Electrostatic micro-lubricating based cutting device

A micro-lubrication and charging device technology, applied in grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of threatening the health of operators, splashing a lot of mist and water, and harming the health of workers, etc. Satisfy the benefits of green environmental protection, improve lubrication and heat transfer capacity, and improve the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings of the description.

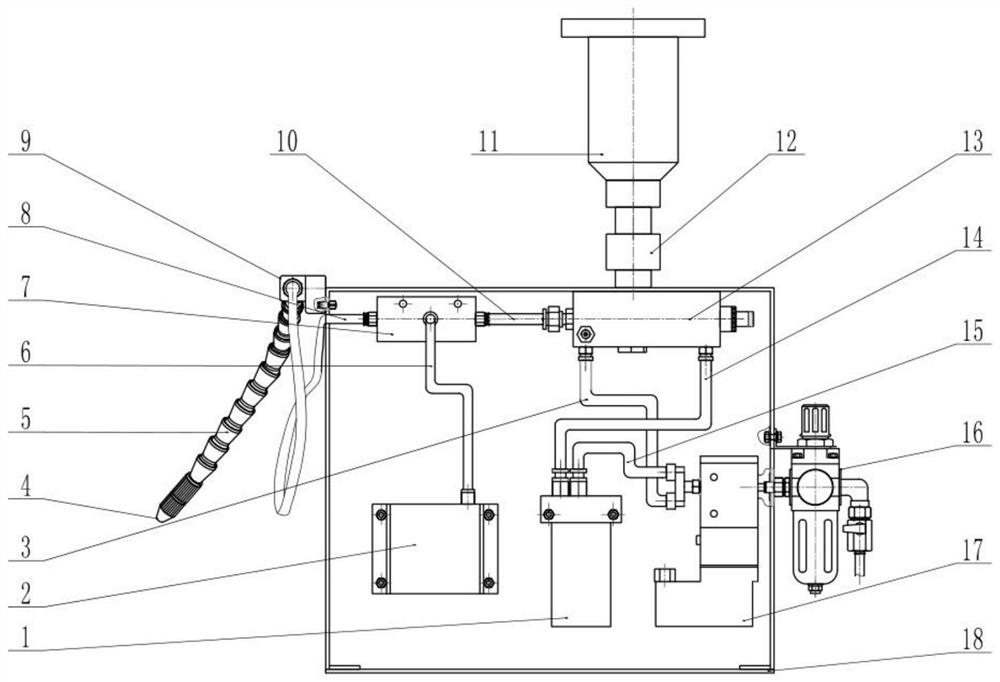

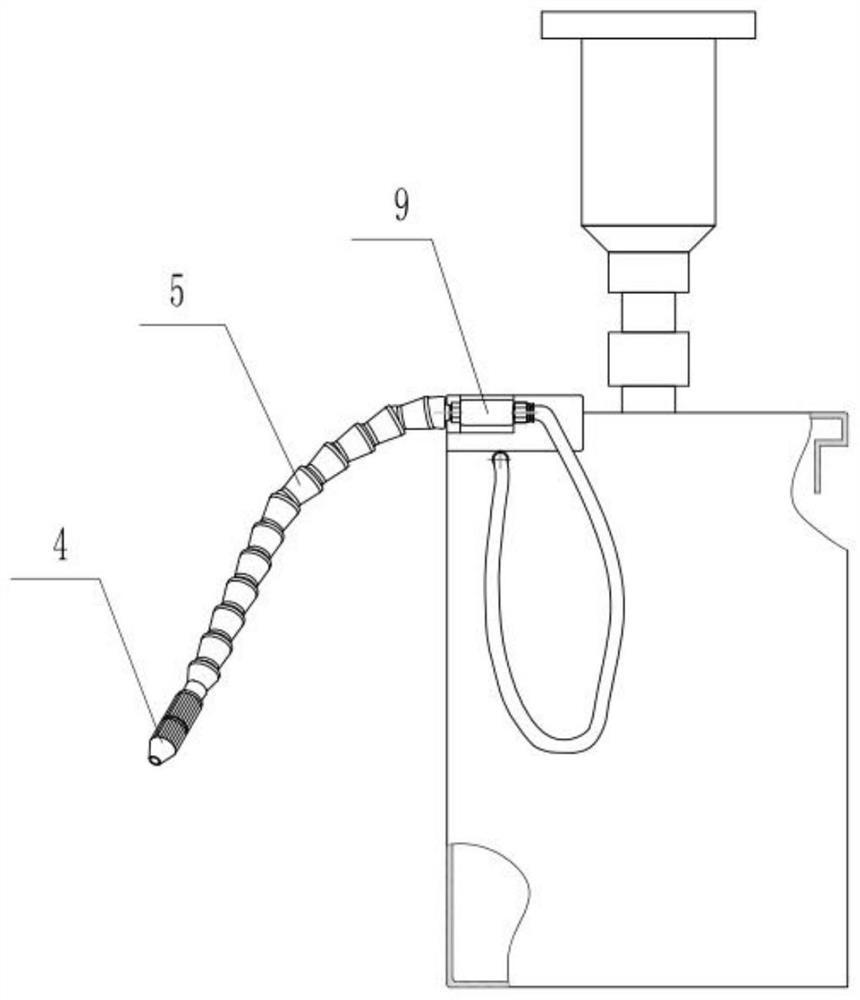

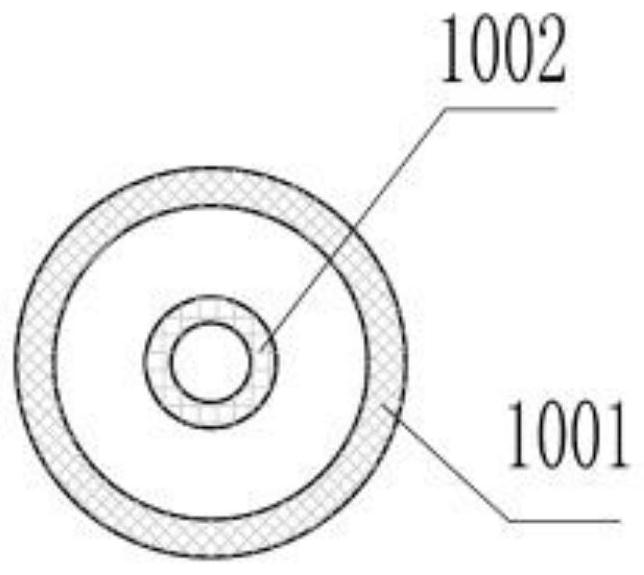

[0025] The purpose of the present invention is to explore the characteristics of existing hydraulic devices and the principle characteristics of plunger pumps and their applications, the application of pneumatic frequency generators and electrostatic generators, and proposes a device based on electrostatic micro-lubrication cutting, using Pneumatic plunger pump cooperates with pulse and frequency to control the entry of gas, and directly merges and charges through the confluence device in the box. This internal device has better applicability and higher durability in the actual factory processing environment, which is beneficial to ensure the required processing efficiency. During the electrostatic micro-lubrication grinding process, the electrostatic field accelerates the diffusion of carbon atoms and the dissolution of cementite, increases the rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com