Patents

Literature

45results about How to "Suitable porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

Method for preparing human-like collagen haemostatic sponge in scale

InactiveCN101695581AImprove mechanical propertiesGood biocompatibilityAbsorbent padsBandagesCross-linkBiocompatibility Testing

The invention discloses a method for preparing human-like collagen haemostatic sponge in scale, which comprises the following steps: dissolving human-like collagen into 1.0 to 2.0 percent solution; dissolving chitosan into 0.5 to 1.0 percent solution by dilute acid; mixing the two solutions evenly, adding glycerin and / or sorbitol into the solution, mixing, stirring and filtering the solution, and then defoaming the solution in vacuum; injecting the mixed solution into a die, pre-freezing the mixed solution at a temperature of between 40 DEG C below zero and 80 DEG C below zero, cross-linking the mixed solution by using 0.1 to 1.0 percent glutaraldehyde solution after freezing and drying, washing the cross-linked product for several times by using distilled water after the cross-linking is finished and vacuum-freezing and drying the washed product again, and then sterilizing the product by Co-60 to obtain a finished product of the human-like collagen haemostatic sponge. Compared with the conventional haemostatic materials broadly applied in clinic, the prepared haemostatic sponge has good mechanical property and excellent biocompatibility, thoroughly stops inevitable virus hidden trouble of animal collagen haemostatic materials, and ensures the safety of the haemostatic material in clinical usage.

Owner:NORTHWEST UNIV(CN)

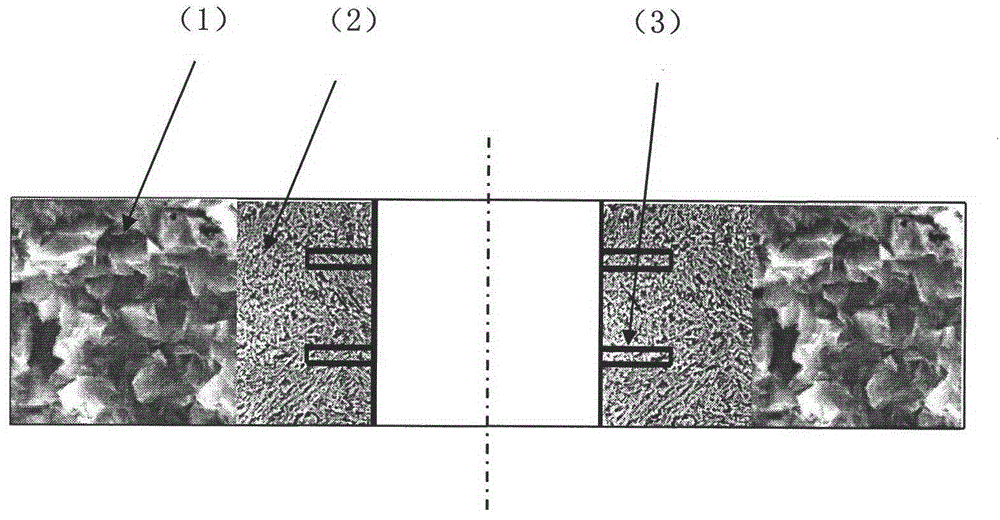

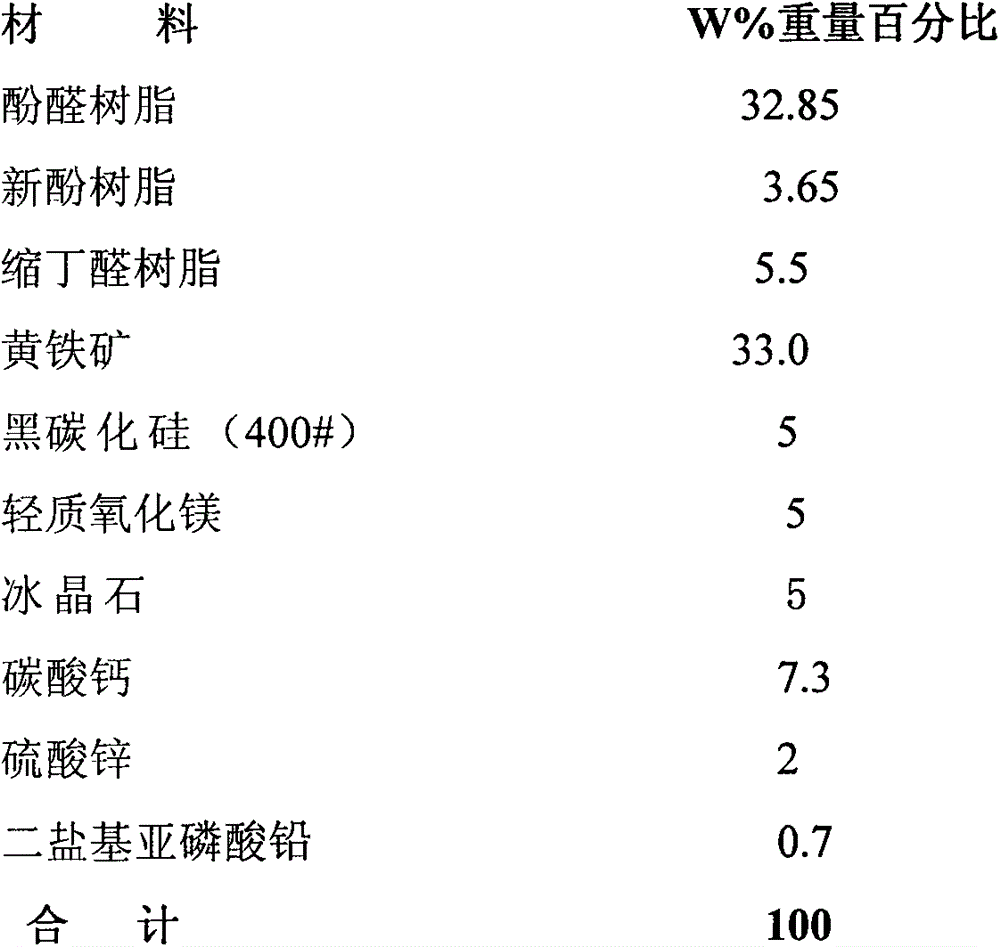

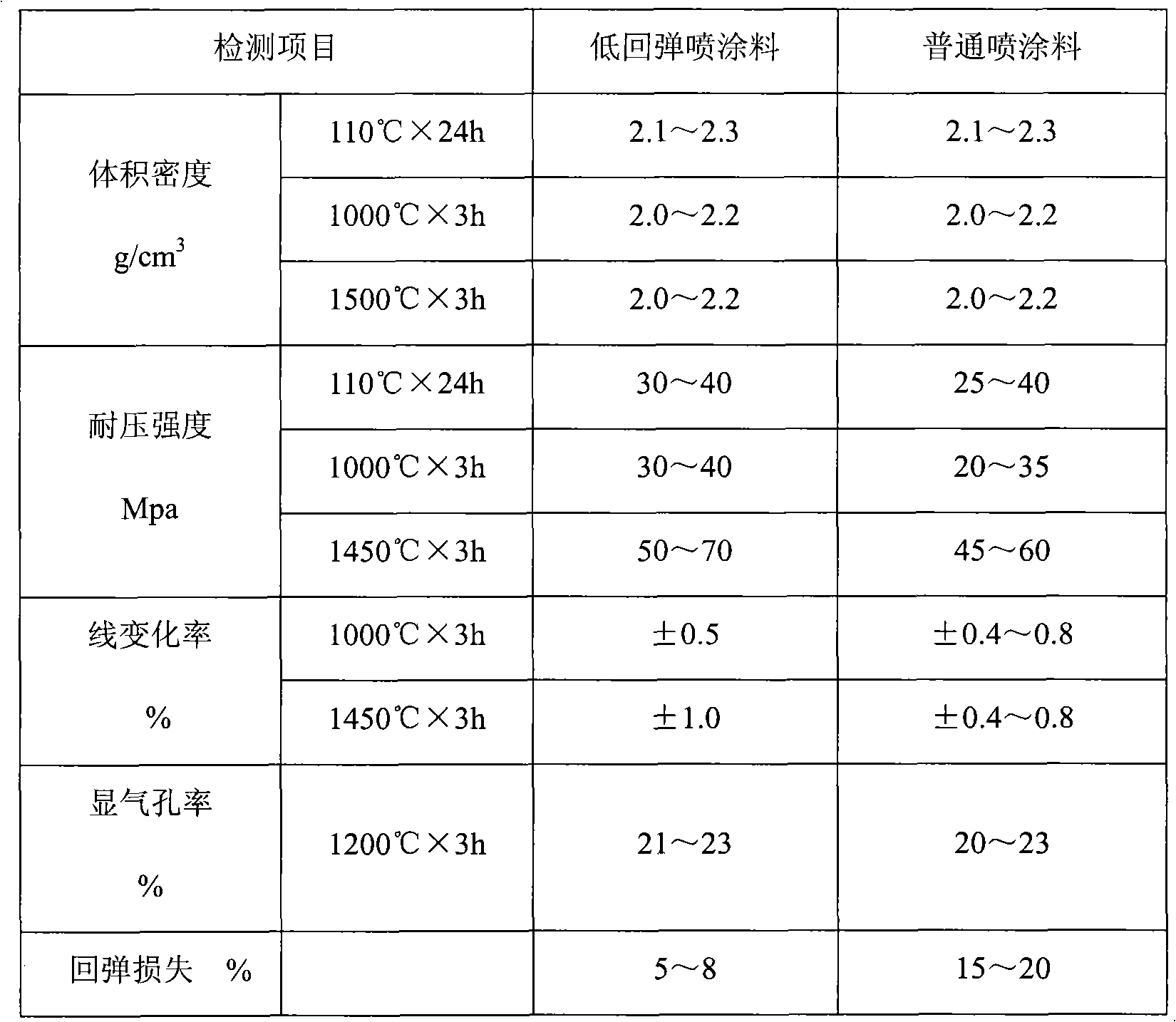

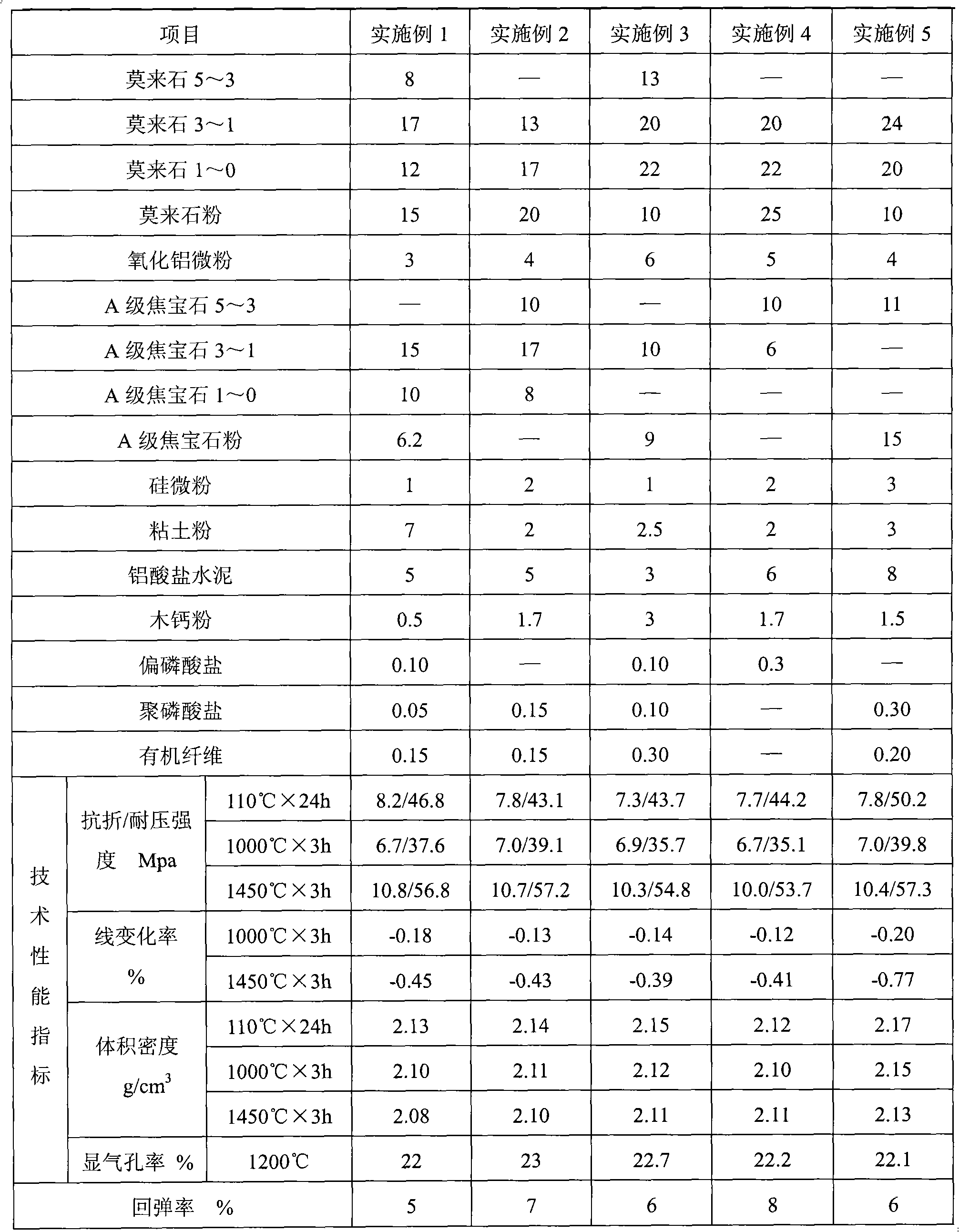

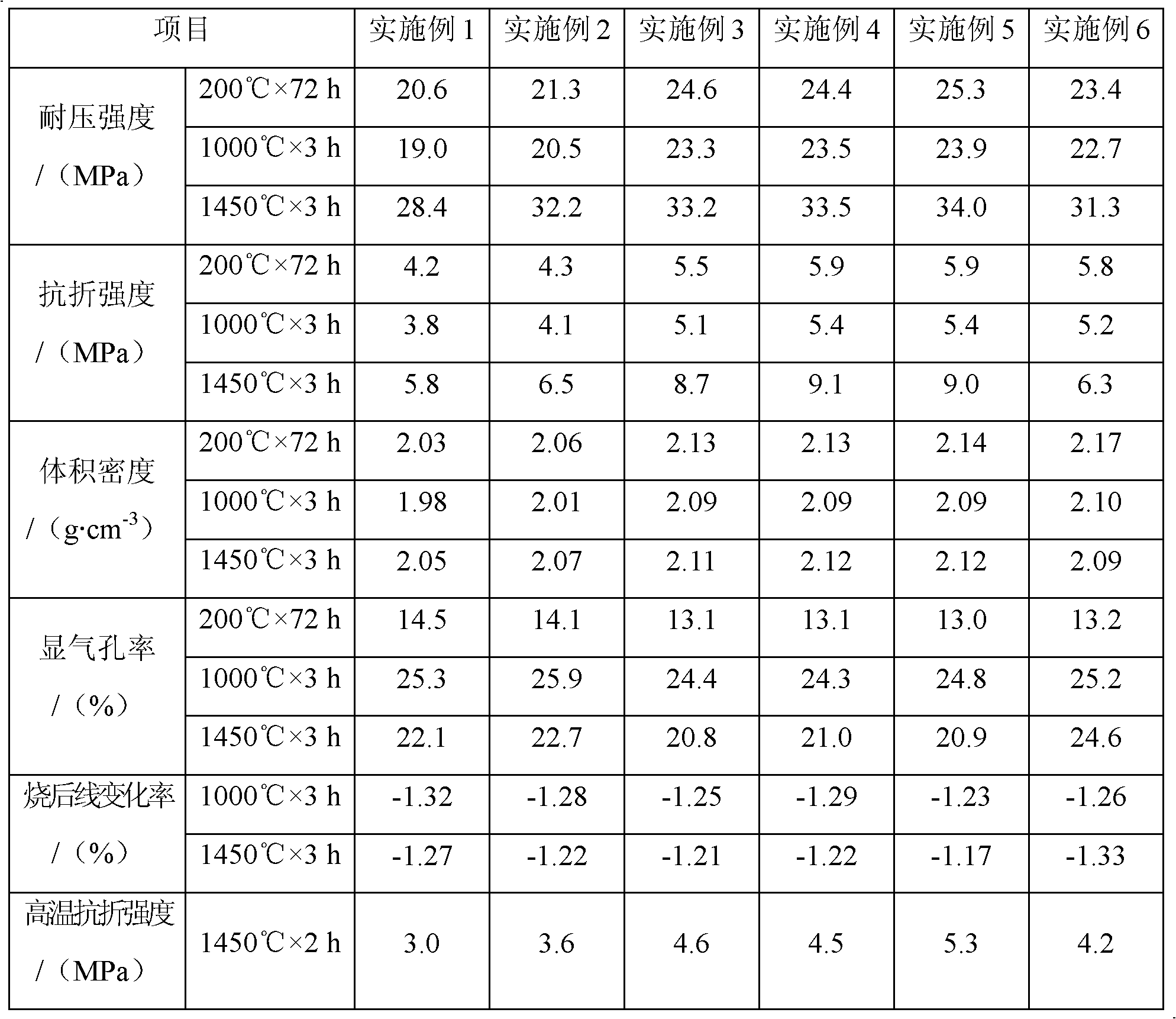

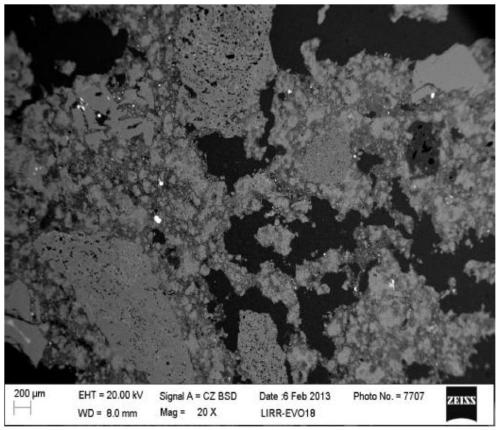

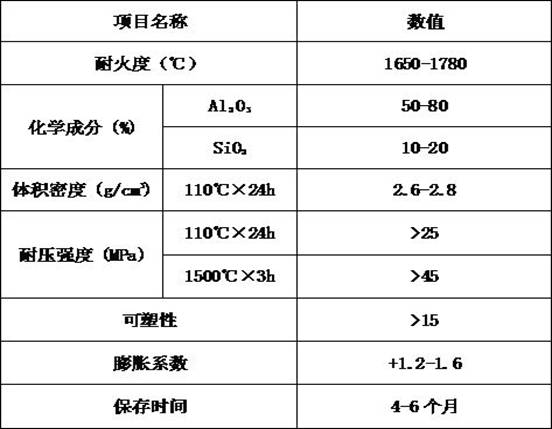

Low springback rate spraying and coating material for thermal-state blast furnace maintenance and preparation method thereof

