Aspheric surface abrasive belt grinding and polishing tool based on hydraulic servos

A technology of hydraulic servo and hydraulic servo system, which is applied in the field of aspheric abrasive belt grinding and polishing tools based on hydraulic servo, can solve the problems of large grinding ratio and unstable grinding and polishing pressure, achieve stable normal force of grinding and polishing, overcome The effect of unstable force and overcoming the problem of inaccurate force control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

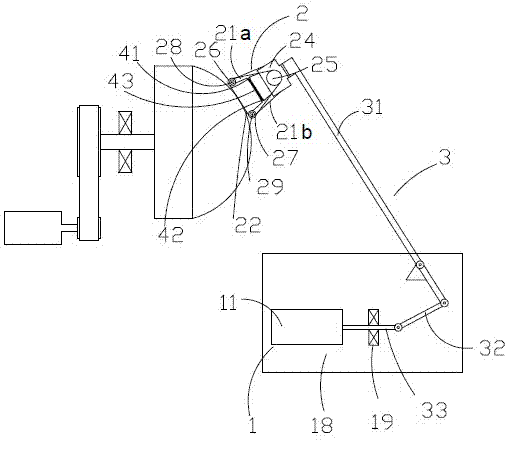

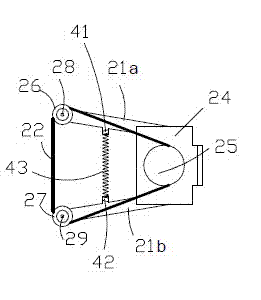

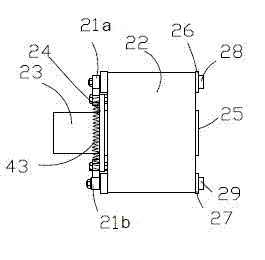

[0023] Figure 1 to Figure 5 Shown is the structural representation of the present invention.

[0024] one of them Figure 1 to Figure 5 The reference signs in are: hydraulic servo system 1, hydraulic cylinder 11, one-way throttle valve 12, three-position four-way solenoid valve 13, overflow valve 14, hydraulic pump 15, filter 16, fuel tank 17, workbench 18 , fixed block 19, abrasive belt tool system 2, third bearing 21, upper foot support rod 21a, lower foot support rod 21b, abrasive belt 22, tool motor 23, support plate 24, abrasive belt wheel 25, first sleeve 26, Second sleeve 27, first bearing 28, second bearing 29, link mechanism 3, long connecting rod 31, short connecting rod 32, hydraulic cylinder piston rod 33, first joint 41, second joint 42, spring 43.

[0025] An aspheric abrasive belt grinding and polishing tool based on hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com