Grinding method for superhard silicon carbide ceramic nano mirror

A super-hard silicon carbide and nano-mirror technology, which is applied in the direction of optical surface grinders, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of high processing costs and high processing technology difficulties, and achieve easy mastery of technology and save The effect of fine grinding and fine grinding process and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

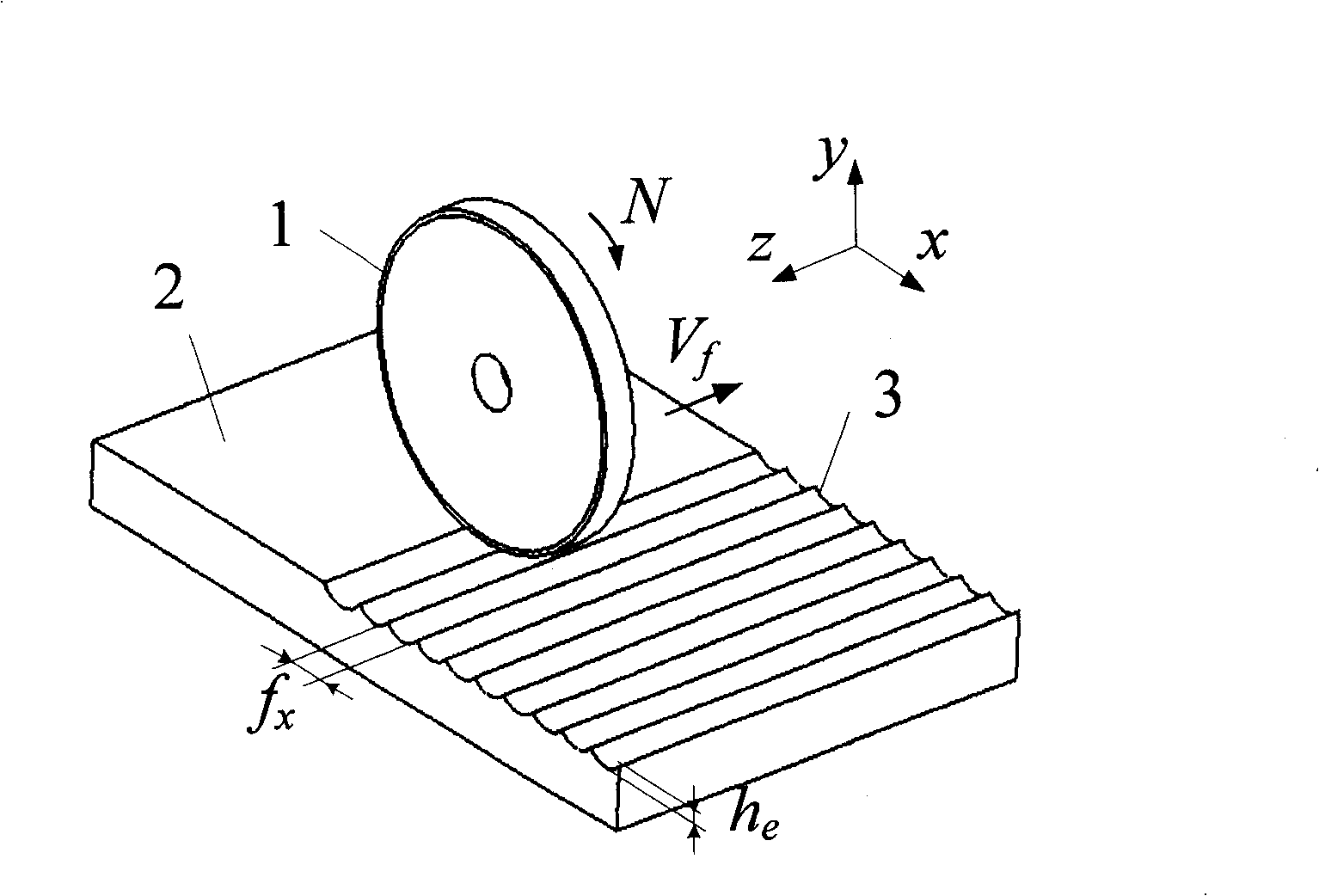

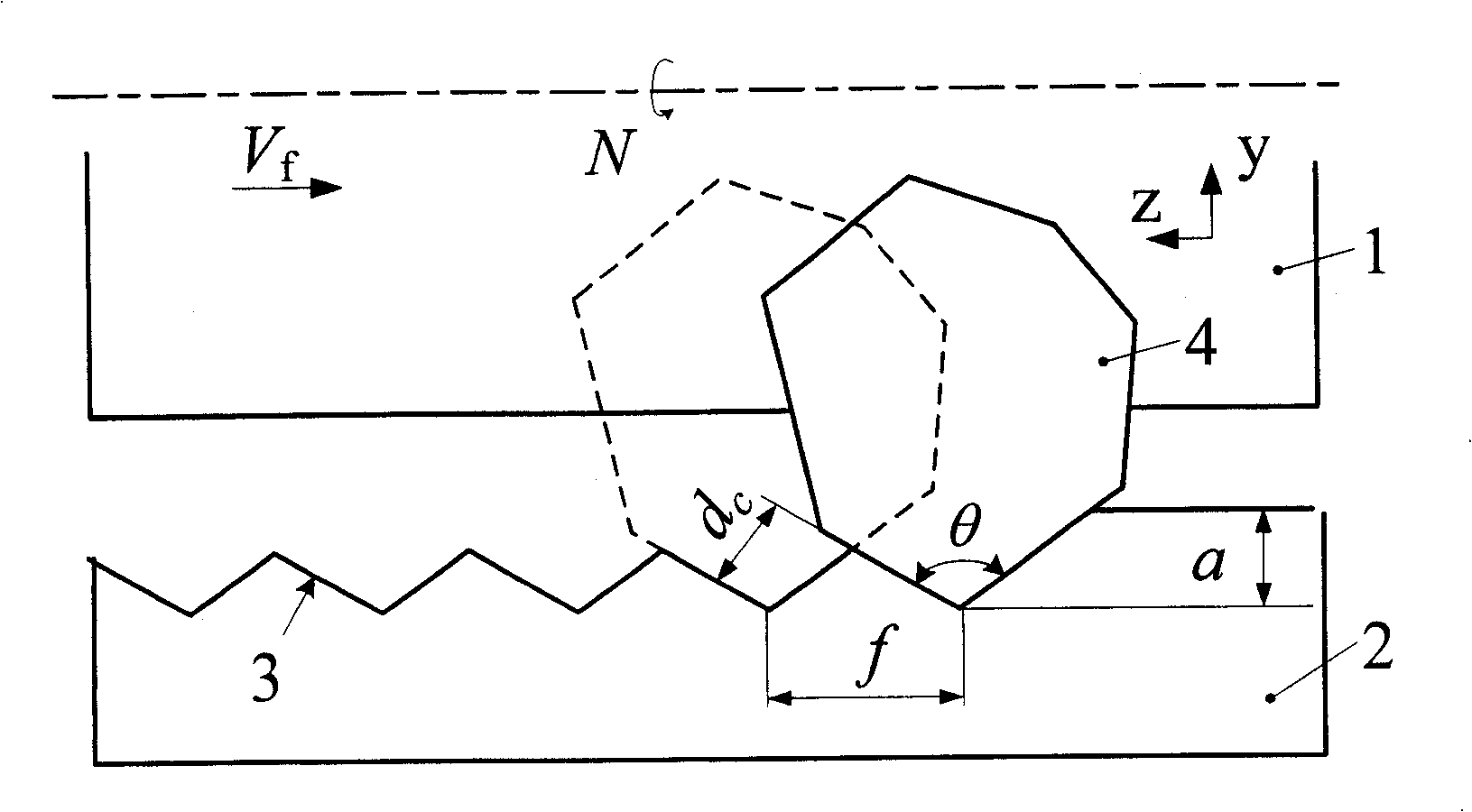

[0037] A #180 rough diamond grinding wheel with a diameter of 180 mm is used on a CNC precision grinding machine (SMRART B818), and the CNC system is used to drive the grinding wheel to travel along the axis of the grinding wheel to perform nano-mirror grinding on reaction sintered silicon carbide ceramics (RB-SiC). Use #180GC grinding stone to sharpen #180 diamond grinding wheel, so that the diamond abrasive grains on the working surface of the grinding wheel can fully emerge and maintain a certain edge height. The sharpening condition is: N=1500r / min, V f =600mm / min, f x =5mm, a=0.3mm, Σa=4mm, BM2 grinding fluid. After sharpening, use cast iron to trim the working surface of the diamond grinding wheel that has been edged to increase the number of effective abrasive grains n g , to increase the average edge angle θ of abrasive grains. Cast iron dressing conditions are: N=3000r / min, V f =1500mm / min, f x =0.1mm, a=5μm, Σa=0.1mm, BM2 grinding fluid.

[0038] During the gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com