The invention provides a low springback rate spraying and coating material for thermal-state blast furnace maintenance and a preparation method thereof. The spraying and coating material comprises the following raw materials in percentage by weight: 30-50% of synthetic mullite particles with the diameter of 5-0mm, 30-50% of A-level flint clay particles with the diameter of 5-0mm, 10-25% of synthetic mullite powder of 200-325 meshes, 0-15% of A-level flint clay powder of 200-325 meshes, 3-8% of aluminate cement, 2-7% of clay powder, 1-3% of silica micropowder of 2-5mu, 3-6% of aluminum oxide micropowder of 5mu, 0-0.3% of polyphosphate, 0-0.3% of metaphosphate, 0.5-3% of lignosulphonate calcium powder and 0-0.3% of organic fiber,The invention has the outstanding characteristics that the springback loss is small, waste of raw materials in the process of construction is reduced on one hand, and the start-up operation of the furnace is facilitated on the other hand; and the spraying and coating material provided by the invention meets the performance requirements on performances such as strength, scouring resistance, scouring and permeation resistance, rapid construction at 150-300 DEGC and the like, and is especially suitable for an unshaped refractory for thermal-state blast furnace lining maintenance. The invention has the outstanding characteristics that the springback loss issmall, waste of raw materials in the process of construction is reduced on one hand, and the start-up operation of the furnace is facilitated on the other hand; and the spraying and coating material provided by the invention meets the performance requirements on performances such as strength, scouring resistance, scouring and permeation resistance, rapid construction at 150-300 DEG C and the like, and is especially suitable for an unshaped refractory for thermal-state blast furnace lining maintenance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

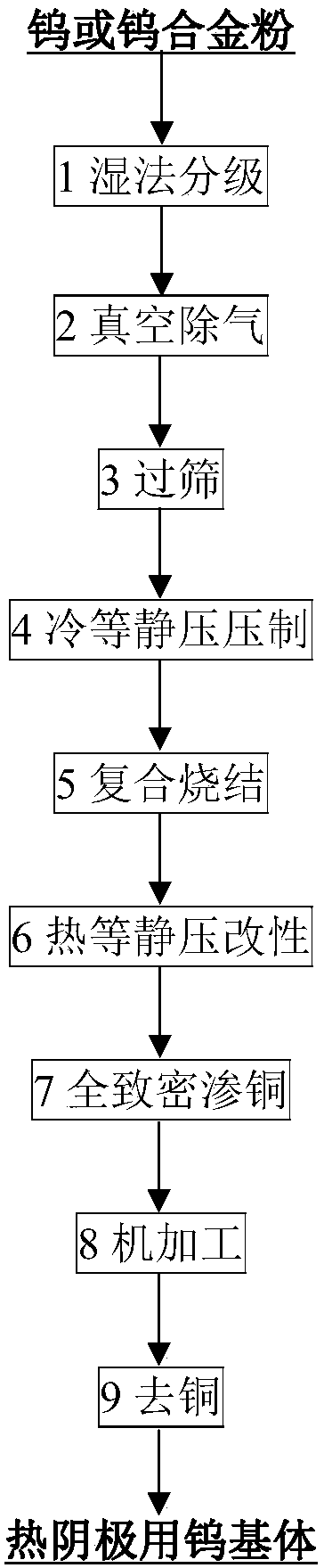

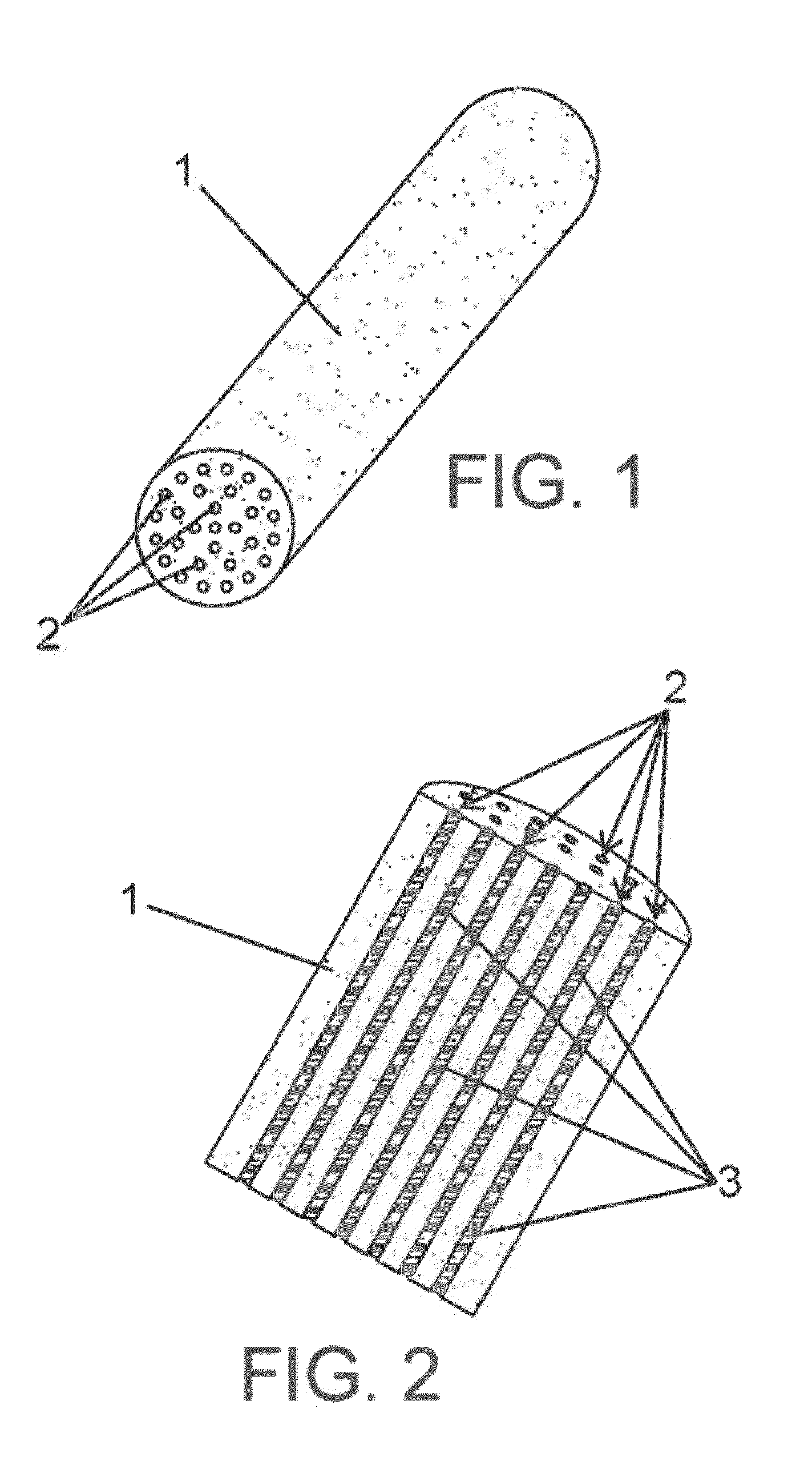

Tungsten matrix for hot cathode and preparing method of tungsten matrix

ActiveCN108251734ASuitable porositySmall apertureDischarge tube/lamp detailsHot isostatic pressingIridium

The invention relates to a tungsten matrix for a hot cathode and a preparing method of the tungsten matrix, and belongs to the microwave vacuum electronic technology and the refractory metal powder metallurgical field. The tungsten matrix for the hot cathode is pure tungsten or tungsten iridium or tungsten osmium or tungsten rhenium alloy, the overall porosity is 13% to 22%, the average pore sizeis 0.2 to 1.5 micrometers, the percentage of close area is smaller than 0.5%, and the framework tensile strength is 150 to 300 MPa. The preparing method comprises the steps that wet classified narrowgranularity and medium-fine particle tungsten or tungsten alloy powder serves as a raw material, and vacuum degassing, screening, isostatic cool pressing, composite sintering, hot isostatic pressure repressing and re-sintering modifying, fully compacted copperizing, final machining and high-temperature vacuum copper removal are executed; the tungsten matrix for the hot cathode is proper in porosity, small in hole diameter, narrow in distribution, extremely low in percentage of close area, high in framework strength, and capable of being used for making low-temperature large current, high reliability and long service life cathodes. The preparing method is high in process controllability, good in product consistency and capable of easily achieving large-scale production.

Owner:GRIMAT ENG INST CO LTD

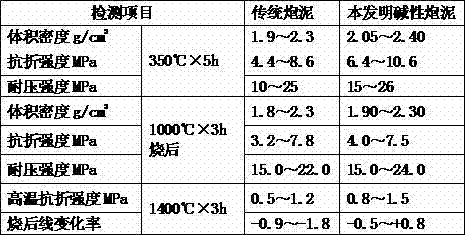

Alkaline stemming

The invention relates to alkaline stemming which is prepared from the following raw materials: 25%-50% of sintered magnesia, 5%-20% of dust coke, 10%-25% of magnesium-carbon reclaimed material, 1%-10% of carbon-containing resin powder, 5%-10% of silicon carbide, 5%-10% of Jiaozuo clay, 1%-5% of alpha aluminum oxide, 5%-20% of light burning magnesium powder, 5%-10% of andalusite, and stemming-dedicated resin accounting for 10%-20% of the total weight of the raw materials. The alkaline stemming provided by the invention has the advantages of good plasticity and adhesion, appropriate porosity, slight volume expansion at high temperature, good sintering property, high strength, scouring resistance, erosion resistance, easiness in tapping and environmental friendliness, and does not discharge pollutant gas in the sintering process; the molten iron scouring resistance of the alkaline material is fully played, and the alkaline stemming does not bring pollution or harmful impurities to molten iron; the harmful impurities in the molten iron can be reduced to purify the molten iron; the harmful components such as phosphorus, sulfur and silicon in the molten iron are reduced; the alkaline stemming provided by the invention has the advantages of long service life, short sintering time, high strength and easiness in tapping, reduces the maintenance cost of an iron notch and is conducive to the stable operation and stable and high yield of a blast furnace.

Owner:通化耐博新材料股份有限公司

Ecological restoration method for coal mine waste rock mountain

InactiveCN109328518AImprove structural stabilityImprove ventilationGrassland seedingSeed and root treatmentSpontaneous combustionRestoration method

The invention discloses an ecological restoration method for a coal mine waste rock mountain. The method comprises the following steps of (1) reducing the slope surface of the waste rock mountain, reducing the slope to 20-30 degrees, stabilizing the slope surface, and setting a drainage system; 2) laying loess on the surface of the spontaneous combustion waste rock mountain, and compacting to isolate an air approach, so that the internal air of pontaneous combustion waste rocks is exhausted and extinguished; (3) conducting seed-spraying on the coal mine waste rock mountain slope by using a loam-like substrate spraying method, specifically, laying a metal mesh on the surface of the compacted loess, and fixing with a bolt, spraying on the subsoil of the loam-like substrate, and spraying on the surface of the loam-like substrate; (4) conducting curing management of the slope, covering a non-woven fabric, reinforcing, watering, fertilizing, conducting pest control, replanting and conducting post-monitoring. The ecological restoration method for the coal mine waste rock mountain adopts loess cover, isolates air to prevent the spontaneous combustion of the waste rocks, and adopts a loam-like soil spraying technology to conduct plant seeding to achieve ecological restoration.

