Polishing method of non-spherical surface optical parts

A technology of optical parts and aspheric surfaces, applied in the field of machinery, can solve the problems that hinder the popularization of aspheric parts processing and production, the quality of parts surface finishing is uncertain, and the real-time control of polishing force cannot be controlled, so as to achieve the benefit of hardware design and The effect of software development, improving the quality of finishing processing, and overcoming the problem of inaccurate force control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

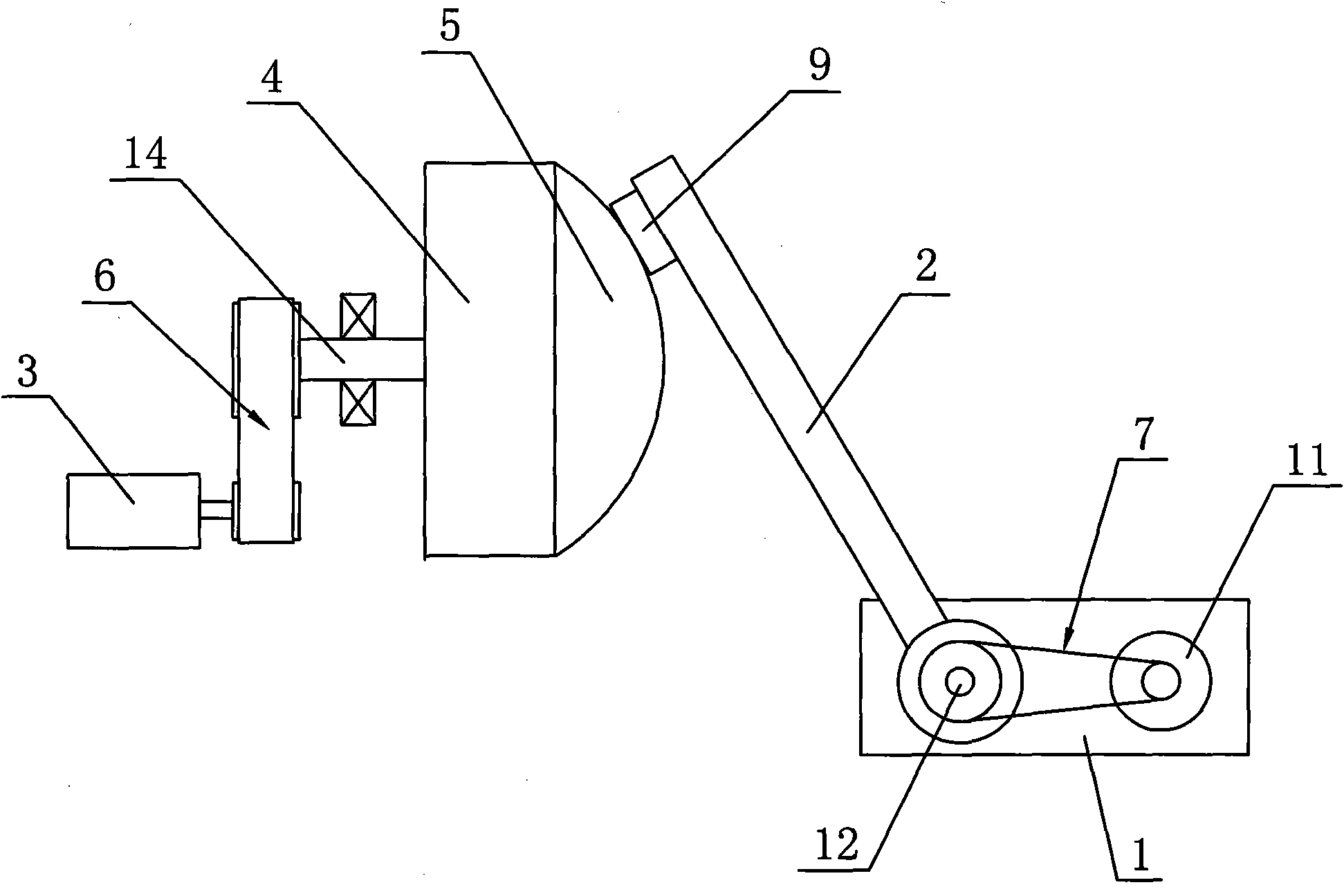

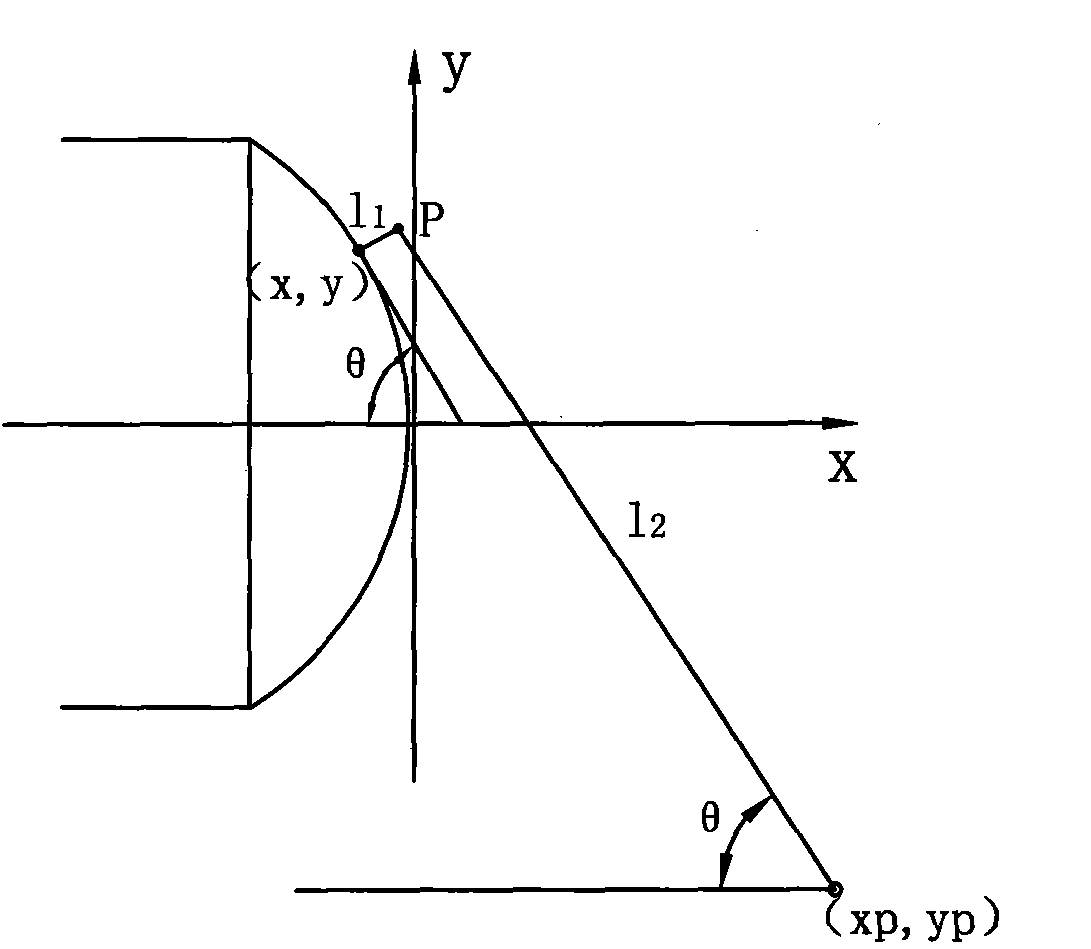

[0019] As shown in the figure, a method for polishing an aspheric optical part includes the following specific steps:

