Composite biofilm carrier for sewage treatment and preparation method thereof

A biofilm carrier, sewage treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effect of saving manufacturing and use costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

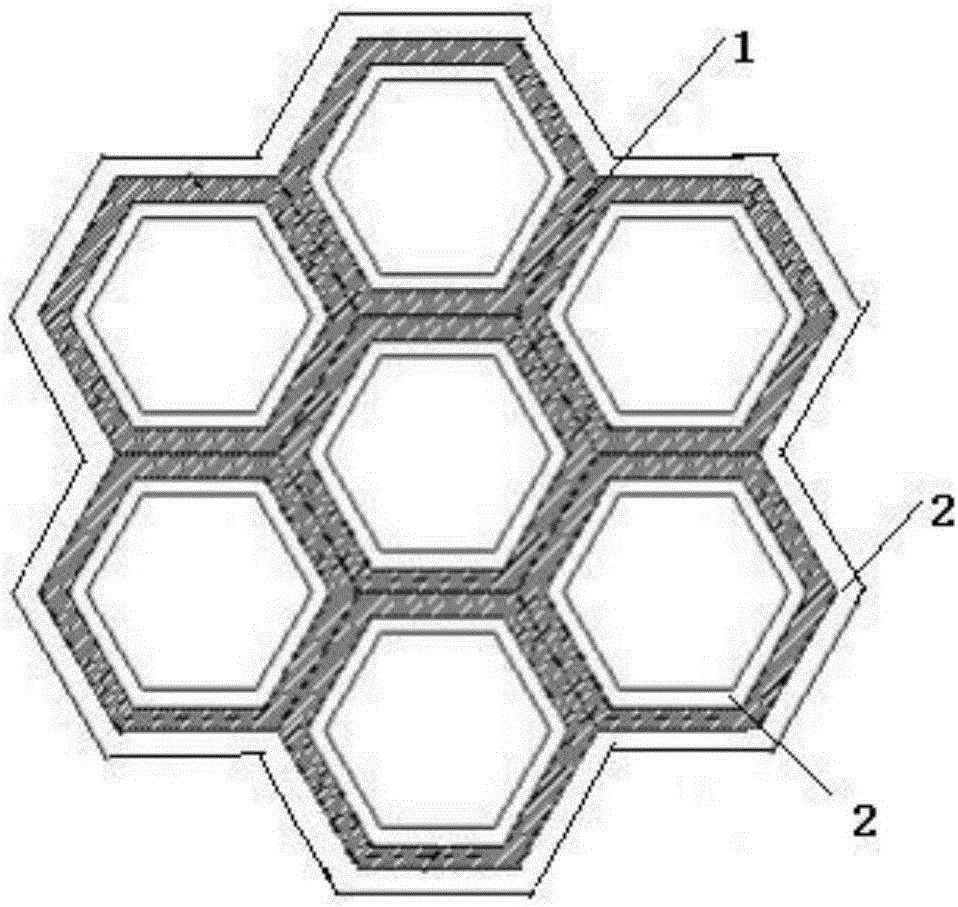

[0030] refer to figure 1 as shown, figure 1 Indicates the carrier structure of honeycomb straight inclined tube, in which 1 means the filler shaped like a honeycomb straight inclined tube, and 2 means the coating coated on the surface of the carrier.

[0031] The preparation method of the carrier is as follows:

[0032] 1) Press the PP filler into a solid filler of honeycomb straight inclined tube type by using a mold;

[0033] 2) dissolving polylactic acid in dichloromethane, dissolving, adding silicate at the same time, preparing polylactic acid-silicate solution;

[0034] 3) immersing the solid filler prepared in step 1) into the solution prepared in step 2) to coat the surface of the filler with polylactic acid and silicate;

[0035] 4) Ventilate and dry the solid filler coated in step 3), and completely volatilize the dichloromethane in the solution to obtain a composite biofilm carrier of polylactic acid-silicate coating coated PP filler

