Patents

Literature

42results about How to "Increase grinding ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

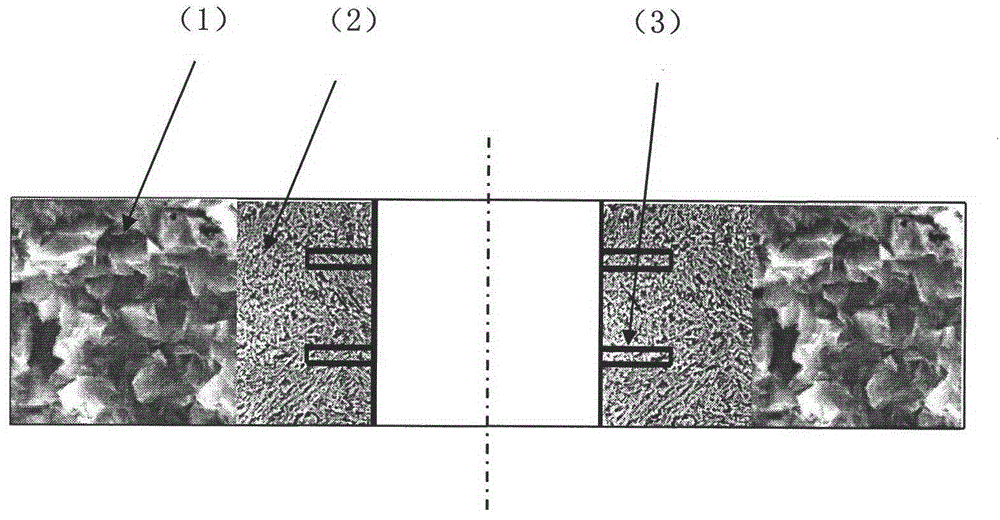

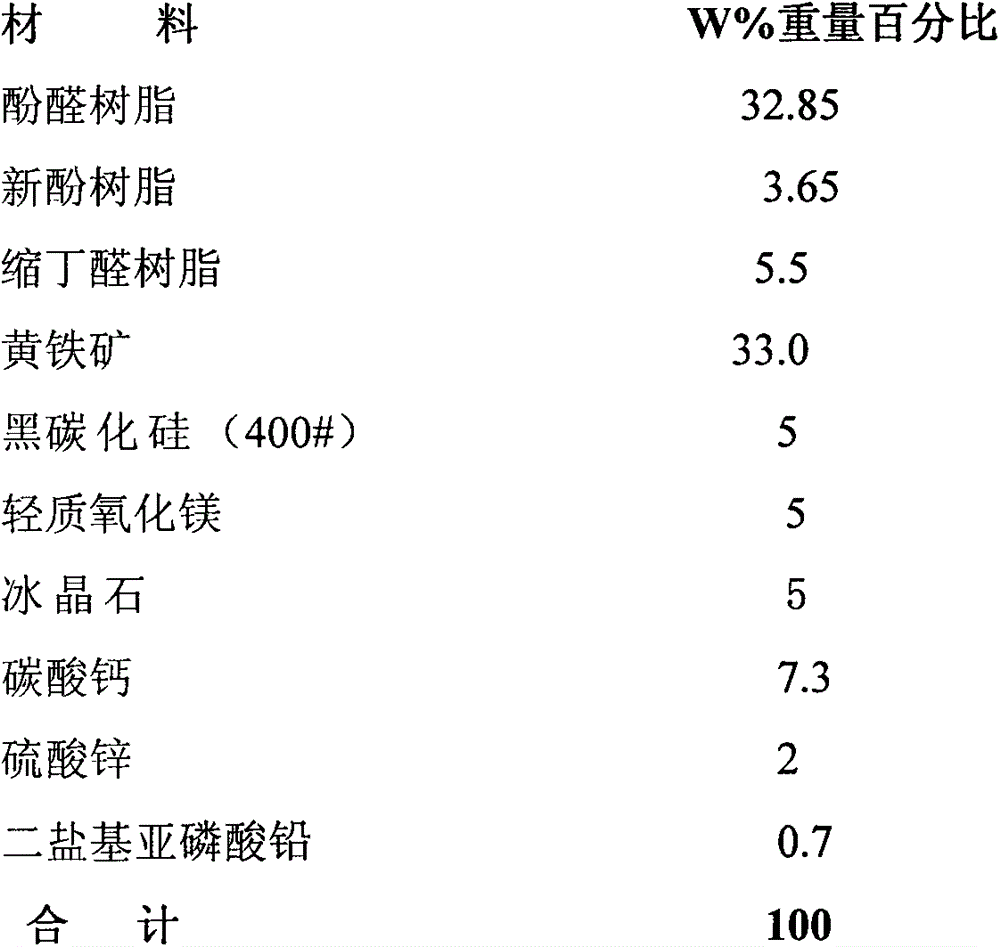

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

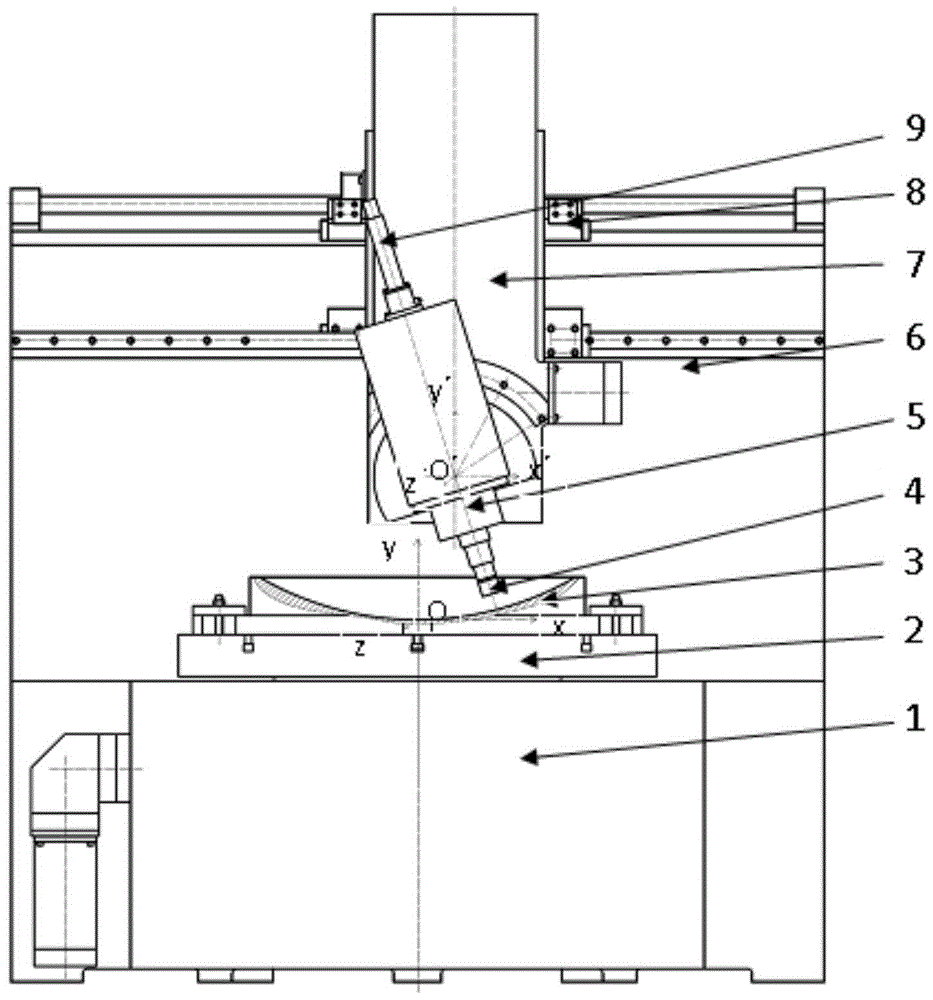

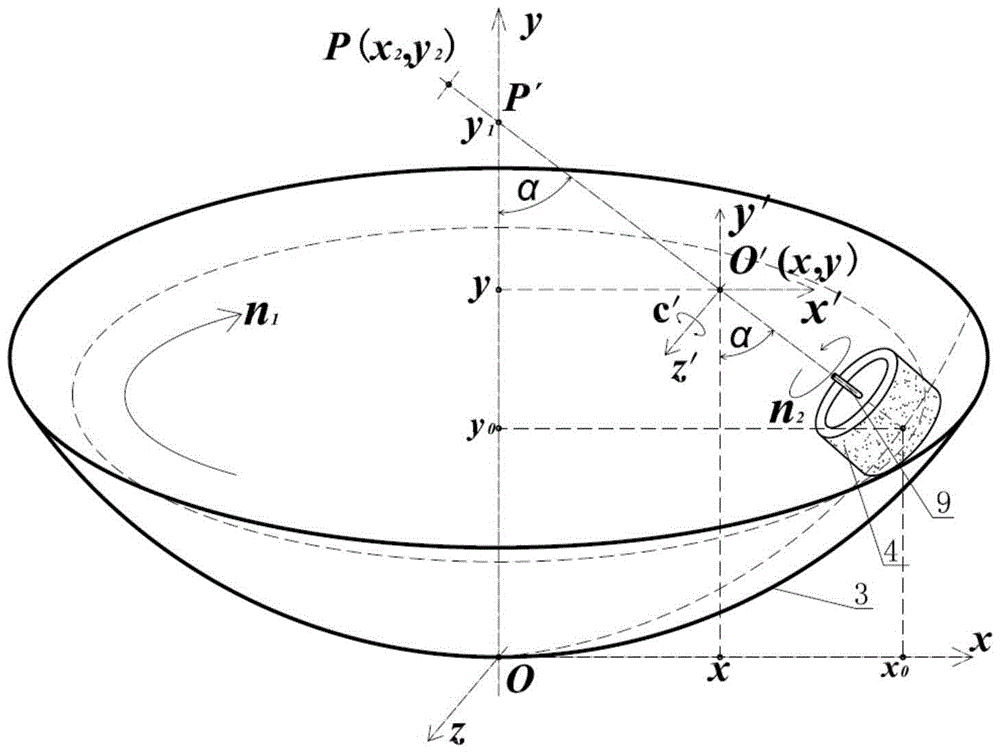

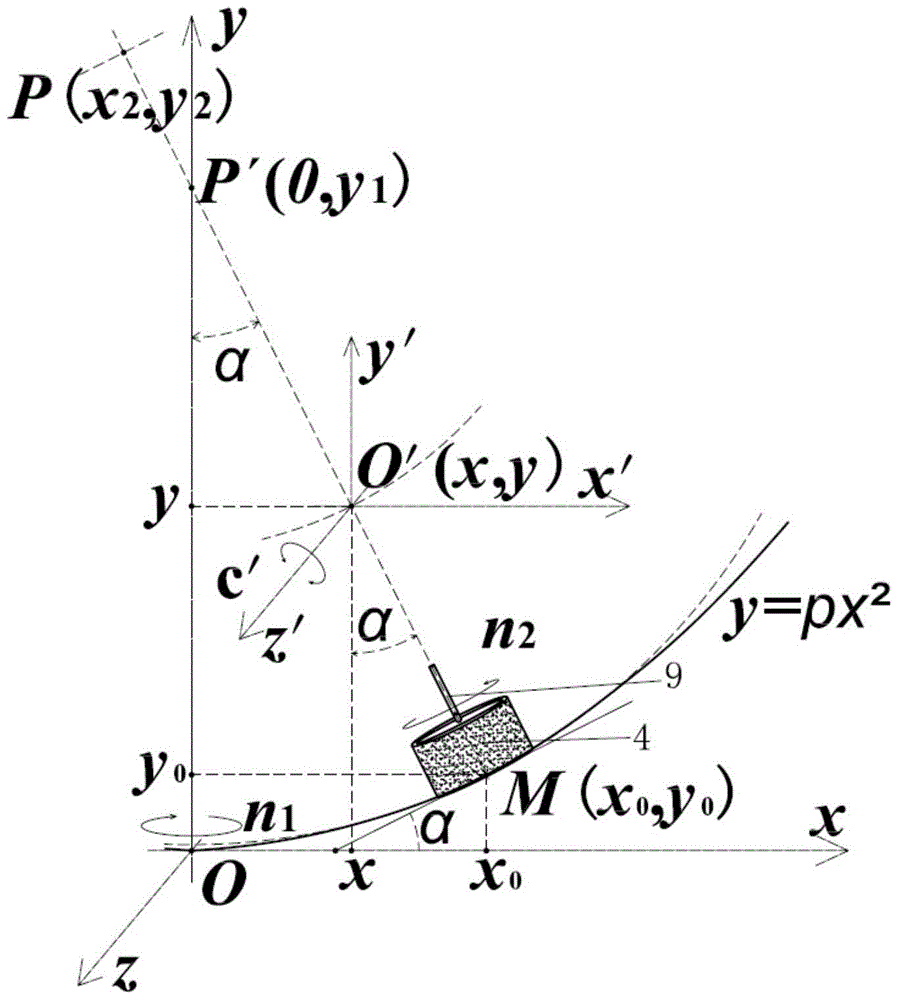

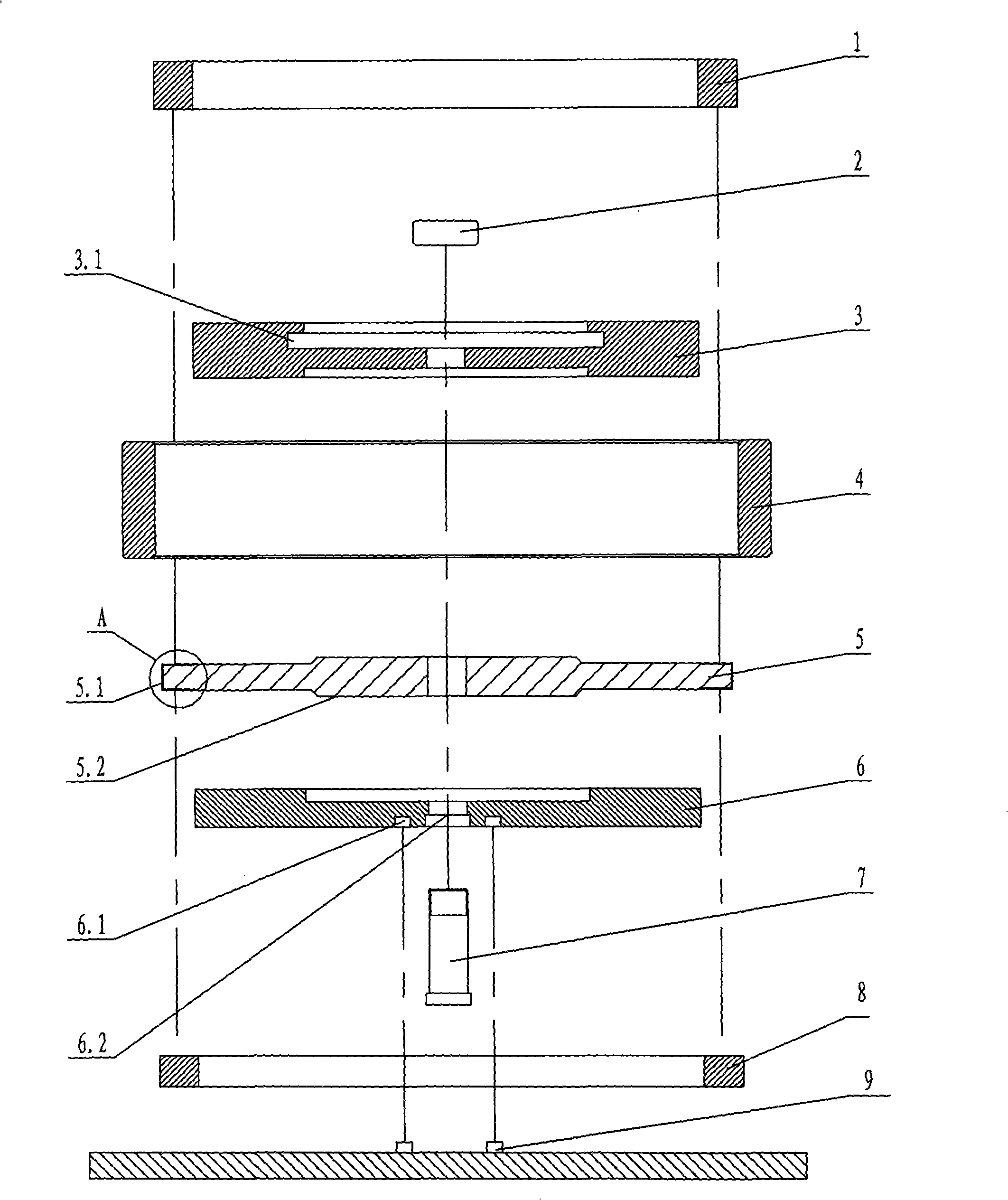

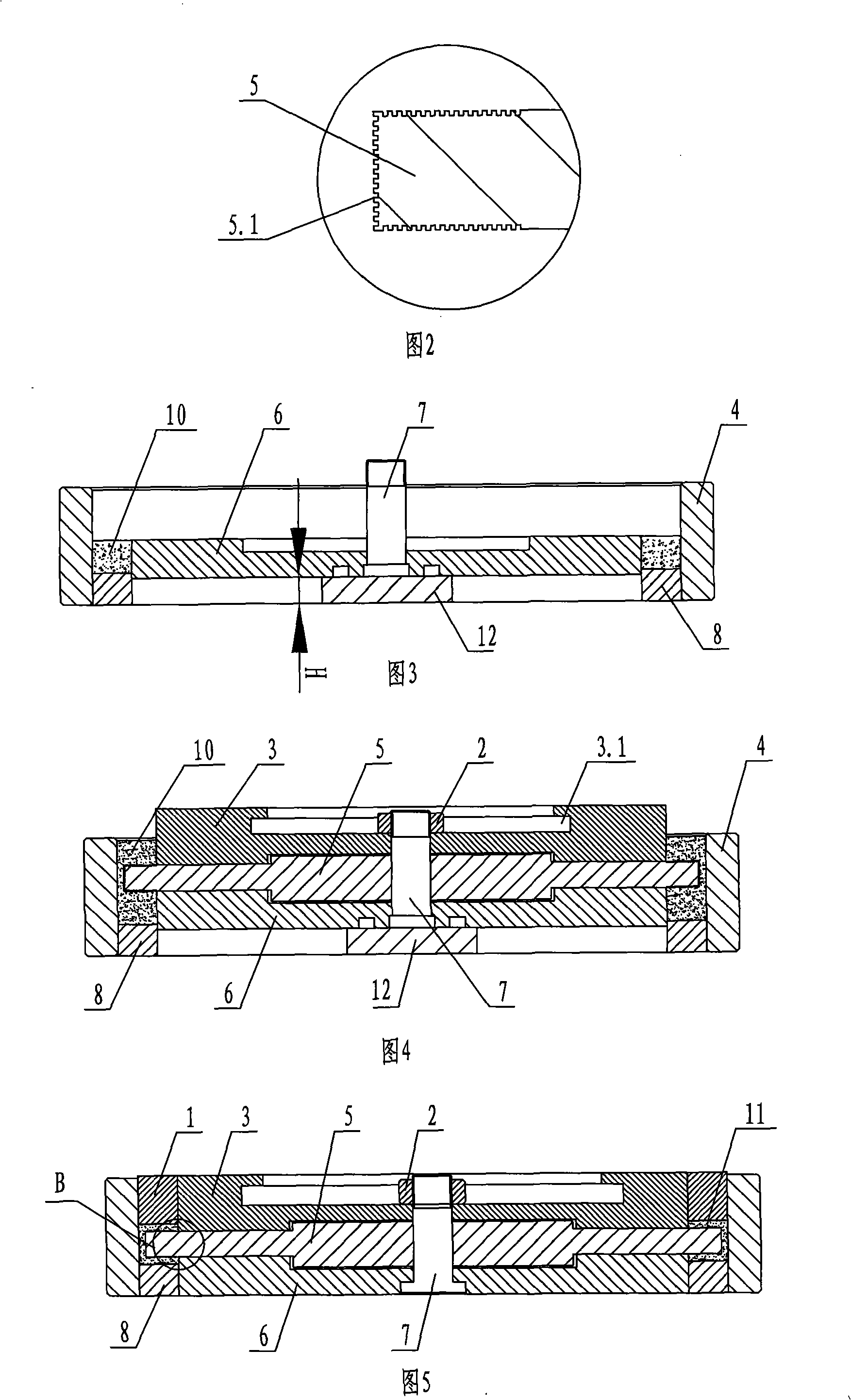

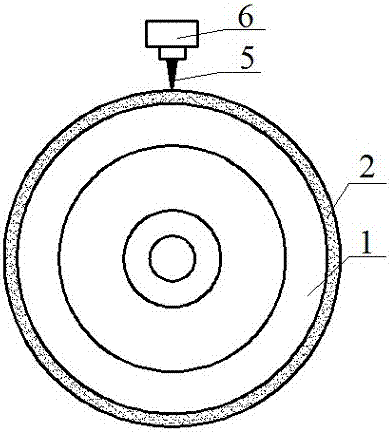

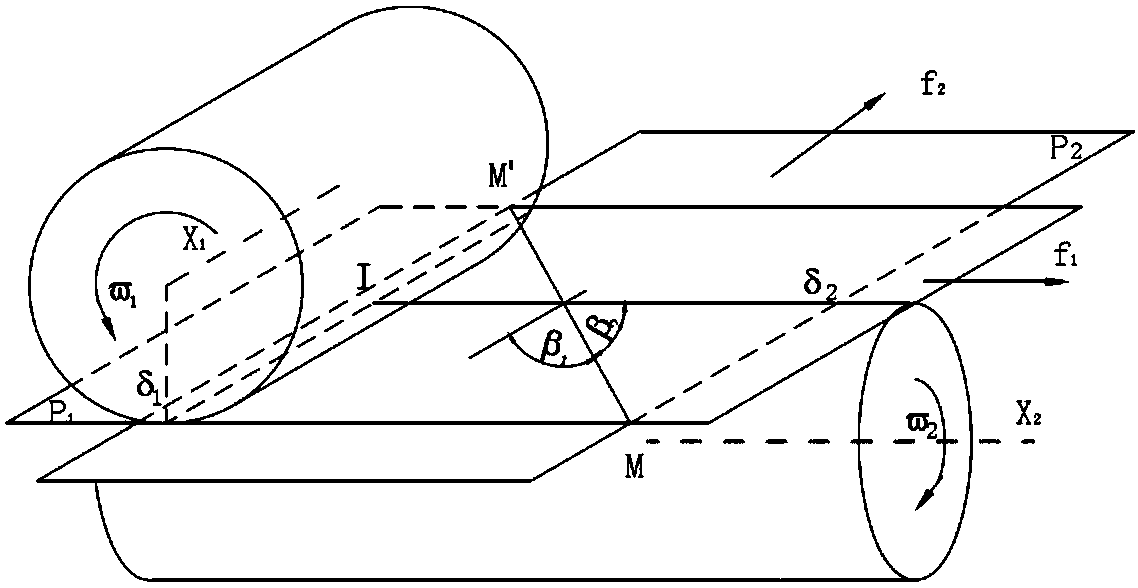

Precise grinding method for large-caliber axisymmetric aspheric surfaces

InactiveCN105014503AAvoid Principle ErrorsGuaranteed motion accuracyGrinding feed controlLensHyperboloidEngineering

