Patents

Literature

158 results about "Volume contraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Volume contraction is a decrease in the volume of body fluid, including the dissolved substances that maintain osmotic balance (osmolytes). The loss of the water component of body fluid is specifically termed dehydration.

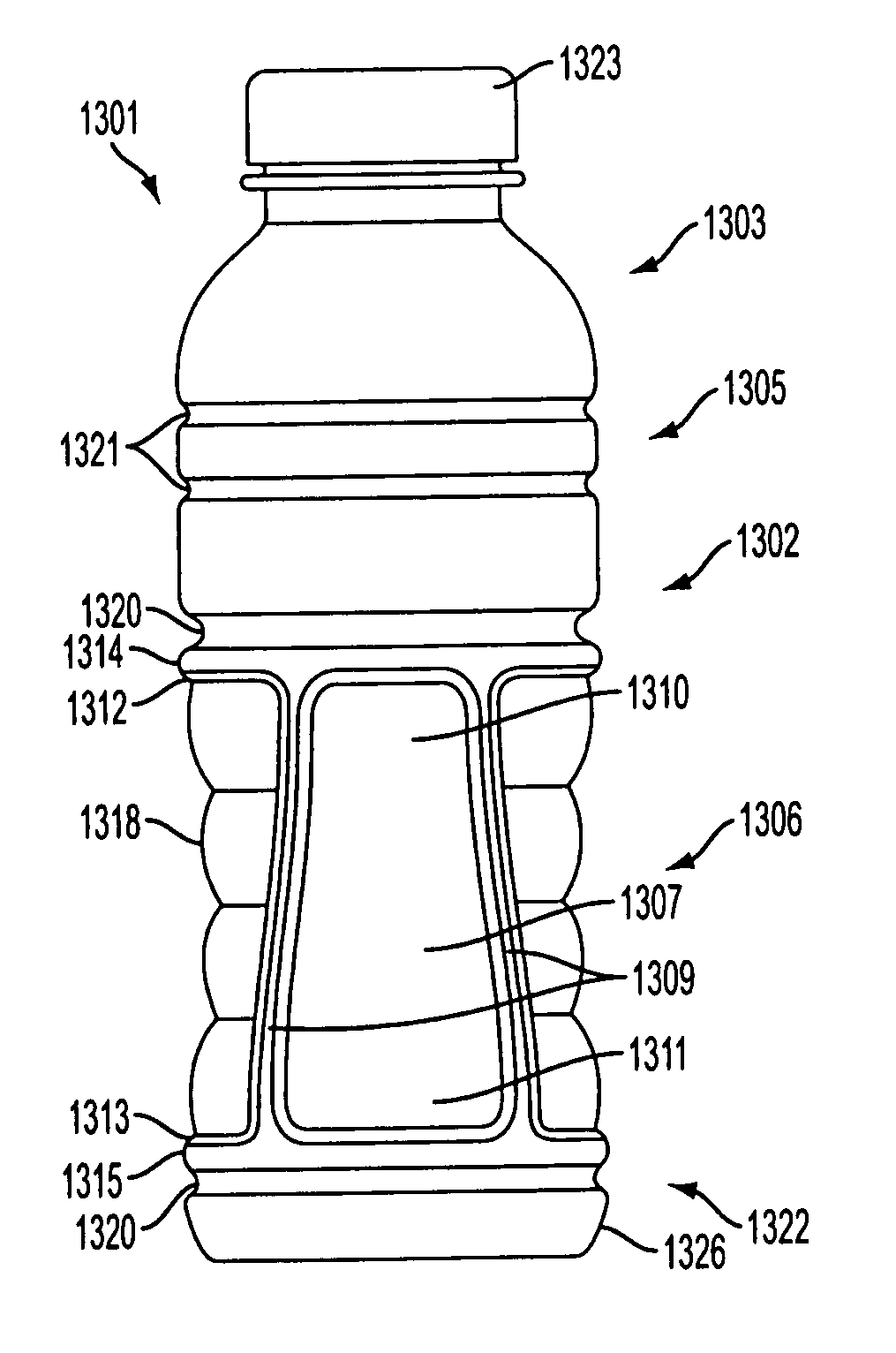

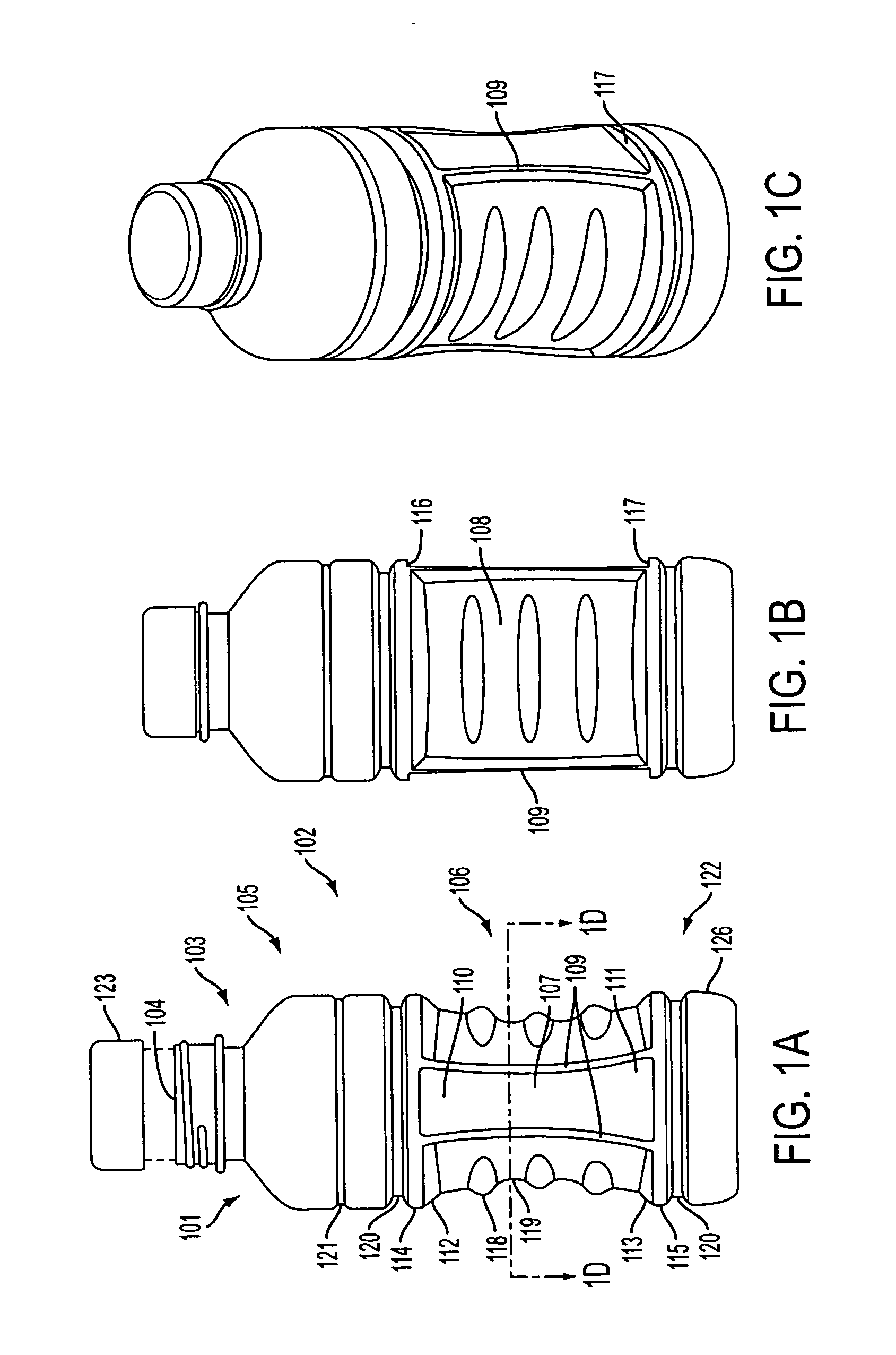

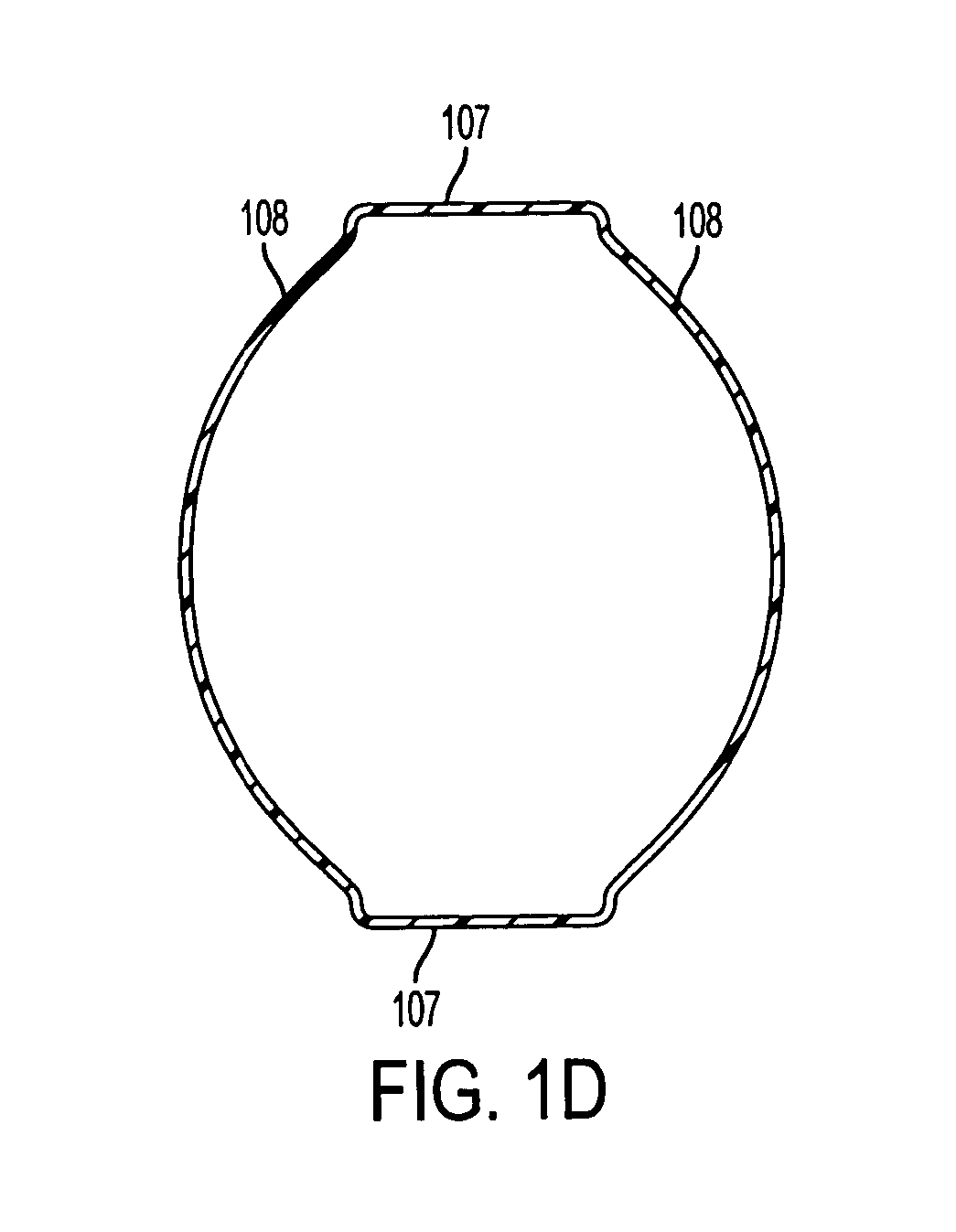

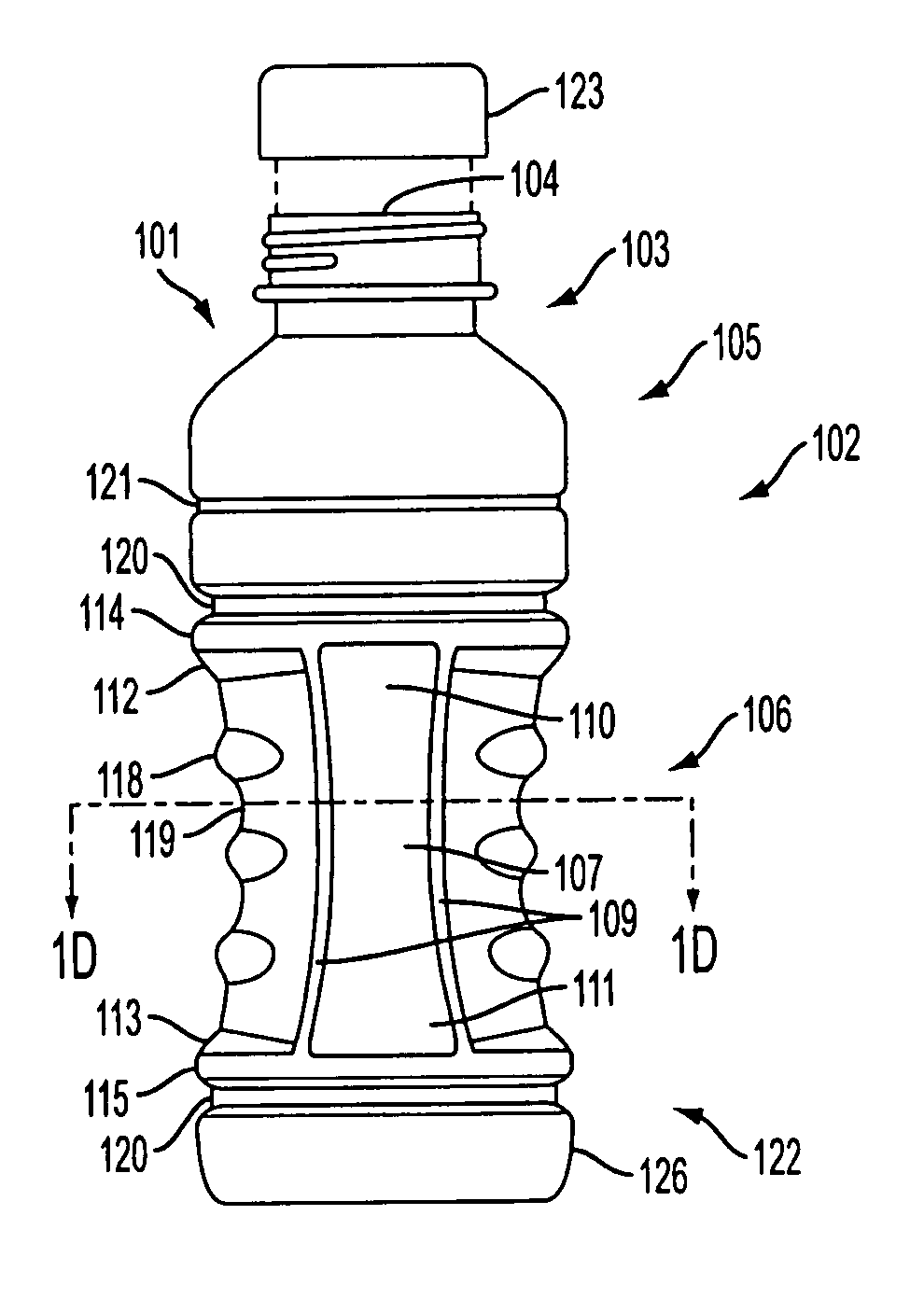

