Patents

Literature

369results about How to "Save manufacturing cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

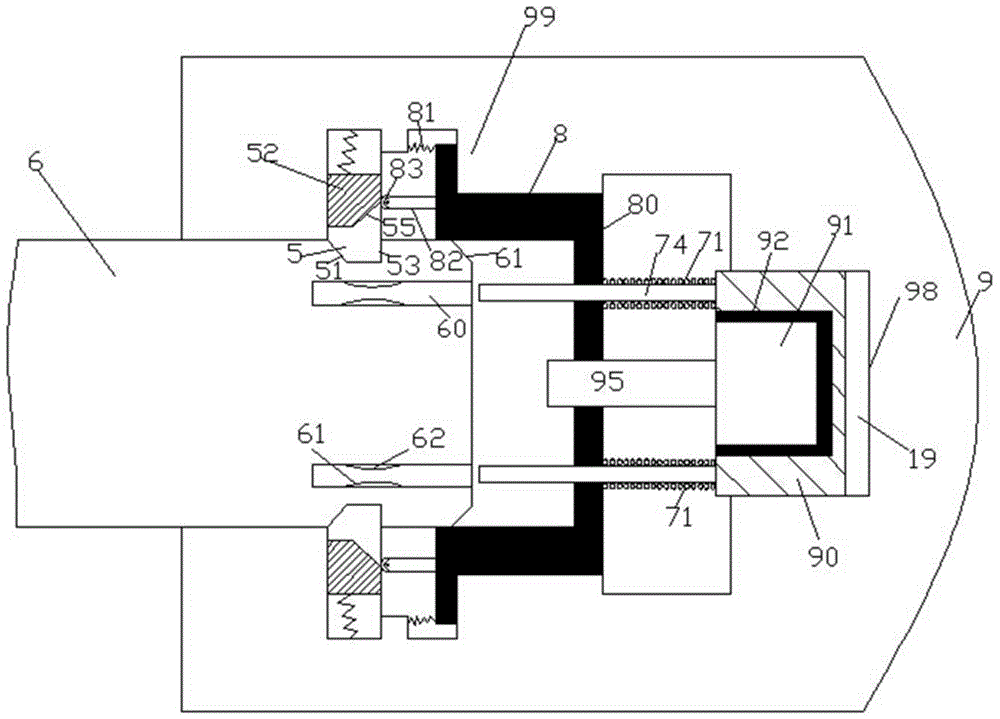

Socket with power-on indication lamp

InactiveCN105186200AAchieve orientationAvoid manual operationCoupling device detailsMechanical engineeringStator

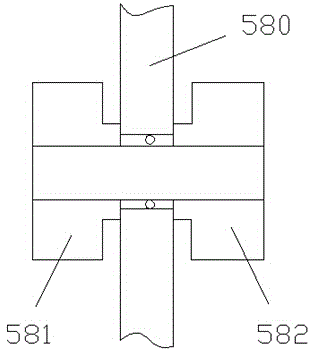

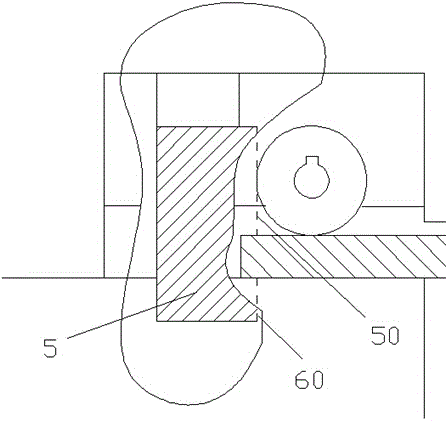

The invention provides a socket with a power-on indication lamp. The socket comprises a socket body (9) and a mounting seat (90) which is installed in the sliding groove (19) of the socket body (9) and can slide left and right. The left end of the sliding groove (19) is provided with a limit projection (92). The right end of the mounting seat (90) is provided with a limit block (900) which is matched with the limit projection (92). The mounting seat (90) is internally equipped with an execution motor (91). The rotor of the execution motor (91) and a screw rod (95) are in power connection. The screw rod (95) is cooperated with the screw hole in the transverse wall member (8) in the socket body (9). The left end wall of the mounting seat (90) is fixedly connected to power supply guide columns (74) which slidingly go through the sliding holes in the transverse wall member (8). The power supply guide columns (74) are used for connecting the power supply holes (60) in the plug (6) inserted into the jack of the socket body (9) to supply power. In each of the power supply guide columns (74), a compression spring (71) is arranged between the surface of the transverse wall member (8) facing the execution motor (91) and the stator of the execution motor.

Owner:肖白玉

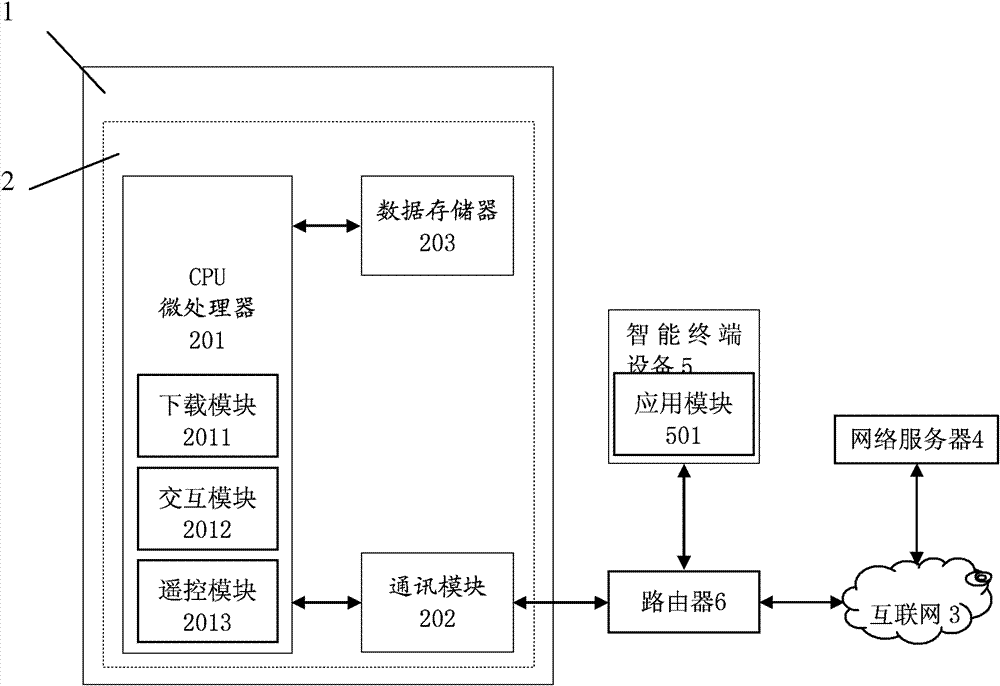

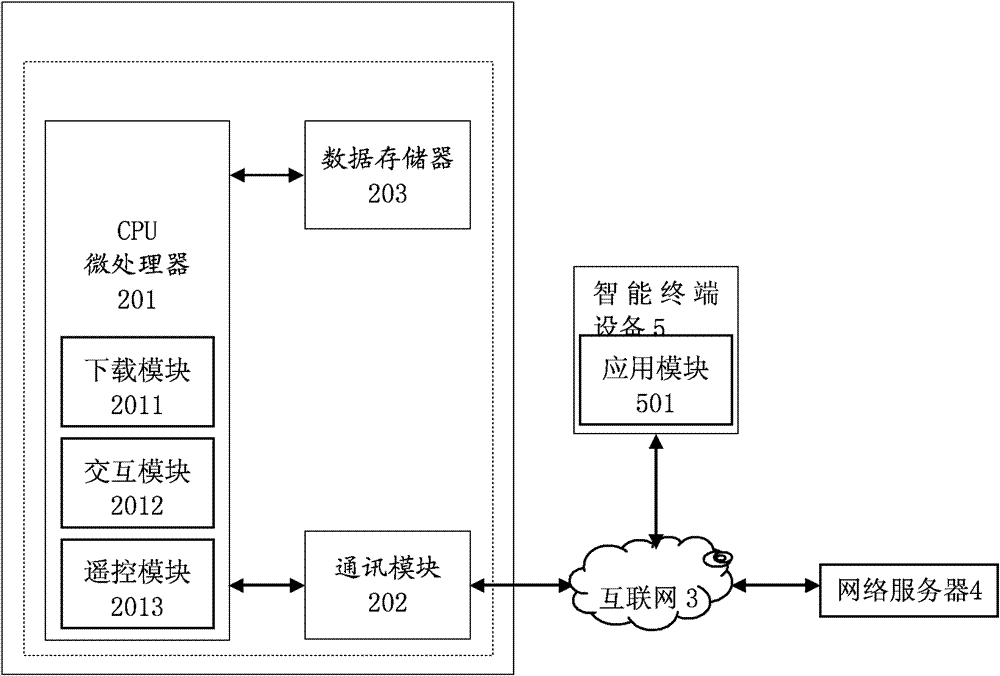

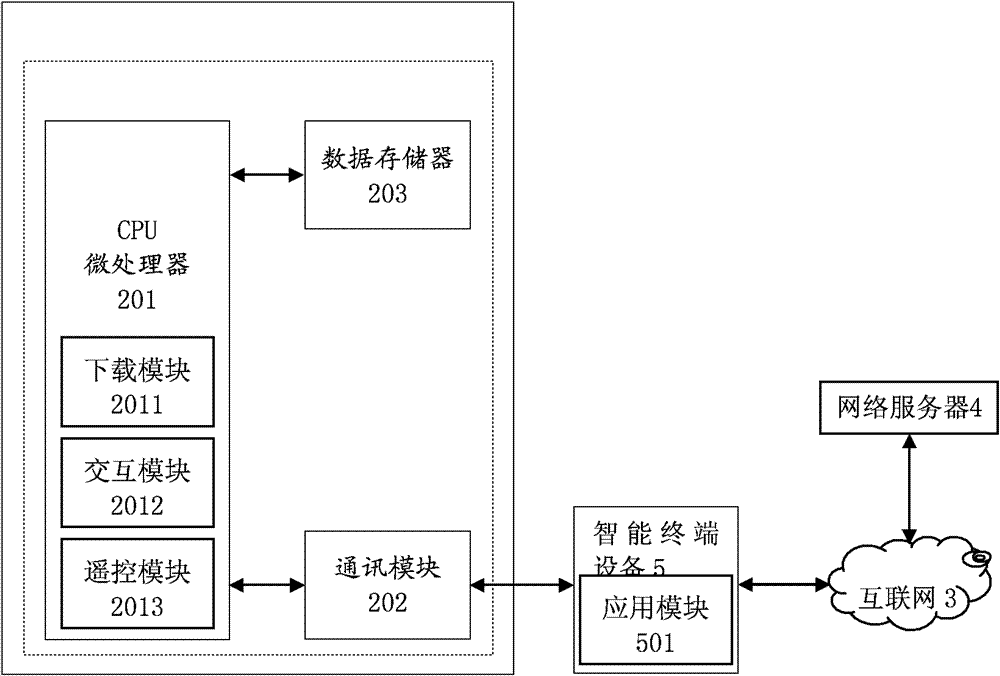

Intelligent cooking apparatus and cooking work method thereof

ActiveCN103196165ARealize remote control cookingSave manufacturing costDomestic stoves or rangesLiquid heating fuelAnimationWireless network

The invention discloses an intelligent cooking apparatus and a cooking work method thereof. The intelligent cooking apparatus comprises an intelligent cooker, an intelligent terminal device and a main control board, and the main control board comprises a CPU microprocessor, a data memory and a communication module. A plurality of wired and wireless network communication modes and work methods are provided against the present conditions of various cooking places to satisfy the application in the different cooking places. The cooker downloads or uploads food cooking processing data through the Internet in a wired or wireless mode to share the cooking methods of various foods. In the cooking process, the intelligent cooking apparatus sends the cooking temperature, the cooking power and the cooking time of a current intelligent cooker and prompts of operations carried out by a user at present to the intelligent terminal device, and the man-machine interaction interface of the intelligent terminal device is utilized to prompt the user to carry out corresponding operations in a character, voice or animation mode in order to simplify complex cooking. The cooking temperature, the cooking power and the cooking time of the intelligent cooker are remotely controlled through the intelligent terminal device to realize the remote control of cooking.

Owner:珠海优特智厨科技有限公司

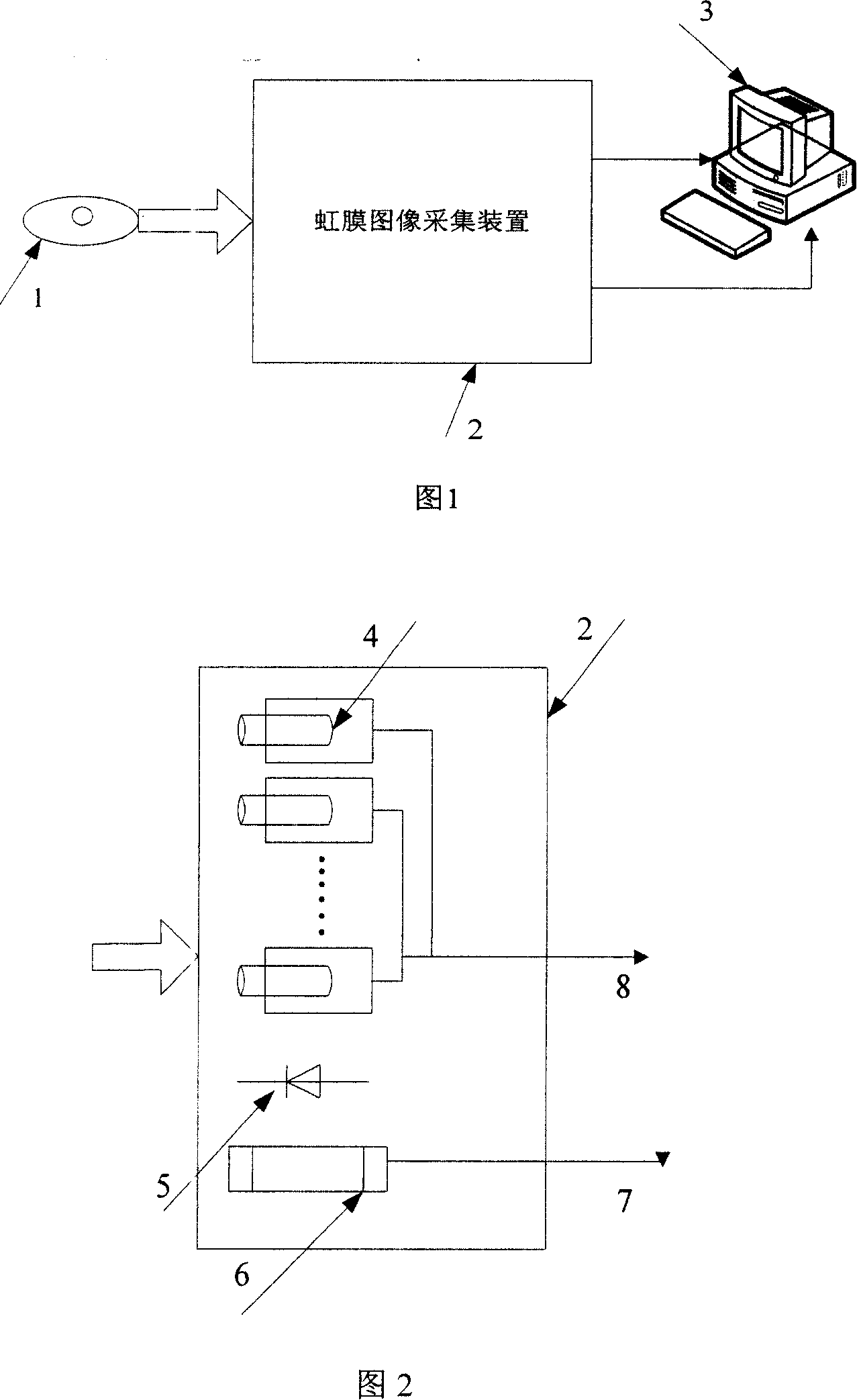

Large field-depth iris image capturing system and method based on multiple cameras with fixed focus

ActiveCN101154264AOvercome limitationsImprove usabilityCharacter and pattern recognitionImaging qualityDepth of field

The invention which relates to an optical instrument and detection imaging technique discloses a large field depth iris image acquisition system and a method based on a plurality of fixed-focus cameras. The system comprises an iris image collecting device and an image recognition device. The method comprises the following steps: respectively imaging the iris by means of the fixed-focus cameras having different imaging object distance ranges and producing a multi-path fixed-focus image results; choosing one or a plurality of multi-path fixed-focus image results through distance measurement or image quality evaluation method; carrying out image processing and identification of chosen qualified iris image data. The invention effectively integrates the imaging ranges of different fixed-focus cameras in the mode of self-adapting switchover, thereby taking advantages of the cameras and at same time removing disadvantages of the cameras, enlarging the integral imaging range of the acquisition system, and improving the feasibility of an iris recognition system. Compared with the prior iris imaging method adopting a zoom camera, the invention has the advantages of low cost, quick and noiseless focusing.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

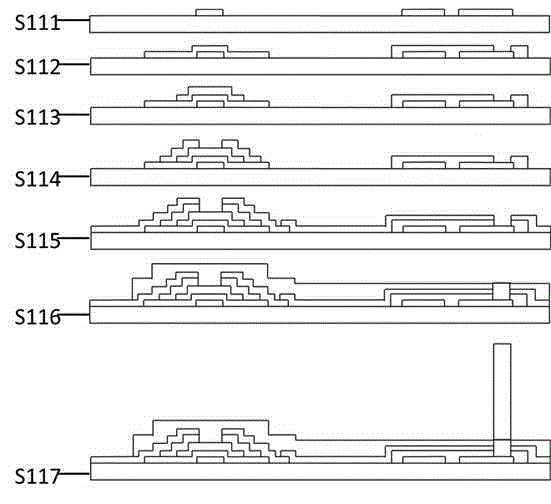

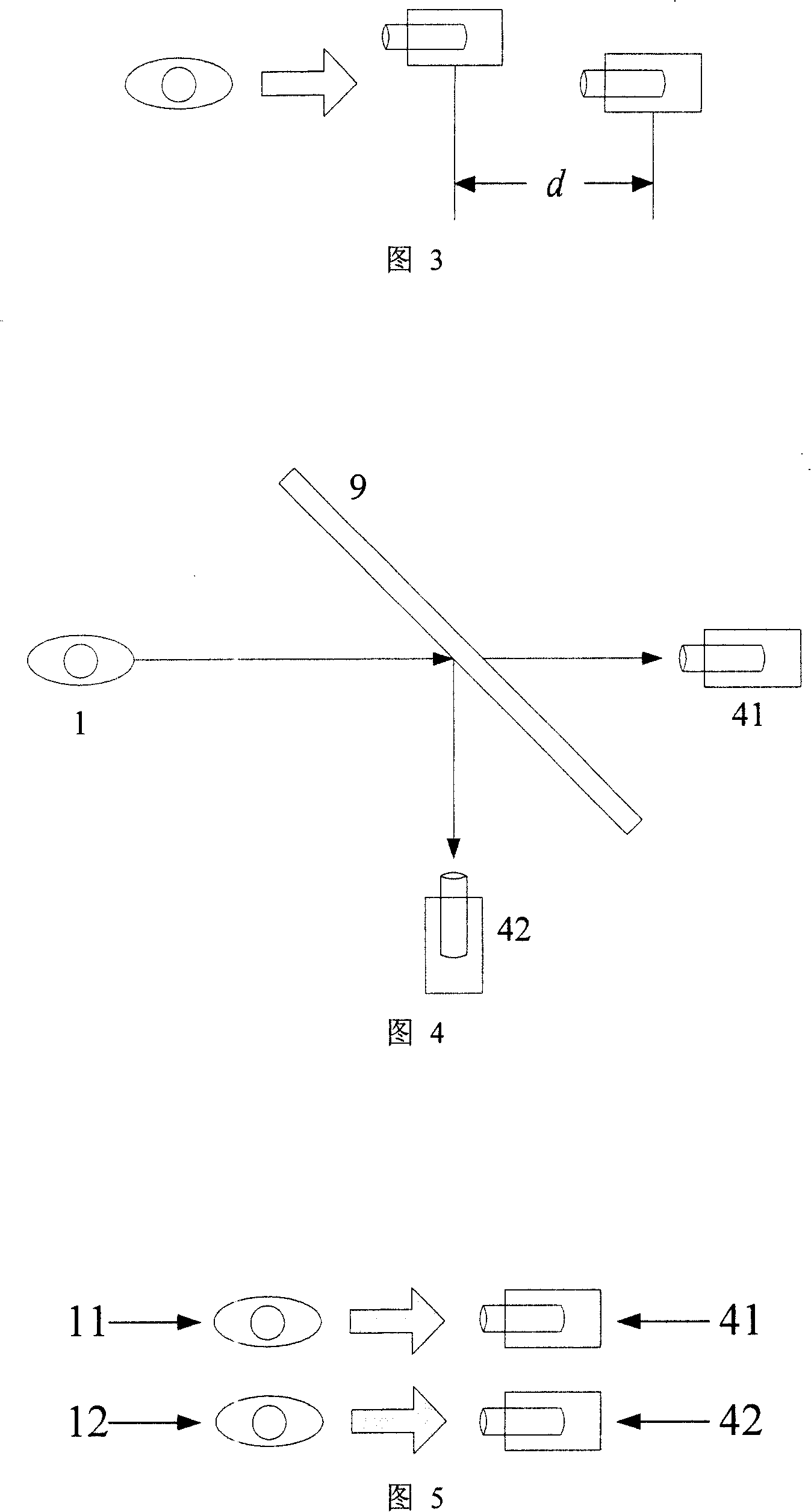

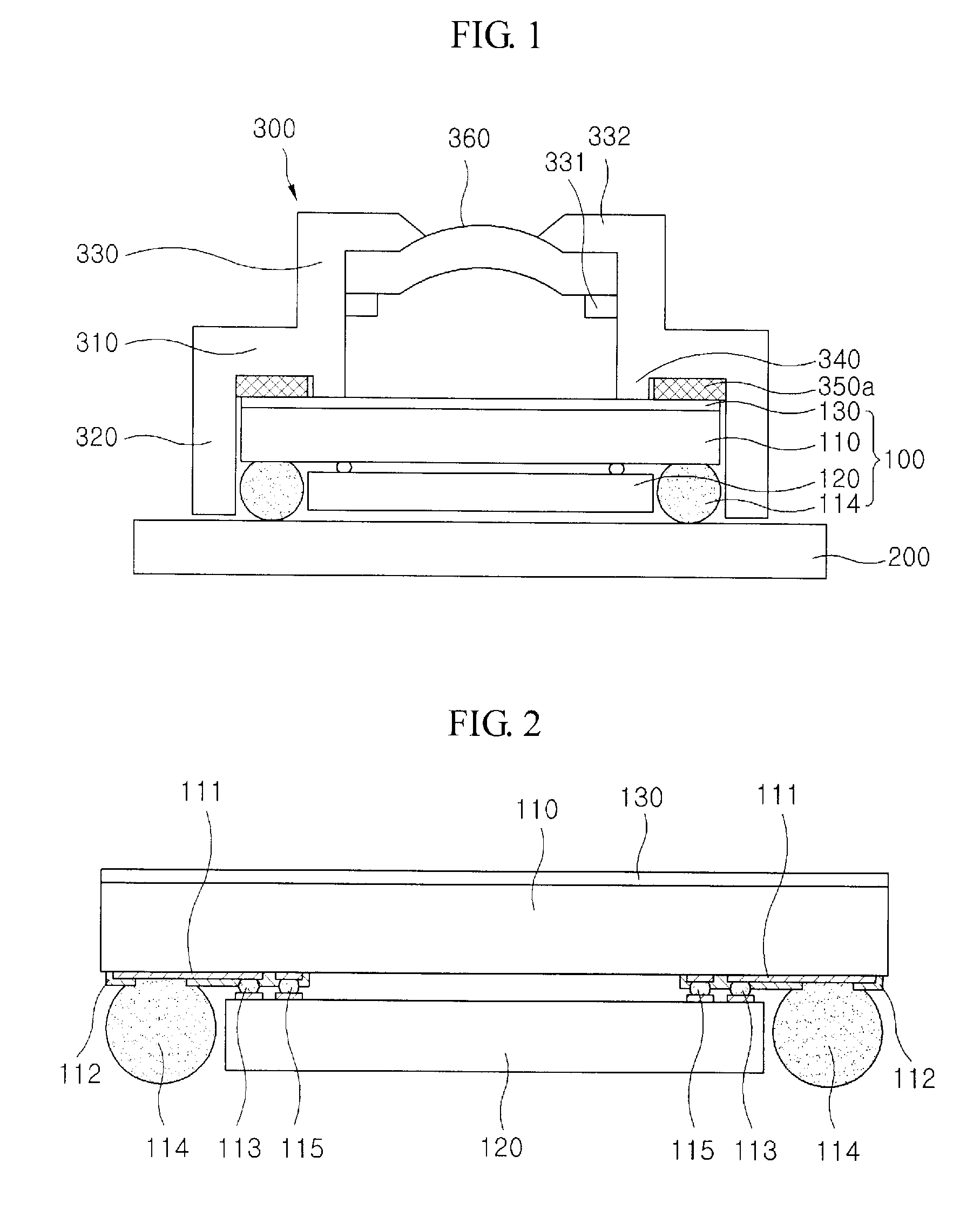

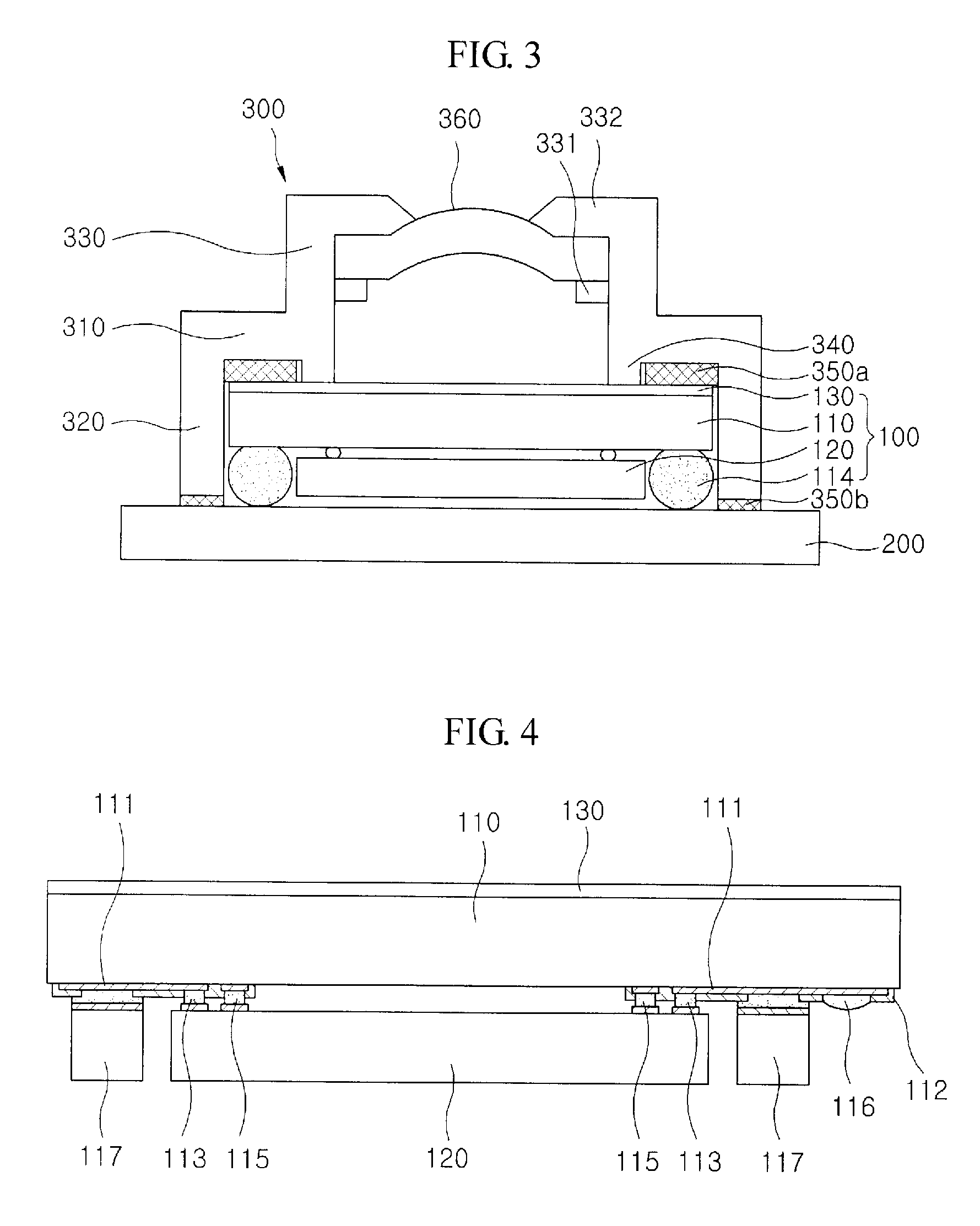

Image sensor camera module and method of manufacturing the same

ActiveUS20100141825A1Save manufacturing costReduce manufacturing costAdhesive processesTelevision system detailsCamera lensImage sensor

The present invention relates to an image sensor camera module and a method of manufacturing the same. An image sensor camera module according to the present invention includes a lens; a lens housing having the lens mounted thereto; an image sensor package adhering to a portion of an inside of the lens housing; and a protruding portion for maintaining a gap between the lens and the image sensor package, wherein the image sensor package adheres to the lens housing at an outside of the protruding portion. According to the present invention, since a lens barrel is not used and a focus adjusting process is not performed, the process simplification and automation process can be achieved, thereby saving a manufacturing cost and obtaining uniform focus quality. Further, it is possible to prevent an image defect from being generated by foreign substances, thereby improving a yield.

