Processing technology of rigid flexible wheels of robot speed reducer

A processing technology and robot technology, which is applied in the processing technology field of the rigid flexible wheel of the new robot reducer, can solve the problems of high cost, easy damage to the finished bearing, and failure of the reducer, so as to achieve good lubrication and cooling effect, prolong the service life, The effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

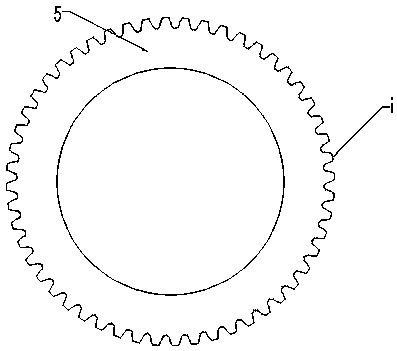

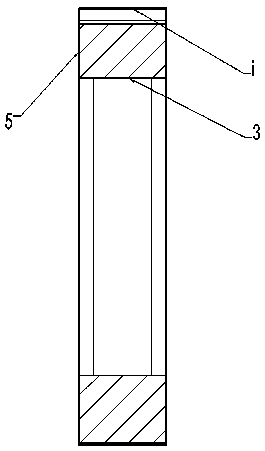

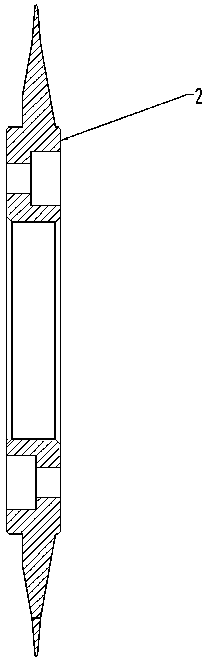

[0035] Examples such as Figure 3-8 As shown, the processing technology of the rigid flexible wheel of the robot reducer includes the following steps:

[0036] 1. Precision casting or forging the rigid flexible wheel 5 rough;

[0037] 2. Hot extruding the blank of the rigid flexible spline 5;

[0038] 3. Roughly machining the blank of the rigid flexible spline 5, roughing the outer circle and inner hole of the rigid flexible spline 5;

[0039] 4. Heat-treat the rough-machined rigid flexible wheel 5 to prepare for subsequent finishing;

[0040] 5. Based on the outer circle of the rigid flexspline 5, finish machining the outer tooth i of the rigid flexspline and the inner raceway e of the rigid flexspline, and leave allowances for subsequent ultra-finishing;

[0041] 6. Carry out heat treatment to the rigid flexible spline 5 after finishing;

[0042] 7. Superfinishing the rigid flexible wheel 5 by one-time clamping;

[0043] Take one end face of the rigid flexible wheel 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com