A ground workpiece, a grinding wheel main shaft and a grinding wheel grinding tool are involved in a precise grinding method for large-caliber axisymmetric aspheric surfaces. The ground workpiece is fixedly arranged on a rotating working table. The top face of the ground workpiece is an aspheric surface. The grinding wheel main shaft is arranged on a y-axis feed slide base connected with an x-axis feed slide base. The grinding wheel grinding tool is fixed to the grinding wheel main shaft. The precise grinding method is characterized in that the rotating central line of the grinding wheel main shaft is controlled by a three-axis linkage control model to coincide with the normal of a grinding point on the generatrix of the aspheric surface all the time so that principle errors caused by grinding feed movement tracks can be avoided and the movement precision can be ensured; The aspheric surface is ground through the end face of the grinding wheel grinding tool so that the grinding ratio can be increased; and meanwhile, loss of the grinding wheel grinding tool is compensated for through a real-time detection method so that the grinding efficiency can be improved. A movement mechanism is simple, the grinding efficiency is improved, the grinding accuracy is ensured, and the precise grinding method can be suitable for grinding paraboloids of revolution, hyperboloids of revolution, ellipsoids of revolution and other large axisymmetric aspheric surfaces.

Owner:SHANGHAI JIAO TONG UNIV +1

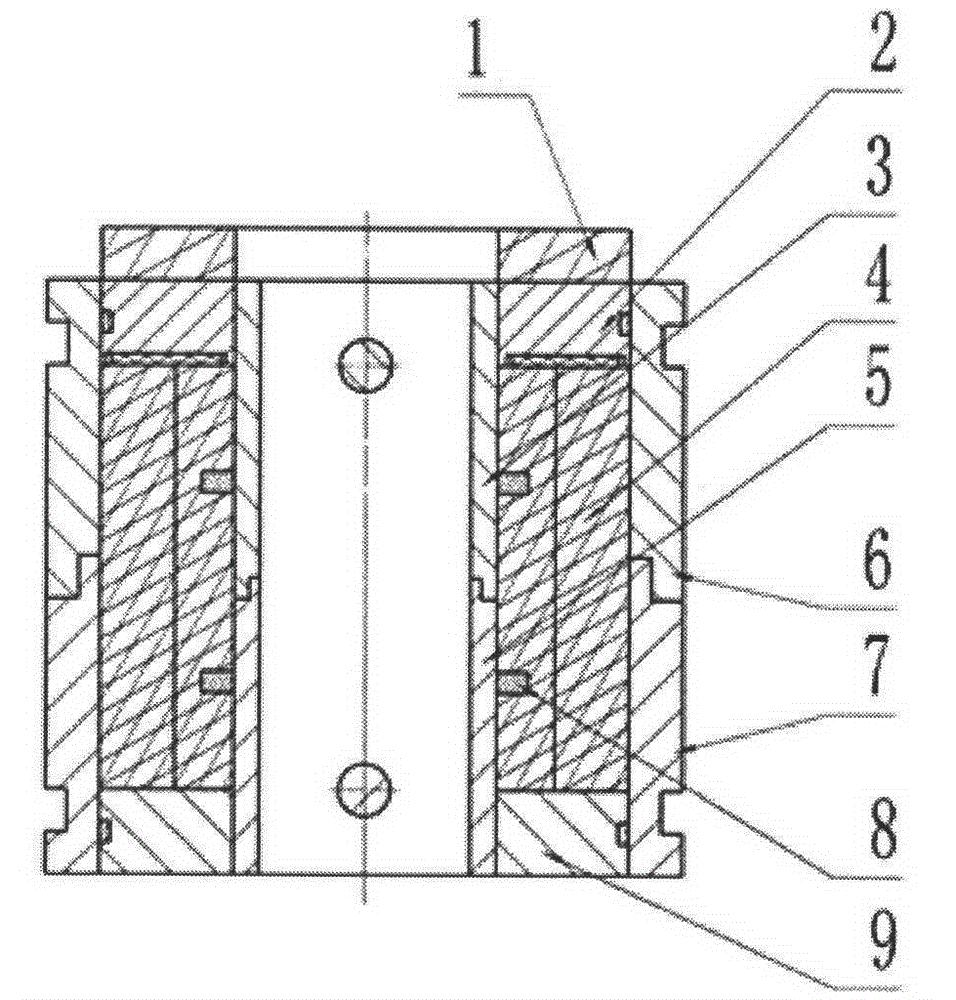

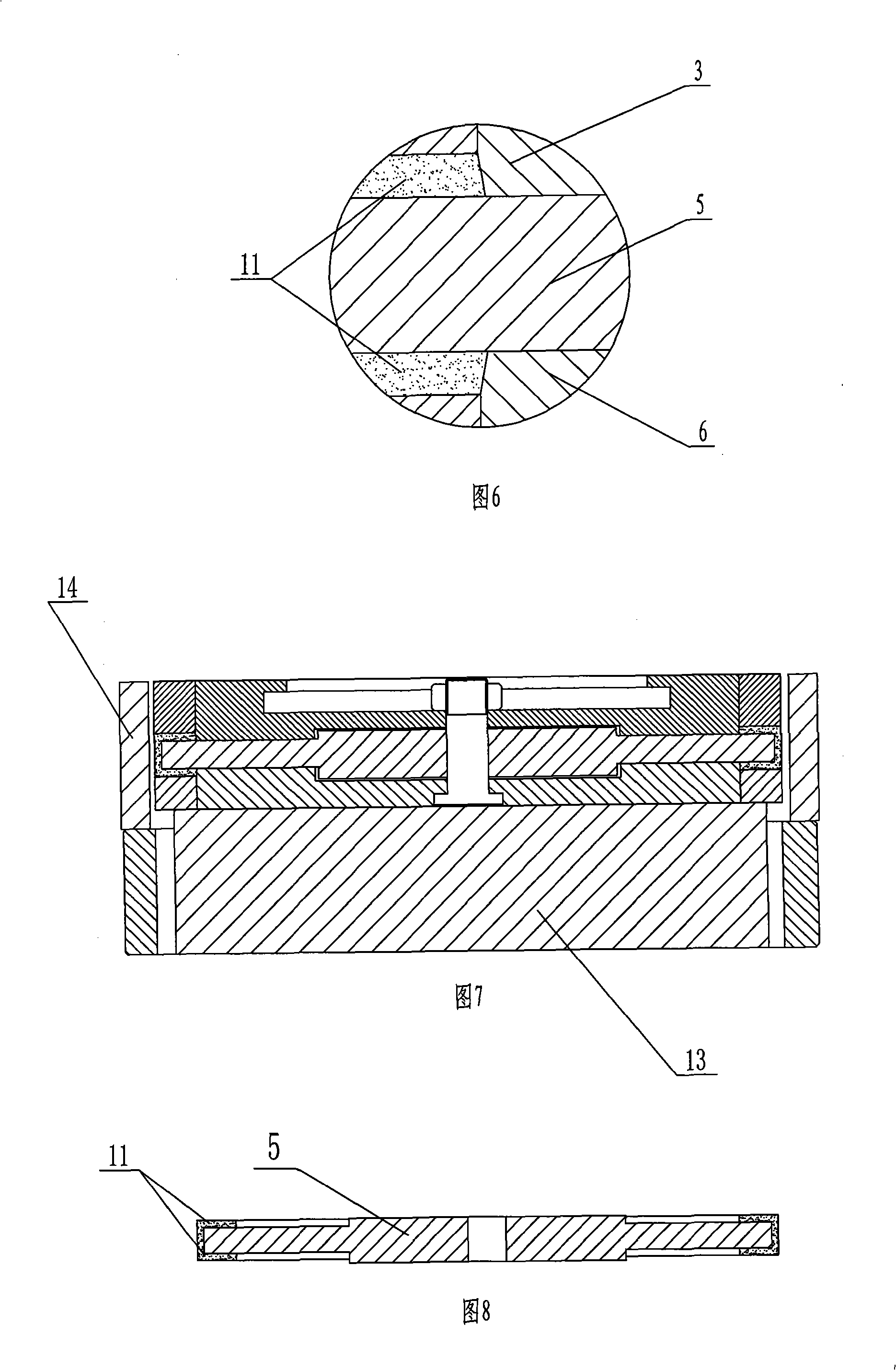

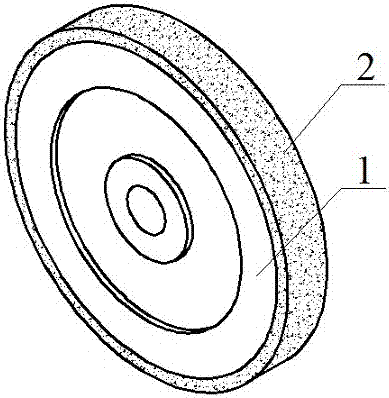

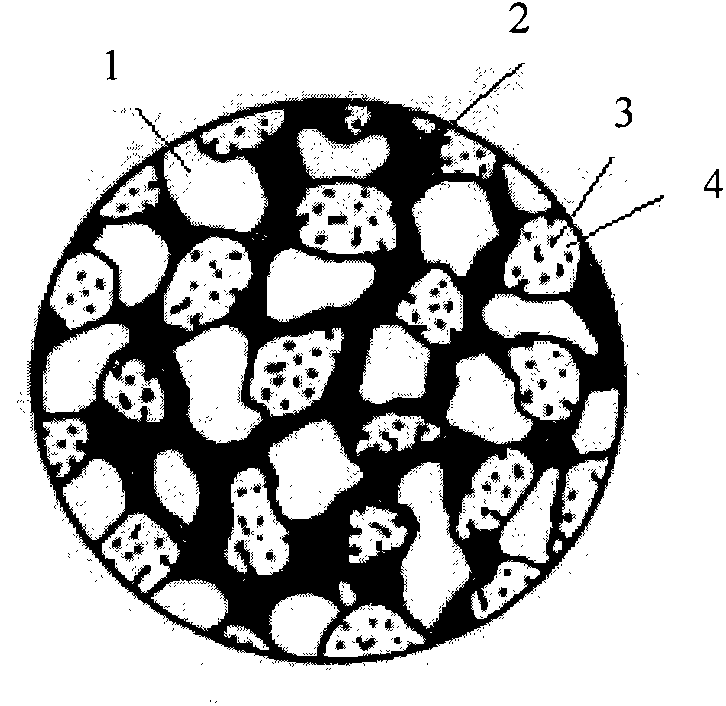

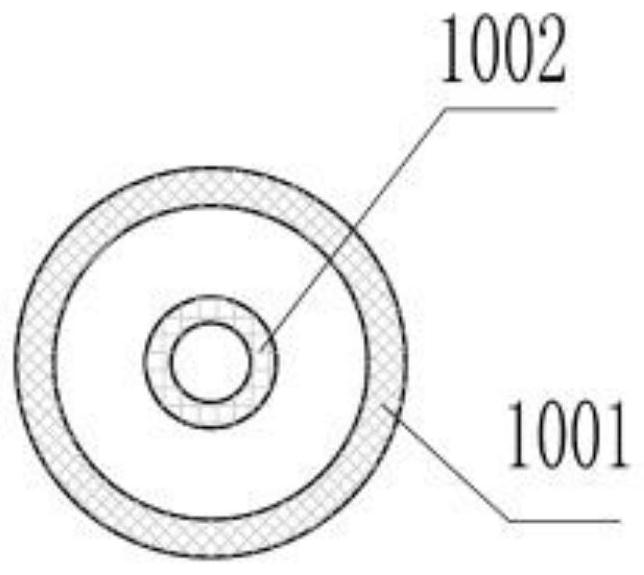

Resin cement cubic boron nitride grinding wheel and preparation method thereof

ActiveCN101332587AExtend your lifeIncrease grinding ratioBonded abrasive wheelsMetal working apparatusPass rateBoron nitride

The invention relates to a resinoid wedding agent cubic boron nitride grinding wheel and a manufacturing method thereof, the resinoid wedding agent cubic boron nitride grinding wheel comprises a grinding wheel matrix and a grinding layer, the grinding layer is arranged on the external wall of the grinding wheel matrix and peripheries of an upper end face and a lower end face; the grinding layer includes 12-40% of cubic boron nitride (nickel plating), 25-50% of Dialok939p resin, 1-10% of villaumite grinding aid, 1-10% of a solid lubricant filler, 10-30% of a powder filler with high thermal conductivity and 1-15% of oxide filler by volume percentage of the grinding layer. A specially designed hot pressing dies and separately batch feeding method are adopted, which causes the pressed products to have homogeneous structure and consistent density; the formula of the grinding wheel is simple, and the designed die has the advantages of simple and reasonable structure, easy die filling and die release, the product obtained has high once-pass rate, homogeneous structure and consistent density; the grinding wheel has good grinding performance and long service life, can perform peripheral grinding and end face grinding, and is equivalent to three grinding wheels with the same specification, the matrix and making cost are saved, production cost is reduced, the product value is improved.