Owner:OPTOPAC

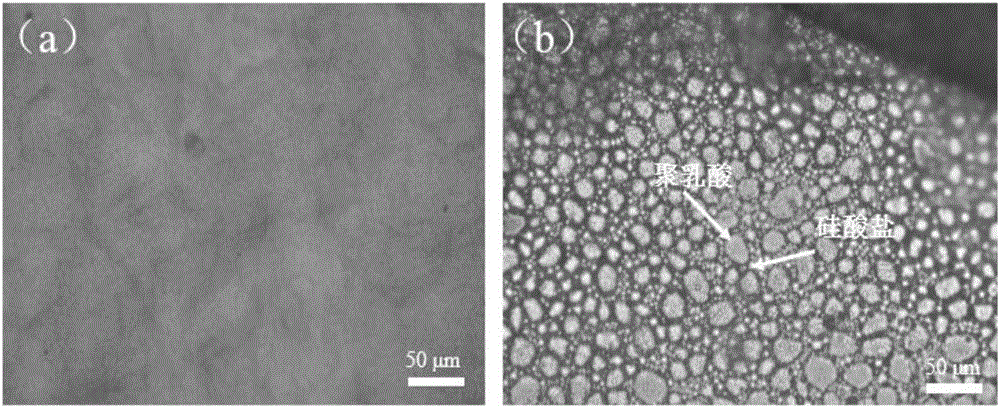

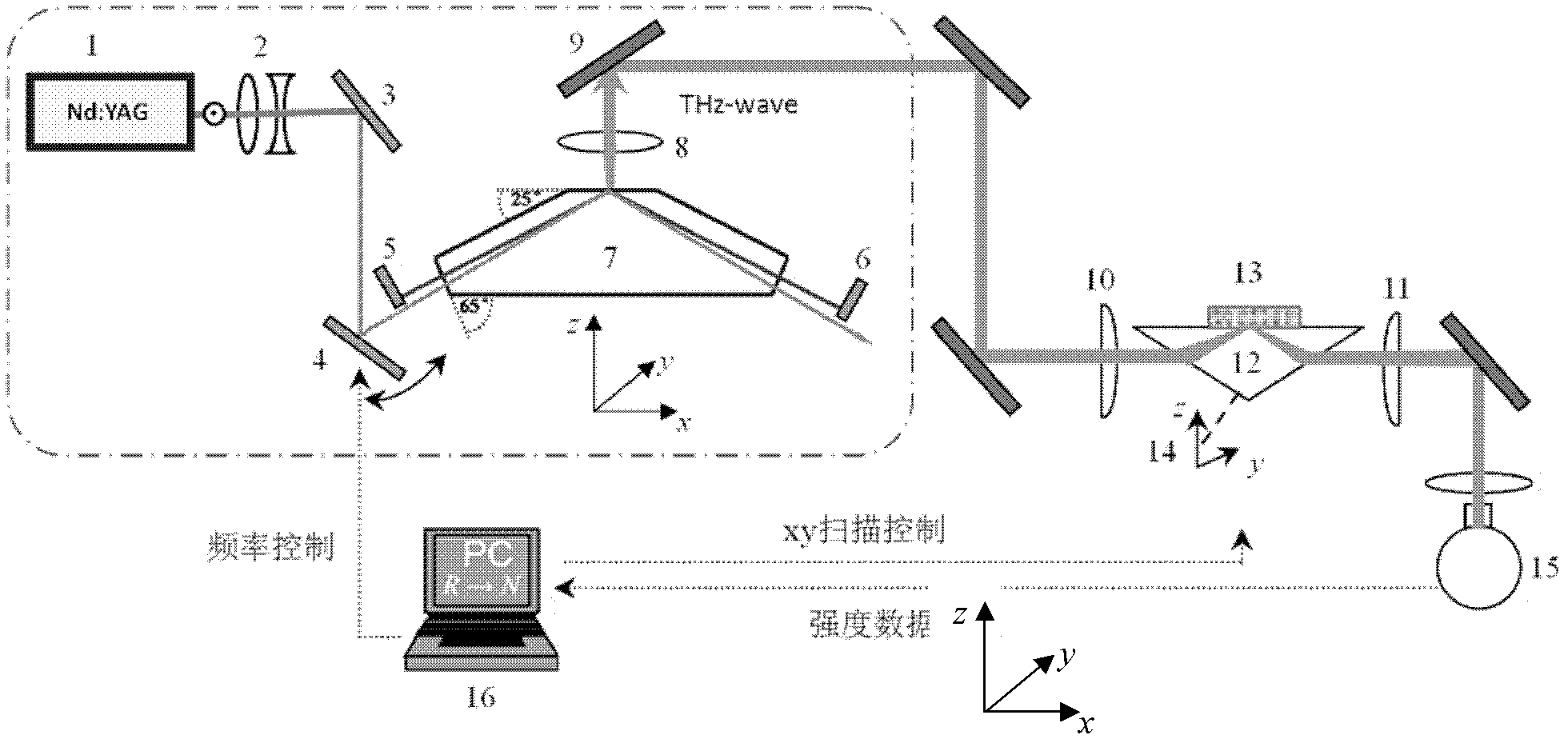

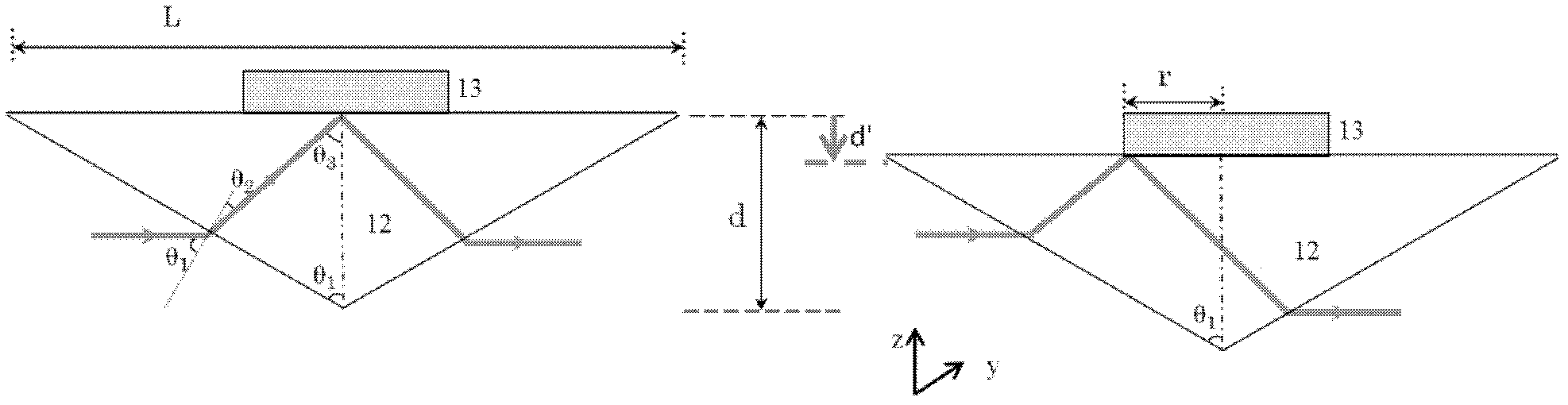

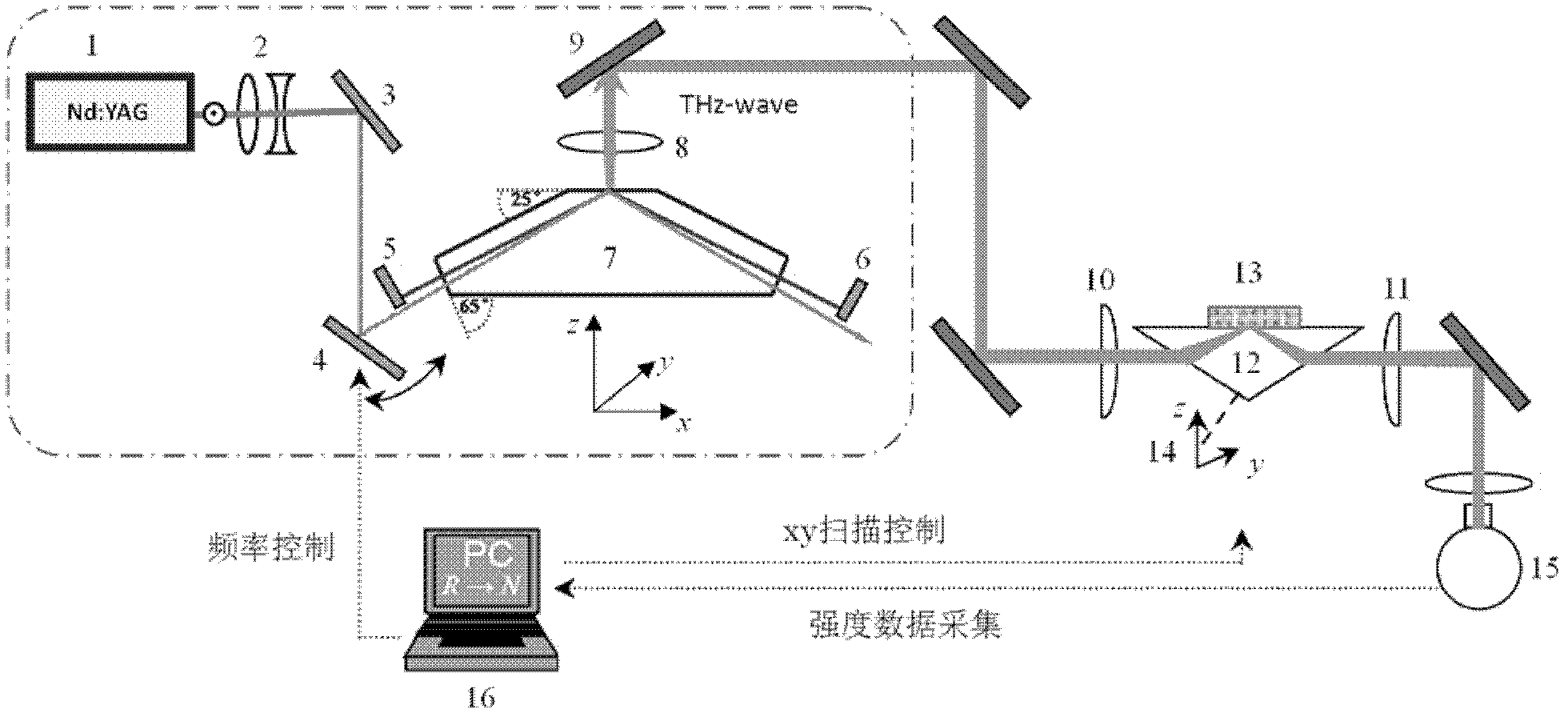

Biological tissue moisture measurement device and method based on terahertz wave attenuated total reflectance (ATR)

InactiveCN102590125AOvercome the disadvantages of complex preparationAvoid Destructive AnalysisColor/spectral properties measurementsMeasurement deviceFrequency conversion

The invention relates to non-linear optical frequency conversion and the application of the non-linear optical frequency conversion and provides a method and a device which can widen the preparation requirements for a biological sample, do not need preparation of the sample, are high in measurement sensitivity, and can achieve high resolution, fast and real-time biological sample moisture content and distribution imaging measurement. The technical scheme is that the biological tissue moisture measurement device based on terahertz wave attenuated total reflectance (ATR) is composed of a tunable terahertz (THz) radiation source, a non-spherical face lens assembly, a total reflection prism, a two-dimensional mobile scanning platform, a terahertz wave detector and a computer. The total reflection prism is placed in the middle of the non-spherical face lens assembly, the face to be tested of a biological sample to be tested clings to the top face of the total reflection prism fixed on the two-dimensional mobile scanning platform, terahertz (THz) waves are projected to the terahertz detector through the non-spherical face lens assembly, and a detection result of the terahertz detector is output to the computer. The biological tissue moisture measurement device and the method based on the terahertz wave attenuated total reflectance (ATR) are mainly used for biological sample moisture content and distribution imaging measurement.

Owner:TIANJIN UNIV

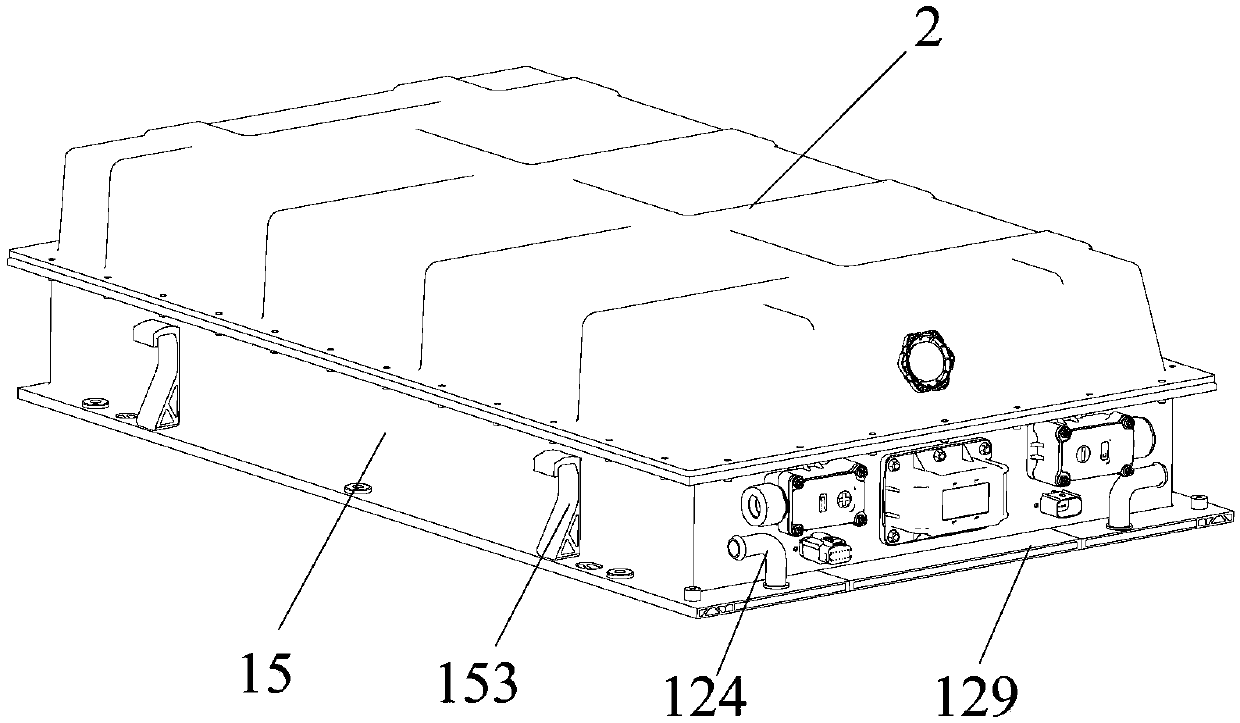

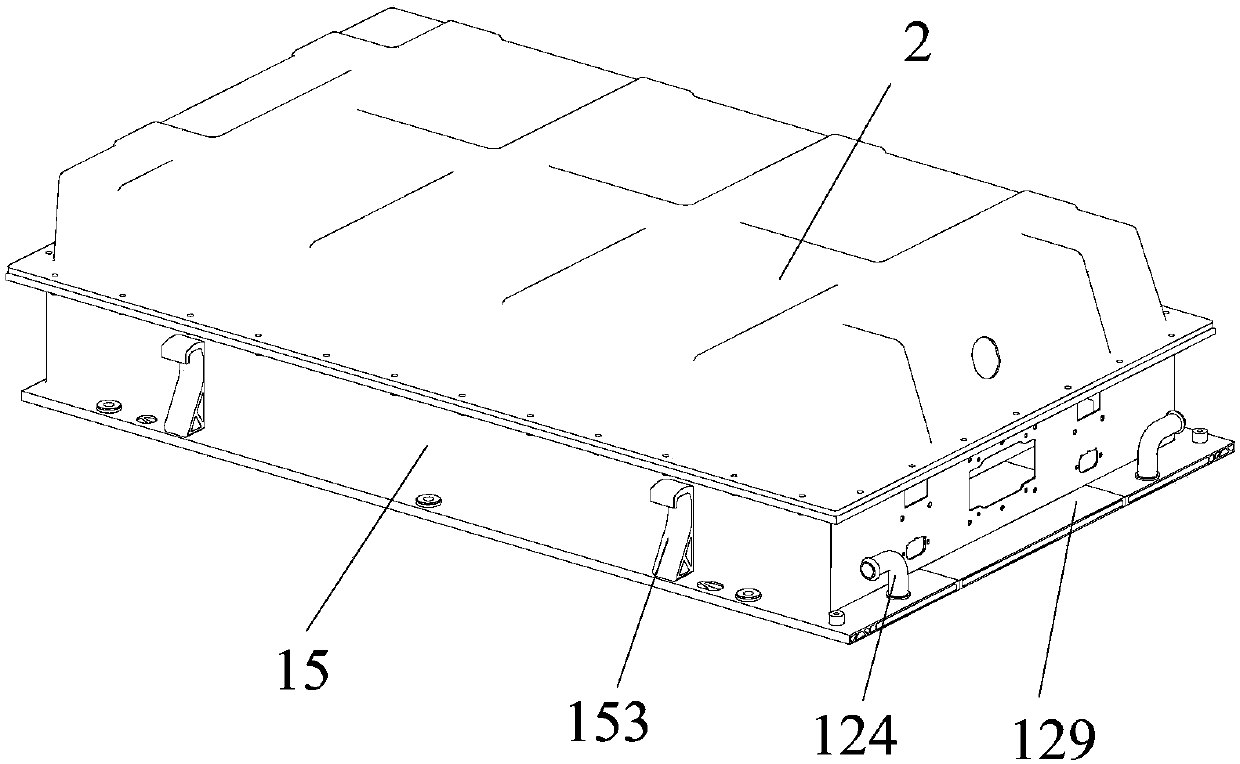

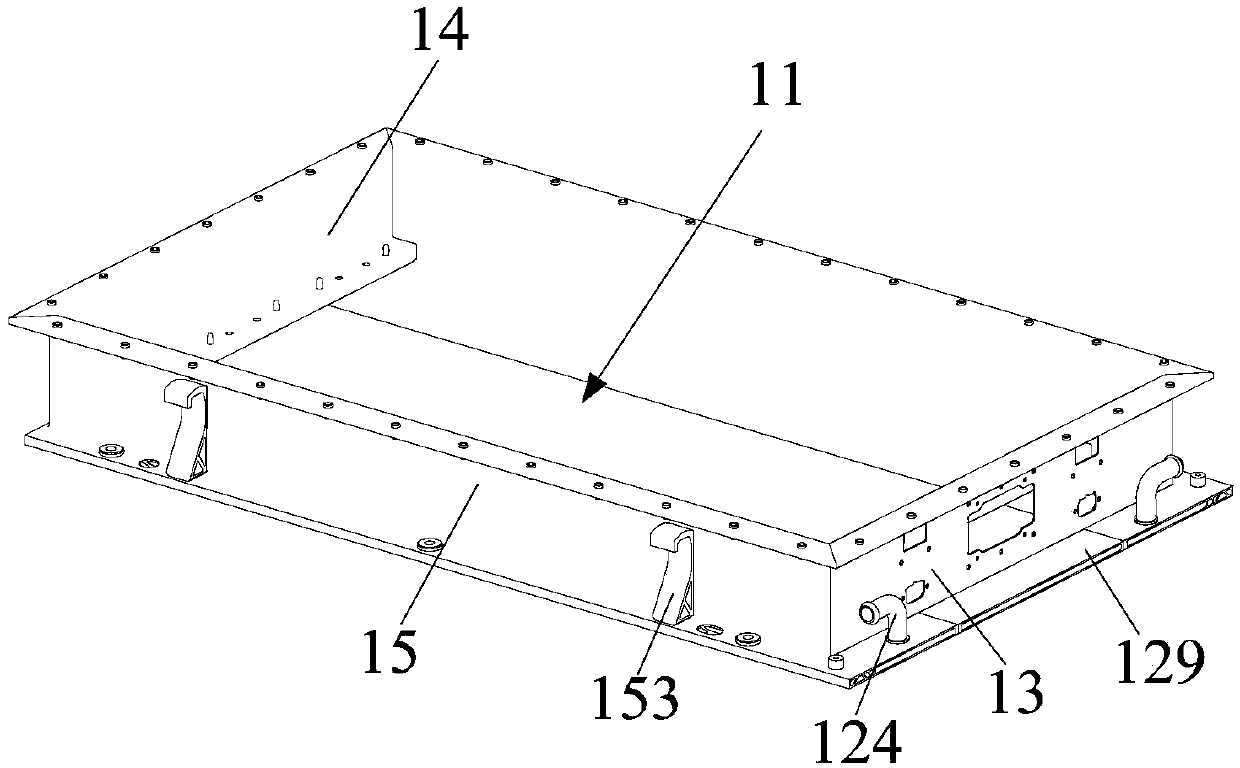

Integrated water-cooled power battery box

PendingCN108039434AMeet the intensityFulfil requirementsBattery isolationSecondary cellsPower batteryMechanical property

The invention relates to the technical field of electric cars, in particular to an integrated water-cooled power battery box. The integrated water-cooled power battery box provided by the invention comprises a box cover, a box body and a temperature regulating power system, wherein the box body is made of an aluminum alloy material and is manufactured by an extrusion moulding technology; a circulating flow passage is formed in the wall of the box body; a circulating loop for a temperature regulating medium to flow circularly is arranged inside the wall of the box body; and the temperature regulating power system can drive the temperature regulating medium to circularly flow in the circulating loop. In such a way, a water cooling board and a battery box are designed in an integrated manner,a hollow aluminum alloy section is adopted to achieve lightweight design, mechanical properties such as strength and rigidity are met, the integrated water-cooled power battery box is simpler in structure, better in technical performance and smaller in occupied space, and the comprehensive cost can be reduced; the heat-dissipating, cooling and temperature-raising and heating functions can be achieved by using one set of temperature regulating power system, the integrated water-cooled power battery box is simpler in structure, more convenient and fast to use and smaller in occupied space, themanufacturing cost and the using cost can be reduced, and the heat-dissipating efficiency and the heating efficiency can be improved.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

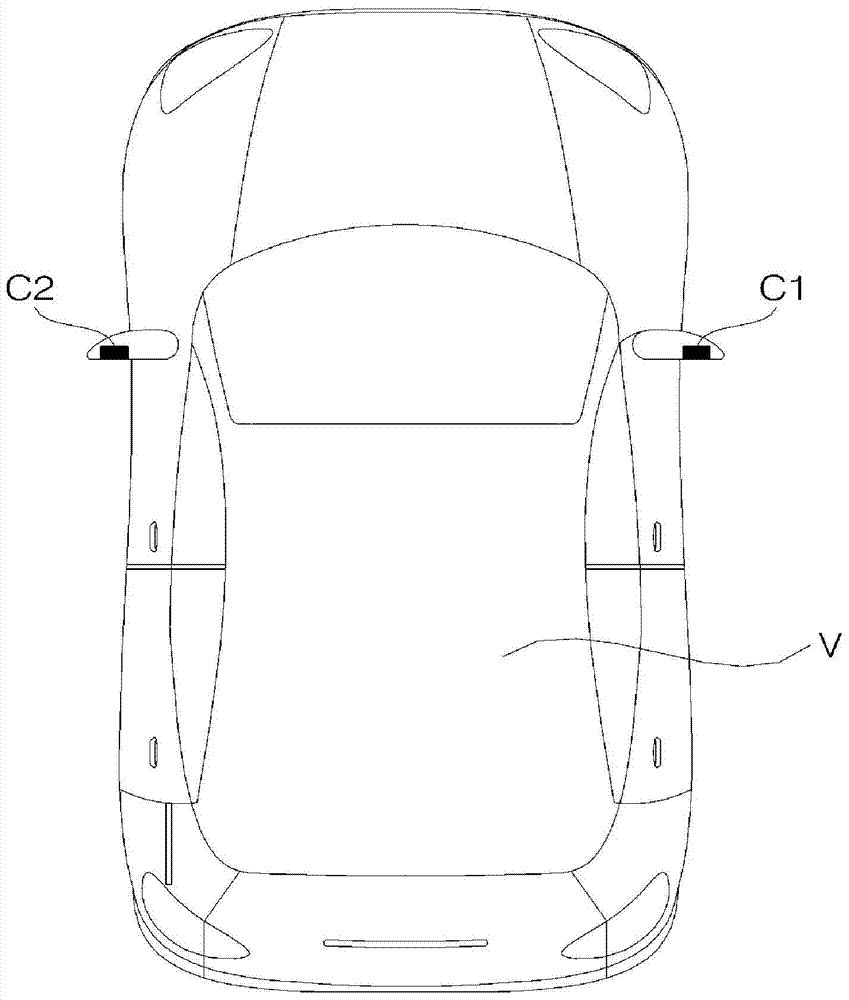

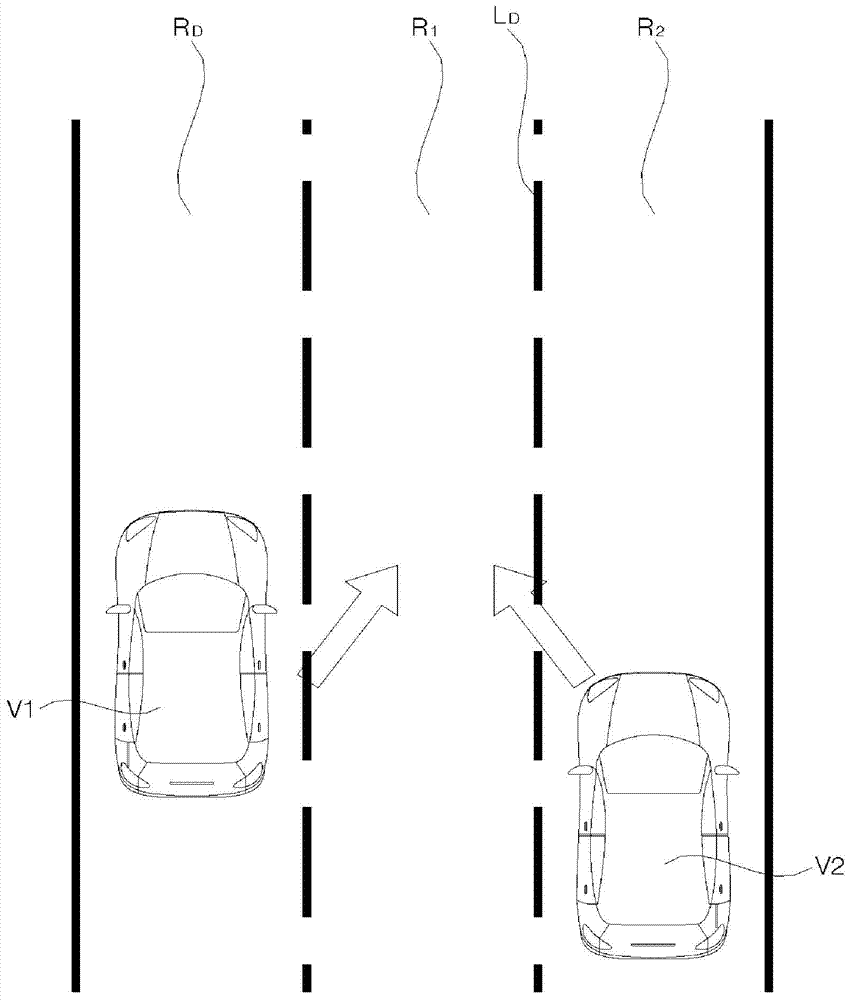

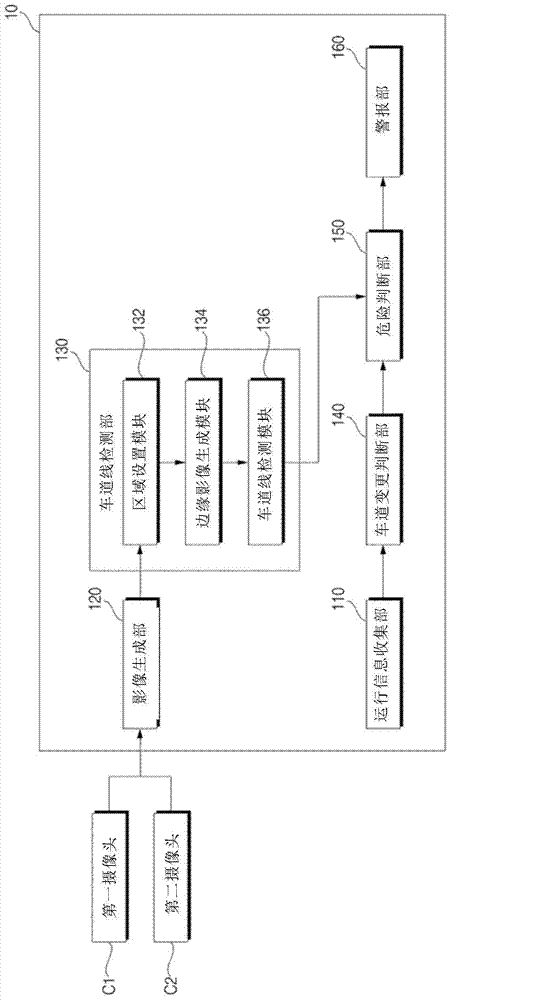

Apparatus for assisting in lane change and operating method thereof

ActiveCN104760593AEnsure safetySave manufacturing costRoad vehicles traffic controlVehicle sub-unit featuresSimulationReal-time computing

Disclosed are an apparatus for assisting in a lane change and an operating method thereof. The apparatus includes a driving information collecting unit, an image generating unit, a line detecting unit, a lane change determination unit, and a danger determining unit. The apparatus calculates a danger of an accident based on an image photographed by a camera and notifies a driver of the danger of the accident in advance when two or more vehicles, which are travelling with one lane interposed therebetween, simultaneously change lanes toward the same lane, thereby enabling a driver of a vehicle to be safe according to a lane change before the driver actually changes the lane.