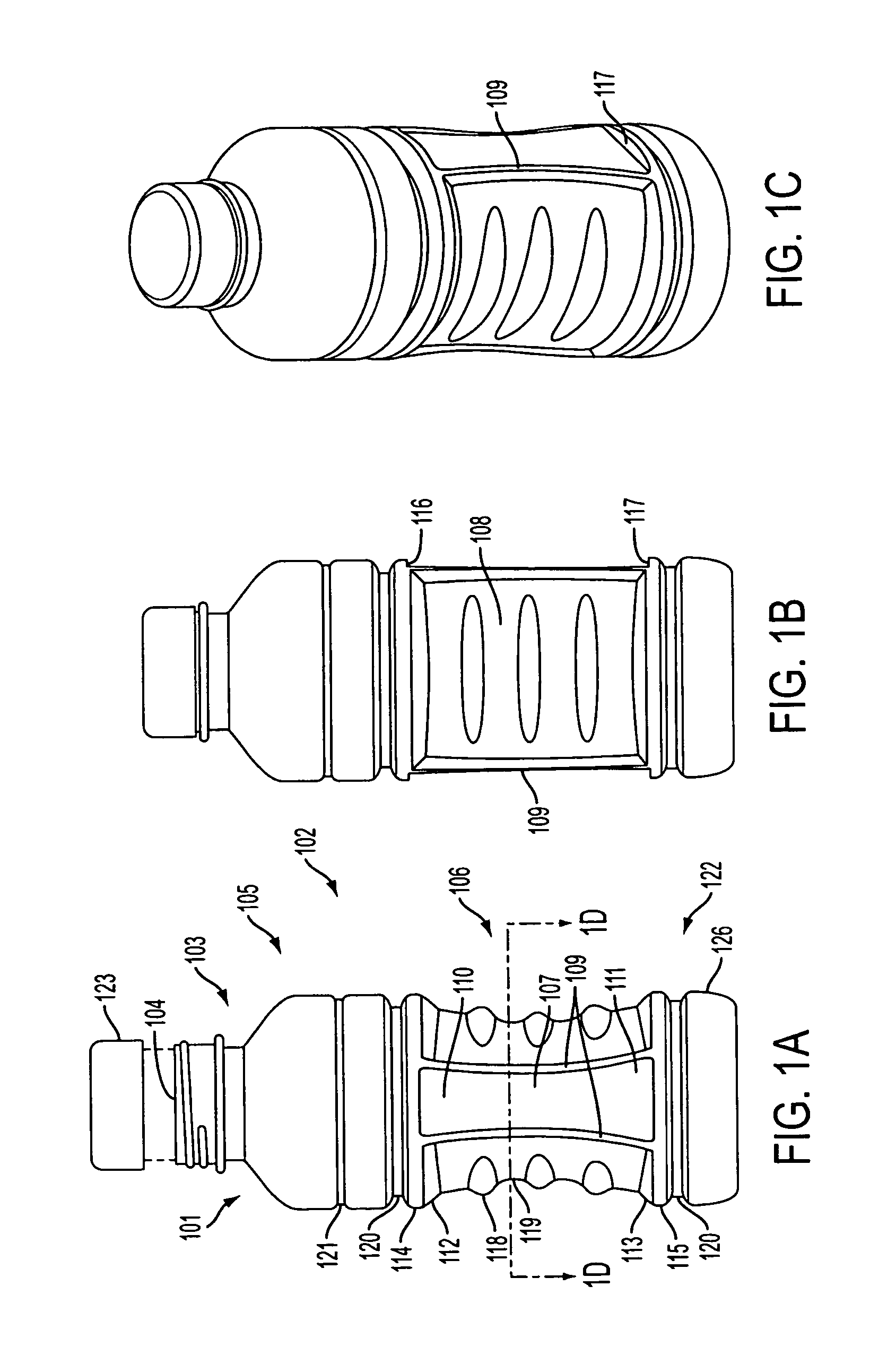

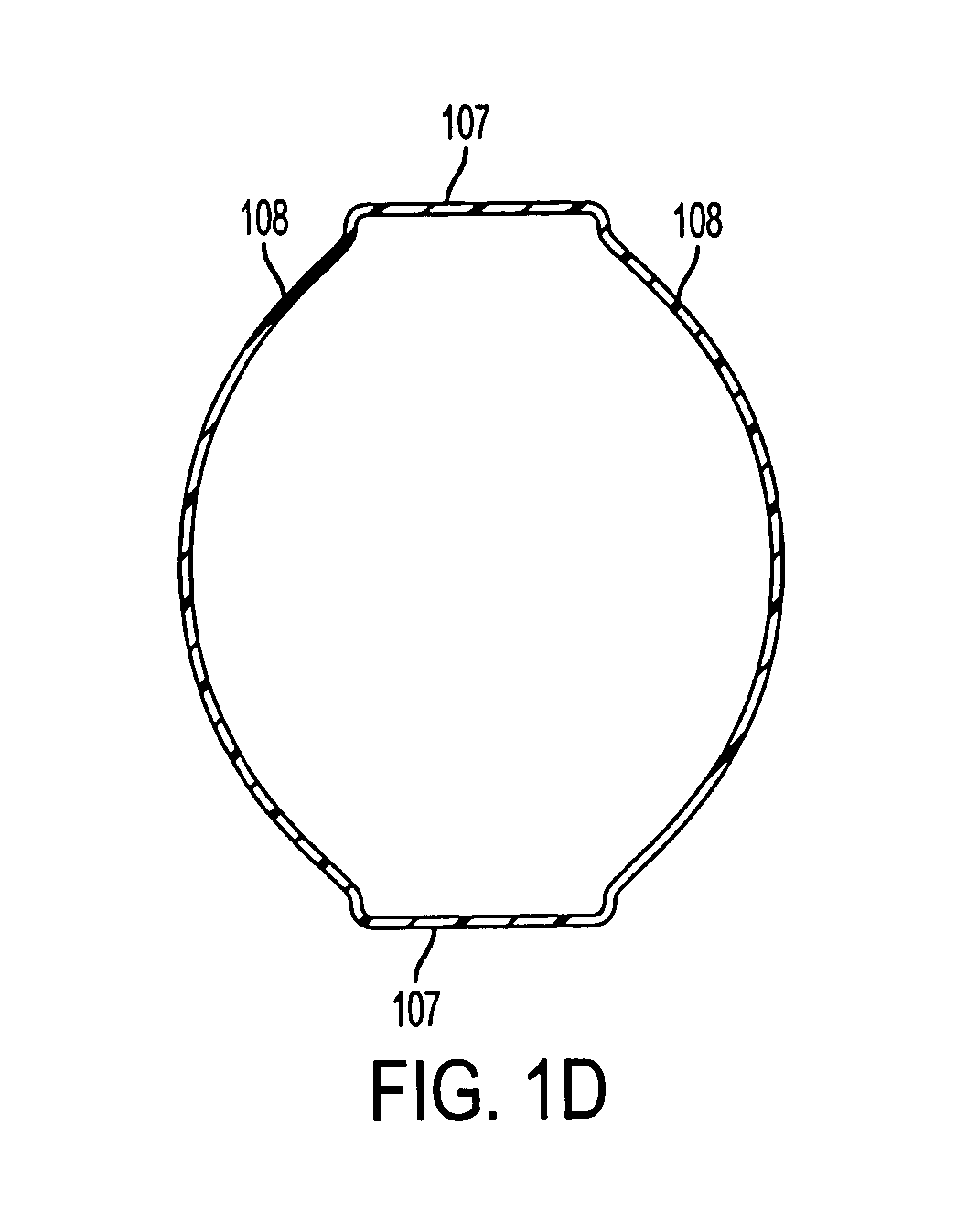

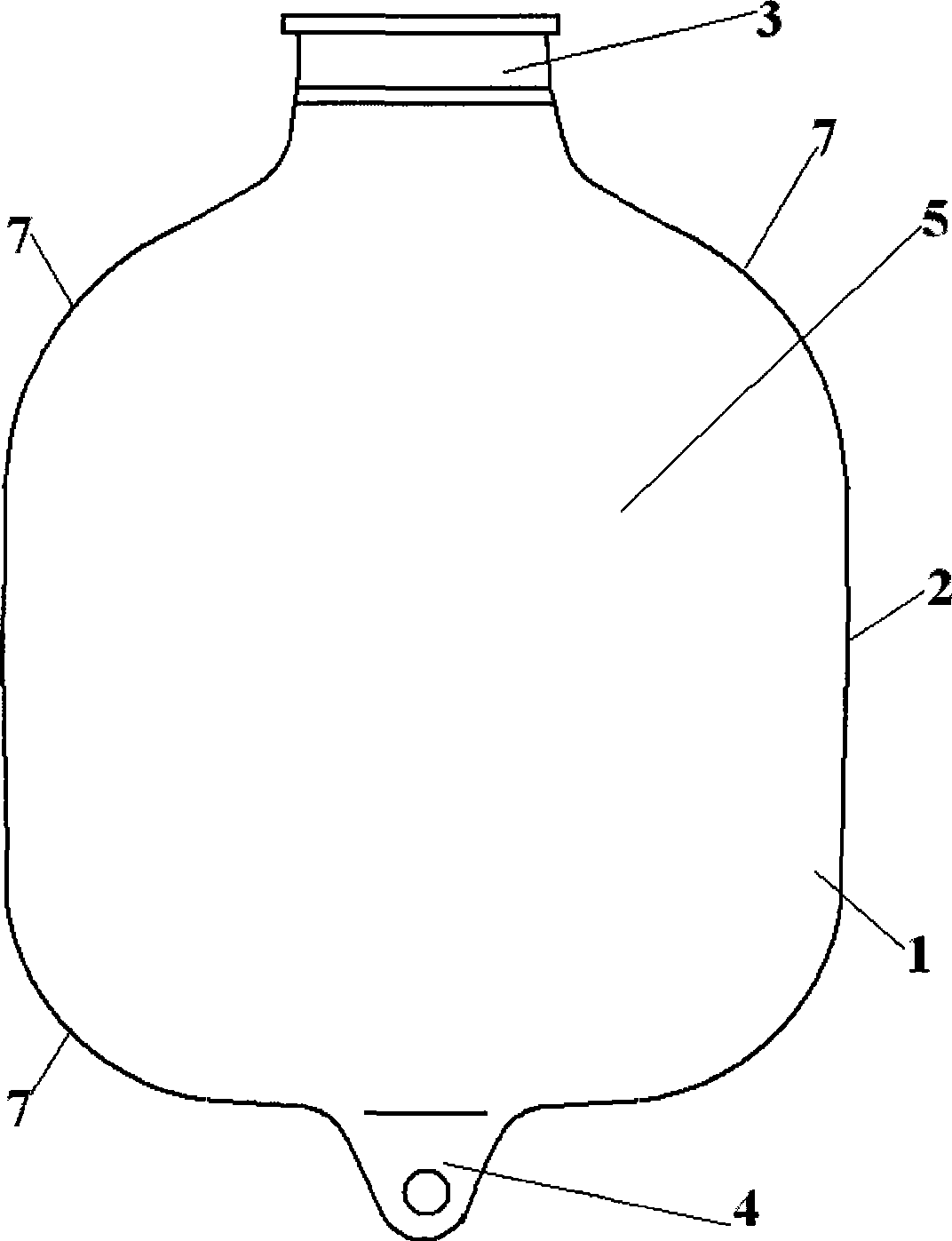

Multi-panel plastic container

ActiveUS20070075032A1Reduce internal pressureReduce distortion problemsBottlesLarge containersEngineeringMechanical engineering

The present invention relates to a container adapted to increase volume contraction and reduce pressure having four panels that are adapted to contract inwardly from vacuum forces created by contraction of container contents.