Owner:广东奔朗新材料股份有限公司

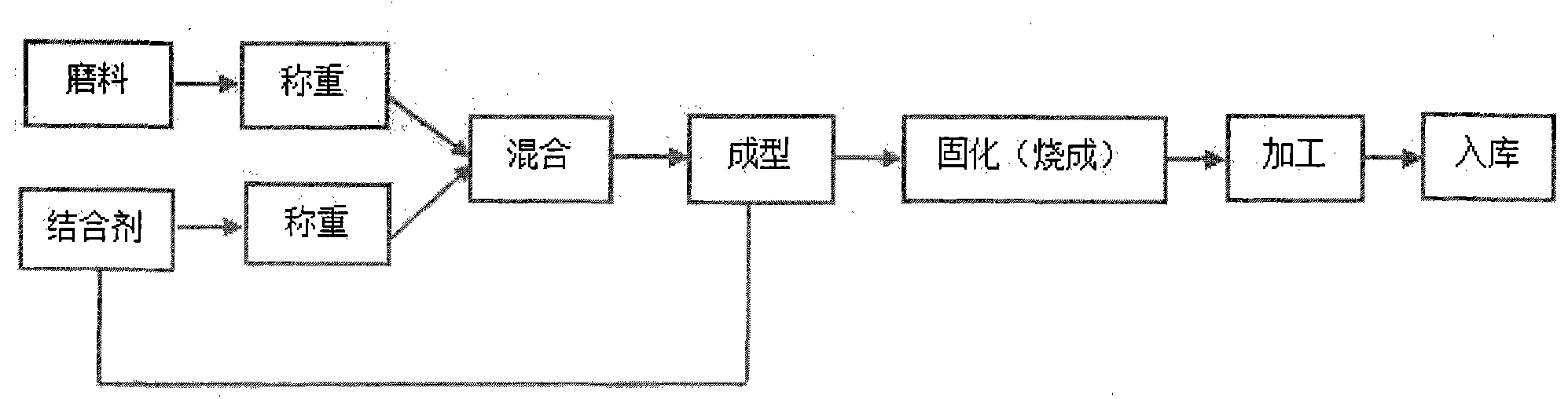

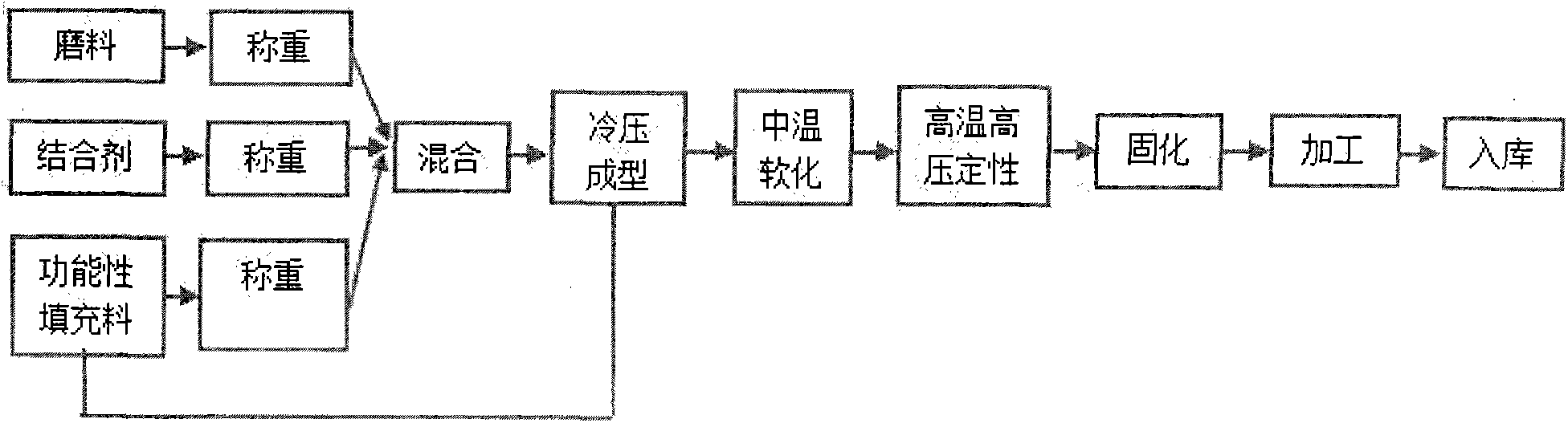

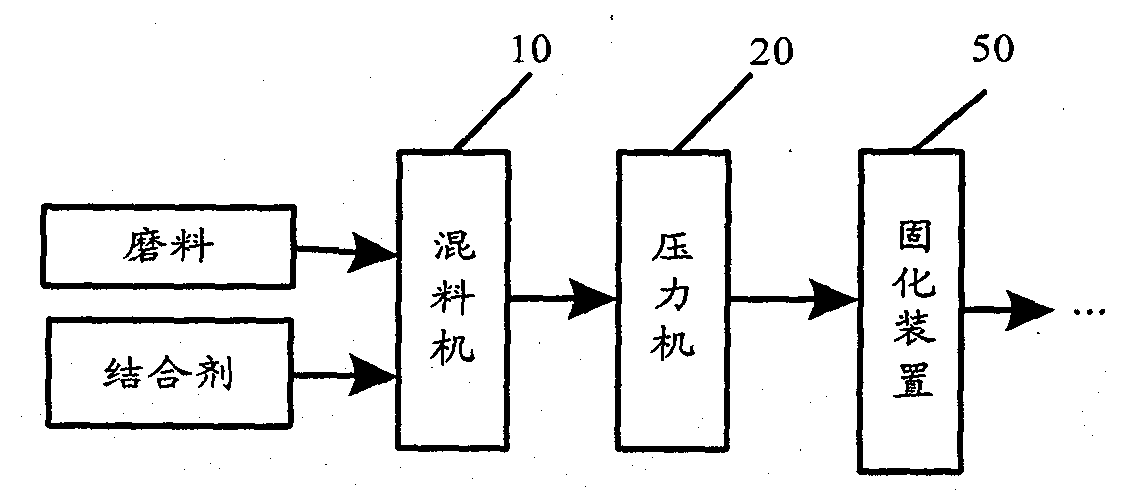

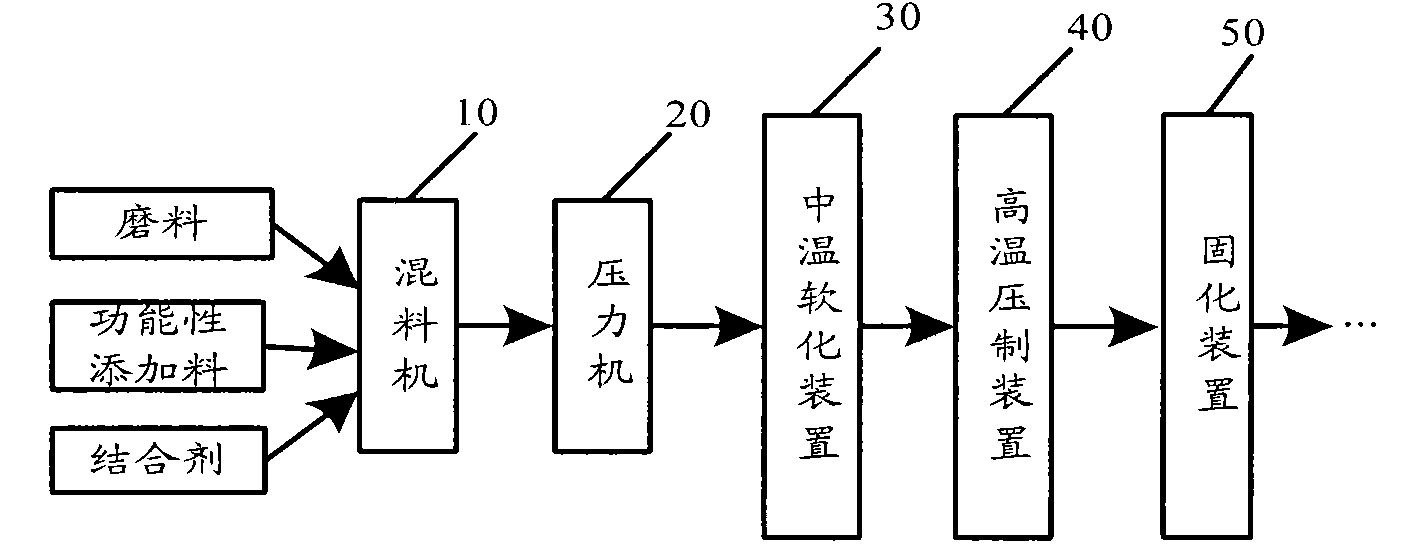

Grinding wheel manufacturing method

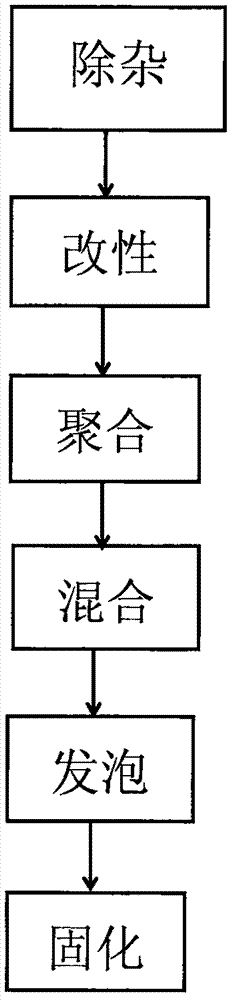

InactiveCN103962978AIncrease grinding ratioImprove efficiencyAbrasion apparatusGrinding devicesRoom temperatureMixed materials

The invention discloses a grinding wheel manufacturing method which comprises the following steps of material mixing, wherein quantified grinding materials and binding agents are mixed and prepared according to a technical formula; extrusion forming, wherein the prepared mixed materials are added in a die cavity to be extruded and formed; curing and sintering, wherein a formed grinding wheel is placed in a curing oven or a curing kiln for curing. In the material mixing process, a certain ratio of functional filling with is further added to be mixed with the grinding materials and the binding agents. After the mixed materials are extruded and formed at normal temperature, the mixed materials are subjected to at least one more extrusion after being softened at intermediate temperature. Compared with the prior art, the utilization rate of the grinding wheel grinding materials is improved in the way that the new functional filling is added in the material mixing process on the basis of the existing production technology, the intermediate-temperature softening process and the high-temperature and high-pressure forming process are added based on the primary cold press forming, an assembling line production mode is adopted, production efficiency is improved, and produced grinding wheels have the advantages of being good in binding power, high in grinding efficiency and abrasion resistance, little in dust, and the like.

Owner:田继华

Steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents

ActiveCN102363286AImprove the speed of useExtended service lifeAbrasion apparatusCeramic compositeTissue density

The invention relates to a steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents, which is in a structure made of polycrystalline solid materials with the coexistence of glass and crystals and adopts the bonding agents of clay, feldspar, boron-containing microcrystal glass, pyrophyllite and soapstone to be made into high-intensity and low-shrinkage engineering ceramic bonding agents, good performance of the glass and the ceramics such as high mechnical intensity, wear resistance, corrosion resistance and the like are integrated, then, the glass and the ceramics are combined with mixed grinding materials, a molding pressing method is adopted for the high-pressure double-side pressing process forming, the low-temperature firing is adopted, the positive pressure reducing atmosphere heat simulation crystallization is adopted at the 800 DEG C heat insulation section, and the mixed grinding material and micro porous glass phase high-intensity microcrystal engineering ceramic composite structure is formed, so the intensity and the bonding degree of the steel blank grinding abrasion wheel are greatly improved, the use linear speed of the abrasion wheel is accelerated, and the safety factor is high. The steel blank grinding abrasion wheel belongs to the novel efficient special steel blank grinding abrasion wheel with the characteristics that the intensity andthe hardness are high, the tissue density is uniform, the grinding ratio is great under the condition of high-speed grinding, workpieces can not be damaged through firing, and the automation of iron and steel industries is easy to realize.

Owner:江苏华东砂轮有限公司

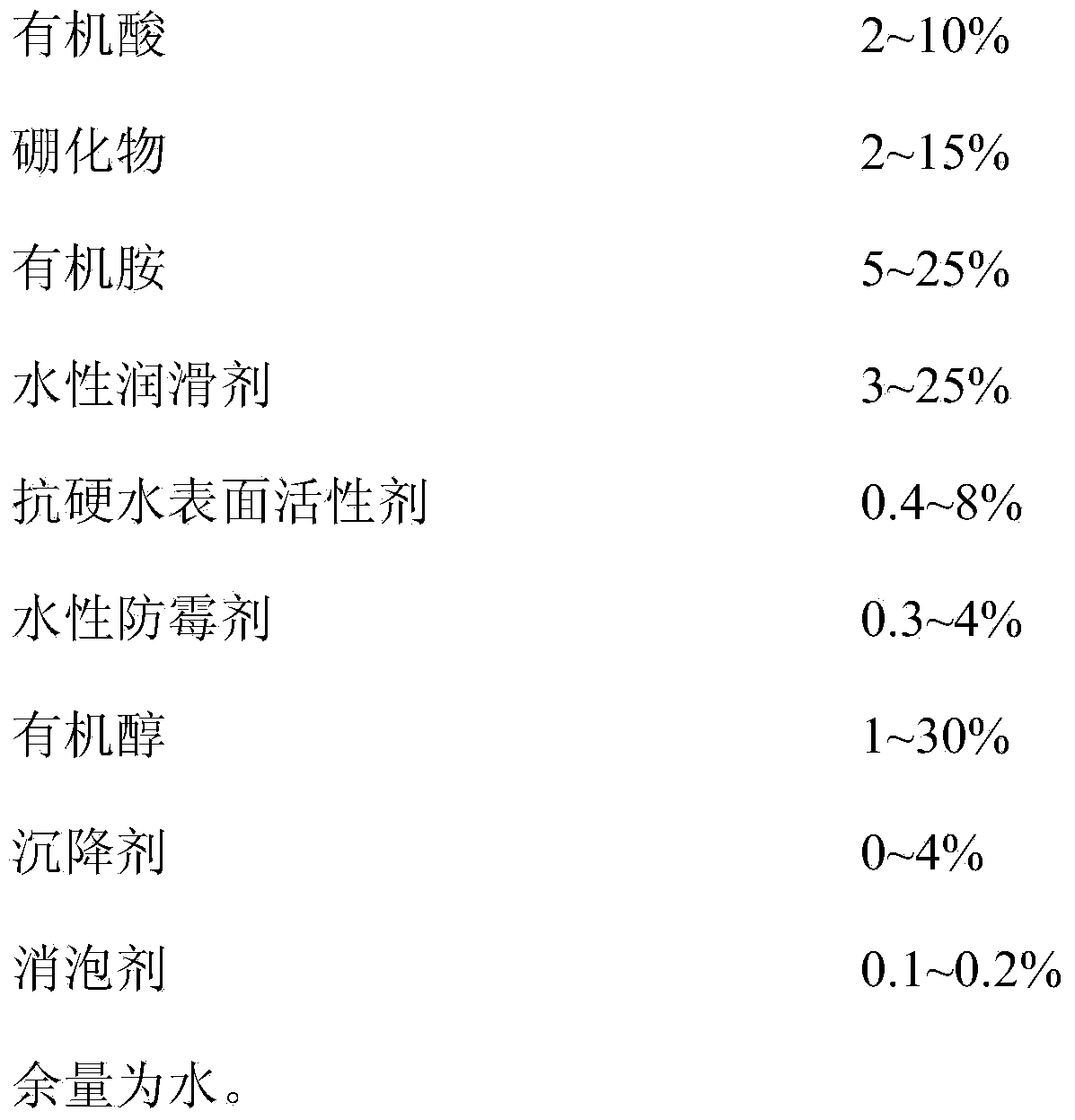

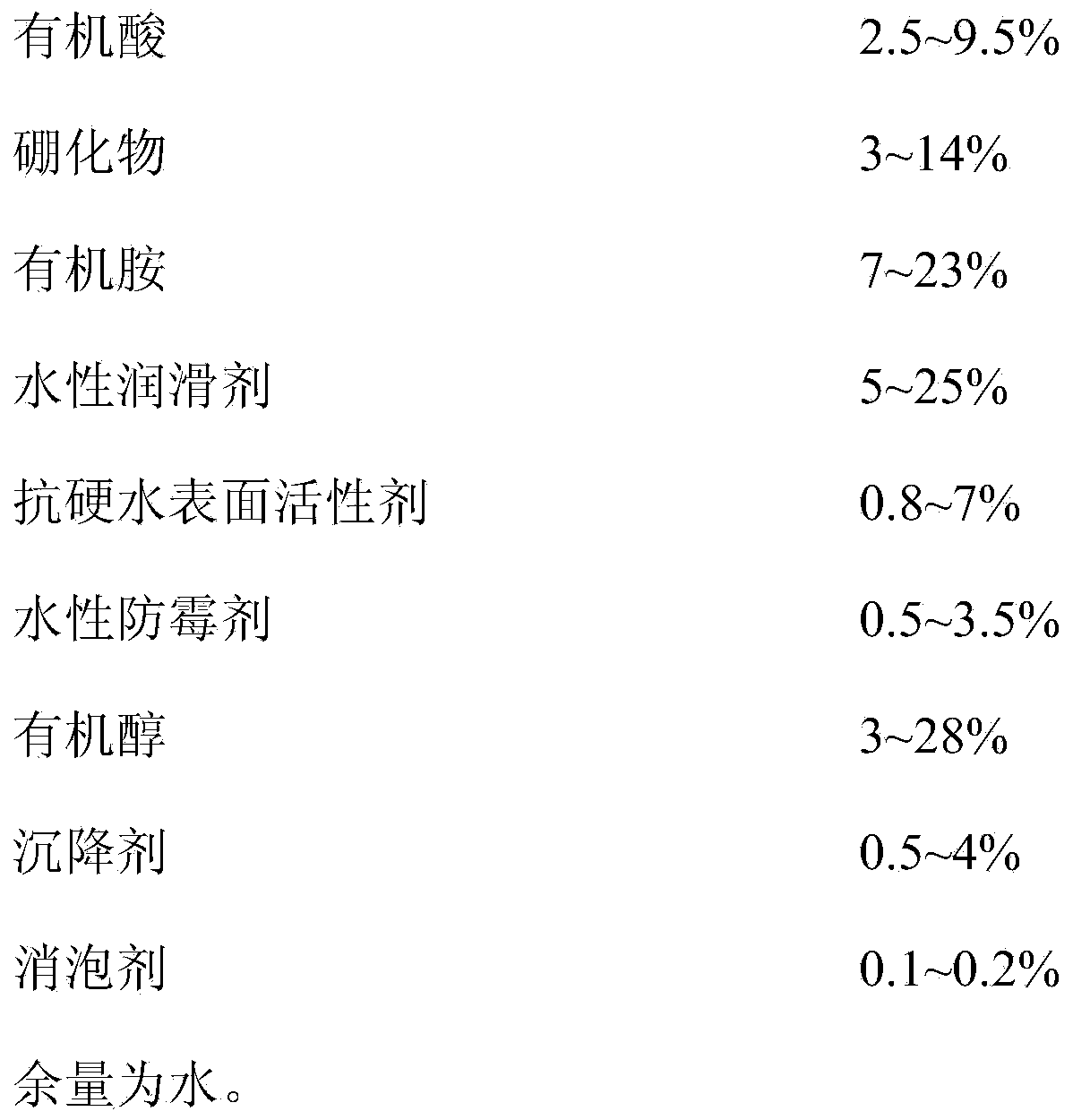

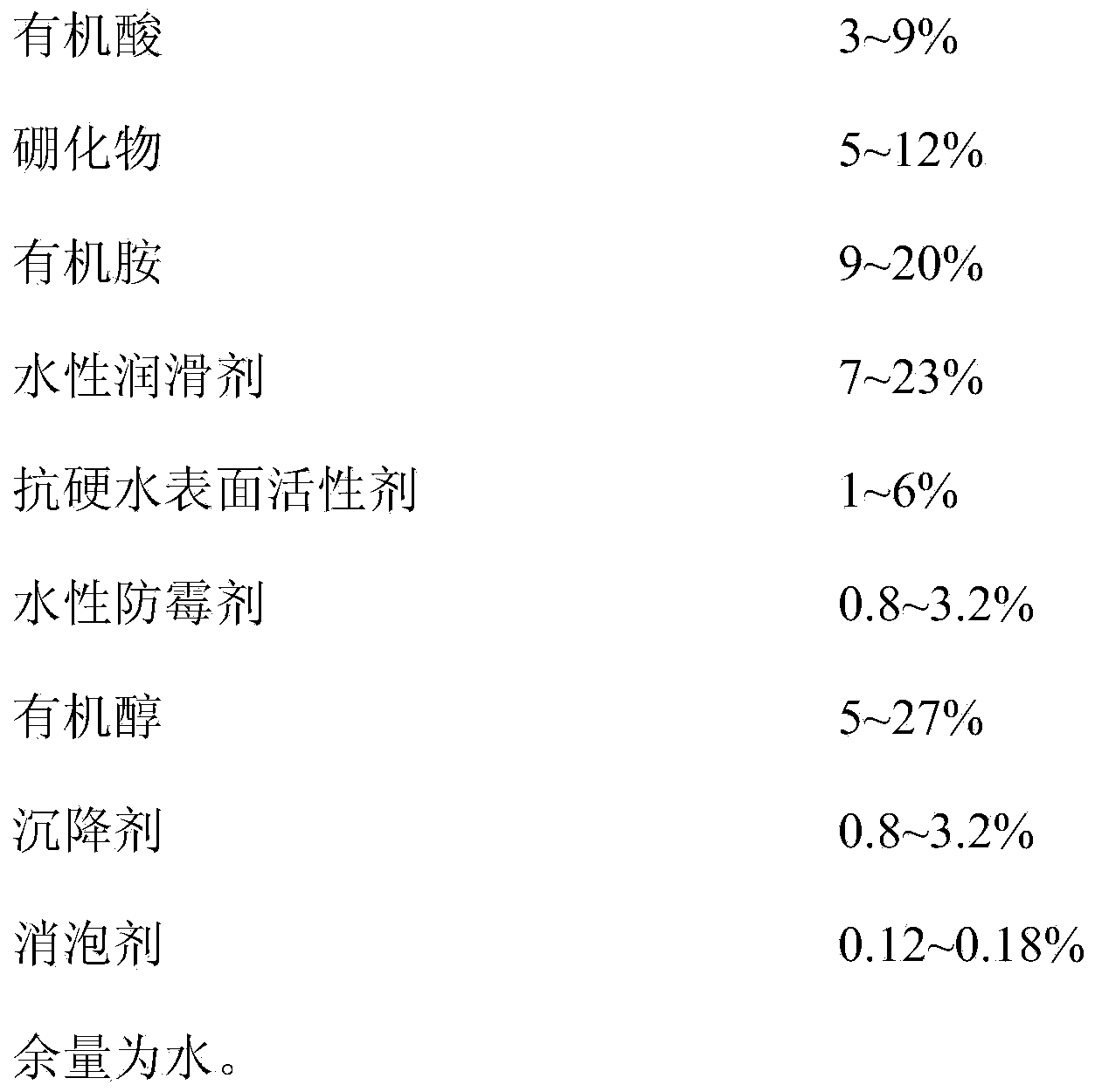

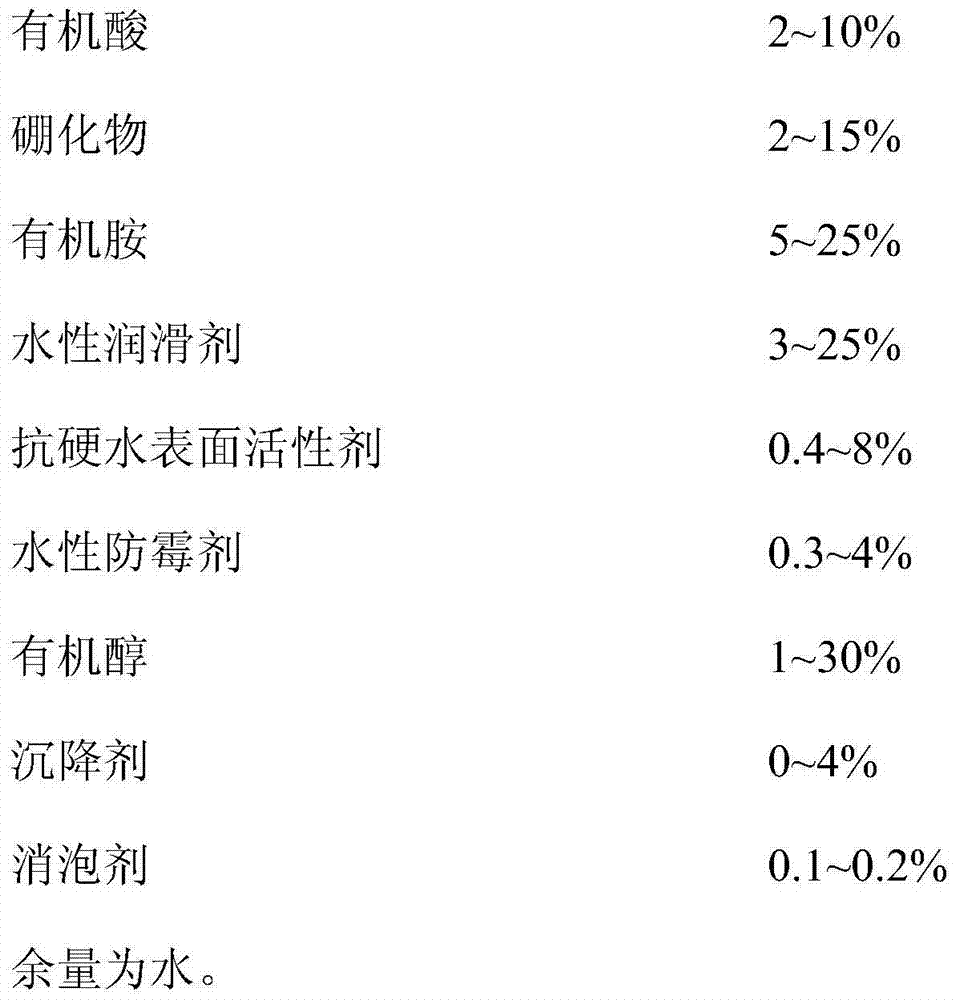

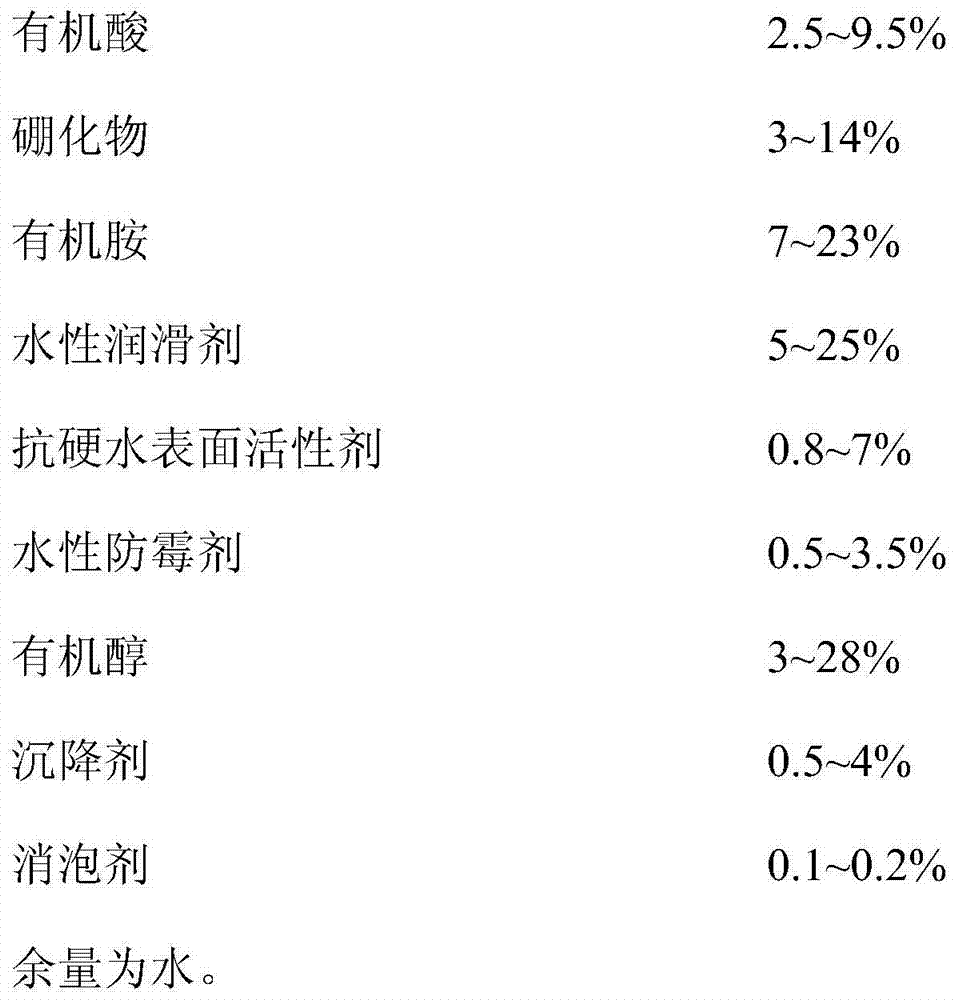

Full-synthetic glass grinding fluid

ActiveCN103525533AImprove general performanceGuaranteed service lifeLubricant compositionWater basedBoride

The invention discloses an environment-friendly glass grinding fluid, which is efficient, and long in service. The full-synthetic glass grinding fluid is prepared from an organic acid, a boride, an organic amine, a water-based lubricant, a hard water-resisting surfactant, a water-based mould inhibitor, an organic alcohol, a settling agent, a defoaming agent and water in a mixing manner. The glass grinding fluid disclosed by the invention has excellent cooling property, anti-rotting ability and lubricating abrasion resistance, and outstanding hard water resistance, can be recycled for a long period of time, can ensure the working accuracy and the service life of a tool, and has excellent cleaning performance; the blocking phenomenon of a grinding wheel can be effectively prevented; the product is good in settleability; processing is facilitated; the product is free of poison, environment-friendly, free of pollution, small in smell, good in working performance, good in compatibility with a paint of equipment, low in pH value, free of bad effects on skin and the like; the phenomenon that the paint of the equipment peels off is not generated. The grinding fluid disclosed by the invention is simple in reparation method, low in cost, excellent in performance, and good in market prospect at present.

