNA dimmers. Besides, the lysis solution is stable in property and free of influences of seasons, temperature, saline ion concentration and the like and can carry out nucleic acid adsorption by fully cooperating with magnetic beads to achieve the optimal nucleic acid extraction effect. The scrubbing solution for extracting nucleic acid through the magnetic bead method can effectively remove residual impurities and avoid loss of nucleic acid, and a small quantity of the residual scrubbing solution does not influence the PCR application effect, so that the accuracy of detection results is guaranteed.

Owner:BEIJING NAGENE DIAGNOSTIC REAGENT CO LTD

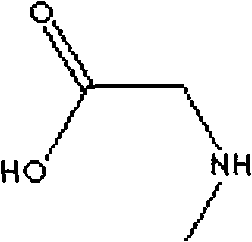

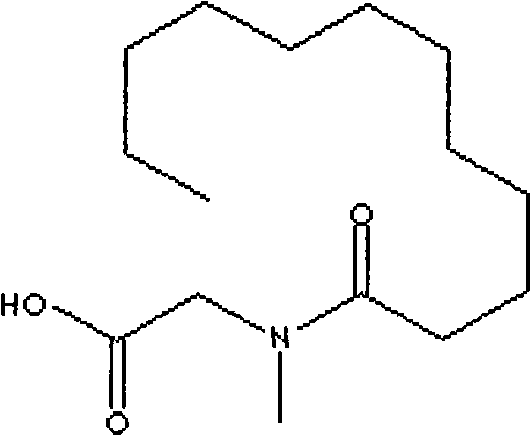

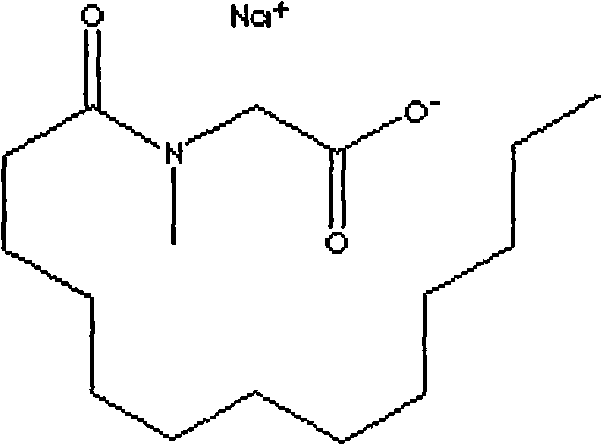

Corrosion inhibitor for after polishing detergent

ActiveCN101525563AFree from erosive propertiesFree from oxidationNon-surface-active detergent compositionsDetergent compounding agentsVolatile corrosion inhibitorPhysical chemistry

The invention relates to a corrosion inhibitor for an after polishing detergent. A creatine compound which is taken as the corrosion inhibitor is creatine and a salt compound thereof. The corrosion inhibitor is used in the after polishing detergent for chemical mechanical polishing, and can protect the surface of a processing object from corrosion when the after CMP (chemical mechanical polishing) cleaning is carried out. A chemical formula which can best display the characteristics of the corrosion inhibitor is shown.

Owner:UWIZ TECH

Compound emulsifiable paste for treating acne and preparation method thereof

InactiveCN101884642AImprove solubilityPromote absorptionHydroxy compound active ingredientsAerosol deliveryVitamin CGlycerol

The invention relates to compound emulsifiable paste for treating acne and a preparation method thereof, in particular to a medicament for treating acne and a preparation method thereof. The compound emulsifiable paste solves the problems of long treatment course and skin oxidation, dim skin and formation of color spots in the healing process in the conventional medicament for treating the acne. The compound emulsifiable paste is prepared from clindamycin hydrochloride, metronidazole, vitamin A, vitamin C, an emulsifying agent, stearic acid, albolene, glycerol monostearate, lanolinum, glycerol and purifying water. The preparation method comprises the following steps of: adding the vitamin A into uniform solution prepared from the stearic acid, the albolene, the glycerol monostearate and the lanolinum to obtain an oil phase; dissolving the glycerol and the emulsifying agent into the purifying water, adding the clindamycin hydrochloride, the metronidazole and the vitamin C, and stirring uniformly to obtain a aqueous phase; and adding the oil phase into the aqueous phase, stirring, homogenizing and standing the mixture to obtain the compound emulsifiable paste for treating the acne. The treatment period of the compound emulsifiable paste is between 14 and 24 days, skin is bright and clean after healing, and the compound emulsifiable paste can treat the acne, seborrheic dermatitis, acne rosacea and folliculitis.

Owner:哈尔滨乐泰生物科技有限公司

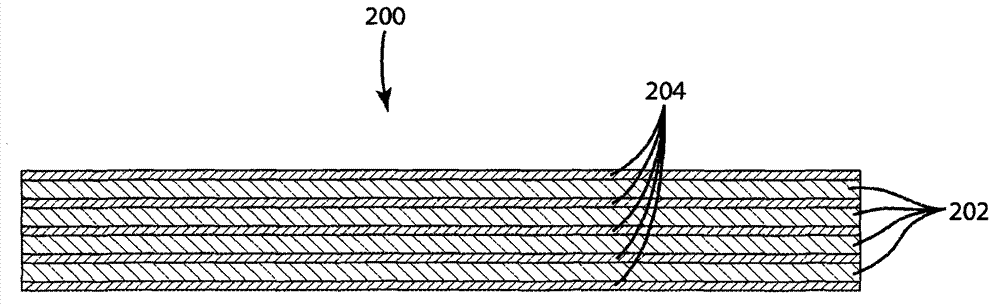

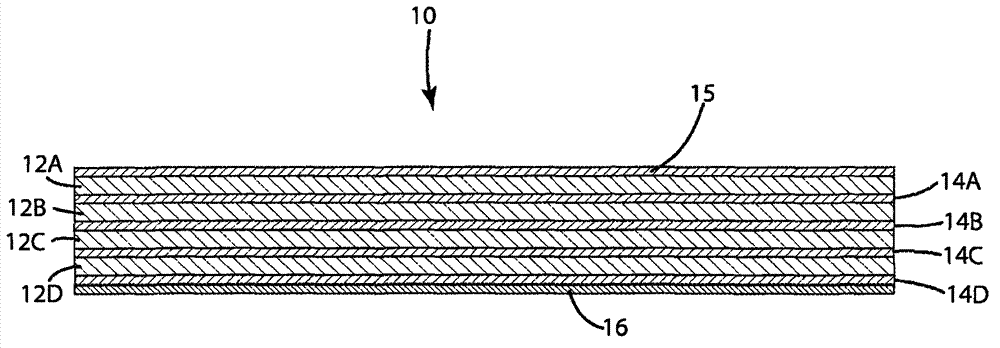

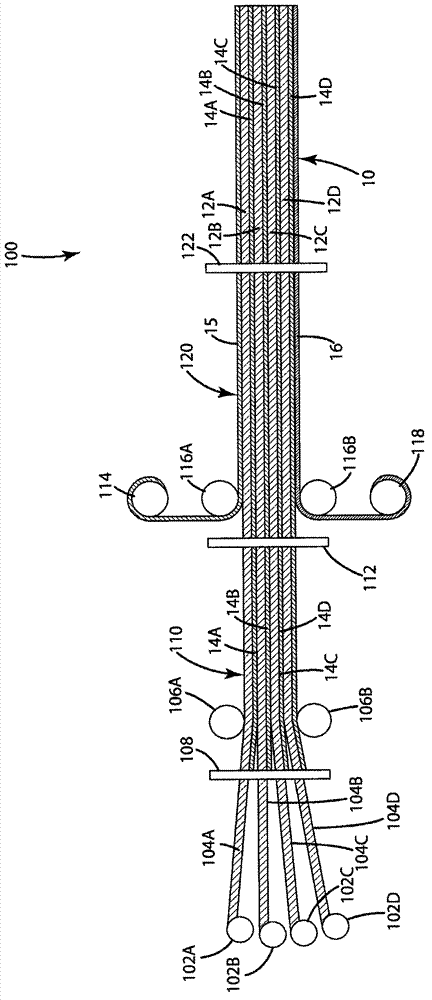

Magnetic flux guide component

InactiveCN103714938AGood repeatabilityImprove reliabilityTransformers/inductances coolingMagnetsAdhesiveConductive materials

The invention relates to a magnetic flux guide component. A laminated flux guide with a cover layer and a thermally conductive layer disposed on opposite sides of a plurality of alternating layers of high permeability and electrically insulating materials is provided. The thermally conductive layer may be a metal, such as aluminum. The present invention also provides a method of manufacturing including the general steps of: providing a plurality of rolls of high permeability material; providing a roll of thermally conductive material, providing a roll of cover material; applying an electrically insulating adhesive between adjacent layers of the high permeability material; feeding the high permeability material layers with the applied adhesive into pressure rollers to form a pre-laminate; feeding the thermally conductive layer, the pre-laminate and the cover layer into pressure rollers to join them under pressure into a final laminate and cutting the final laminate into the desired shape.

Owner:ACCESS BUSINESS GRP INT LLC

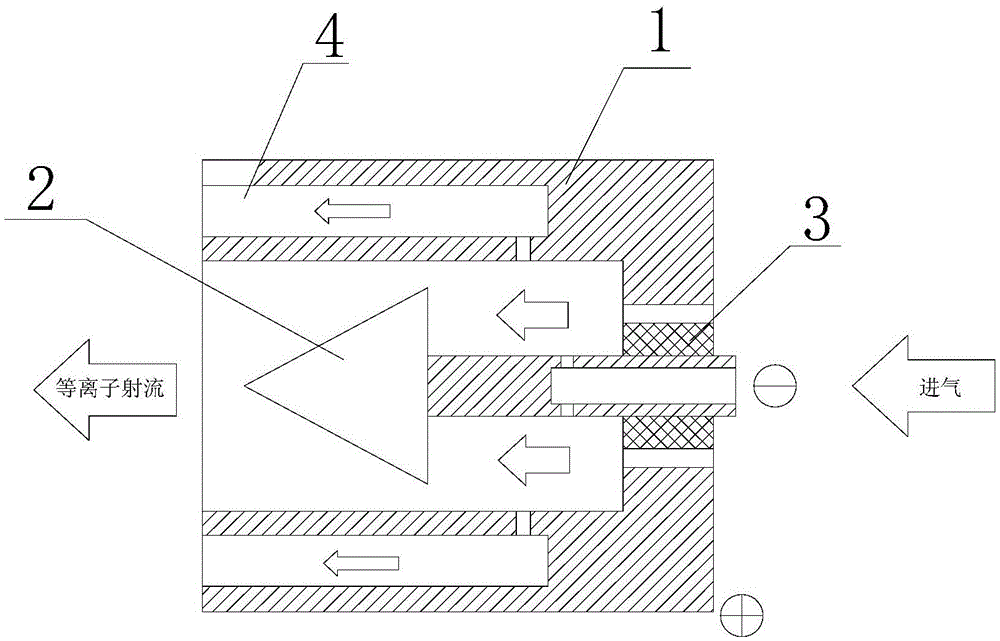

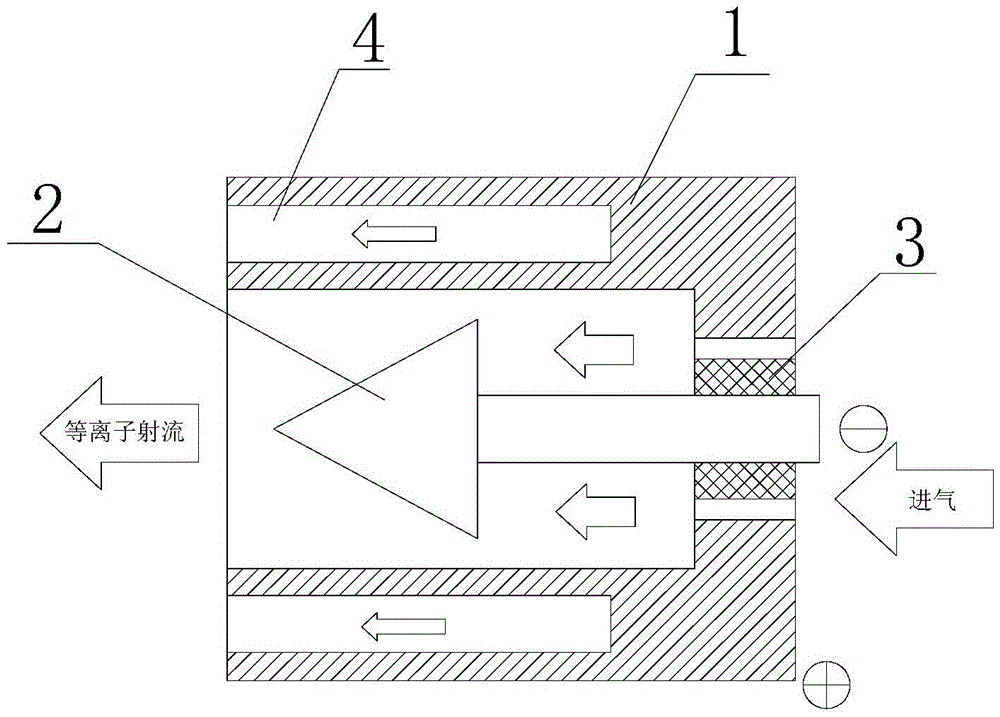

Plasma generator based on glide arc discharge principle

The invention discloses a plasma generator based on a glide arc discharge principle. The invention provides the plasma generator which can guarantee an anode to be cooled and can establish a protective atmosphere of a molten pool. The plasma generator comprises a cathode, the anode, a working gas channel, an insulator and an anode gas channel, wherein the cathode and the anode are installed and mutually matched through the insulator, a nozzle of the working gas channel is positioned between the cathode and the anode, the anode surrounds the cathode, the anode gas channel is formed in the anode, and an outlet of the anode gas channel is formed in the tail end of the anode, so as to form a protective gas nozzle of the molten pool. The anode gas channel is formed, so that the anode can be cooled by utilizing gas when the plasma generator is operated, thereby effectively controlling the temperature of the anode, and additionally, the gas sprayed from the anode gas channel can establish the protective atmosphere of the molten pool around plasma jet.