Owner:HYUNDAI MOBIS CO LTD

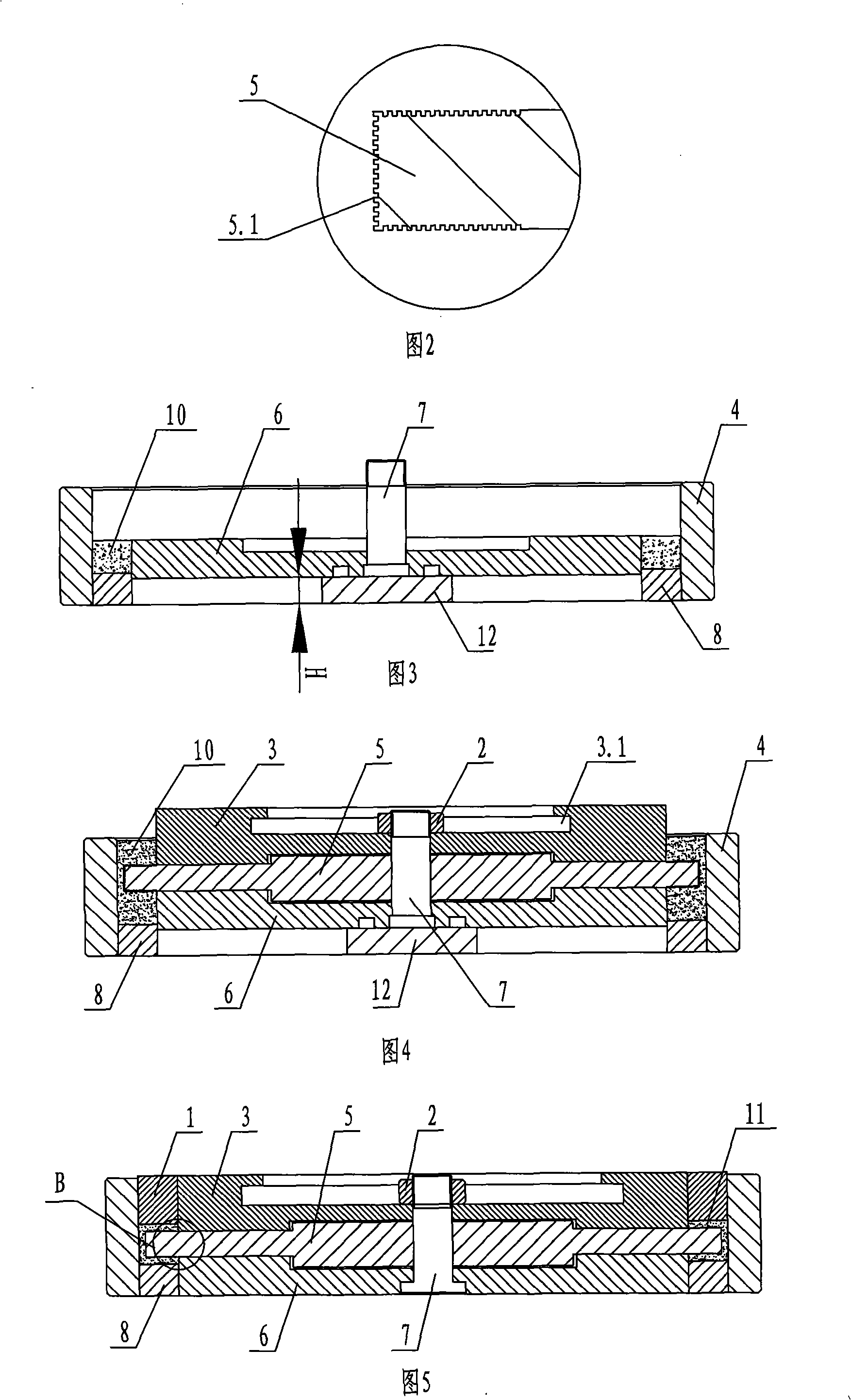

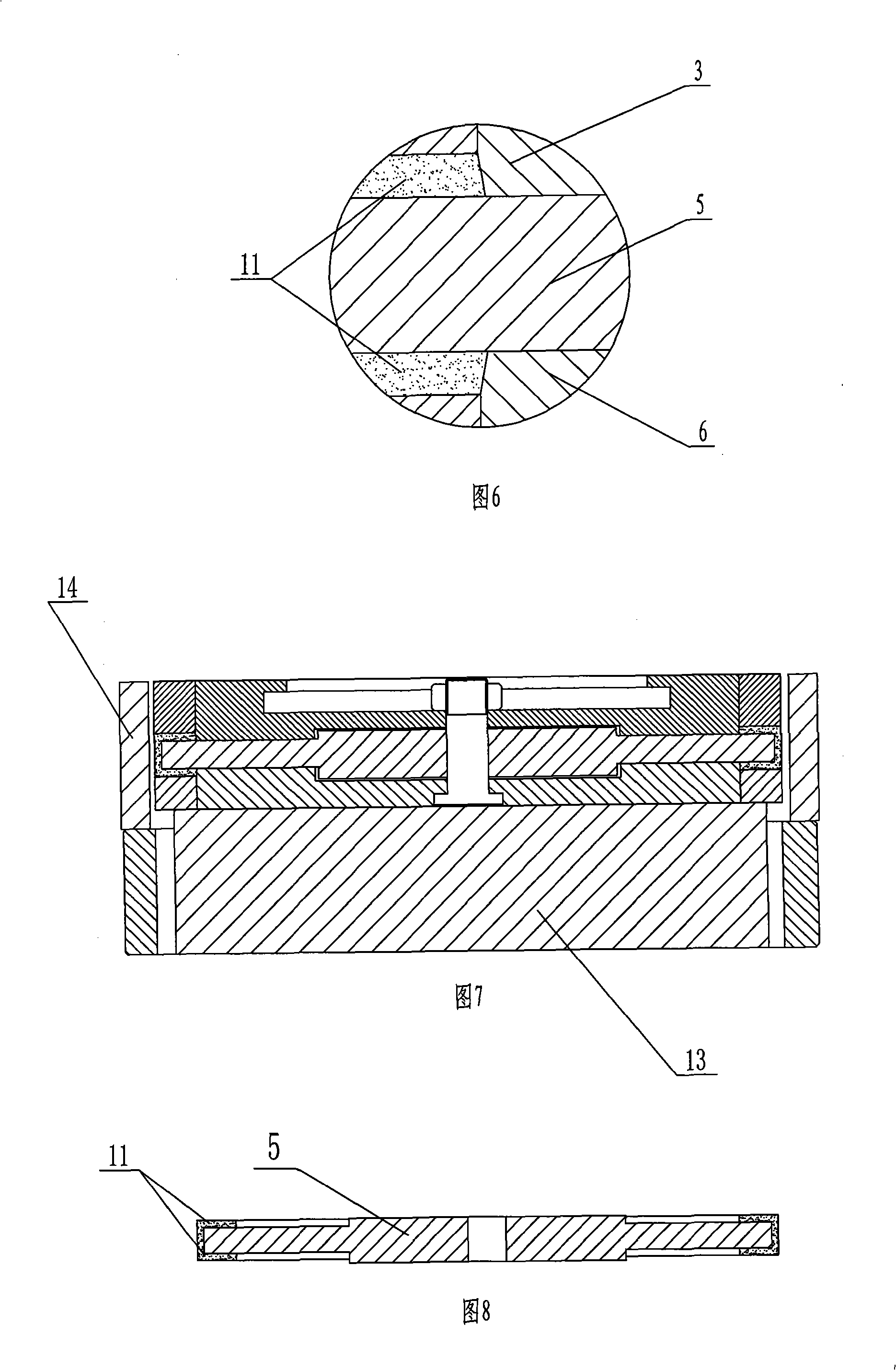

Resin cement cubic boron nitride grinding wheel and preparation method thereof

ActiveCN101332587AExtend your lifeIncrease grinding ratioBonded abrasive wheelsMetal working apparatusPass rateBoron nitride

The invention relates to a resinoid wedding agent cubic boron nitride grinding wheel and a manufacturing method thereof, the resinoid wedding agent cubic boron nitride grinding wheel comprises a grinding wheel matrix and a grinding layer, the grinding layer is arranged on the external wall of the grinding wheel matrix and peripheries of an upper end face and a lower end face; the grinding layer includes 12-40% of cubic boron nitride (nickel plating), 25-50% of Dialok939p resin, 1-10% of villaumite grinding aid, 1-10% of a solid lubricant filler, 10-30% of a powder filler with high thermal conductivity and 1-15% of oxide filler by volume percentage of the grinding layer. A specially designed hot pressing dies and separately batch feeding method are adopted, which causes the pressed products to have homogeneous structure and consistent density; the formula of the grinding wheel is simple, and the designed die has the advantages of simple and reasonable structure, easy die filling and die release, the product obtained has high once-pass rate, homogeneous structure and consistent density; the grinding wheel has good grinding performance and long service life, can perform peripheral grinding and end face grinding, and is equivalent to three grinding wheels with the same specification, the matrix and making cost are saved, production cost is reduced, the product value is improved.

Owner:广东奔朗新材料股份有限公司

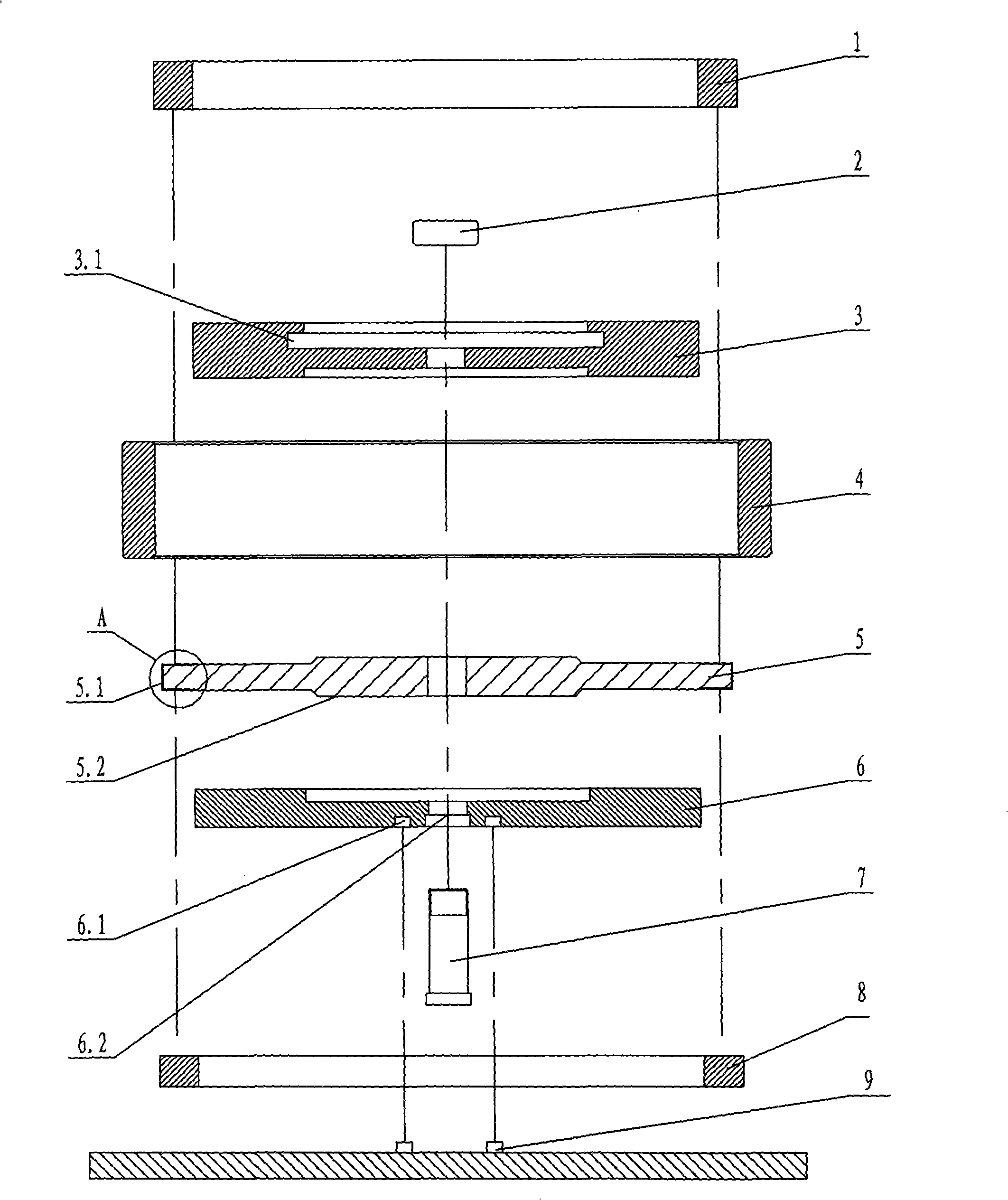

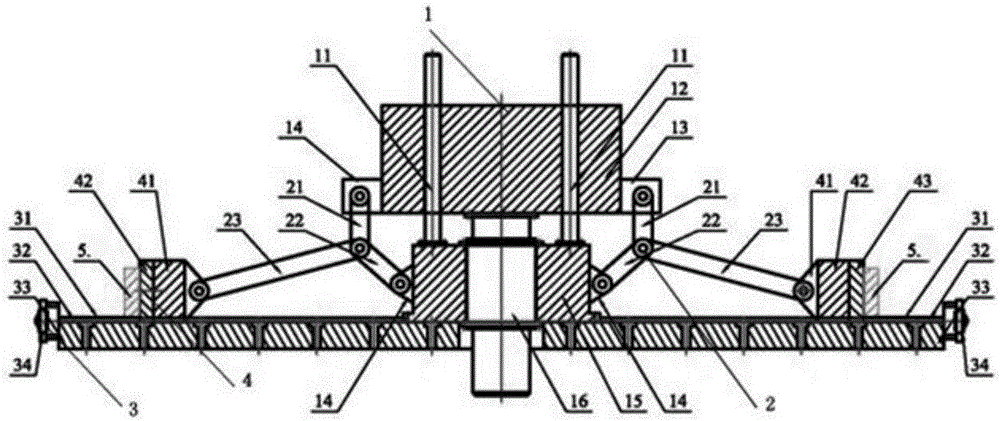

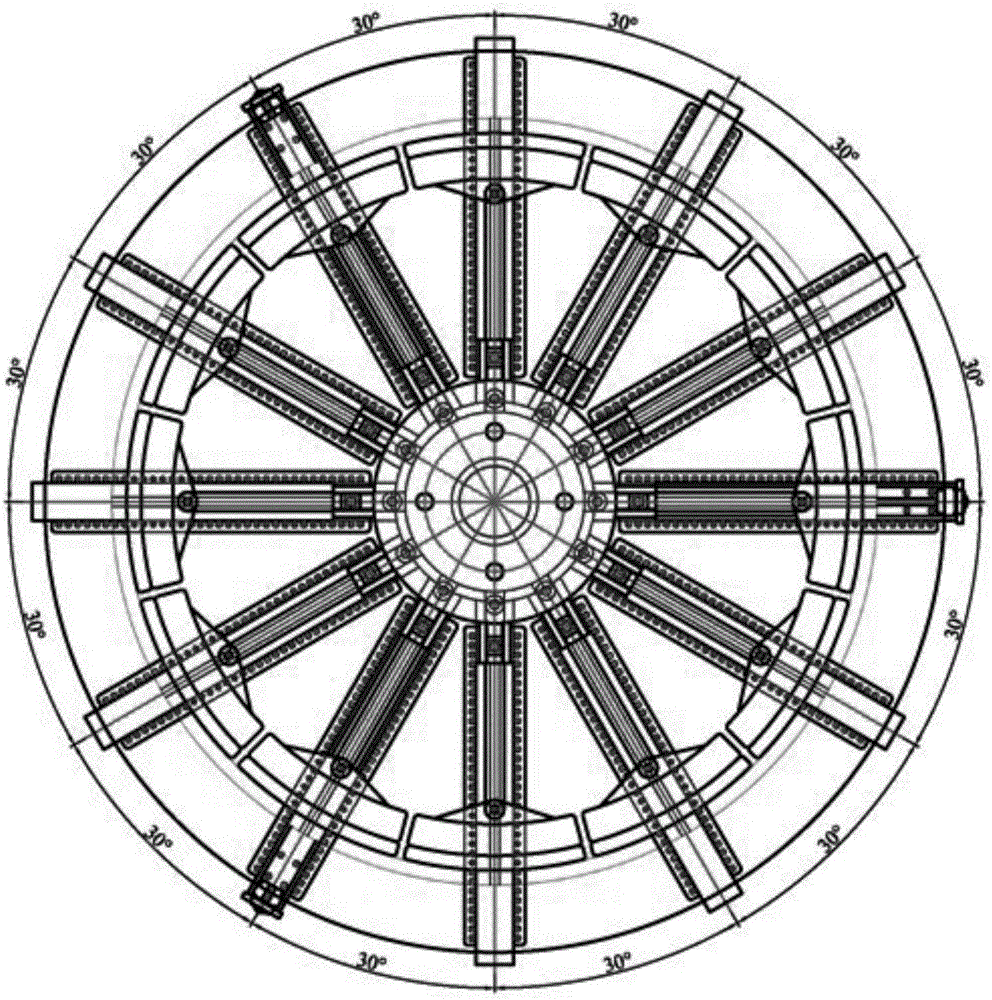

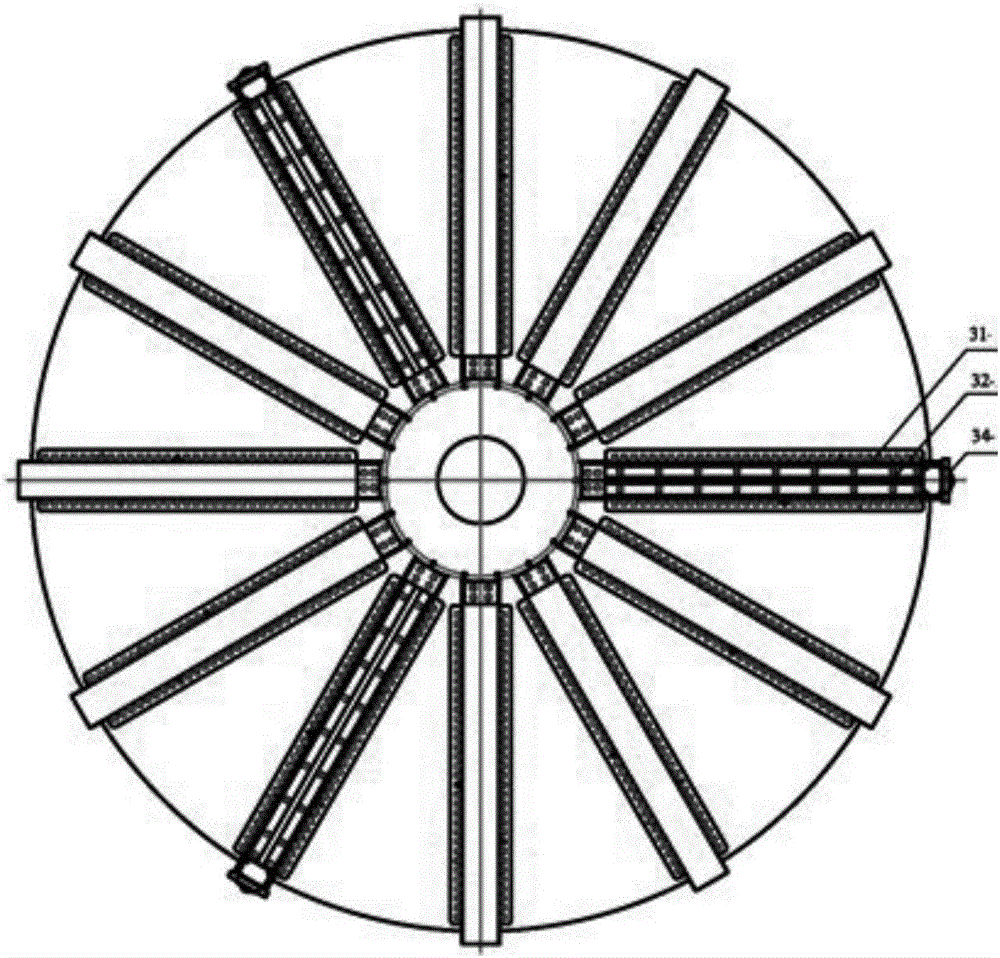

Mechanical expanding machine for large-diameter ring piece

ActiveCN106216538AEasy to useMeet the needs of expanding forceShaping toolsHydraulic cylinderEngineering

The invention discloses a mechanical expanding machine for a large-diameter ring piece. The mechanical expanding machine for the large-diameter ring piece comprises a piston cylinder, a supporting disk, a fixed workbench and a sliding block. The fixed workbench is arranged at the center of the upper surface of the supporting disk. The piston cylinder is installed in the fixed workbench and is connected with the lower end face of the fixed workbench through a piston rod. At least two hinged rod force amplifying devices are evenly arranged in the circumferential direction of the fixed workbench. Sectioned male dies corresponding to the hinged rod force amplifying devices are evenly distributed on the supporting disk in the circumferential direction of the fixed workbench. The bottom of each sectioned male die is provided with a guide groove, and each sectioned male die slides in a radial guide rail on the supporting disk under the action of the corresponding hinged rod force amplifying device. According to the mechanical expanding machine for the large-diameter ring piece, a hinged rod force amplifying mechanism is adopted, force exerted by the hydraulic cylinder on the sliding block is amplified, and therefore the mechanical expanding machine can obtain large output force. The mechanical expanding machine for the large-diameter ring piece is particularly suitable for expanding of the large-diameter ring piece with the diameter larger than 5 m. In addition, the hinged rod force amplifying mechanism is convenient to use and maintain, accessories of the hinged rod force amplifying mechanism are convenient to replace, and the production and manufacturing cost of the hinged rod force amplifying mechanism is low.