Owner:CO2 PAC

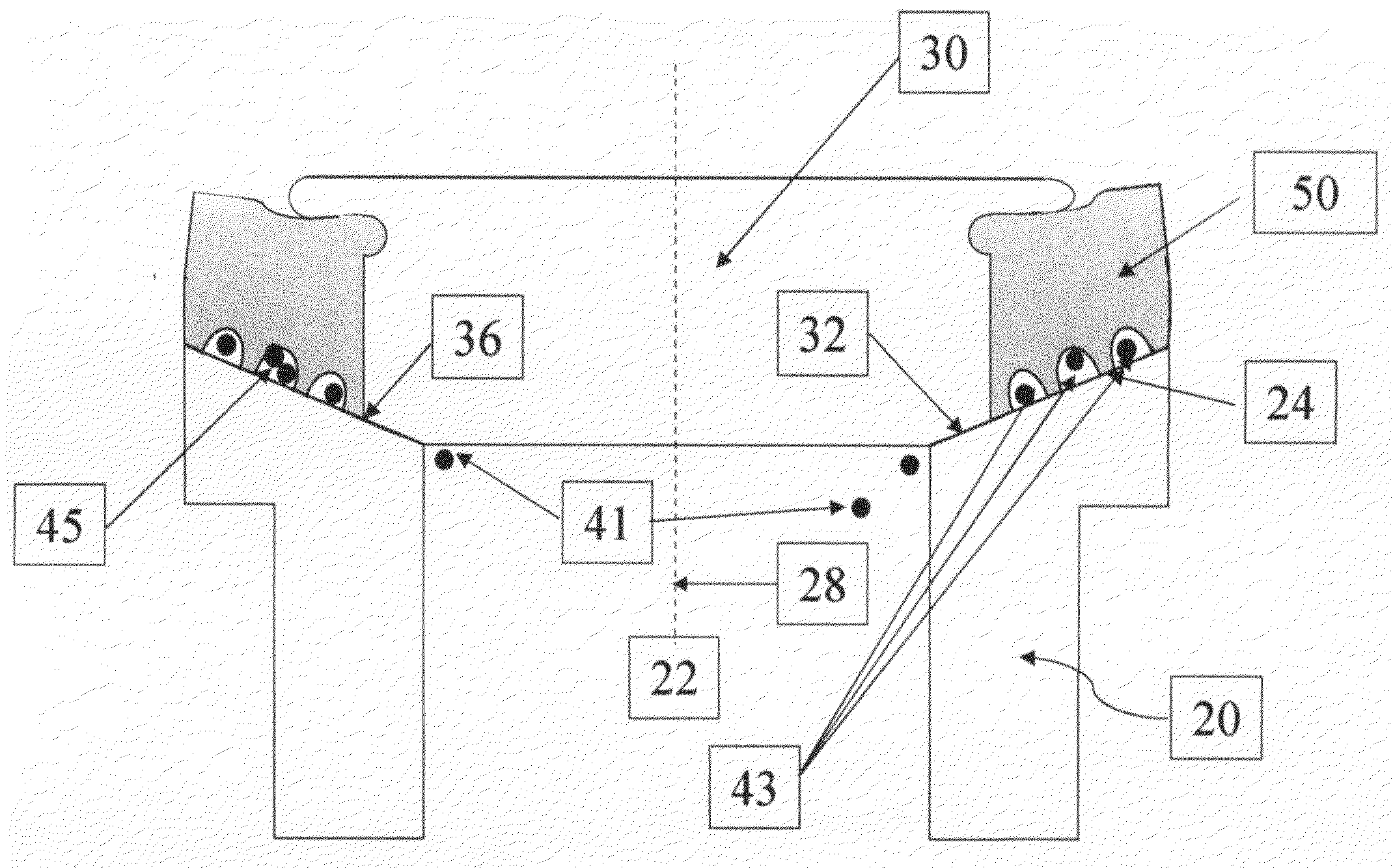

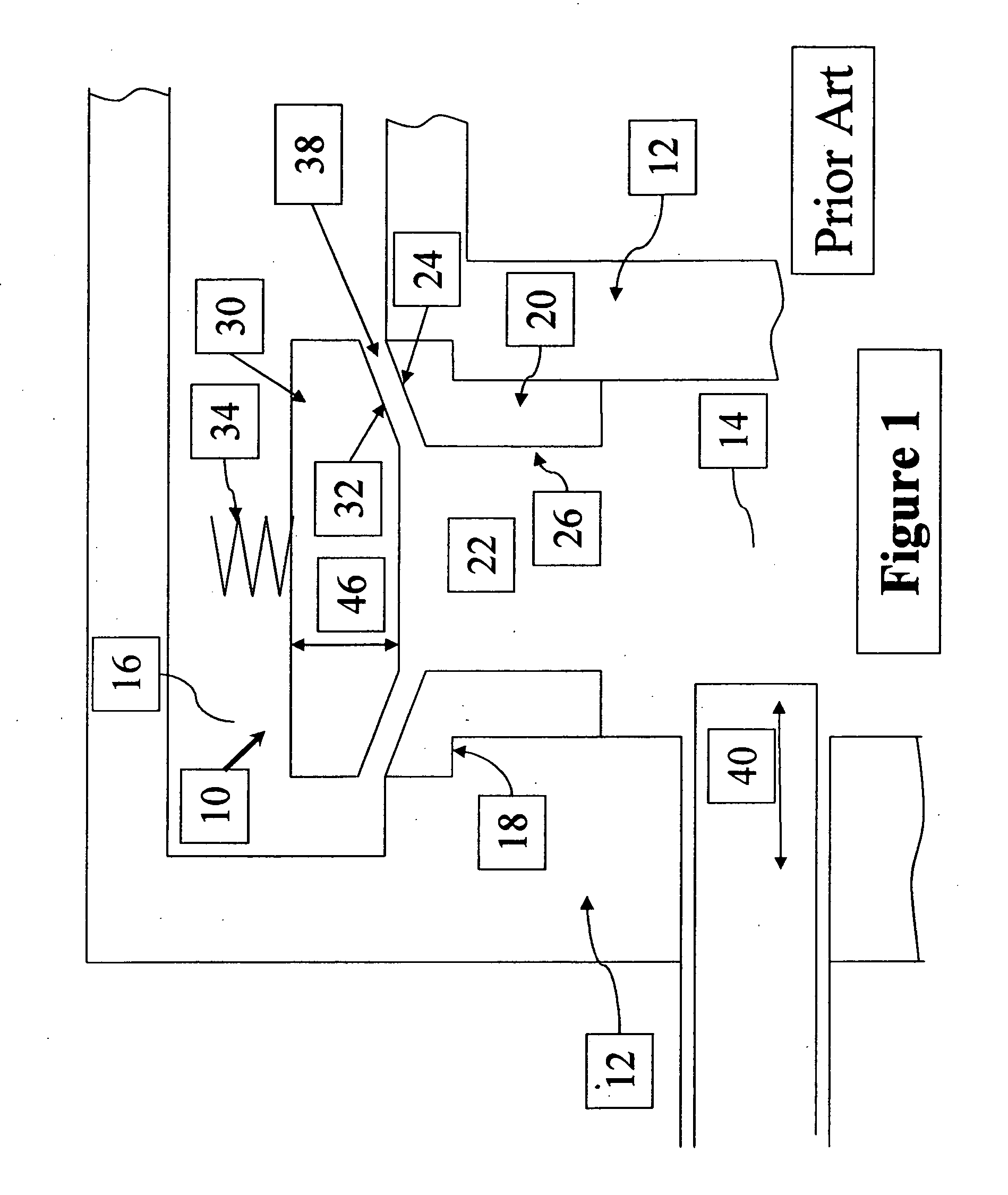

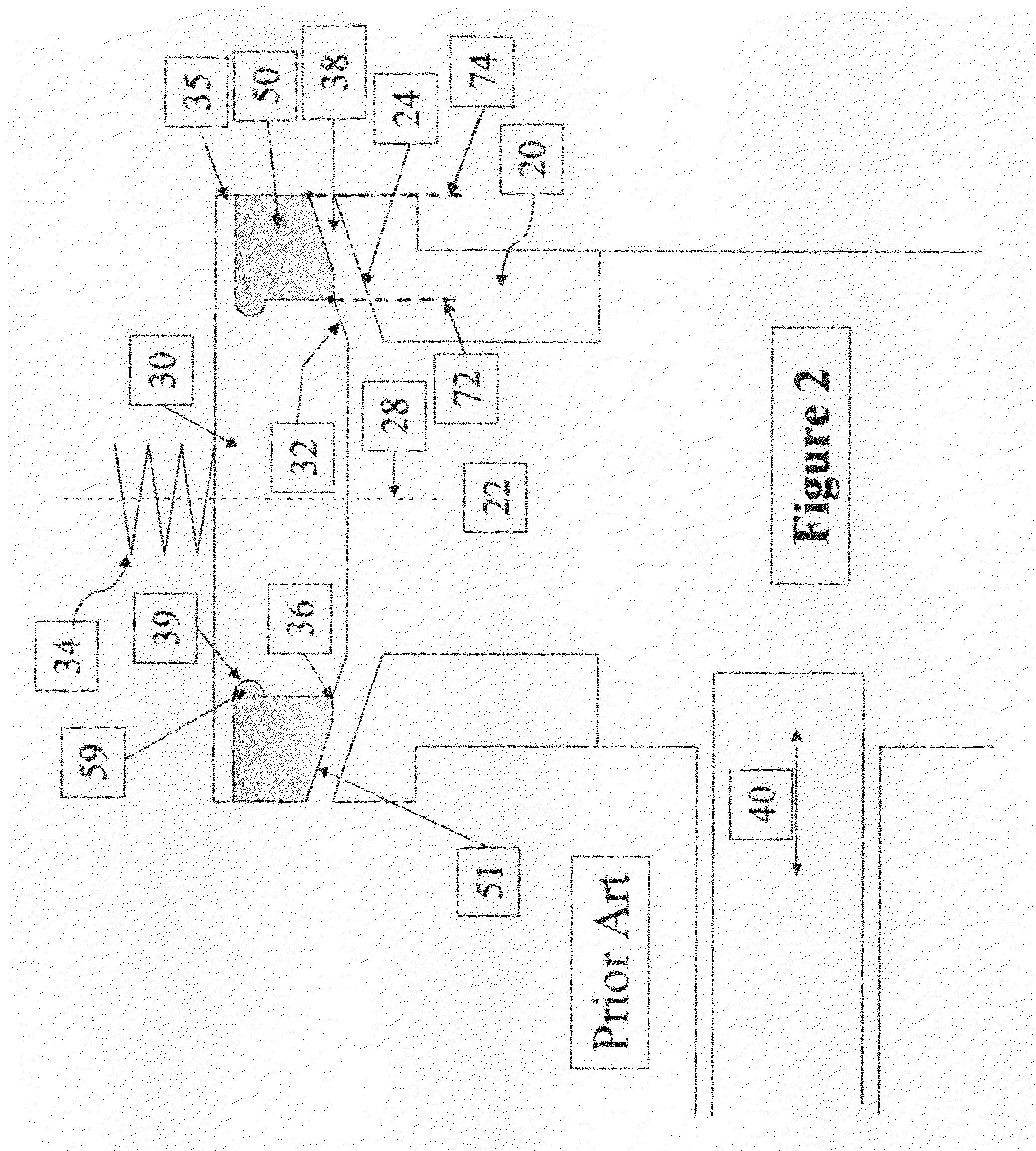

Valve apparatus

InactiveUS20090314979A1Reduces percentage deformationReduce distortionPositive displacement pump componentsCheck valvesSolid particleEngineering

A valve apparatus that has a longitudinal axis therethrough comprises a valve seat member, a valve closure member, a fluid flow path, and a resilient valve insert member. The valve seat member comprises a hollow bore and a first frustoconical contact surface that has an inner perimeter and an outer perimeter. The valve closure member comprises a valve body and a second frustoconical contact surface that is adapted to seal against the first frustoconical contact surface in a strike face area. The valve closure member is movable along the longitudinal axis of the valve apparatus. The fluid flow path extends through the bore of the valve seat member and between the valve seat member and the valve closure member. This fluid flow path is closed when the second frustoconical contact surface is sealed against the first frustoconical contact surface. The resilient insert member is attached to the valve closure member. It has an inner perimeter and an outer perimeter, the inner perimeter being adjacent to the strike face area on the second frustoconical surface. The resilient insert member is offset and adapted to contact the first frustoconical contact surface and form a hydraulic seal therewith at the inner perimeter of the insert member, before the first frustoconical contact surface comes in contact with the second frustoconical surface as the valve closes. The offset of the insert member is greater at its outer perimeter than at its inner perimeter, and is greater at its outer perimeter than the diameter of the largest particle in any fluid to be pumped. The insert is deformable but substantially non-compressible and comprises a particle retaining means to accommodate solid particles that are trapped between the insert and the valve seat member when the valve closes. The particle retaining means has at least one cavity (void space) that is in fluid contact with the flow path for fluids between the valve seat member and valve closure member when the valve is open. The cavity has an opening in fluid contact with the flow path for fluids when the valve is open and is large enough to accommodate one or more solid particles within the interior of the cavity. The volume of the cavity contracts as the valve closes, whereby solid particles are screened from the fluid and retained within the cavity, and whereby clear fluid is forced out of the cavity into the flow path and directed inwardly toward the bore of the valve seat member through the gap between the first and second frustoconical contact surfaces.