Owner:CHENGDU BULEIDE TECH CO LTD

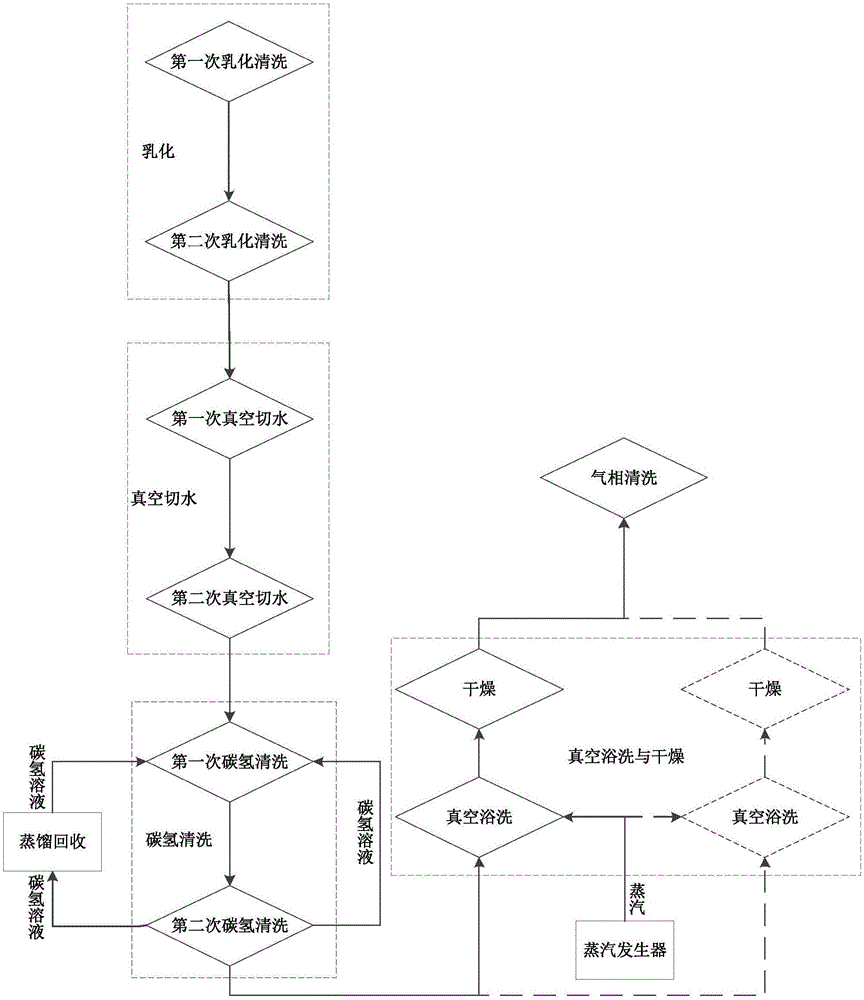

High-precision washing process for raw part of gold coin or silver coin

The invention discloses a high-precision washing process for a raw part of a gold coin or a silver coin and relates to the field of surface clearing of work pieces. The high-precision washing process comprises the following sequentially-set steps: emulsification, vacuum water shearing, hydrocarbon washing, vacuum bath-washing and gas-phase washing; therefore high-precision washing of the raw part of the gold coin or silver coin can be realized by means of control on vacuum degree, temperature of a detergent, ultrasonic wave frequency and washing time in each step. The high-precision washing process disclosed by the invention is complete in pollutant treatment, high in yield, high in automation degree in each step and capable of satisfying the environment protection requirements by adopting an environment-friendly detergent in each step.

Owner:SHENZHEN XINCHENGNUO ENVIRONMENTAL PROTECTION IND CO LTD

Drawing production process of monel alloy pipe

The invention relates to a drawing production process of a monel alloy pipe, particularly a production process for pipes with an outer diameter smaller than [Phi]12 mm, and belongs to the field of alloy pipe preparation technology. The process comprises the steps of performing vacuum melting, performing peeling extrusion, grinding, cold rolling, rolling, drawing to a finished product, carrying out on-line detection of faults, sizing on a drawing straightening machine, carrying out pressure tests, annealing, detecting and storing. On basis of a conventional process, the drawing production process takes use of a drawing technology, and has high yield and high efficiency.

Owner:江苏隆达超合金股份有限公司

Cleaning method of smooth finish surface and its cleaning articles

InactiveCN1380145AFree from pollutionFree from wear and tearFlexible article cleaningTectorial membraneSurface cleaning

The method for cleaning surface of object incldues the following steps: coating the surface of object to be cleaned with a layer of surface-cleaning protective film agent uniformly; decomposing and absorbing dirts attached on the described object surface by using said surface-cleaning protective film agent; after 3-8 min. said surface-cleaning protective film agent is solidified and formed into alayer of protective film; tearing said protective film away from the surface of said object, the dirts can be removed so as to attain the goal of cleaning object surface.

Owner:黄勇

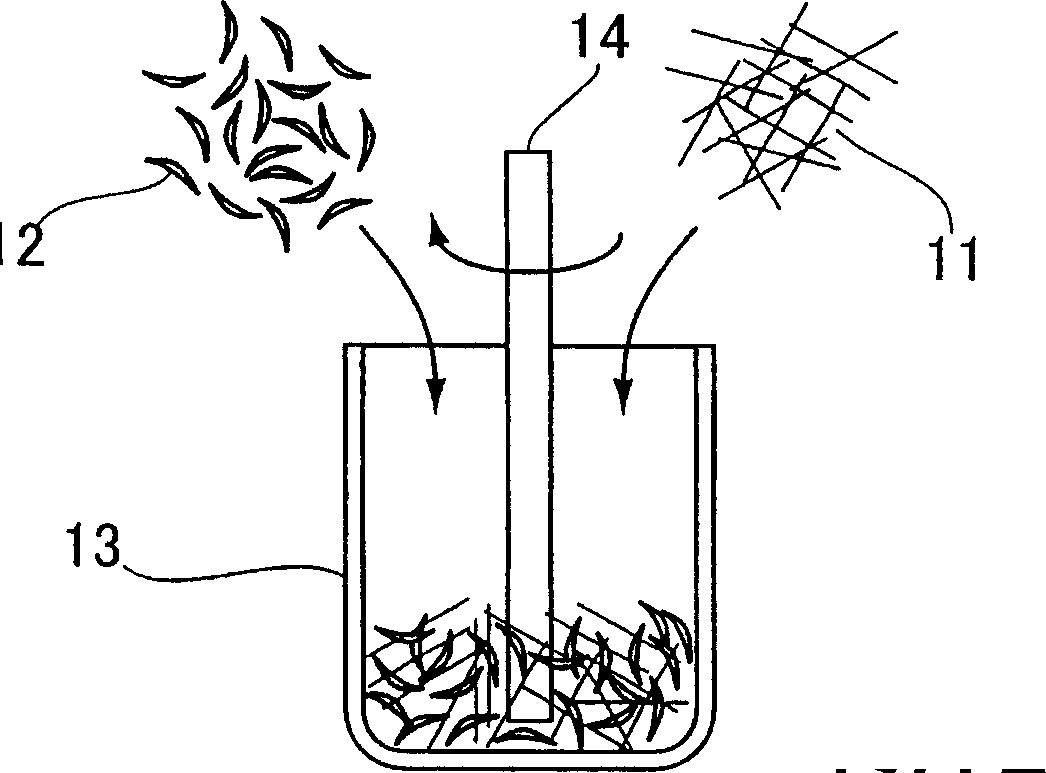

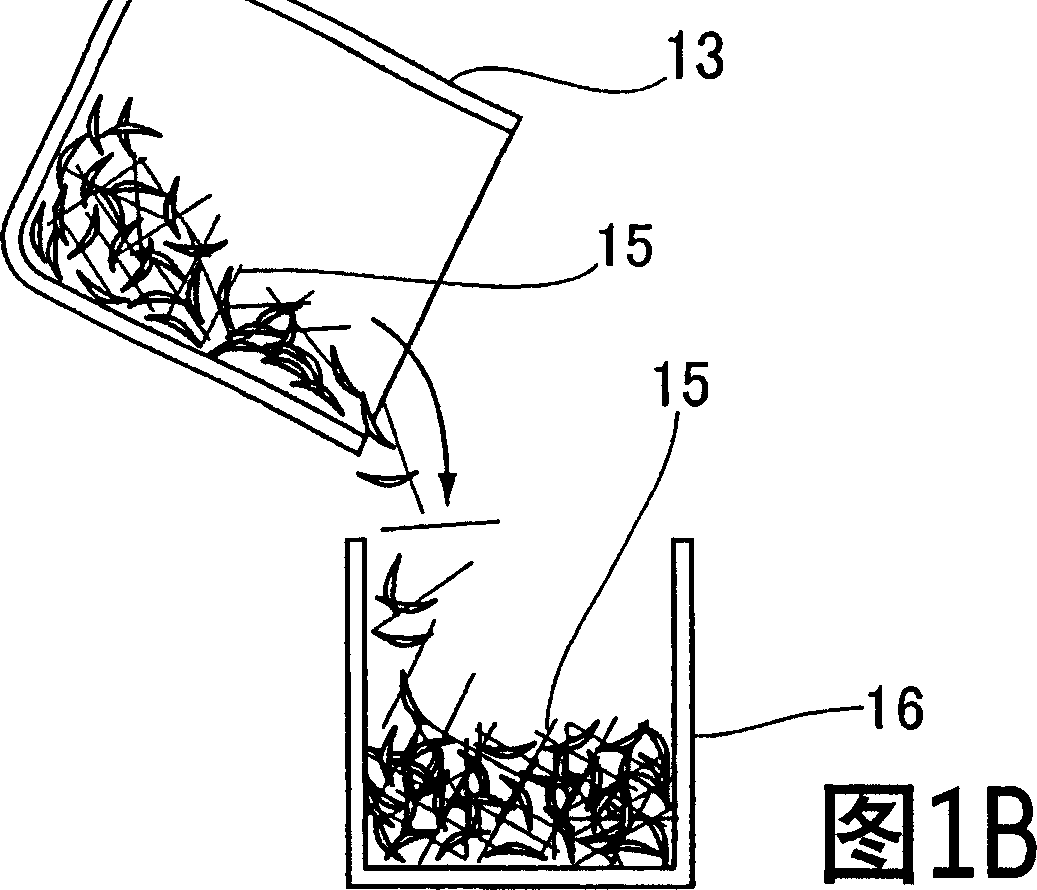

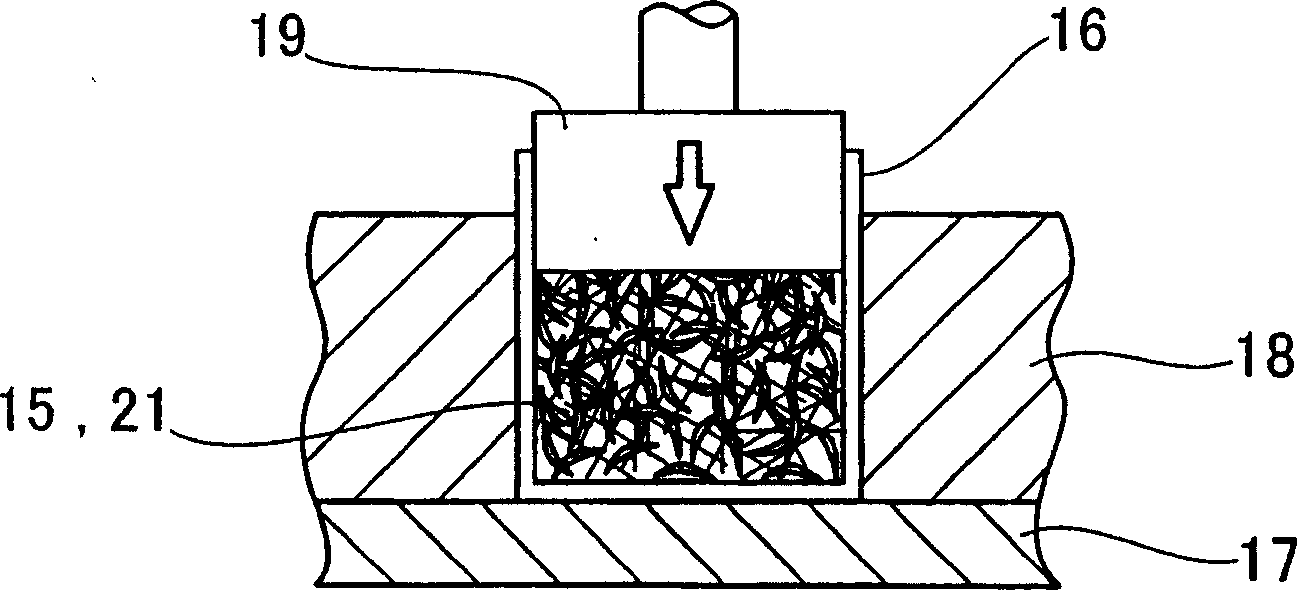

Method for manufacturing nanocarbon-metal composite material

InactiveCN1869262AEvenly dispersedHigh mechanical strengthNanostructure manufactureTransportation and packagingMetallic materialsMetal

A composite material composed of nanocarbon materials and metallic materials for a matrix is extrusion molded to have the nanocarbon materials oriented in one direction.

Owner:NISSEI PLASTIC IND CO LTD +1

Lead-free soldering tin crease and its production

InactiveCN1981978AFree from oxidationGood storage stabilityWelding/cutting media/materialsSoldering mediaOrganic solventBoiling point

A non-lead tin solder cream with high storage stability, wetting power for soldering, heat shock resistance, and solder strength is proportionally prepared from Sn-Zn based non-lead alloy powder, flux and protective activated film layer containing neutral organic solvent with high boiling point, neutral resin and activating agent with high decomposing temp through mixing and grinding said alloy powder with the raw materials of said activated film in vacuum, adding flux, and stirring.

Owner:梁树华

Manufacturing method of titanium-copper-stainless steel three-layer composite plate for pots

InactiveCN107443868AImprove cleanlinessFree from oxidationCooking-vessel materialsLamination ancillary operationsSheet steelTitanium

The invention discloses a manufacturing method of a titanium-copper-stainless steel three-layer composite plate for pots. The manufacturing method comprises the following steps: (1) polishing contact surfaces of a titanium plate, a copper plate and a stainless steel plate, and brushing the outer surfaces of the plates with a separating agent; (2) polishing one surfaces, contact with the three-layer laminated plate, of two steel plates, welding a side plate to a polished surface of one steel plate, and forming an exhausting pipe hole; (3) putting the three-layer laminated plate on the steel plate, and buckling the two steel plates so as to form a closed space between the side plate and the steel plates; (4) pressing and flattening the five-layer combined blank, and sequentially carrying out spot welding fixation and electric welding to seal peripheral gaps; (5) vacuumizing the combined blank by virtue of the exhausting pipe hole to maintain the five-layer combined blank at a vacuum state, so as to obtain a vacuum plate blank; (6) heating the vacuum plate blank, and carrying out calendering compositing by virtue of a hot mill; (7) heating the calendering composite plate, so as to eliminate stress in air; and (8) separating the steel plates, so as to obtain the composite plate.