Owner:CENT SOUTH UNIV

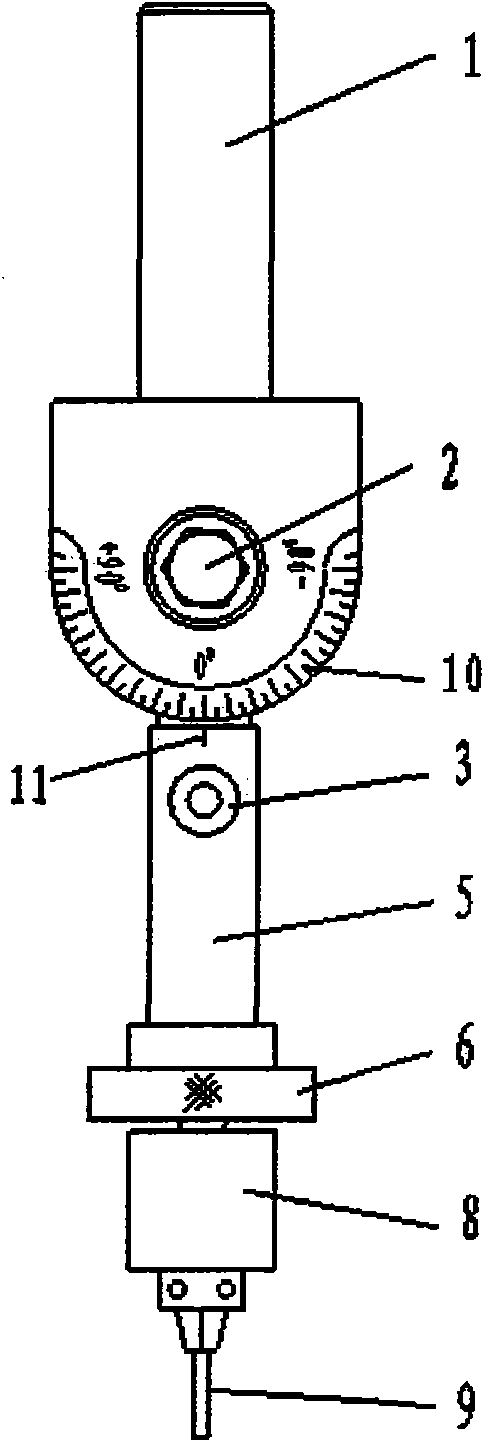

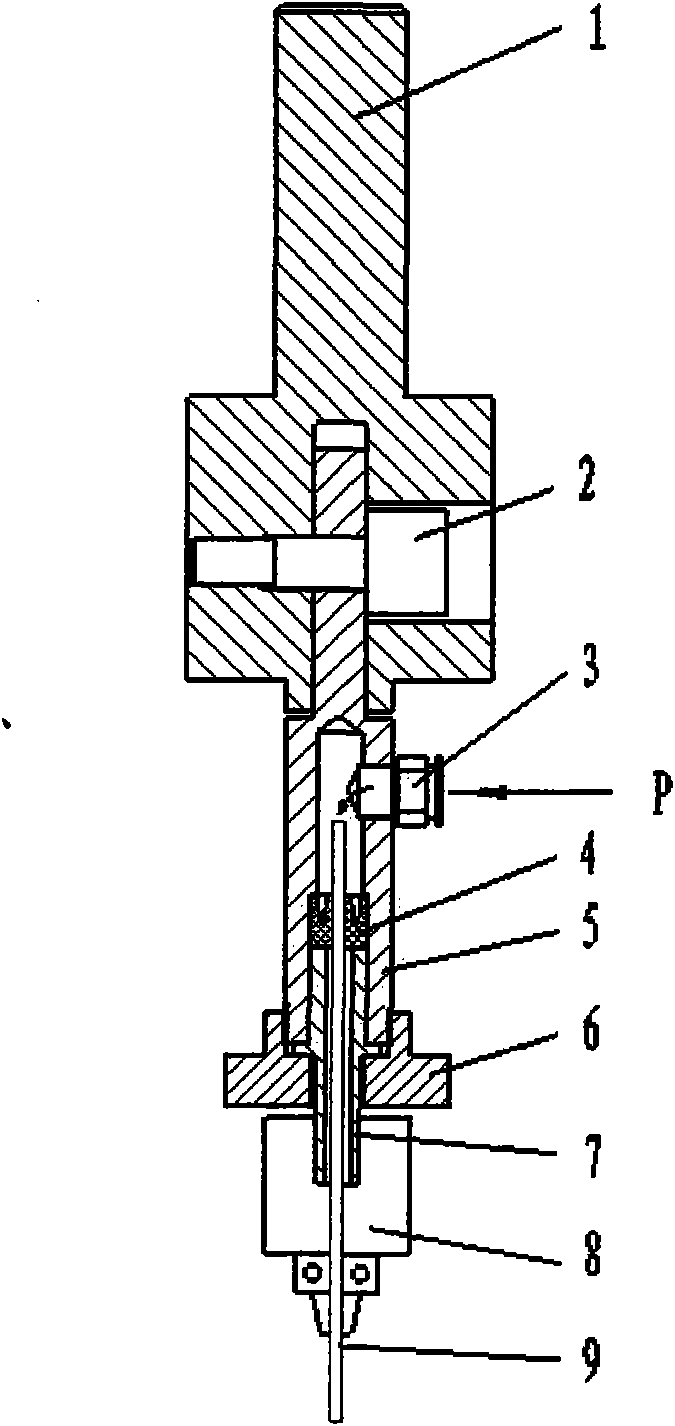

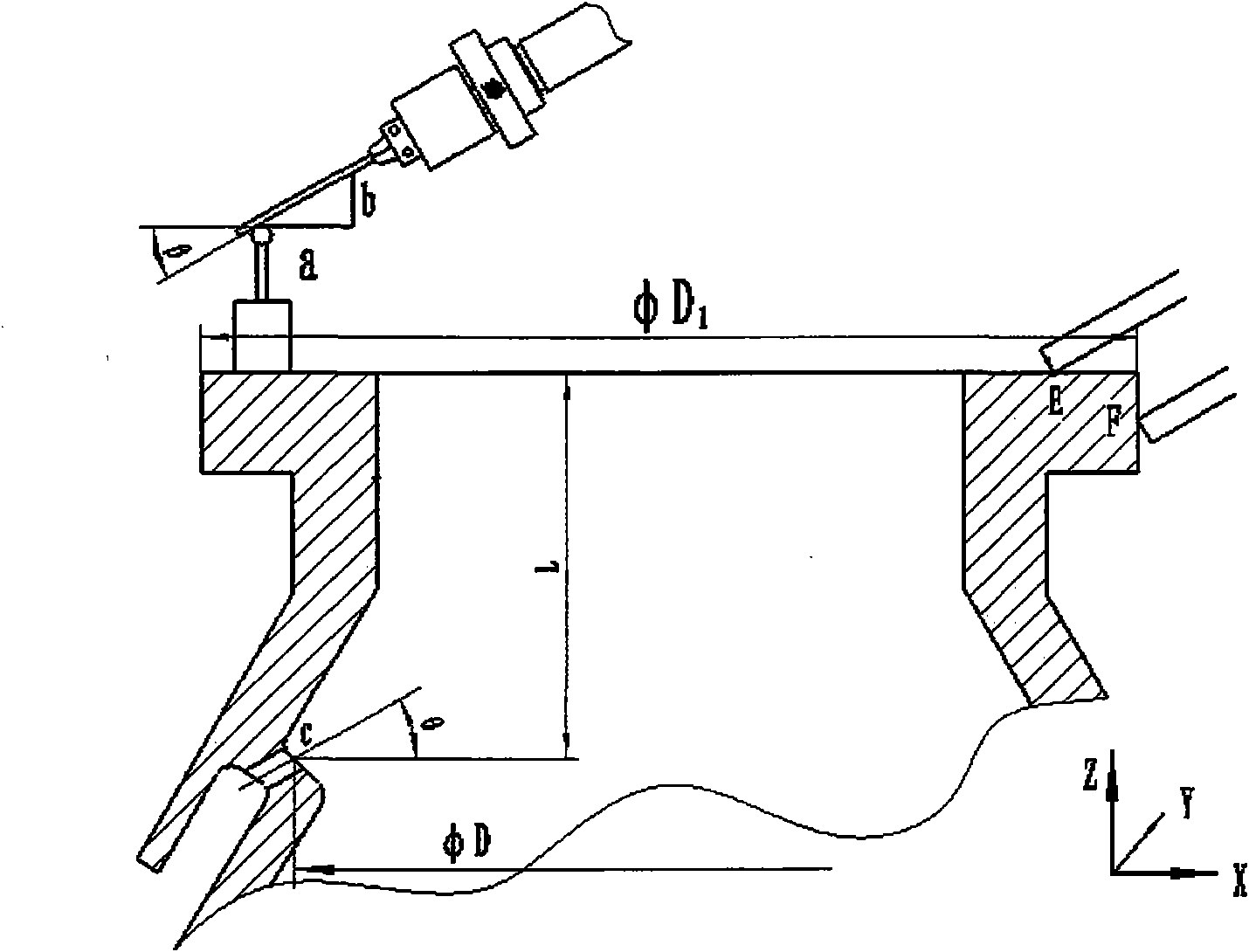

Inclined hole electrosparking processing device and method for adjusting position and angle of electrode

The invention relates to an inclined hole electrosparking processing device, comprising a joint body, an electrode deflection shaft, a positioning clamping screw, a tightening screw cap, a positioning shaft and a hollow small hole electrode. A connecting rod of the electrode deflection shaft is located in a rectangular slotted hole of the joint body; an equal-diameter end of a positioning shaft is located in a shaft hole of the electrode deflection shaft and is tightened up; a rubber sealing piece is located in the shaft hole of the electrode deflection shaft and the hollow small hole electrode penetrates through a drill chuck and is placed into the positioning shaft. In the invention, according to the inclined angle between the inclined hole and the X axis or Y axis and degree scale on the joint body, the inclined angle beta between the electrode and the X axis or the Y axis is initially adjusted, and the electrode is moved along the negative direction of Z axis or the positive direction of the X axis to obtain the actual inclined angle beta between the electrode and the X axis or the Z axis. In addition, the corresponding position of the inclined hole electrode and the inclined hole center C is identified to obtain coordinates of the Z axis and X axis of a machine tool, so that the problems of the existing small hole electrosparking processing device such as high cost, long cycle, difficult positioning of the electrode and low positional precision of processing holes and the like are solved and 0-90-degree inclined hole electrosparking processing is realized.

Owner:NANTONG ZHONGLING INSULATION MATERIALS +1

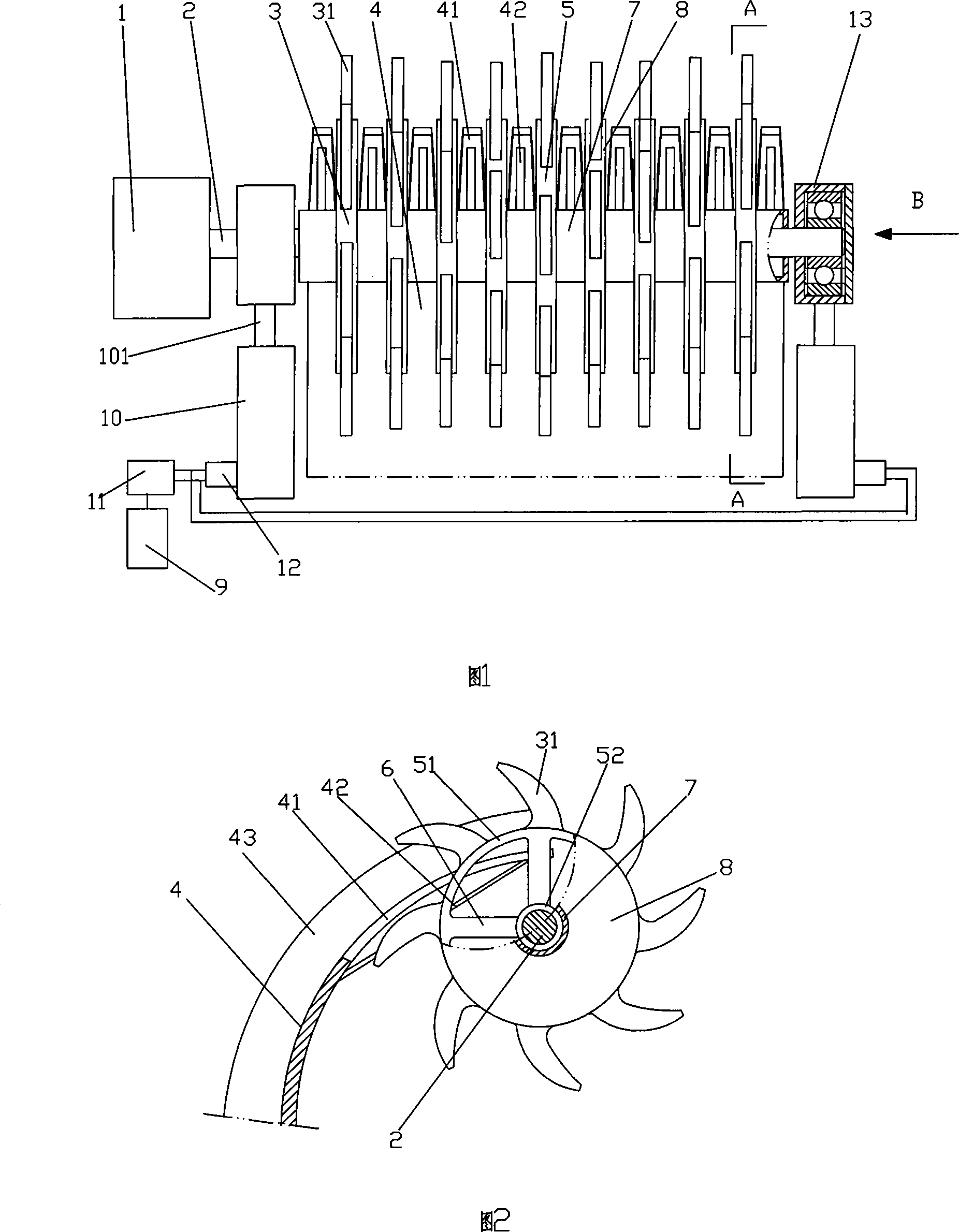

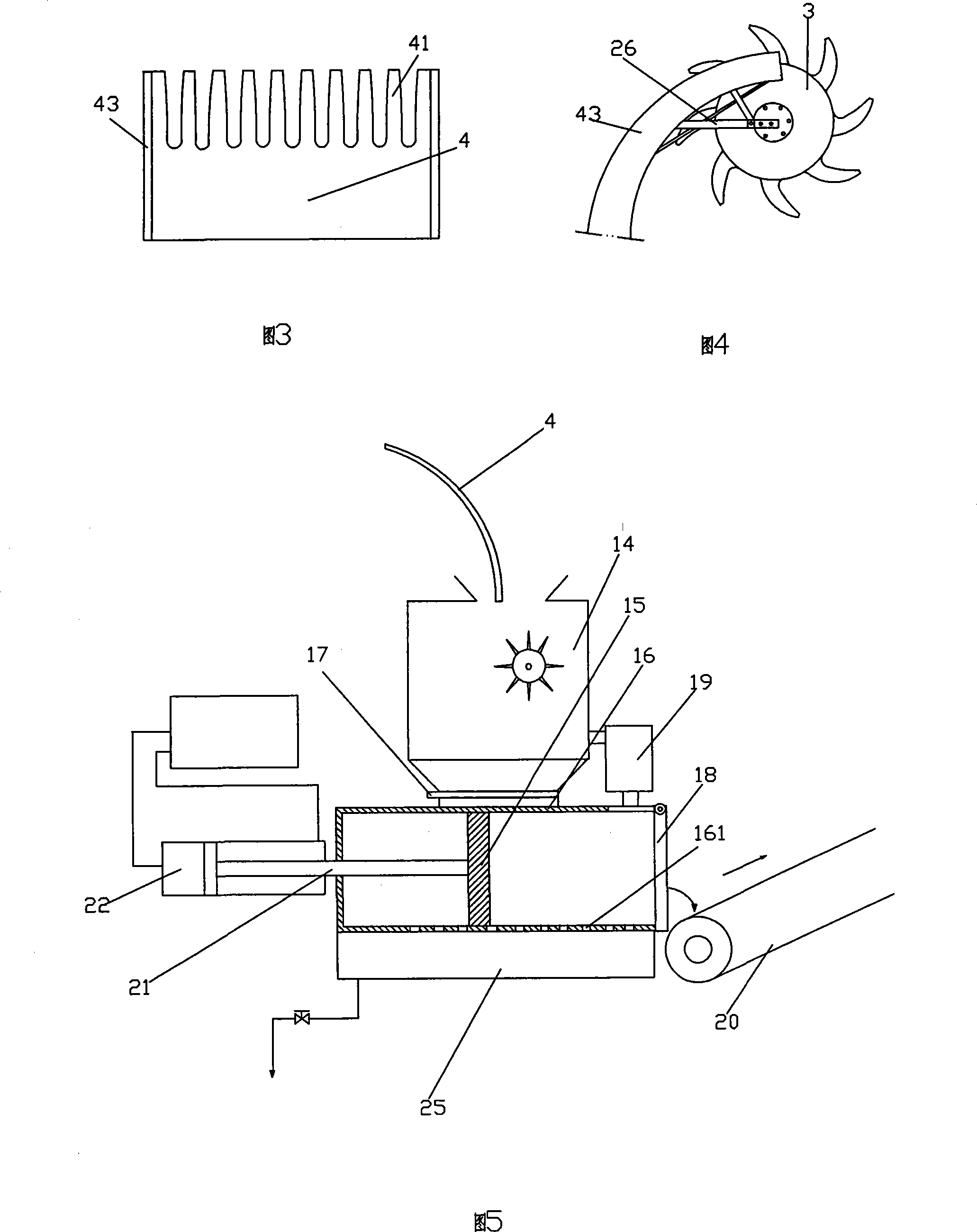

Device for cleaning waters floating material

The invention discloses a water area flotage cleaning device, which comprises a power device, a catcher, a separator and a flotage processing and recycling device, wherein the catcher comprises a rotary shaft and at least one catching gear, the power device matches with the rotary shaft to drive the rotary shaft, the catcher gear is arranged relative to the rotary shaft radial direction and is fixed and matched with the rotary shaft, the separator and the non-rotary part of the catcher are relatively fixed, the separator is arranged from the upper side to the lower side, the upper side is set in a comb gear shape, the comb gear shape is composed of at least two separating gears arranged in axial direction, the adjacent separate gears are arranged on both sides of the catcher gear with a gap to the catcher gears. The invention has simple and compact structure, high mechanic degree, small energy consumption, short flow, small occupancy area, easy operations, high work efficiency, environment protection property, convenient maintenance, simple process, and can maximally save labors, resources and process cost.

Owner:CHONGQING UNIV

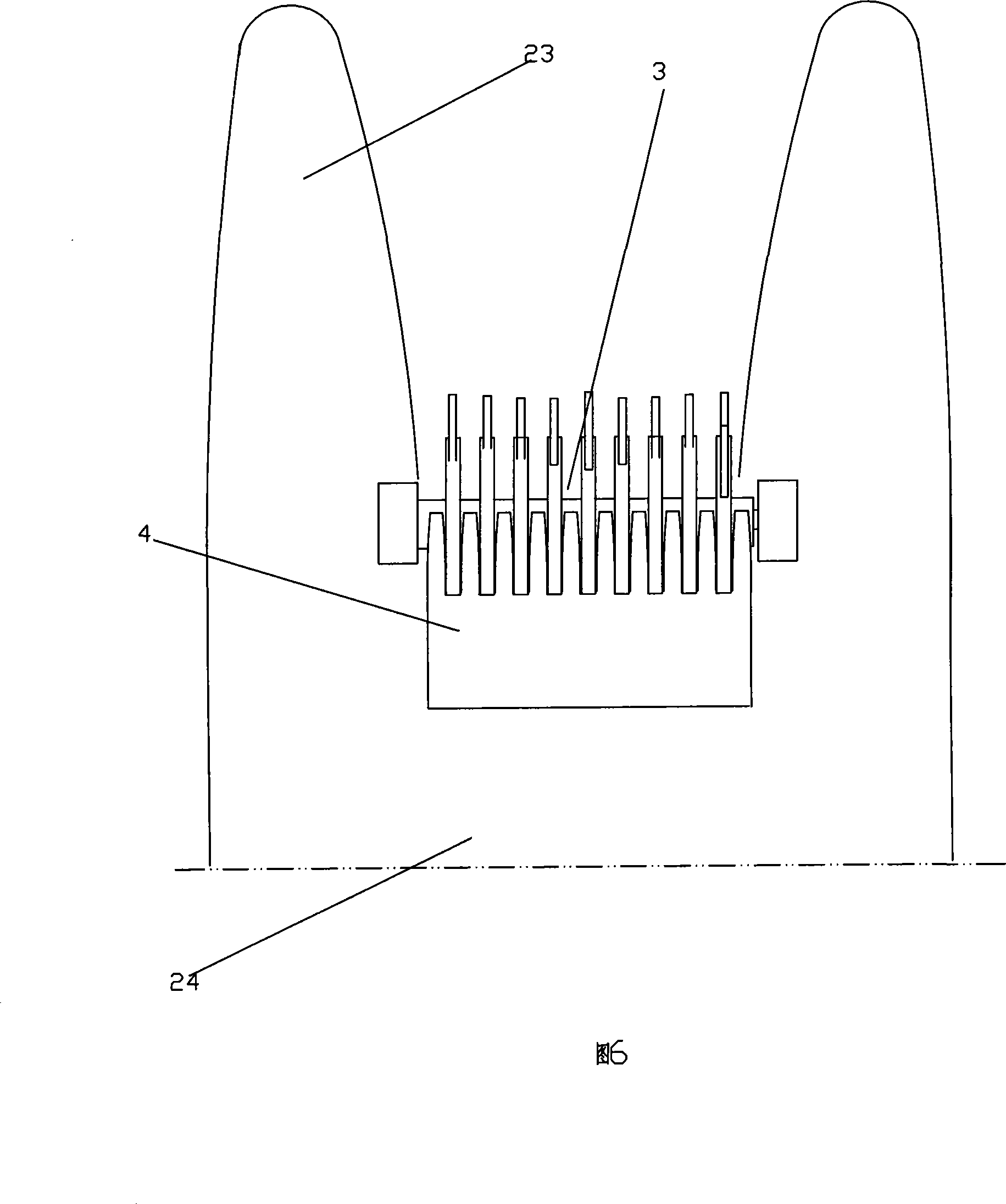

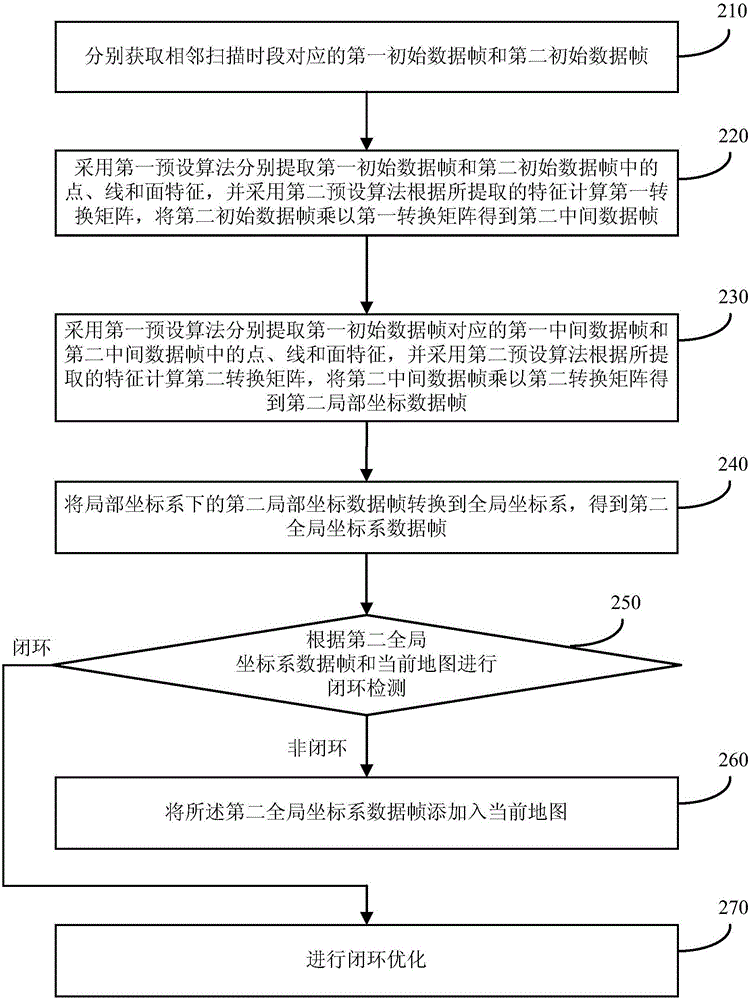

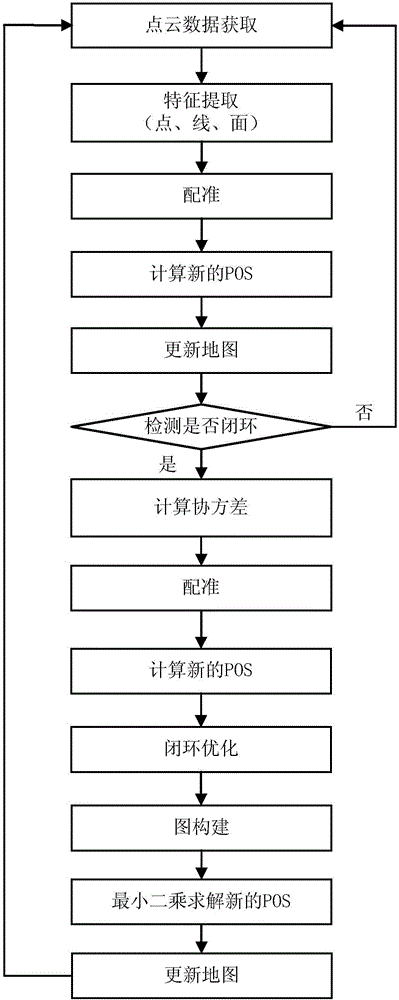

Map making method, device and system based on laser radar

ActiveCN107179086AHigh precisionImprove accuracyInstruments for road network navigationNavigational calculation instrumentsRadarTransfer matrix

An embodiment of the invention discloses a map making method, device and system based on laser radar. The method comprises: respectively acquiring two preliminary data frames which correspond to adjacent scanning periods; respectively extracting point, line and surface features in the two preliminary data frames by a first preset algorithm; calculating a first transfer matrix by a second preset algorithm according to the extracted features; implementing registration of the two preliminary data frames; respectively extracting point, line and surface features of two middle data frames by the first preset algorithm and implementing registration again; and transforming local coordinate data frames, which are obtained by secondary registration, under a local coordinate system to a global coordinate system and updating the map. According to the technical scheme in the embodiment, the precision and accuracy of the obtained map can be improved, the map drawing efficiency is improved, and the occupied space and manufacturing cost of the system are saved.

