Self-lubricating bearing device for high-temperature molten salt pump

A technology of self-lubricating bearings and high-temperature molten salt, which is applied to components, pumps, pump components, etc. of pumping devices for elastic fluids, and can solve the problems of insufficient lubrication of sliding surfaces, affecting the service life of pumps, increasing friction, etc. problem, achieve good lubrication and cooling effect, ensure stable operation and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

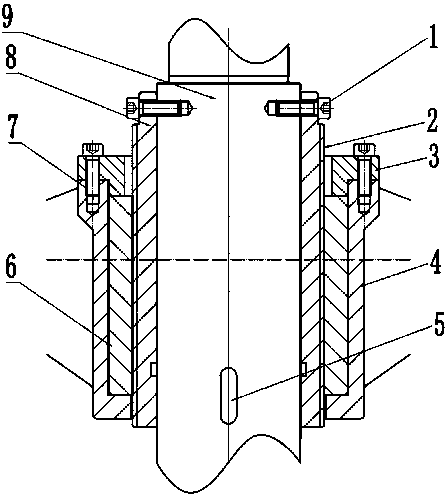

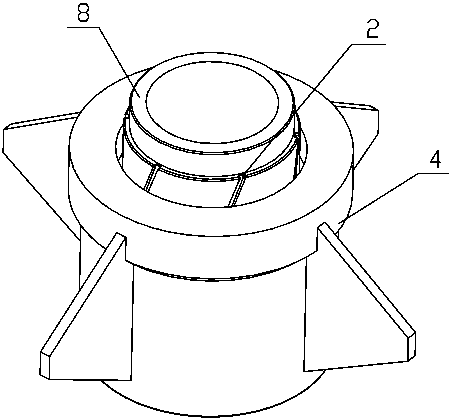

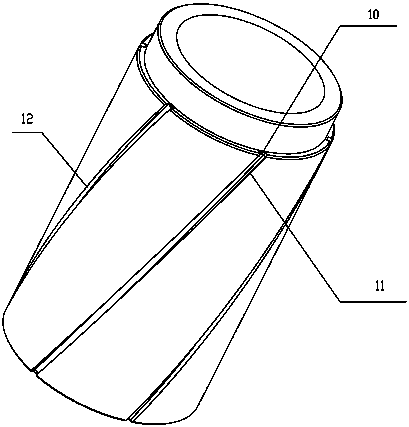

[0018] A self-lubricating bearing device for a high-temperature molten salt pump, including a shaft 9, a shaft sleeve 8, a bush 6 and a bearing seat 4, the shaft 9 is sleeved with a fixed shaft sleeve 8, and the shaft sleeve 8 is installed in the bearing housing 4 , A bushing 6 is set between the bearing seat 4 and the bushing 8, the bushing 6 is installed outside the bushing 8, the bushing 6 is installed in the bearing seat 4, and the lower end of the bearing seat 4 is bent inward to block the bushing 6 The upper end of the bearing seat 4 is fixed with the bushing gland 3 used to cover the bushing 6, the two ends of the bushing 8 protrude outside the bushing 6, and the two ends of the shaft 9 protrude to the bushing 8, the outer wall of the shaft sleeve 8 is evenly provided with a number of spiral channels 2, the lower end of the shaft sleeve 8 is provided with a lubricating medium inlet flow channel, and the upper end is provided with a lubricating medium outlet flow channel....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com