Owner:东莞太平洋博高润滑油有限公司

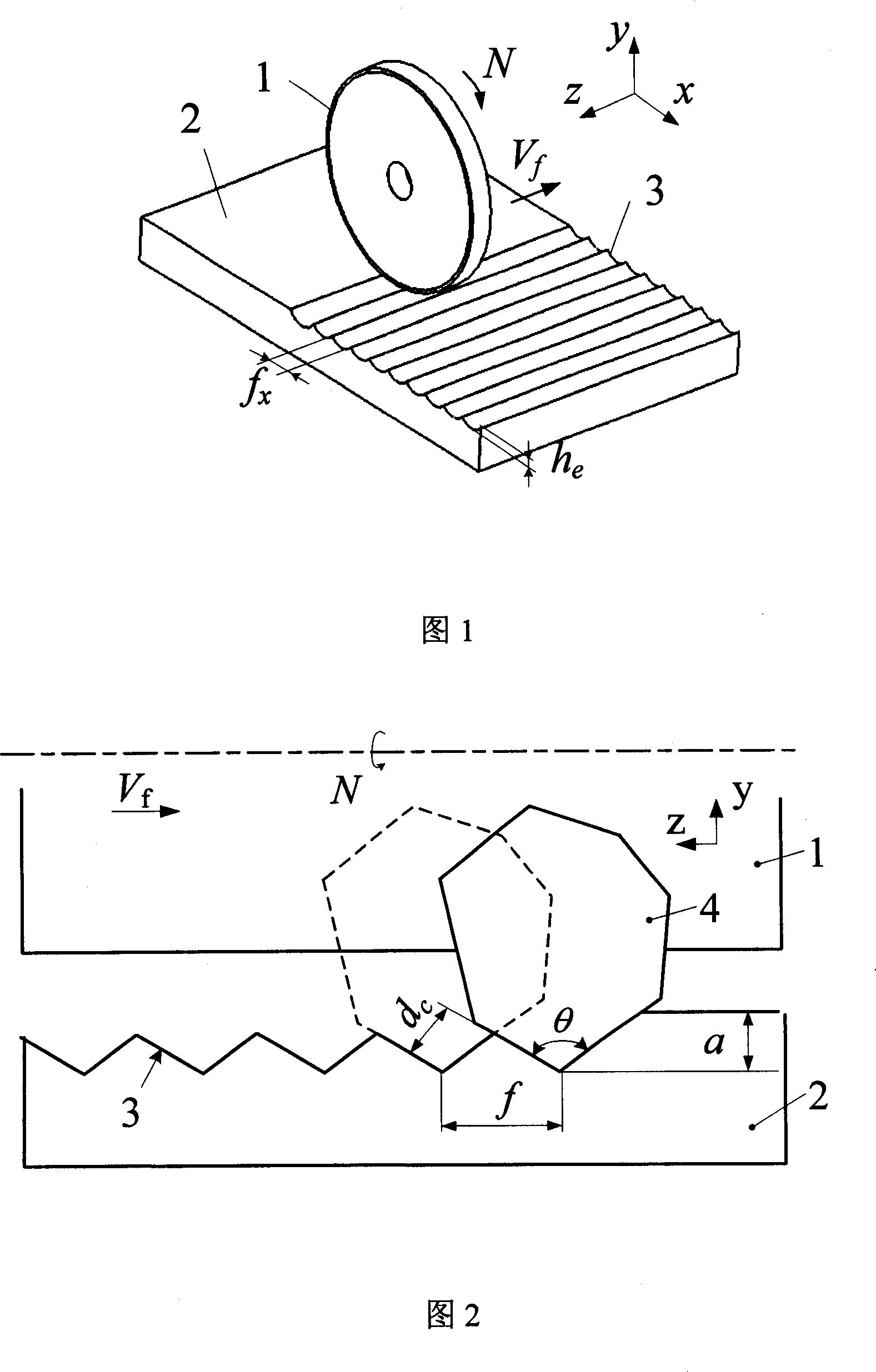

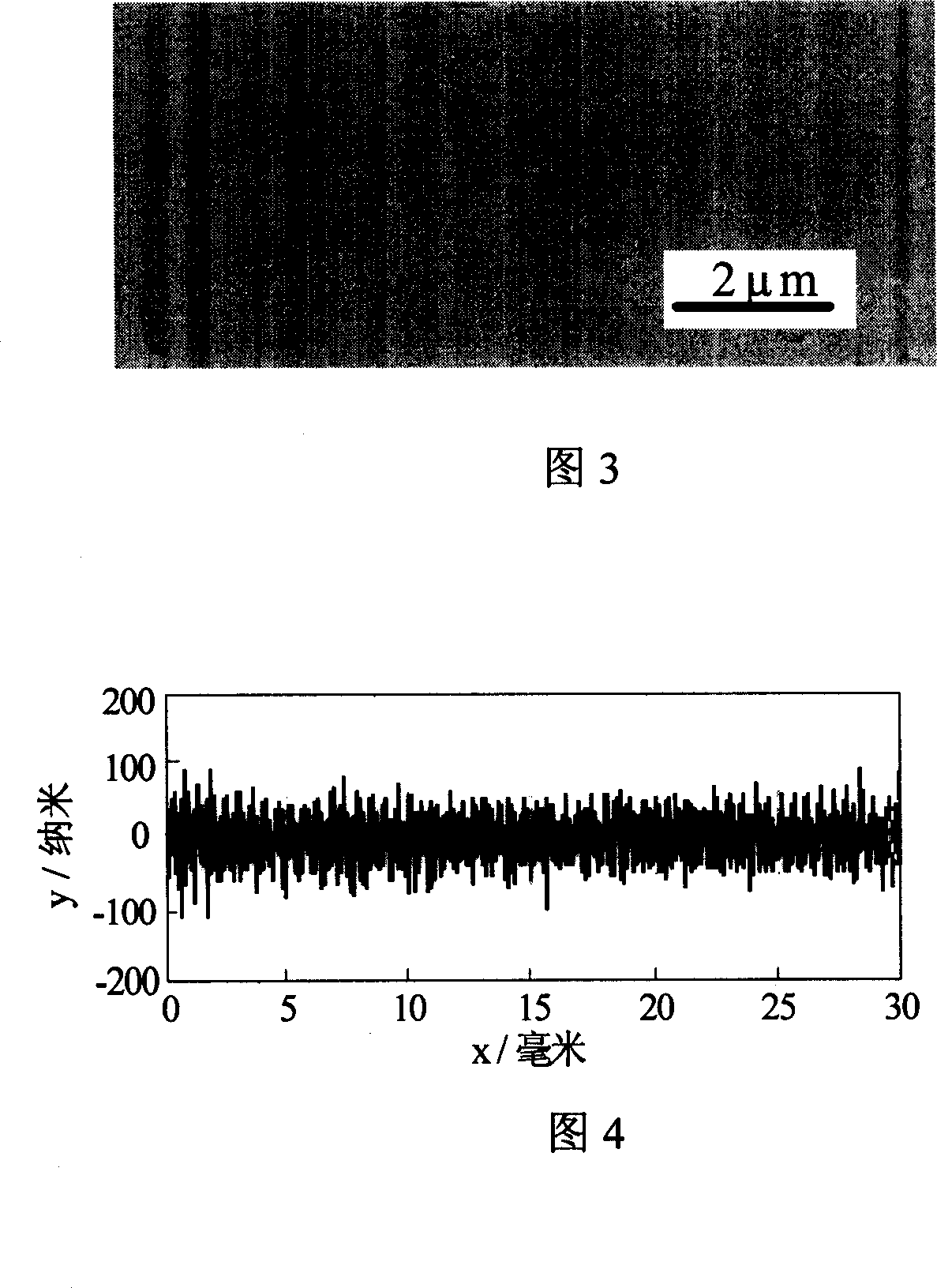

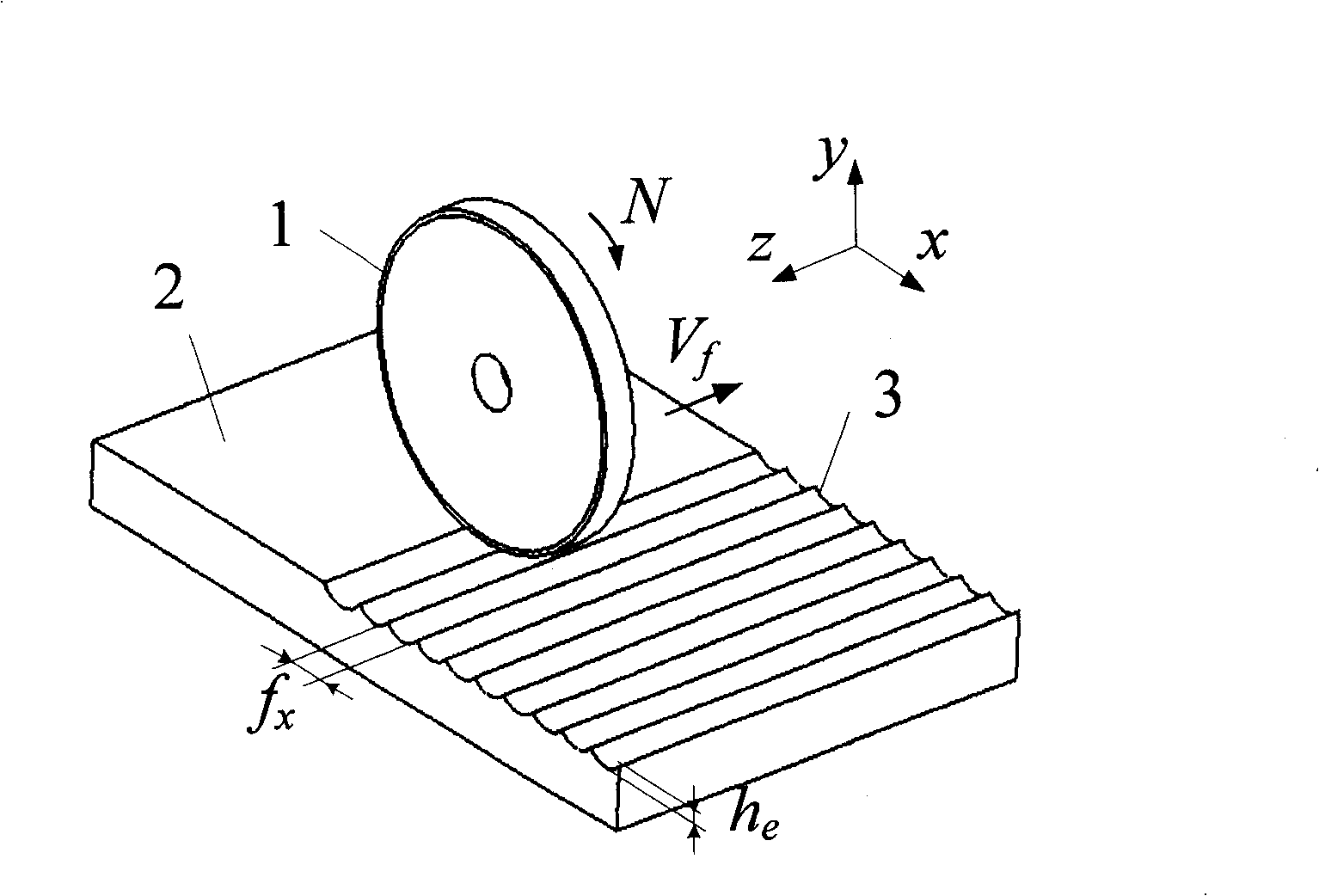

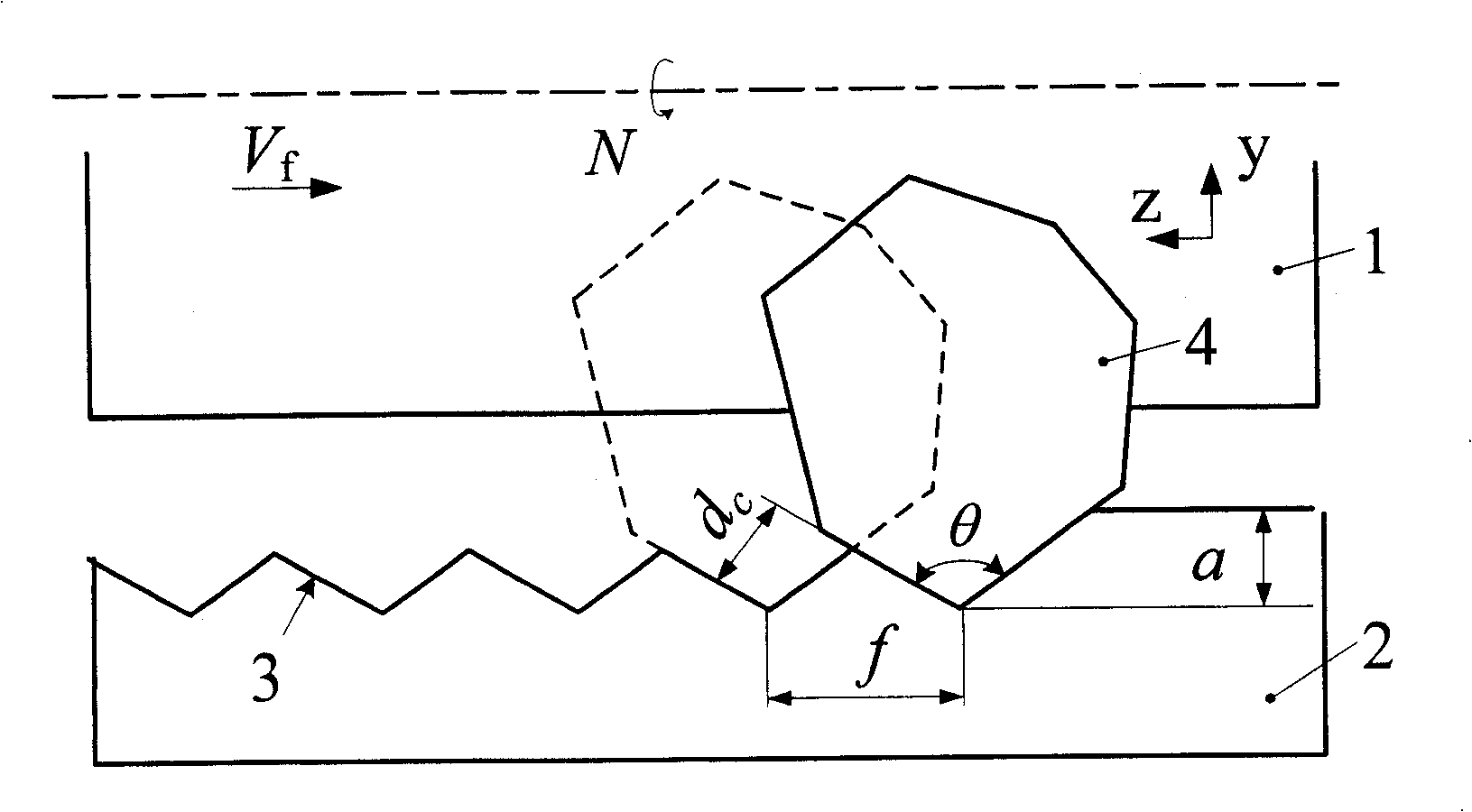

Grinding method for superhard silicon carbide ceramic nano mirror

InactiveCN1986151AImprove processing efficiencyOmit fine grindingOptical surface grinding machinesAbrasive surface conditioning devicesGrinding wheelMachine tool

The superhard silicon carbide ceramic nanometer mirror grinding process includes grinding the workpiece with dressed and shaped coarse diamond wheel in Z direction for plastic domain grinding with the cutting depth controlled within 100 nm; shifting the coarse diamond wheel in X direction for the distance fx and performing the next grinding so as to form envelope trace of height he on the surface of the workpiece and form flat smooth nanometer mirror. In the conditions of proper grinding wheel diameter Dish washer, fx smaller than 100 microns, the envelope trace height he will smaller than 15 nm. The present invention makes it possible to realize super precision surface machining in the machine tool of only micron level or submicron level precision. The present invention has low cost, great grinding ratio and high machining efficiency.

Owner:SOUTH CHINA UNIV OF TECH

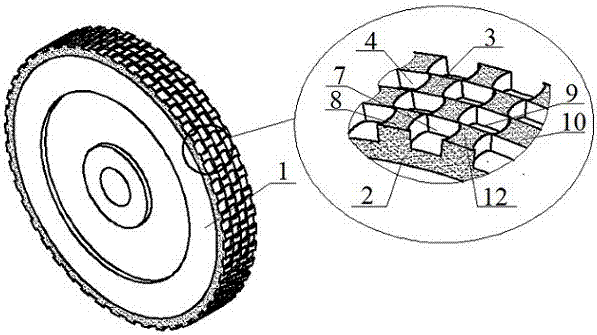

CVD diamond grinding wheel with ordered micro-structured surface and making method thereof

ActiveCN107962510AIncrease the number of effective sharpeningImprove surface qualityBonded abrasive wheelsGrinding devicesMaterial removalGas phase

The invention discloses a CVD diamond grinding wheel with an ordered micro-structured surface and a making method thereof. The grinding wheel is characterized in that a layer of diamond film is deposited on the outer circumferential face of a grinding wheel hub, a large number of staggered in-order micro grinding units are machined on the whole outer circumferential face of the diamond film, and the top ends of the grinding units are in kidney shapes. The making method is characterized in that through the chemical vapor deposition that is CVD, the diamond film is deposited on the outer circumference face of the grinding wheel hub, a pulse laser beam is adopted to machine the large number of micro grooves with the same geometric dimensioning in the outer circumference face of the whole diamond film, and the large number of micro grinding units are formed; the grinding units are arranged in a staggered and in-order manner, the top face of each grinding unit is in a kidney shape, according to the grinding wheel, the effective sharpening number of the grinding wheel during grinding can be improved, the chip formation efficiency and the surface material removal rate are improved, the cutting performance is improved, the surface machining quality and the cutting efficiency can be improved, the holding force of the grinding wheel hub to the grinding units can be increased, and the service life of the grinding wheel can be obviously prolonged.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Heat-resistant anti-impact grinding wheel material

The invention discloses a heat-resistant anti-impact grinding wheel material. The heat-resistant anti-impact grinding wheel material is prepared from diamond, silicon carbide whiskers, aluminum borate whiskers, potassium titanate whiskers, aluminum oxide whiskers, yttrium oxide, cerium oxide, feldspar, fluorite, modified phenolic resin, polyurethane resin, polyethylene wax emulsion, calcium lignosulphonate, slag, glass fibers, carbon fibers, a pore forming agent and alloy powder. The heat-resistant anti-impact grinding wheel material is reasonable in composition. An obtained grinding wheel is excellent in bending strength, microhardness, impact toughness, wear resistance, heat dissipation performance and heat resistance, not likely to burst apart and high in safety coefficient and meanwhile has the beneficial effects of being high in grinding efficiency and grinding ratio, good in grinding quality, long in service life and the like. Good economic benefits are achieved.