Owner:JIANGSU LVYAN ECOLOGY TECH CO LTD

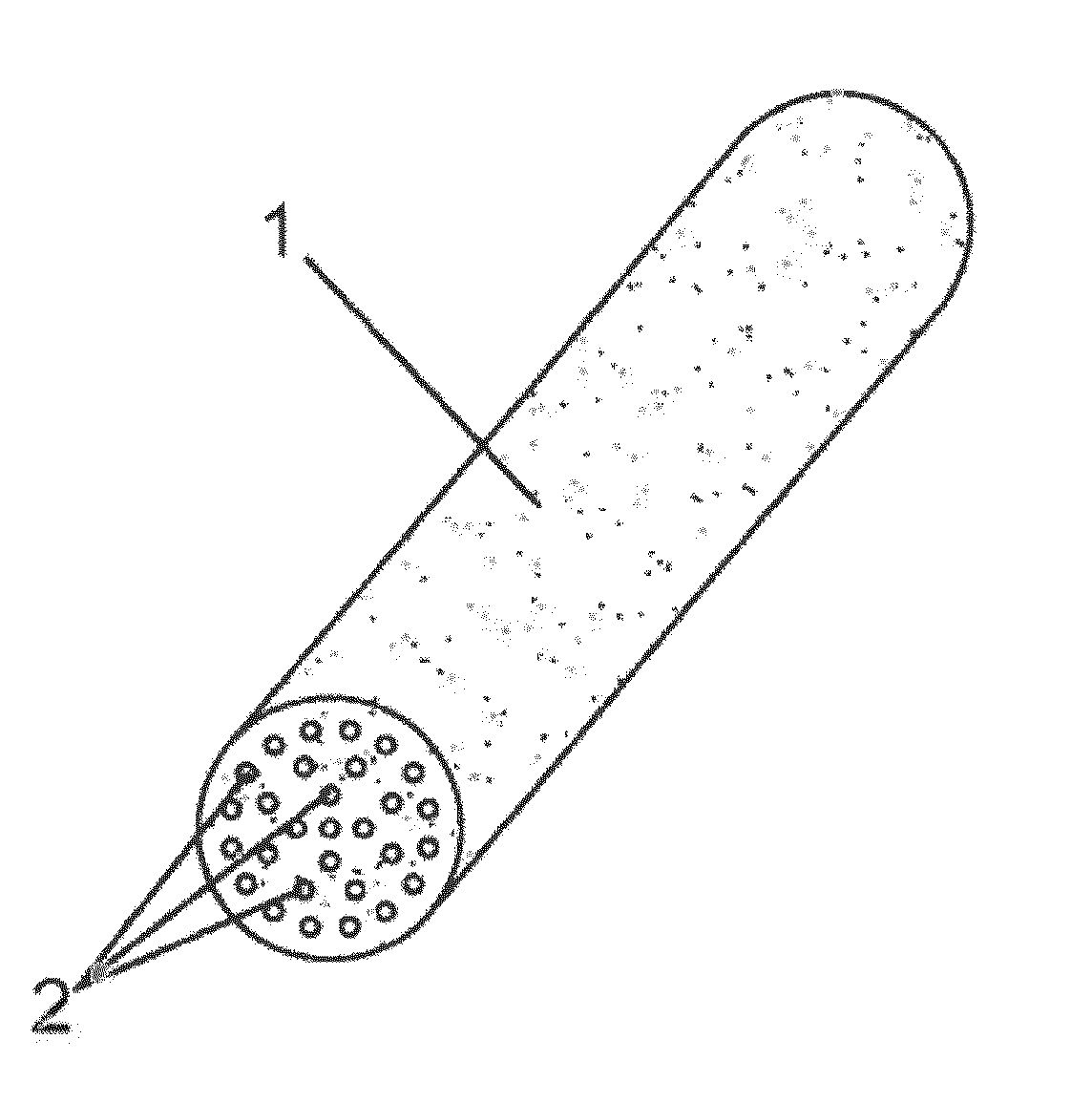

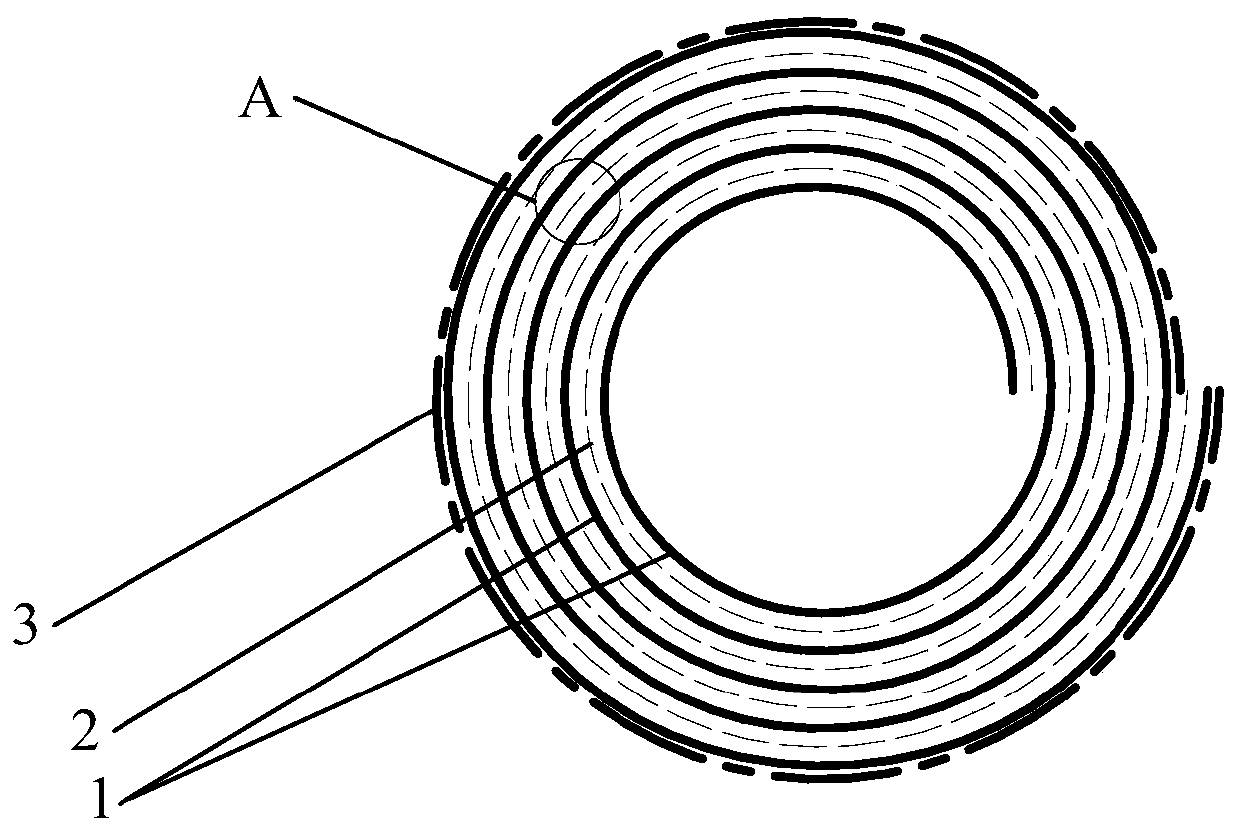

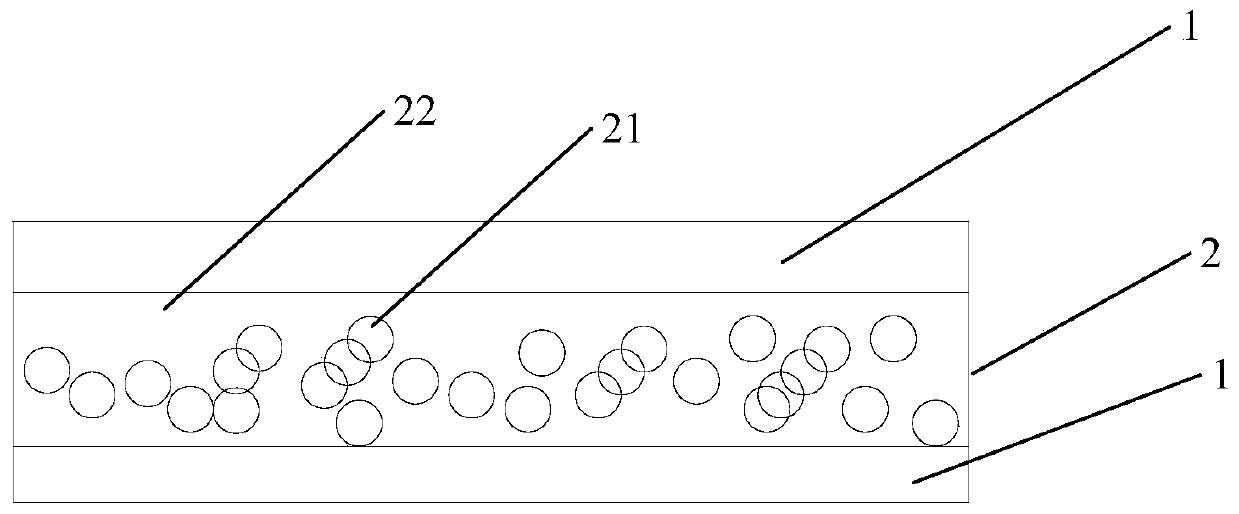

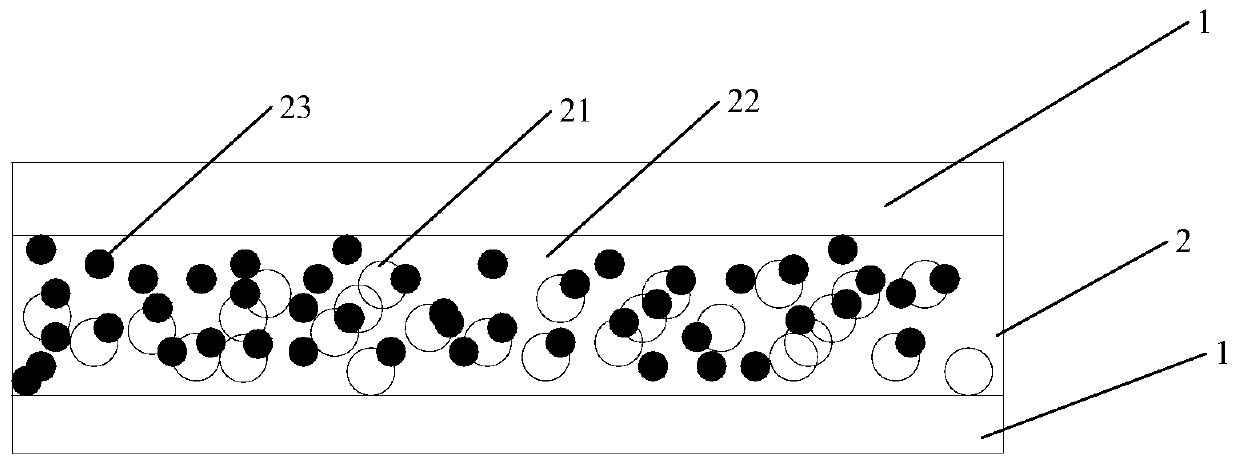

Ceramic filtration membrane

InactiveUS20150258508A1Suitable porositySuitable strengthMembranesSemi-permeable membranesPorosityFiltration membrane

The present invention relates to a ceramic filtration membrane with a porous support (1) formed by sintering aluminum oxide particles and metal oxide particles at a temperature greater than 1300° C. and less than 1500° C., comprising fine aluminum oxide particles with a particle size of less than 10 μm, and coarse aluminum oxide particles with a particle size of 20 μm-150 μm, where the fine aluminum oxide particles represent a percentage by weight. of 3%-10% with respect to the total weight of the porous support (1), the porous support (1) having a porosity greater than 28% with a pore size of 1 μm-7 μm, bending strength greater than 45 MPa and suitable chemical resistance, giving rise to ceramic filtration membranes with ceramic layers (3) having a pore size of 1 nm to 1000 nm.

Owner:LIKUID NANOTEK

Method for preparing biodegradable blood vessel external scaffold material used in tissue engineering

InactiveCN101559238AStrong mechanical propertiesGood biocompatibilityProsthesisImmunocompatibilityRefrigerated temperature

The invention discloses a method for preparing a biodegradable blood vessel external scaffold material used in tissue engineering, comprising the steps as follows: using distilled water to dissolve human-like collagen to be a 1%-3% solution; using diluted acid to dissolve chitosan to be a 0.5%-1.5% solution; mixing the two solutions evenly, adding aqueous glutaric dialdehyde solution with the concentration of 20-50% according to mass percentage, mixing and stirring, and filtering followed by vacuum de-foaming; pouring the mixed solution into a tube-shaped die, cross-bonding at 4 DEG C for 1-3 days, placing the same into a refrigerator with the temperature being negative 80 DEG C for refrigerating, and then drying to obtain the blood vessel external scaffold material. Compared with the prior art, the prepared scaffold material has excellent mechanicalness, bio-compatibility, blood compatibility and immunity compatibility, is much lower in immunological rejection response, and can eradicate the potential virus hazard which can not be avoided by animal collagen, causing the security to be improved vastly.

Owner:NORTHWEST UNIV(CN)

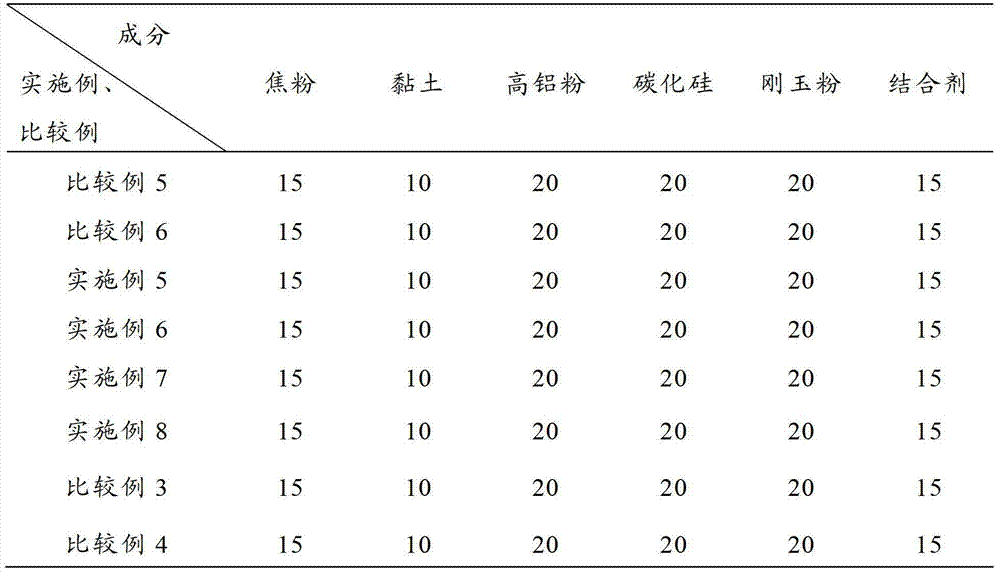

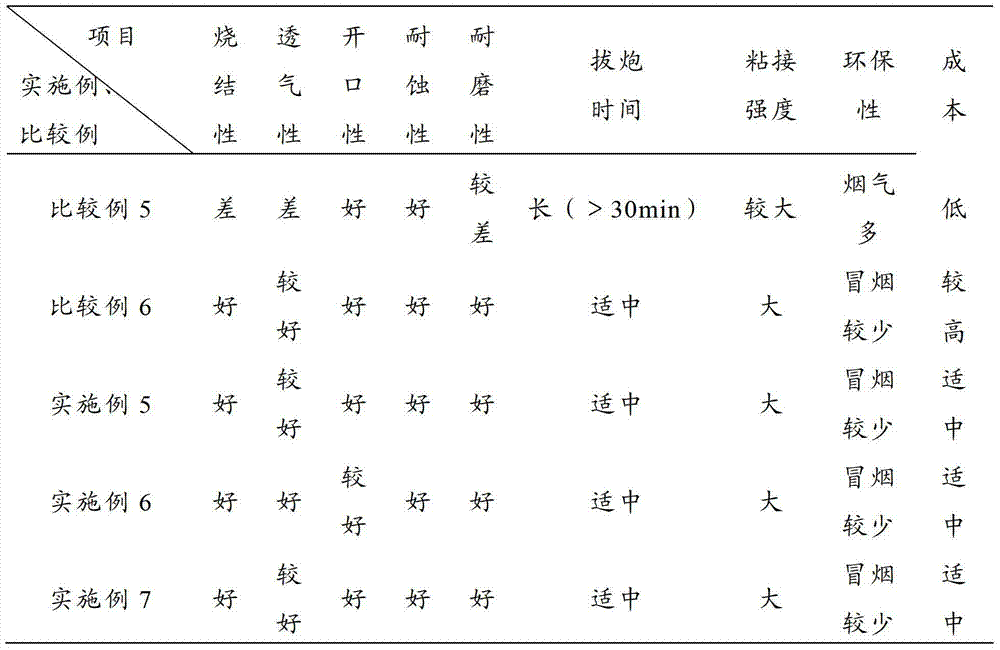

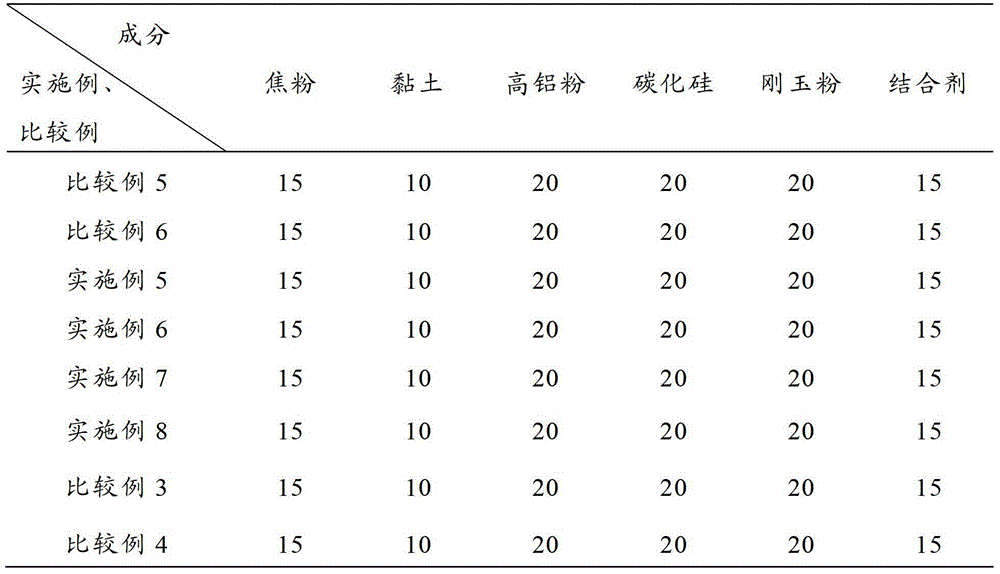

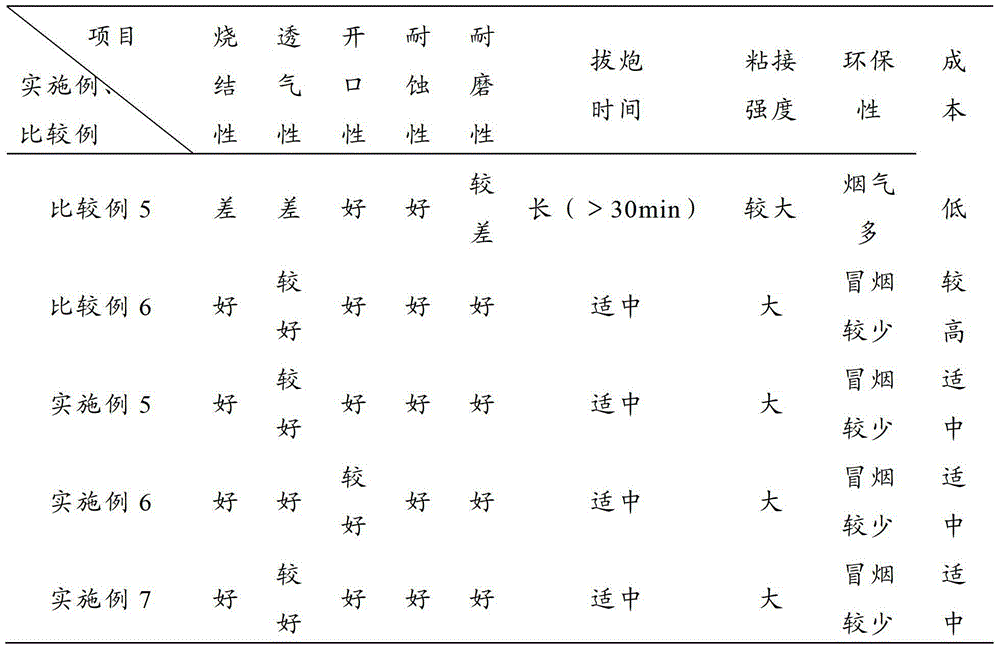

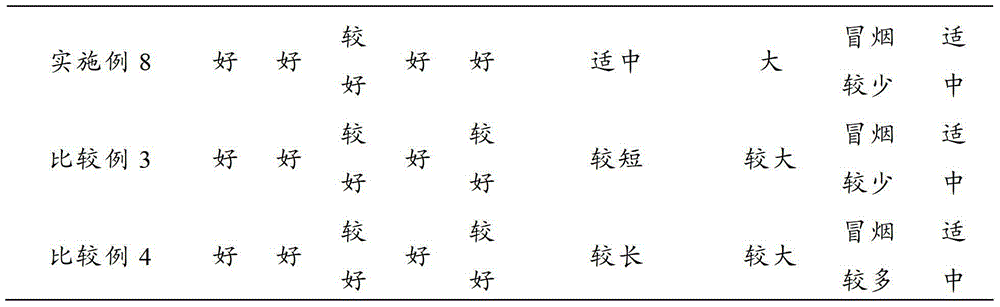

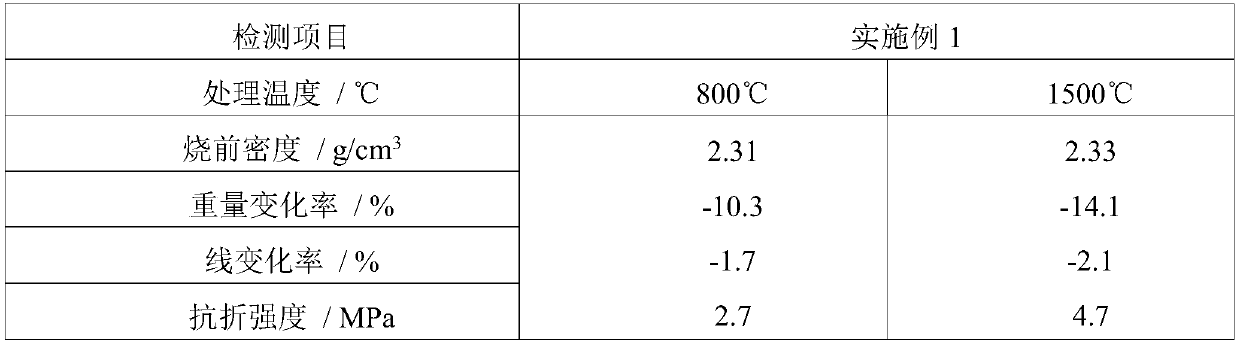

Phenolic resin composition for stemming, preparation method of composition and stemming