Owner:MCINTIRE WILLIAM RAY

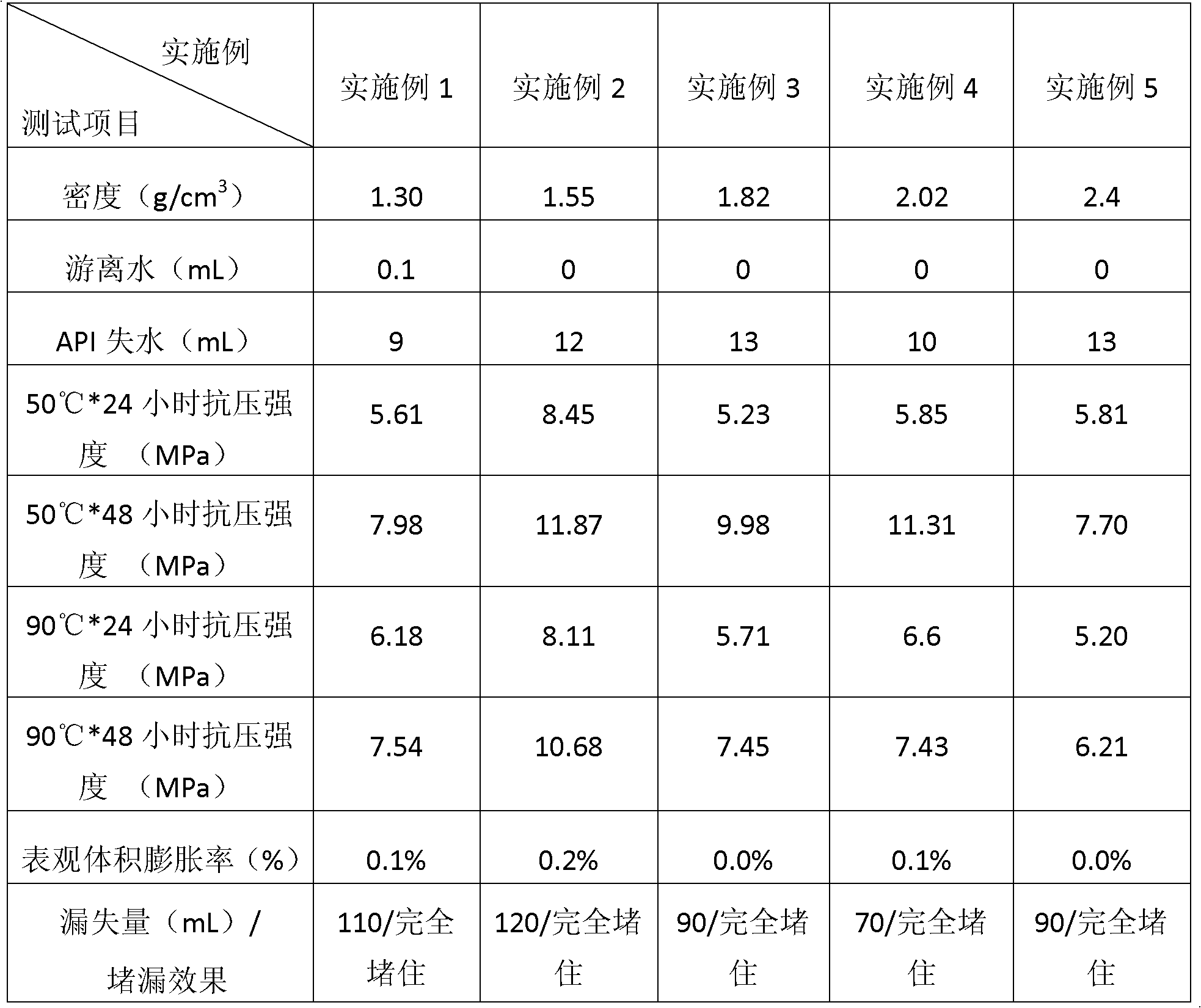

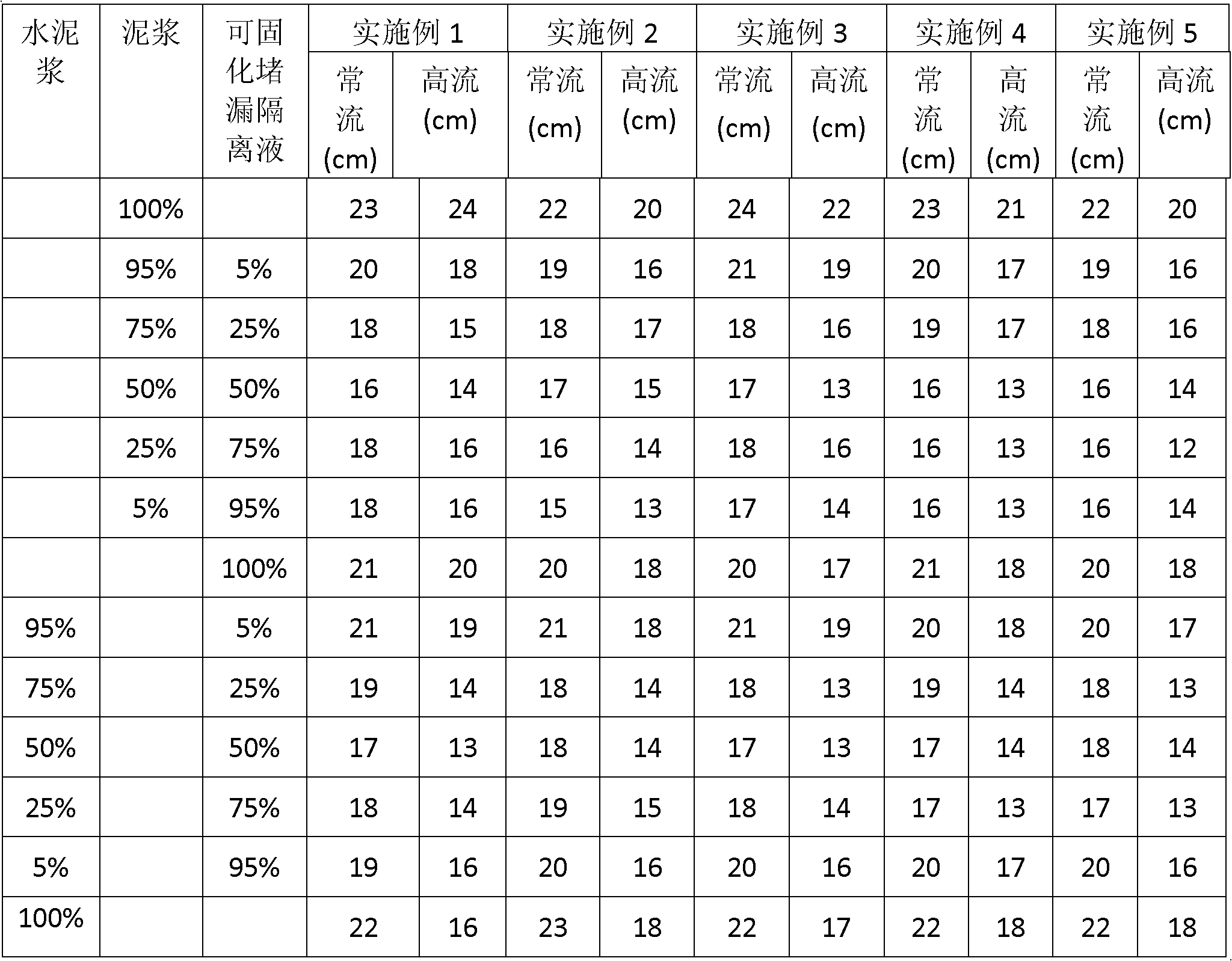

Curable leaking stoppage spacer fluid and preparation method thereof

The invention relates to a curable leaking stoppage spacer fluid and a preparation method thereof. The spacer fluid comprises the following components according to parts by weight: 450 parts of fresh water, 400-600 parts of curing agent, 3-10 parts of stabilizing agent, 2-20 parts of suspending agent, 10-40 parts of activating agent, 10-60 parts of activating auxiliary agent and 10-700 parts of density regulator, wherein the curing agent is slag powder; the stabilizing agent is clay; the suspending agent is sodium bentonite or calcium bentonite; the activating agent is the mixture of sodium hydroxide and sodium carbonate; the activating auxiliary agent is the mixture of sodium silicate and calcium oxide; and the density regulator can be iron ore powder for well cementation or coal ash hollow microsphere. After the curable leaking stoppage spacer fluid is cured, the lamination capability can reach more than 5MPa, the spacer fluid shows good chemical compatibility with mud and cement paste and good curing performance between 30-130 DEG C; after the spacer fluid is cured, the appearance of a formed cured body has non volume contraction; therefore, the spacer fluid can effectively pack a stratum dropping passage and provides guarantees for the follow-up operation of oil and gas wells.

Owner:SOUTHWEST PETROLEUM UNIV

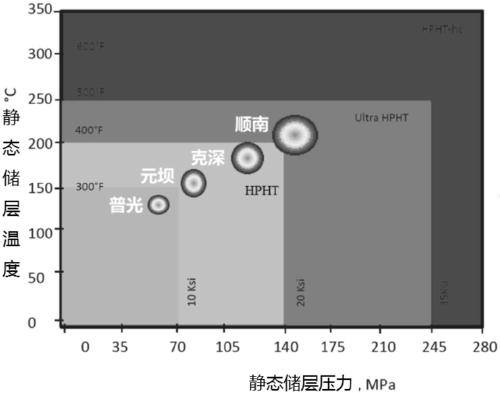

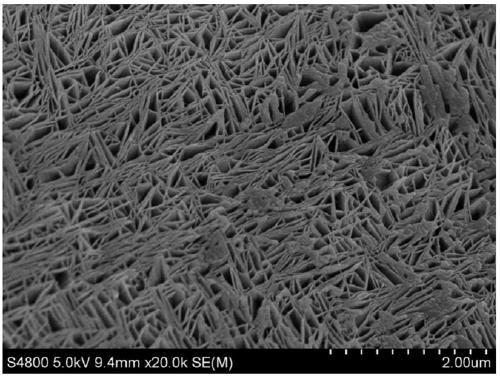

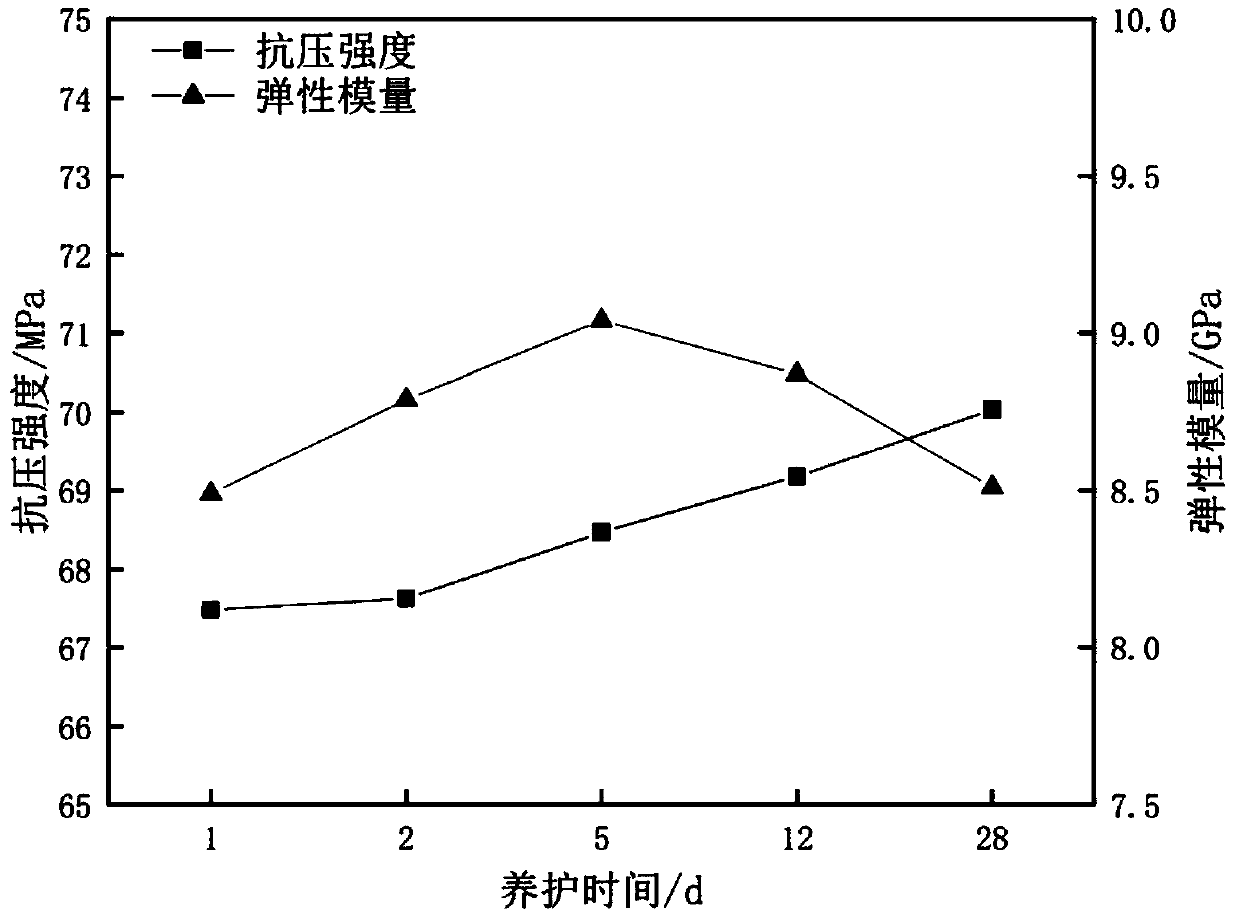

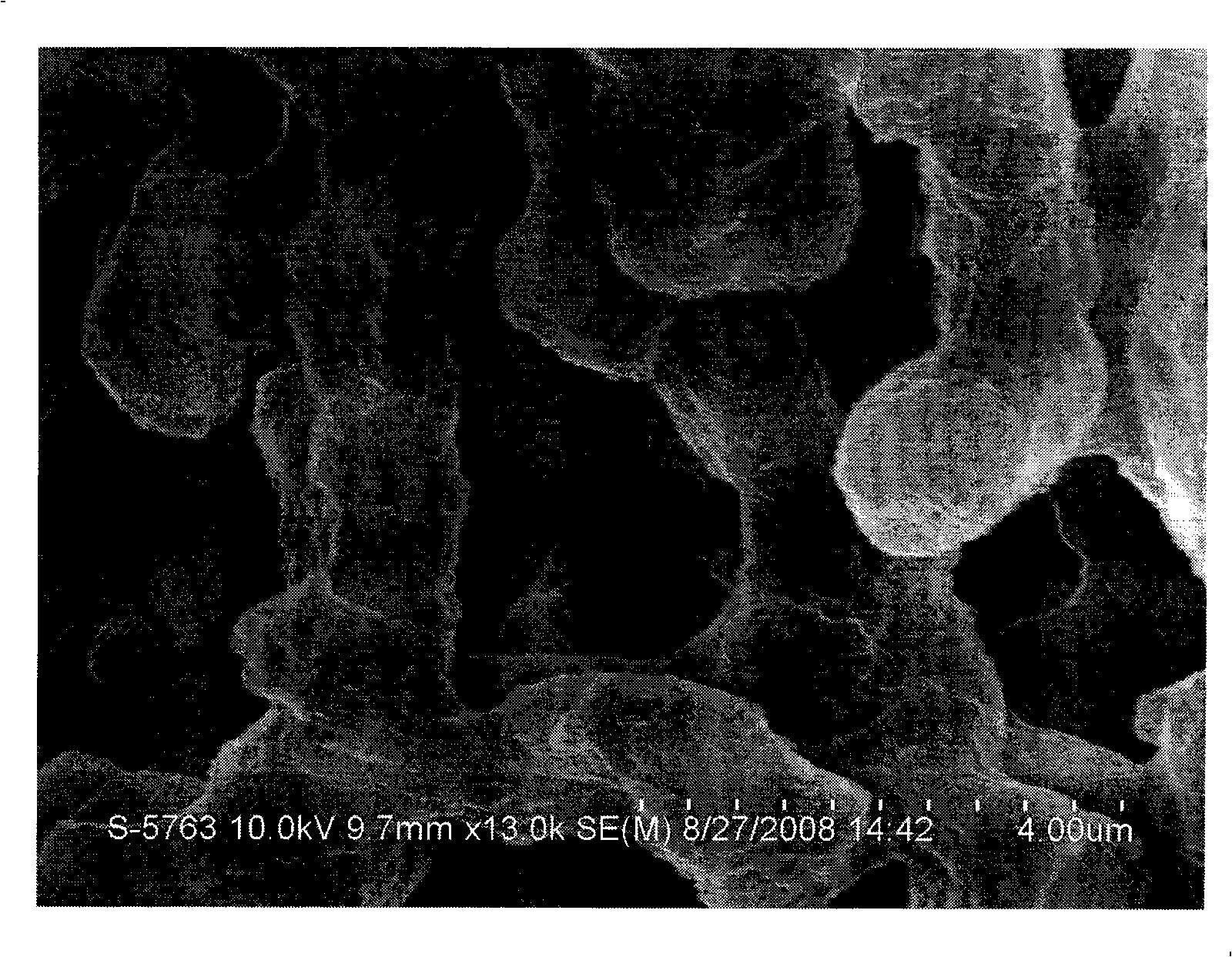

Nano-material mixed modified superhigh-temperature high-performance well cementing slurry system and preparation method thereof