Owner:安徽昌悌进出口贸易有限公司

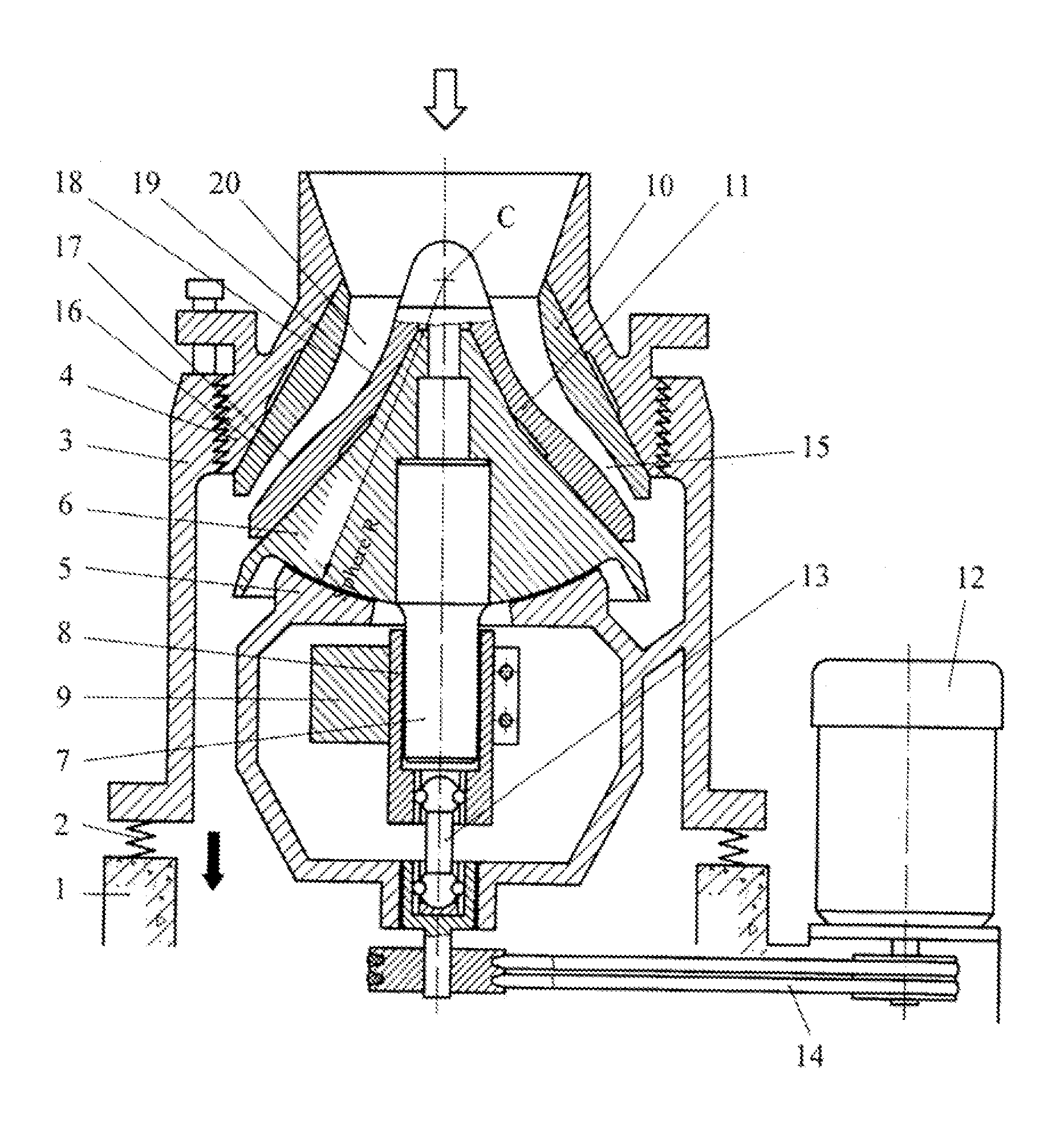

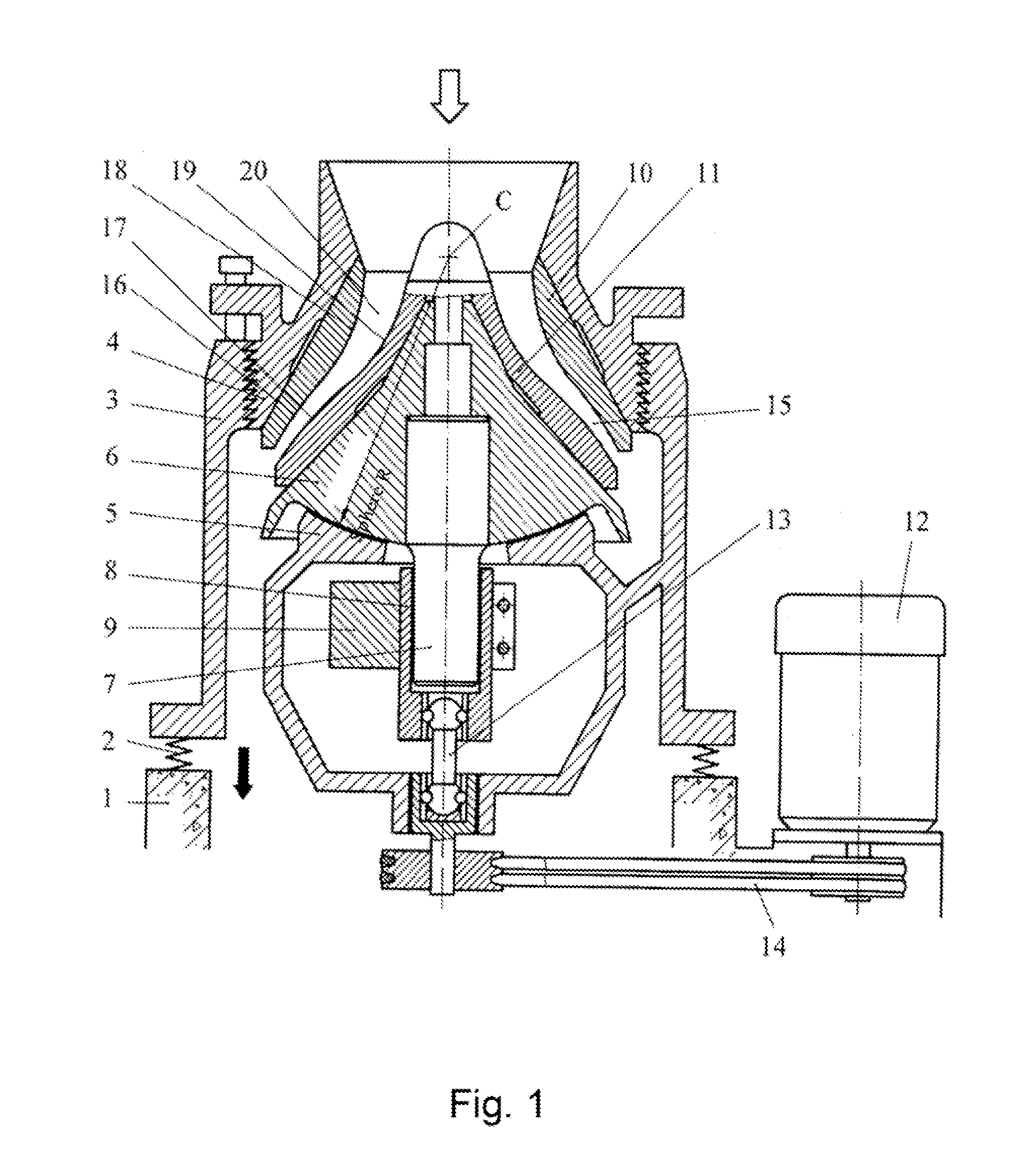

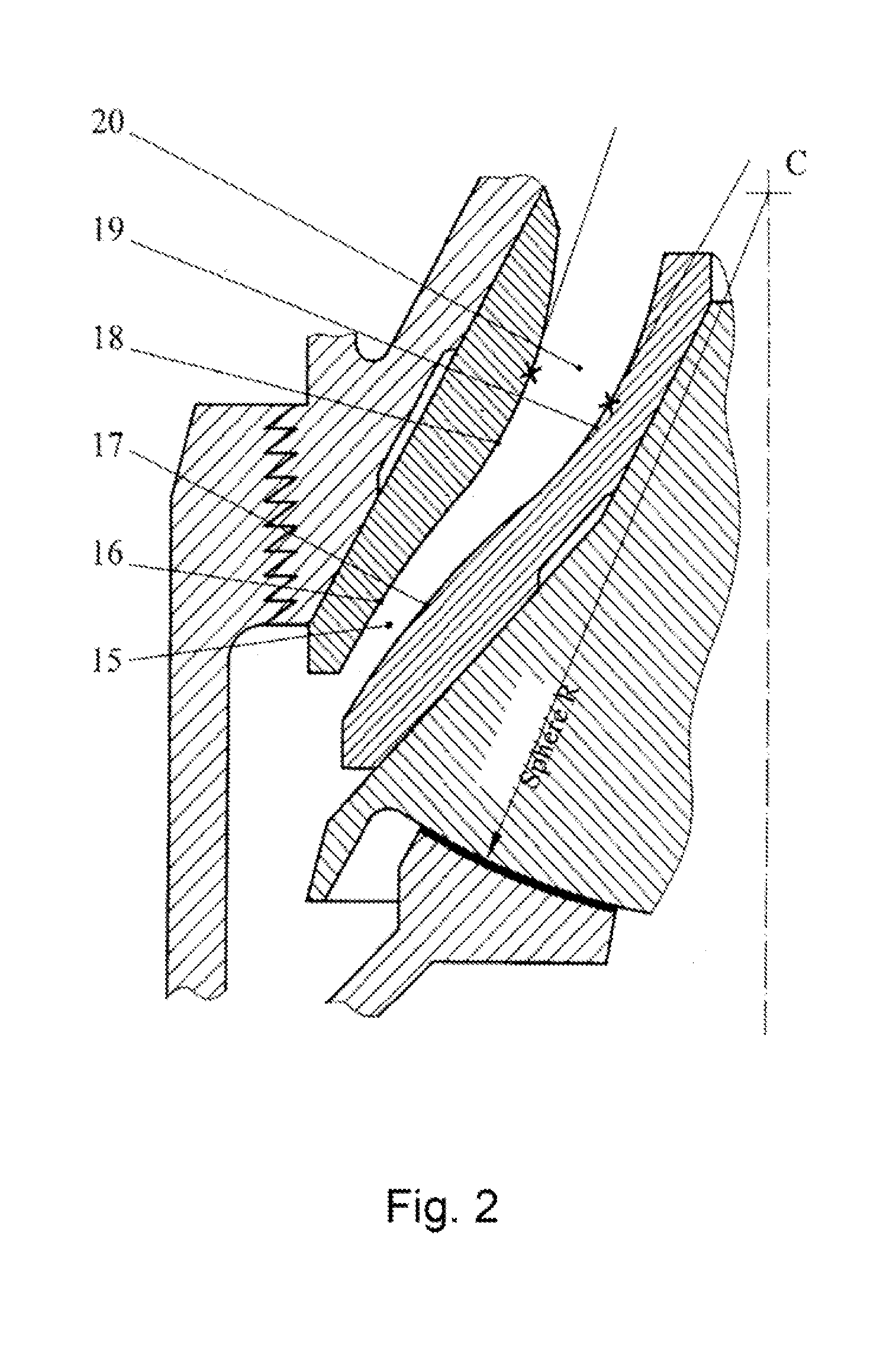

Parabolic vibratory impact mill

InactiveUS20150129696A1High grinding ratioSlow down material flowGrain treatmentsEnergy expenditureMechanical engineering

A parabolic vibratory impact mill is proposed which comprises a housing having an outer cone, an inner cone and a power-operated vibrator. The shells of the cones have working surfaces in the form of parabolic generatrices: in the bottom part, the concavity of the parabolae is oriented toward the axis of the mill; in the top part, the convexity of the parabolae is oriented toward the axis of the mill. Conditions are created for the autogenous grinding of large pieces in the top part and small pieces in the bottom part, wherein the material partially decelerates in the transition region between the top parabolae and the bottom parabolae, providing for the metered feeding of the bottom region. The advantageous vertical distribution of the load in the grinding chamber provides a grinding ratio of 30 with little wear on the shells and low energy expenditure.

Owner:TRANSMICRON

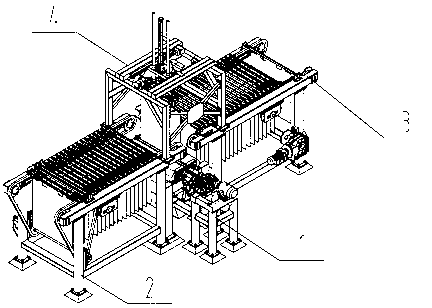

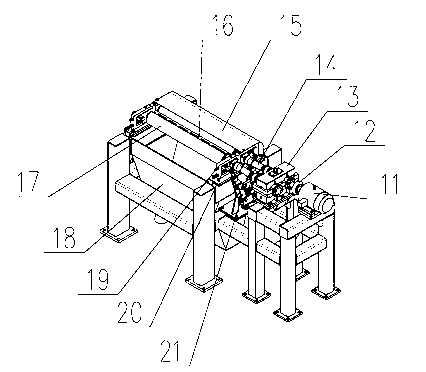

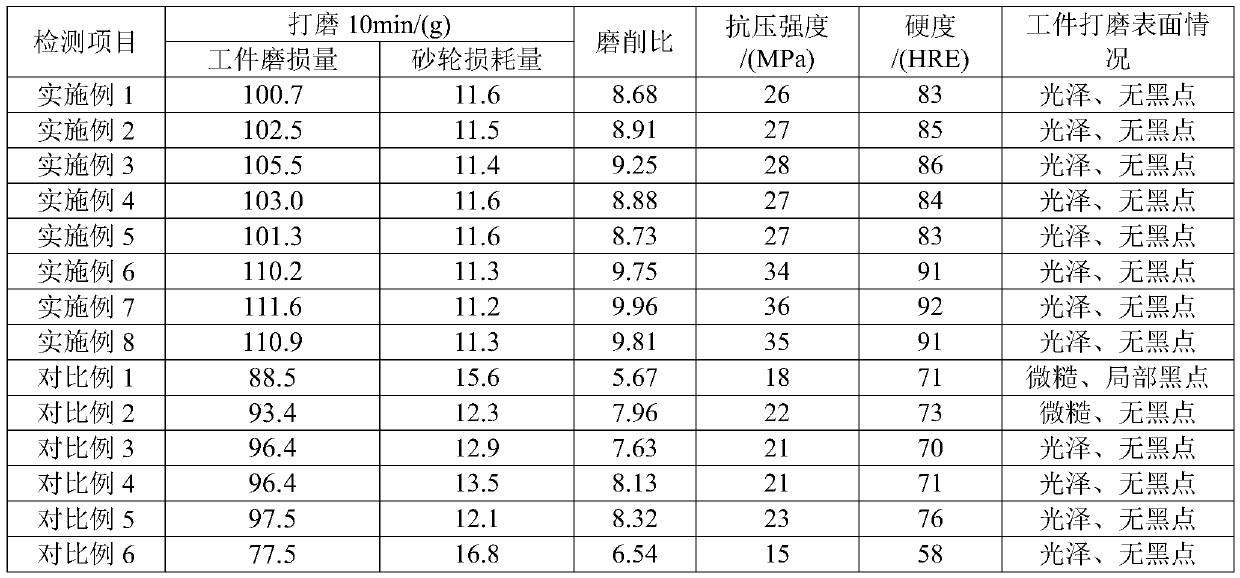

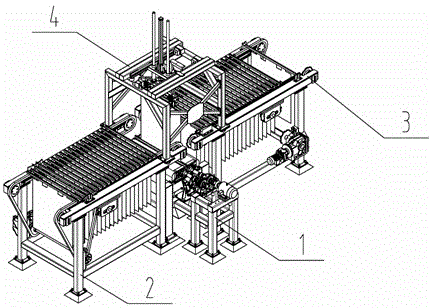

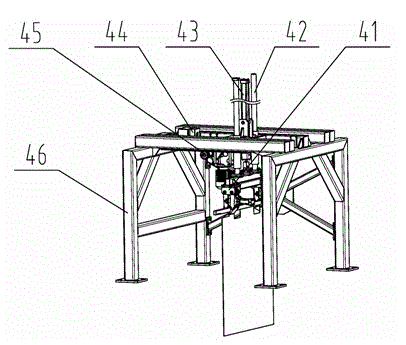

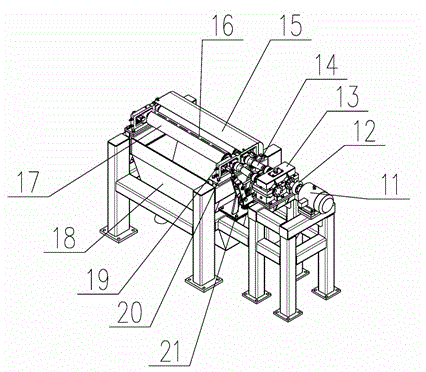

Abrasive belt grinder for metal polishing

ActiveCN103182670AImprove resection rateIncrease grinding ratioBelt grinding machinesGrinding/polishing safety devicesEngineeringSurface grinding

The invention discloses an abrasive belt grinder for metal polishing. A grinding device is arranged on the middle part of the abrasive belt grinder; a plate receiving chain conveying device is arranged at the front end of the abrasive belt grinder; a plate discharging chain conveying device is arranged at the rear end of the abrasive belt grinder; a two-dimensional shifting device is arranged on the upper part of the abrasive belt grinder; in the grinding device, a motor, a shaft coupler, a double-output shaft gearbox and a sliding polishing roller are arranged on the upper part of a rack; and a slide gear clamp is arranged on the lower part of the rack. According to the abrasive belt grinder for metal polishing, an abrasive belt is used as a grinding tool, so that the abrasive belt grinder for the metal polishing has a higher resection rate and a higher grinding ratio in comparison with the conventional steel wire brush polishing way, and therefore, a production efficiency problem and a surface burning problem of plate polishing are solved, and the service life of the plate is prolonged. Meanwhile, the distance between the grinding rollers in the grinding device is adjusted by the spring, so that the pressure, which is applied to the two sides of the starting sheet by the grinding roller, can be adjusted to be equal, and therefore, the uniformity quality of the plate surface grinding is improved.

