Fabricated steel plate road structure and construction method thereof

A road structure and construction method technology, applied to roads, roads, side ditches/curbs, etc., can solve the problems of increasing material turnover times and service life, increasing capital investment, large construction waste, etc., to increase turnover times and The effect of service life, emission reduction and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

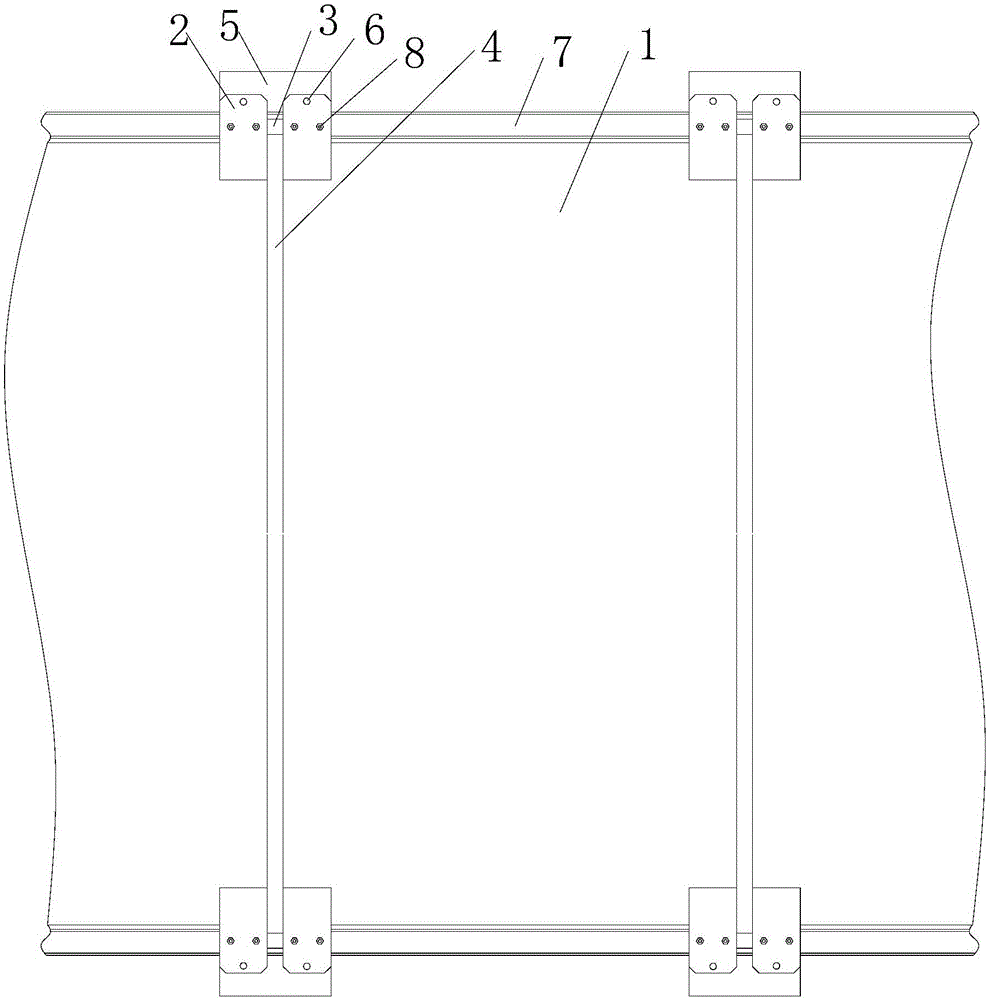

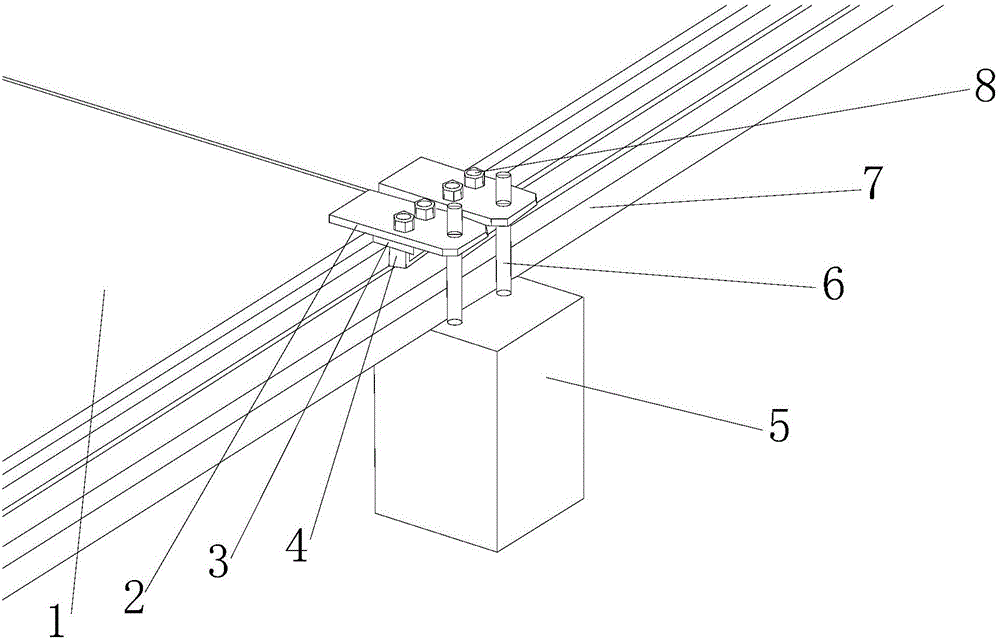

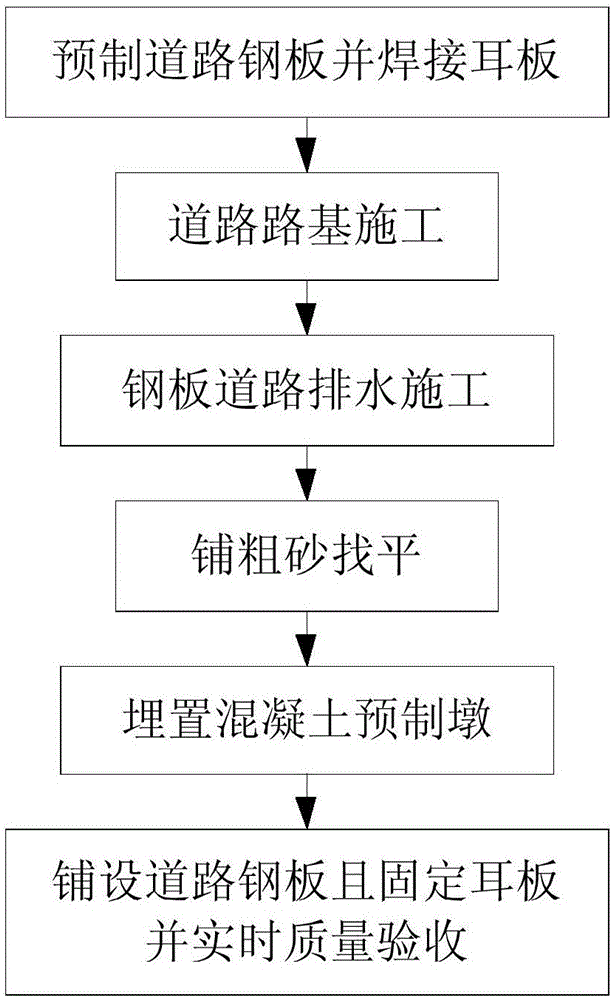

[0032] Such as figure 1 and figure 2 As shown, an assembled steel plate road structure according to the present invention includes a plurality of rectangular road steel plates 1 successively laid on the road subgrade along the length direction of the road subgrade, and two adjacent road steel plates 1 contact the bottom of the gap and Extending into the road subgrade, water guide grooves 4 are provided. Concrete prefabricated piers 5 extending into the ground are arranged on both sides of the road subgrade and at the bottom of each water guide groove 4, and prefabricated concrete piers 5 are pre-embedded There are two steel bars 6, and each row of concrete prefabricated piers 5 is provided with a drainage channel 7 which is located below the water outlet of the water guide channel 4 and discharges the road surface water to the sedimentation tank. There is an ear plate 2 that prevents the road steel plate 1 from moving. There are ear plate fixing through holes and ear plate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com