Owner:BEIJING GREEN VALLEY TECH CO LTD

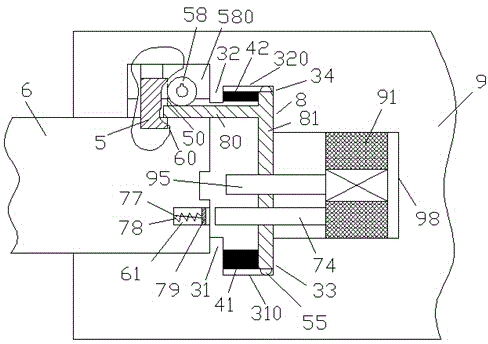

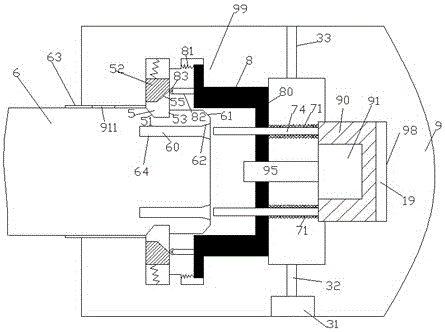

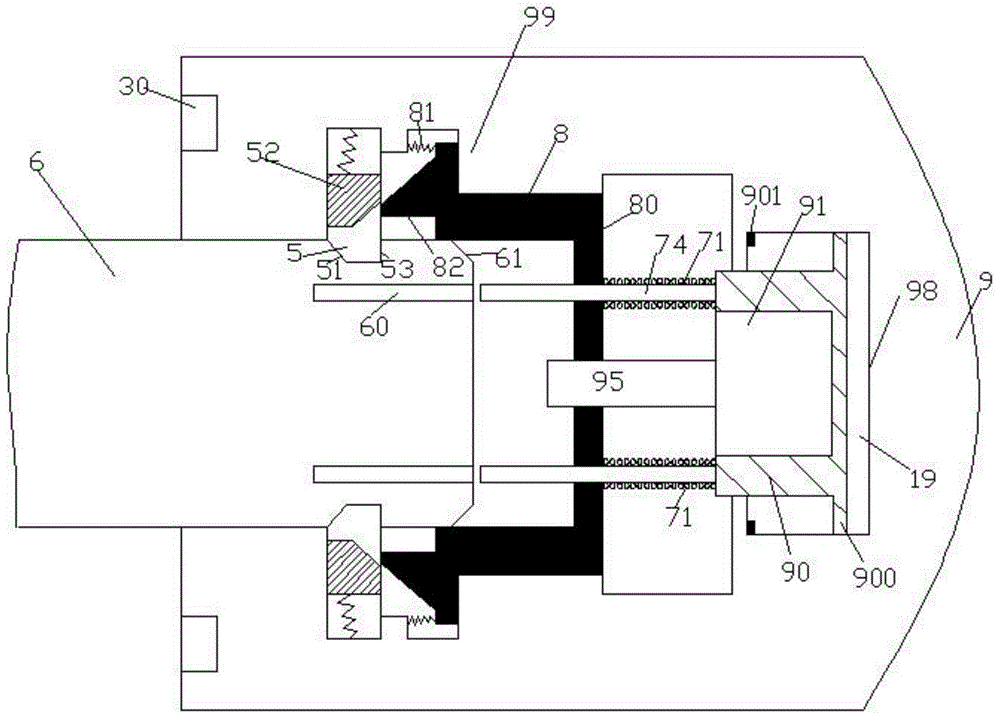

Safe socket with stable power supply

InactiveCN104934780AAchieve insertionAchieve orientationCoupling device detailsMechanical engineeringStator

A safe socket with stable power supply comprises a socket body (9) and a soleplate (90) which can be slidingly installed in a slide groove (19) of the socket body (9) along a left and right direction. The soleplate (90) is provided with an execution motor (91). A rotor of the execution motor (91) is connected to a screw (95) in a power connection mode. The screw (95) is cooperated with a screw hole in a transverse wall component (8) in the socket body (9). A left end wall of the soleplate (90) is fixedly connected to a power supply guide post (74) which slidingly passes through and forms sliding fit with a slide hole arranged in the transverse wall component (8). The power supply guide post (74) is used for jointing a power supply hole (60) in a plug (6) which is inserted into a jack of the socket body (9) so as to provide power. On each power supply guide post (74), a compression spring (71) is arranged between a side surface of the transverse wall component (8), which faces towards the execution motor (91), and a stator of the execution motor.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

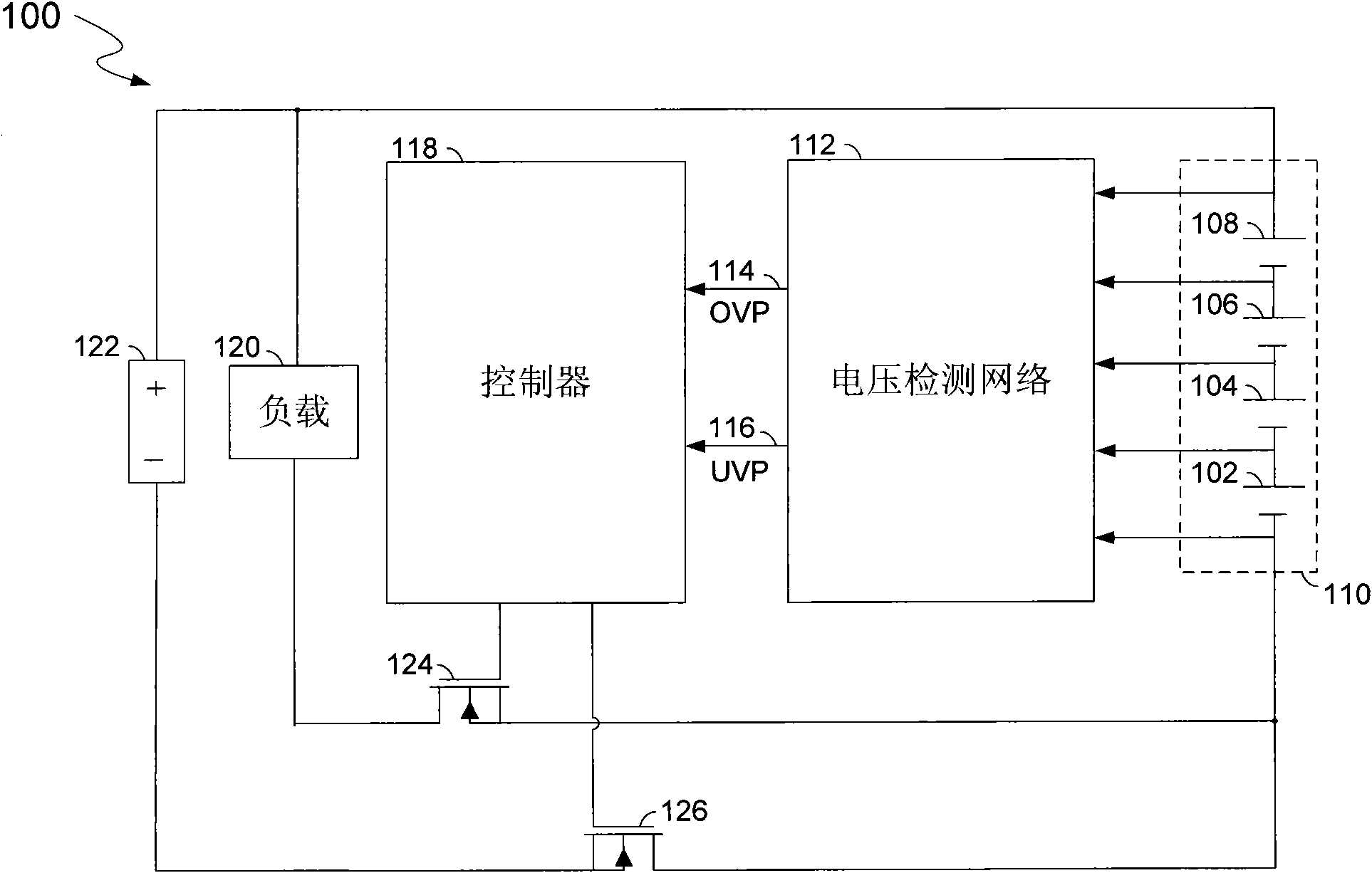

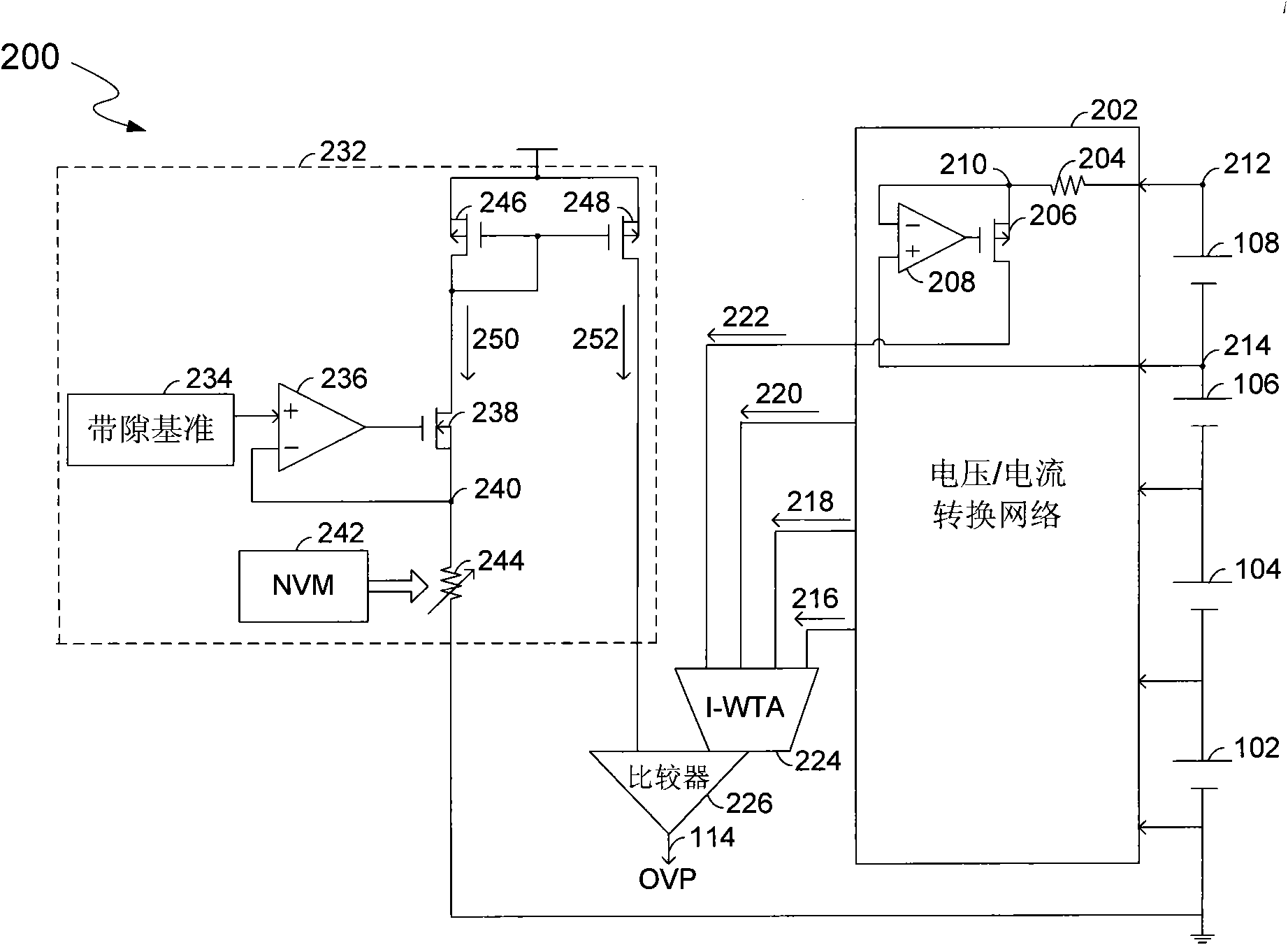

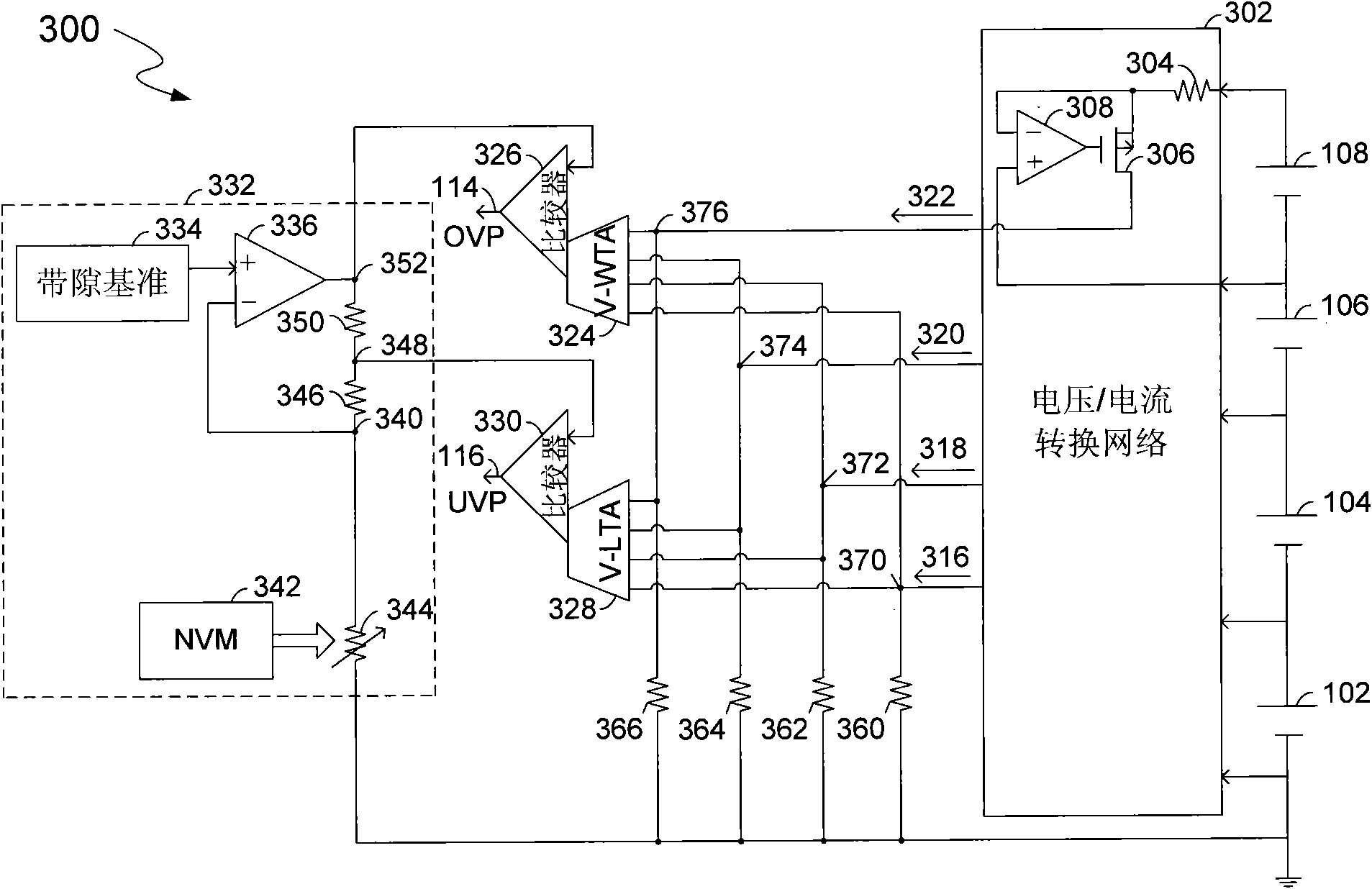

Multi-cell battery pack protection circuit

ActiveCN101799491ASave manufacturing costSave power consumptionCurrent/voltage measurementEmergency protective circuit arrangementsLow voltageNetwork connection

A voltage detection circuit can include a status sensing network and a comparing network. The status sensing network can simultaneously detect a cell voltage for each battery cell of a plurality of battery cells. The comparing network can simultaneously compare the detected cell voltages with a predetermined voltage threshold by comparing the maximum of the cell voltages with a first (high-voltage) threshold, and by comparing the minimum of the cell voltages with a second (low-voltage) threshold. The comparing network can also generate an indication signal when a cell voltage does not satisfythe respective voltage threshold.

Owner:AOTU ELECTRONICS WUHAN

[wireless remote controller]

InactiveUS20070008168A1Save manufacturing costConvenient to carryTelevision system detailsElectric signal transmission systemsEngineeringUSB

A wireless remote controller includes a transmitter unit, which has a data storage device with an Express Card interface connectable to a main system directly for enabling the main system to store data into or fetch data from a flash memory of the data storage device, and a control device with operating buttons and a transmitting antenna, and a receiver unit, which is receivable in an open chamber of the housing of the transmitter unit when not in use and has a USB interface for connection to the main system for receiving control signals from the transmitter unit and transmitting received control signals to the connected main system.

Owner:RAYTAC CORP

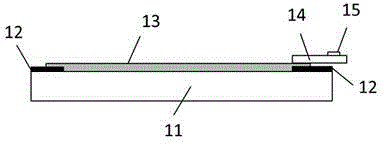

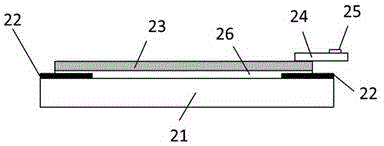

A method for 3D manufacturing an OGS capacitive touch screen

InactiveCN104407749ASimple processSave production raw material costAdditive manufacturingIncreasing energy efficiencyCapacitanceEngineering

The invention relates to a method for 3D manufacturing an OGS capacitive touch screen, the method comprising steps of: providing a glass panel, producing a plurality of patterned transparent conductive layers and a plurality of transparent conductive electrodes on a surface of a visible region of the glass panel; producing a patterhned light-shielding film around the glass panel; producing a first connection electrode at a connecting passage; producing a second electrode at a surface of the light-shielding film close to the first connection electrode; electrically connecting an FPC with a touch IC chip to a pin of the second connection electrode by thermal pressure to form a final integrated OGS touch screen. By the method of the invention, a capacitive touch screen is manufactured by a 3D printing. The method of the invention has a simple process, omits several complex processes of the traditional process such as exposure, developing and etching, and saves materials; and also the method of the invention improves effectively the performance and the reliability of the OGS touch screen and thus improves the product yield and the production efficiency.

Owner:FUZHOU UNIV

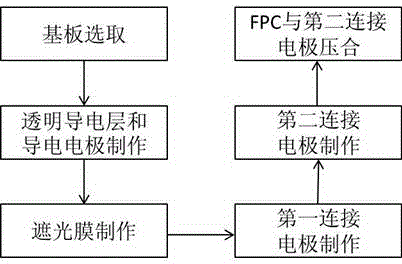

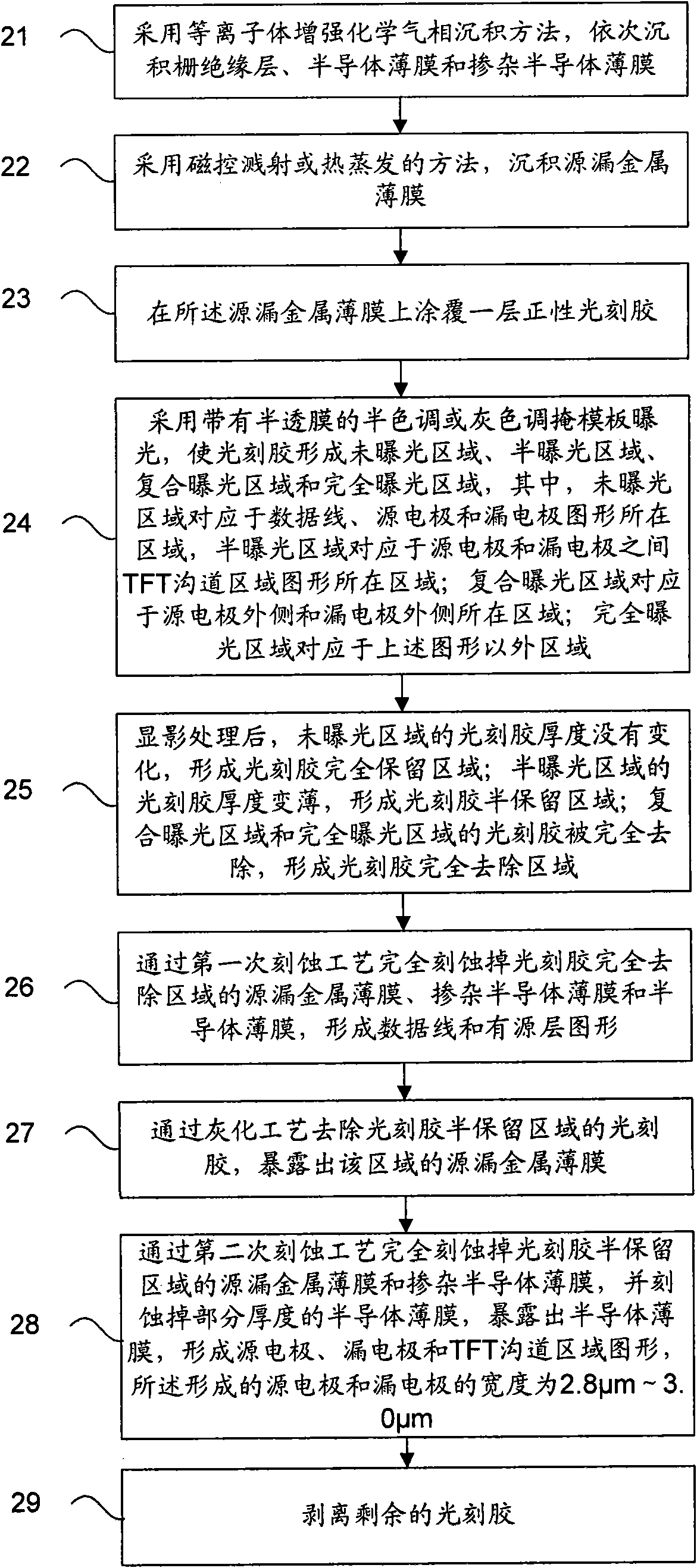

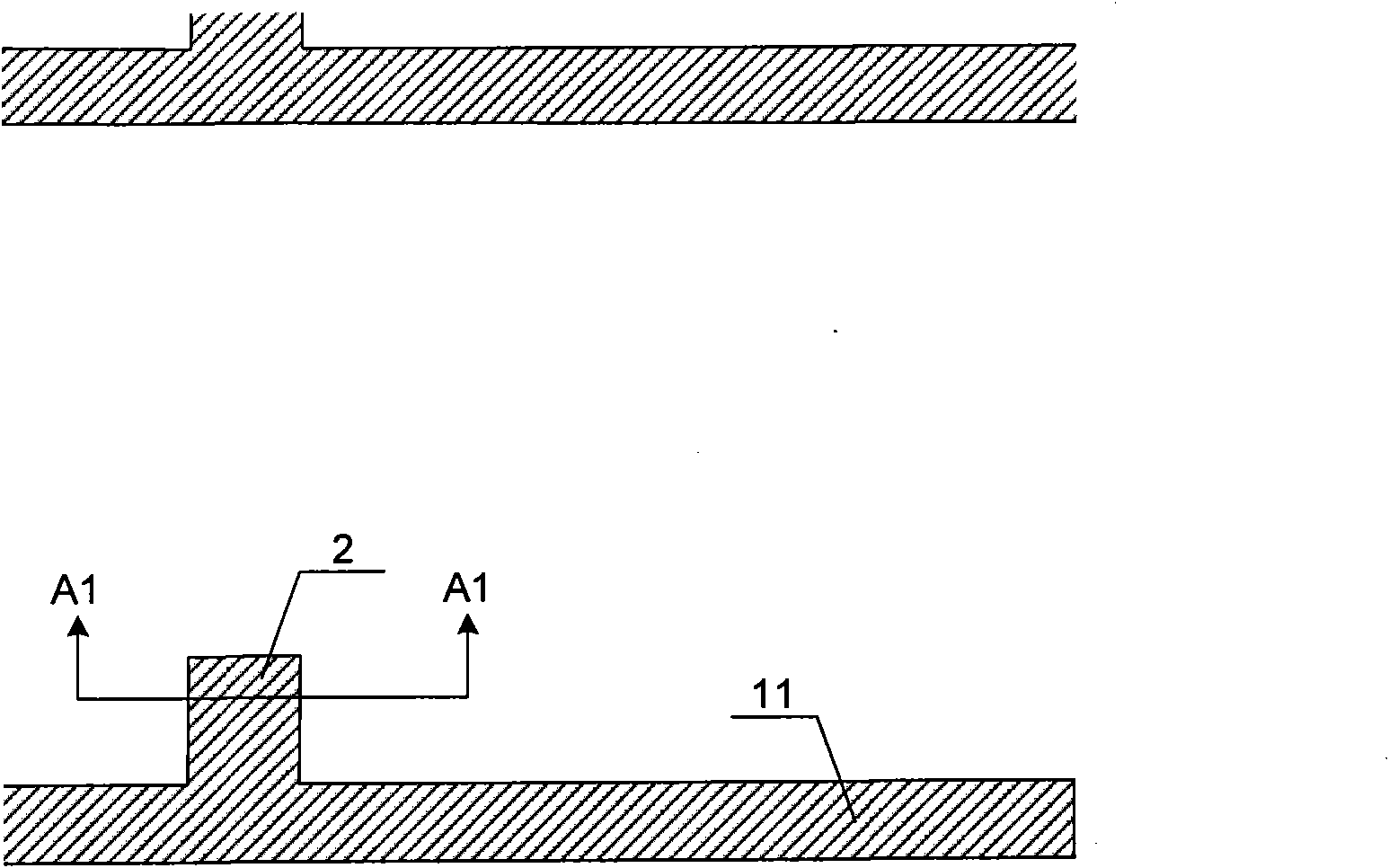

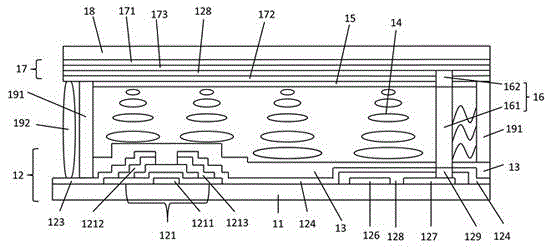

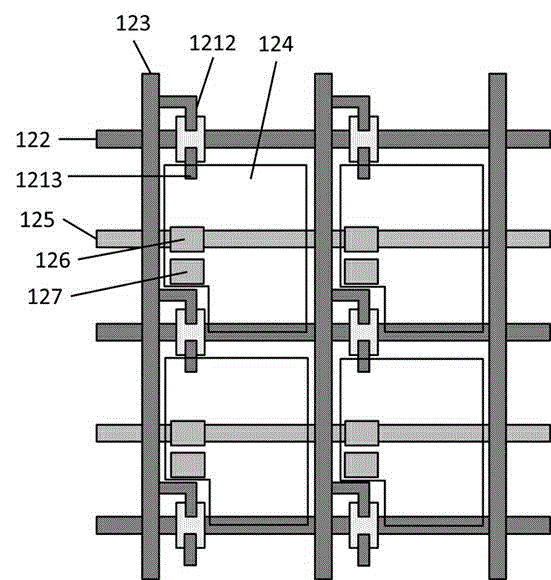

TFT-LCD (Thin Film Transistor Liquid Crystal Display) array substrate and manufacture method thereof

ActiveCN101807549AReduce widthSmall sizeTransistorSolid-state devicesInsulation layerComposition process

The invention relates to a TFT-LCD (Thin Film Transistor Liquid Crystal Display) array substrate and a manufacture method thereof. The manufacture method comprises the steps of: depositing a grid metal film, forming a grid line and a grid electrode pattern by using a composition process; depositing a grid insulation layer, a semiconductor film, a doped semiconductor film and a source / drain metal film, forming an active layer, a data line, a source electrode, a drain electrode and a TFT channel region pattern by adopting a halftone or gray tone mask template with a semipermeable membrane through a composition process, wherein the widths of the formed source electrode and the formed drain electrode are 2.8-3.0 mu m; depositing a passivation layer, and forming a passivation layer through hole pattern by using the composition process; and depositing a transparent conductive film, forming a pixel electrode pattern by using the composition process, and connecting the pixel electrode with the drain electrode through a passivation layer through hole. The widths of the source electrode and the drain electrode are greatly reduced by adopting the halftone or gray tone mask template with the semipermeable membrane, therefore, the invention improves the aperture opening rate, can increase the brightness and lower the brightness of a backlight board.

Owner:BOE TECH GRP CO LTD +1

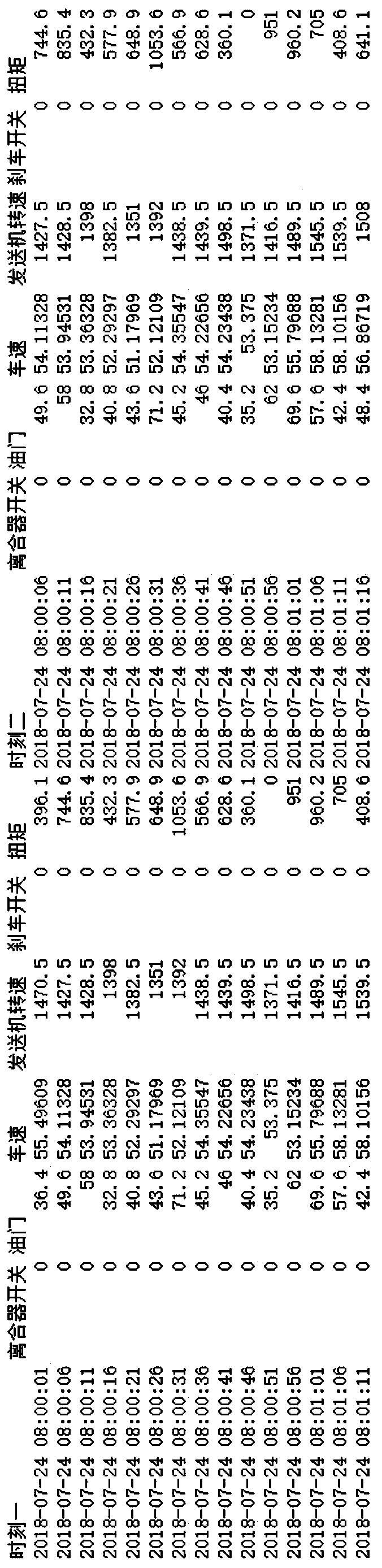

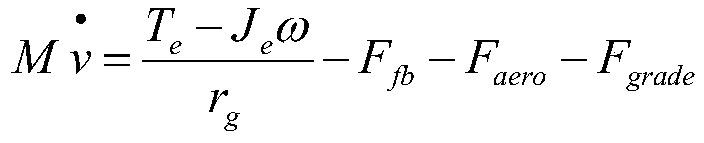

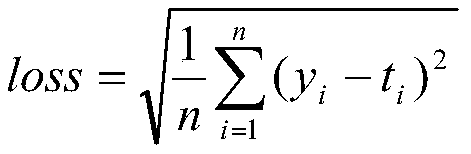

Whole vehicle load prediction method based on LSTM neural network

ActiveCN110148230AImprove forecast accuracySave manufacturing costRegistering/indicating working of vehiclesDetection of traffic movementShort-term memoryLoad model

The invention provides a whole vehicle load prediction method based on an LSTM neural network. The method comprises the following steps of collecting vehicle data through a vehicle-mounted terminal; integrating vehicle data, and carrying out data cleaning and standardized processing to obtain training data; training through a long-term and short-term memory neural network model to obtain a load model; and inputting predicted data into the trained load model to predict and acquiring load data. By using the whole vehicle load prediction method based on the LSTM neural network, a big data calculating platform is used, based on an application of the neural network model in a prediction field, a longitudinal dynamic vehicle mass calculation equation is combined, and real-time and accurate prediction of the whole vehicle load can be realized.