The invention relates to a nano-material mixed modified superhigh-temperature high-performance well cementing slurry system and a preparation method thereof. The slurry system comprises the followingingredients in parts by weight: 100 parts of oil well cement, 15-25 parts of coarse silica sand, 15-20 parts of fine silica sand, 1-10 parts of nano-silicon dioxide, 1-10 parts of nano-calcium carbonate, 0.2-1 part of a defoaming agent, 4-10 parts of a fluid loss agent, 0-3 parts of a drag reduction agent, 0.5-4 parts of a retarder and 30-100 parts of water. In the slurry system, set cement has excellent compressive strength and toughness under superhigh temperature, and the compressive strength and the elasticity modulus cannot be obviously changed as the maintenance time is prolonged. The slurry system has good rheological property, lower water loss and proper thickening time, and the comprehensive properties of the slurry system can completely meet the related requirements of site wellcementing construction, so that the technical support is provided for well cementing under high temperature. A nano-material obtained by mixing the nano-silicon dioxide and the nano-calcium carbonateis added, and micropores of the set cement can be effectively filled, so that the system becomes denser. Therefore, the volume shrinkage of the set cement is relieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

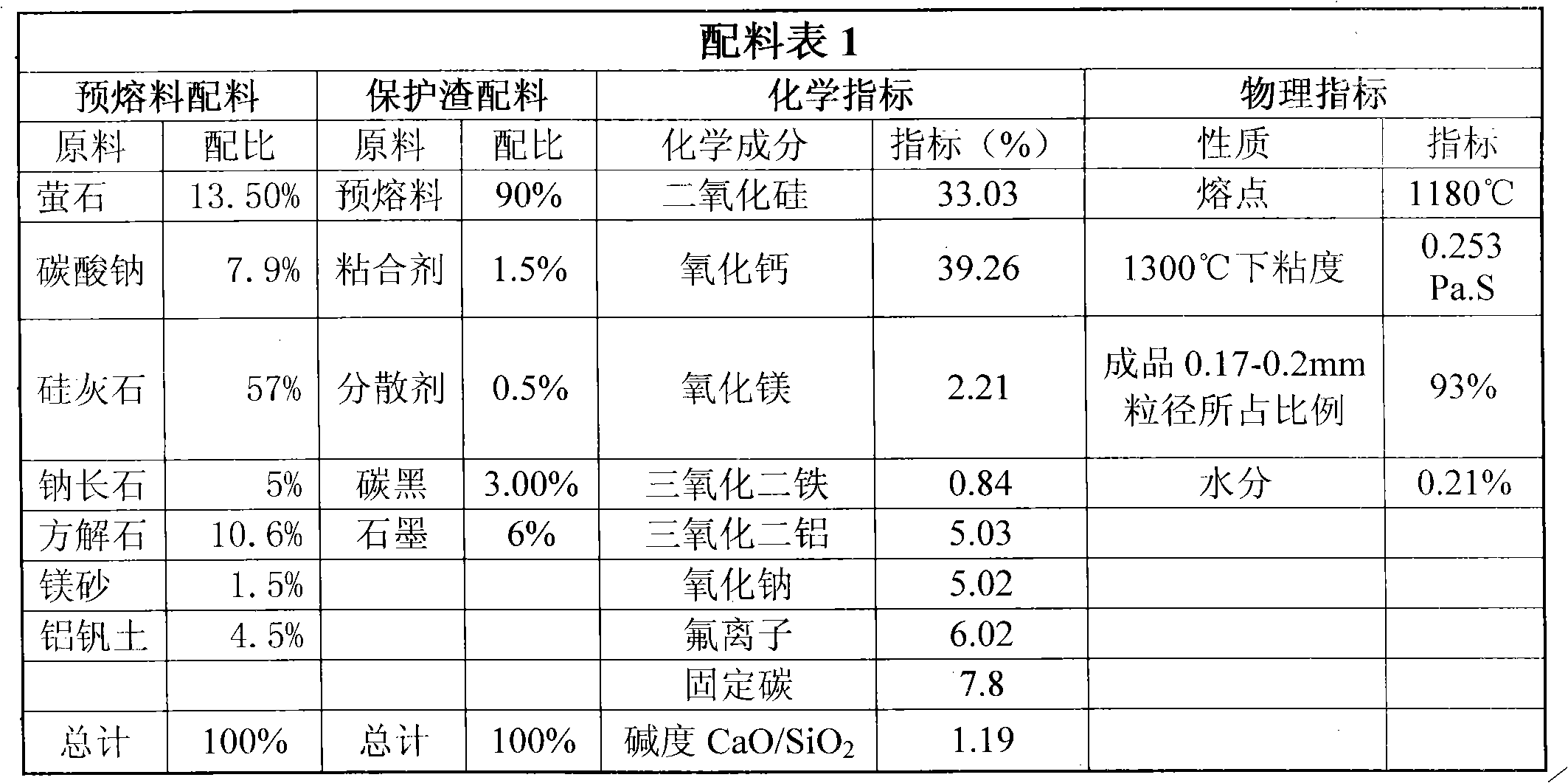

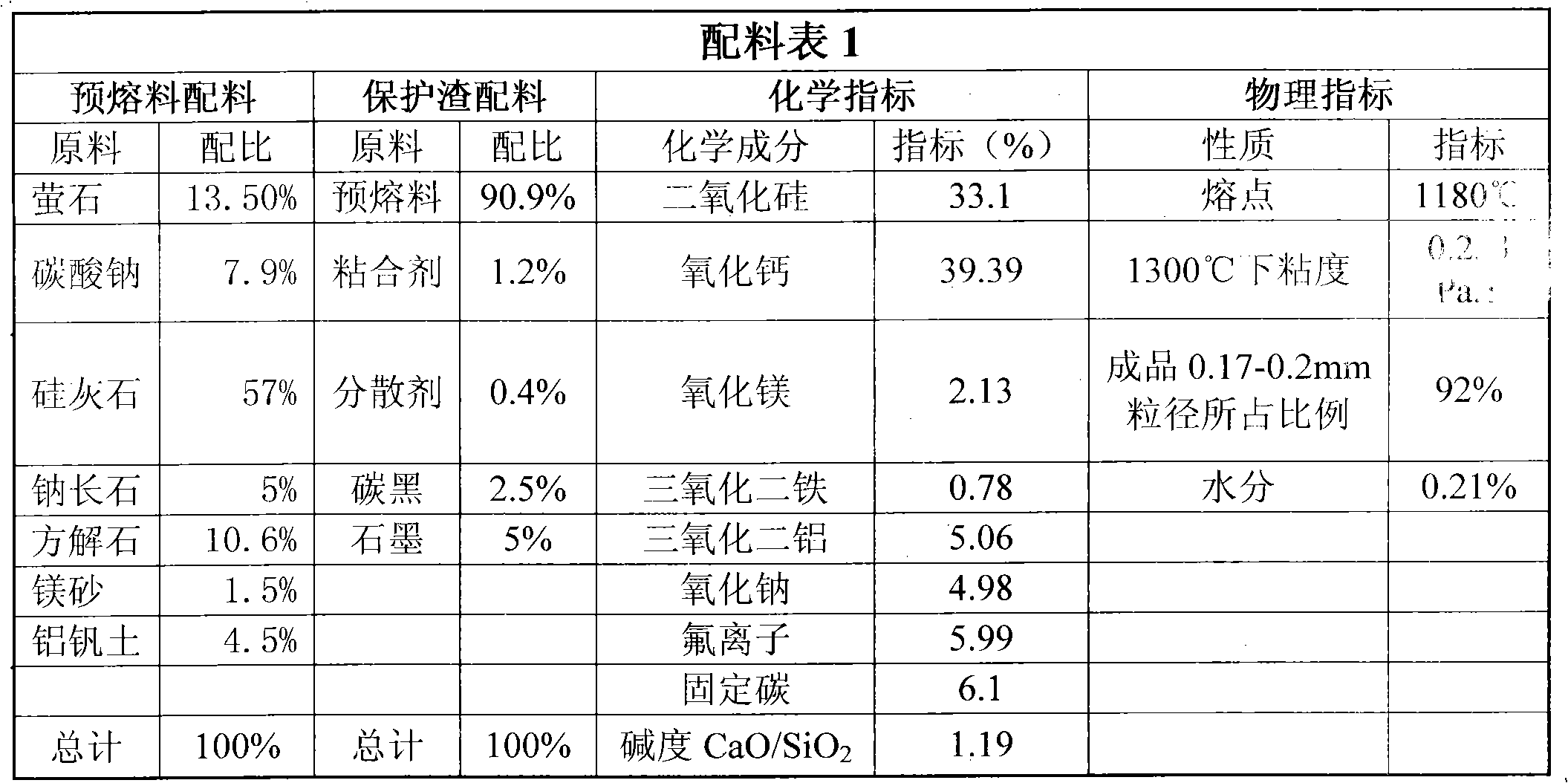

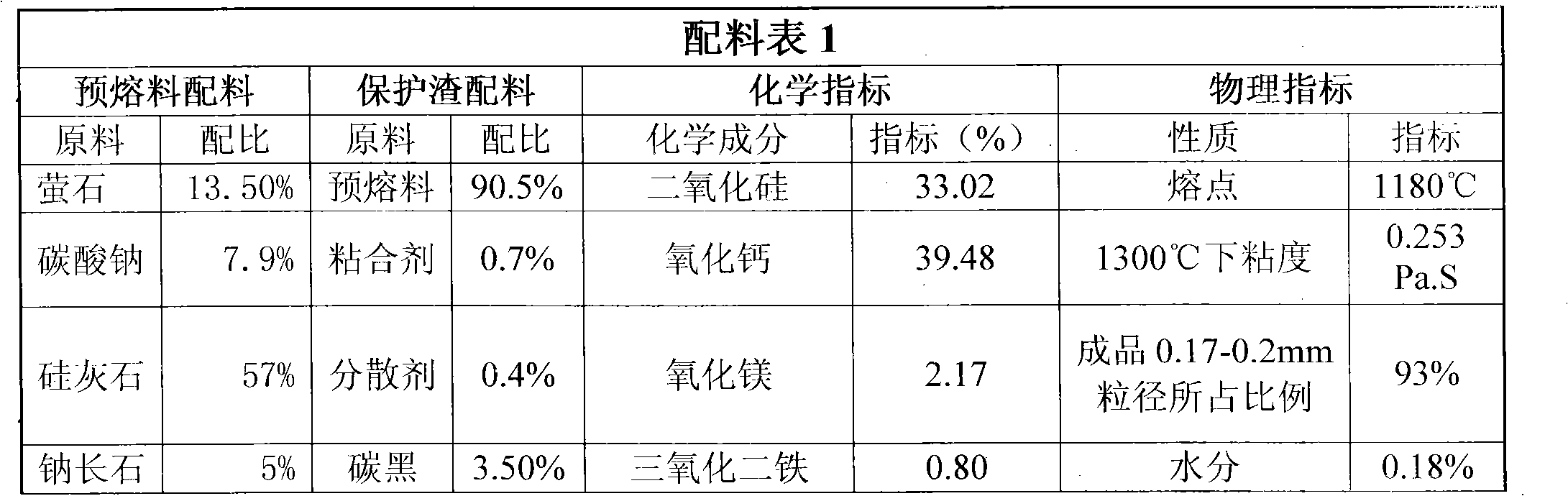

Continuous casting crystallizer covering slag special for extra-thick slab peritectic steel and preparation method thereof

ActiveCN102029366ALarge thermal resistanceReduce the speed of heat transfer to the outsideAlkalinityHeat resistance

The invention discloses continuous casting crystallizer covering slag special for extra-thick slab peritectic steel and a preparation method thereof. In the covering slag, a peritectic reaction is performed in the process of solidifying the peritectic steel, and the overquick or overlarge volume contraction of the peritectic steel leads to the surface quality problems such as casting blank cracks, and causes dangers in a continuous casting process. In consideration of the characteristics of the peritectic steel, the covering slag for the extra-thick slab peritectic steel shall be cooled slowly and has higher alkalinity and melting points so as to increase the heat resistance of a slag membrane of the covering slag, reduce the speed of transferring heat outwards by casting blanks, and increase the uniformity of heat transfer.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Composite nano silver paste and rapid sintering packaging method

InactiveCN107833651ALow costSmall volume shrinkageMaterial nanotechnologyTransportation and packagingHigh temperature electronicsElectron