Owner:BAOJI TITANIUM IND

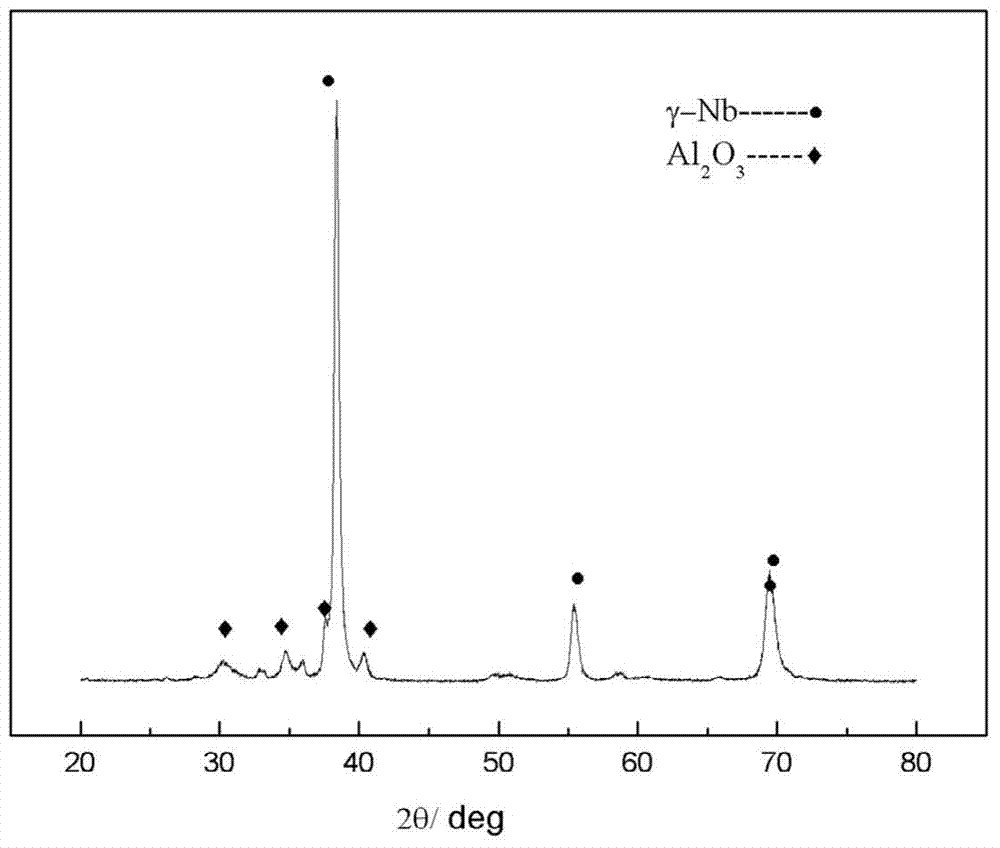

Method for preparing high-temperature composite coating on niobium-based surface by utilizing sol-gel method

ActiveCN103614713ASimple process equipmentEasy to operateSolid/suspension decomposition chemical coatingChemical treatmentProcess equipment

The invention discloses a method for preparing a high-temperature composite coating on a niobium-based surface by utilizing a sol-gel method. The method comprises the following steps: step 1, pretreating a niobium-based alloy specimen; step 2, preparing an intermediate bonding layer of the niobium-based alloy specimen in a chemical treatment manner; step 3, preparing Al2O sol-gel; step 4, performing dip-coating and drying; and step 5, performing vacuum heat treatment, thereby obtaining the high-temperature-resistant oxidation coating containing the intermediate bonding layer. The method has the advantages that 1, the process equipment is simple and easy to operate; the components of the coating are uniform and are controllable in thickness; the influence of the high temperature on the tissue property of a niobium substrate is avoided due to the adoption of a low heat treatment temperature; 2, the internal stress caused by the difference of thermal expansion coefficients between the substrate and the coating is effectively reduced under the action of the intermediate bonding layer, so that the combination between the coating with the substrate is improved; the capability of the coating for protecting the substrate from being oxidized is improved.

Owner:GUANGXI UNIV

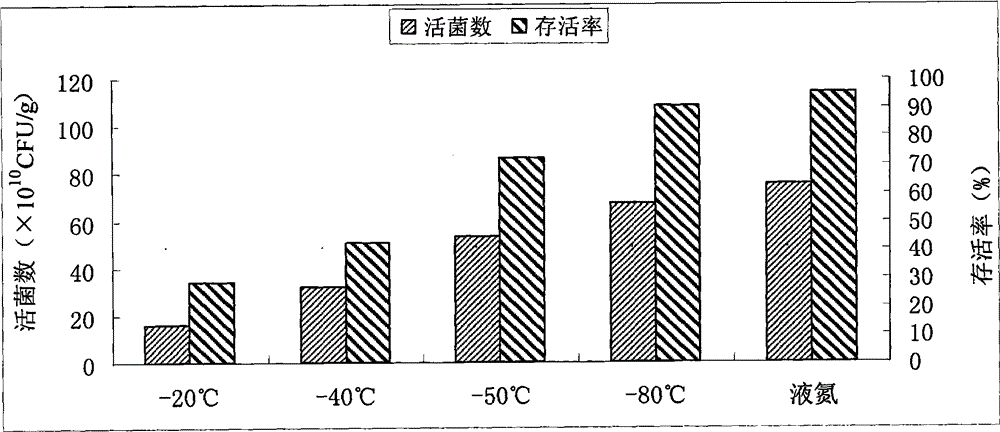

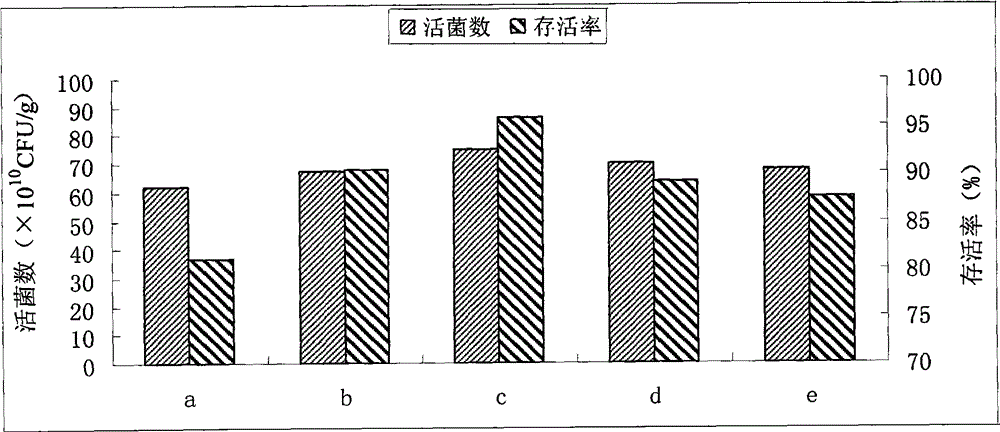

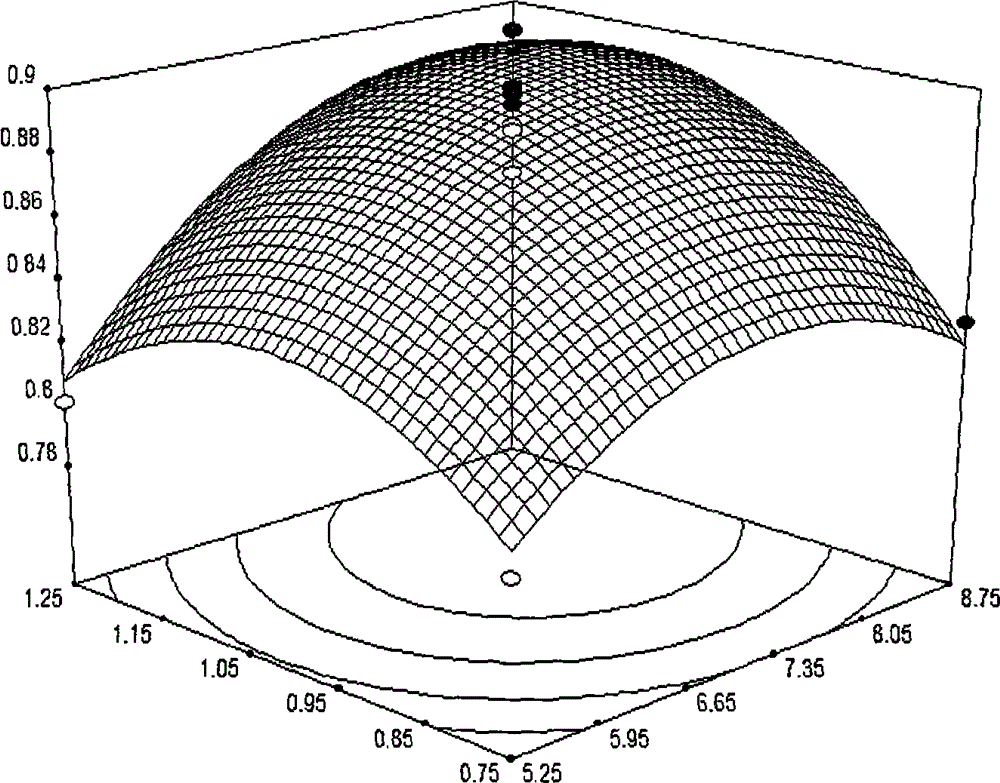

Protection agent applied to feeding enterococcus faecium freeze-drying preparation and preparation method of protection agent

InactiveCN104560717AProtective structureProtective functionMicroorganism based processesMicroorganism preservationHigh densityFreeze-drying

The invention relates to a preparation method of a protection agent and a freeze-drying preparation for vacuum freeze-drying of feeding enterococcus faecium. By virtue of the preparation method of the freeze-drying protection agent and the freeze-drying preparation, a high-density fermentation solution of enterococcus faecium WEI-10CGMCC No.7746 is processed by vacuum freeze-drying, the maximum number of live bacteria of freeze-dried bacteria powder reaches 8.2*10<11> CFU / g; and the freeze-drying protection rate is 98%. The freeze-drying preparation can be preserved for one year at -20 DEG C, and the loss rate of the live bacteria is smaller than 5%; and the freeze-drying preparation can be preserved for 6 months at the room temperature, and the loss rate of the live bacteria is smaller than 10%. The preparation method can be used for producing high-yield and storable freeze-drying preparation of the feeding enterococcus faecium.