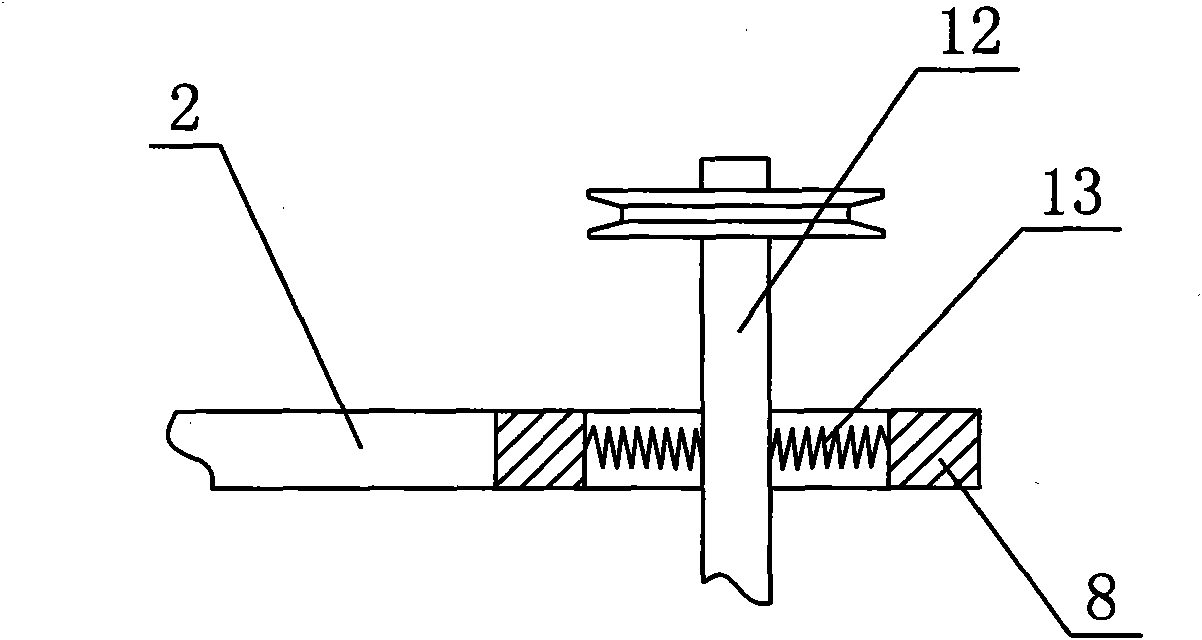

[0020] (1), the first motor 11 and the first transmission shaft 12 are installed on the servo workbench 1 in the CNC machine tool, and the first transmission mechanism 7 is connected on the first motor 11 to drive the first transmission shaft 12 to rotate, and then The turntable 8 is coaxially sleeved on the first transmission shaft 12, and a compliance control device composed of three evenly distributed springs 13 is connected between the turntable 8 and the first transmission shaft 12, and the turntable 8 is fixedly connected with one end of the rotating arm 2. , the other end of the rotating arm 2 is fixedly connected to the grinding tool 9;

[0021] (2), the second transmission mechanism 6 is connected on the second moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com