Owner:兴民智通(武汉)汽车技术有限公司

Substrate packaging structure

InactiveCN101486404ASave manufacturing costGood Pack Load RateContainers to prevent mechanical damageDamagable goods packagingInventory managementEngineering

The invention discloses a packing structure of a substrate, which comprises a case body, a liner body and a lid body, wherein the case body comprises a bottom plate and a plurality of lateral plates which are connected with the bottom plate, and a first containing space is formed by the encirclement of the lateral plates and the bottom plate; the liner body is detachably configured in the first containing space and provided with a plurality of buffer walls which are higher than the lateral plates, and a second containing space is formed by the encirclement of the buffer walls along the lateral plates and the bottom plate in the first containing space; and the lid body is covered above the case body. The packing structure of the substrate can change the liner body according to the size of the substrate to be packed, and the buffer walls of the liner body are higher than the lateral plates of the case body, thus not only saving mould manufacturing cost and inventory management cost of the packing structure of the substrate, but also having good packing loading rate.

Owner:AU OPTRONICS CORP

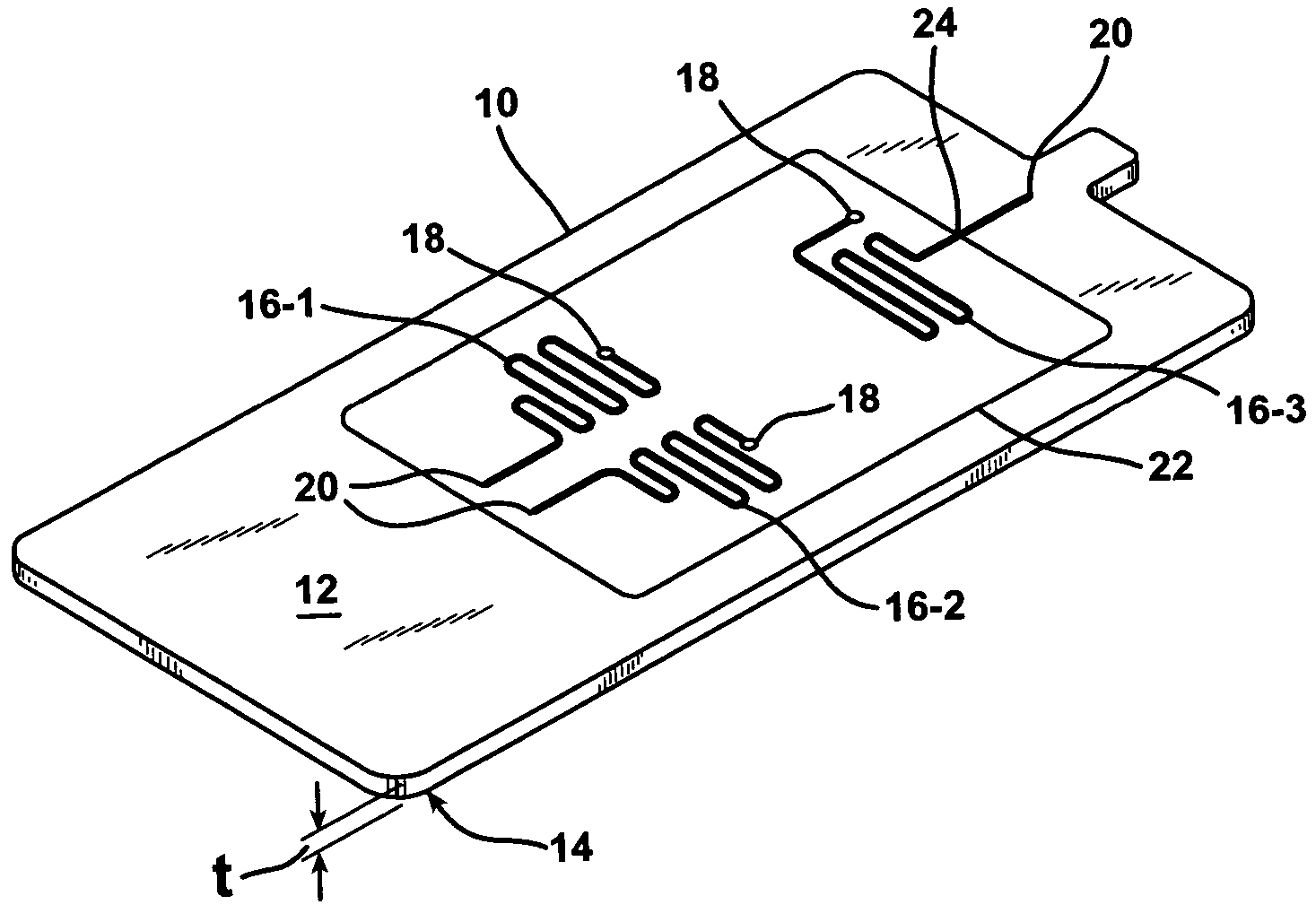

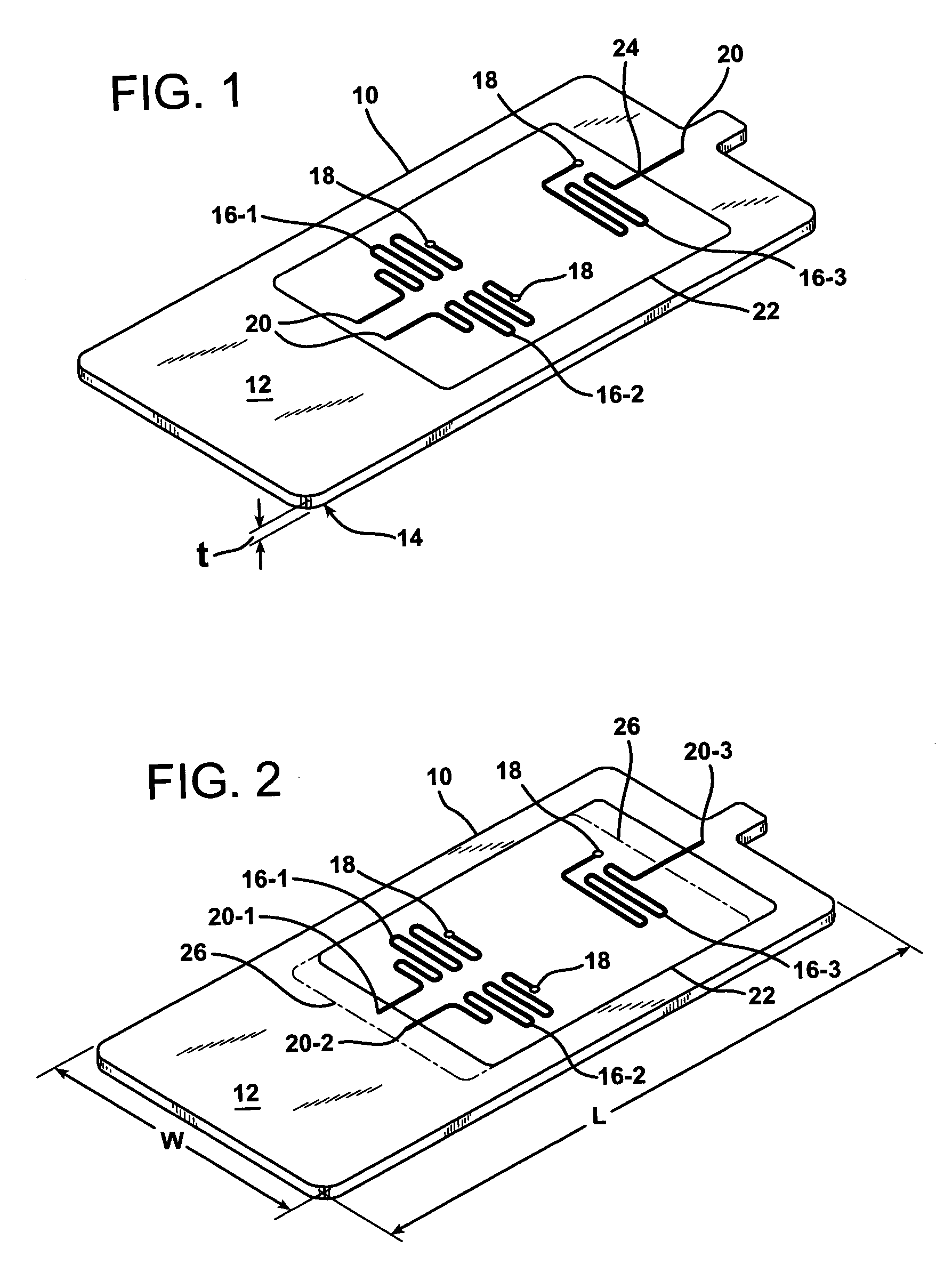

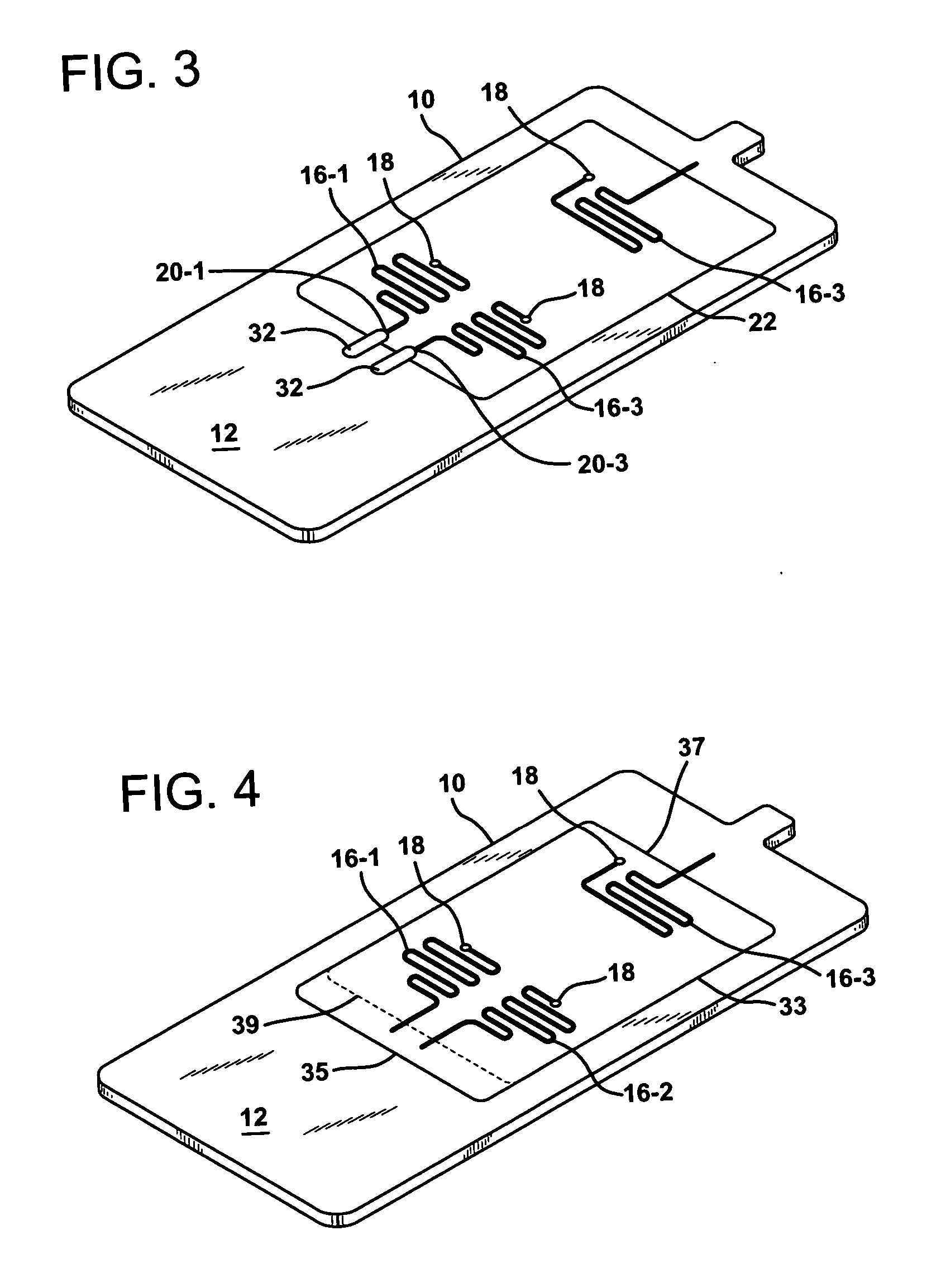

Inkjet printheads having multiple label placement positions for air diffusion vents

ActiveUS20050110851A1Save manufacturing costReduce usagePrintingElectrical and Electronics engineeringAtmosphere

The invention teaches placing labels over air diffusion vents on inkjet printheads depending upon a content of the inkjet printhead. In one embodiment, the inkjet printhead contains one or three inks in its interior and has three air diffusion vents in a lid that fluidly communicate with the interior. If the interior has one ink, a label covers the entirety of two of the three air diffusion vents to substantially prevent the two air diffusion vents from communicating with atmosphere. If the interior has three inks, a label only covers a portion of each of the three air diffusion vents and allows each to fluidly communicate with atmosphere. In this manner, single or tri-color inkjet printhead manufacturing can occur with a single lid having a multiplicity of label placement positions. The labels can have similar dimensions, dissimilar length dimensions or other.

Owner:SLINGSHOT PRINTING LLC

Power supply apparatus with stable power supply and moving roller

InactiveCN104934786AAchieve orientationAvoid manual operationCoupling device detailsScrew threadElectrical and Electronics engineering

A power supply apparatus with stable power supply and a moving roller is disclosed. The power supply apparatus comprises a main body (9) and a plug (6) which is inserted into a jack of the main body (9). A locking and unlocking motor (91) is arranged in the main body (9). A rotor of the locking and unlocking motor (91) is connected with a screw (95) in a power connection mode. The screw (95) forms screw-thread fit with a screw hole of a movable component (8) in the main body (9). A stator of the locking and unlocking motor (91) is fixedly connected to a power supply guide rod (74) which forms sliding fit with and slidingly passes through a slide hole arranged in the movable component (8). The power supply guide rod (74) is used for jointing a power supply hole (61) in the plug (6) which is inserted into the jack of the main body (9) so as to carry out power supply.

Owner:衢州市洼帝尔数控设备有限公司

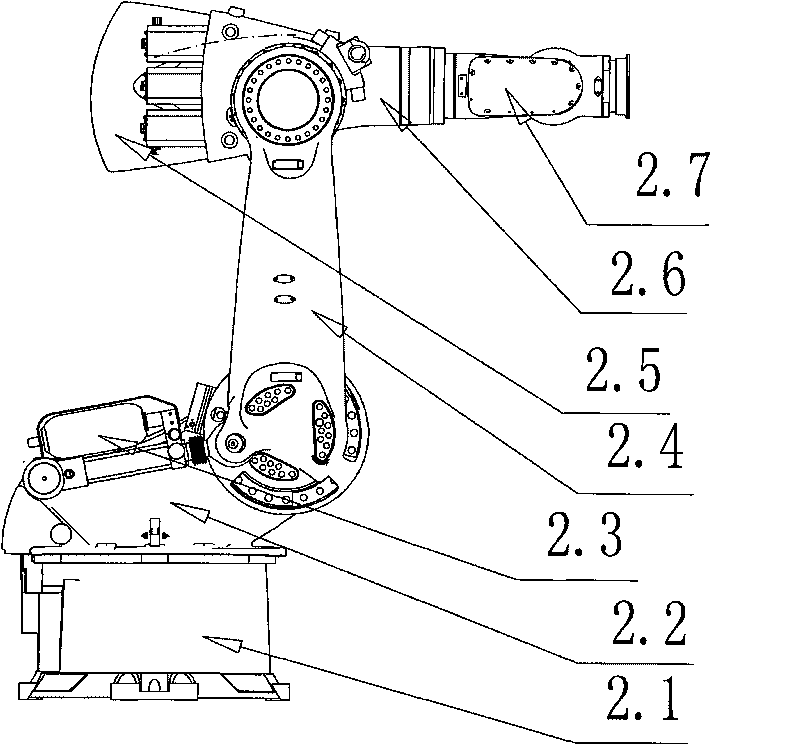

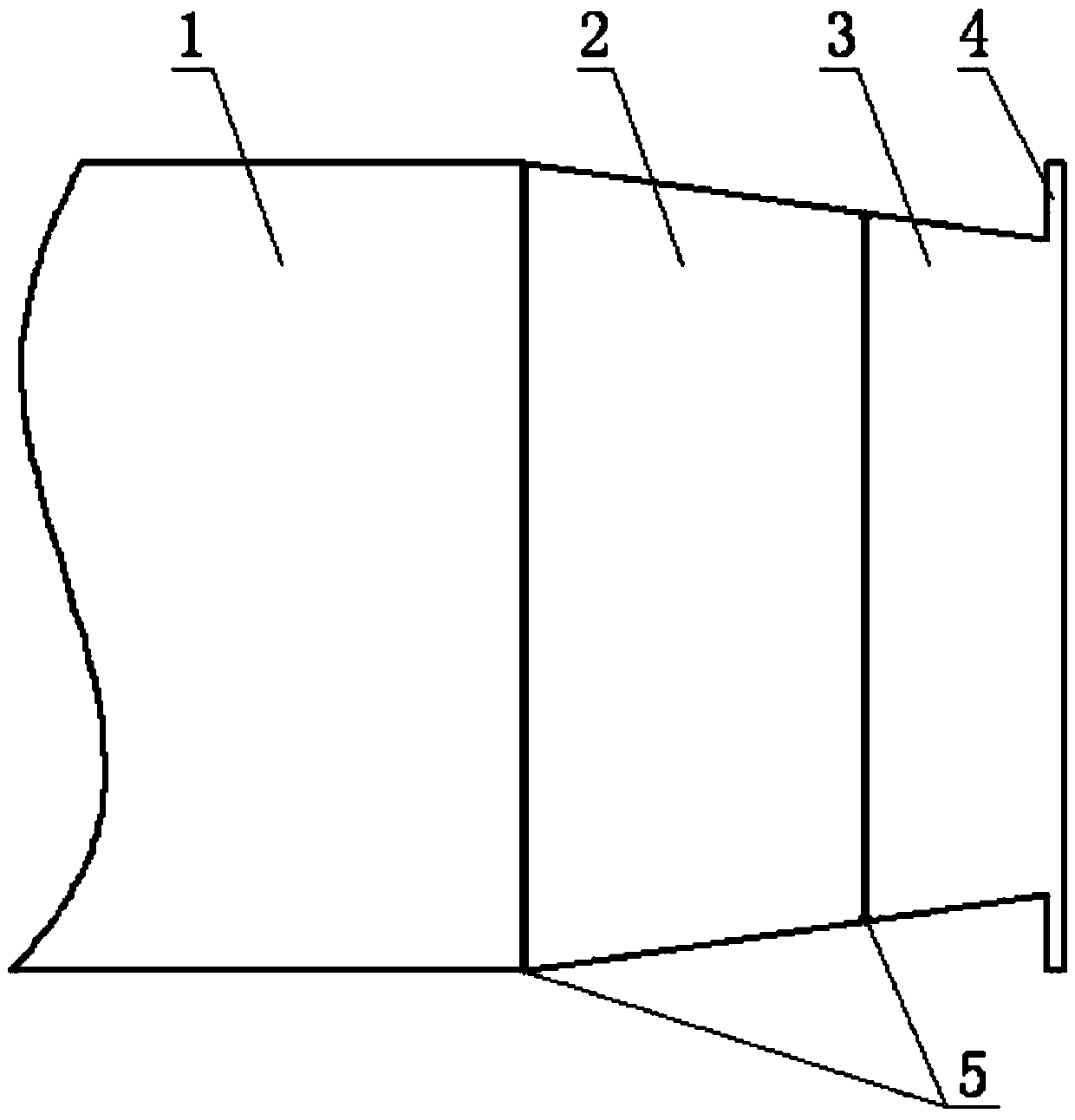

Stacking robot system of cold-end glass on floatation glass production line

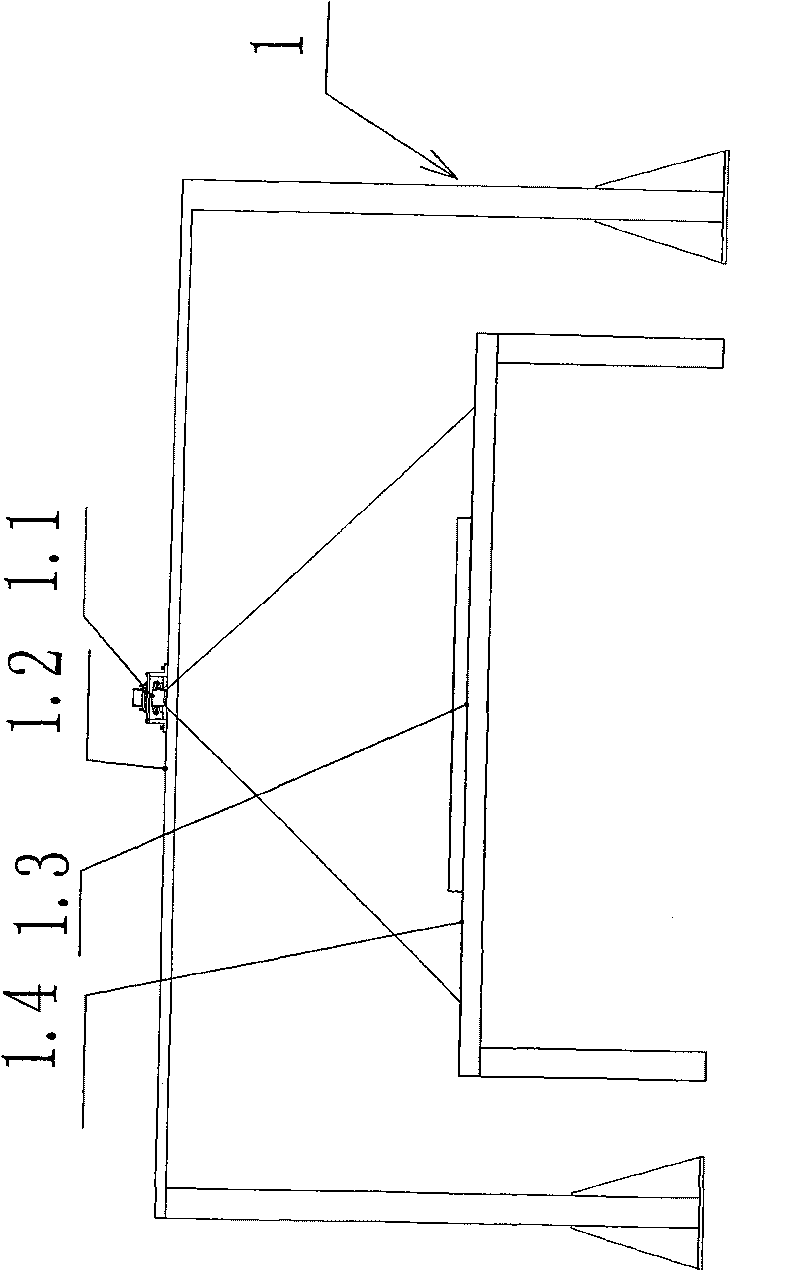

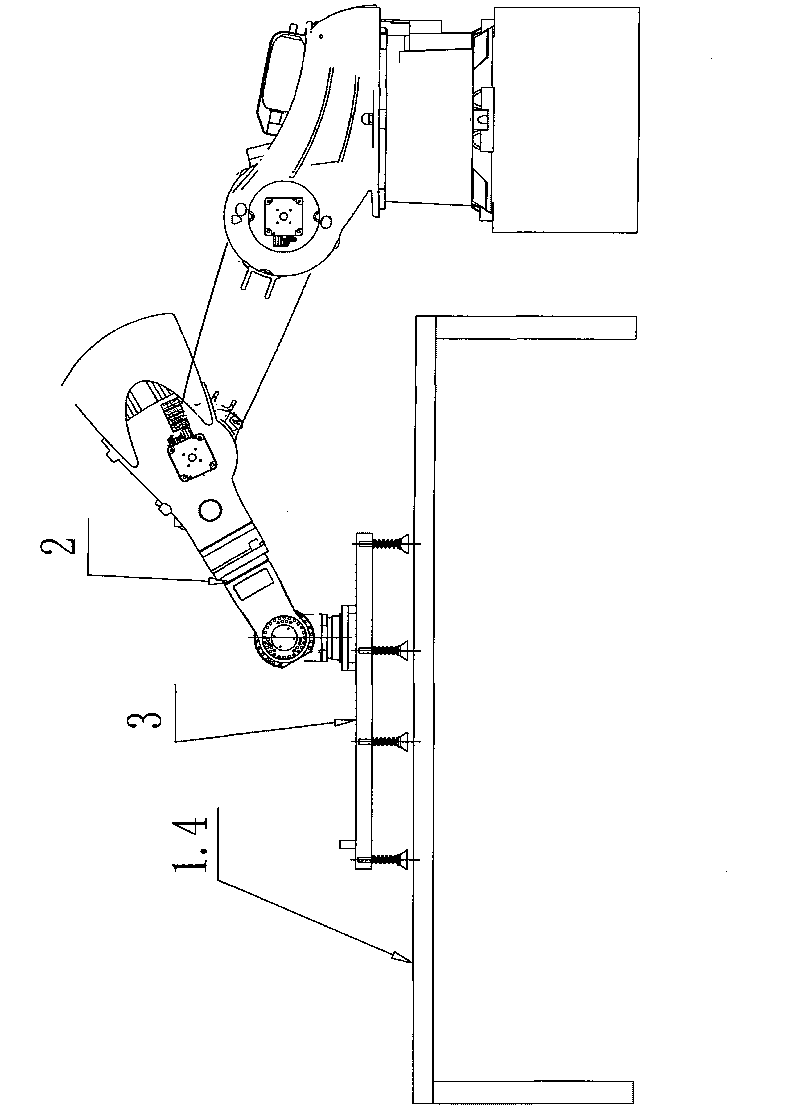

ActiveCN101704454ASave manufacturing costReduce land costProgramme-controlled manipulatorStacking articlesProduction lineRobotic systems

The invention relates to a stacking robot system of cold-end glass on a floatation glass production line, comprising a vision system, a roller way (1) and a plurality of stacking mechanical hands, wherein the vision system and the roller way (1) comprise a roller way (1.4), an installation rack (1.2) and a photographic system (1.1); each stacking mechanical hand comprises a mechanical hand (2), a sucking disc combination rack (3) and two double-station rotary tables (4), wherein the sucking disc combination rack (3) comprises a sucking disc rack (3.1), a plurality of sucking disc mechanisms (3.2), a set of two-point detection assembly (3.6), a set of one-point detection assembly (3.5) and four sets of anti-collision detection assemblies (3.10, 3.11, 3.12); the two-point detection assembly (3.6) is transversely arranged on the bottom of the sucking disc rack (3.1), the one-point detection assembly (3.5) is longitudinally arranged on the bottom of the sucking disc rack (3.1), and the four anti-collision detection assemblies (3.10, 3.11, 3.12) are arranged on the sucking disc rack (3.1) in a rectangle shape. The stacking robot system of the cold-end glass on the floatation glass production line can automatically realize the grading stacking casing.

