Blast furnace gun mud added with SiAlON synthesized through coal ash and preparation method of blast furnace gun mud

A technology of fly ash and taphole clay, which is applied in the field of refractory materials, can solve the problems of undiscovered taphole clay for blast furnace tapholes, and uninvolved application of SiAlON materials, and achieves important economic and social benefits, good opening performance, and reduced cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

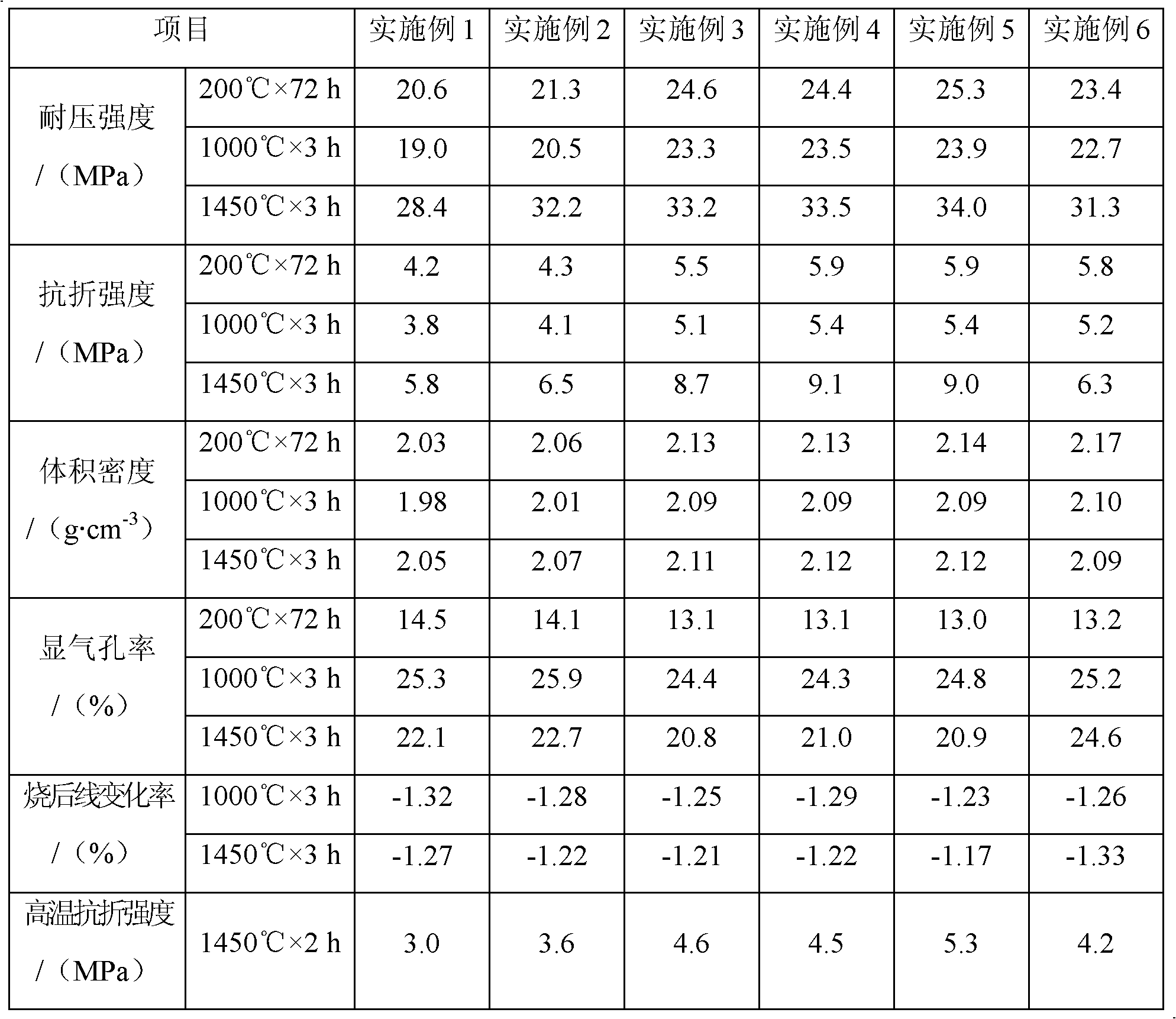

[0022] Embodiment 1, the raw material of gun clay adopts high alumina bauxite clinker particles and fine powder, Al 2 o 3 Content > 88%, particle size ≤ 8mm, 50 kg; silicon carbide particles and fine powder, SiC content > 90%, particle size ≤ 3mm, 19 kg; coke powder, particle size ≤ 3mm, 10 kg; clay fine powder, granules Size ≤ 0.1mm, 10 kg; asphalt powder, particle size ≤ 0.1 mm, 10 kg; SiAlON fine powder synthesized from fly ash discharged from coal-fired power plants, SiAlON phase content > 60%, particle size ≤ 0.1 mm, 1 kg; Binder tar is added, 15 kg. The performance indicators of the clay products are shown in Table 1.

Embodiment 2

[0023] Embodiment 2, the gun clay raw material adopts high alumina bauxite clinker particles and fine powder, Al 2 o 3 Content > 88%, particle size ≤ 8mm, 28 kg; silicon carbide particles and fine powder, SiC content > 90%, particle size ≤ 3mm, 20 kg; coke powder, particle size ≤ 3mm, 20 kg; clay fine powder, granules Size≤0.1mm, 15kg; asphalt powder, particle size≤0.1mm, 7kg; SiAlON fine powder synthesized from fly ash discharged from coal-fired power plants, SiAlON phase content>60%, particle size≤0.1mm, 10kg; Binder tar is added, 17 kg. The performance indicators of the clay products are shown in Table 1.

Embodiment 3

[0024] Embodiment 3, the raw material of gun clay adopts fused brown corundum particles and fine powder, Al 2 o 3Content > 95%, particle size ≤ 8mm, 28 kg; silicon carbide particles and fine powder, SiC content > 90%, particle size ≤ 3mm, 20 kg; coke powder, particle size ≤ 3mm, 20 kg; clay fine powder, granules Size≤0.1mm, 15kg; asphalt powder, particle size≤0.1mm, 7kg; SiAlON fine powder synthesized from fly ash discharged from coal-fired power plants, SiAlON phase content>60%, particle size≤0.1mm, 10kg; Binder tar is added, 16 kg. The performance indicators of the clay products are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com