The invention provides a composite nano silver paste preparation method and a rapid sintering packaging method. The preparation method comprises steps that S1, cleaning treatment and centrifugation ofmicron silver sheets are carried out; S2, nano silver particles and an organic solvent are mixed into the micron silver sheets acquired in S1, and the ultrasonic process and stirring are carried out;and S3, an organic carrier and the surfactant are added to the mixed solution acquired in S2, and the ultrasonic process and stirring are carried out to acquire the composite nano silver paste. The packaging method comprises steps that S1, the silver paste is coated through dispensing or screen printing; S2, a chip coated with the composite nano silver paste and a substrate are aligned and stacked; and S3, hot press welding or ultrasonic hot press welding is utilized for sintering to complete interconnection. The method is advantaged in that rapid sintering and packaging of the composite nanosilver paste are realized, material cost is reduced, the preparation process is environmental friendly, the packaging process and the equipment are simplified, production efficiency is improved, energy saving and emission reduction are facilitated, volume contraction caused by continuous sintering in the service process of a nano silver paste sintering body can be reduced, service life and reliability of a packaging device are improved, and the method is suitable for high reliability low temperature packaging interconnection of high temperature electronic devices in the electronic packaging field.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +1

Composite phase-change material for mobile heat supply and preparation method thereof

ActiveCN103113854ANo precipitationFast heat storage and releaseChemical industryHeat-exchange elementsMolten stateMass ratio

The invention discloses a composite phase-change material for mobile heat supply and a preparation method thereof. The composite phase-change material is formed by compounding 97.5-99.5 wt% of mixed inorganic salts and 0.5-2.5 wt% of non-metal nano material. The preparation method comprises the following steps: mixing a plurality of inorganic salts according to mass ratio, stirring, adding into a vacuum heating furnace, and heating into a molten state, wherein the temperature of the vacuum heating furnace is controlled at 40-50 DEG C higher than the phase-change temperature of the mixed inorganic salts; and adding the non-metal nano material into the molten salts, and magnetically stirring for more than half an hour to prepare the uniform and stable molten-state composite phase-change material. Compared with the prior art, the composite phase-change material disclosed by the invention has the advantages of high heat-conducting property, high heat accumulation density, small volume shrinkage and the like, can satisfy different application requirements, and is especially suitable for moderate-temperature waste heat recovery.

Owner:QINGDAO AOHUAN NEW ENERGY GRP CO LTD

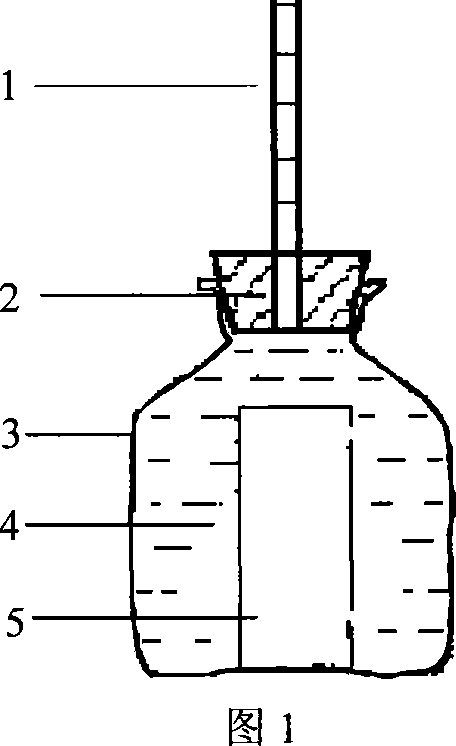

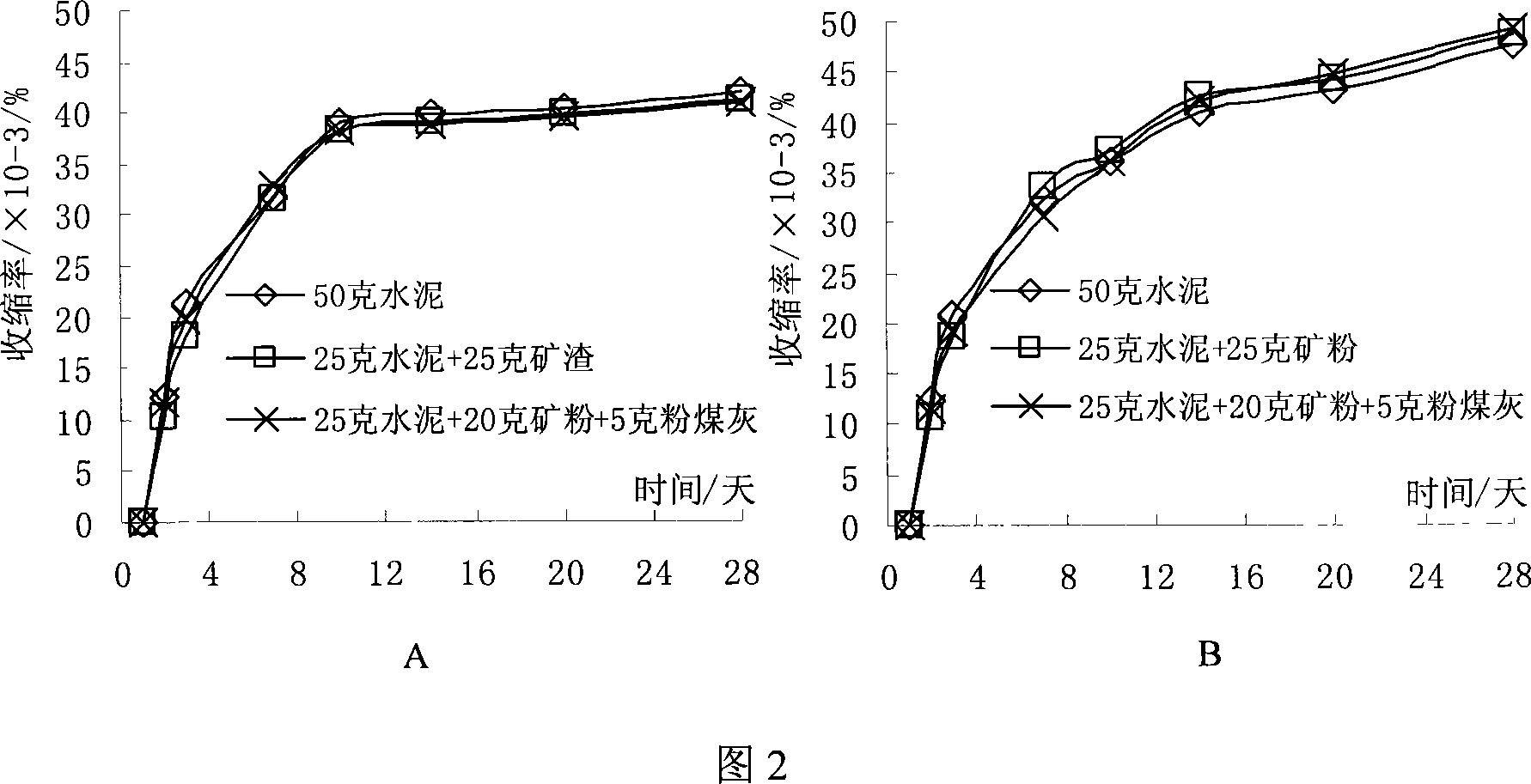

Cement self-shrinking value test method

The invention relates to a method for testing the contraction value of cement, comprising that shaping cement slurry into a cylinder container according to needed material ratios, using wax to seal solidified cement slurry, using the sealed solidified cement slurry as object sample to be arranged into a vending jar, filling water into the vending jar, adding a plug, dropping water into buret to full, dropping liquid wax or other insoluble oil liquid to the water level of the buret to avoid water evaporation, arranging the device in a standard maintenance room, reading the level initial number when the liquid level is stable, via the scale change, watching the volume contraction rule of slurry, according to the different test periods. Compared with traditional method, the invention can accurately represent the volume change of cement slurry.