Owner:JIANGSU JINMING IND ROBOT AUTOMATION

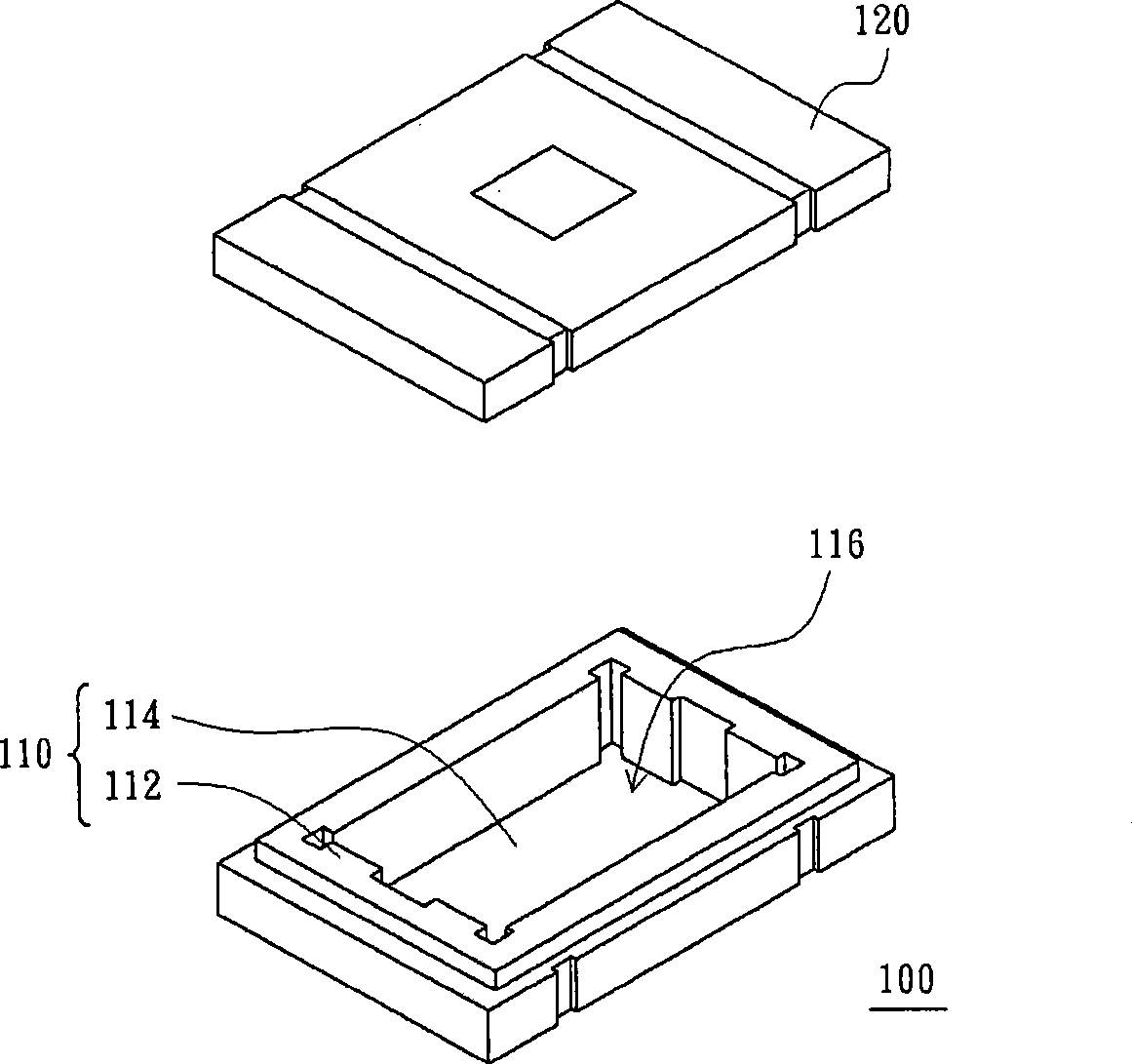

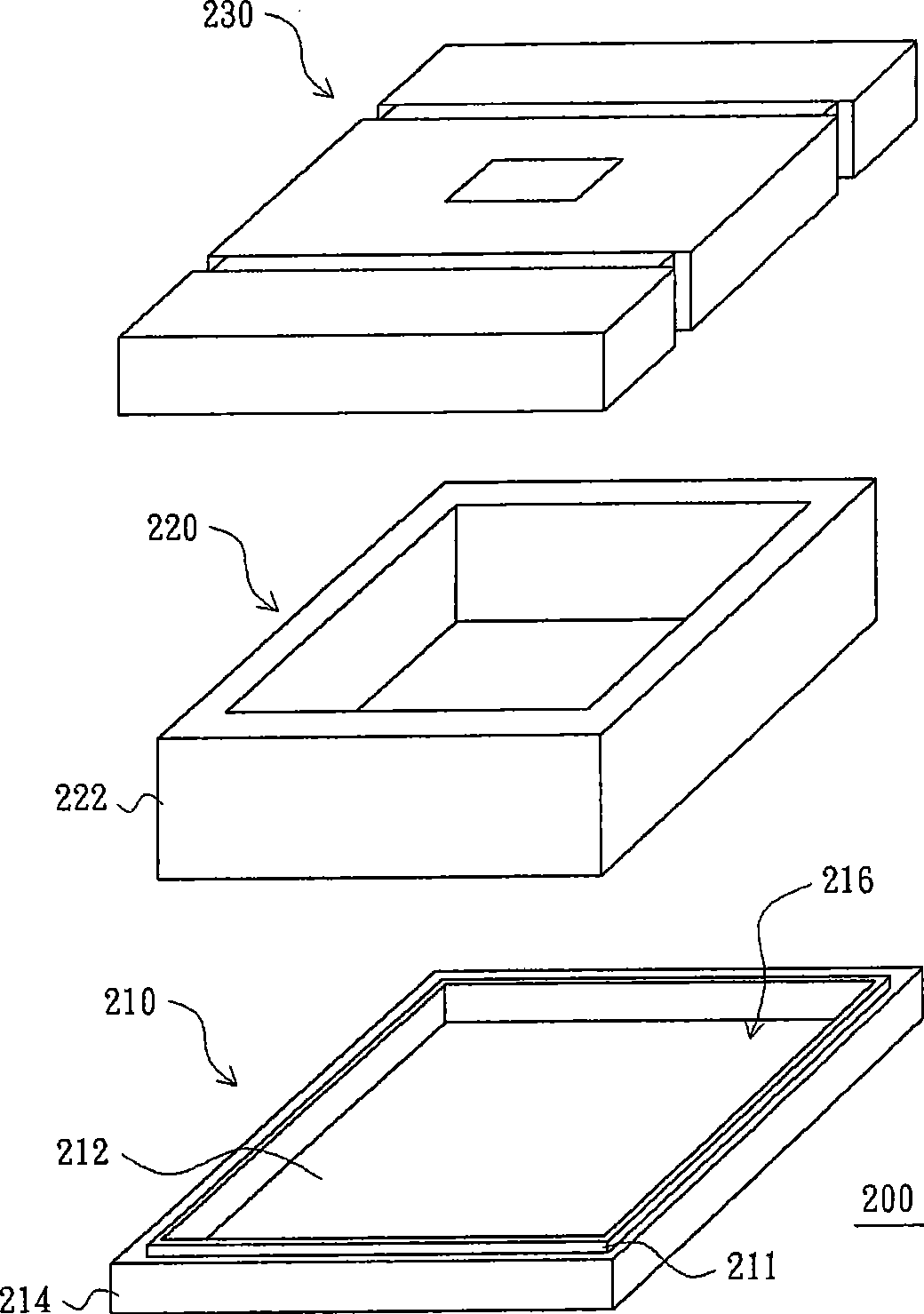

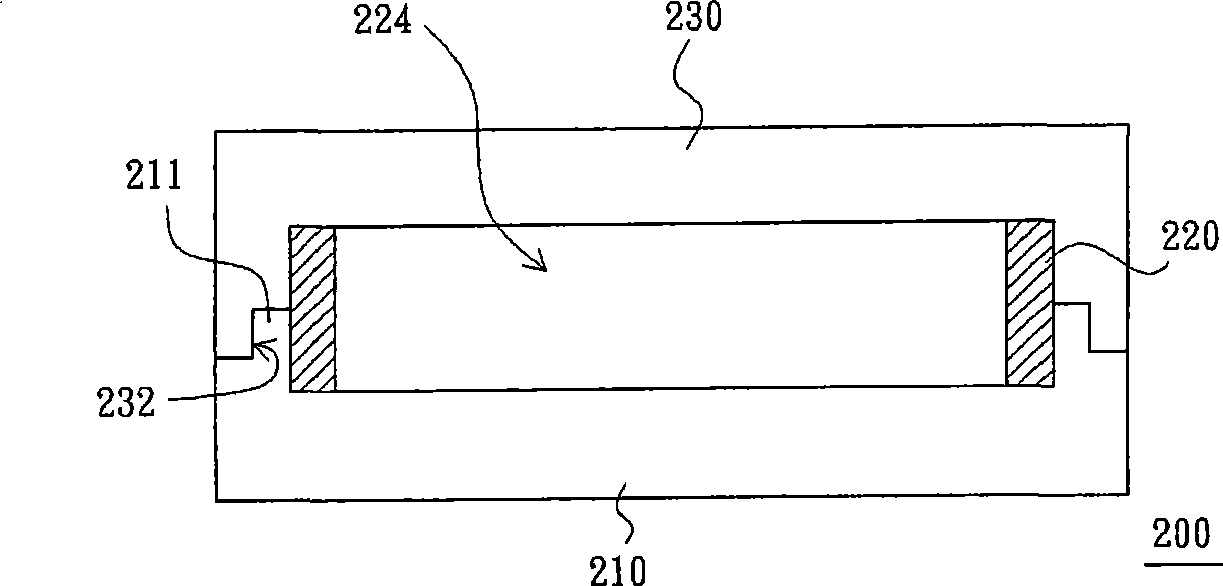

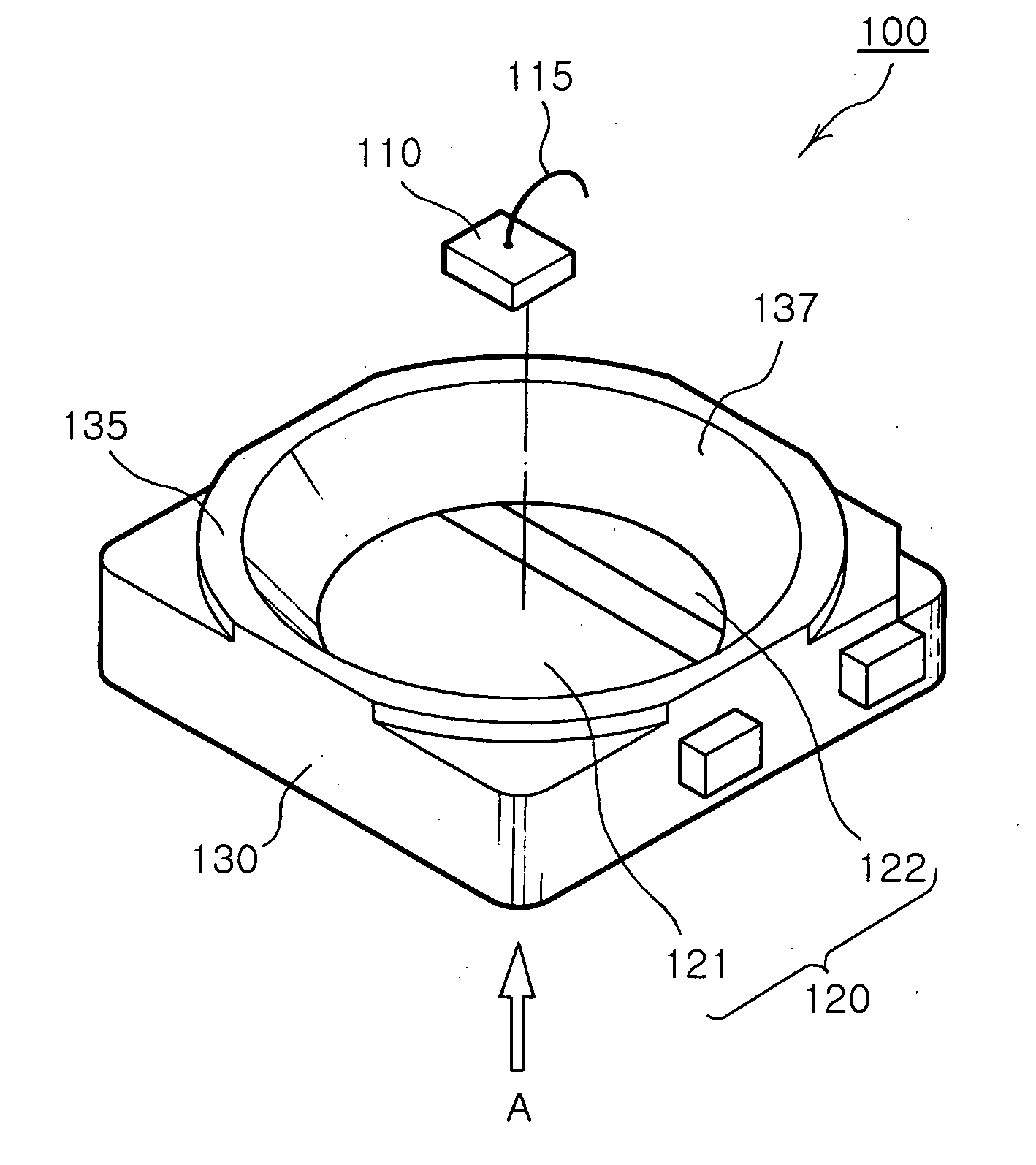

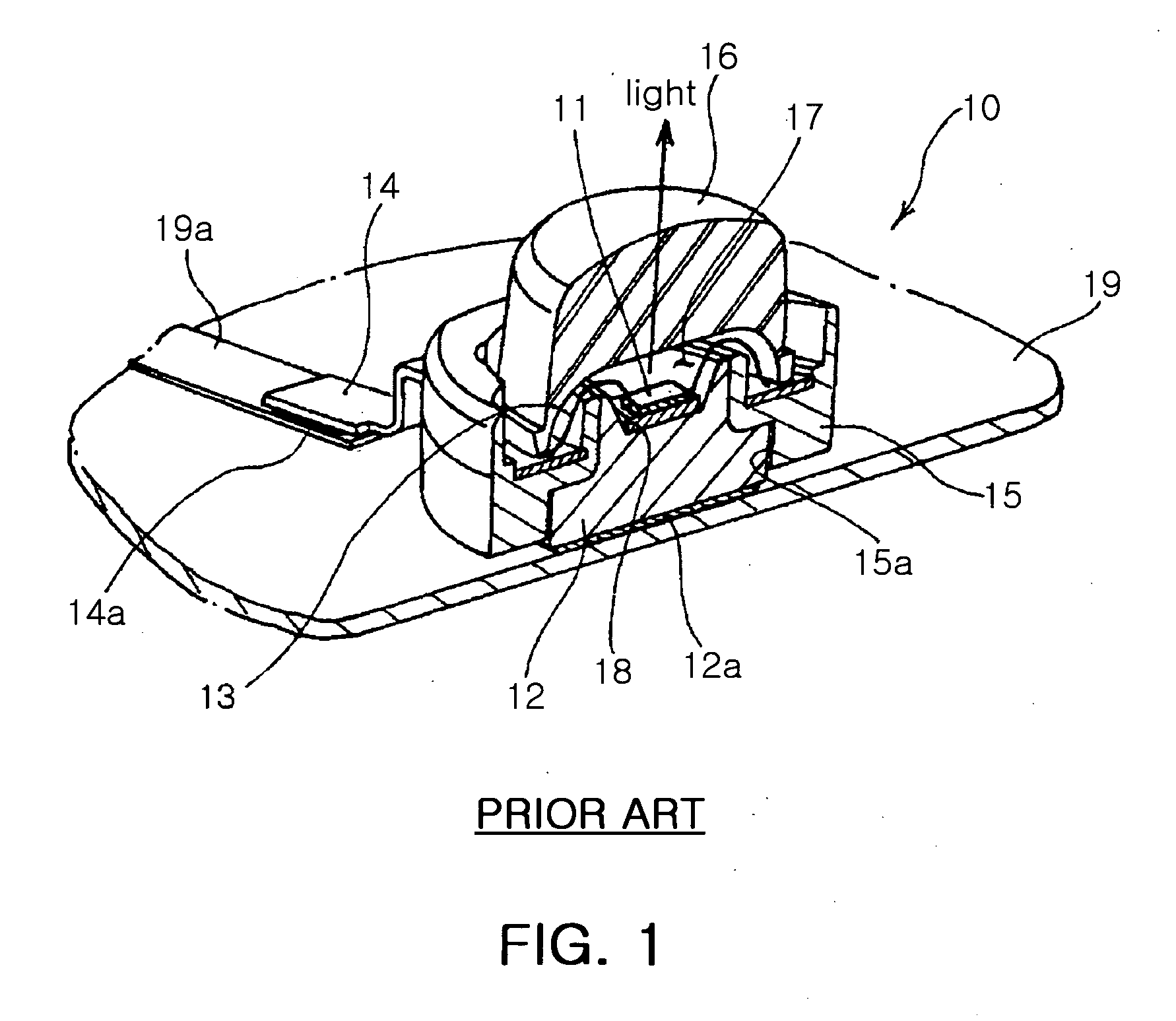

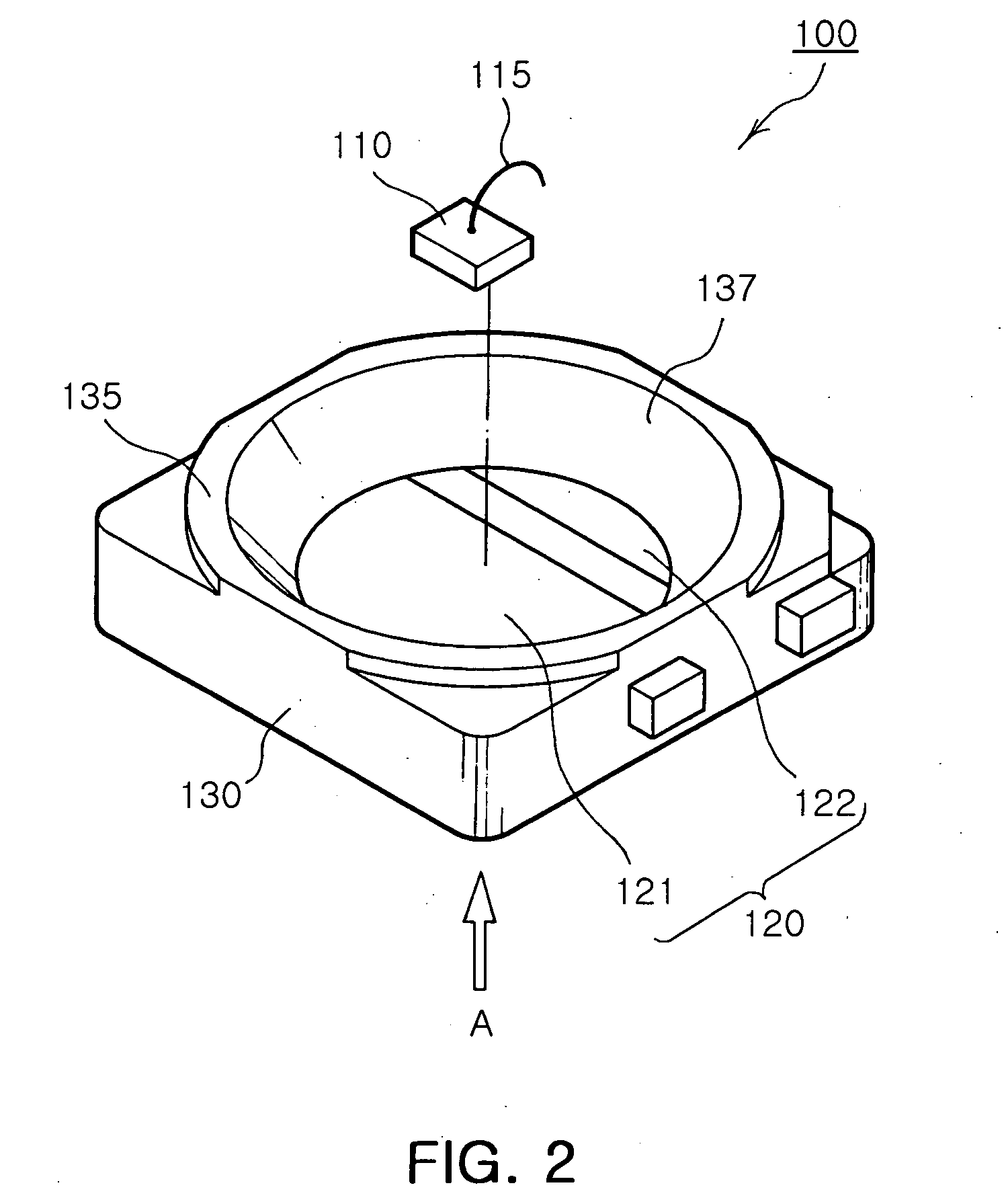

LED package

InactiveUS20070108460A1Save manufacturing costImprove light extractionSolid-state devicesSemiconductor devicesOptoelectronicsManufacturing cost reduction

An LED package is provided. A light emitting chip generates light when current is applied. A frame is electrically connected to the light emitting chip via a wire, and has the light emitting chip mounted thereon. A molding fixes the frame thereto, and has a cavity surrounding the light emitting chip and an embossed protrusion formed on a top surface thereof. A lens is domed upward from the embossed protrusion along an outer periphery of the embossed protrusion. The lens is made of a light transmissible resin filled in the cavity. The invention ensures a sufficient view angle of light generated from the LED chip, thereby increasing light extraction efficiency. This consequently simplifies an assembly process, allowing mass production and reducing manufacturing costs.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

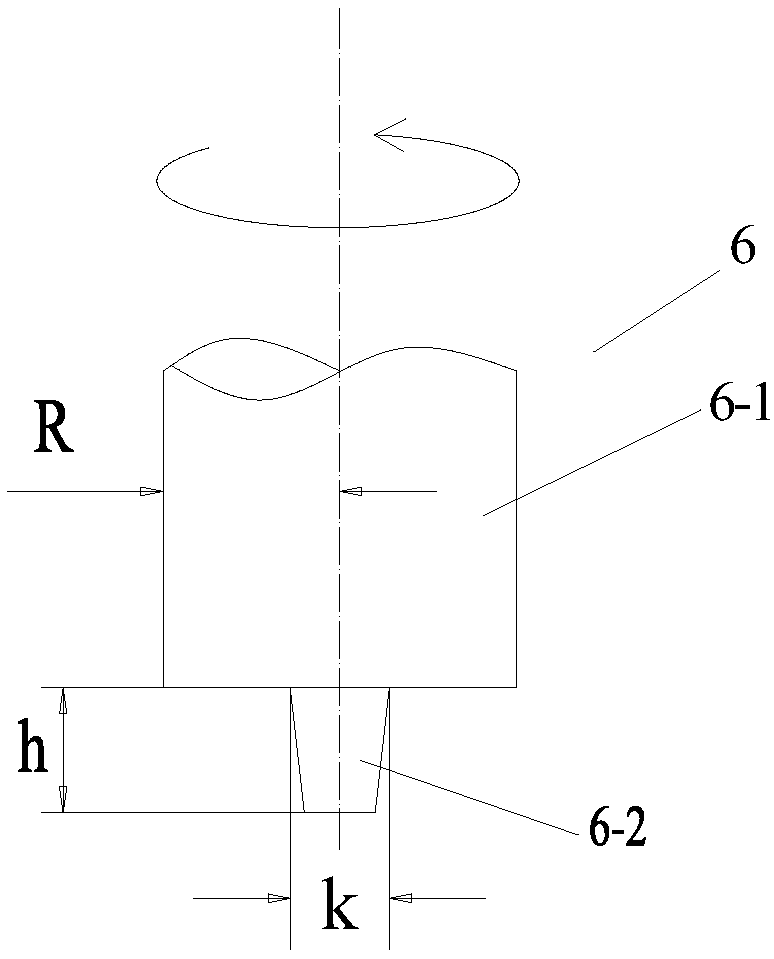

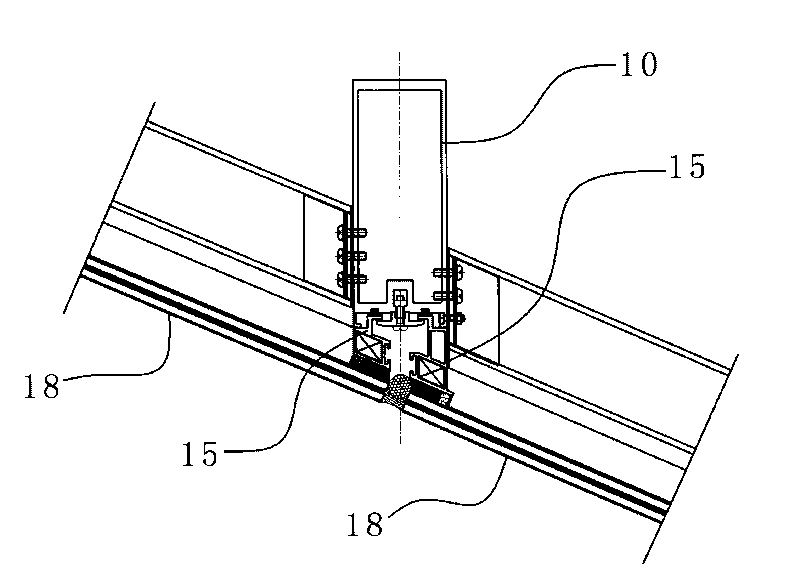

Stir friction welding method for hollow aluminum extruded section splicing arc plate

ActiveCN108723578AReduce incoming materialsLower requirementWorkpiece edge portionsNon-electric welding apparatusFriction weldingRailway passenger car

The invention discloses a stir friction welding method for a hollow aluminum extruded section splicing arc plate, and belongs to the field of welding method of a large arc roof plate component of an aluminum alloy car body of a railway passenger car. For stir friction welding of the aluminum alloy car body roof arc plate component of the railway passenger car, and a welding sequence of one-step reversed assembling and two-step forward assembling and a control method for weldment assembly interval values are proposed; a thickened protrusion is arranged on the position, adjacent to a weld seam,of the outer surface of the aluminum alloy hollow extruded section, the protrusion width and the diameter of the root of a stirring needle are maintained at a ratio of 95% to 105%, in order to ensurethe size of a post-weld workpiece, during the two-step forward assembling, when pre-fabrication reverse deformation friction stir welding is conducted, a thickened raised metal is filled in the gap generated at the weld seam of the outer surface of the pre-fabrication deformed curved section aluminum alloy hollow extruded section by the rotary extrusion of a stirring head, and the friction stir welding does not require additional raised metal grinding removal work; the method ensures the structural size requirement of aluminum alloy product components of the curved section hollow extruded section.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