Owner:JIANGXI NERIN EQUIP

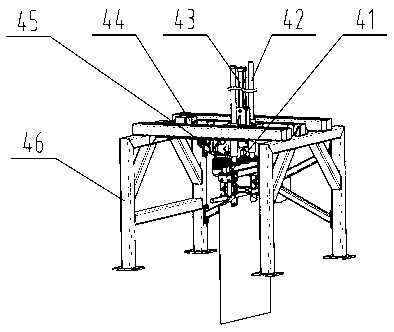

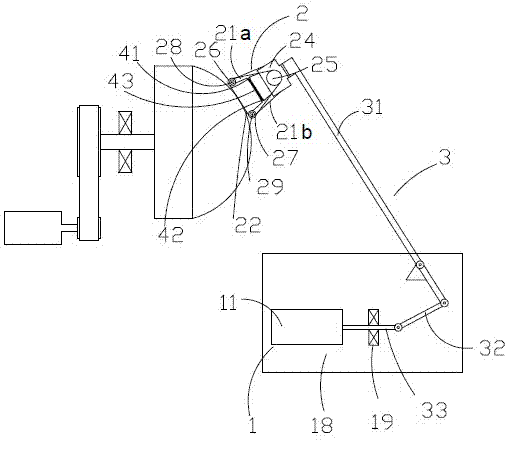

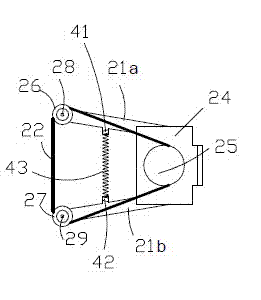

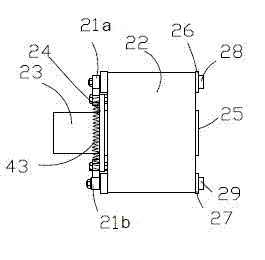

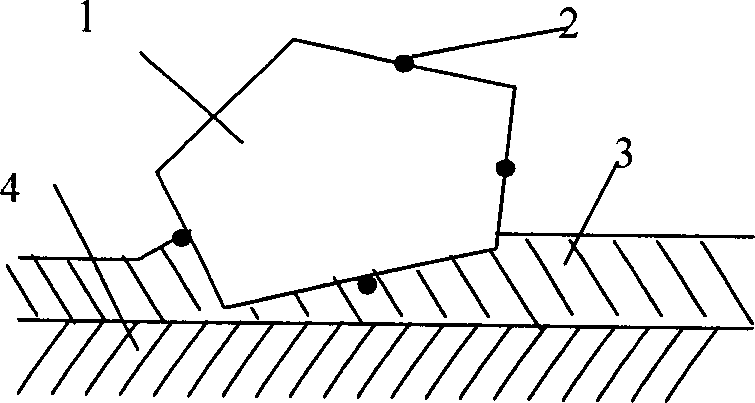

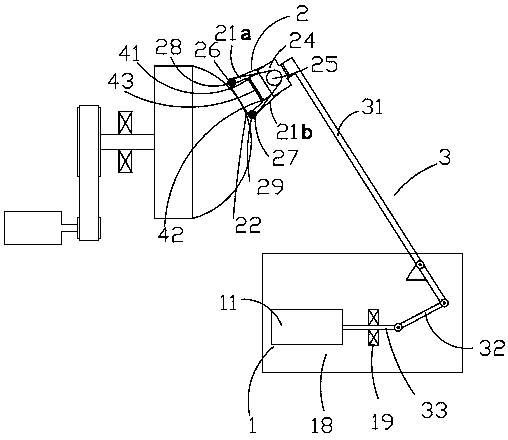

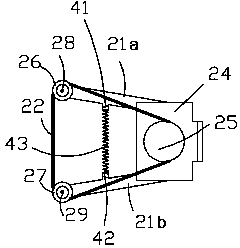

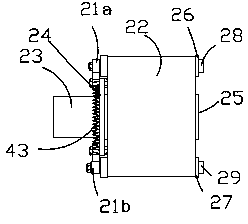

Aspheric surface abrasive belt grinding and polishing tool based on hydraulic servos

InactiveCN102814714AOvercoming the problem of inaccurate force controlControl the polishing pressureBelt grinding machinesGrinding/polishing safety devicesHydraulic cylinderSolenoid valve

The invention relates to an aspheric surface abrasive belt grinding and polishing tool based on a hydraulic servos. The aspheric surface abrasive belt grinding tool comprises a hydraulic servo system and an abrasive belt tool system connected through a link mechanism, and the abrasive belt tool system comprises an abrasive belt driven by a tool motor, an upper foot support rod and a lower foot support rod, wherein the upper foot support rod and the lower foot support rod are connected through a third bearing. The hydraulic servo system comprises a hydraulic cylinder, the hydraulic cylinder is sequentially connected with a single-way throttle valve, a three-position four-way solenoid valve, an overflow valve, a hydraulic pump, a filter and an oil tank, and the hydraulic servo system adjusts a grinding and polishing pressure of the abrasive belt by controlling strokes of the link mechanism and stabilizes the grinding and polishing pressure through the overflow valve. The aspheric surface abrasive belt grinding and polishing tool solves the problem that the grinding and polishing pressure of the abrasive belt in a grinding and polishing process of aspheric surface optical elements is unstable, and simultaneously the aspheric surface abrasive belt grinding and polishing tool has the advantages of being capable of self adapting to workpiece curved surfaces, good in effects of discharging grinding and polishing sweeps, big in grinding ratio, high in grinding and polishing efficiency, simple in structure and low in manufacture cost.

Owner:NINGBO UNIV

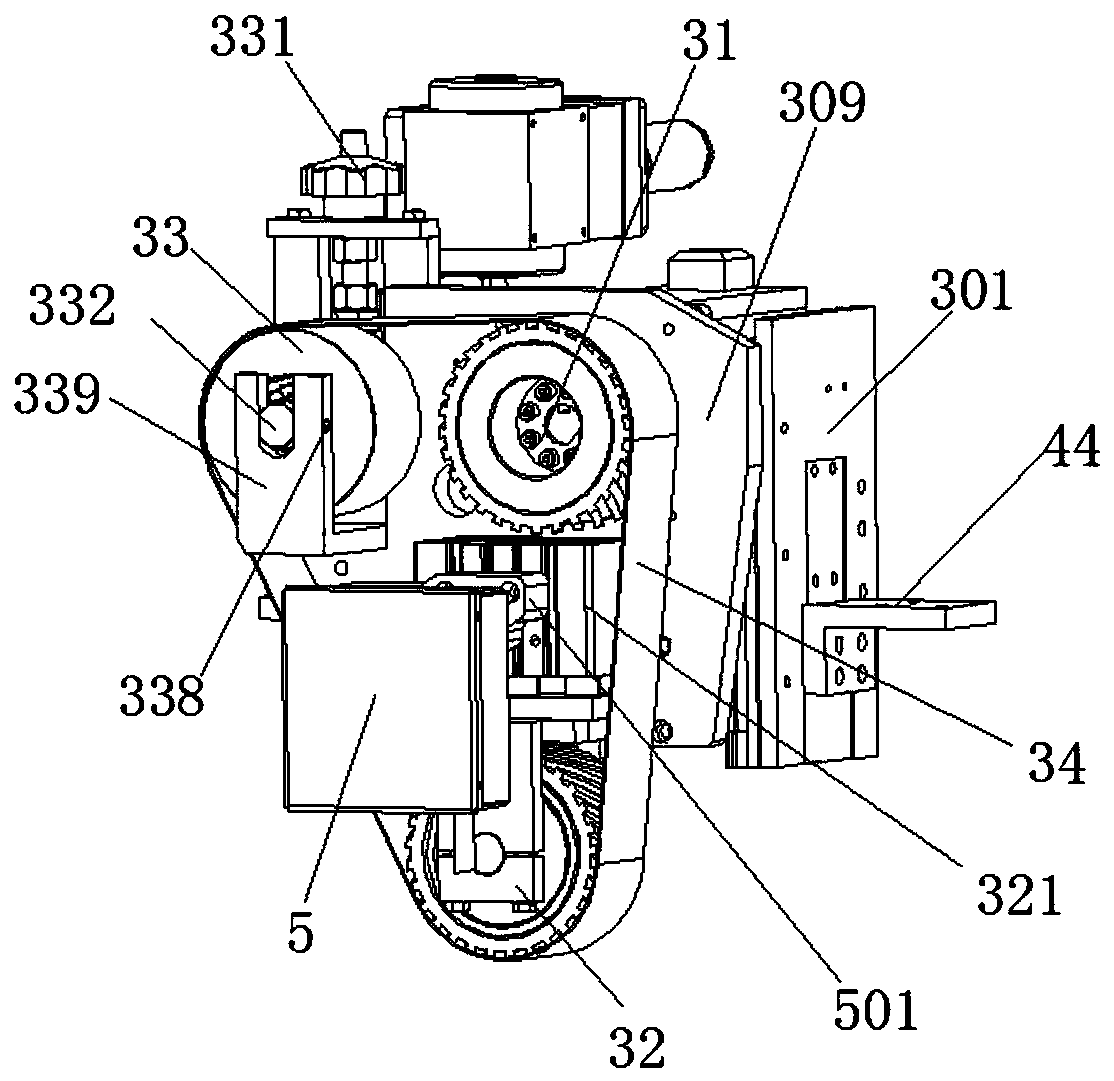

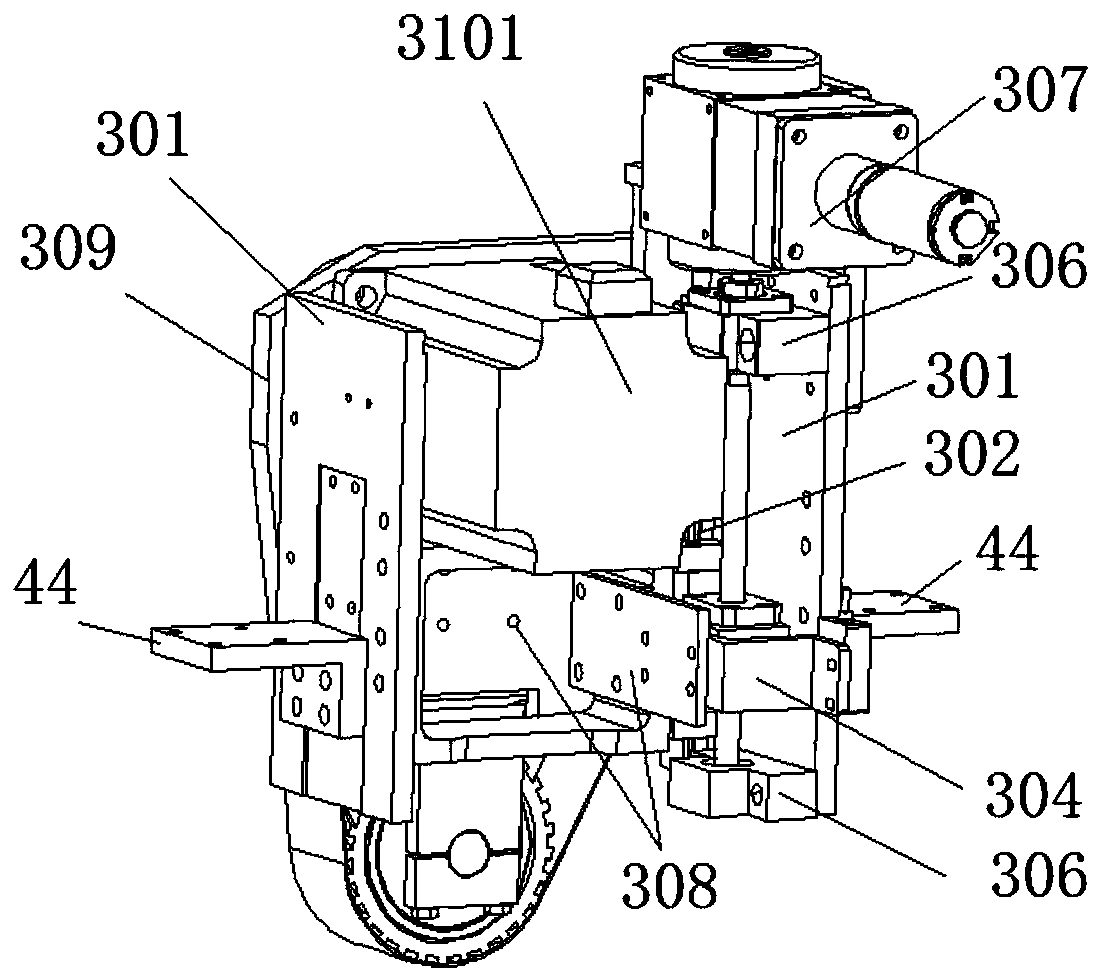

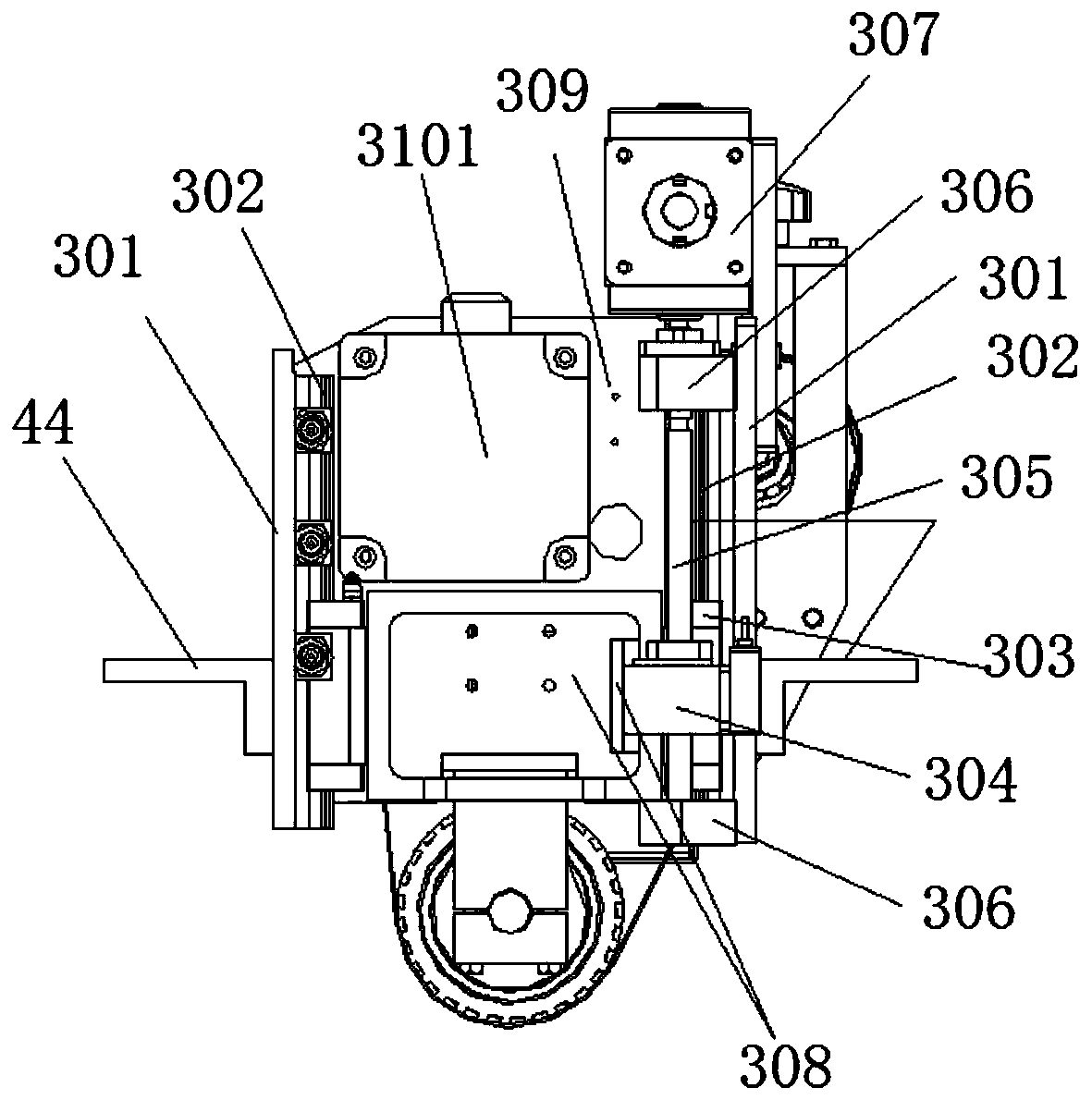

Spiral steel pipe end welding line coping and polishing robot

ActiveCN111451898AImprove grinding accuracyRealize high-precision fully automaticPolishing machinesBelt grinding machinesRobot handWeld line

The invention provides a spiral steel pipe end welding line coping and polishing robot. A two-freedom-degree fine grinding executing mechanism provided with a laser outline instrument is arranged at the executing end of a multi-freedom-degree mechanical arm, the grinding precision and the polishing precision of the mechanical arm are improved while motion control is simplified, and the technical problems that the quality of a welding bead at the pipe end of a spiral steel pipe ground through a multi-freedom-degree grinding mechanical arm in the prior art cannot meet the technology index requirements regulated by the API Spec5L standard and the GBT97111-1997 standard; and manual secondary coping is still needed are solved. The spiral steel pipe end welding line coping and polishing robot can be used for spiral steel pipe outer welding line grinding and is suitable for spiral steel pipe inner welding line grinding, and base metal is not damaged during coping; after coping, the remnant height can be smaller than or equal to 0.1 mm to the minimum and is far higher than the requirements of the API Spec5L standard and the GBT97111-1997 standard; and the laser outline instrument cooperates with a special detection algorithm, and high-precision scanning detection for precision smaller than 0.05 mm can be achieved; and the powerful technology support is provided for high-precision welding line coping.

Owner:宝鸡宇喆工业科技有限公司

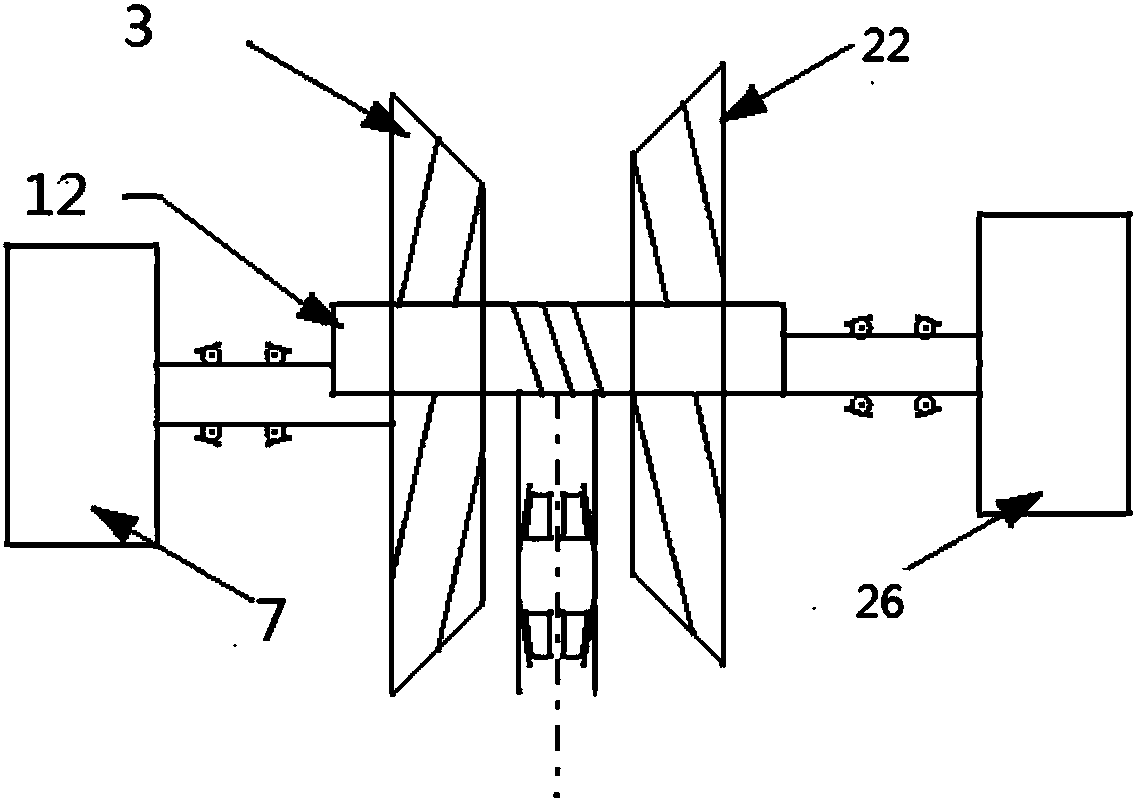

Novel grinding wheel production equipment

InactiveCN104044089AIncrease grinding ratioImprove efficiencyAbrasion apparatusGrinding devicesBLENDER/MIXERIron sulfide

The invention discloses novel grinding wheel production equipment. The novel grinding wheel production equipment comprises a blender mixer, a pressing machine and a solidification device, wherein a grinding material and a binding agent are added into the blender mixer; functional filler with a certain proportion is also added into the blender mixer, such as silicon carbide fine powder, corundum powder, cryolite powder, iron sulfide powder, fluorite powder, silicon oxide powder and calcium oxide powder, and the functional filler is mixed with the grinding material together. Compared with the prior art, the novel grinding wheel production equipment has the advantages that since the new functional additive is added in the mixing process on the basis of the existing grinding wheel production process, the utilization rate of the grinding material of a grinding wheel is improved, on the basis of carrying out primary cold press molding, an intermediate temperature softening device and a high temperature pressing device are added, a flow line production mode is adopted, the production efficiency is improved, the produced grinding wheel has good cohesive force, the grinding efficiency is high, the abrasion resistance is high, dust is little, and the like.

Owner:田继华

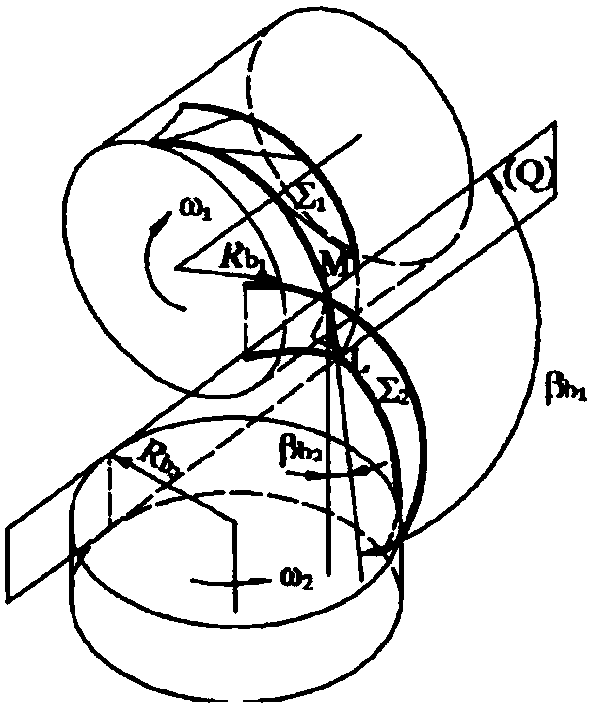

Gear honing machine tool without axial feed and gear honing method

The invention discloses a gear honing machine tool without axial feed and a gear honing method. A left tooth face honing wheel is fixedly connected with a thread at the tail end of a left tooth face honing wheel transmission shaft through a cone hole of the left tooth face honing wheel by means of a first fastening nut; a right tooth face honing wheel is fixedly connected with a thread at the tailend of a right tooth face honing wheel transmission shaft through a cone hole of the right tooth face honing wheel by means of a second fastening nut; a machined gear is placed parallel to a work table, and two cooling hoses are placed close to a grinding area. The left tooth face honing wheel and the right tooth face honing wheel are meshed with the machined helical gear, and the honing qualityand the honing allowance of the honing wheels for the machined helical gear are controlled by adjusting the rotating speed of two servo motors and the relative phase angle phi of the two servo motors.The gear honing machine tool is a special machine tool for finish machining of cylindrical hardened helical gears produced in batches or in large quantities. Compared with other similar machine tools, the gear honing machine tool has the advantages of simple mechanism, convenient operation, and low cost of manufacturing and later maintenance.