The invention provides a phenolic resin composition for a stemming and a preparation method of the composition. According to the method, 30-50wt% of thermosetting phenolic resin, 5-20wt% of organic solvent and the balance of a carbon-containing organic binder are mixed to obtain the phenolic resin composition for stemming. The invention further provides a stemming. The stemming comprises a refractory aggregate and a binding agent, wherein the binding agent is the phenolic resin composition provided by the invention. According to the phenolic resin composition for the stemming, the thermosetting phenolic resin and the carbon-containing organic binder are mixed and used together, and the proportions of the thermosetting phenolic resin and the carbon-containing organic binder are controlled in the specified ranges, and then an appropriate amount of the organic solvent is added, so that the stemming has a moderate curing speed. Moreover, the stemming comprising the phenolic resin composition provided by the invention has the advantages of good plasticity and cohesive property, proper porosity, small high-temperature volume shrinkage, good sintering performance, high strength, scouring resistance, erosion resistance, good opening performance and the like and hardly causes environmental pollution.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

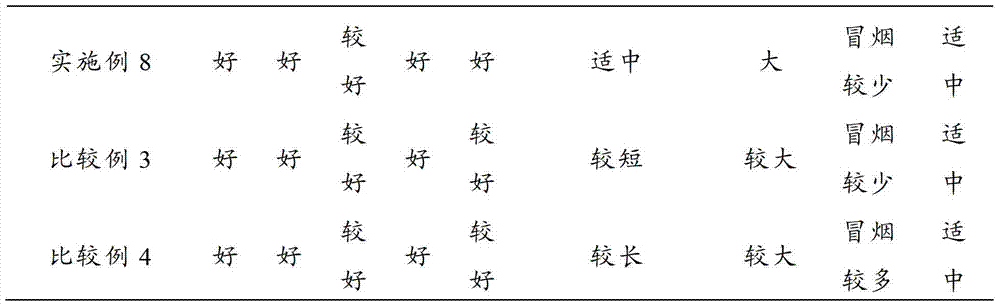

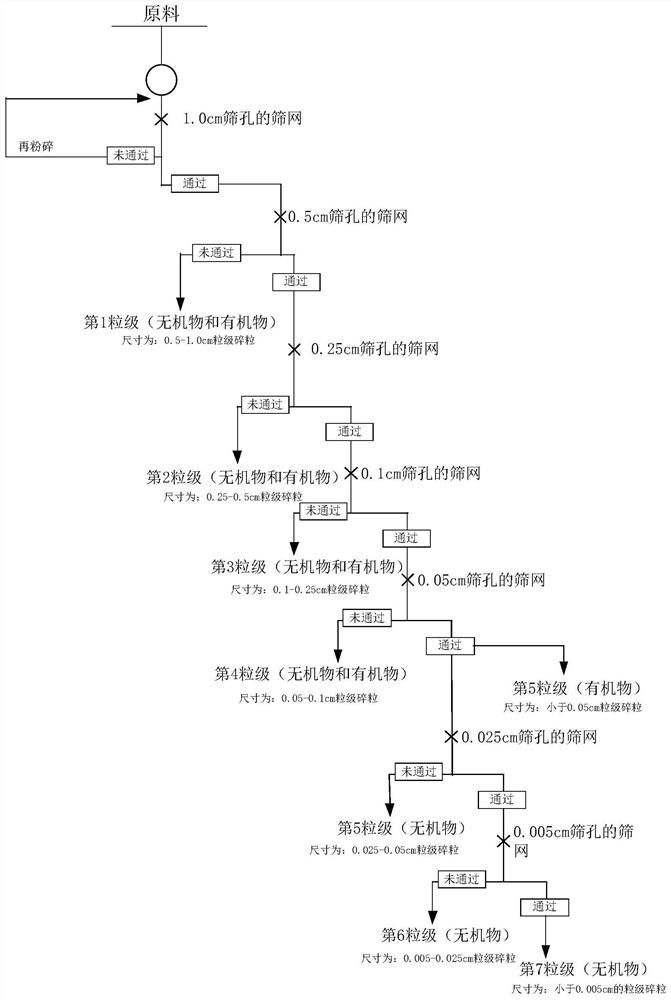

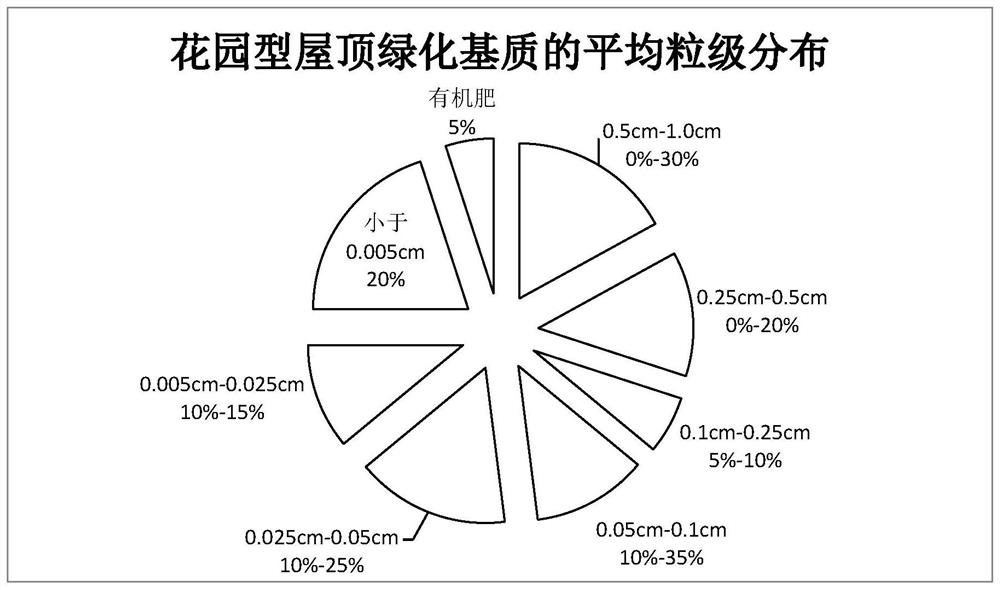

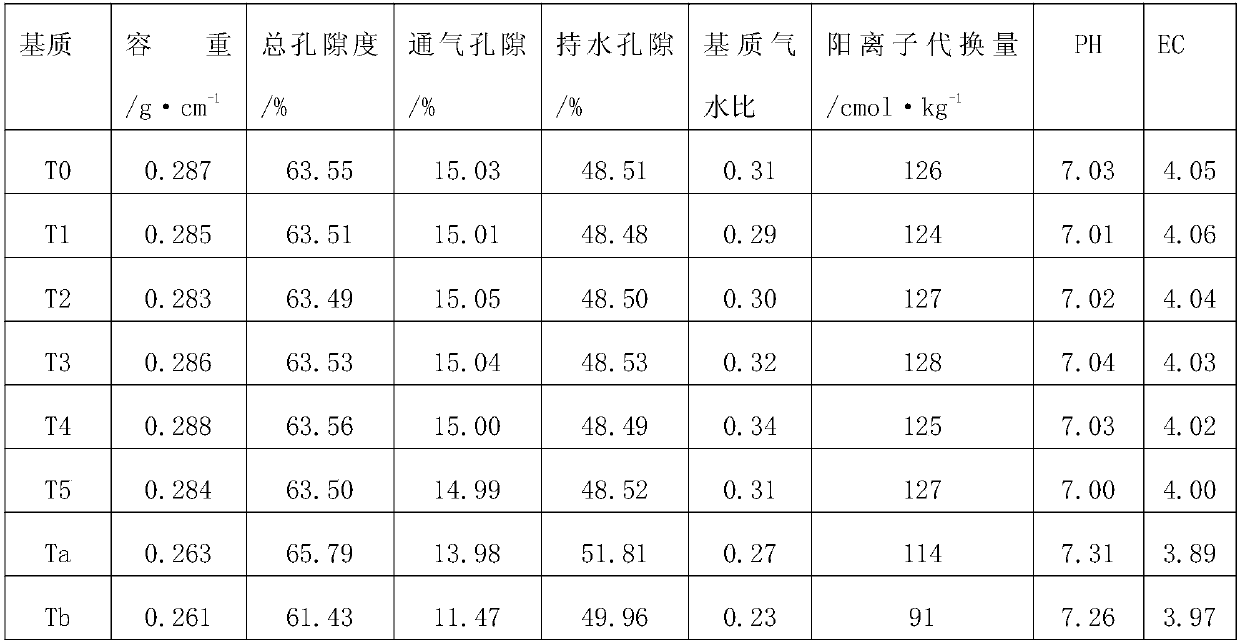

Garden type roof greening matrix and manufacturing method thereof

ActiveCN111602578ASuitable porosityAvoid Substrate SinkingGas current separationRoof improvementFertilizerFlower garden

The invention belongs to the technical field of plant growth matrices, and particularly relates to a garden type roof greening matrix and a manufacturing method thereof. The garden type roof greeningmatrix comprises an organic matter and an inorganic matter, wherein the volume percentage of the inorganic matter is 80%-85%; the volume percentage of the organic matter is 15%-20%; in the inorganic matter, the weight percentage of crushed particles with the particle size of 0.05 cm to 0.5 cm is 15-65%; and in the organic matter, the weight percentage of crushed particles with the size of 0.05 cmto 0.5 cm is 15-65%. The garden type roof greening matrix provided by the invention mainly meets the requirements of high-grade three-dimensional greening, can be intelligently managed aiming at the construction and management of gardens with multiple plant types and multi-layer structures and gardens in the air, and high roof load is required. The roof planting with dense plants and a multi-layerstructure can be met, the roof is light in weight, water and fertilizer can be preserved, roots can be easily inserted, permeable drainage is facilitated, water and oxygen can be preserved, roof plants grow reasonably, and green ecological materials are provided for ecological city construction, sponge city construction and fourth-generation residential construction in the future.

Owner:刘克锋

Blast furnace gun mud added with SiAlON synthesized through coal ash and preparation method of blast furnace gun mud

InactiveCN103172389AImprove performanceImprove plasticitySolid waste disposalPorosityHigh resistance

The invention provides a blast furnace gun mud added with SiAlON synthesized throughcoal ash and a preparation method of the blast furnace gun mud. The gun mud is characterized in that industrial corundum particles and fine powder, silicon carbide particles and fine powder, coke powder, clay fine powder and asphalt powder are adopted and used as the main raw materials; proper SiAlON fine powder which is synthesized by the coal ash discharged by a coal fired power plant is added; and the oil tar is used as a bonding agent. The blast furnace gun mud has the beneficial effects that: 1, the prepared gun mud is excellent in the following performances, high plasticity, high bonding performance, excellent sintering performance, proper air porosity, low high-temperature volume shrinkage, high resistance to slag-iron erosion, high flushing performance, and high open performance; 2, the industrial waste that is coal ash is used as the synthetic raw material of the adopted SiAlON material, so that the cost of the raw material is low, and as a result, the production cost of the gun mud is relatively low; 3, the industrial waste that is the coal ash is used as the raw material for synthesizing the SiAlON material, and a novel mode is also provided for comprehensively utilizing the coal ash; and 4, the blast furnace gun mud has important economic benefit and social benefit.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Catalyst carrier, catalyst composite filtering element as well as preparation method and device thereof

PendingCN109745857ASuitable porosityImprove high temperature stabilityDispersed particle filtrationFiberActive component

The invention provides a catalyst carrier, a catalyst composite filtering element as well as a preparation method and a device thereof. A fiber layer of the catalyst carrier is formed by fiber paper shaft rolls and has self support together with an auxiliary carrier with an adhesive property, and in addition, fiber paper has a good filtering property and is good in high temperature stability and low in price; in addition, on one hand, the auxiliary carrier has a fixing function on a main carrier, and the catalyst is prevented from migration or damage in the use process; on the other hand, theauxiliary carrier is also capable of loading active components, the ratio of the loaded active components is increased, and furthermore the catalysis property can be improved; furthermore, the catalyst carrier is simple in preparation process, low in process cost and material cost and excellent in filtering property and catalysis property.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

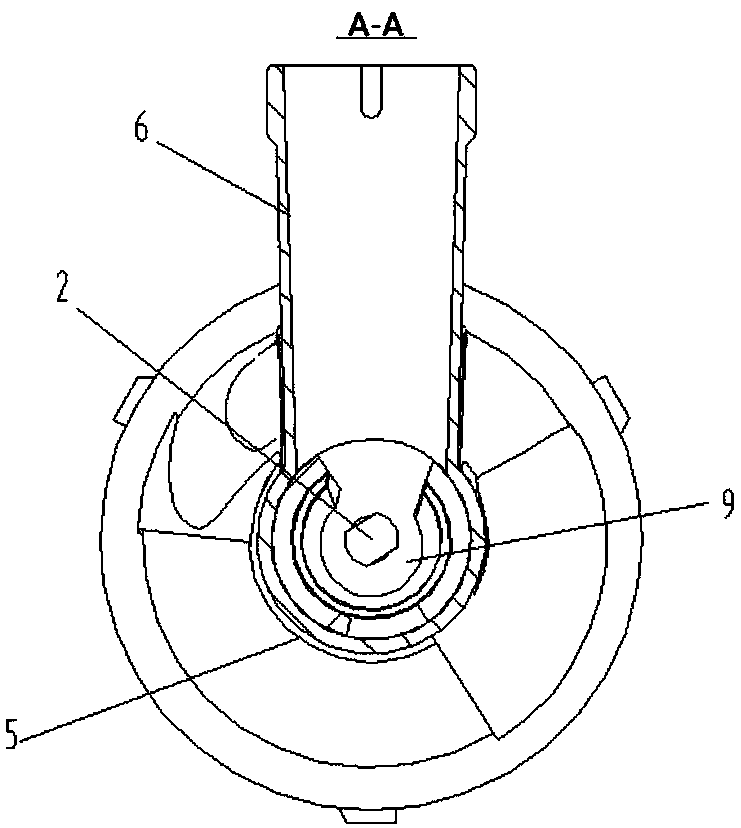

Ball-like food processing apparatus and meat mincing machine thereof

The invention discloses a ball-like food processing apparatus and a meat mincing machine thereof. The ball-like food processing apparatus comprises a shell, a material feeding pushing mechanism and aball-like food molding mechanism, wherein the material feeding pushing mechanism and the ball-like food molding mechanism are arranged in the shell, the ball-like food molding mechanism is communicated to the material outlet channel of the material feeding pushing mechanism, the material feeding pushing mechanism is connected to the ball-like food molding mechanism through a drive shaft, the ball-like food molding mechanism comprises a fixing disk, a driving disk and a ball-like food molding rotation disk, the fixing disk is fixed in the shell and is provided with an ejection guide rail, the driving disk is connected to the drive shaft and is arranged on the outer side surface of a fixing seat, the ball-like food molding rotation disk is arranged between the fixing seat and the material feeding pushing mechanism, the disk surface of the ball-like food molding rotation disk is provided with a plurality of ball-like food molding units, the driving disk and the ball-like food molding rotation disk form synchronous driving connection, the ball-like food molding rotation disk drives the plurality of the ball-like food molding units to rotate, and are corresponding to the material outletchannel of the material feeding pushing mechanism one by one to complete food filling, extrusion and ball-like food production is performed by the ejection guide rail in the shell, and the produced ball-like food is pushed and discharged from the ball-like food port of the shell. According to the present invention, by matching the ball-like food processing apparatus and the meat mincing machine,the rapid ball-like food production of minced meat can be achieved.