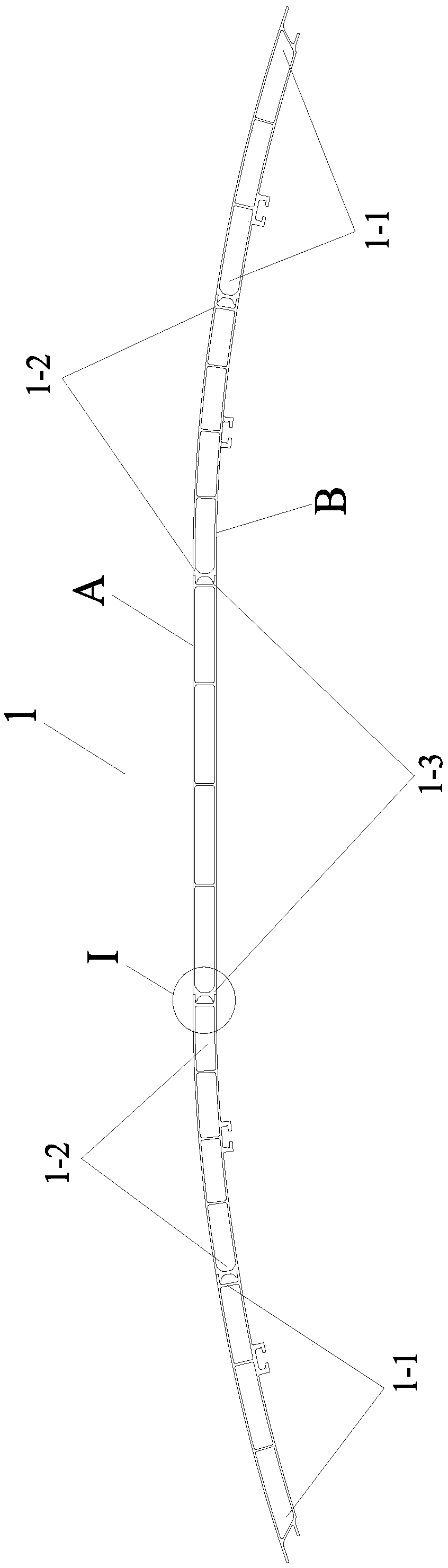

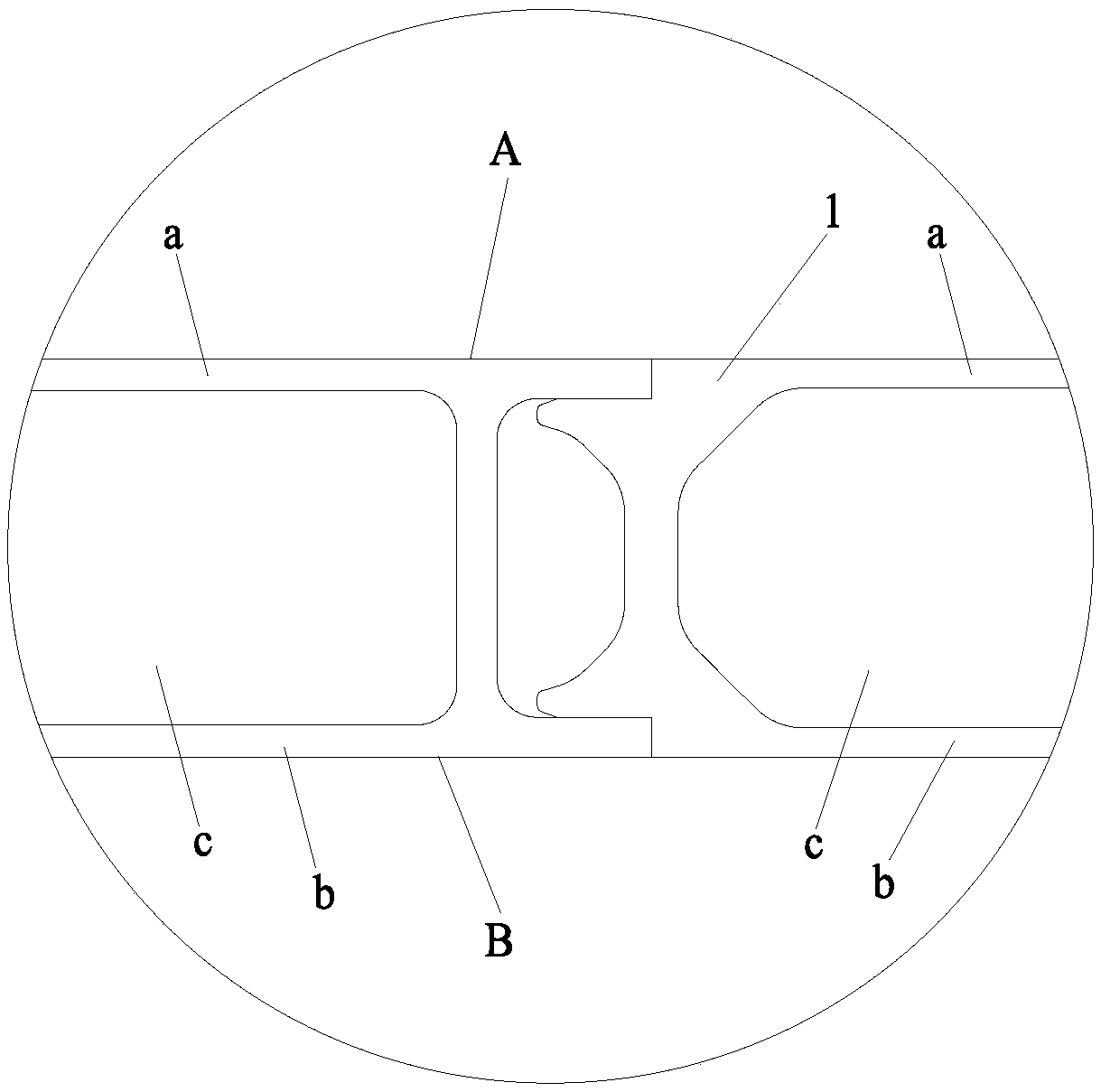

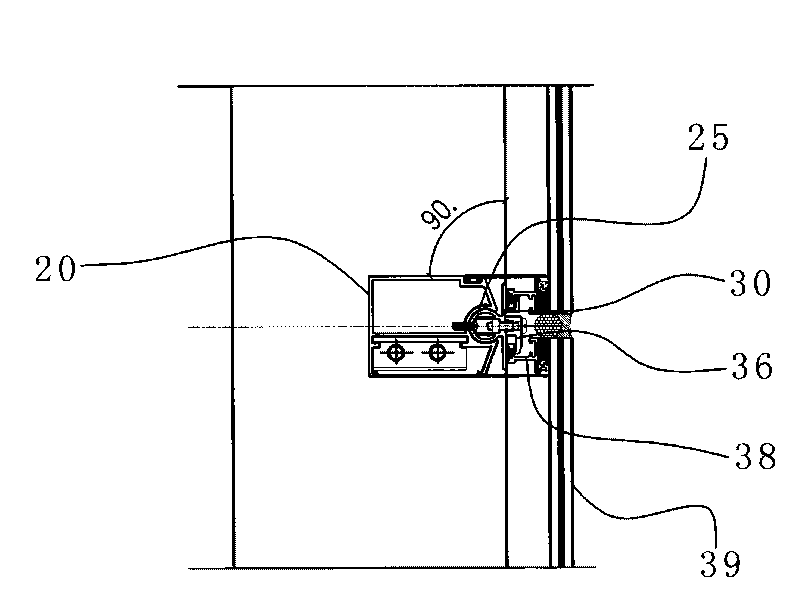

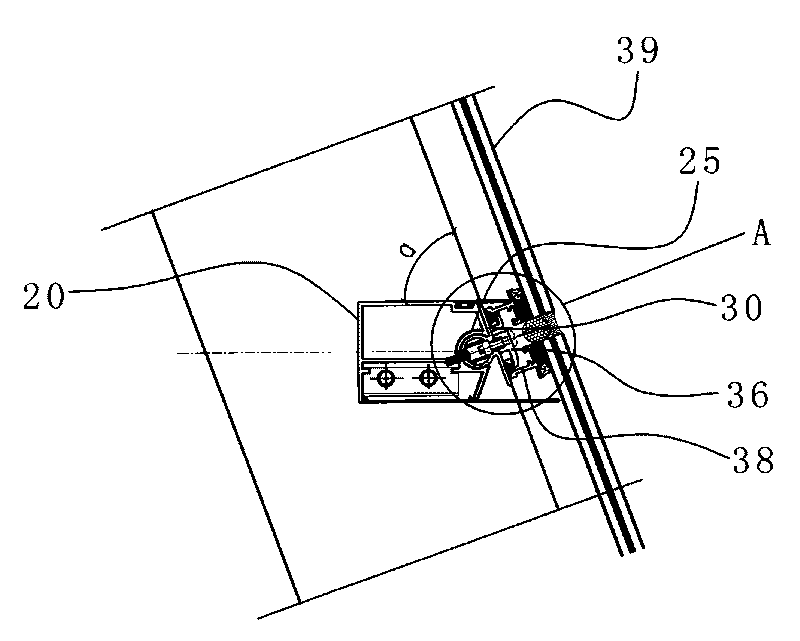

Glass curtain wall hidden frame

ActiveCN101736837AReduce specification requirementsSave manufacturing costWallsKeelBuilding construction

The invention discloses a glass curtain wall hidden frame which comprises a keel assembly, an auxiliary frame and a pressure plate, wherein the keel assembly comprises a main keel and a keel accessory, the main keel and the keel accessory are hinged, the pressure plate is installed on the keel accessory, and the auxiliary frame is compressed on the keel accessory. When the glass curtain wall hidden frame is used, the installation angle can be adjusted as required, thereby easily realizing the installation of a frame type glass curtain wall between a glass plate block and a building upright post (building crossbeam) in different angles, easily realizing the effect of a slope glass curtain wall in different angles, reducing the specification requirements for installing the main keel or the auxiliary frame on the curtain wall, saving the manufacturing cost and the production period of a mould, simultaneously improving the installation accuracy of the slope glass curtain wall, improving the universality of the frame installed on the curtain wall, greatly reducing the opening mould quantity of an aluminum shaped material, having no need of predefining and manufacturing frame fittings with different specifications, shortening the construction period of curtain wall installation and providing a technical guarantee for the standardization of a curtain wall frame.

Owner:GUANGZHOU JANGHO CURTAIN WALL SYST ENG +2

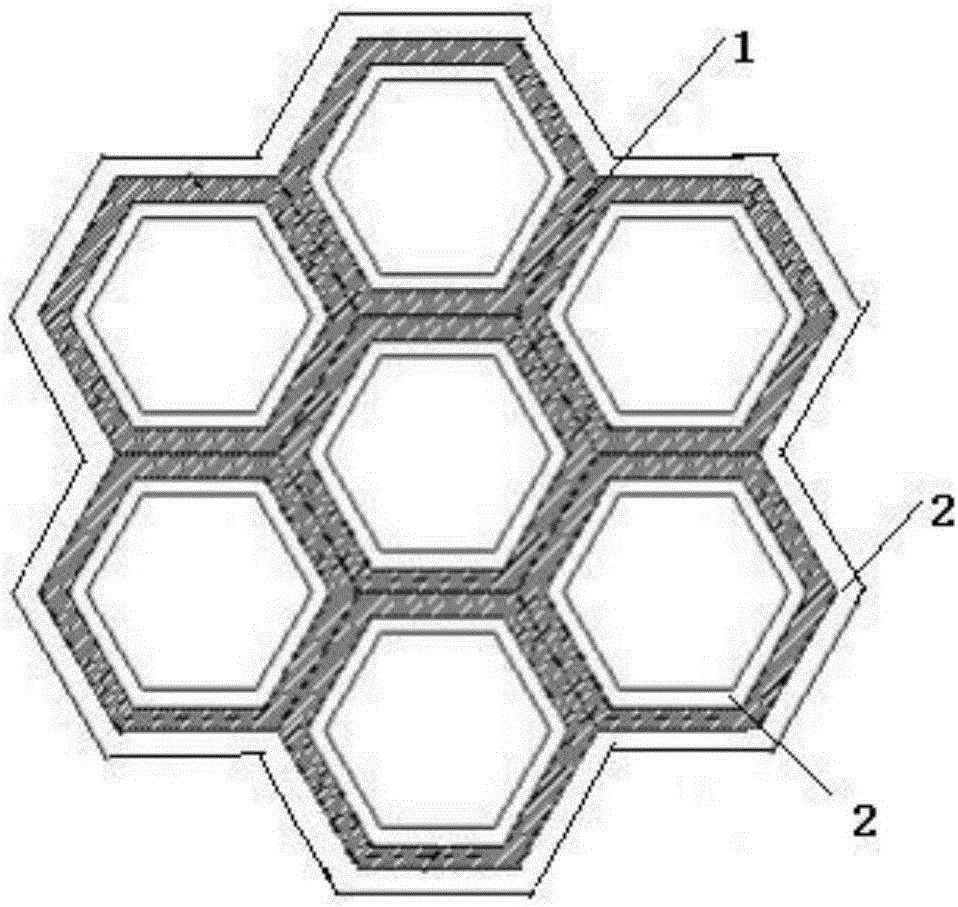

Composite biofilm carrier for sewage treatment and preparation method thereof

InactiveCN105819565AImprove processing efficiencyPromote growthBiological water/sewage treatmentBiofilmHoneycomb

The invention discloses a composite biofilm carrier for sewage treatment and a preparation method thereof. The carrier is composed of solid filler and a coating arranged on the surface of the solid filler in a wrapping mode. The filler is in a honeycomb straight inclined tube shape, a ripple shape, a cubic shape, a cylinder shape or a fiber shape. The surface of the carrier is beneficial to growth of a biofilm, and it is convenient to improve sewage treatment efficiency; it is convenient to regulate and control density of the biofilm carrier, and the carrier is adapted to requirements for treatment of different types of sewage. In addition, due to the fact that a degradable material is adopted as the surface material of the biofilm carrier, as the degradable material is decomposed gradually, the aged biofilm carrier falls off automatically, after the biofilm falls off, the polymer carrier is taken out, the biofilm carrier can be reused after being coated with the degradable material again, therefore the defects that the biofilm is excessively thick and prone to heading formation and blocks a packed bed are overcome, and the manufacturing and use cost of the biofilm carrier is saved. The invention further discloses a preparation method of the composite biofilm carrier, and the method is simple and feasible.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

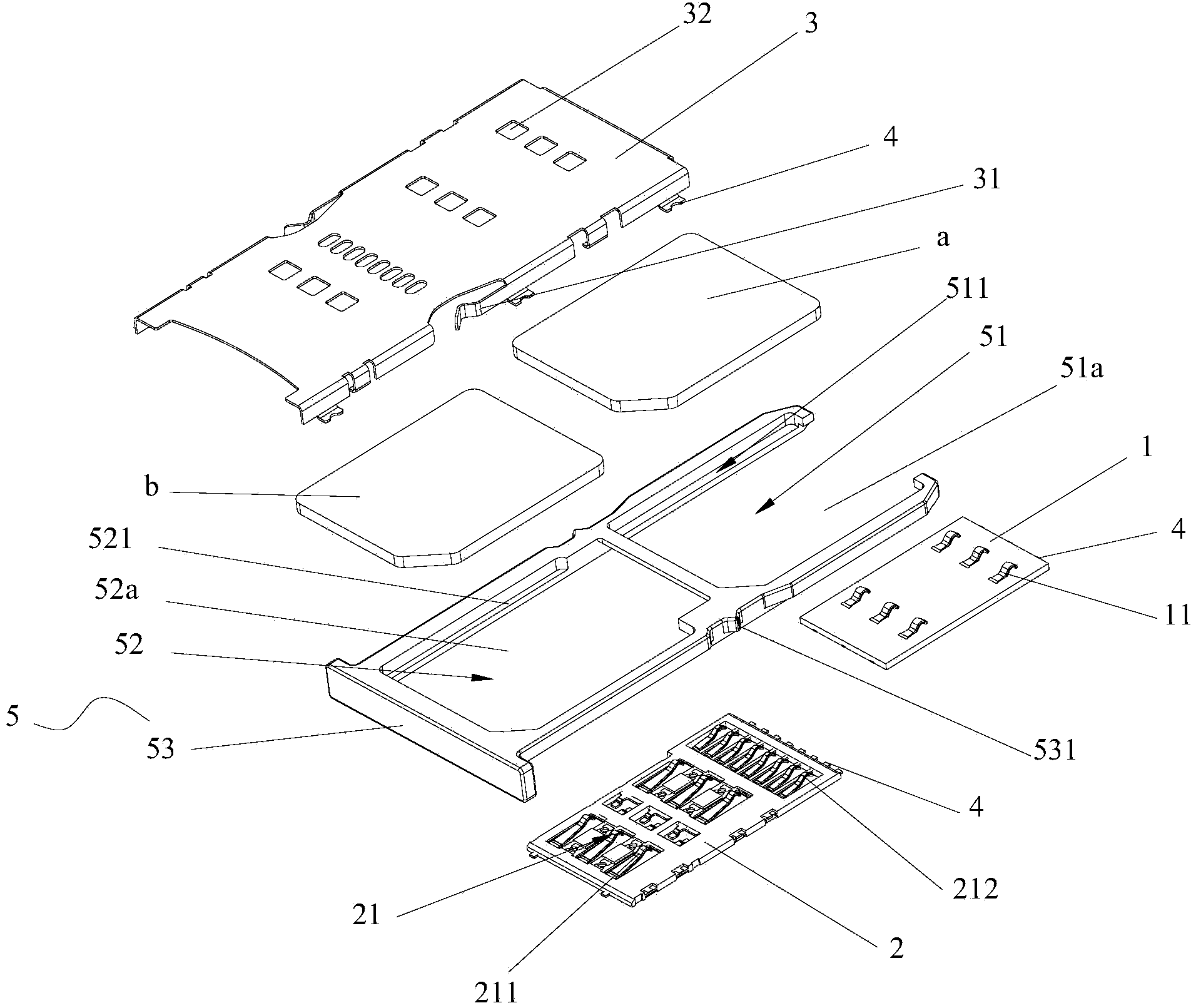

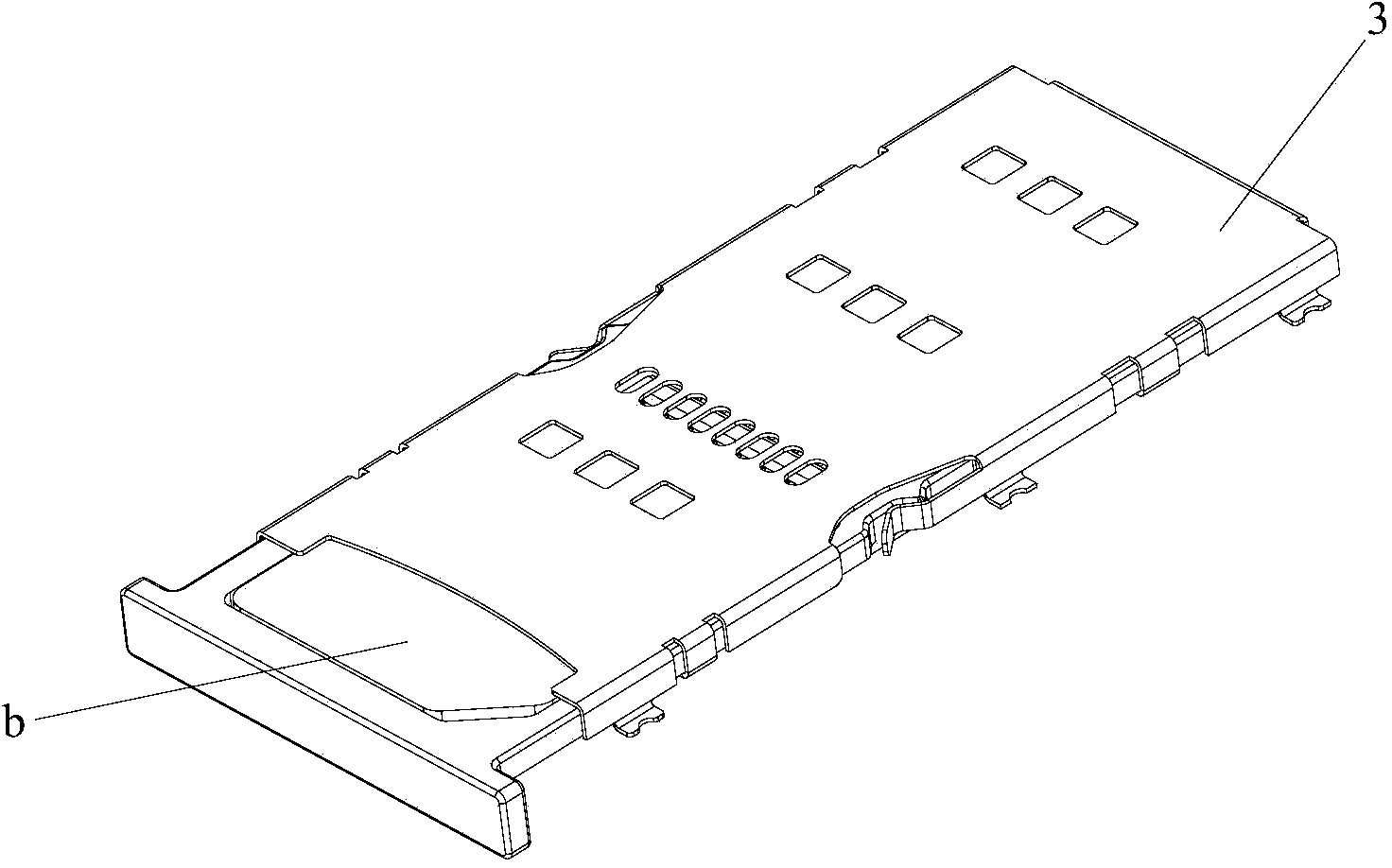

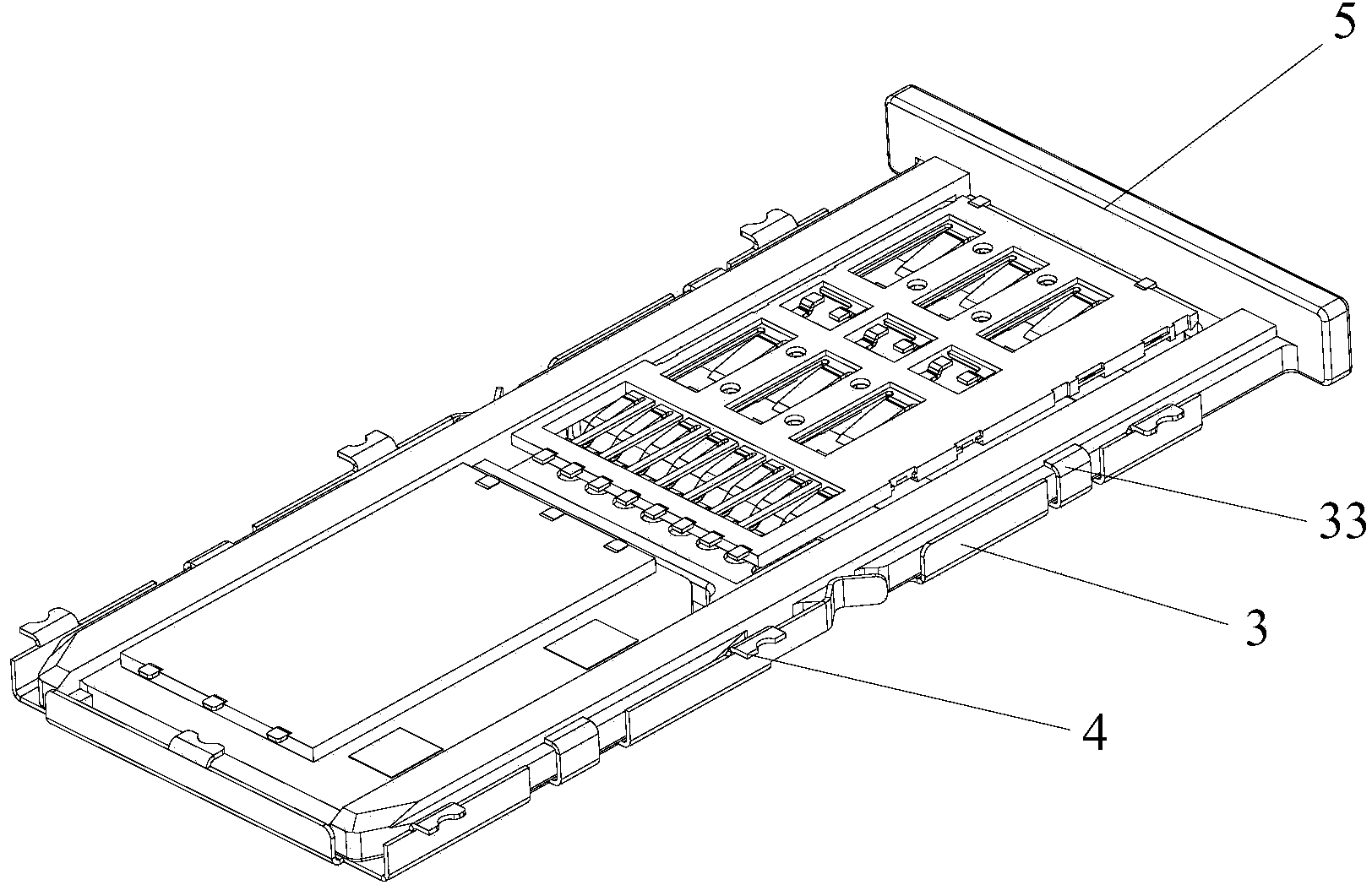

Combined card connector and cell phone

InactiveCN103730744ASave design costSave manufacturing costCoupling contact membersTelephone set constructionsEngineeringMotherboard

The invention is applied to the field of cell phones and provides a combined card connector. The combined card connector comprises a first card base, a second card base, a metal clamping cover and a clamping support, wherein the first card base and the second card base are arranged in an abreast mode, the metal clamping cover is arranged on the first clamping base and the second clamping base, the clamping support is provided with a first card arranging position and a second card arranging position to be respectively used for supporting a first card and a second card, and an inner cavity enabling the clamping support to slide in a drawer mode in the inner cavity is formed by enclosing the metal clamping cover and the two clamping bases. The combined card connector is provided with the clamping support provided with the first card arranging position and the second card arranging position, the combined card connector is provided with the first card base in electric contact with the card and the second card base, wherein the second card base is suitable for different cards and respectively in contact communication with the cards, and the inner cavity enabling the clamping support to slide in a drawer mode is formed by enclosing the metal clamping cover and the two clamping bases, so that when it is necessary to change a Micro-SIM card scheme into a Micro-SIM card+Micro-SD card scheme, a user only needs to replace the clamping support and the double cards on the clamping support without changing the whole card connector and a circuit main board of the cell phone, and cell phone design and manufacturing cost further can be saved.

Owner:SHENZHEN LINKCONN ELECTRONICS

Welding process of large-diameter annular part

ActiveCN104191095AReduce welding shrinkageReduced clamping man-hoursElectron beam welding apparatusUltimate tensile strengthVacuum chamber

The invention discloses a welding process of a large-diameter annular part. The welding process particularly comprises the following steps that (1) cleaning is carried out before welding; (2) primary positioning connection is carried out on the part to be welded through a manual padding argon arc welding tack-weld method; (3) the end, with a flange edge, of the part to be welded is fixed to a disk; (4) densification tack-welding is carried out on the connecting position of the part through vacuum electron beams; (5) sealing welding is carried out on the intervals of densification tack-welding in the step (4) through vacuum electron beams; (6) the part is taken out of a vacuum chamber, excess weld metal of a manual argon arc welding point is ground through a hand blower gun; (7) welding is carried out through vacuum electron beams. Through the welding process, the welding shrinkage amount of the part is largely reduced, the design and manufacturing expenses caused by a vacuum electron beam welding clamp in a traditional welding process are saved, and therefore the welding and machining cost is reduced. Meanwhile, the clamping work time of the part is saved, the labor intensity is relieved for a worker, and the production efficiency of the part is improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Novel power supply safety socket

InactiveCN105098524AAchieve insertionAchieve orientationCoupling device detailsEngineeringMechanical engineering

A novel power supply safety socket comprises a socket body and an installation seat (90), wherein the installation seat (90) can be arranged in a sliding groove (19) of the socket body (9) in a left-right sliding way and is provided with an execution motor (91), a rotor of the execution motor (91) is in power linkage with a screw rod (95), the screw rod (95) is matched with a screw hold in a cross wall part (8) in the socket body (9), a left end wall of the installation seat (90) is fixedly connected with power supply guide columns (74) which penetrate through and are matched with a sliding hole arranged in a cross wall part (8) in a sliding way, the power supply guide columns (74) are used for connecting with power supply holes in a plug (6) inserted into a jack of the socket body (9) for supplying power, and on each power supply guide column (74), a compression spring (71) is arranged between the side surface, facing the execution motor (91), of the cross wall part (8) and a stator of the execution motor.

Owner:诸暨市柯晶机械技术开发有限公司

Integrated touch function display screen and manufacture method thereof

ActiveCN104407726AImprove the display aperture ratioSave production raw material costNon-linear opticsInput/output processes for data processingColor gelEngineering

The invention relates to an integrated touch function display screen and a manufacture method thereof. The integrated touch function display screen is characterized by comprising a first substrate, a thin film transistor, a first alignment layer, a liquid crystal molecular layer, a second alignment layer, a plurality of isolation columns, a colorful optical filter layer and a second substrate. The display screen can be manufactured by adopting traditional processes and also can be manufactured by adopting 3D technology, and a touch and display function can be realized if the integrated touch function display screen is provided with a driving and processing assembly. The isolation columns of the invention realizes an isolating and supporting function, and meanwhile, a lead on the second substrate can be connected to the first substrate; and a touch unit is arranged below the display screen to effectively increase a display opening rate. Meanwhile, parts of the processes adopt a 3D printing technology, and the manufacture method is greatly simplified when the manufacture method is compared with a traditional method, multiple complex processes, such as exposure, development, etching and the like, in the traditional processes can be omitted, and production raw materials and the manufacture cost are saved and lowered.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[wireless remote controller] [wireless remote controller]](https://images-eureka.patsnap.com/patent_img/178737a1-3e24-4a12-ac4e-a8e18d58e118/US20070008168A1-20070111-D00000.png)

![[wireless remote controller] [wireless remote controller]](https://images-eureka.patsnap.com/patent_img/178737a1-3e24-4a12-ac4e-a8e18d58e118/US20070008168A1-20070111-D00001.png)

![[wireless remote controller] [wireless remote controller]](https://images-eureka.patsnap.com/patent_img/178737a1-3e24-4a12-ac4e-a8e18d58e118/US20070008168A1-20070111-D00002.png)