Owner:JILIN UNIV

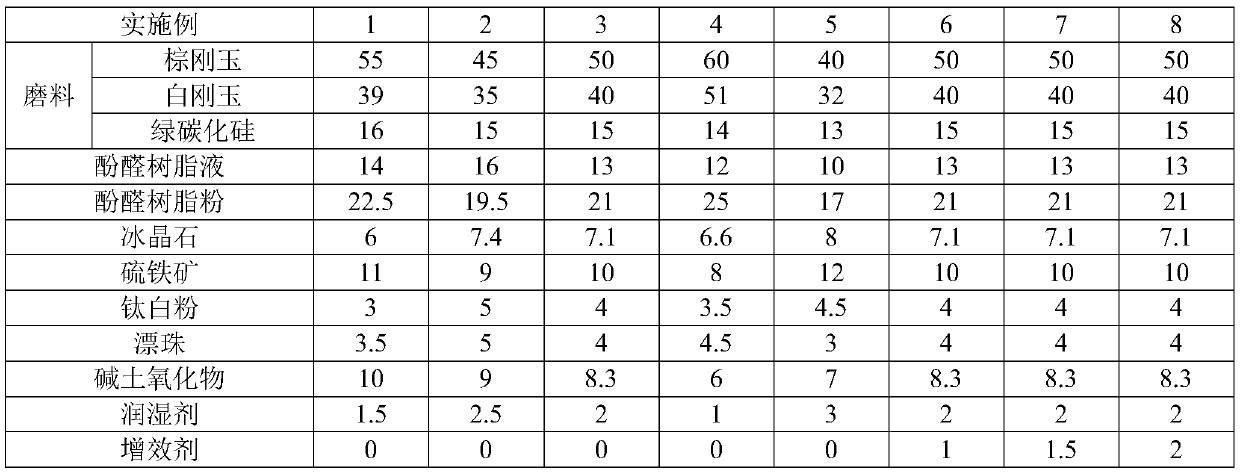

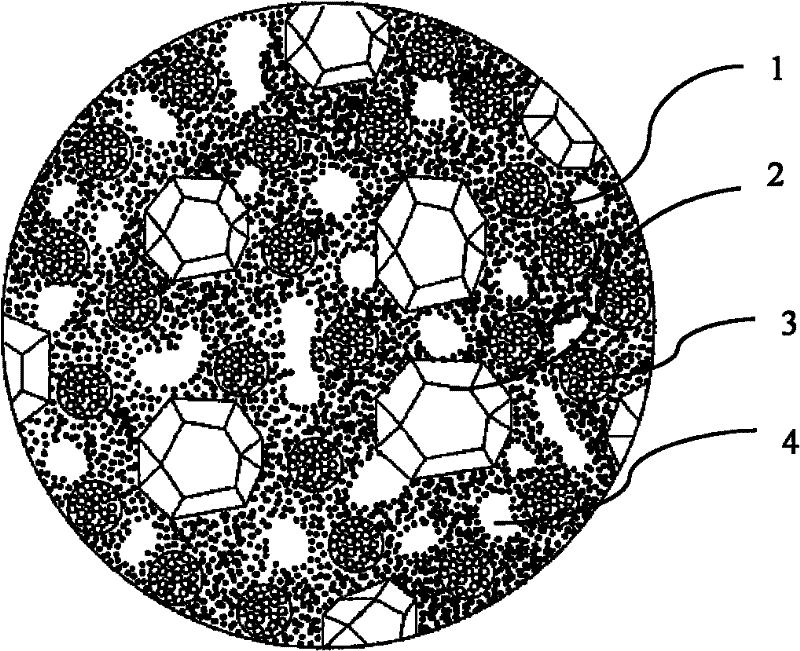

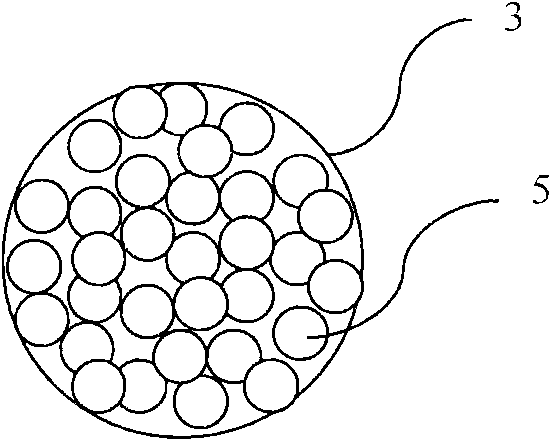

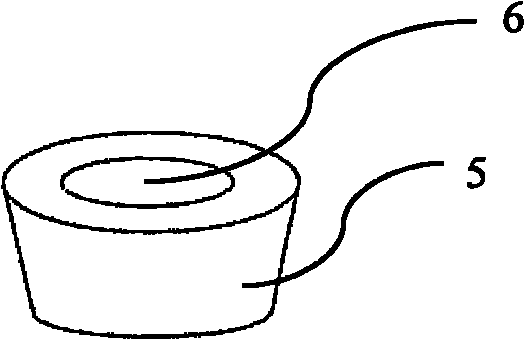

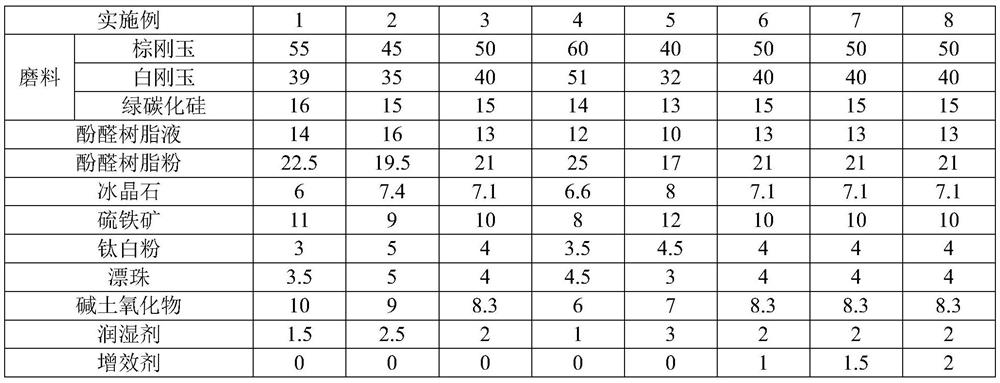

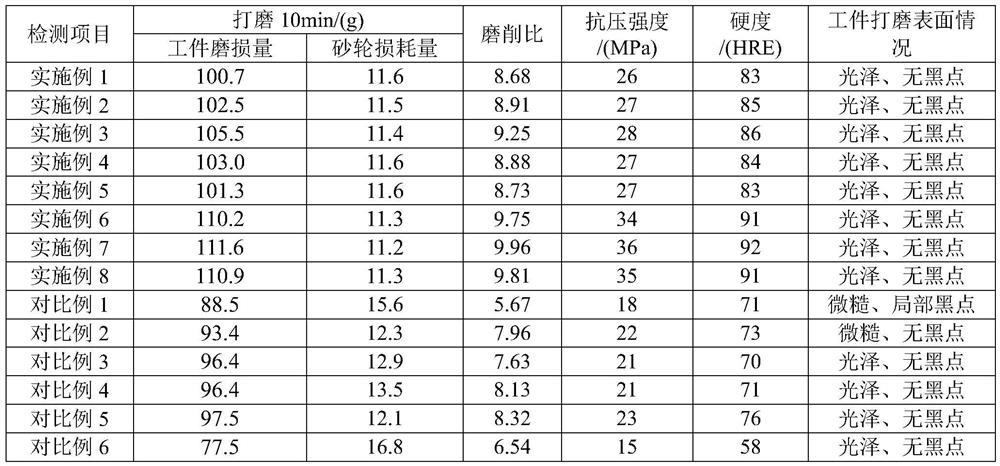

Resin grinding wheel and preparation method thereof

ActiveCN110977793AFull responseFully associativeAbrasion apparatusCompressive resistanceAlkaline earth oxides

The invention relates to a resin grinding wheel and a preparation method thereof, and belongs to the technical field of resin grinding wheel production, and the resin grinding wheel comprises the following raw materials of an abrasive, phenolic resin liquid, phenolic resin powder, cryolite, pyrite, titanium dioxide, floating beads, alkaline earth oxide and a wetting agent. According to the resin grinding wheel, the raw materials are cooperated, under the conditions that the polished surface of a workpiece is glossy and free of black spots, the resin grinding wheel has high workpiece abrasion loss and grinding ratio and low grinding wheel loss, the service life of the resin grinding wheel is prolonged, meanwhile, the resin grinding wheel further has high compressive strength and hardness, and the resin grinding wheel has a good using effect. According to the preparation method of the resin grinding wheel, by adding the annular magnetic field, twice mechanical pressing and twice curing,the raw materials are fully reacted and self-combined, the density and bonding strength of the resin grinding wheel are improved, the resin grinding wheel shows good comprehensive performance, and meanwhile the preparation method has the advantage of being convenient to control.

Owner:郑州九天工贸有限公司

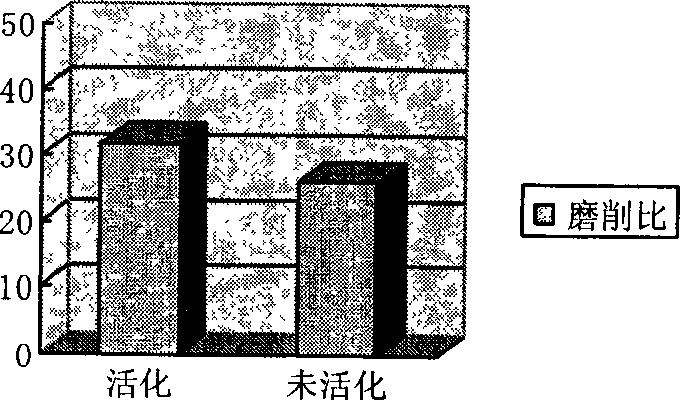

Method of manufacturing electroplating cubic boron nitride tool by using surface activation treatment technology

The invention discloses an electroplating cubic boron nitride tool manufacturing method of adopting surface activation processing. The method includes cubic boron nitride pretreatment, tool matrix pretreatment, electroplating solution preparation, and CBN tool electroplating; CBN pretreatment adopts sensitizing and activating treatment; finally dipping CBN in electroplating solution to electroplate. The advantages of the invention are improving CBN grain surface activation in CBN pretreatment, forming dispersal palladium particle at CBN surface, increasing binding force between CBN and plate, processing efficiency and using life, and economizing CBN.

Owner:TIANJIN UNIV

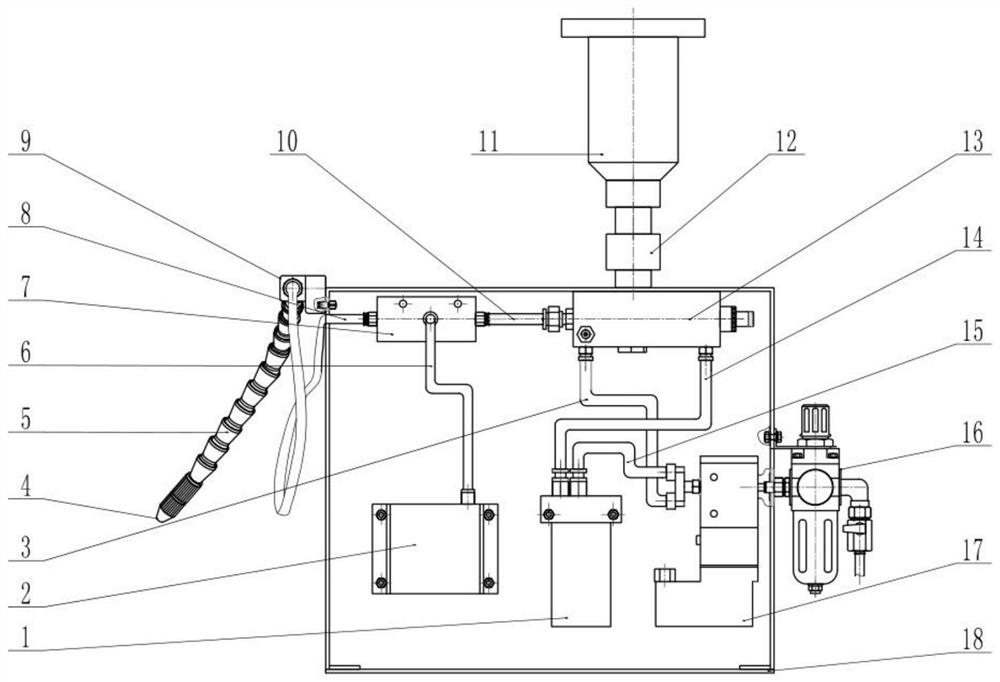

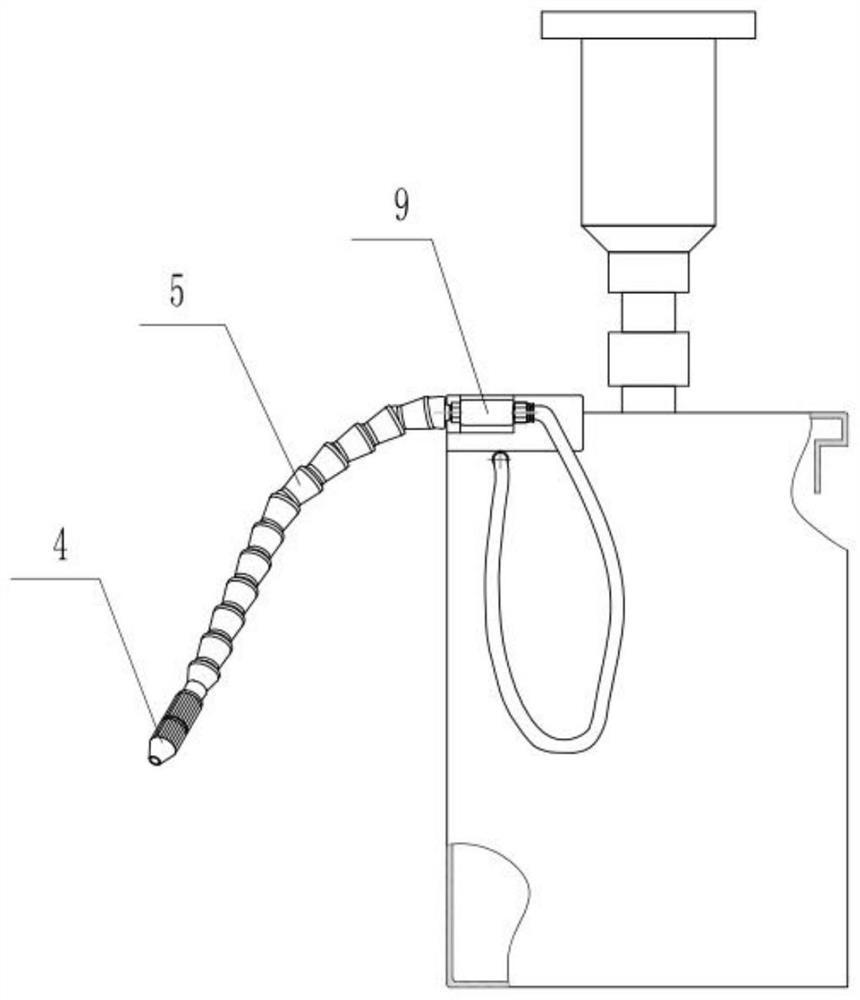

Electrostatic micro-lubricating based cutting device

PendingCN111993283AGood lubricating and cooling effectImprove processing qualityGrinding machinesLubricationElectromagnetic valve

The invention discloses an electrostatic micro-lubricating based cutting device. The device comprises a box body, wherein a liquid storage device used for storing cutting fluid is arranged at the topof the box body, an air source adjusting processor is arranged on the side surface of the box body, a pneumatic plunger pump, an electromagnetic valve, an electrostatic generator, a gas-liquid electric converging device and a pneumatic frequency generator are arranged in the box body, the air source adjusting processor is connected with the electromagnetic valve in the box body, a first air pipe and a third air pipe are arranged on the electromagnetic valve, the electromagnetic valve is connected with the pneumatic plunger pump through the first air pipe, the electromagnetic valve is connectedwith the pneumatic frequency generator through the third air pipe, and the pneumatic frequency generator is connected with the pneumatic plunger pump through a second air pipe. The electrostatic micro-lubricating based cutting device has the beneficial effects that the charged lubricating fluid under the condition of electrostatic micro-lubrication has better lubricating and cooling capacity, sothat the processing quality of a workpiece is improved, the use of the lubricating fluid is reduced, and the environment-friendly benefit can be further met.

