Resin cement cubic boron nitride grinding wheel and preparation method thereof

A technology of cubic boron nitride and bonding agent, which is applied in the direction of bonded grinding wheels, manufacturing tools, metal processing equipment, etc., can solve problems such as narrow application range, achieve good sharpness, prevent clogging, and increase the effect of grinding ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

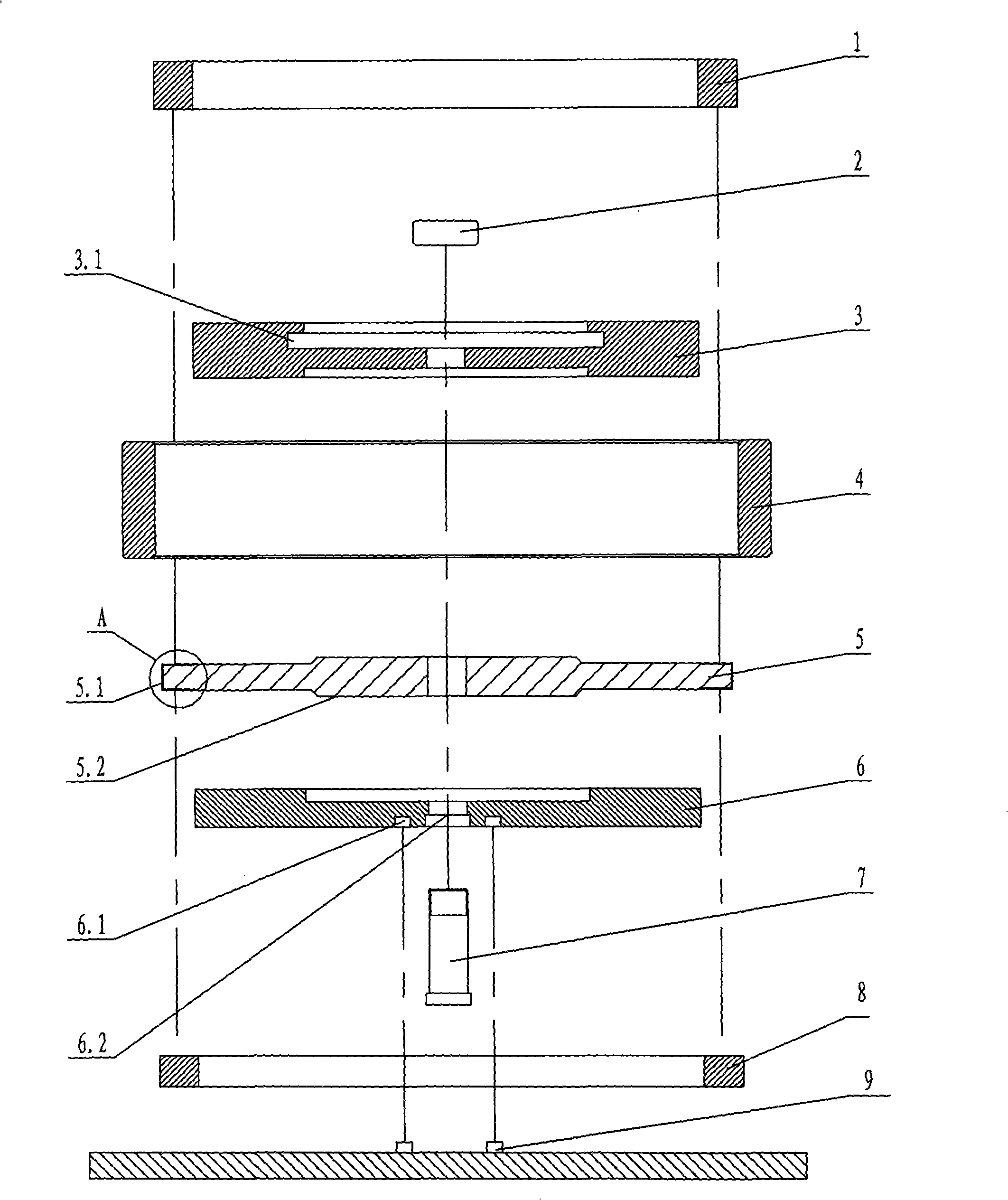

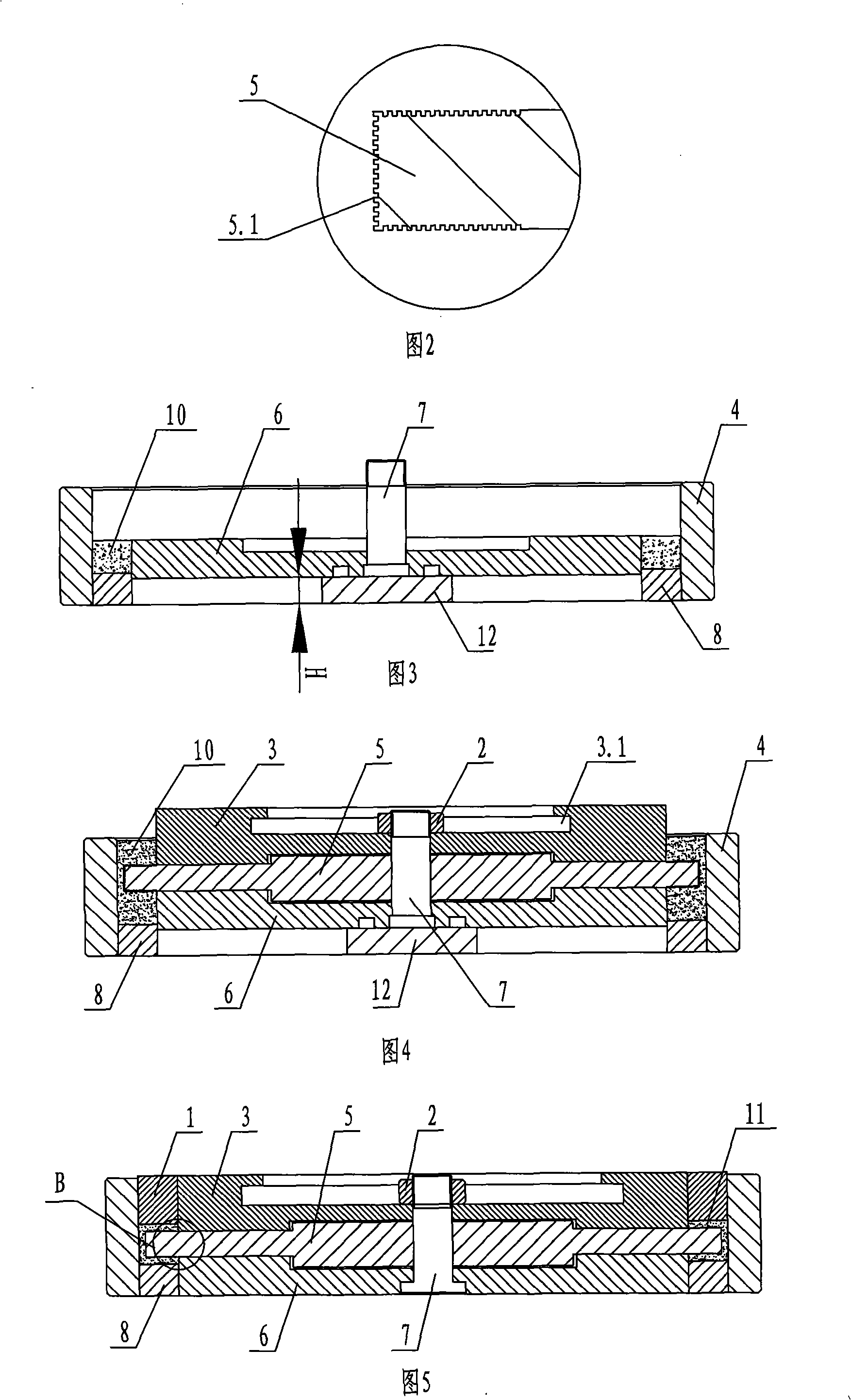

