Corrosion inhibitor for after polishing detergent

A technology of corrosion inhibitor and cleaning agent, applied in the direction of detergent compounding agent, detergent composition, non-surface active detergent composition, etc., which can solve problems such as poor interface, residual BTA, and decreased reliability of wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

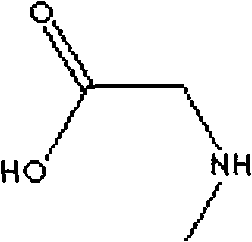

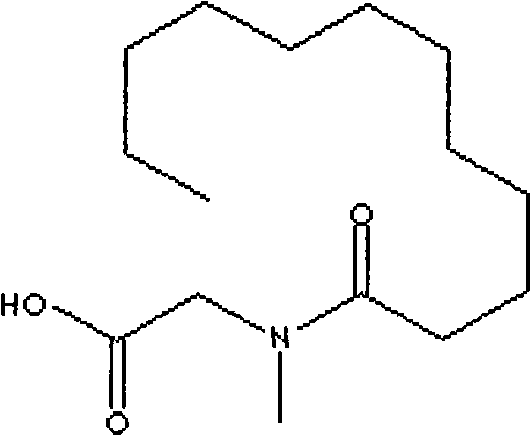

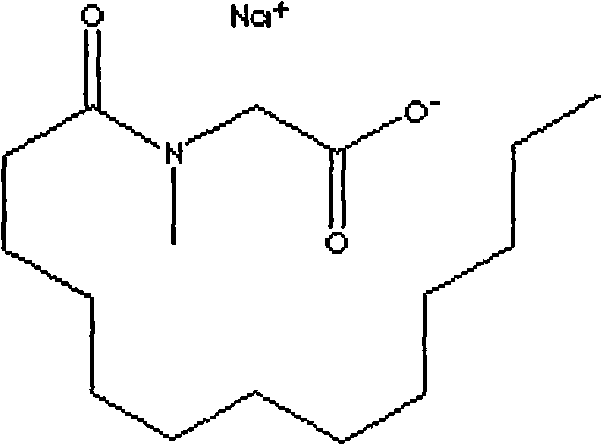

[0023] According to Table 1, a post-grinding cleaning test was performed using the post-grinding cleaners composed of the components of Comparative Examples 1 to 3, and the copper loss rate on the wafer surface in each comparative example was compared. Wherein, the chemical formula of the sodium cocoyl sarcosinate is as formula four:

[0024]

[0025] Formula four

[0026] (RCON(CH 3 )CH 2 COONa, CAS61791-59-1)

[0027] citric acid

(wt%)

(wt%)

lauryl sarcosine

ppm

Cocoyl Sarcosine

ppm

Comparative example 1

0.2

0.2

0

0

Comparative example 2

0.2

0.2

20

0

Comparative example 3

0.2

0.2

0

20

[0028] Table I

[0029] The post-grinding cleaning test was carried out according to the following conditions, and the results of copper loss analysis by TXRF (total reflection X-ray fluorescence spectroscopy) are rec...

Embodiment 2

[0038] According to the list in Table 3, the post-CMP cleaning test was carried out using the post-grinding cleaner composed of the components of Comparative Examples 4 to 5, and the copper loss rate on the wafer surface was compared among the comparative examples.

[0039] citric acid

(wt%)

(wt%)

Comparative example 4

0.25

0.0085

0

Comparative example 5

0.25

0.0085

10

[0040] Table three

[0041] The post-grinding cleaning test was performed according to the following conditions, and the average results of copper loss analyzed by TXRF (total reflection X-ray fluorescence spectroscopy) are recorded in Table 4.

[0042] Wafer type: 2 pieces of 2000A thick copper clad wafer

[0043] Cleaning unit: Ontrack post CMP brush box (Lam Research, CA USA)

[0044] Cleaning agent flow rate: 300ml / min

[0045] Cleaning time: 50 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com