Owner:LIANCHUANG SANJIN ELECTRIC APPLIANCE SHENZHEN

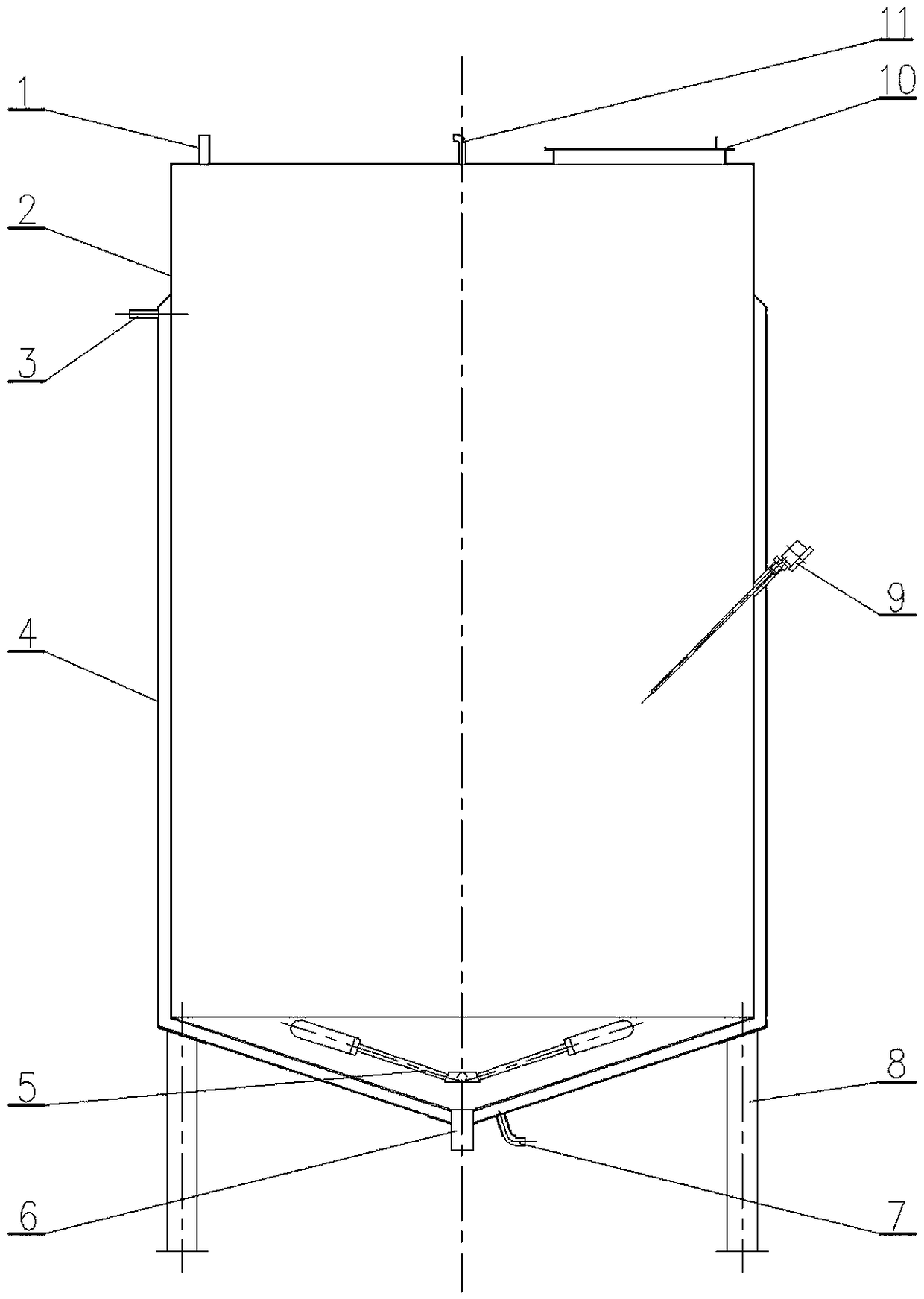

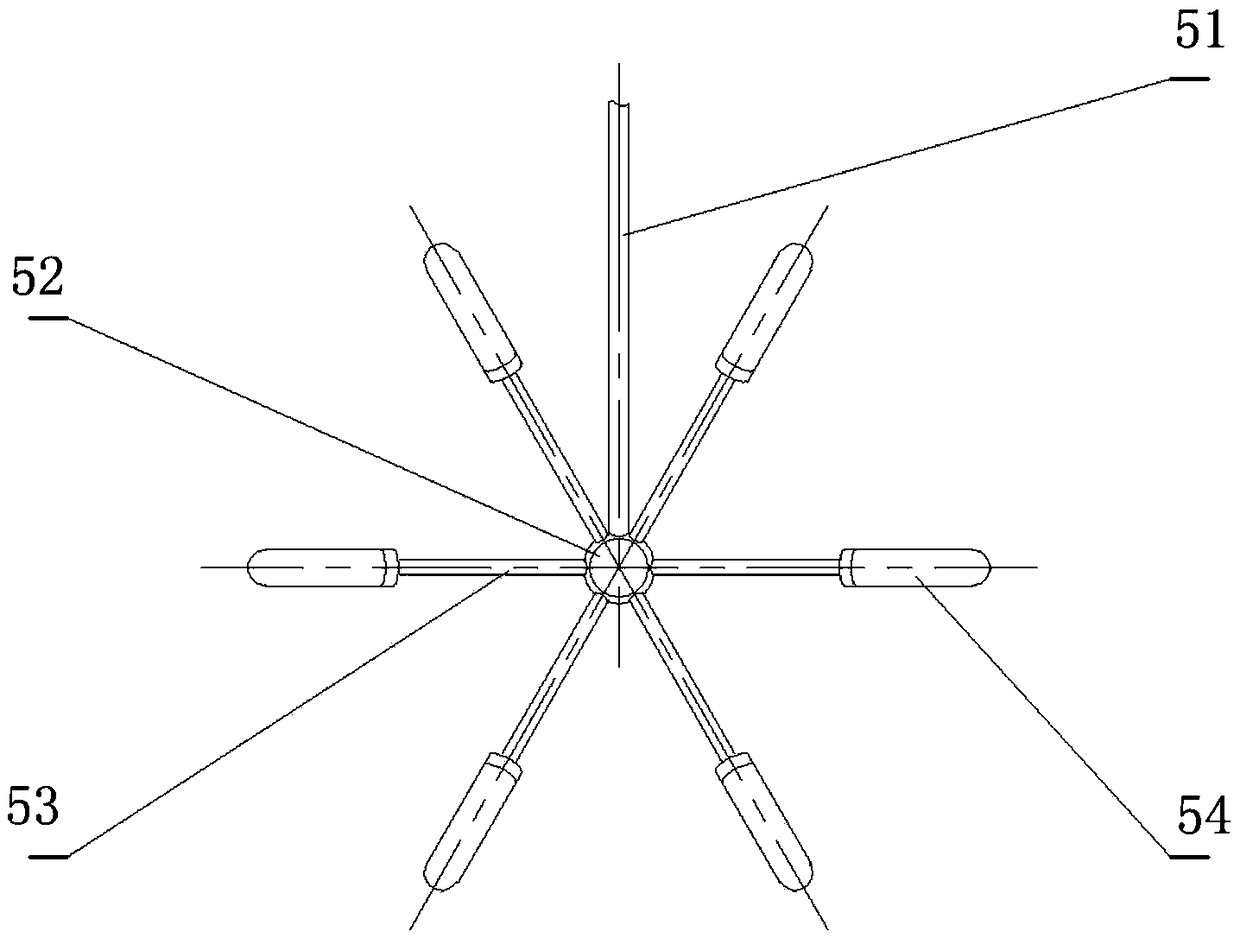

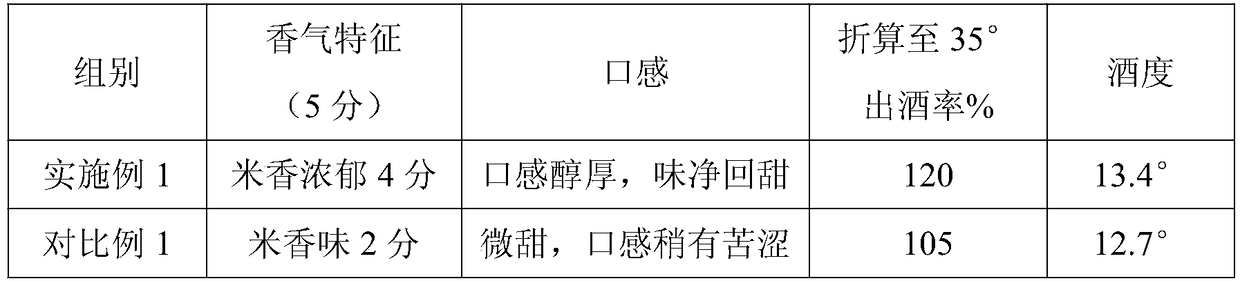

Ventilating bacteria culture-saccharification and fermentation integrated preparation process for rice-flavor baijiu and special bioreactor

The invention discloses a ventilating bacteria culture-saccharification and fermentation integrated preparation process for rice-flavor baijiu and a special bioreactor, and belongs to the technical field of baijiu making. The preparation process comprises the following steps: rice cooking, koji adding, spreading, bacteria culture-saccharification and fermentation. The special bioreactor comprisesa tank body, a feed port, a discharge port, a water adding port, an exhaust port, an air supply device, a thermometer, a jacket, a jacket water inlet, a jacket water outlet and support legs, wherein the bottom of the tank body can be a conical, oval or flat-bottomed head; the air supply device is located 0.02-0.2 m right above the bottom of the tank body and supplies sufficient oxygen in the bacteria culture-saccharification stage, follow-up fermentation is facilitated, liquor yield is increased, and liquor flavor is improved. Bacteria culture-saccharification and fermentation are performed onthe same bioreactor, so that equipment use ratio is increased remarkably, space is saved, labor intensity of an operator is reduced, and production efficiency is improved.

Owner:广西轻工业科学技术研究院有限公司

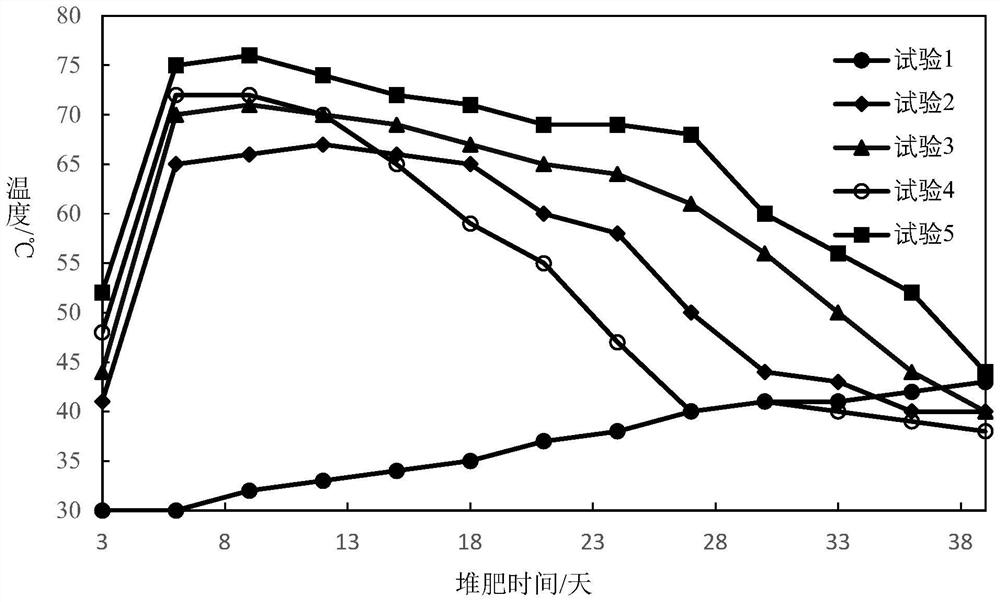

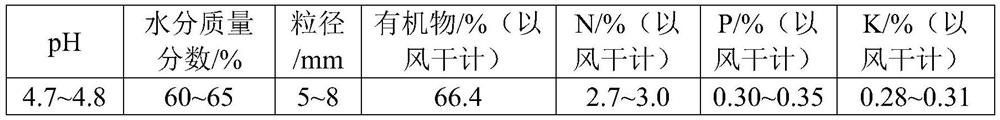

Organic culture medium applicable to bare place facilities of coastal mud flats

InactiveCN107935687AGood physical and chemical propertiesSuitable porosityAnimal corpse fertilisersExcrement fertilisersWater contentChemistry

The invention provides an organic culture medium applicable to bare place facilities of coastal mud flats. The organic culture medium comprises the following raw materials: plant wastes, organic fertilizers and rice husk carbon. The organic culture medium is prepared by flattening and crushing plant wastes by using a crushing machine, adding the organic fertilizers to adjust the ratio of carbon tonitrogen, adjusting the water content, adding microorganism composted composite bacterial agents and chitosan, uniformly stirring by using a pile turning machine, forming a conical pile, turning andmixing by using the pile turning machine every other 2-4 days, composting for 10-18 days till the mixture is brown or black brown, free of smell and soft and elastic when being held by hand and the ratio of carbon to nitrogen is reduced, and the water content is reduced, so as to obtain a composted mixture after composting is completed, and by mixing the composted mixture and the completely carbonized rich husk carbon according to a ratio. The medium is rich in raw material source, agricultural wastes are sufficiently utilized, the production cost is reduced, the purposes of environment protection and regeneration are achieved, local production of cultivation mediums in coastal mud flats is achieved, and the transportation cost is reduced.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