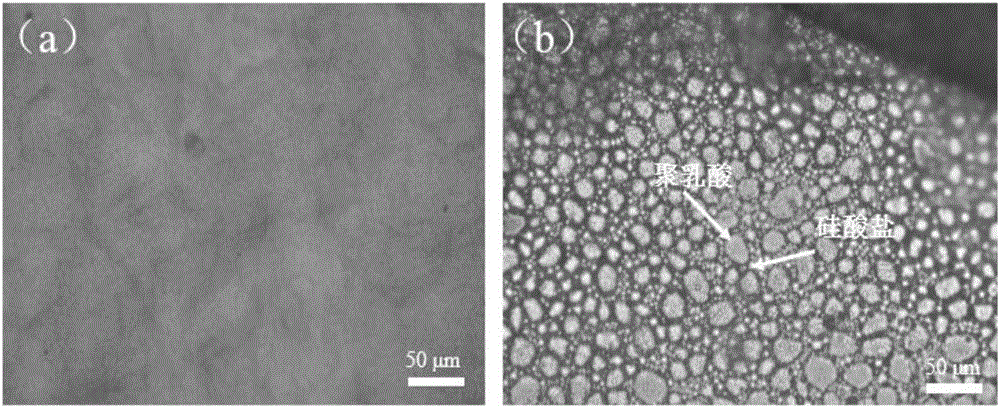

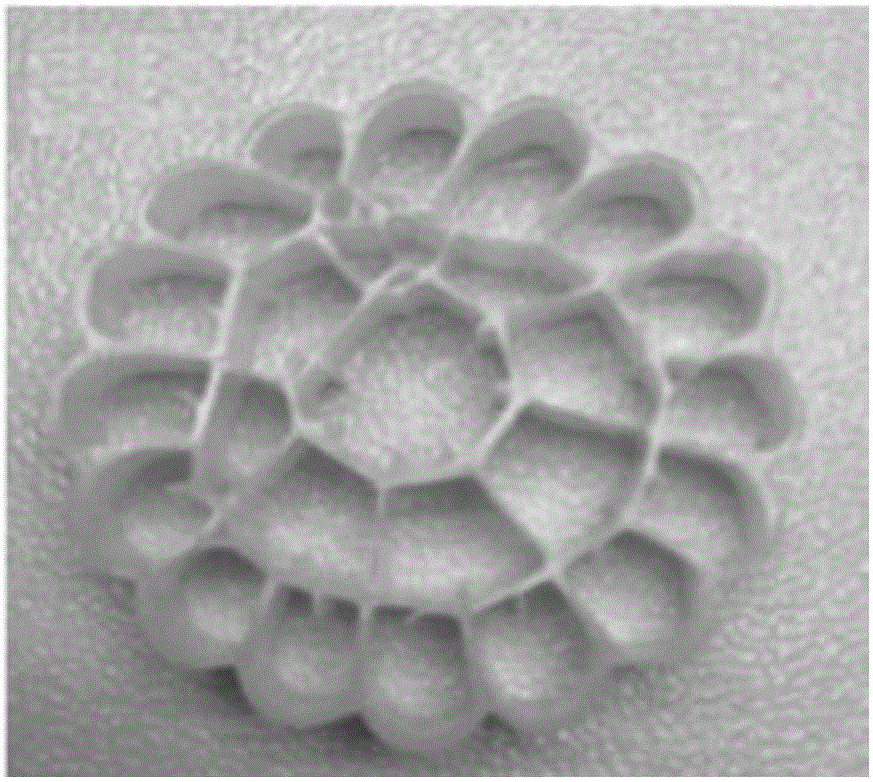

[0036] figure 2 Represent...

Embodiment 2

[0040] The packing of the support structure is corrugated:

[0041] The preparation method of the carrier is as follows:

[0042] 1) Mix ceramic particles and calcium alginate and use a mold to press into a solid filler of honeycomb straight inclined tube type;

[0043] 2) dissolving starch and calcium sulfate in dichloromethane to form a solution;

[0044] 3) immersing the solid filler prepared in step 1) into the solution prepared in step 2) to coat the surface of the filler with a coating;

[0045] 4) ventilating and drying the solid filler coated in step 3) to obtain a composite biofilm carrier.

[0046] The carrier prepared in Example 2 was subjected to a biofilm growth experiment, and it can also achieve biofilm fixation and film-hanging maturation, and has good decontamination ability.

Embodiment 3

[0048] The filler of the carrier structure is of fibrous type:

[0049] The preparation method of the carrier is as follows:

[0050] 1) Mix glass pellets and polyethylene terephthalate and use a mold to press into a honeycomb straight inclined tube-shaped solid filler;

[0051] 2) dissolving aliphatic polyester and diatomaceous earth in dichloromethane to form a solution;

[0052] 3) immersing the solid filler prepared in step 1) into the solution prepared in step 2) to coat the surface of the filler with a coating;

[0053] 4) ventilating and drying the solid filler coated in step 3) to obtain a composite biofilm carrier.

[0054] The carrier prepared in Example 3 was subjected to a biofilm growth experiment, and it can also achieve biofilm fixation and film-hanging maturation, and has good decontamination ability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com