Owner:BEIJING DAWEIJIA BIOTECH SHARE CO LTD +1

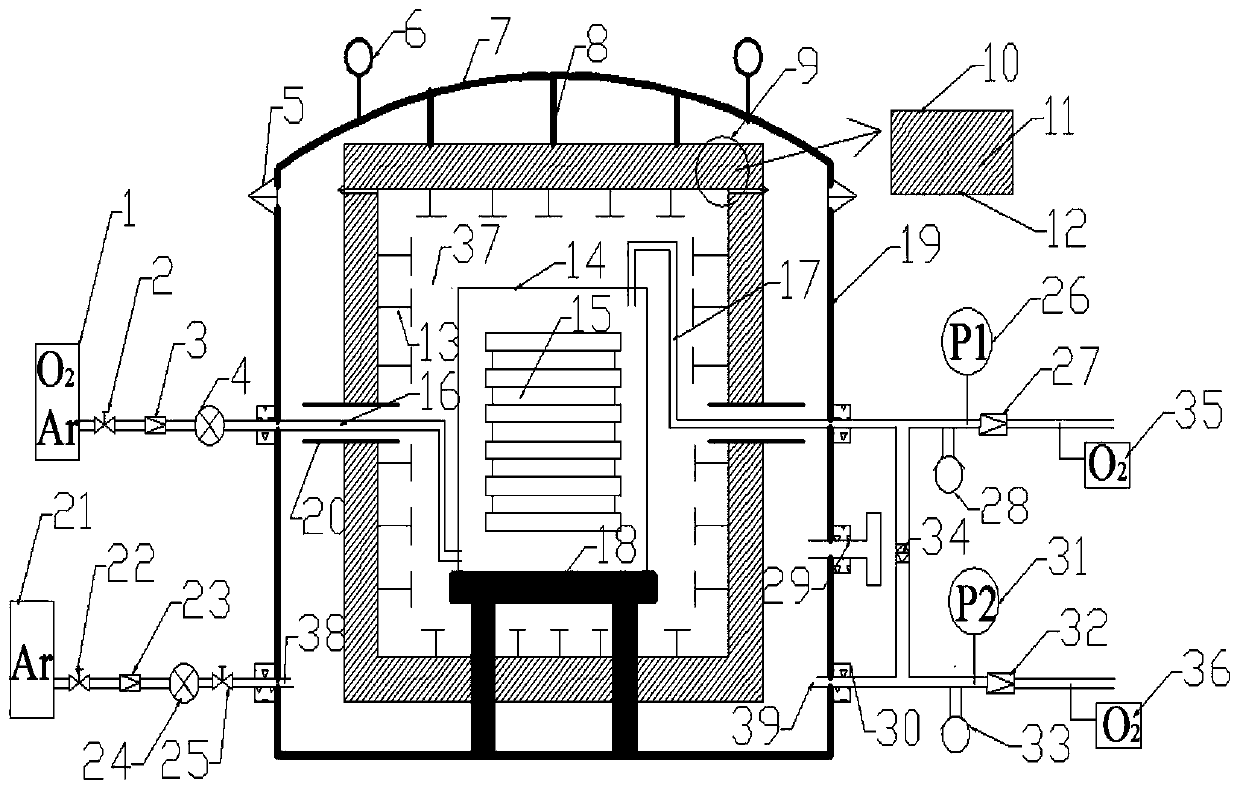

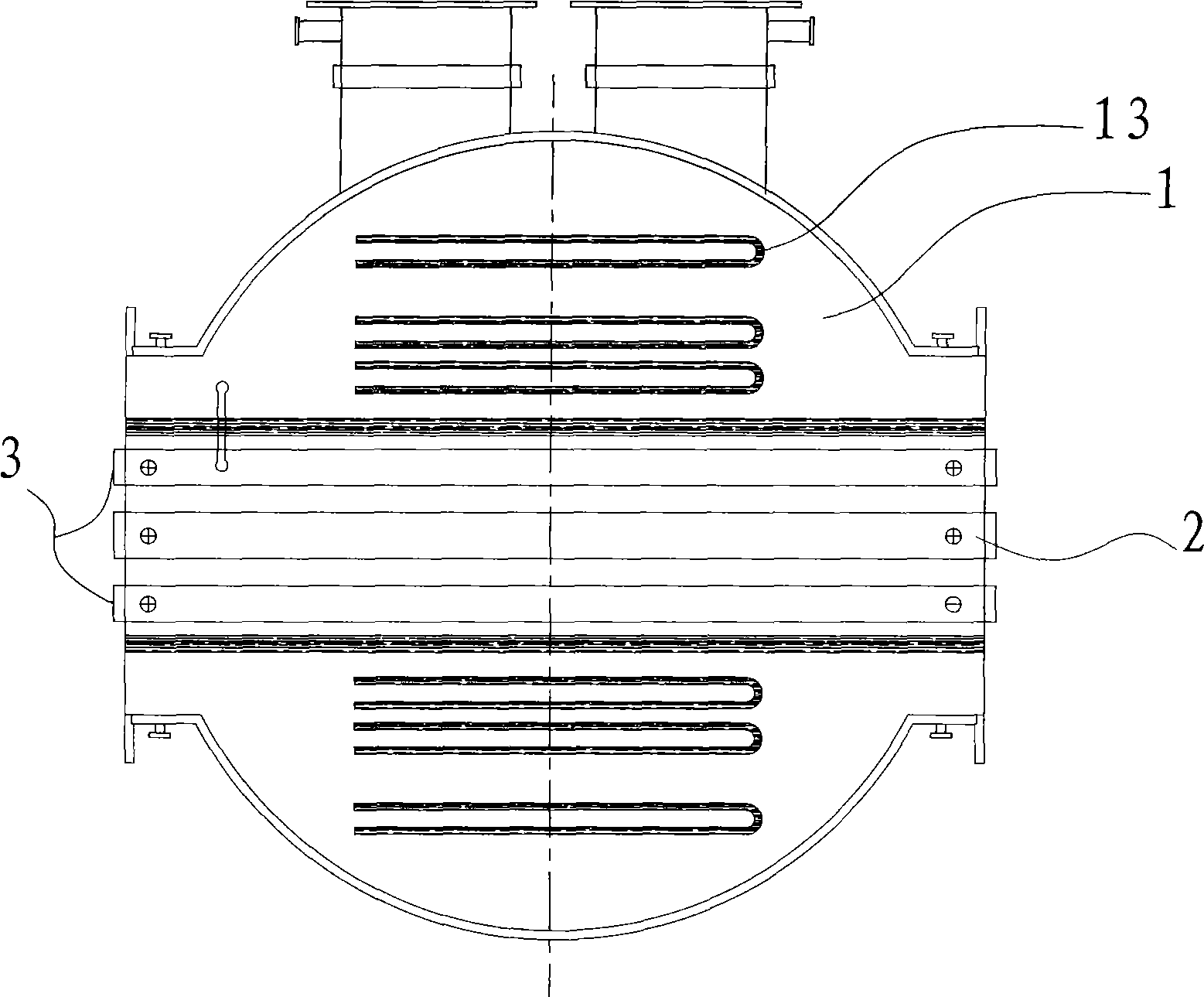

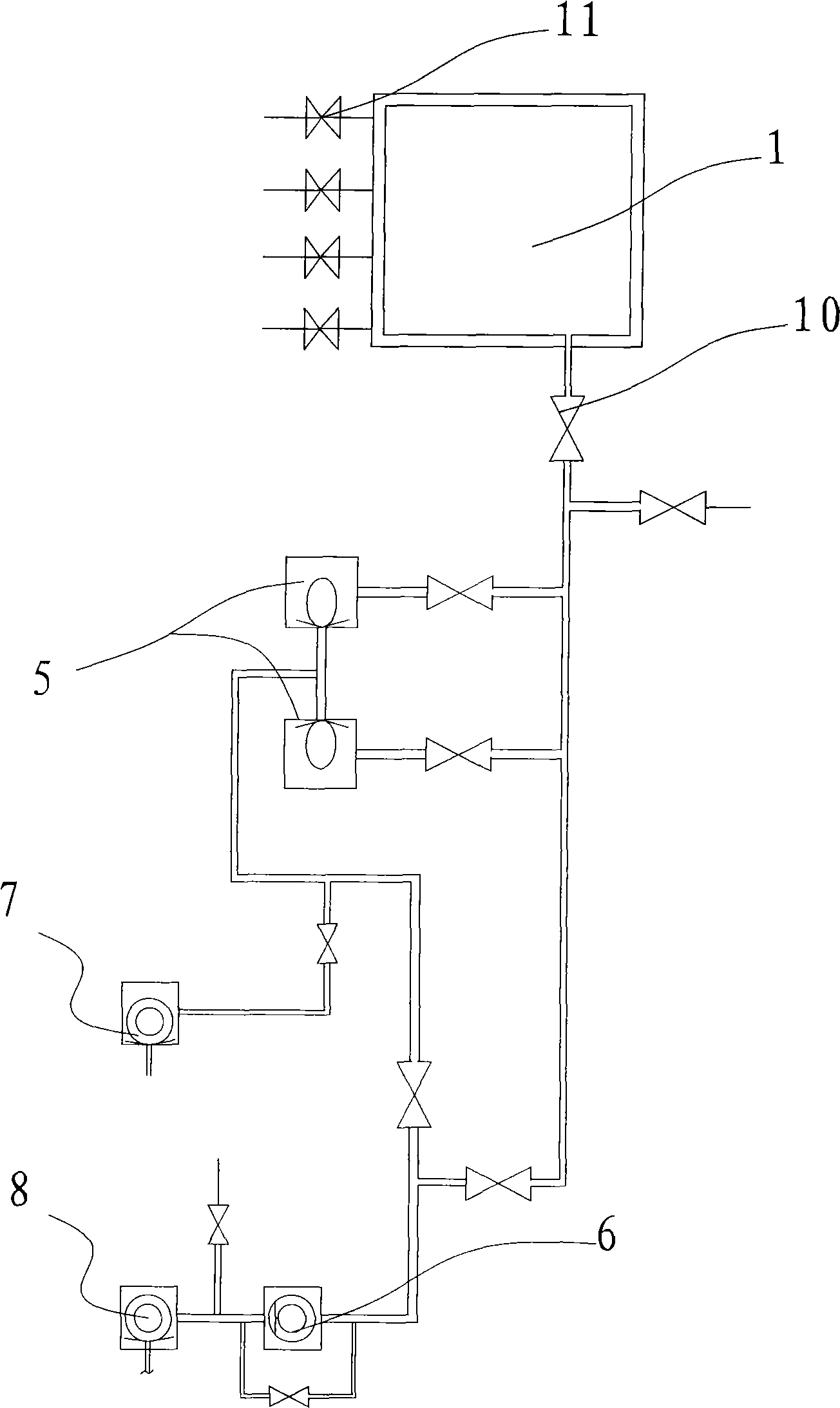

Large Bi-2212 superconducting coil heat treatment furnace system and pressure control method thereof

ActiveCN110953889AHeat treatment temperature controlGuaranteed cleanlinessSuperconductors/hyperconductorsMaintainance of heating chambersIntrinsic safetyInsulation layer

The invention discloses a large Bi-2212 superconducting coil heat treatment furnace system and a pressure control method of the large Bi2212 superconducting coil heat treatment furnace system. The system comprises a pressure-resistant furnace shell, a pressure-resistant furnace cover, a heat insulation layer, a heating chamber, a uniform-temperature radiation screen, a gas pipeline, a safety device and the like. Heat-treatment high temperature and high pressure system design requirements of a Bi-2212 superconducting coil are met. Due to the design of the uniform-temperature radiation screen ina heat treatment furnace, on one hand, the heat treatment temperature uniformity of the superconducting coil is improved, and on the other hand, the cleanliness of the superconducting coil is ensured. The pressure control method comprises the following stages of gas replacement in a pressure-resistant furnace shell, gas replacement in the uniform-temperature radiation screen, and synchronous pressurization and gas micro-feeding and micro-discharging. The large Bi-2212 superconducting coil heat treatment furnace system and the pressure control method of the large Bi2212 superconducting coil heat treatment furnace system have the advantages that the system adopts intrinsic safety design, the safety, reliability and performance-cost ratio are high. The system is suitable for processing largeBi-2212 superconducting coils with the outer diameters of 0.1-3m and the heights of 0.1-3m. The heat treatment temperature of the superconducting coil can be effectively controlled, the temperature uniformity of the superconducting coil can reach + / -5 DEG C, and the superconducting performance of the Bi-2212 superconducting coil is improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

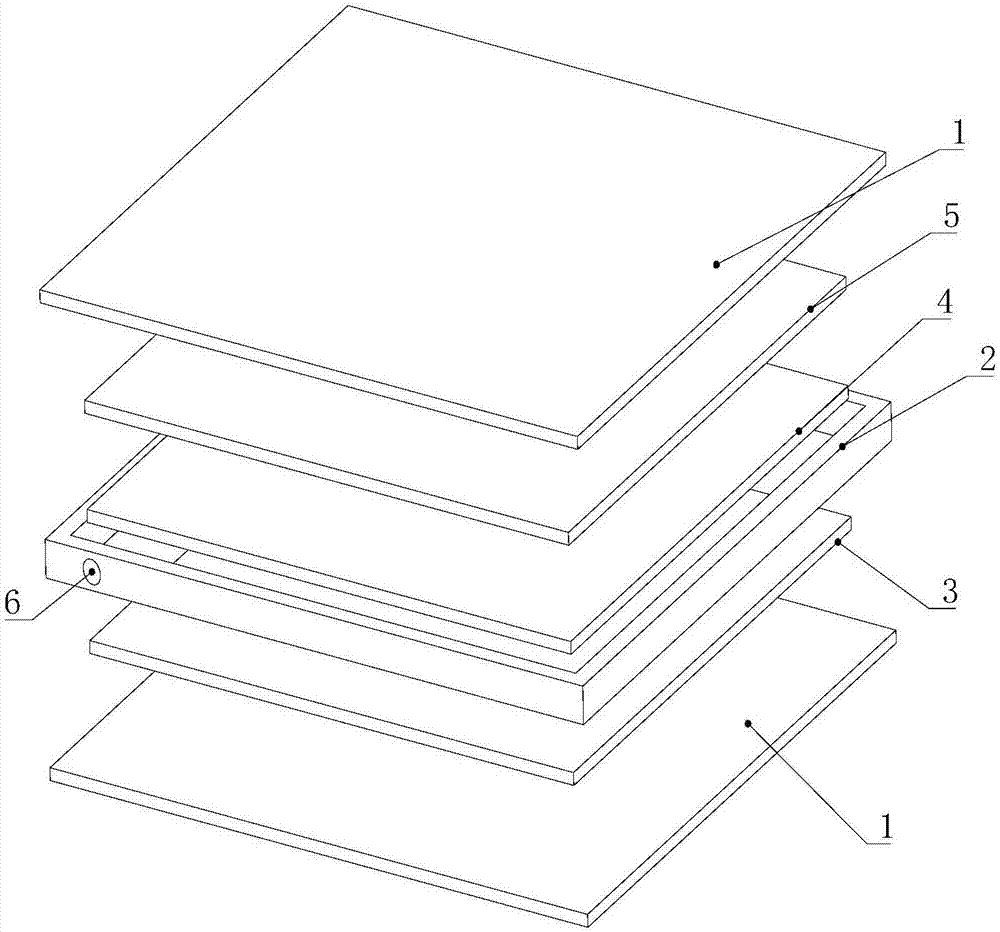

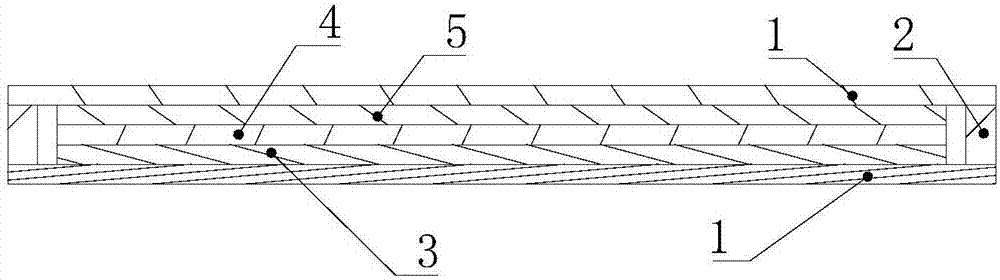

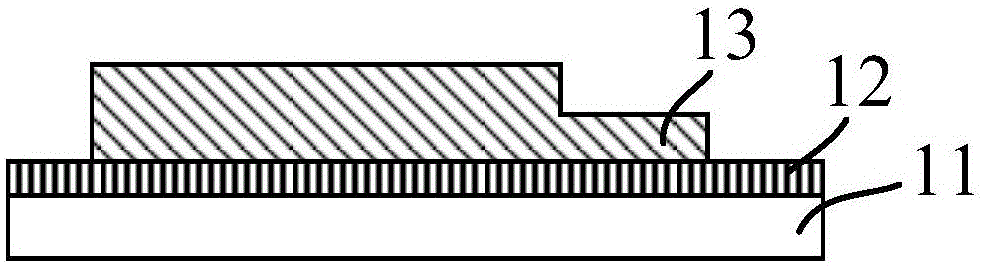

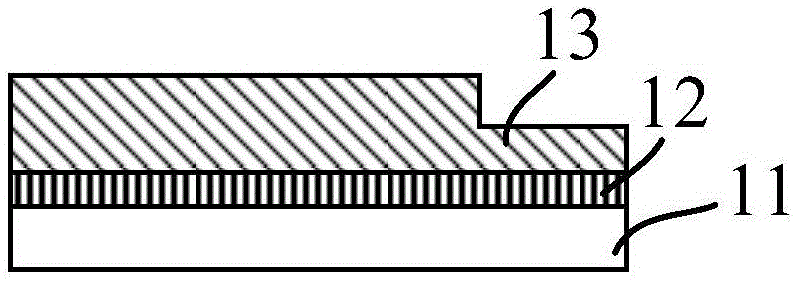

Organic thin film transistor array substrate and manufacturing method therefor

ActiveCN105140178AFree from oxidationReduce the number of processesSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerIndium tin oxide