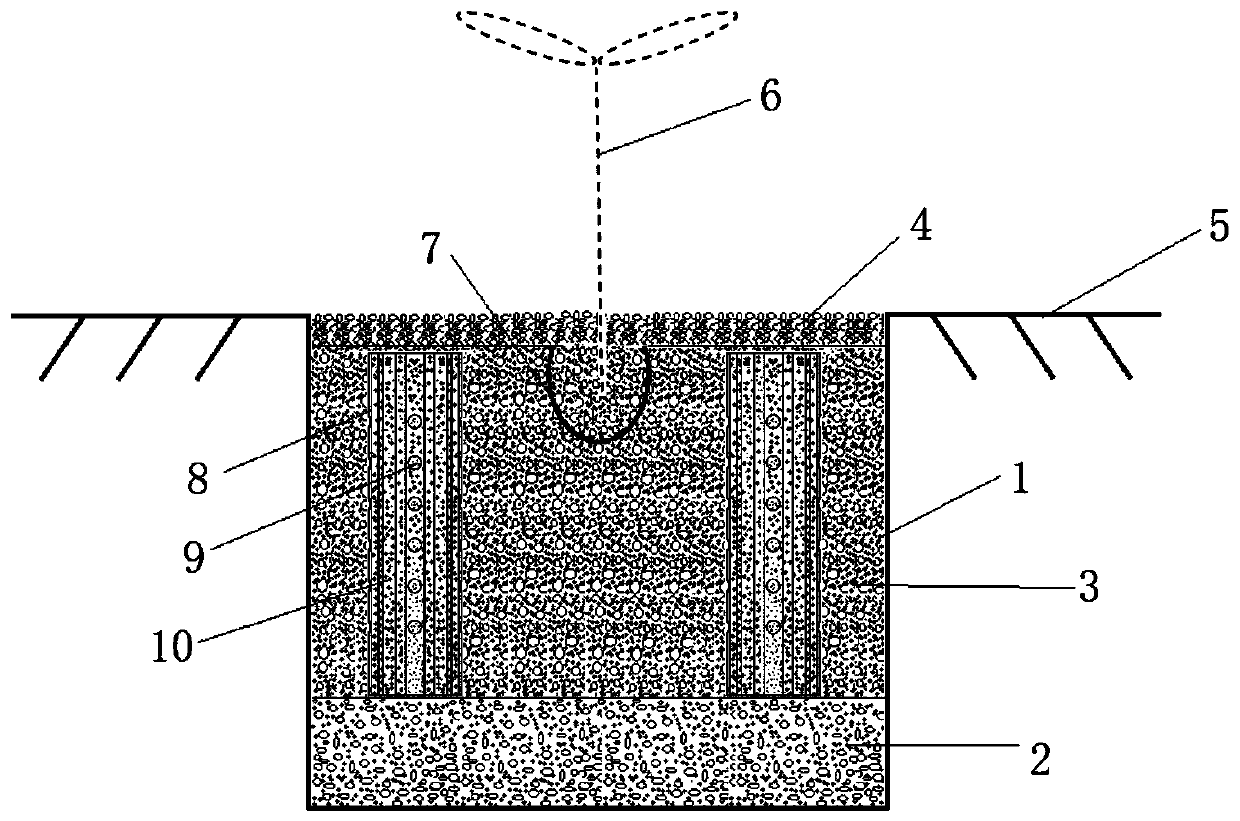

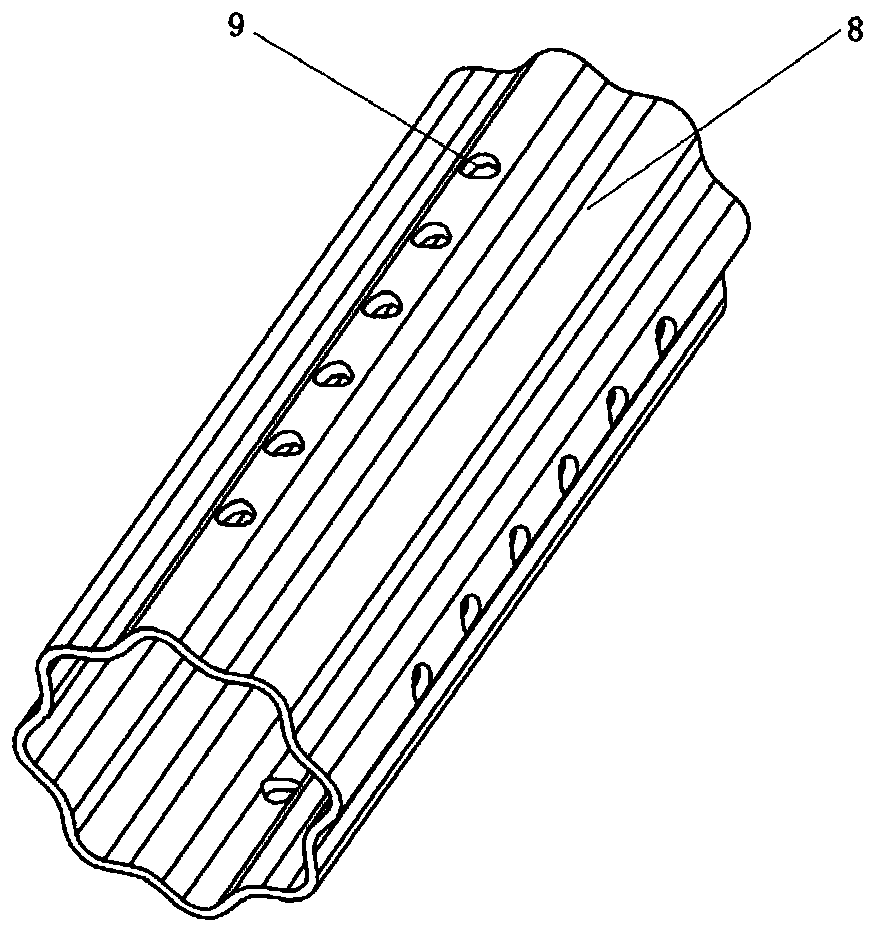

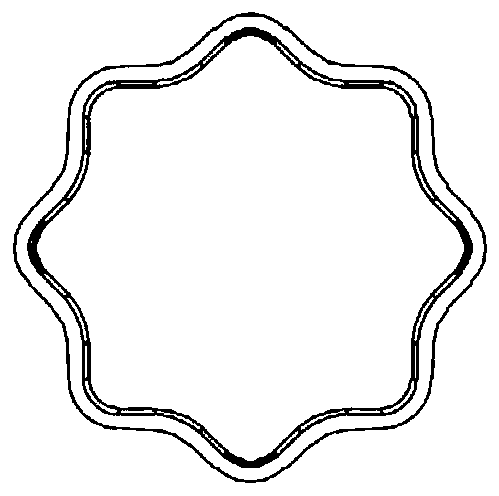

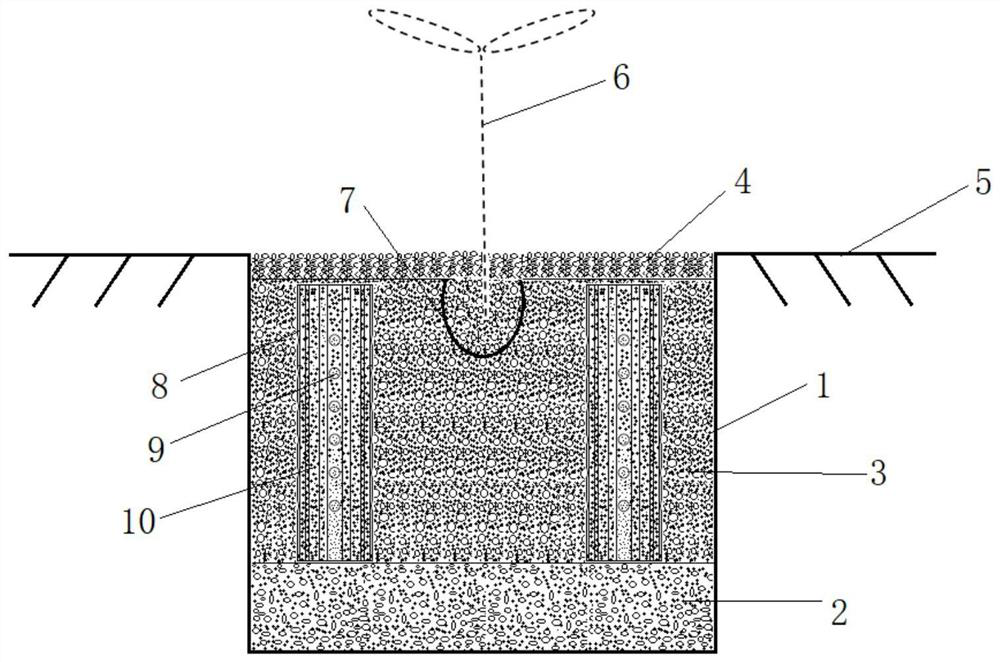

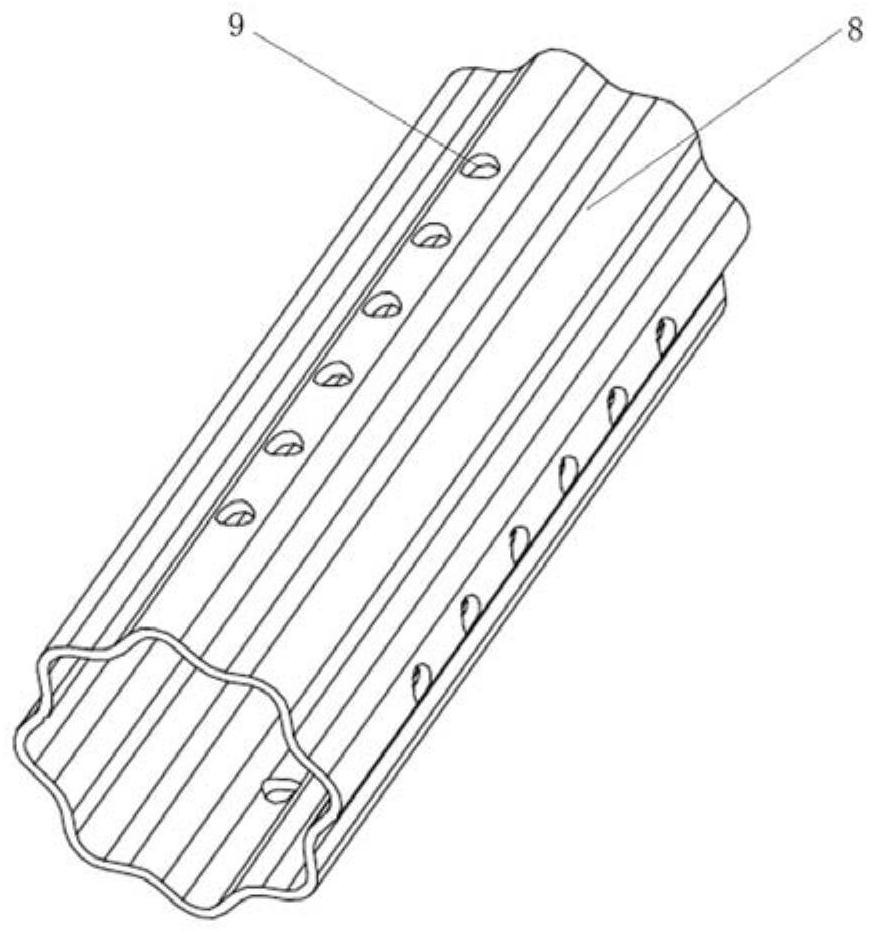

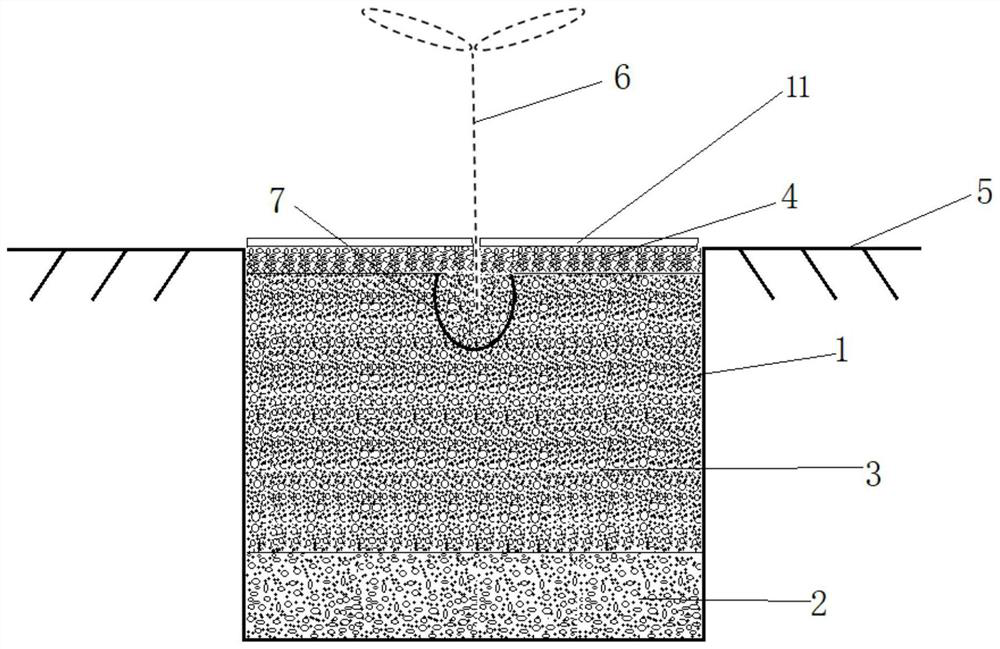

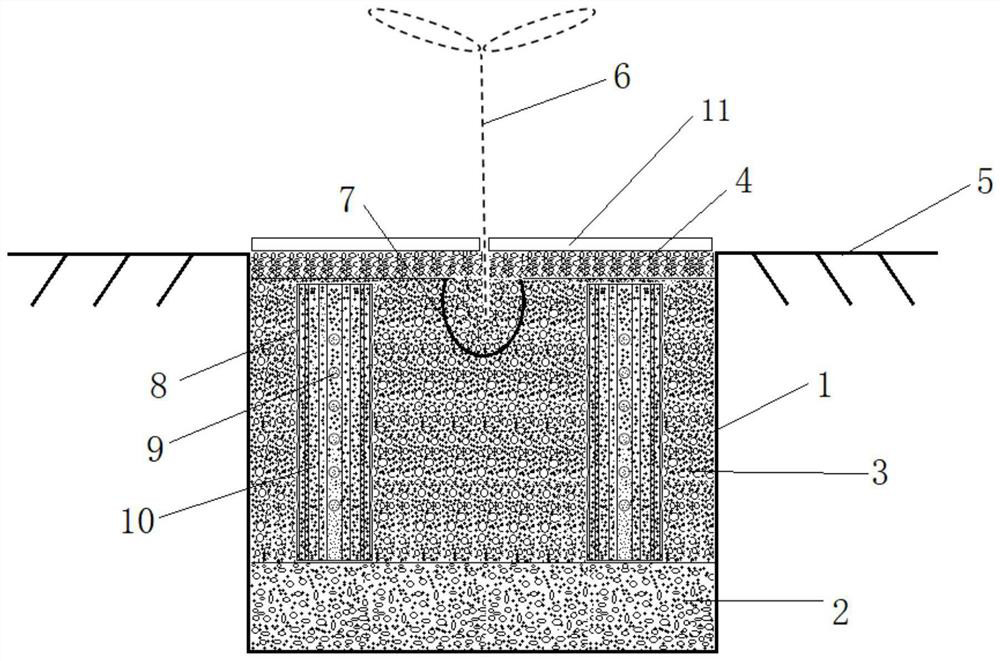

Street tree planting method and tree hole structure

ActiveCN110881337AEasy to breathePromote absorptionGrowth substratesCulture mediaAgricultural engineeringStructural engineering

The invention provides a street tree planting method, which includes the following steps: a. digging a tree hole at a place where a street tree is to be planted; b. paving a mixture of formulation soil and bluestone grains at the bottom of the tree hole to form a bottom layer, wherein the volume ratio of the formulation soil to the bluestone grains is 2: 8; c. arranging a planting device at the upper part of the bottom layer and paving a mixture of formulation soil and bluestone grains to form an intermediate layer, and reserving a planting pit for planting a street tree in the intermediate layer, wherein the planting device is positioned in the intermediate layer, and the volume ratio of the formulation soil to the bluestone grains is 5: 5; d. planting the street tree to be planted into the planting pit and filling the mixture of soil and bluestone grains with the volume ratio of 5: 5; and e. paving bluestone grains at the upper part of the intermediate layer to form an upper layer. The invention further provides a tree hole structure suitable for the planting method, the structure is beneficial to root respiration and absorption of water and fertilizers, and can provide a growthenvironment matched with street trees.

Owner:上海市绿化管理指导站

Phenolic resin composition for stemming, preparation method of composition and stemming

The invention provides a phenolic resin composition for a stemming and a preparation method of the composition. According to the method, 30-50wt% of thermosetting phenolic resin, 5-20wt% of organic solvent and the balance of a carbon-containing organic binder are mixed to obtain the phenolic resin composition for stemming. The invention further provides a stemming. The stemming comprises a refractory aggregate and a binding agent, wherein the binding agent is the phenolic resin composition provided by the invention. According to the phenolic resin composition for the stemming, the thermosetting phenolic resin and the carbon-containing organic binder are mixed and used together, and the proportions of the thermosetting phenolic resin and the carbon-containing organic binder are controlled in the specified ranges, and then an appropriate amount of the organic solvent is added, so that the stemming has a moderate curing speed. Moreover, the stemming comprising the phenolic resin composition provided by the invention has the advantages of good plasticity and cohesive property, proper porosity, small high-temperature volume shrinkage, good sintering performance, high strength, scouring resistance, erosion resistance, good opening performance and the like and hardly causes environmental pollution.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Novel environment-friendly anhydrous stemming for blast furnace iron notch and preparation method of stemming

InactiveCN109776069AReduce pollutionPromote environmental protectionCeramicwareClaywaresPorosityEnvironmental resistance

The invention relates to a novel environment-friendly anhydrous stemming for a blast furnace iron notch. The novel environment-friendly anhydrous stemming for the blast furnace iron notch is characterized by being prepared, by mass, 10-20 parts of coke, 10-20 parts of calcined pyrophyllite particles, 10-20 parts of brown fused alumina particles, 10-20 parts of bauxite powder, 5-10 parts of ferro silicon nitride, 5-10 parts of silicon carbide powder, 10-20 parts of clay, 5 parts of a carbon-based composite material and 5-10 parts of a composite binding agent. The novel environment-friendly anhydrous stemming for the blast furnace iron notch and a preparation method of the stemming have the following advantages that the pollution is small, the environment-friendly performance is good, and the stemming is a first choice of am iron and steel enterprise; the plasticity and cohesive property are good, the stemming is easily extruded into gaps and cracks, and the gaps and cracks are easily filled with the stemming; the porosity is proper, and moisture is conveniently discharged during drying; the volume contraction is small at high temperature, so that the cracks are prevented; the stemming is good in sintering performance, high in strength and resistant to flushing and corrosion; the stemming is easily cracked, the iron notch is deep, and the iron outlet time is long.

Owner:上海宝金冶金技术有限公司 +1

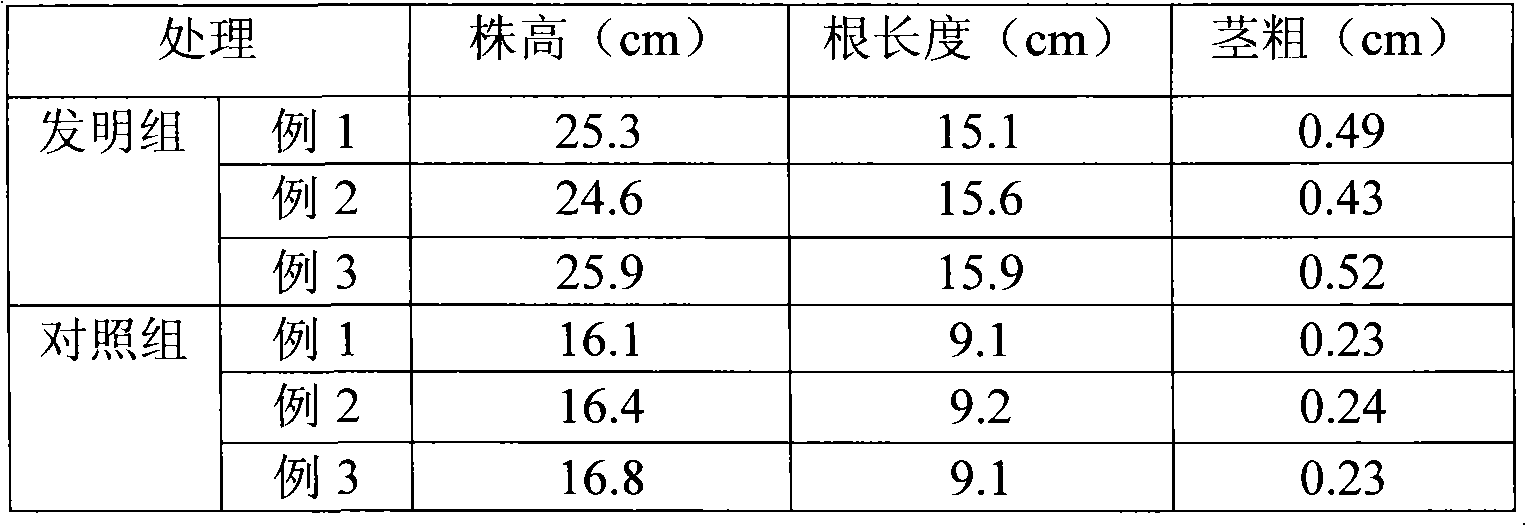

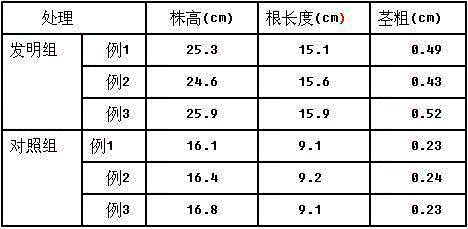

Lily culture substrate

InactiveCN102090311AReduce dosagePromote growth and developmentCultivating equipmentsSoilless cultivationNutrientPerlite

The invention discloses a lily culture substrate which belongs to the field of plant culture substrates, in particular to the field of lily culture substrates. The substrate is characterized by consisting of pindstrup No.5 substrate soil and perlite in the volume ratio of (2-3):1. The invention has the advantages that the substrate can provide a good nutrient condition and an appropriate degree of porosity for the growth of crops, reduces the using amount of peat cube, and remarkably promotes the growth and the development of lily mainly in the aspects of plant height, root length, root number and stalk thickness.

Owner:DASHUN INT FLOWER

Plant flower culture medium

InactiveCN114766323APromote fermentationIncrease production capacityGrowth substratesCulture mediaBiotechnologyMicrobiology

The invention discloses a plant flower culture medium, which comprises organic medium particles, the organic medium particles are obtained by fermenting and decomposing fermentation raw materials through a fermentation inoculant, then sterilizing and granulating, the fermentation raw materials comprise 88-92 wt% of vinasse, 4-6 wt% of chicken manure, 2-3 wt% of expanded perlite and 2-3 wt% of coco coir, the plant flower culture medium has the advantages of accelerating fermentation and improving productivity, the vinasse is recycled, and the yield is increased. The environment is protected.

Owner:杭州三纬生态园林有限公司

Improved smokeless environment-friendly stemming and manufacturing method thereof

An improved smokeless environment-friendly stemming comprises, by weight, 30-50% of flint clay aggregate, 8-12% of Suzhou No.1 mud, 1-1.5% of monatomic silicon fine powder, 5-10% of andalusite, 1-3% of cerium oxide fine powder, 3-5% of zirconium-silicon micro powder, 8-15% of corundum fine powder, 5-10% of zirconite powder, 3-5% of silica powder, 8-15% of a binding agent, 0.2-0.5% of a humectant and 0.1-0.3% of a plasticizer. The improved smokeless environment-friendly stemming is simple in production process, moderate in cost, easy to operate, and compact in structure, no smoke is released inthe using process, more environmental friendliness is achieved, the scouring resistance is good, chambering is not prone to happening, opening and blocking are easy, plasticity is good, the body density is proper, the phenomena of iron clamping and iron notch breaking are avoided, baking is not needed, direct installation and use can be achieved, and the heating hardening time is short.