Owner:TONGJI UNIV

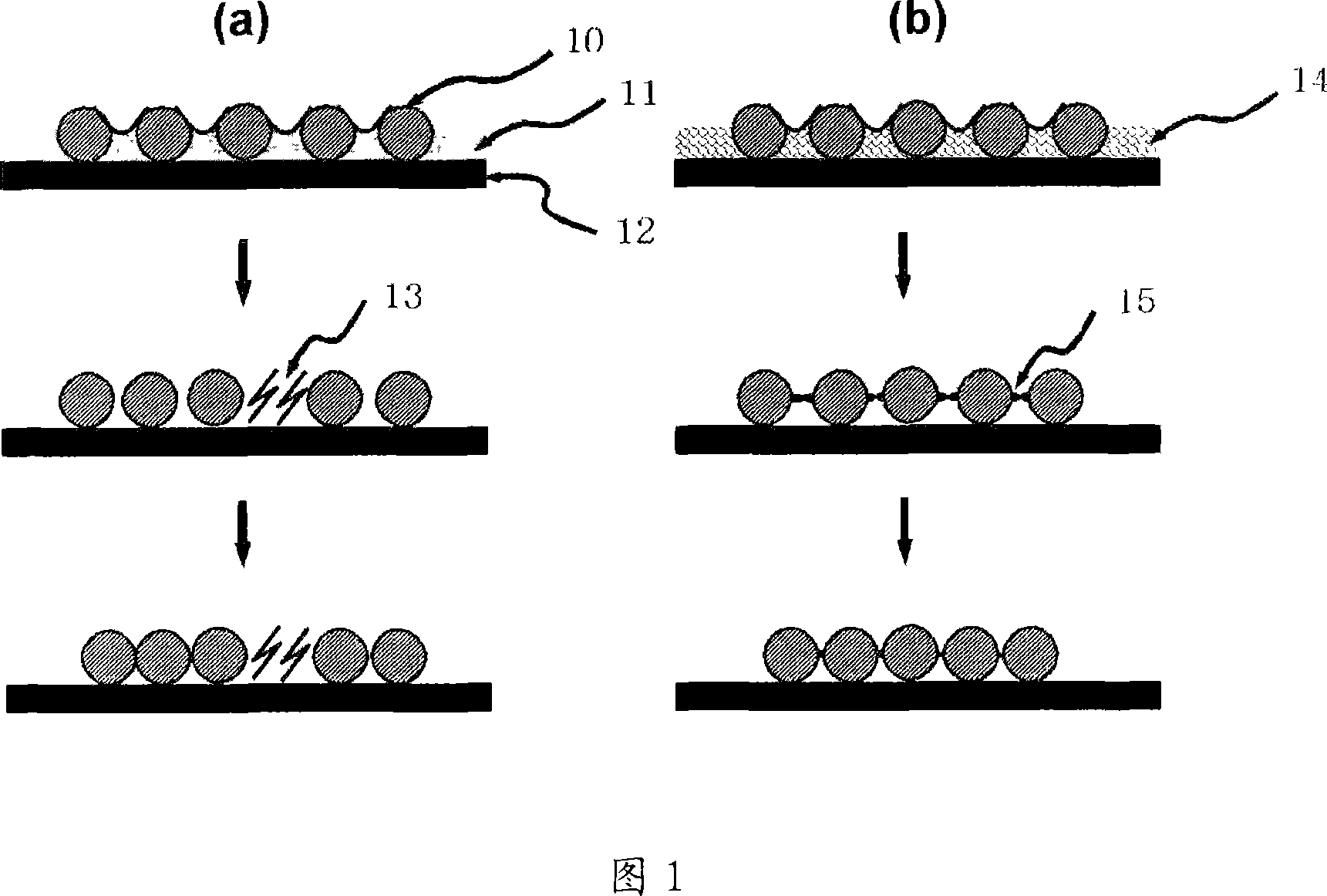

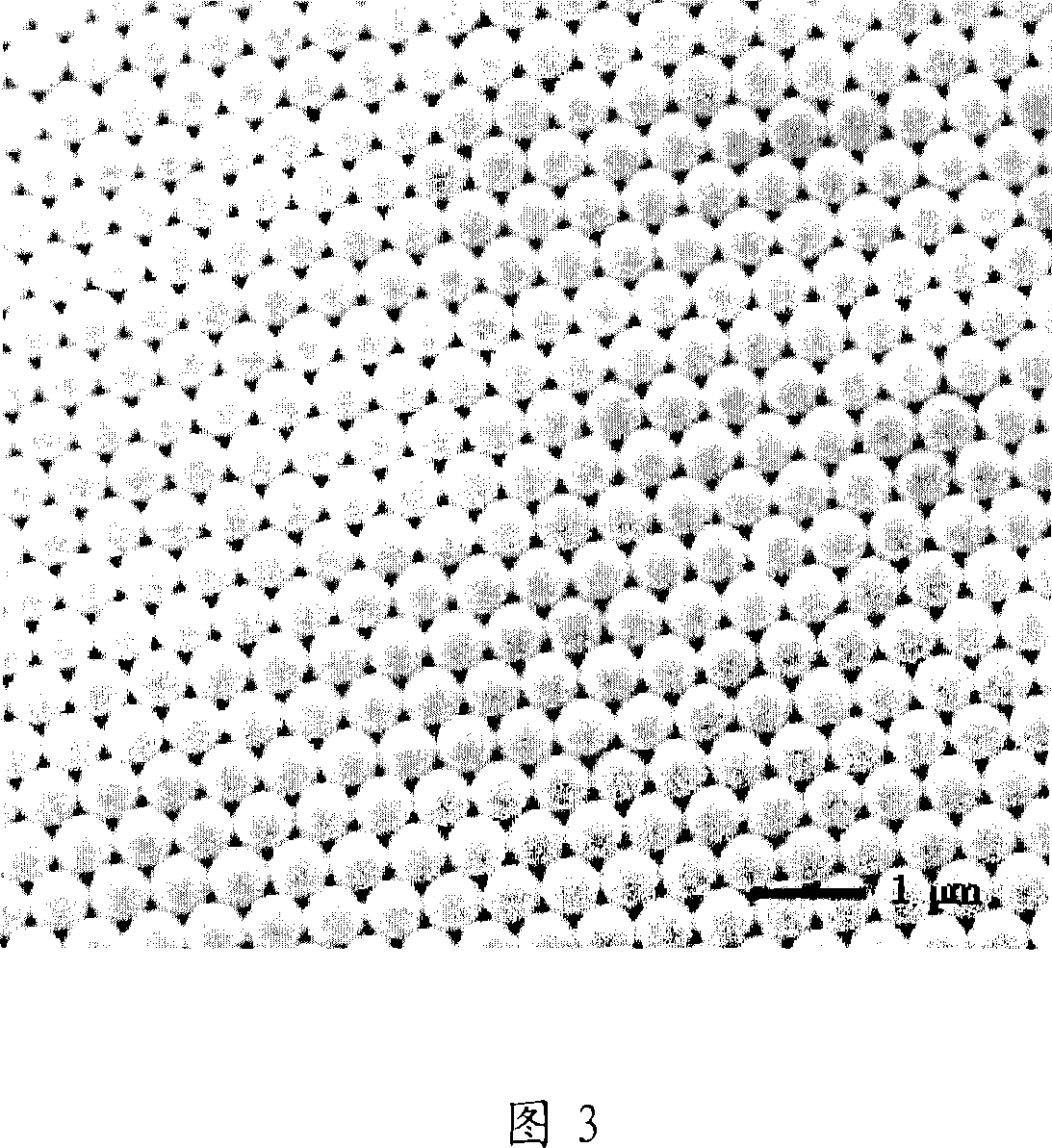

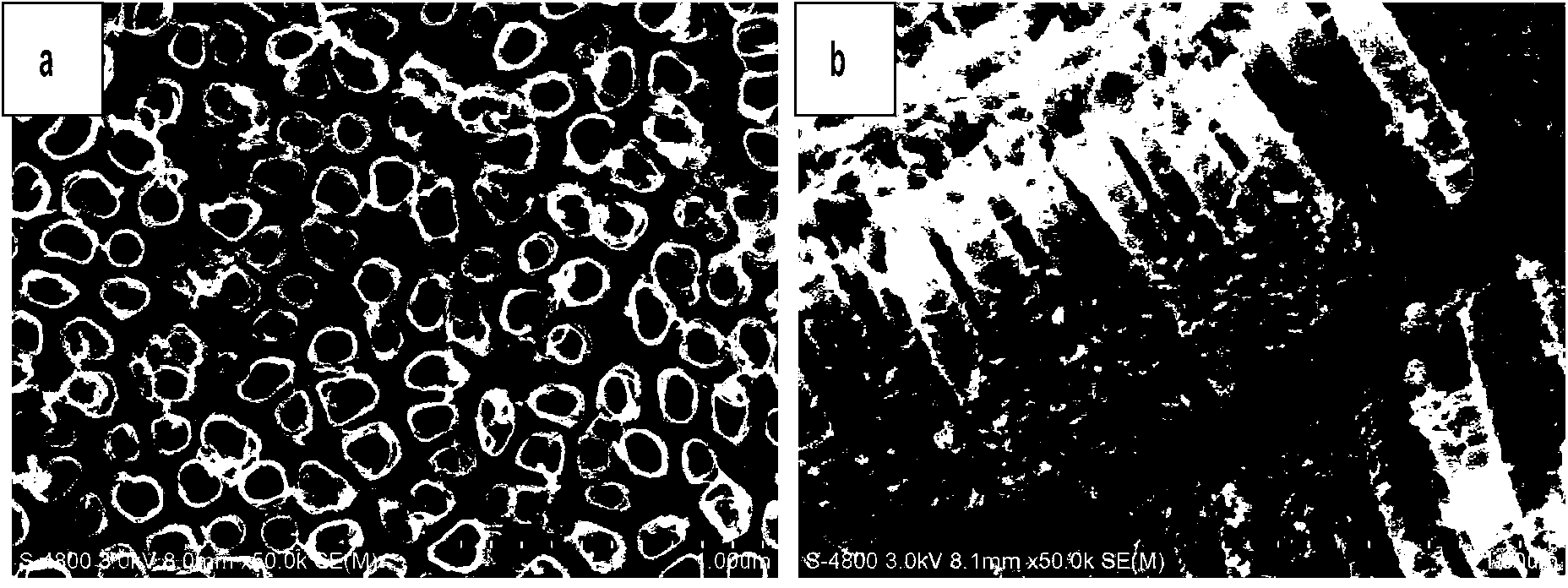

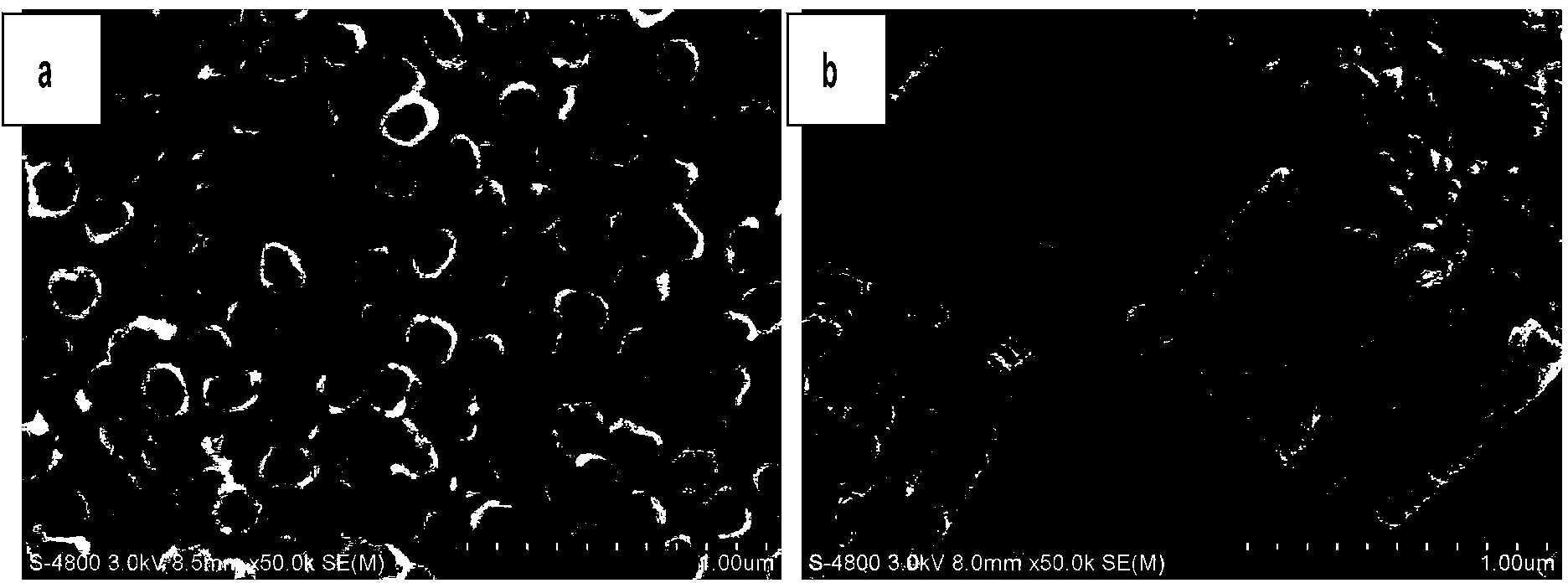

Colloidal photonic crystals using colloidal nanoparticles and method for preparation thereof

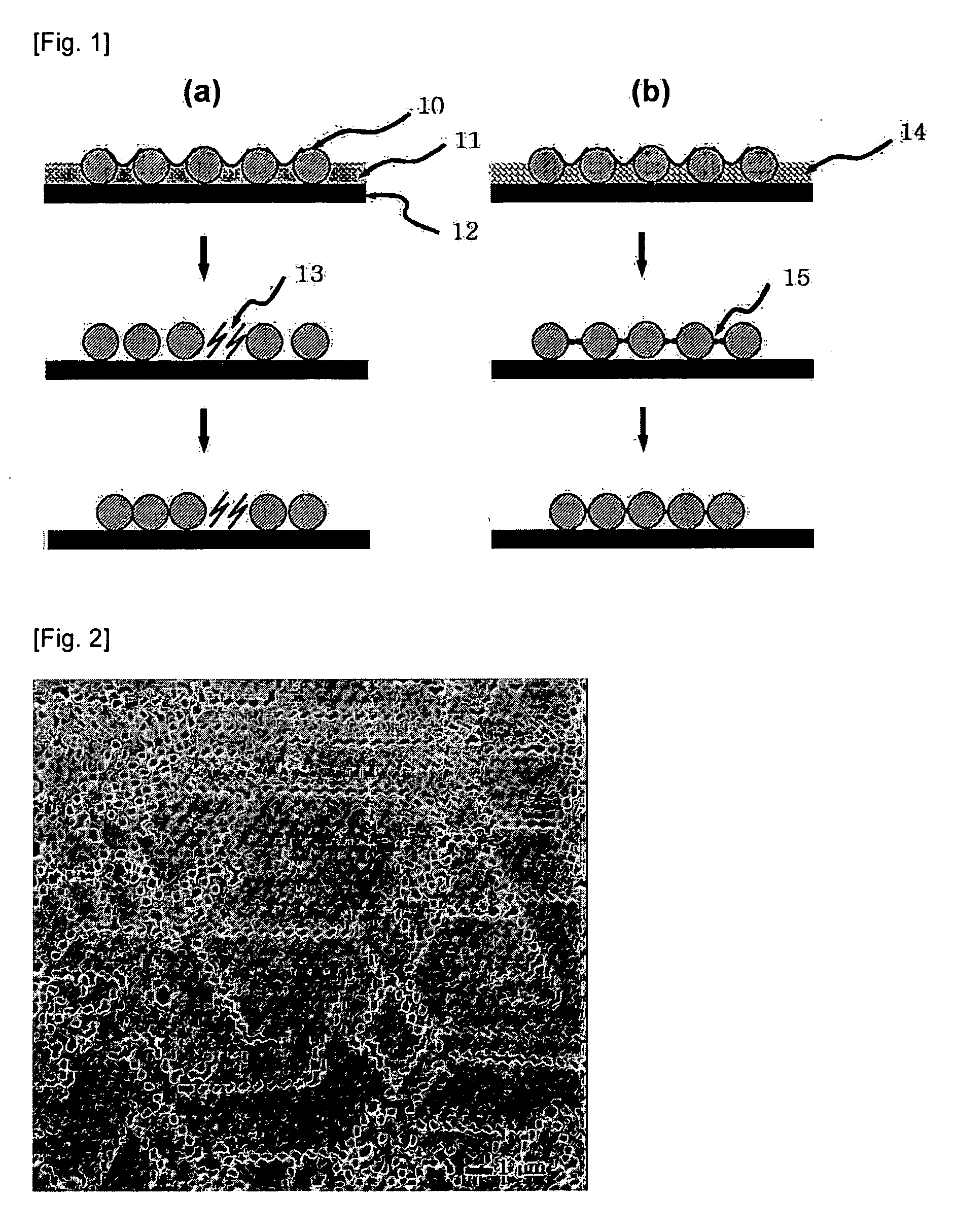

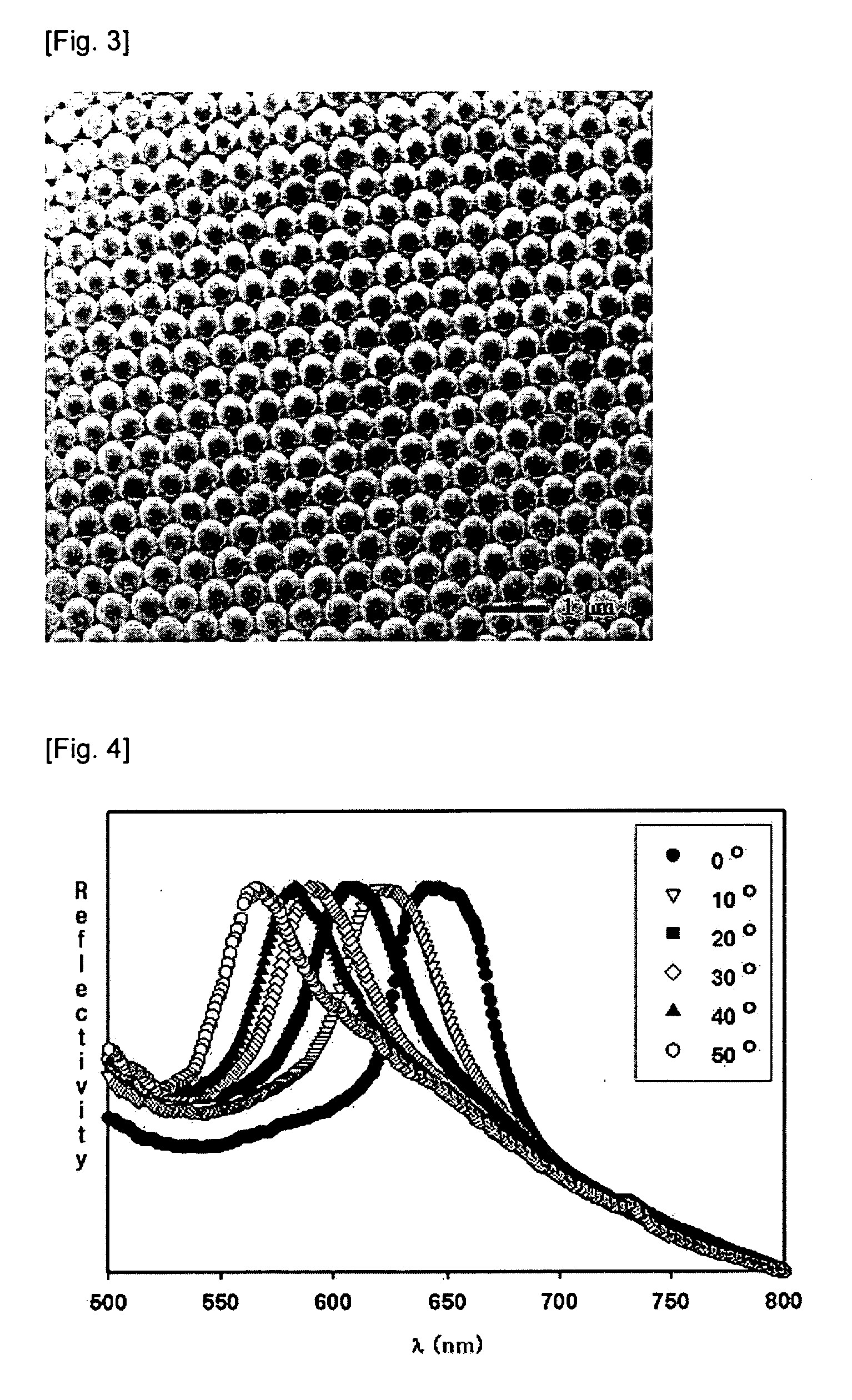

The present invention relates to colloidal photonic crystals using colloidal nanoparticles and a method for the preparation thereof, wherein by adding a viscoelastic material into a solution containing the colloidal nanoparticles when preparing the colloidal photonic crystals, a uniform volume contraction occurs due to the elasticity of the viscoelastic material even when a nonuniform volume contraction occurs while drying a dispersion medium in the colloidal solution. Thus, it is possible to prepare 2 or 3 dimensional colloidal photonic crystals of large scale with no defects in less time.