The invention discloses an organic thin film transistor array substrate and a manufacturing method therefor. The manufacturing method comprises: continuously depositing on a substrate to form a metal layer thin film, then depositing an indium tin oxide (ITO) layer, coating a photoresist layer to form source and drain patterns, a data line and an anode of a pixel electrode simultaneously after a first manufacturing process for a mask, then manufacturing an organic semiconductor layer, an organic insulation layer, a gate electrode, a scanning line and a passivation layer in sequence, finally digging the covered passivation layer in the position of the pixel electrode (namely the OLED anode) to expose the electrode at the bottom layer, and then plating an OLED material layer on the exposed ITO pixel electrode to form an OLED device.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

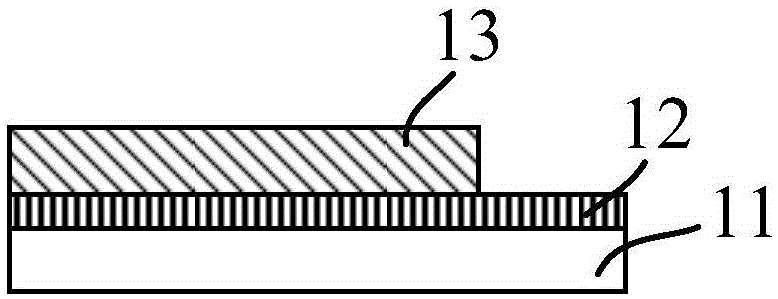

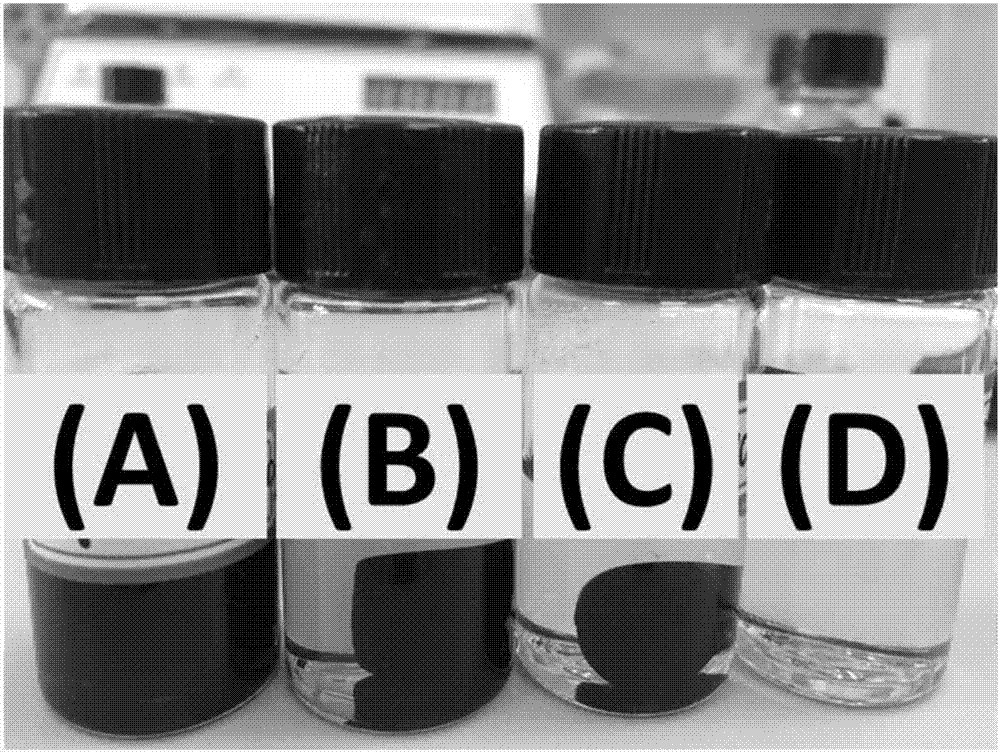

Graphene/black phosphorus nanosheet/sulfur-containing ionic liquid composite aerogel and preparation method thereof

ActiveCN107416846AAvoid reunionGood dispersionCarbon compoundsSulfur compoundsBlack phosphorusCvd graphene

The invention discloses graphene / black phosphorus nanosheet / sulfur-containing ionic liquid composite aerogel, which includes a graphene three-dimensional framework, as well as black phosphorus nanosheets and a sulfur-containing ionic liquid that are supported thereon; the black phosphorus nanosheets are coated with the sulfur-containing ionic liquid. The graphene / black phosphorus nanosheet / sulfur-containing ionic liquid composite aerogel has a three-dimensional porous network structure and has high elasticity, high resilience, high electric-conductivity and excellent stability. The composite aerogel increases products of black phosphorus and broadens application range of the black phosphorus. The invention also provides a preparation method of the graphene / black phosphorus nanosheet / sulfur-containing ionic liquid composite aerogel.

Owner:SHENZHEN UNIV

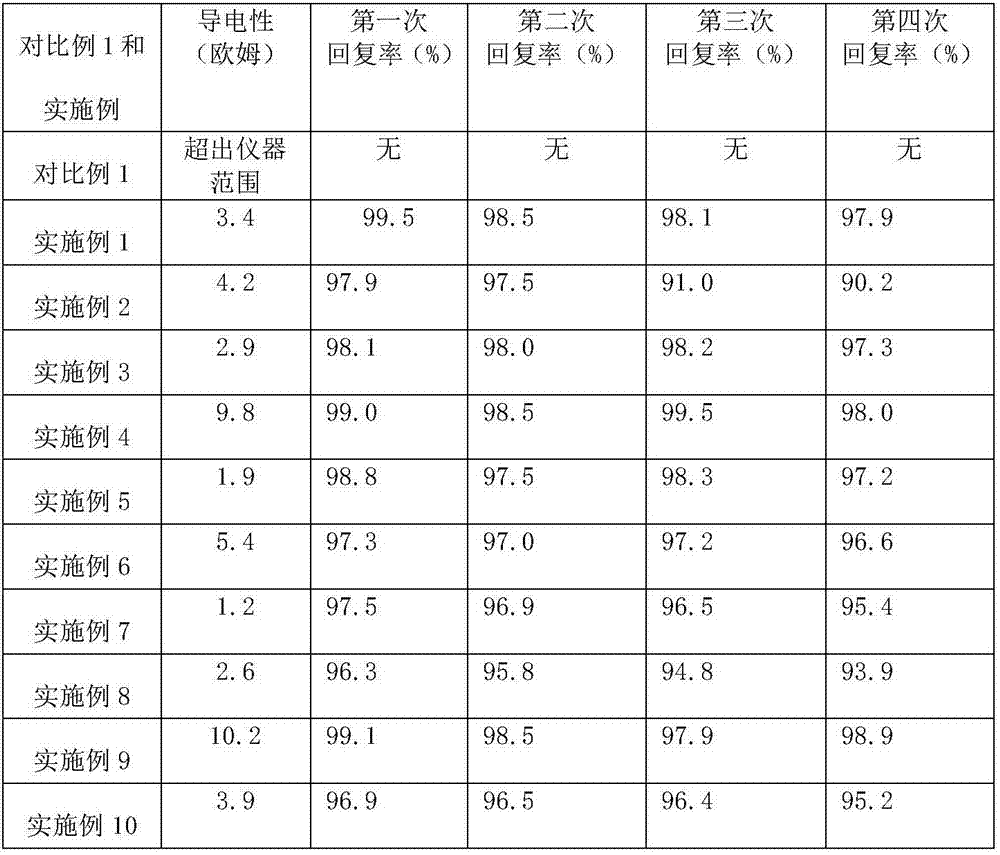

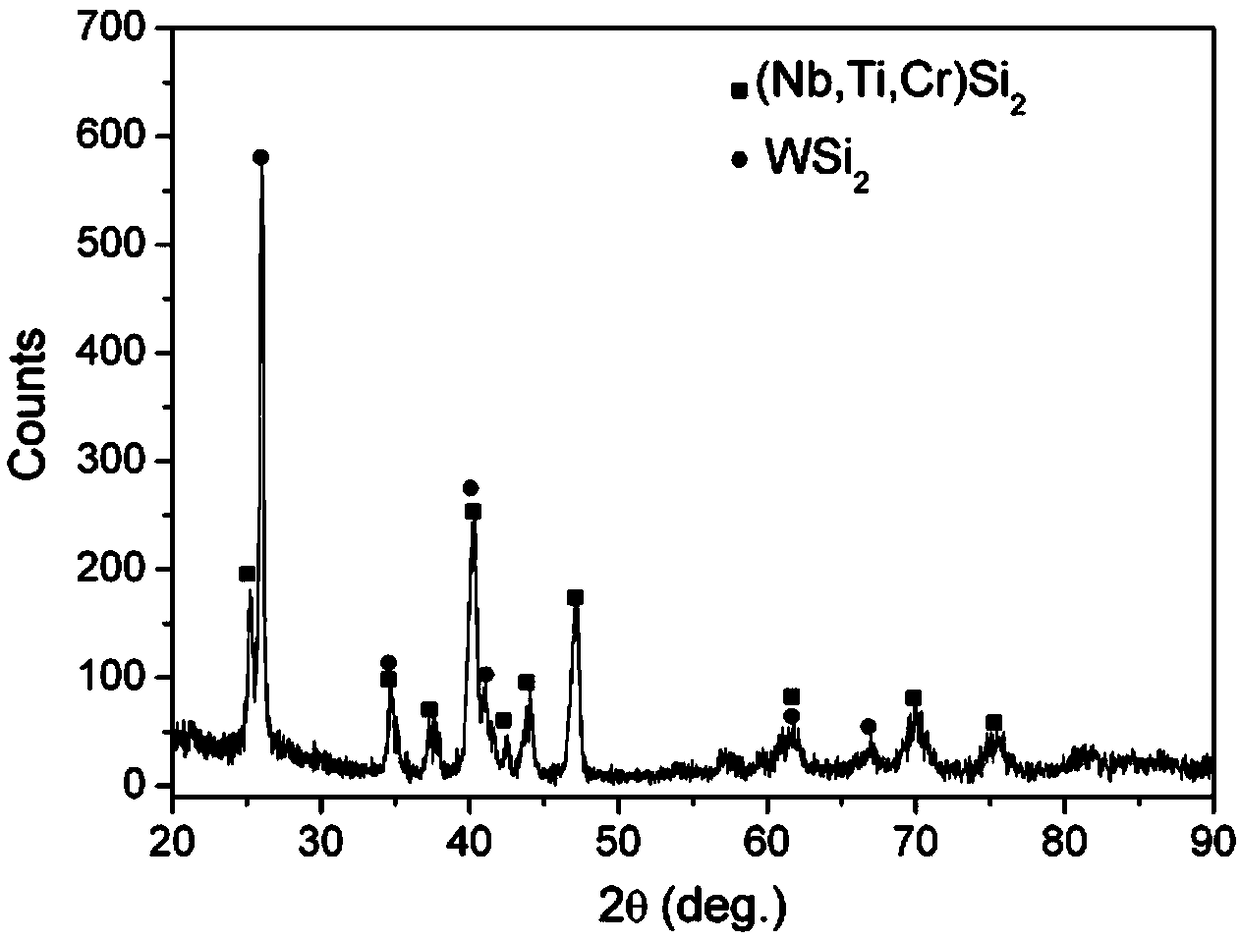

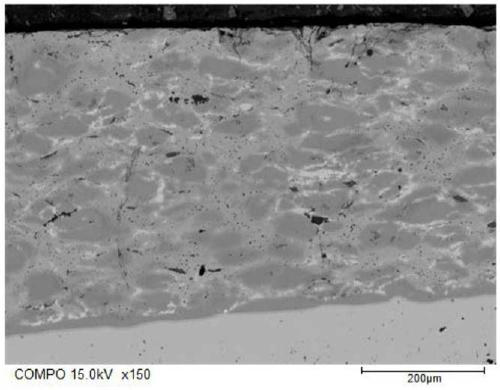

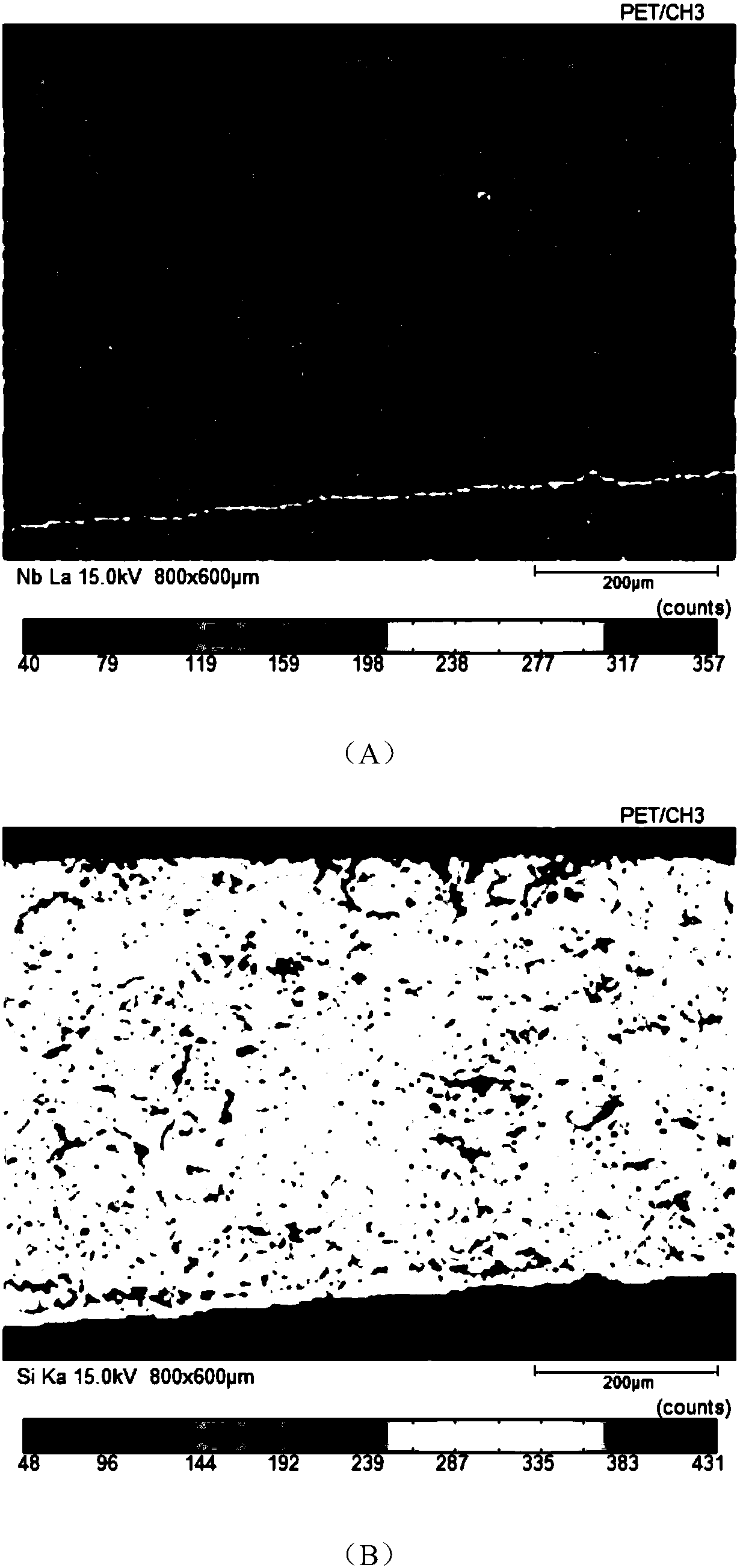

High-temperature-resistant multi-component silicide coating on surface of niobium alloy and preparation method of high-temperature-resistant multi-component silicide coating