Owner:JIANGSU JIANGNENG NEW MATERIAL TECH

Cultivation substrate for Lilium

InactiveCN105474925AReduce dosagePromote growth and developmentCultivating equipmentsSoilless cultivationPorosityLilium

The invention belongs to the field of plant cultivation substrates and particularly belongs to the field of a cultivation substrate for Lilium. The cultivation substrate for the Lilium is characterized by being prepared from pindstrup 5# substrate soil and pearlite according to the volume ratio of (3-4): 2. The cultivation substrate for the Lilium has the advantages that the substrate can be used for providing good nutrient conditions and appropriate porosity for the growth of crops, the use level of peat is reduced, and the substrate has an obvious promotion action on the growth and development of the Lilium, being mainly manifested as the obvious increase of plant height, root length, root quantity and stem diameter.

Owner:QINGDAO SEIICHI INTPROP SERVICE CO LTD

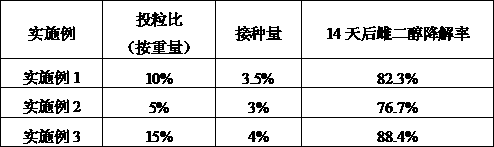

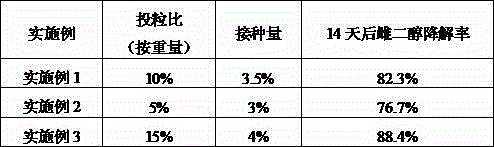

A method for remediating estradiol in soil based on immobilized microorganism technology

InactiveCN105039301BFixedWill not cause secondary pollutionContaminated soil reclamationMicroorganism based processesPyrophylliteSoil remediation

The invention relates to a method for remediation of estradiol in soil on basis of the immobilized microbial technology, relates to a method for soil remediation. The method comprises the following steps: mixing pyrophyllite, decorticated cottonseed meal and pine needle according to the weight part ratio of pyrophyllite to decorticated cottonseed meal to pine needle being 4:1:1 to obtain a microbial immobilized carrier material, sterilizing, inoculating a bacterium suspension which accounts for 2-5% of the total weight of the carrier, additionally adding an enrichment medium according to the dosage of 1.5 ml of enrichment medium for 1 g of the carrier each day to obtain immobilized microbial granules, and determining a proper feed ratio of the prepared immobilized microbial granules according to the weight of soil, so as to be used for remediation of estradiol contaminated soil. According to the method for remediation of estradiol in soil on basis of the immobilized microbial technology, provided by the invention, estradiol in soil is degraded by utilizing the immobilized microbial technology, and the degradation effect of estradiol under different environment temperatures, pH values and soil moisture contents and other soil environment conditions can be examined.

Owner:SHENYANG UNIV

Vegetable seedling raising medium and vegetable seedling raising method adopting same

InactiveCN109042222APrevent blightInhibition of reproductionGrowth substratesCulture mediaDisinfectantHusk

The invention provides a vegetable seedling raising medium and a vegetable seedling raising method adopting the same. The vegetable seedling raising medium is prepared from, by weight, 25-35 parts ofbiogas residues, 15-20 parts of fish pond mud, 10-18 parts of vermiculite, 6-10 parts of carbonized rice husk, 10-15 parts of cockroach dung, 3-5 parts of river sand, 1-1.5 parts of bamboo vinegar and0.04-0.07 part of germicidal disinfectant. The vegetable seedling raising method adopts the vegetable seedling raising medium as a seedling raising medium; the vegetable seedling raising medium has awide selection range of raw materials and a simple preparation process, sufficient nutrients are provided for seedling raising of vegetables, and vegetable seedlings grow vigorously and have high disease resistance.

Owner:和县绿缘温室科技有限公司

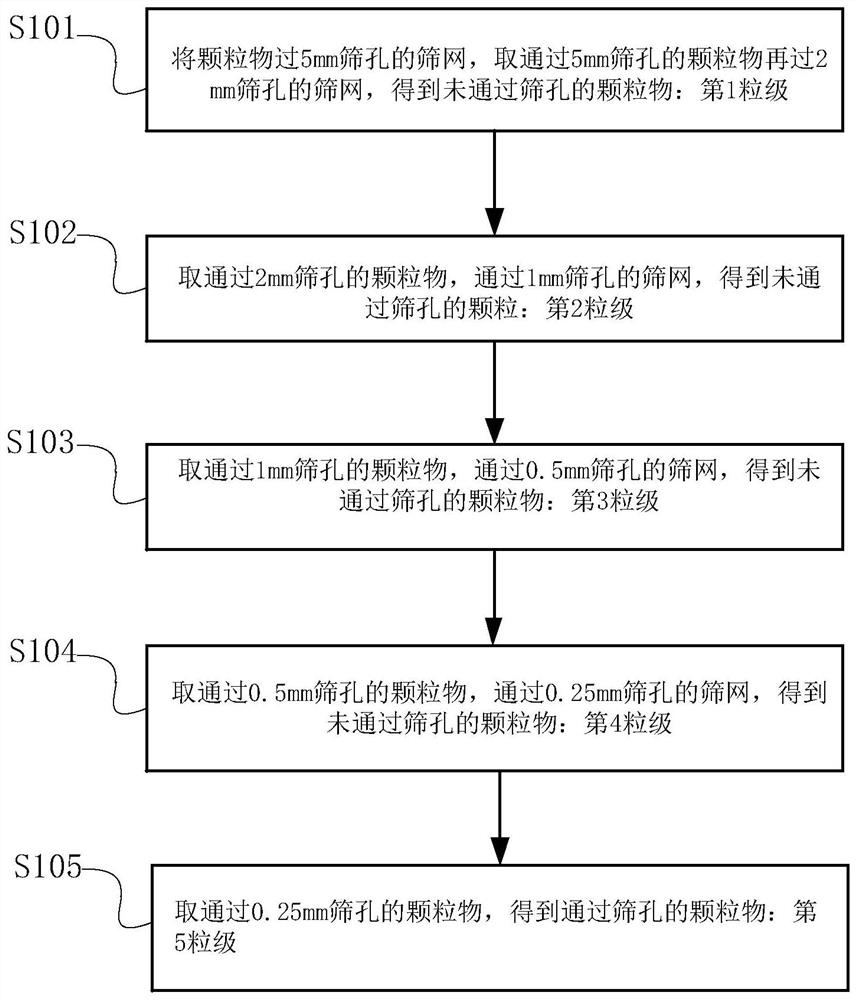

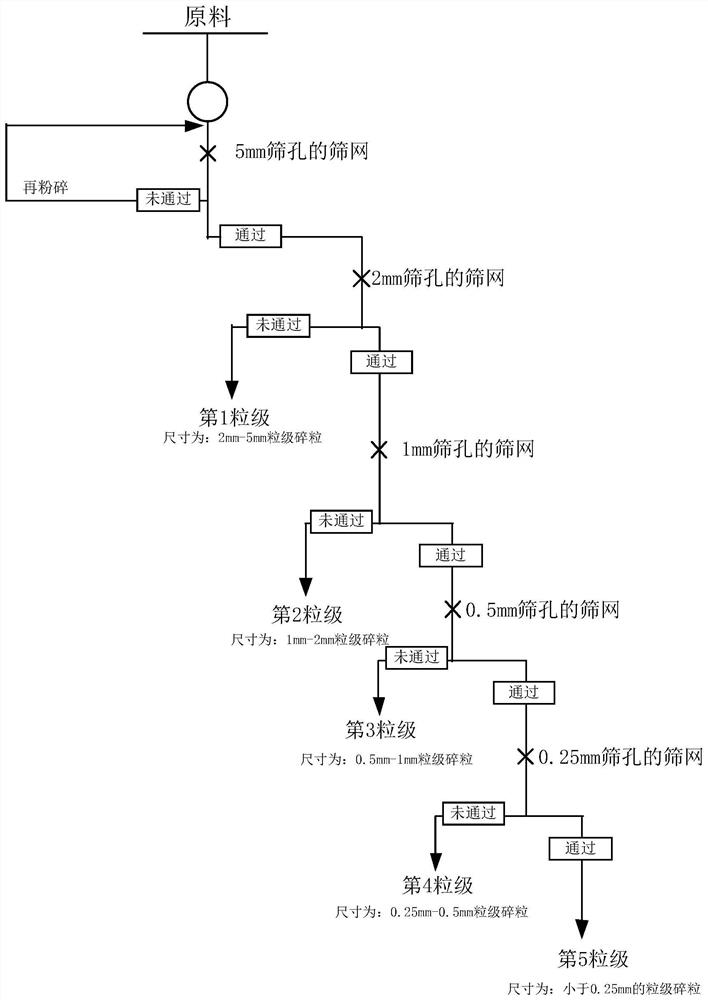

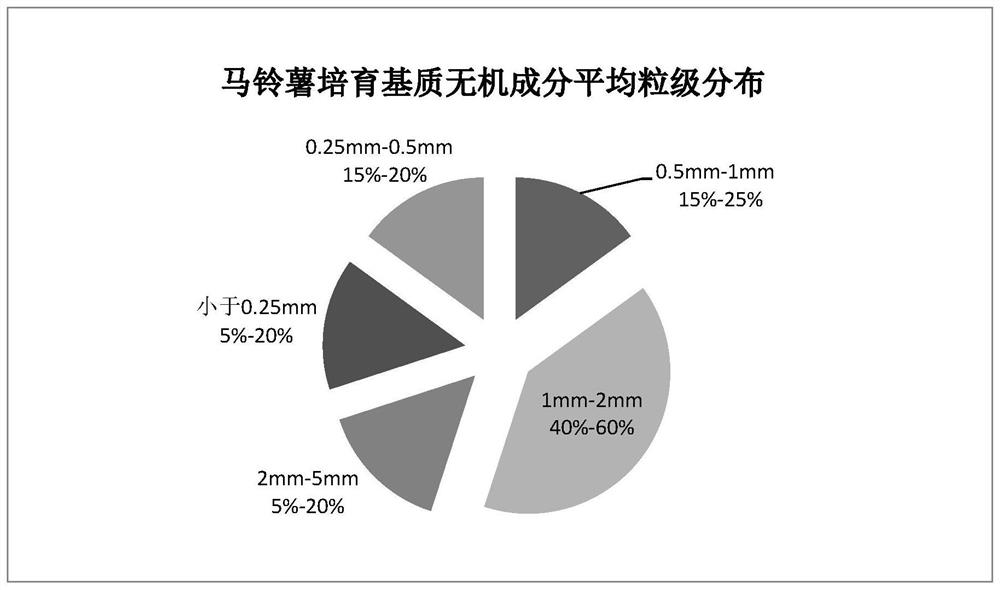

Potato virus-free seedling culture medium produced by mechanical composition method and preparation method thereof

The invention discloses a potato virus-free seedling culture medium and a preparation method thereof. The potato virus-free seedling culture medium comprises inorganic components, wherein the inorganic components comprise, by volume, 15%-20% of crushed grains with the size fraction of 0.25 mm-0.5 mm, 15%-25% of crushed grains with the size fraction of 0.5 mm-1 mm and 40%-60% of crushed grains withthe size fraction of 1 mm-2 mm. According to the potato virus-free seedling culture medium, the multiple inorganic matter components are used as raw materials, the scientific and reasonable seedlingculture medium is established by regulating and controlling the size fractions with different grain sizes in the medium and controlling the medium gap proportion, namely pore size distribution, water,oxygen and nutrition supply required by potato virus-free seedling culture is met to the maximum extent, and large-scale, factory-like, efficient and low-cost cultivation and production of high-quality potato seeds are realized.

Owner:刘克锋

A kind of street tree planting method and tree hole structure

ActiveCN110881337BEasy to breathePromote absorptionGrowth substratesCulture mediaAbsorption of waterStreet tree

Owner:上海市绿化管理指导站

Planting system and planting method suitable for southern magnolia

InactiveCN113508699AEasy to breathePromote absorptionRoot feedersGrowth substratesAbsorption of waterMagnolia grandiflora L.

The invention provides a planting system and planting method suitable for southern magnolia. The planting system comprises a plant pit and a planting matrix. The planting matrix comprises a lower layer located at the bottom of the plant pit, wherein the lower layer is formed by a mixture of formula soil and filling particles according to the volume ratio of (1-2): 9; a middle layer located on the upper portion of the lower layer, wherein the middle layer is formed by a mixture of formula soil and filling particles according to the volume ratio of (4-5): 5, planting pits used for planting southern magnolia are reserved in the middle layer, and the mass water content of the middle layer is 65-75%; and an upper layer on the upper portion of the middle layer, wherein the upper layer is formed of filling particles. The three-layer structure of the planting matrix has appropriate porosity and good air permeability and water permeability, respiration of root systems and absorption of water and fertilizer are facilitated, and a growth environment matched with the southern magnolia can be provided for the southern magnolia.

Owner:上海市绿化管理指导站

A kind of waterless gunpowder and preparation method thereof

The invention provides an anhydrous taphole clay, which uses high-alumina aggregate, corundum, silicon carbide, boron nitride, pitch and coke as main raw materials, through the synergistic combination of additives soft clay and tar, through batching, mud grinding and It is prepared after forming; the parts by weight of the main raw materials and additives are: high alumina aggregate 20~24, corundum 23~24, silicon carbide 20~25, boron nitride 3~5, pitch 6~8, coke 8 ~10 parts, soft clay 5~8, tar 14~15; The present invention also provides a kind of preparation method of anhydrous gunpowder, at first raw material is stirred evenly to obtain mixed raw material; Milled at 55°C for 40~50? min; then transfer the milled mud to the molding machine, extrude the mud from the squeeze port at 55~65°C, divide the block according to 5~7kg per piece, and carry out no less than 10 times of throwing mud process, make. The anhydrous taphole clay prepared by the invention has high strength, good volume stability, strong slag resistance and erosion resistance, and good opening performance.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

