Self-lubricating grinding tool and preparation method thereof

A self-lubricating and grinding tool technology, applied in abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of metal surface corrosion, human harm, easy precipitation of sulfur and odor, etc., and achieve the effect of meeting the hardening requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

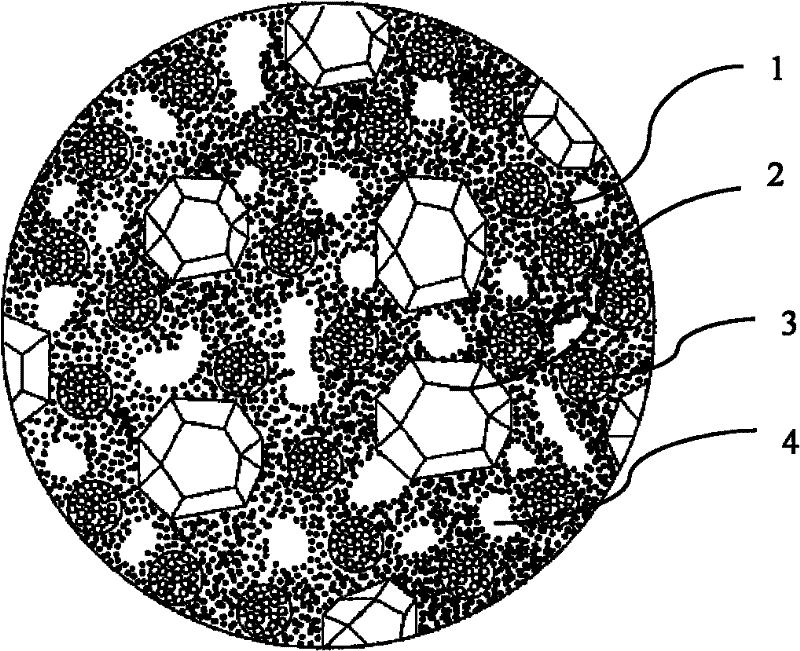

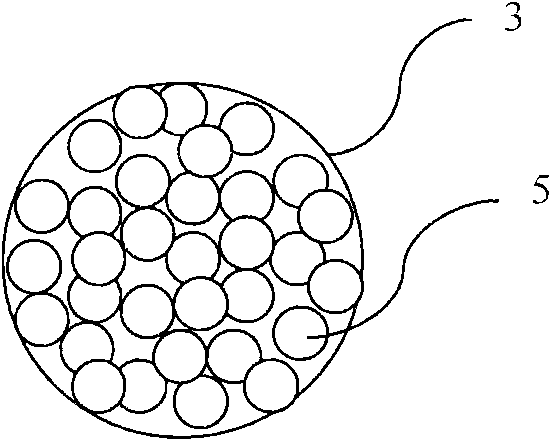

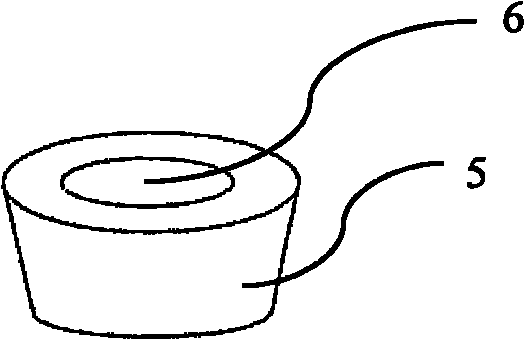

[0045] Such as figure 1 The self-lubricating abrasive tool shown is composed of four parts: binder 1, abrasive material 2, cyclodextrin inclusion compound agglomerated particles 3 and pores 4. Bonding agent 1 is used to consolidate abrasive grains and lubricant microcapsules; abrasive grain 2 cuts the workpiece during grinding; figure 2 As shown, the agglomerated particles 3 are composed of multiple cyclodextrin inclusion complex monomers 5, and the size is between 100 and 300 nm. During the grinding process, the agglomerated particles and each cyclodextrin inclusion complex monomer will be rubbed and squeezed. Under the action of force, the lubricant is released from the cyclodextrin inclusion compound to provide lubrication; the pores 4 can accommodate the lubricant and grinding debris entering the grinding area to improve the grinding conditions; as image 3 As shown, the cyclodextrin inclusion complex monomer 5 has an inner cavity 6, which is a non-polar cavity, and lubr...

Embodiment 2

[0047] A method for preparing the self-lubricating grinding tool described in embodiment 1, comprising the steps: (the parts of the following components are all calculated by weight)

[0048] (1) Preparation of β-cyclodextrin inclusion compound containing oily agent or extreme pressure agent: mix 5-20 parts of β-cyclodextrin and 100 parts of water, heat to 50-80°C to make β-cyclodextrin Saturated dextrin solution; add 20 to 50 parts of ethanol solution containing 1 to 3 parts of oily agent or extreme pressure agent drop by drop under continuous stirring; control the temperature of the mixed solution to drop to room temperature at a rate of 10 ° C to 20 ° C per hour, continue Stir for 2 to 4 hours; place the inclusion system in a refrigerated environment at around 0°C for 24 hours, filter out the precipitate, wash and dry to obtain the inclusion compound of oily agent or extreme pressure agent and β-cyclodextrin; use Airflow milling classifier, crush the obtained β-cyclodextrin...

Embodiment 3

[0051] The self-lubricating abrasive tool of this embodiment is prepared by the following method:

[0052] 1) Preparation of lubricant microcapsules (inclusion compounds) with β-cyclodextrin (β-CD) as the wall material:

[0053] The representative natural polymer material β-cyclodextrin is selected as the microcapsule wall material, the oily agent ethylene glycol oleate (T403) and the extreme pressure agent sulfurized isobutylene (T321), chlorinated paraffin (T301), diphosphite N-butyl ester (T304) is used as the core material of microcapsules to prepare lubricant microcapsules.

[0054] Mix 10 parts of β-cyclodextrin and 100 parts of water, heat to 60-65°C to make a saturated solution of β-cyclodextrin; add drop by drop an ethanol solution containing 1 part of oily agent or extreme pressure agent 20 parts; control the temperature of the mixture to drop to room temperature at a rate of 15°C per hour, and continue to stir for 2 hours; place the inclusion system in a refrigerat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com