ActiveCN109023338AInhibition of medium temperature "pest" oxidationImprove high temperature oxidation resistanceHeat inorganic powder coatingNiobium alloyMetal powder

The invention discloses a high-temperature-resistant multi-component silicide coating on the surface of niobium alloy and a preparation method of the high-temperature-resistant multi-component silicide coating. The high-temperature-resistant multi-component silicide coating has the phase composition of [(Nb(1-x-y)TixCry)(1-z),Rz]Si2, wherein R is one or more of the metal elements of Mo, W, Zr, Hfand Ta; x, y and z respectively represent mole numbers of the corresponding elements; 0.05<=x<=0.2; 0.05<=y<=0.3; and 0.05<=z<=0.4. The preparation method comprises the following steps: first, metal elementary powder and silicon elementary powder are weighed and thrown into a mixer to be fully mixed for 12-24 h; the mixed multi-component metal powder covers a niobium alloy workpiece, then, the covered niobium alloy workpiece is placed in a graphite crucible, and the graphite crucible is placed in a discharge plasma sintering furnace for sintering; and a sample of the sintered coating is subjected to homogenization heat treatment in a vacuum or protective atmosphere. The invention provides the discharge plasma sintering and homogenization heat treatment compounded preparation process. The process is simple. The coating structure is homogeneous. Ingredients are controllable. The coating has favorable high-temperature oxidation resistance at 1,200-1,600 DEG C.

Owner:CHINA UNIV OF MINING & TECH

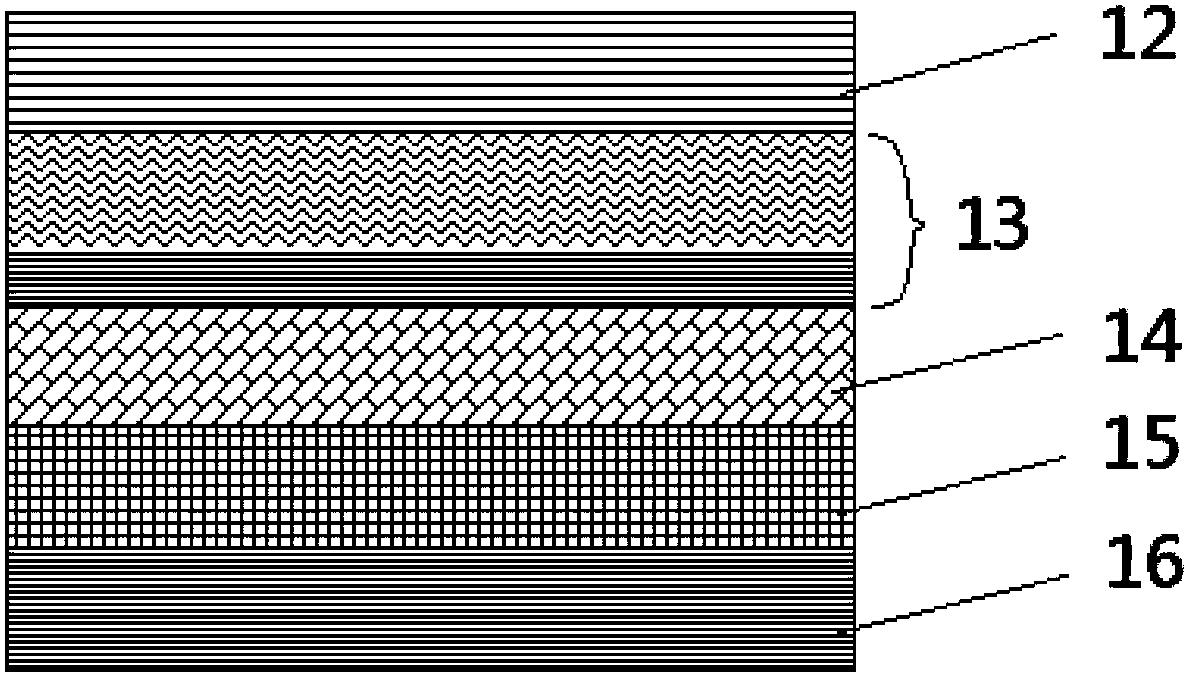

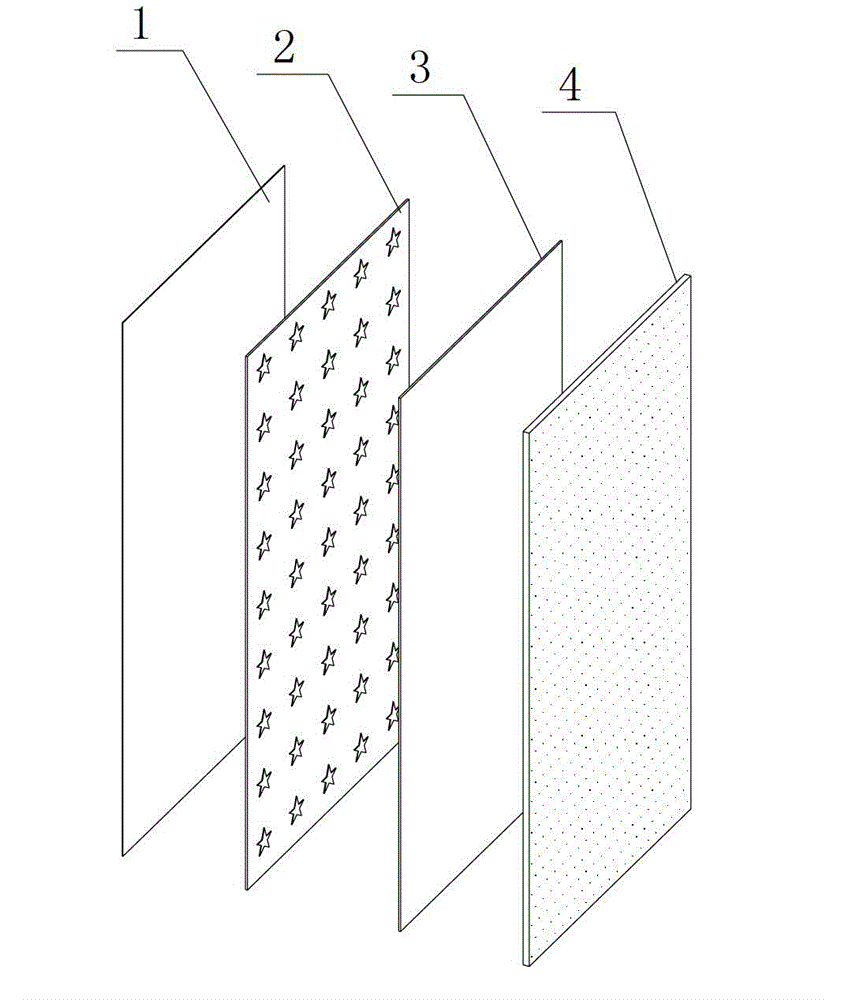

Preparation method for BOPET high-imitation metal wiredrawing VCM film

ActiveCN103692722ASave production costSave manufacturing costSynthetic resin layered productsMetal layered productsUltravioletBoPET

The invention discloses a preparation method for a BOPET (biaxially oriented polyester) high-imitation metal wiredrawing VCM film. The method includes: conducting surface wiredrawing treatment on one side of a transparent BOPET film; coating one surface without surface wiredrawing treatment by a polyurethane UV curable paint, carrying out UV photo-curing and heat curing, and performing natural cooling to obtain a surface hardened coating; coating the surface subjected to surface wiredrawing treatment with a model SC-400 pre-aluminizing prime coat to obtain a fastness enhanced coating; conducting vacuum aluminizing processing on the fastness enhanced coating to obtain a vacuum aluminized layer; and coating the aluminized surface of the vacuum aluminized layer with a model SC-500 topcoat, thus obtaining an antioxidant protective coating. Single-layer BOPET is adopted as a film main material, thus reducing the dosage of a raw material film, saving the production cost, prolonging the product life and improving the tolerance to various adverse conditions. The film obtained by the method has the visual effects of an imitated metal wire drawing board, thus realizing the purpose of high simulation of different material wiredrawing metal boards.

Owner:SHANGHAI RADIX VACUUM METALIZING

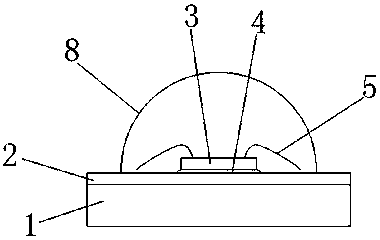

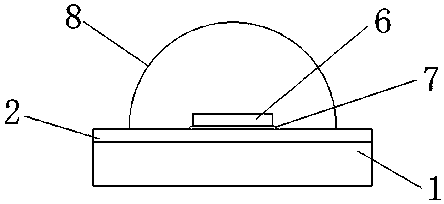

Bracket-free packaged LED light source and preparation method thereof

PendingCN107634134AImprove sealingReduce machine labor costsSemiconductor devicesLed packagingAdhesive

The invention discloses a bracket-free packaged LED light source, which comprises a silver plated copper piece, a first molding adhesive, a wafer and a second molding adhesive, and is characterized inthat the silver plated copper piece is provided with the first molding adhesive thereon and is connected with the first molding adhesive, the wafer is arranged on the first molding adhesive and is connected with the first molding adhesive, the second molding adhesive is packaged on the first molding adhesive, and the wafer is packaged in the second molding adhesive. Another purpose of the invention lies in providing a preparation method of the bracket-free packaged LED light source. The preparation method comprises the steps of S1, preparing materials; S2, manufacturing a silver plated copperpiece; and S3, performing an LED packaging process on the silver plated copper piece. According to the bracket-free packaged LED light source provided by the invention, the molding adhesives are adopted for packaging after the silver plated copper piece is fixed and welded, the sealing performance is improved, and the combination of the silver plated copper piece and the molding adhesives is provided. Meanwhile, the traditional bracket is removed, a bracket-free packaging mode is realized, the machine and labor cost at the upstream and the downstream is greatly reduced, and the cost is saved.

Owner:SHENZHEN LEPOWER CO LTD

Production method for novel crystal tablecloth

ActiveCN102907999AAvoid direct contactFree from oxidationLamination ancillary operationsSynthetic resin layered productsMetal coatingColour loss

The invention relates to a production method for a novel crystal tablecloth, which is characterized by comprising the following working procedures: 1, performing heat-laminating on a PET (polyester) film protecting layer and a first PVC (polyvinyl chloride) electrostatic film layer; 2, printing patterns or a metal coating on the first PVC electrostatic film layer from a polyester film with the printed patterns or the metal coating in a heat transfer printing manner; 3, performing heat-laminating on the first PVC electrostatic film layer and a second PVC electrostatic film layer, and sandwiching the patterns or the metal coating between the two electrostatic film layers; 4, performing heat-laminating on the second PVC electrostatic film layer and a thickened PVC layer; 5, performing high-temperature plasticizing treatment; 6, performing embossing treatment on the outer surface of the thickened PVC layer, so as to form an embossed surface or a frosted surface; 7, cooling for shaping; and 8, winding, thus obtaining the novel crystal tablecloth finished product. The crystal tablecloth finished product produced by adopting the production method disclosed by the invention is environment-friendly, high-temperature-resistant, anti-scratch and anti-damage, and free from colour loss, colour change and colour fading, and has a 3D (three-dimensional) visual effect.