Owner:ZHEJIANG UNIV OF TECH

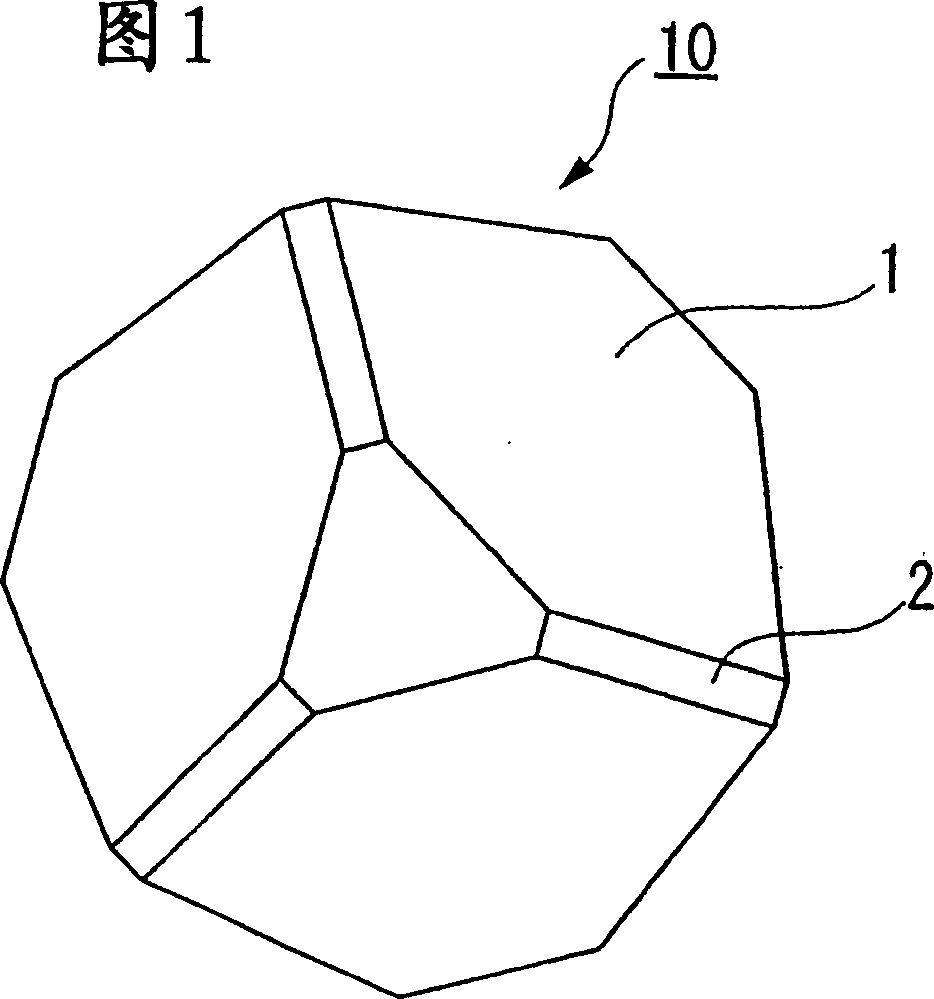

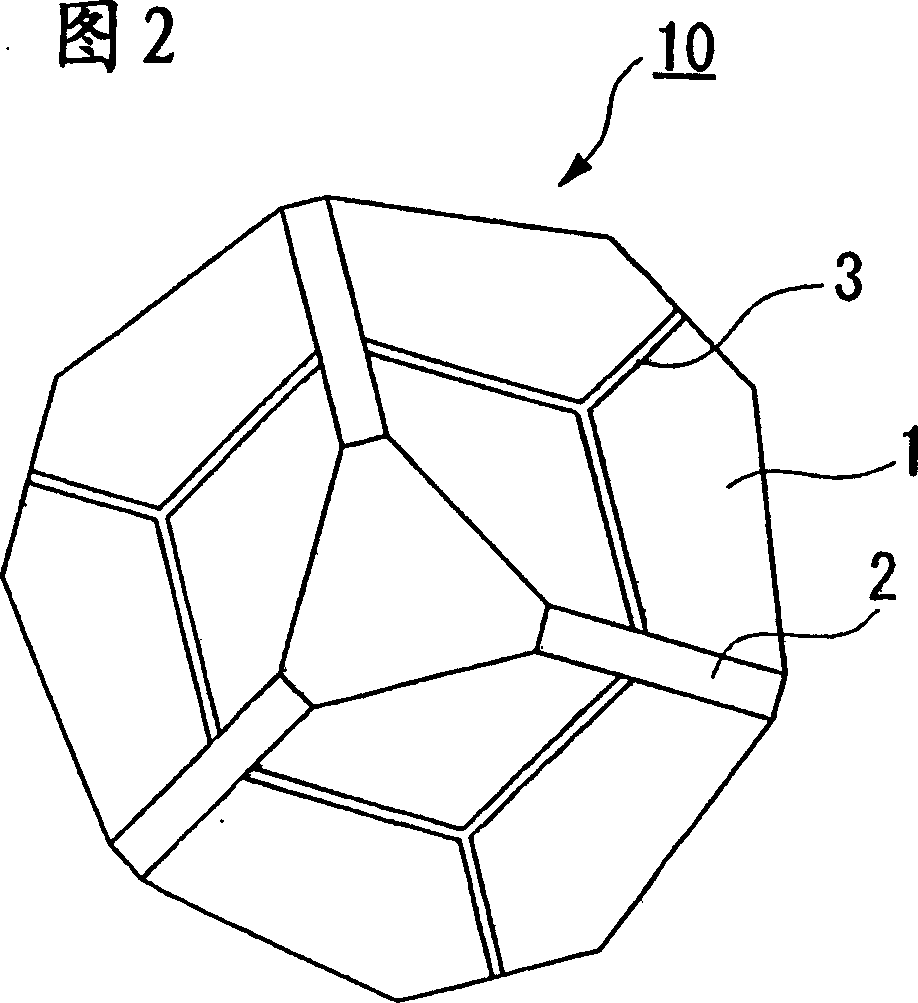

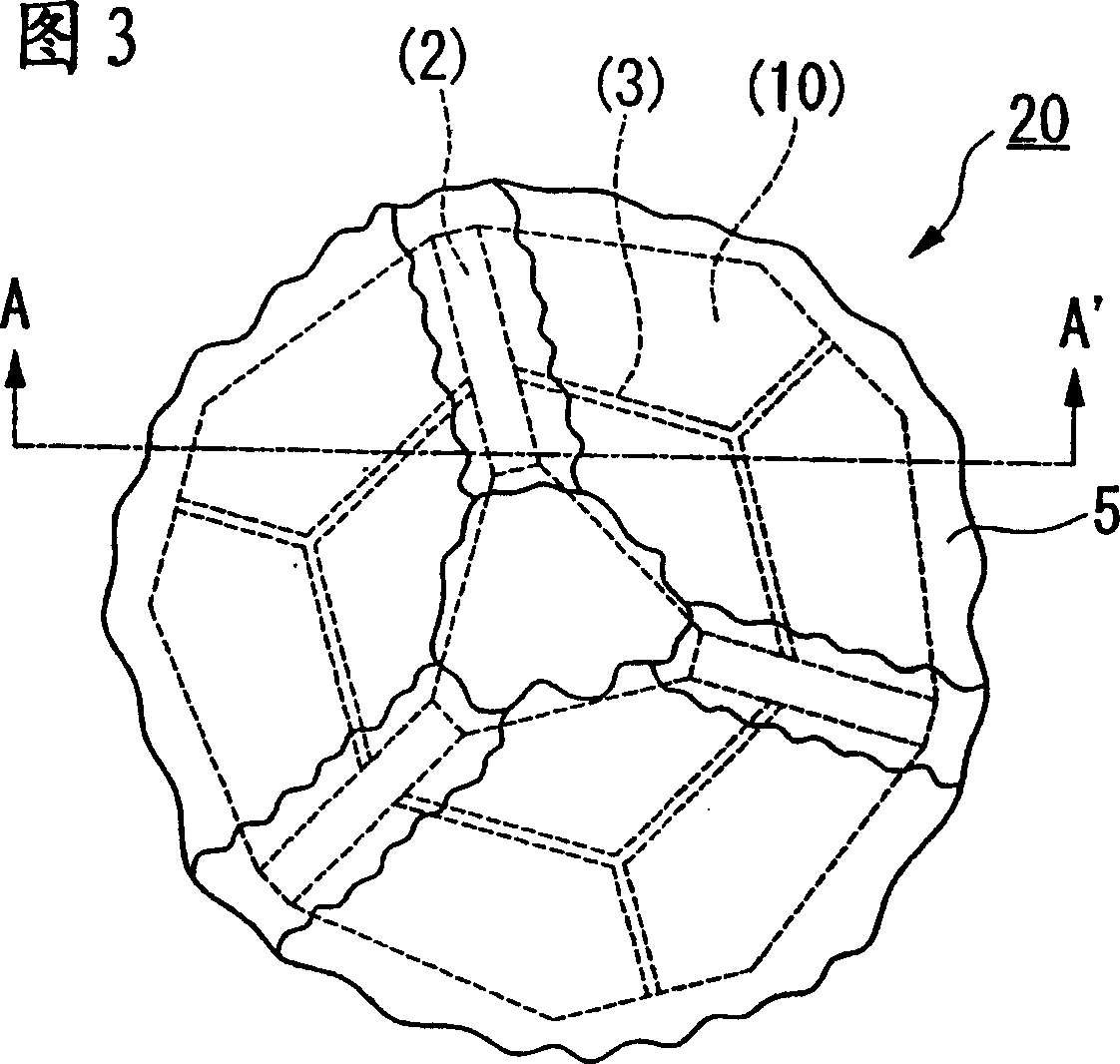

Metal-coated cubic boron nitride abrasive grain, production method thereof, and resin bonded grinding wheel

ActiveCN1723254AIncrease grinding ratioSimplify the manufacturing processOther chemical processesAbrasion apparatusGrindstoneBoron nitride

Cubic boron nitride abrasive grains which have been provided, on the surface thereof, with grooves having a ratio (w / d) of a width (w) to a depth (d) of less than 1 and a ratio (w / L) of a width (w) to a longth (L) of less than 0.1, and then coated with a metal. The cubic boron nitride abrasive grains exhibit an improved holding power (binding strength) between the metal coating film and the cubic boron nitride abrasive grain, and thus can be used for producing a resin-bonded grindstone which exhibits the combination of a high grinding ratio (long life) and a low grinding power value (good cutting quality).

Owner:SHOWA DENKO KK

Heavy-load resin grinding wheel for billet grinding and manufacturing method thereof

ActiveCN109759962AReduce brittle failureIncrease grinding ratioAbrasion apparatusGrinding devicesPyriteGrinding wheel

The invention relates to a heavy-load resin grinding wheel for billet grinding and a manufacturing method thereof. The manufacturing method comprises the steps that a coating material is used for forming a coating film on the abrasive particle surfaces, and coated abrasive particles are obtained; the coated abrasive particles and a binding agent are mixed, and a molding material is obtained; hot pressing is carried out on the molding material to obtain a grinding wheel blank; heat treatment is carried out on the grinding wheel blank, and the heavy-load resin grinding wheel for billet grindingis manufactured; and the elastic modulus of the coating material is at least 12% lower than the elastic modulus of the binding agent, wherein the coating material comprises polyvinyl butyral powder, the polyvinyl butyral powder accounts for more than 65% of the mass fraction of the coating material, and the binding agent is a mixture of thermosetting resin powder, pyrite powder, cryolite powder, lime powder and the binding agent. By means of the method, the impact load generated in the grinding wheel grinding process is weakened, damage of impact force generated during grinding to the abrasiveparticles can be effectively reduced, brittle failures in the using process of the grinding wheel are effectively reduced, and the grinding ratio of the grinding wheel is improved.

Owner:昆山鑫轮超硬磨具有限公司

Microcrystalline ceramic corundum abrasive and manufacturing method thereof

ActiveCN109956741AImprove grinding effectHigh removal rateOther chemical processesCalcium Chloride HexahydrateUltimate tensile strength

The invention discloses a microcrystalline ceramic corundum abrasive and a manufacturing method thereof. According to the abrasive of the invention, 2.2-2.4 parts by weight of lanthanum nitrate hexahydrate and 8-10 parts of dilute nitric acid with the mass fraction of a solute being 5-10% modify 71-82 parts by weight of aluminum chloride hexahydrate, and then the product passes through high-temperature atomized sodium hydroxide gel with the mass fraction of a solute being 10% to obtain 30-35 parts by weight of alumina-based ceramic micro-powder. The abrasive of the invention has the technicaleffects of microcrystalline structure, fine and dense cutting edge, high strength, good toughness, good self-sharpening performance, high removal rate of grinding and high grinding ratio.

Owner:SHANDONG TIANHUI GRINDING WEAR TECH DEV CO LTD

Self-lubricating grinding tool and preparation method thereof

InactiveCN101758463BSatisfy Hardening RequirementsSustained and effective releaseAbrasion apparatusMachine partsHigh surface

Owner:ZHEJIANG UNIV OF TECH

Cooling liquid used for aluminium alloy grinding and manufacturing method thereof

ActiveCN101942353BIncrease grinding ratioImprove diffusivityLubricant compositionMetallurgyDistilled water

The invention provides a cooling liquid which is matched with any grinding wheel and can grind aluminum alloy components, and ensure the component dimensional accuracy and the surface roughness requirement. The cooling liquid of the invention comprises the following components by weight percent: 5%-8% of neutral soap, 15%-20% of colleseed oil, 3%-6% of glycerol, 60%-70% of distilled water, 6%-8% of defoamer and 11%-15% of water.

Owner:AVIC STANDARD PARTS MFG

Resin sand wheel containing sulfuric acid slag for milling steel rail

The invention discloses a resin sand wheel containing sulfuric acid slag for milling a steel rail. The resin sand wheel is prepared from the following substances in weight percentage: 50-70% of corundum, 15-25% of brown fused alumina, 0.5-3% of furfural, 8-14% of phenolic resin powder, 3-6% of barite, 2-10% of kryocide and 0.5-5% of the sulfuric acid slag, wherein the granularity of the corundum is 12-16 meshes; and the brown fused alumina is high-temperature roasted brown fused alumina. According to the invention, the sane wheel is manufactured by the sulfuric acid slag, so that not only can the production cost be reduced, but also the pollution of the sulfuric acid slag to an environment is effectively reduced, thus being of great significance to environmental friendliness.

Owner:CHANGZHOU HONGFU GRINGDING WHEEL

A kind of resin grinding wheel and preparation method thereof

ActiveCN110977793BIncrease grinding ratioExtended service lifeAbrasion apparatusBlack spotCompressive strength

The invention relates to a resin grinding wheel and a preparation method thereof, belonging to the technical field of resin grinding wheel production. The raw materials of the resin grinding wheel include abrasive, phenolic resin liquid, phenolic resin powder, cryolite, pyrite, titanium dioxide, floating beads, alkaline earth oxide ,lubricant. The resin grinding wheel, through the synergistic effect between the raw materials, makes the resin grinding wheel have a higher workpiece wear and grinding ratio under the condition of the polished surface of the workpiece and no black spots, and also has a lower grinding wheel loss. The service life of the resin grinding wheel is improved, and the resin grinding wheel also has good compressive strength and hardness, so that the resin grinding wheel has a good use effect. The preparation method of the resin grinding wheel, by adding a circular magnetic field, twice machine pressing, and twice curing, the raw materials are fully reacted and self-combined, the density and bonding strength of the resin grinding wheel are increased, and the resin grinding wheel shows good comprehensive performance. , but also has the advantage of being easy to control.

Owner:郑州九天工贸有限公司

Grinding method for superhard silicon carbide ceramic nano mirror

InactiveCN100436054CImprove processing efficiencyIncrease grinding ratioOptical surface grinding machinesAbrasive surface conditioning devicesGrinding wheelMachine tool

The superhard silicon carbide ceramic nanometer mirror grinding process includes grinding the workpiece with dressed and shaped coarse diamond wheel in Z direction for plastic domain grinding with the cutting depth controlled within 100 nm; shifting the coarse diamond wheel in X direction for the distance fx and performing the next grinding so as to form envelope trace of height he on the surface of the workpiece and form flat smooth nanometer mirror. In the conditions of proper grinding wheel diameter Dish washer, fx smaller than 100 microns, the envelope trace height he will smaller than 15 nm. The present invention makes it possible to realize super precision surface machining in the machine tool of only micron level or submicron level precision. The present invention has low cost, great grinding ratio and high machining efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Aspheric surface abrasive belt grinding and polishing tool based on hydraulic servos

InactiveCN102814714BOvercoming the problem of inaccurate force controlControl the polishing pressureBelt grinding machinesPositioning apparatusHydraulic cylinderSolenoid valve

The invention relates to an aspheric surface abrasive belt grinding and polishing tool based on a hydraulic servos. The aspheric surface abrasive belt grinding tool comprises a hydraulic servo system and an abrasive belt tool system connected through a link mechanism, and the abrasive belt tool system comprises an abrasive belt driven by a tool motor, an upper foot support rod and a lower foot support rod, wherein the upper foot support rod and the lower foot support rod are connected through a third bearing. The hydraulic servo system comprises a hydraulic cylinder, the hydraulic cylinder is sequentially connected with a single-way throttle valve, a three-position four-way solenoid valve, an overflow valve, a hydraulic pump, a filter and an oil tank, and the hydraulic servo system adjusts a grinding and polishing pressure of the abrasive belt by controlling strokes of the link mechanism and stabilizes the grinding and polishing pressure through the overflow valve. The aspheric surface abrasive belt grinding and polishing tool solves the problem that the grinding and polishing pressure of the abrasive belt in a grinding and polishing process of aspheric surface optical elements is unstable, and simultaneously the aspheric surface abrasive belt grinding and polishing tool has the advantages of being capable of self adapting to workpiece curved surfaces, good in effects of discharging grinding and polishing sweeps, big in grinding ratio, high in grinding and polishing efficiency, simple in structure and low in manufacture cost.

Owner:NINGBO UNIV

Modified resin grinding wheel and manufacturing method thereof

InactiveCN107953275ALower surface energyGood dispersionBonded abrasive wheelsGrinding devicesFoaming agentToluene

The invention discloses a modified resin grinding wheel which comprises a grinding body and a reinforcing plate arranged inside the grinding body for strengthening rotating strength of the grinding body. The modified resin grinding wheel is characterized in that the grinding body is prepared from the following raw materials in parts by weight: 52-68 parts of abrasive materials, 9-12 parts of bisphenol A epoxy resin, 1-3 parts of a coupling agent, 1-3 parts of methylbenzene, 9-12 parts of a toluene solution, 6-9 parts of a foaming agent and 6-8 parts of auxiliaries. The modified resin grindingwheel has the characteristics of being good in polishing and grinding performance, high in grinding ratio, low in grinding wheel wear rate, non-toxic, light and low in cost.

Owner:NINGBO DAHUA GRINDING WHEEL

Abrasive belt grinder for metal polishing

ActiveCN103182670BImprove resection rateIncrease grinding ratioBelt grinding machinesGrinding/polishing safety devicesGear wheelEngineering

The invention discloses an abrasive belt grinder for metal polishing. A grinding device is arranged on the middle part of the abrasive belt grinder; a plate receiving chain conveying device is arranged at the front end of the abrasive belt grinder; a plate discharging chain conveying device is arranged at the rear end of the abrasive belt grinder; a two-dimensional shifting device is arranged on the upper part of the abrasive belt grinder; in the grinding device, a motor, a shaft coupler, a double-output shaft gearbox and a sliding polishing roller are arranged on the upper part of a rack; and a slide gear clamp is arranged on the lower part of the rack. According to the abrasive belt grinder for metal polishing, an abrasive belt is used as a grinding tool, so that the abrasive belt grinder for the metal polishing has a higher resection rate and a higher grinding ratio in comparison with the conventional steel wire brush polishing way, and therefore, a production efficiency problem and a surface burning problem of plate polishing are solved, and the service life of the plate is prolonged. Meanwhile, the distance between the grinding rollers in the grinding device is adjusted by the spring, so that the pressure, which is applied to the two sides of the starting sheet by the grinding roller, can be adjusted to be equal, and therefore, the uniformity quality of the plate surface grinding is improved.

Owner:JIANGXI NERIN EQUIP

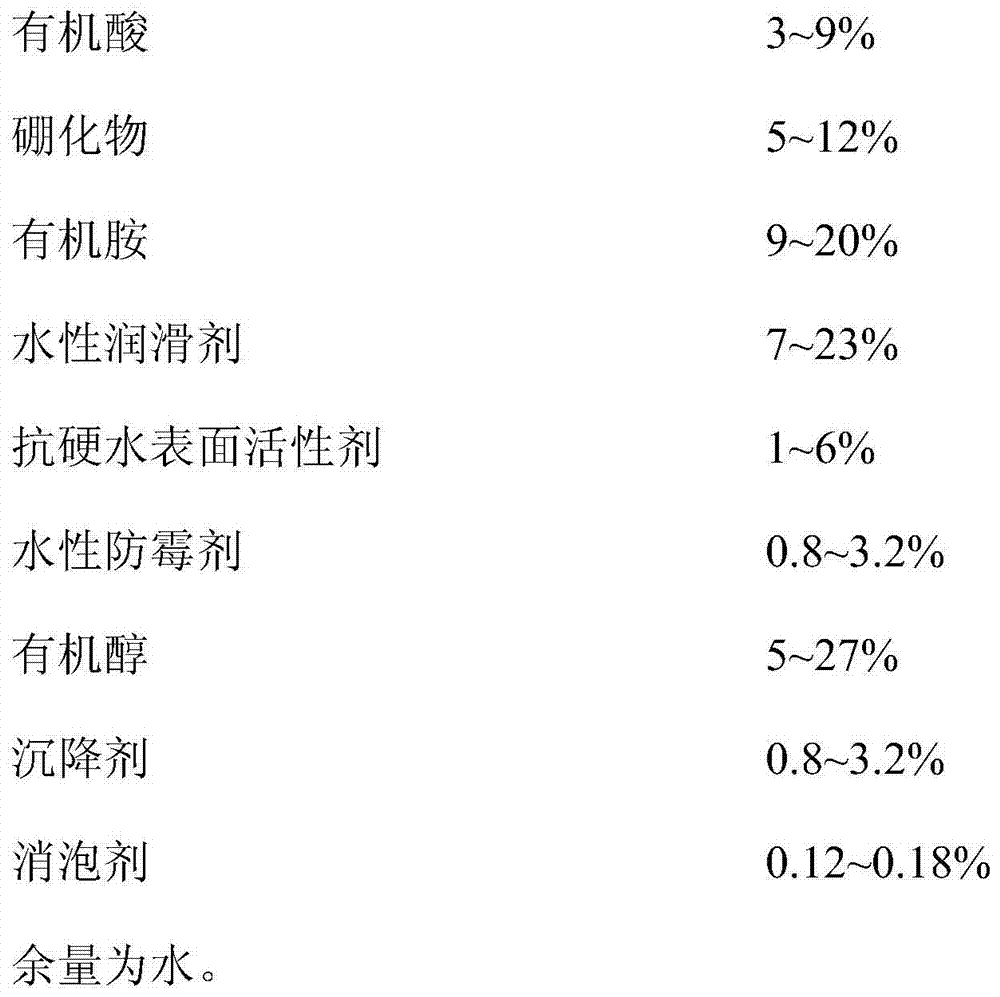

Full-synthetic glass grinding fluid

ActiveCN103525533BImprove general performanceGuaranteed service lifeLubricant compositionWater basedBoride

The invention discloses an environment-friendly glass grinding fluid, which is efficient, and long in service. The full-synthetic glass grinding fluid is prepared from an organic acid, a boride, an organic amine, a water-based lubricant, a hard water-resisting surfactant, a water-based mould inhibitor, an organic alcohol, a settling agent, a defoaming agent and water in a mixing manner. The glass grinding fluid disclosed by the invention has excellent cooling property, anti-rotting ability and lubricating abrasion resistance, and outstanding hard water resistance, can be recycled for a long period of time, can ensure the working accuracy and the service life of a tool, and has excellent cleaning performance; the blocking phenomenon of a grinding wheel can be effectively prevented; the product is good in settleability; processing is facilitated; the product is free of poison, environment-friendly, free of pollution, small in smell, good in working performance, good in compatibility with a paint of equipment, low in pH value, free of bad effects on skin and the like; the phenomenon that the paint of the equipment peels off is not generated. The grinding fluid disclosed by the invention is simple in reparation method, low in cost, excellent in performance, and good in market prospect at present.

Owner:东莞太平洋博高润滑油有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com