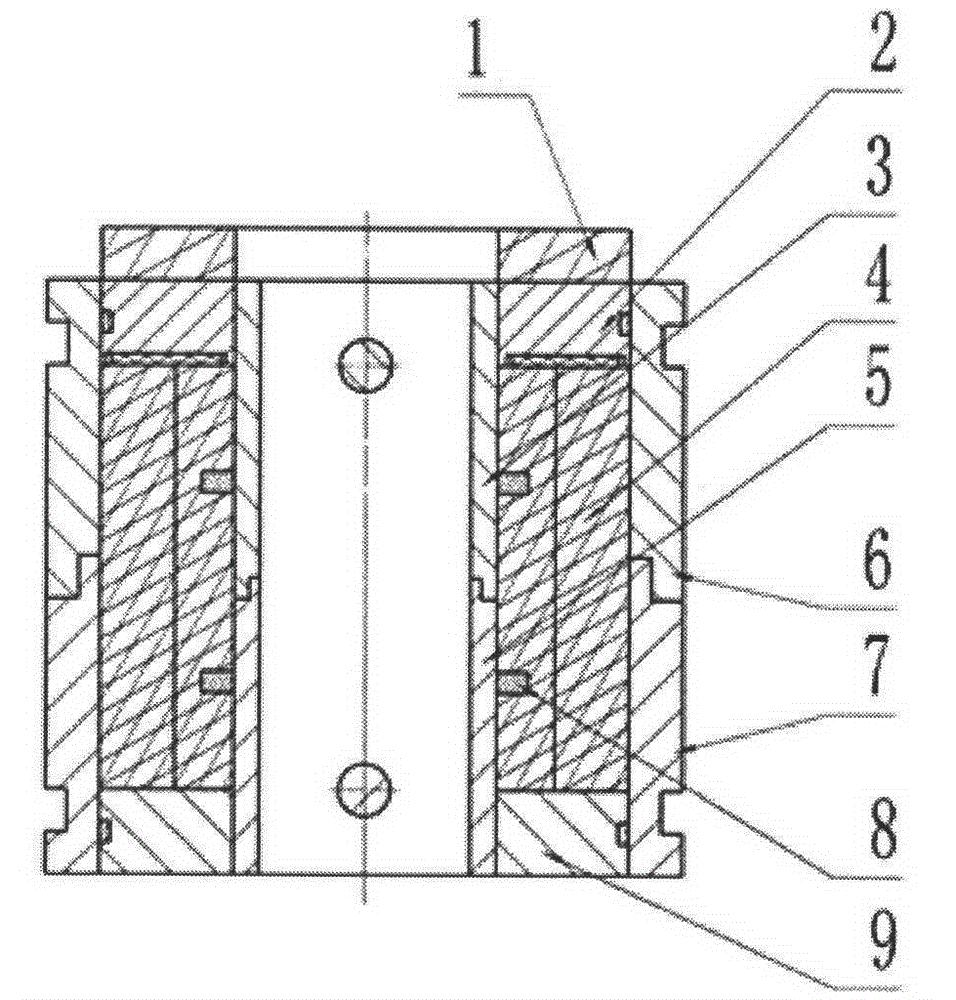

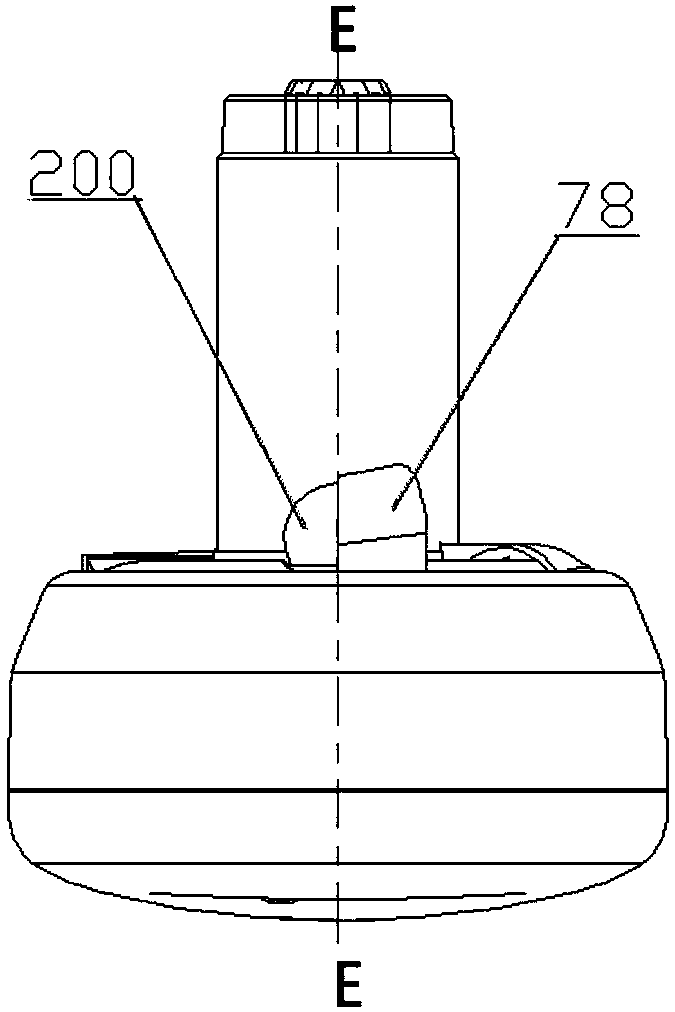

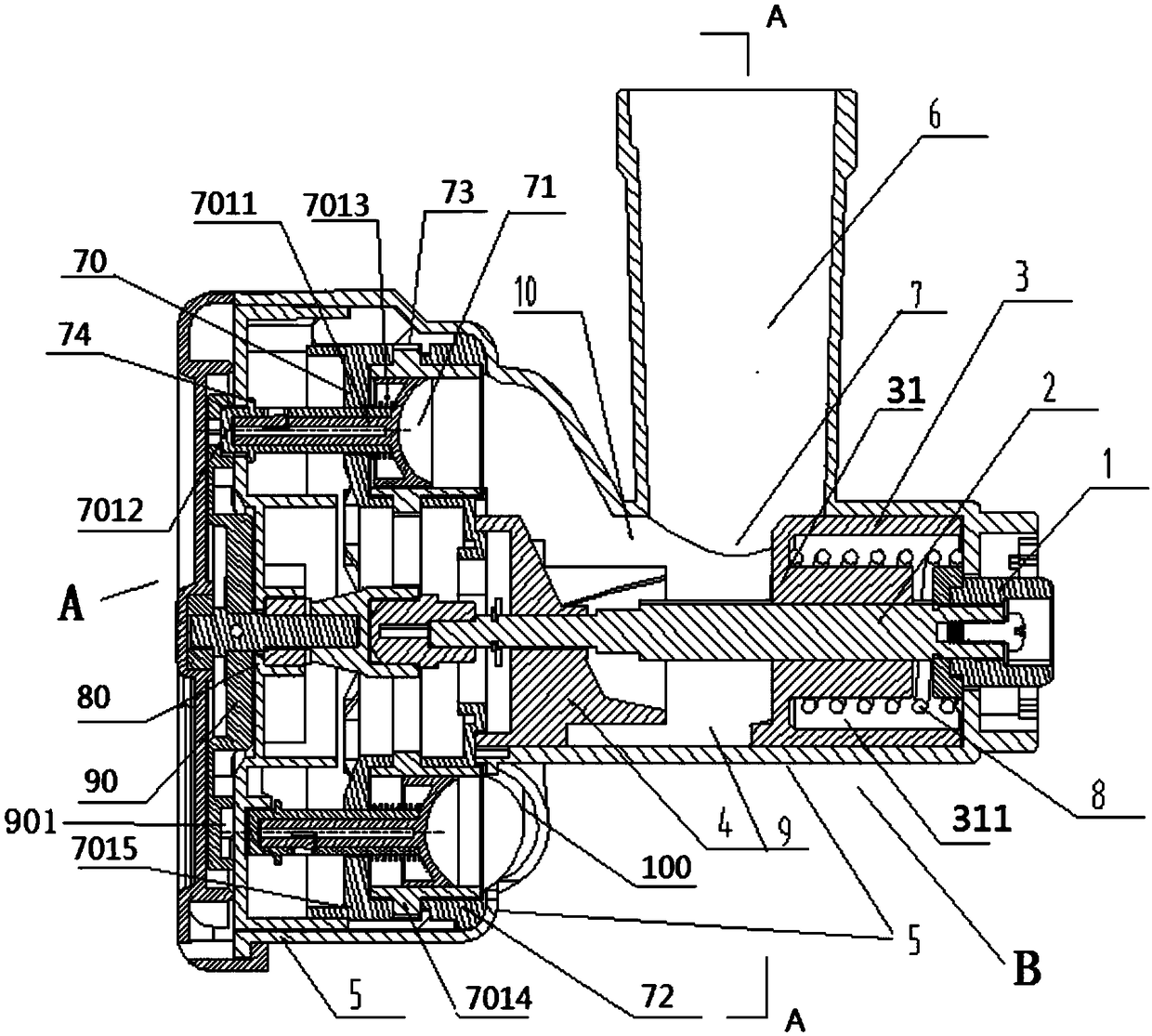

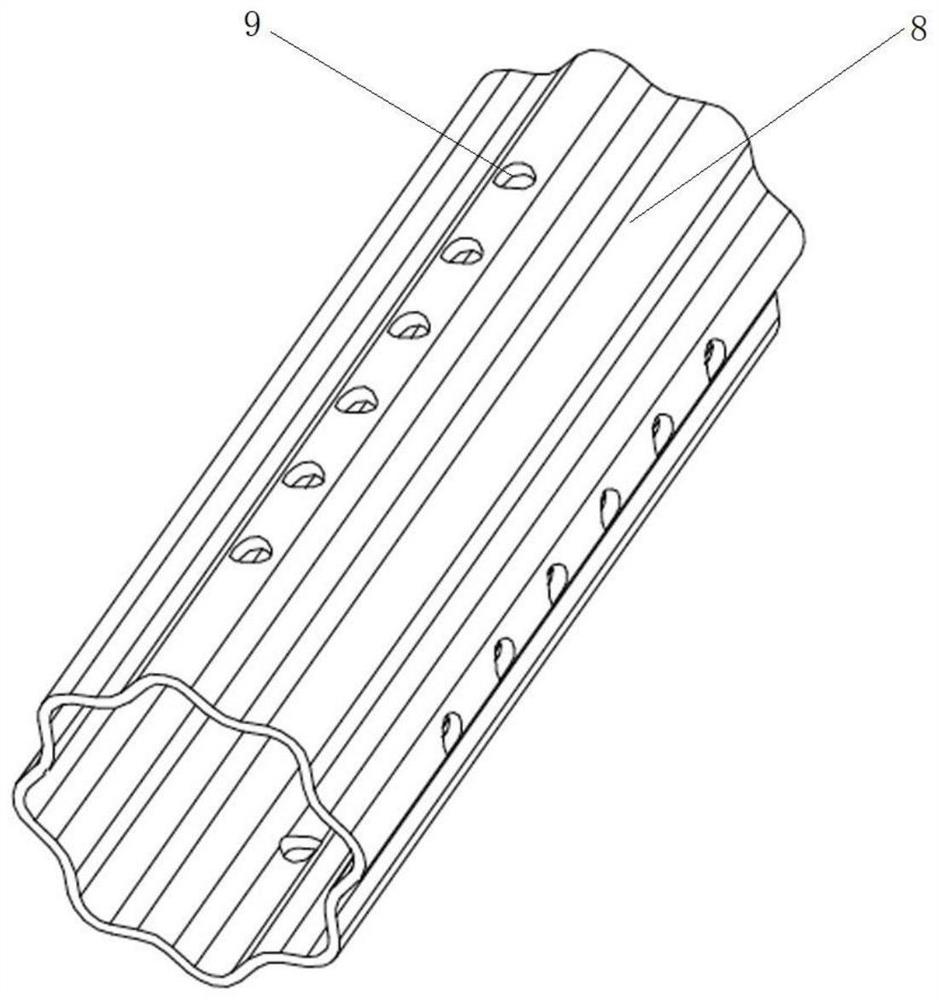

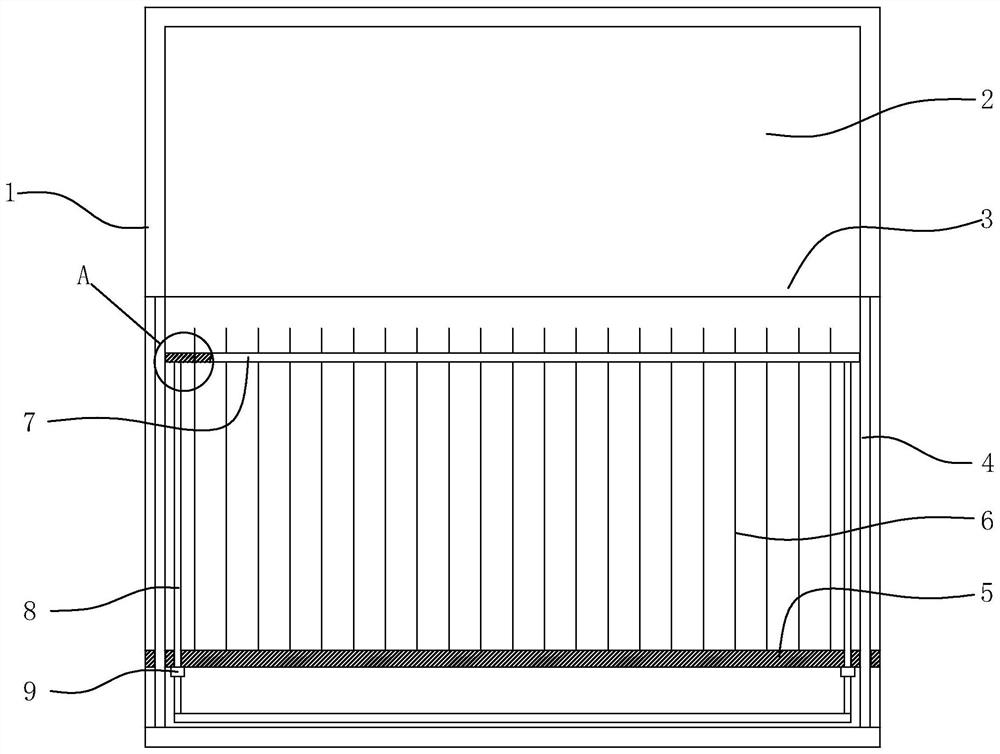

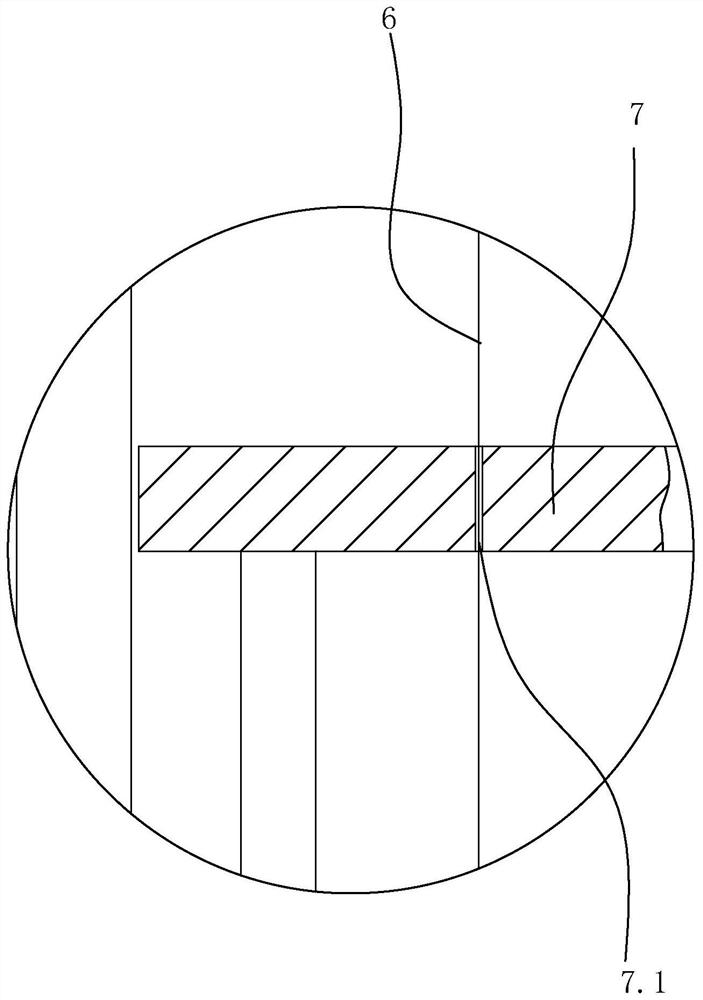

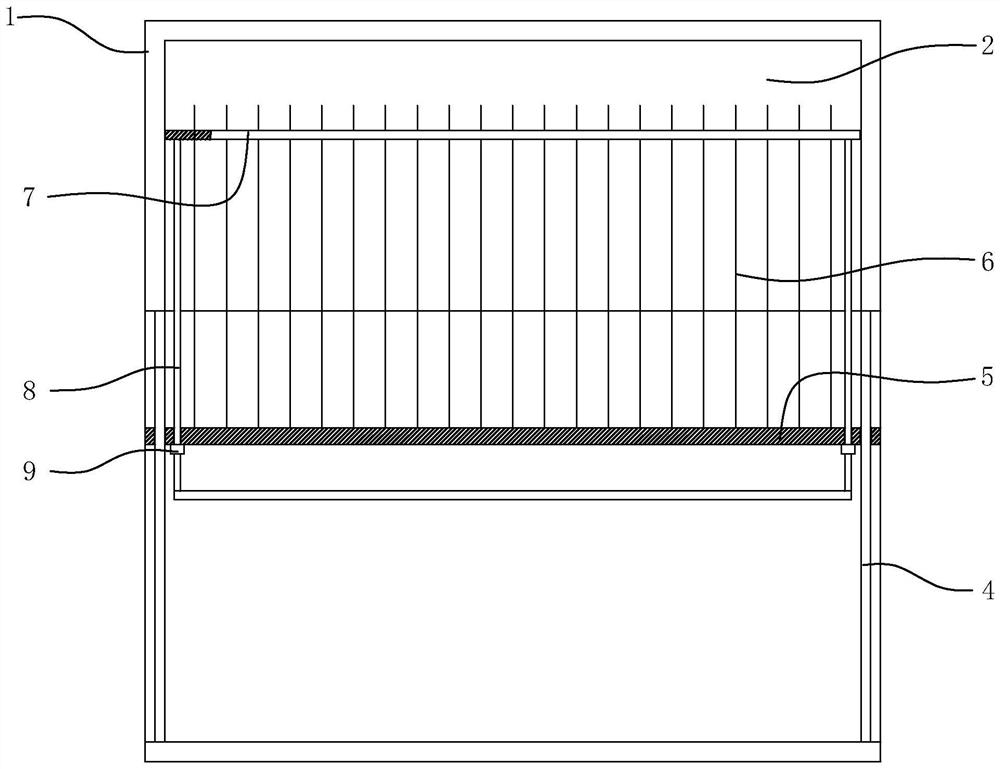

A kind of preparation equipment and preparation method of peach red Guiqi donkey-hide gelatin cake

ActiveCN111481592BImprove qualityGreat tastePharmaceutical product form changeUnknown materialsPolymer scienceEngineering

The invention discloses a preparation equipment and method for Peach Red Guiqi Ejiao Cake, and aims to provide a preparation equipment and method for Peach Red Guiqi Ejiao Cake which can ensure that donkey-hide gelatin cake slices have a suitable porosity and improve the quality and taste of the donkey-hide gelatin cake. Preparation. The preparation equipment of peach red Guiqi donkey-hide gelatin cake comprises a donkey-hide gelatin forming mold device, and the donkey-hide gelatin forming mold device includes a mold base, a forming groove arranged on the mold base, a horizontal guide rod arranged on the mold base, and a vertical guide rod sliding along the horizontal guide rod. Straight side sealing plate, several steel wires set on the vertical side sealing plate, steel wire correction plate parallel to the vertical side sealing plate, horizontal guide hole set on the vertical side sealing plate, slide set in the horizontal guide hole The sliding guide rod and the limit block arranged on the sliding guide rod.

Owner:ZHEJIANG CHINESE MEDICAL UNIV MEDICAL PIECES

Method for remediation of estradiol in soil on basis of immobilized microbial technology

InactiveCN105039301AFixedWill not cause secondary pollutionContaminated soil reclamationMicroorganism based processesMicroorganismPyrophyllite

The invention relates to a method for remediation of estradiol in soil on basis of the immobilized microbial technology, relates to a method for soil remediation. The method comprises the following steps: mixing pyrophyllite, decorticated cottonseed meal and pine needle according to the weight part ratio of pyrophyllite to decorticated cottonseed meal to pine needle being 4:1:1 to obtain a microbial immobilized carrier material, sterilizing, inoculating a bacterium suspension which accounts for 2-5% of the total weight of the carrier, additionally adding an enrichment medium according to the dosage of 1.5 ml of enrichment medium for 1 g of the carrier each day to obtain immobilized microbial granules, and determining a proper feed ratio of the prepared immobilized microbial granules according to the weight of soil, so as to be used for remediation of estradiol contaminated soil. According to the method for remediation of estradiol in soil on basis of the immobilized microbial technology, provided by the invention, estradiol in soil is degraded by utilizing the immobilized microbial technology, and the degradation effect of estradiol under different environment temperatures, pH values and soil moisture contents and other soil environment conditions can be examined.

Owner:SHENYANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com