Owner:鸿威新科(天津)装饰材料有限公司

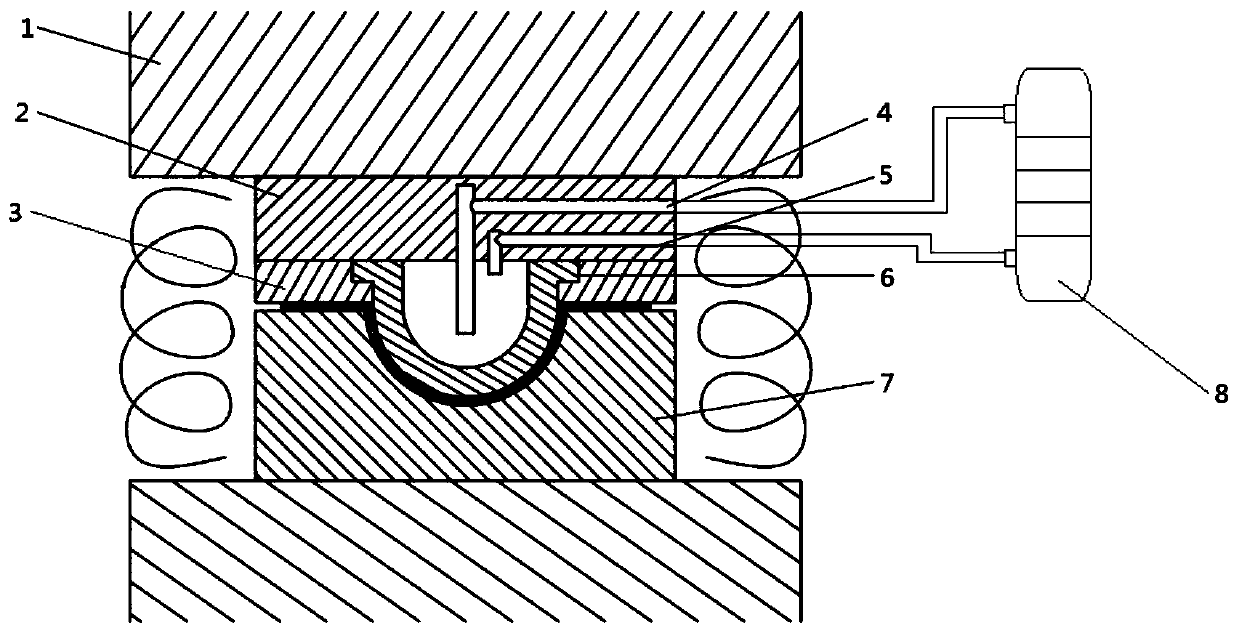

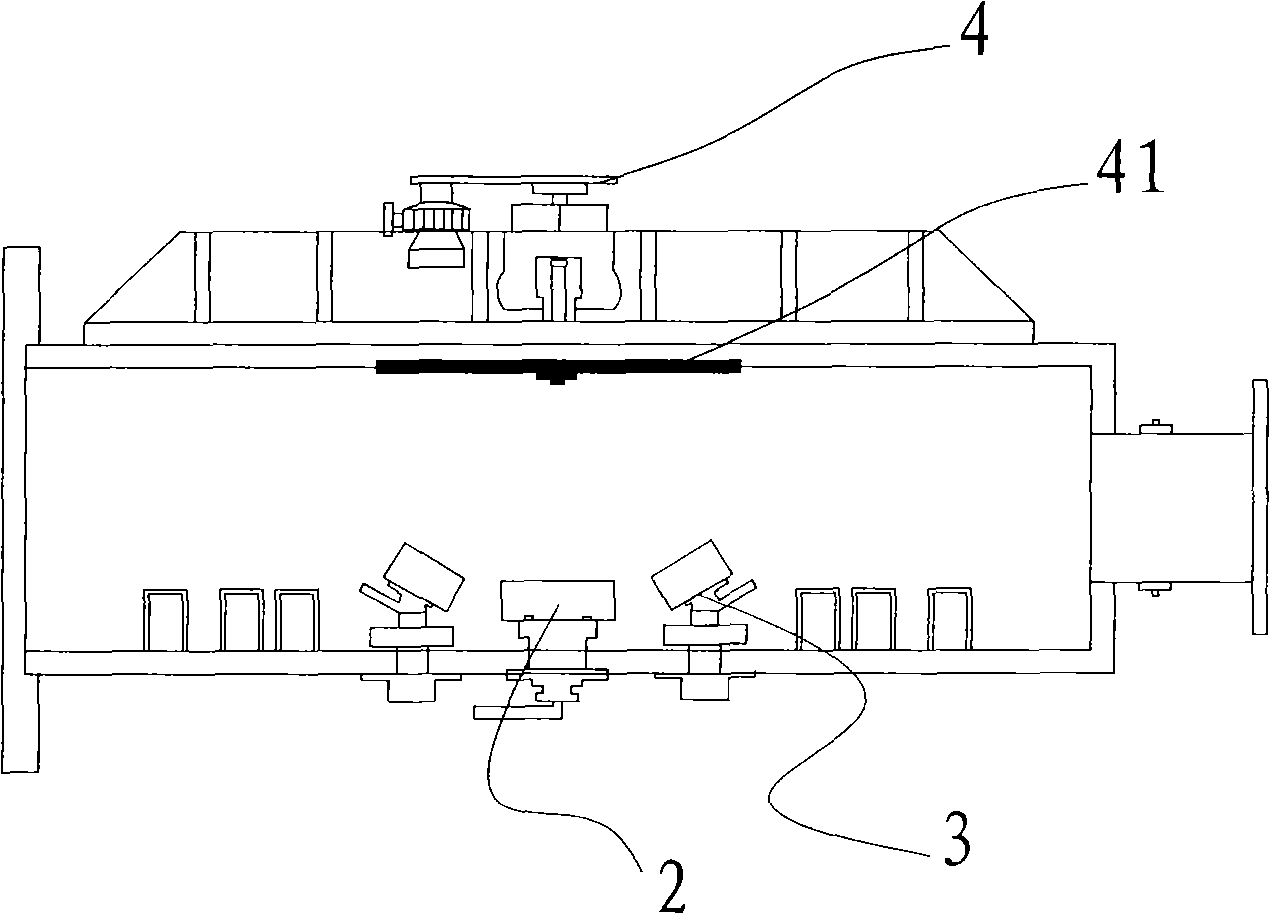

Equal-temperature hot drawing forming device and method for controlling wall thickness uniformity of component

The invention discloses an equal-temperature hot drawing forming device and method for controlling wall thickness uniformity of a component, and relates to the field of equal-temperature hot drawing forming devices and methods by controlling the wall thickness uniformity of the component, which solves the technical problem that in an existing hot drawing technology method, bottom part reduction issevere, and thus blank deformation is nonuniform. The equal-temperature hot drawing forming device includes a hot forming press machine, a die and a gas cooler, wherein the die includes a template, afixing plate, an air inlet pipe, an air outlet pipe, a male die and a female die. The method includes the steps that 1, the die is mounted on the hot forming press machine; 2, heating is conducted, sheet materials are put into, heat insulation is conducted, cooling gas is introduced, drawing forming is conducted, and pressure maintaining is conducted; and 3, the die is opened and is cooled to a room temperature, and inspection and acceptance are conducted. According to the equal-temperature hot drawing forming device and method, circulating helium is introduced into a male die hollow structural cavity through an air passage of an upper male die to lower the temperature of the upper die, the degree of deformation of the contact part of the sheet materials and the upper male die is reduced,the thicknesses of the arc positions of the bottom parts of the sheet materials are increased, and uniform deformation of a formed part is achieved. The equal-temperature hot drawing forming device and method are used for preparing sheet material parts.

Owner:HARBIN INST OF TECH

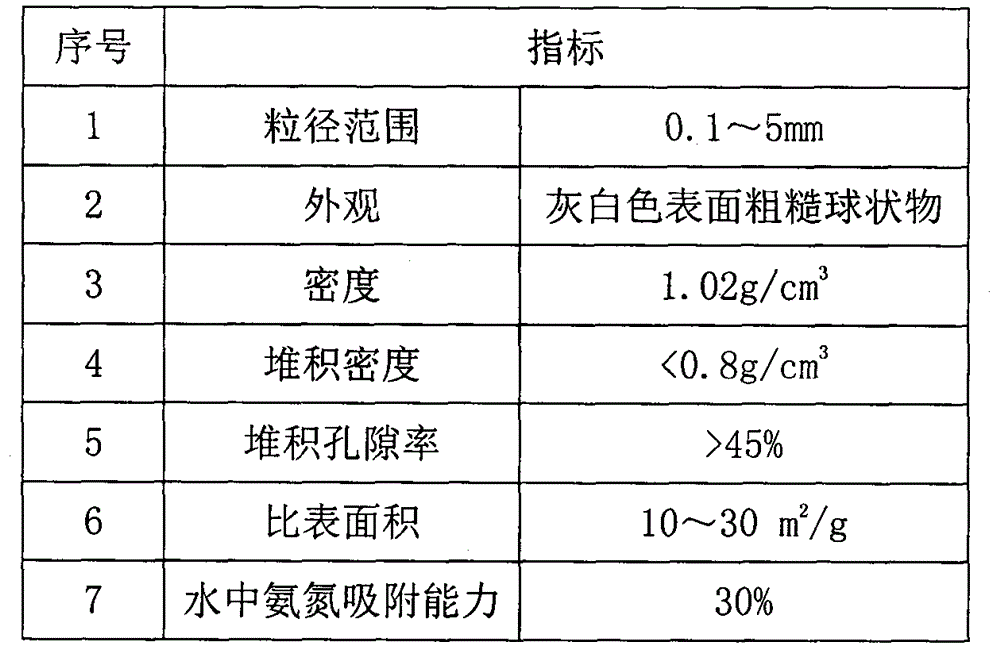

Nano-silver-loaded microcrystal bamboo charcoal ceramic bead and preparation method thereof

ActiveCN104437365ASignificant technological progressFree from oxidationOther chemical processesDispersed particle separationAdhesiveNanostructure

The invention relates to a nano-silver-loaded microcrystal bamboo charcoal ceramic bead and a preparation method thereof. The nano-silver-loaded microcrystal bamboo charcoal ceramic bead is prepared from nano-silver and a microcrystal bamboo charcoal ceramic bead by virtue of surface compounding, wherein the microcrystal bamboo charcoal ceramic bead is prepared from the following components by weight percent: 30%-50% of bamboo charcoal powder, 30%-40% of porous nonmetal mineral powder, 20%-30% of clay and 2%-5% of an adhesive. According to the preparation method, the microcrystal bamboo charcoal ceramic bead is coated with nano-silver, so that nano-silver has a strong support body, doped nano-structure silver is further formed, and the catalytic efficiency of nano-silver is further improved; the microcrystal bamboo charcoal ceramic bead is high in structural strength and can resist high temperature, so that the microcrystal bamboo charcoal ceramic bead can be regenerated by virtue of a roasting manner after being used for a long time, and the adsorption capability and the catalytic degradation and killing effects are recovered; compared with porous-ceramic-loaded nano-silver, the nano-silver-loaded microcrystal bamboo charcoal ceramic bead has relatively good effects in the aspects of water quality purification, air purification and the like, furthermore, the preparation method is simple, and the application is convenient.

Owner:桂林良物造环境科技有限公司

Method for plating glasses to a large area without pollution

InactiveCN101544473AControl thicknessSimple structureVacuum evaporation coatingSputtering coatingMedium frequencyNew materials

The invention relates to the field of new materials and surface techniques, in particular to a method for plating glasses to a large area without pollution. The method comprises the following steps: mounting a medium frequency direct current composite magnetron sputtering device which comprises a direct current plane magnetron sputtering silver target and a replaceable medium frequency twinborn magnetron sputtering target; plaiting a silver film on the surface of a workpiece through the direct current plane magnetron sputtering silver target; and plating a compound film on the surface of the workpiece through the medium frequency twinborn magnetron sputtering target, wherein the workpiece is glass. The method is environmentally-friendly, the process is simple, and the obtained product has long service life.

