Garden type roof greening matrix and manufacturing method thereof

A technology for roof greening and manufacturing method, applied in planting substrates, chemical instruments and methods, roof decoration, etc., can solve the problems of large volume, large environmental conditions, heavy roof load, etc., to reduce replacement frequency, save economic consumption, Avoid the effect of substrate sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

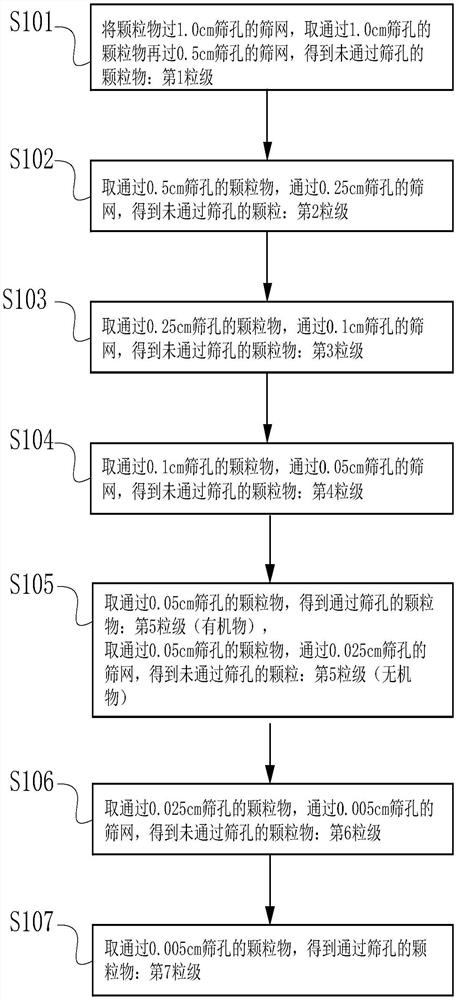

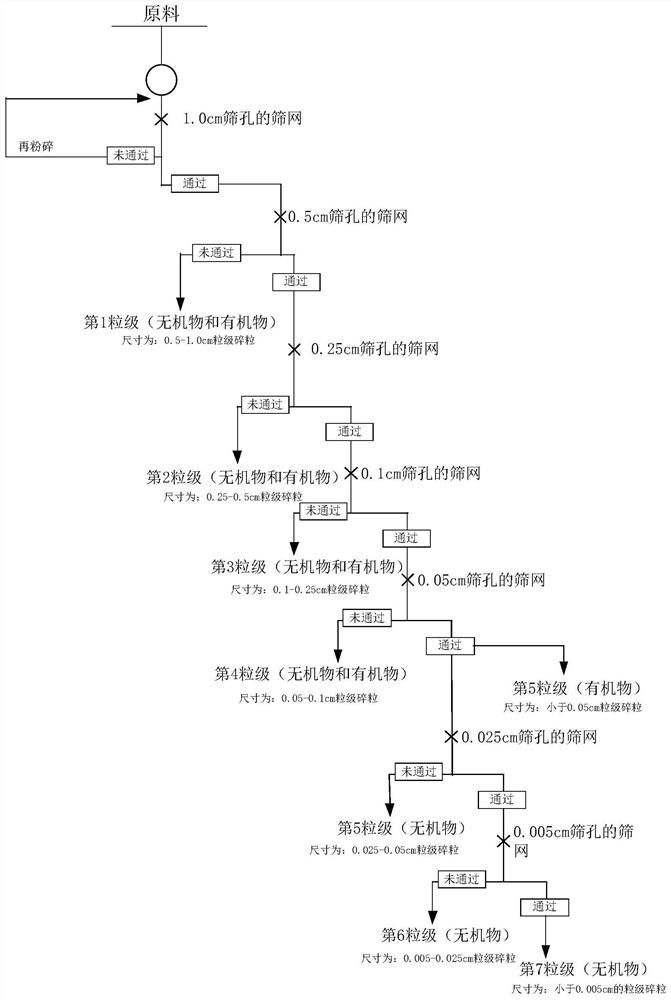

Method used

Image

Examples

Embodiment 1

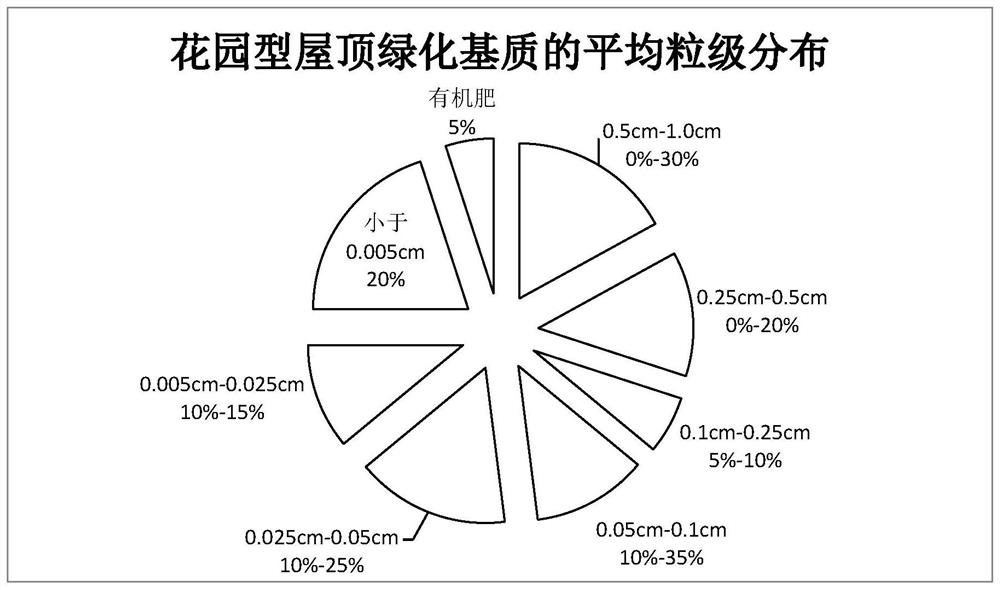

[0078] Example 1, the inorganic matter and the organic matter are mixed according to the proportion, in order to control the particle size ratio in the matrix, among the inorganic matter crumbs, the first granule with a size of 0.5-1.0cm Grade, size 0.25-0.5cm crumbs 2nd grade, size 0.1-0.25cm crumbs 3rd grade, size 0.05-0.1cm crumbs 4th grade, The fifth grade of crumbs with a size of 0.025-0.05cm, the sixth grade of crumbs with a size of 0.005-0.025cm, and the seventh grade of crumbs with a size of less than 0.005cm, of which the first The weight percentage of particle size is 0%-30%, the weight percentage of the second particle size is 0%-20%, the weight percentage of the third particle size is 5%-10%, the weight percentage of the fourth particle size is 10%-35%, The weight percentage of the fifth particle size is 10%-25%, the weight percentage of the sixth particle size is 10%-15%, and the weight percentage of the seventh particle size is less than 20%.

[0079] Among orga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com