Potato virus-free seedling culture medium produced by mechanical composition method and preparation method thereof

A manufacturing method, potato technology, applied in the direction of culture medium, planting substrate, botany equipment and methods, etc., can solve the problems of relatively expensive price, affecting the yield and quality of micro-tubers, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

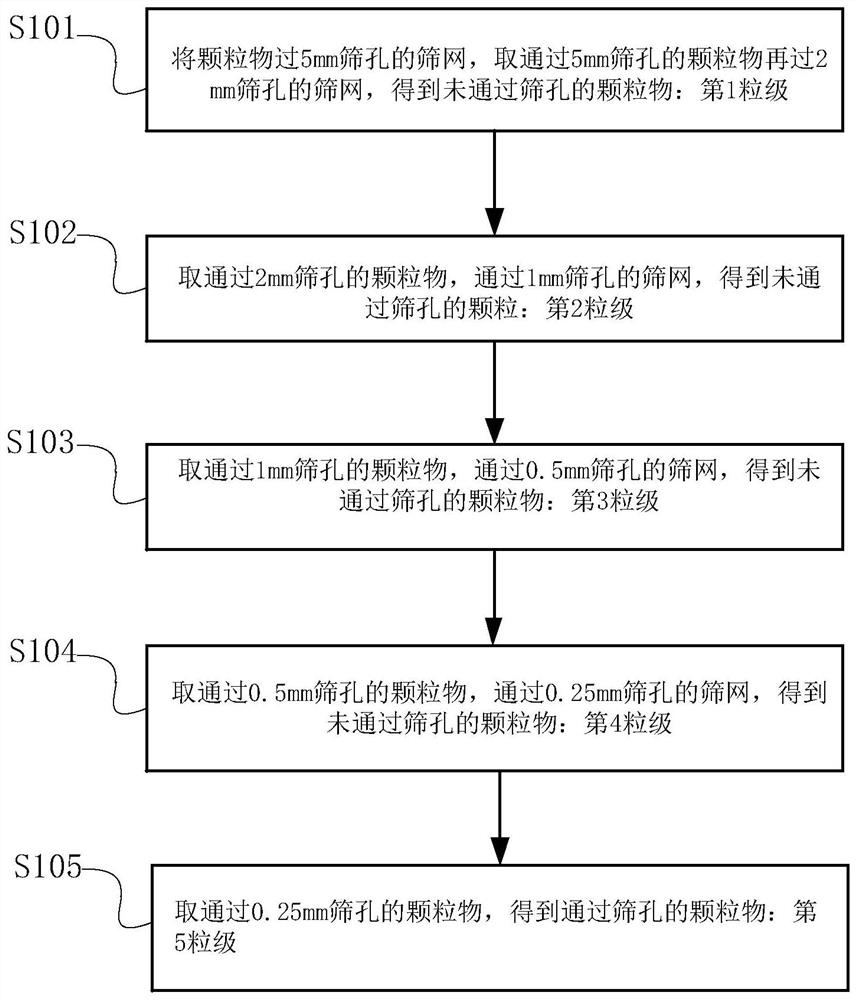

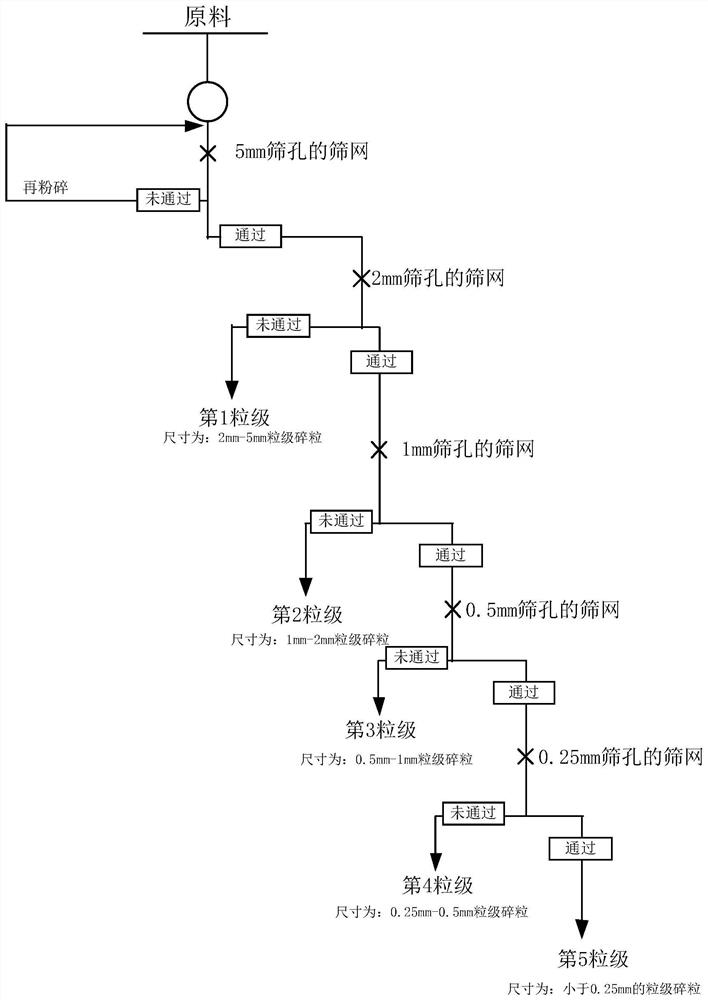

[0072] figure 1 It is a process flow chart of the potato virus-free seedling cultivation substrate manufacturing method of the present invention, figure 2 It is a flow chart of the grain screening process of the potato virus-free seedling cultivation substrate of the present invention, as figure 1 , figure 2 As shown, the screening process includes the following steps:

[0073] The inorganic component raw materials are graded and sieved, and the sieving steps are as follows:

[0074] Step S101, subjecting the crumbs to a grading and sieving process, passing the crumbs through a sieve with a 5mm sieve, taking the crumbs that passed through a 5mm sieve, and then passing through a 2mm sieve to obtain crumbs that did not pass through the sieve : The first grade. Through this step, the first grade of inorganic crumbs and the first grade of organic crumbs can be obtained.

[0075] Further, crush the crumbs that do not pass through the 5mm sieve, and pass the crushed crumbs th...

Embodiment 2

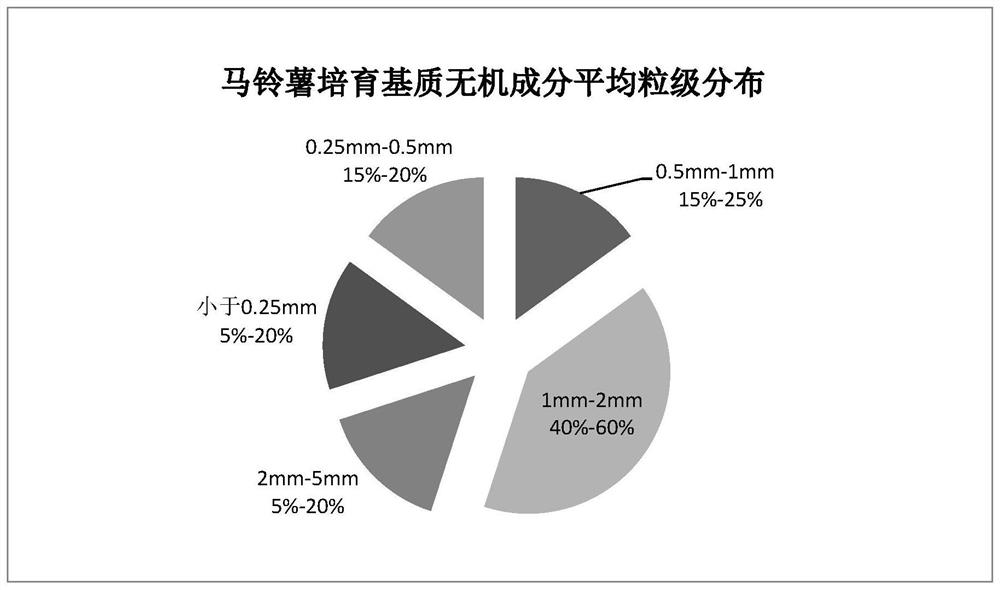

[0090] The manufacturing method is the same as in Example 1, the only difference is that the particle size of the inorganic component crumbs is adjusted to:

[0091] The volume percentage of crushed particles with a size of 2mm-5mm in the inorganic component crushed particles is controlled at 10%, and the volume percentage of crushed particles with a size of 0.25mm or less is controlled at 5%.

[0092] Control the volume percentage of crumbs with a size of 1mm-2mm in the inorganic component crumbs to 45%, the volume percentage of crumbs with a size of 0.5mm-1mm to 20%, and the crumbs with a size of 0.25mm-0.5mm The volume percentage of broken grains is controlled at 20%.

[0093] The inorganic component crumbs are mixed as follows: 10% of the 1st grade, 45% of the 2nd grade, 20% of the 3rd grade, 20% of the 4th grade and 5% of the 5th grade Mix to obtain the inorganic component mixed matrix in formula 2.

[0094] Further, the inorganic component with a volume percentage of 7...

Embodiment 3

[0096] The manufacturing method is the same as in Example 1, the only difference is that the particle size of the inorganic component crumbs is adjusted to:

[0097] In the crushed inorganic components, the volume percentage of crushed particles with a size of 2mm-5mm is controlled at 15%, and the volume percentage of crushed particles with a size below 0.25mm is controlled at 5%.

[0098] Control the volume percentage of crumbs with a size of 1mm-2mm in the inorganic component crumbs at 40%, and control the volume percentage of crumbs with a size of 0.5mm-1mm at 25%, with a size of 0.25mm-0.5mm The volume percentage of particle size broken grains is controlled at 15%.

[0099] The inorganic component crumbs are mixed as follows: 15% of the first fraction, 40% of the second fraction, 25% of the third fraction, 15% of the fourth fraction and 5% of the fifth fraction Mix to obtain the inorganic component mixed matrix in formula 3.

[0100] Further, the potato virus-free seedli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com