Owner:HUZHOU TIAHE AUTOMOBILE PART

Method and device for extracting carbon material from plastic

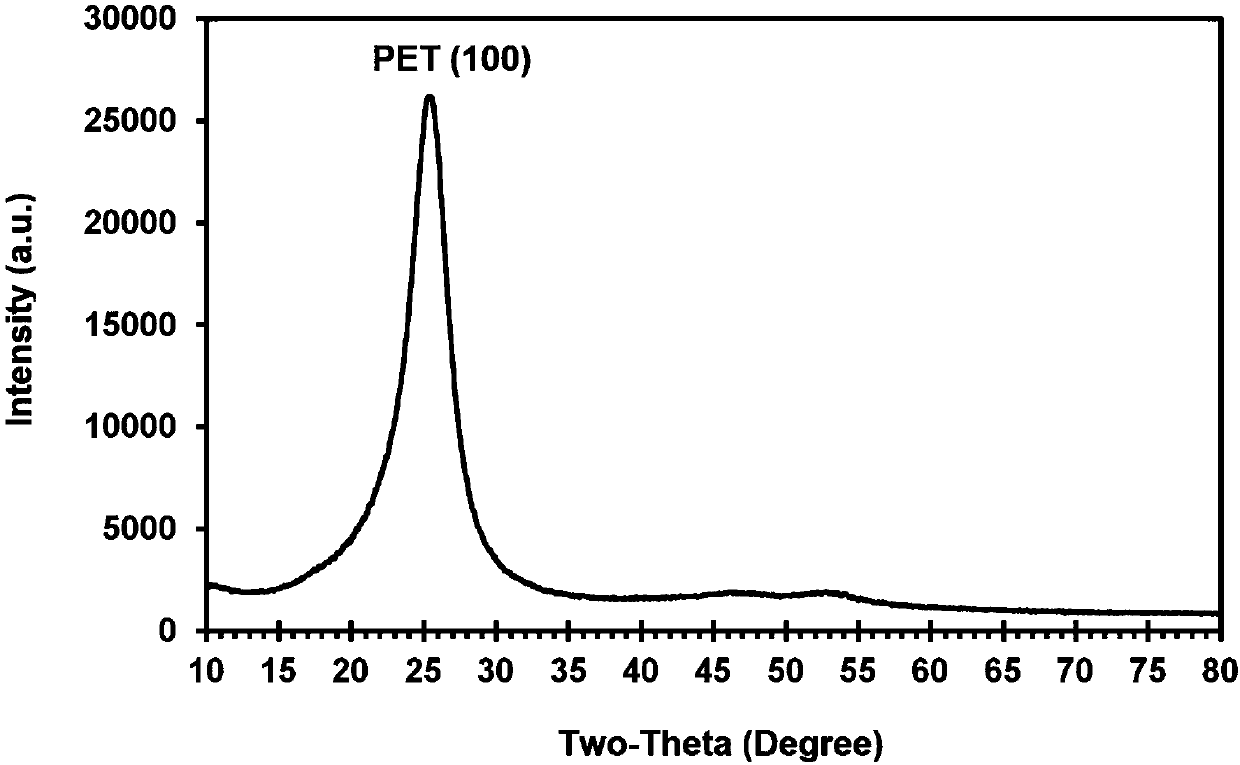

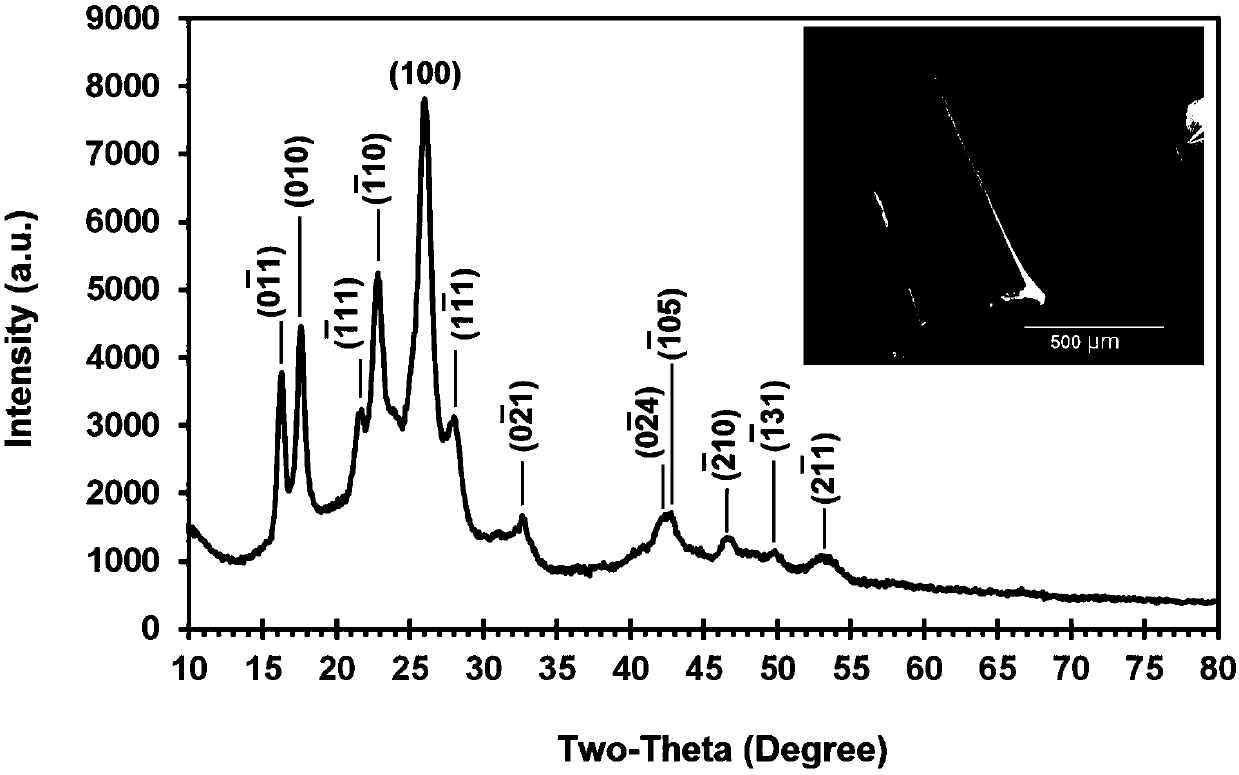

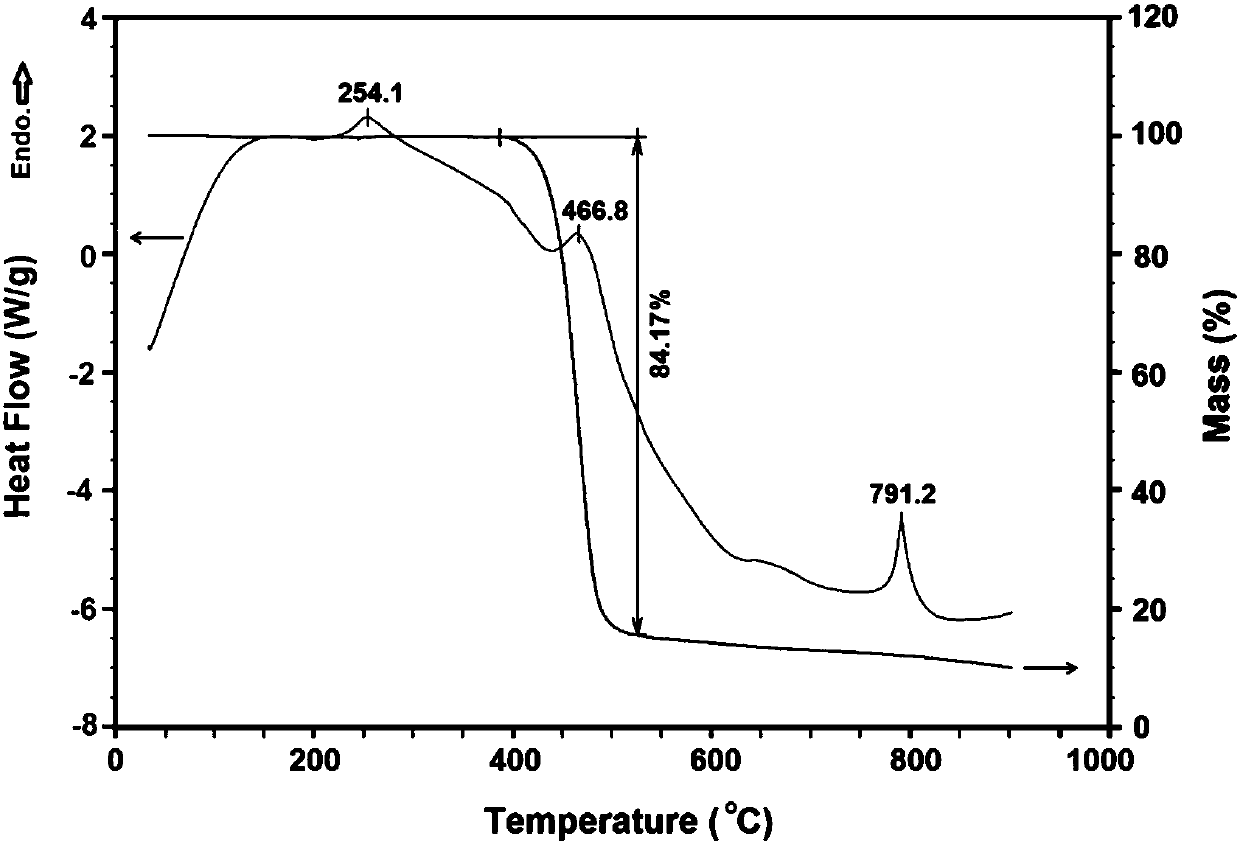

The invention provides a method and device for extracting a carbon material from plastic. The method comprises the steps that at least one plastic material (such as polyterephthalate) in at least onekind of molten salt (such as NaCl) is subjected to thermal treatment to reach above a melting point of the molten salt, and the nanostructured carbon material is formed, wherein the salt is in a molten state, and the carbon material is protected from oxidation; moreover, the molten salt promotes further graphitization of the carbon material, and the product of the molten salt is a nanographite micro-sheet with high conductivity and high surface area; according to the method, a simple, economical and efficient method is provided for producing the conductive carbon material. By means of the method, hardly-degradable plastic waste is also converted into the conductive carbon material with high value, and a significant positive influence is achieved on the environment.

Owner:NORTHEASTERN UNIV LIAONING

Delayed combustion-retarding high temperature-resistant workshop primer and preparation method thereof

ActiveCN104109460AImproving the resistance to burning and high temperature resistanceImprove high temperature resistancePaints with free metalsEpoxyPolyvinyl alcohol

The invention discloses a delayed combustion-retarding high temperature-resistant workshop primer and a preparation method thereof. The workshop primer is prepared from a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 20-80 parts of polyethyl silicate Si-40, 20-80 parts of organic solvent, 1-10 parts of deionized water and 0.5-5 parts of concentrated acid; the component B is prepared from the following raw materials in parts by weight: 15-20 parts of organic solvent, 2-5 parts of polyvinyl acetal, 0-8 parts of alcohol-soluble organic silicon resin, 1-6 parts of epoxy resin, 10-30 parts of delayed combustion-retarding agent, 1-5 parts of coating auxiliaries, 4-8 parts of ferrophosphorous powder with the granularity of 1000-1500 meshes and 20-40 parts of zinc powder with the granularity of 1000-1500 meshes; the ratio of the component A to the component B in parts by weight is (15-90):100. The heat-resistant temperature of the coating obtained by the primer can achieve more than 800DEG C, the burning loss area is extremely small, and smoke is not almost generated during the cutting or welding process.

Owner:GUANGZHOU GEMBOND CHEM

BOPET high-simulation metal wire drawing VCM film, use thereof, and VCM

ActiveCN103692725ASave production costSave manufacturing costSynthetic resin layered productsMetal layered productsBoPETCase hardening

The invention discloses a BOPET high-simulation metal wire drawing VCM film, a use thereof, and a VCM. The VCM film sequentially comprises a surface hardening coat, a transparent BOPET film with one surface subjected to surface wire drawing treatment, a fastness enhancing coat, a vacuum aluminum coat and an anti-oxidation protection coat; the surface hardening coat is an ultraviolet-curable polyurethane coating layer; the fastness enhancing coat is a polyurethane coating layer, and the above polyurethane coating is a primer with the model of SC-400 before aluminizing; and the anti-oxidation protection coat is a polyurethane coating layer, and the above polyurethane coating a top coating with the model of SC-500. The VCM film adopts single-layer BOPET as a film main material, so the consumption of a raw film is reduced, the production and making cost is saved, the life of a product is prolonged, and the tolerances of various bad conditions are improved. The VCM film has a best visual sense effect of a simulation metal wire drawing plate, and truly realizes the high simulation purpose of wire drawing metal plates of different materials.

Owner:SHANGHAI RADIX VACUUM METALIZING

Compound paracetamol and amantadine hydrochloride capsule and preparation method thereof

InactiveCN105748522AEasy to swallowMask bad smellAntipyreticAnalgesicsChlorphenamine maleateBioavailability

The invention discloses a compound paracetamol and amantadine hydrochloride capsule and a preparation method thereof. The compound paracetamol and amantadine hydrochloride capsule comprises chlorphenamine maleate, calculus bovis factitious, caffeine, viregyt hydrochloride, paracetamol and dextrin according to a mass ratio of 1:5:7.5:50:125:4-5. The above compound preparation has the advantages of tidiness, beauty, easy deglutition, fast dispersion in gastric juice, good absorption, high bioavailability and good medicine stability. The preparation method has the advantages of simple operation, easy control, and suitableness for industrial production.

Owner:KAMP PHARMA

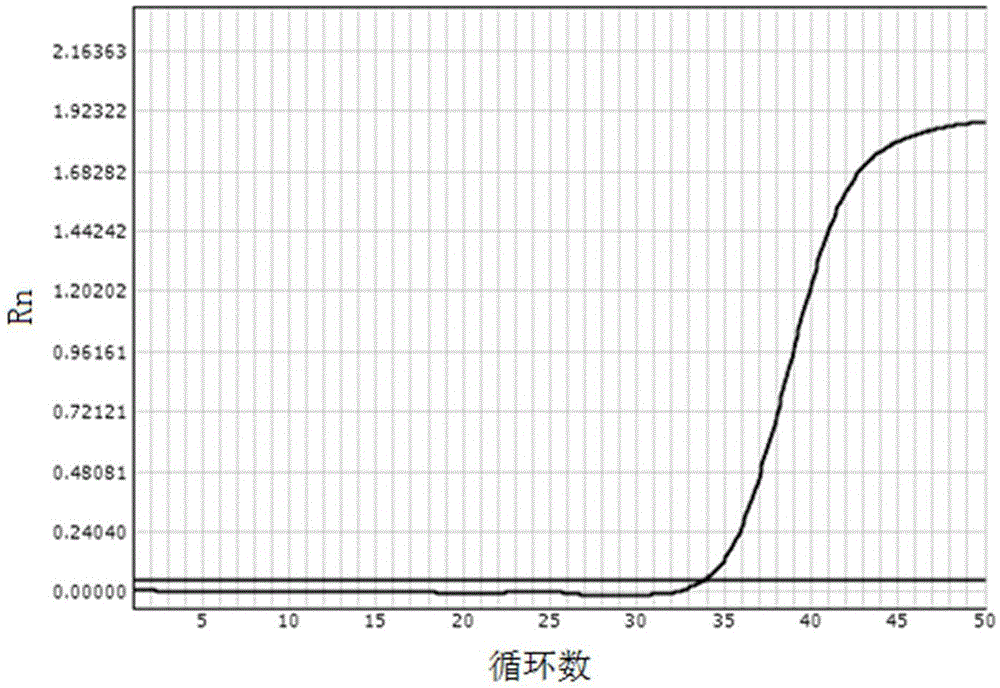

Method for extracting nucleic acid from paraffin-embedded tissue section

The invention discloses a method for extracting nucleic acid from a paraffin-embedded tissue section. The method includes the following steps: S1, performing paraffin embedding slicing; S2, performingcracking, taking out a standby section tissue in S1, adding novel lysate into the section tissue, the volume ratio of the section tissue to the novel lysate being 1 : 50-100, performing centrifugal layering after performing mixing and uniform shaking for 10-15 min under a temperature of 65-75 DEG C, performing standing after layering, and taking an intermediate layer after standing so that mixedliquor can be obtained; S3, performing combination; S4, performing washing; and S5, performing elution. Cells can be fully and effectively cracked by using the novel lysate to perform the cracking ofnucleic acid on the section tissue, so that a cracking process can be accelerated, the nucleic acid can be protected from oxidizing, and the formation of DNA self-dimer can be avoided; and the methodhas the characteristics of being short in using time, high in extraction efficiency and high in extraction quality, so that the method is suitable for being popularized and used.

Owner:凡知医疗科技(江苏)有限公司

Beta PP-R tubular product, and manufacturing method thereof

The invention discloses a beta PP-R tubular product. The beta PP-R tubular product comprises PP-R; PP-R comprises, by mass, 40 to 70% of Beta-PPR, 2 to 4 % of a color master, 0.7 to 2% of nano silicon carbide, 0.5 to 2% of a long-acting oxygen inhibitor, and 1 to 3% of a nucleating agent. The invention also relates to a manufacturing method of the beta PP-R tubular product. The manufacturing method is simple; production efficiency is high; structural strength and performance of obtained products are improved greatly; service life is prolonged significantly; the beta PP-R tubular product possesses super high-temperature resistance, high compression strength, excellent high-temperature creep resistance, low linear expansion coefficient, and high heat distortion temperature; hot-melt conjunction of the beta PP-R tubular product with pipe fittings is convenient; installation is simple; and artificial cost is reduced greatly.

Owner:ZHEJIANG ZHONGDE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com