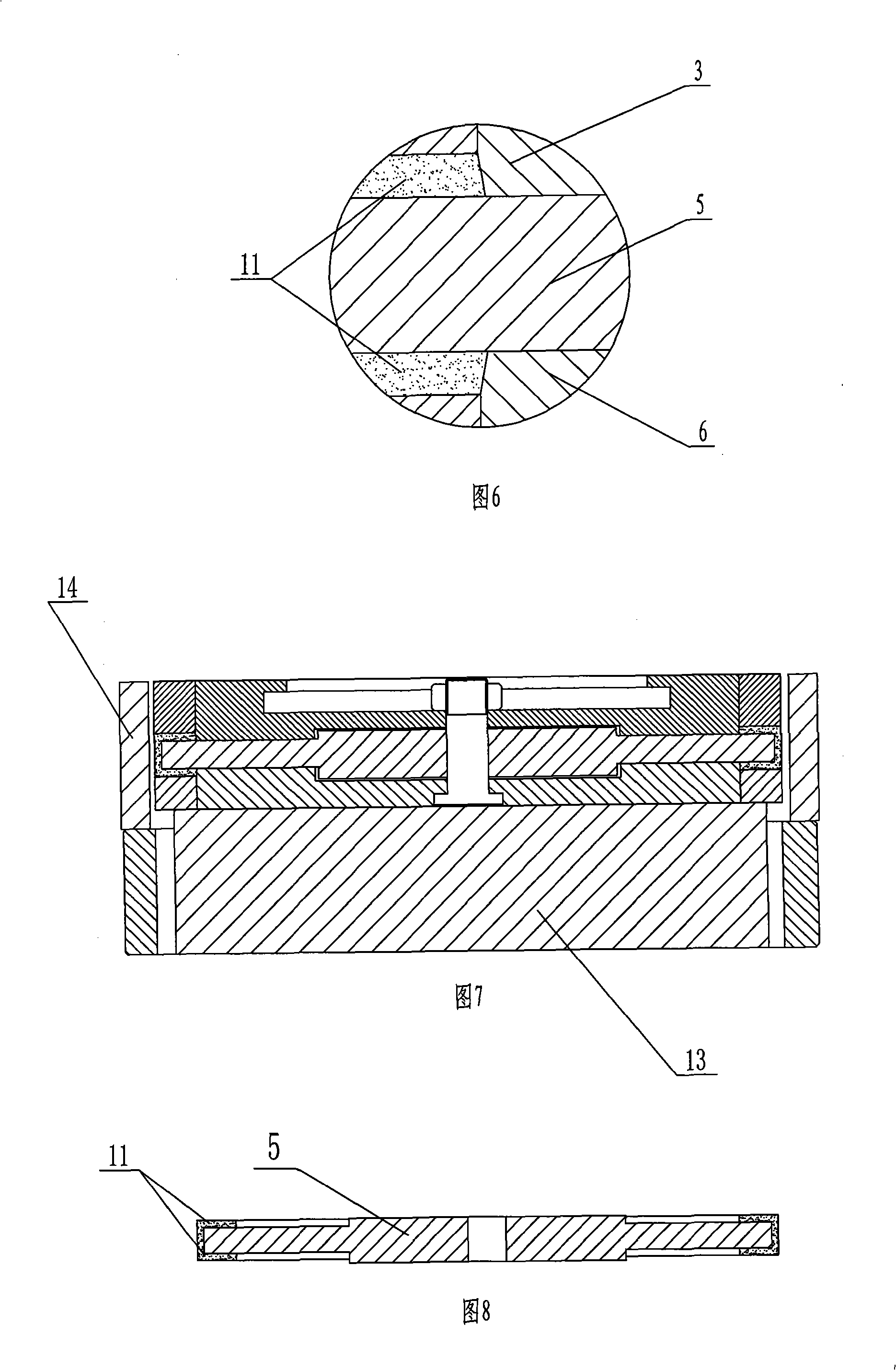

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] Referring to FIG. 8 , the resin-bonded cubic boron nitride grinding wheel includes a grinding wheel base 5 and an abrasive layer 11 , and the abrasive layer is arranged on the outer wall of the grinding wheel base 5 and the periphery of the upper and lower end surfaces. The section of the abrasive layer 11 is upside down U-shaped. The grinding wheel base 5 is in the shape of a disc, and the surface in contact with the abrasive layer is provided with a cog 5.1 for consolidation, as shown in Figure 2, with a protrusion 5.2 in the center of both ends.

[0022] The preparation method of the resin bonded cubic boron nitride grinding wheel is characterized in that the abrasive cubic boron nitride with a volume percentage of 25-40% is first wetted with a coupling agent, and then mixed with Dialok939p resin 25-35%, fluorine salt grinding aids 2-5%, 2-5%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com