Owner:LG CHEM LTD

Colloidal photonic crystals using colloidal nanoparticles and method for preparation thereof

ActiveUS20070163486A1No surface defectsLess timeFrom gel statePolycrystalline material growthColloidal nanoparticlesColloidal particle

The present invention relates to colloidal photonic crystals using colloidal nanoparticles and a method for the preparation thereof, wherein by adding a viscoelastic material into a solution containing the colloidal nanoparticles when preparing the colloidal photonic crystals, a uniform volume contraction occurs due to the elasticity of the viscoelastic material even when a nonuniform volume contraction occurs while drying a dispersion medium in the colloidal solution. Thus, it is possible to prepare 2 or 3 dimensional colloidal photonic crystals of large scale with no defects in less time.

Owner:LG CHEM LTD

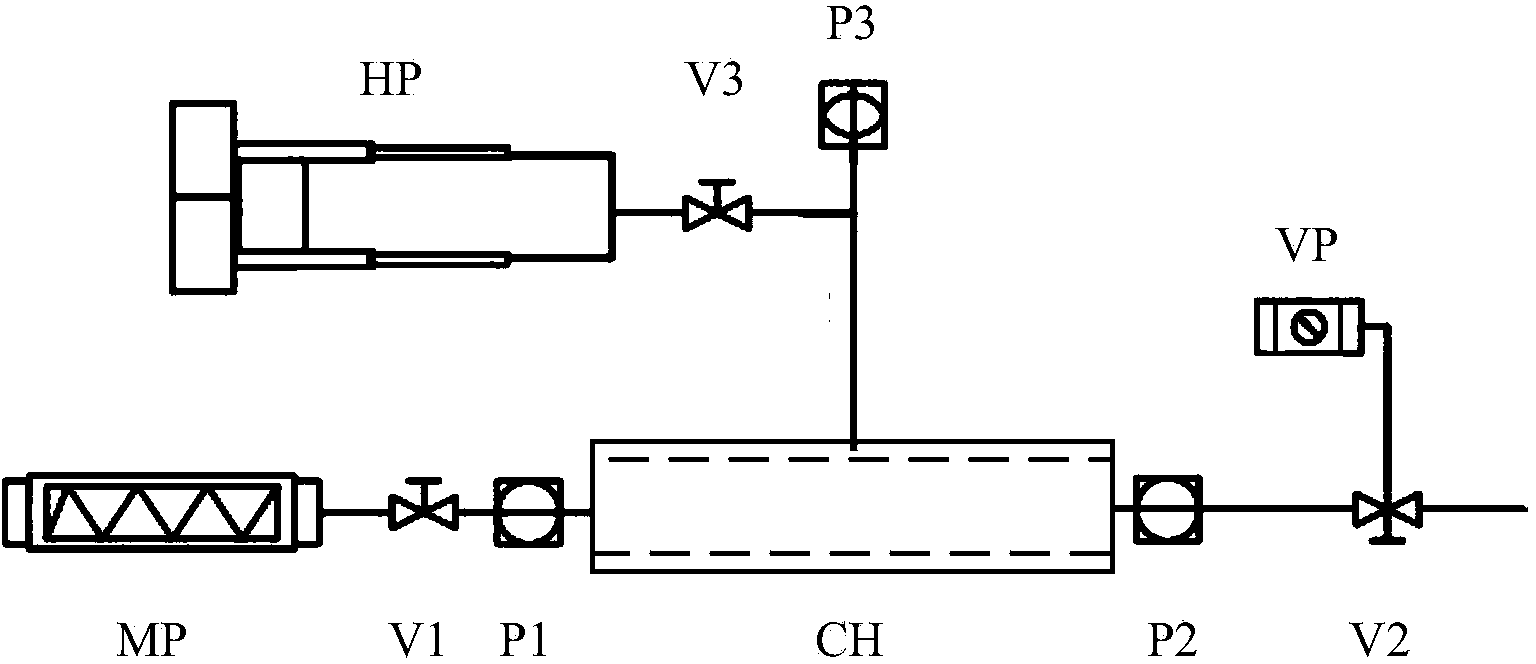

Device and method for testing core pore compressibility

ActiveCN104374683AHigh precisionImprove accuracyPermeability/surface area analysisPorosityLine tubing

The invention relates to a device and a method for testing core pore compressibility. The method comprises the steps of selecting a core to be tested, wherein the core to be tested can be a low-porosity and low-permeability core; measuring the pore volume of the core by a saturated brine weighing method; calculating the volume coefficient of the brine used by an experiment; drawing volume shrinkage curves of a core holding unit and a connecting pipeline of the core holding unit; measuring the blank volumes of the core holding unit and the connecting pipeline of the core holding unit; measuring a core pore volume under each net effective pressure; calculating the measured results to obtain the core pore volume compressibility under all net effective pressures. By the device and the method, the core pore compressibility of the large-sized abnormal high-pressure low-permeability reservoir with can be tested and analyzed, and the error of the test results can be reduced.

Owner:PETROCHINA CO LTD

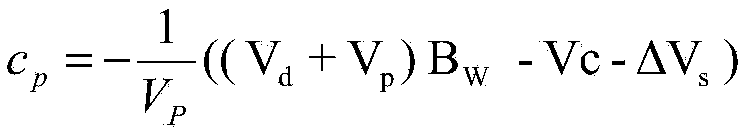

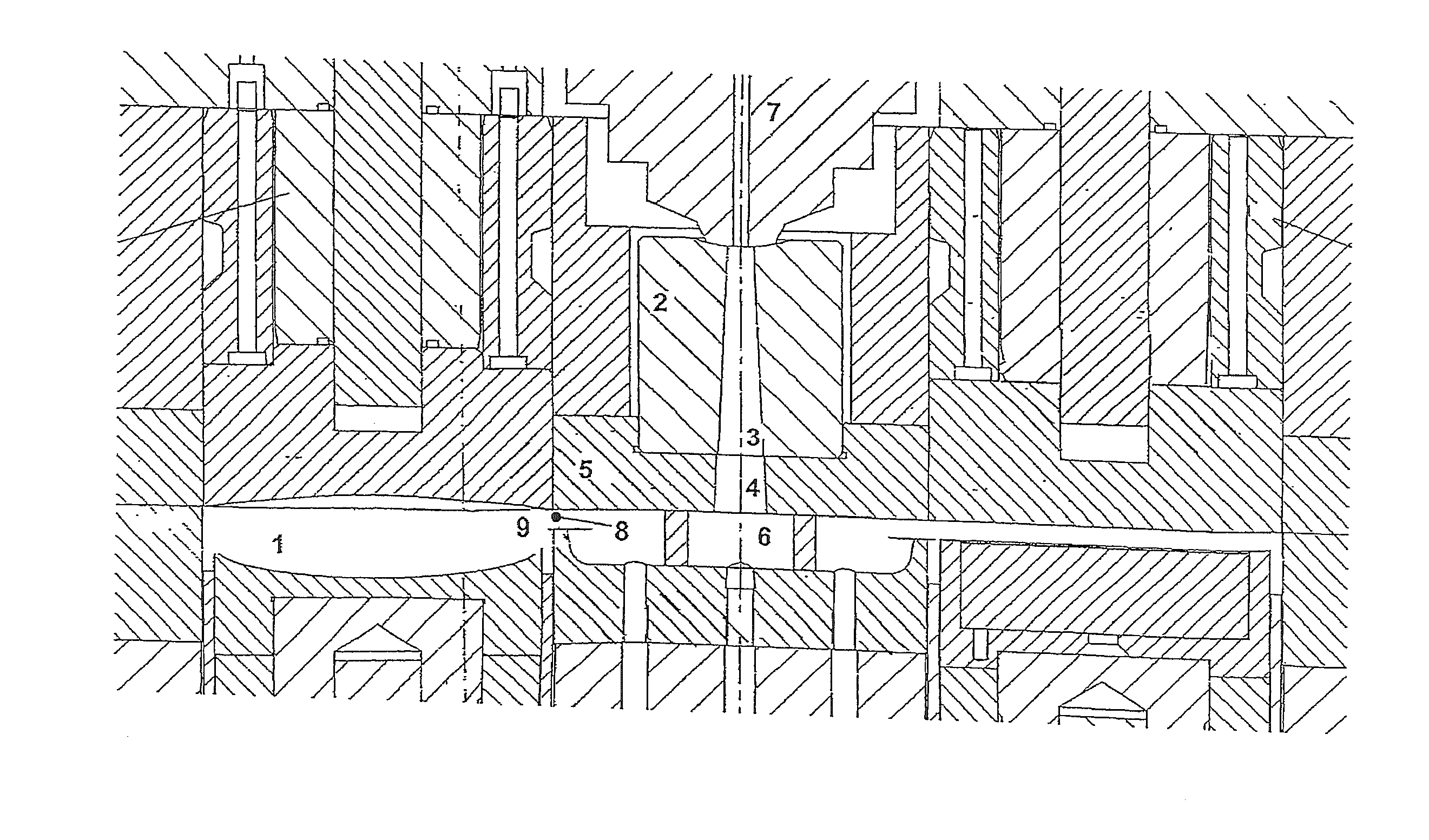

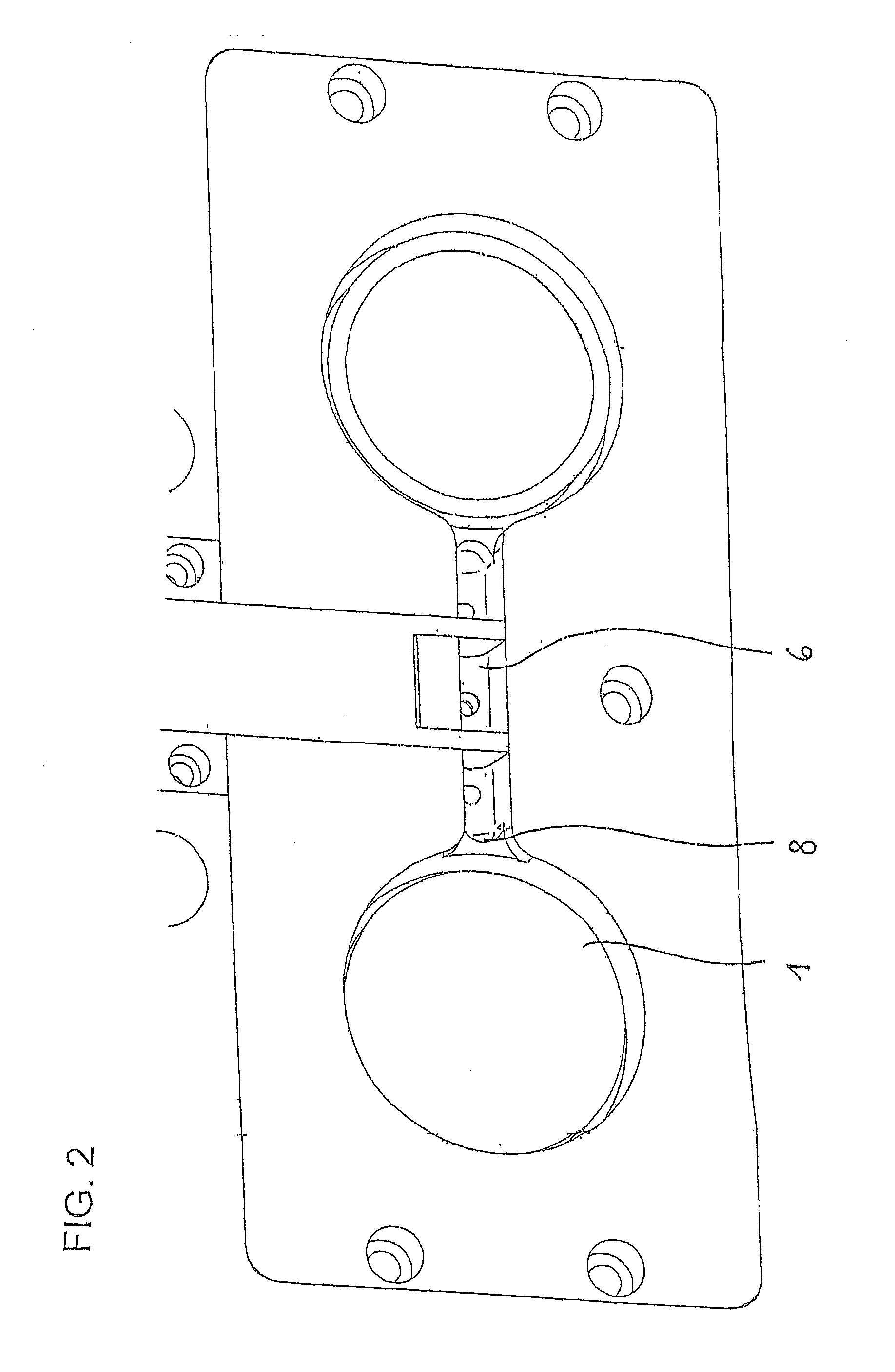

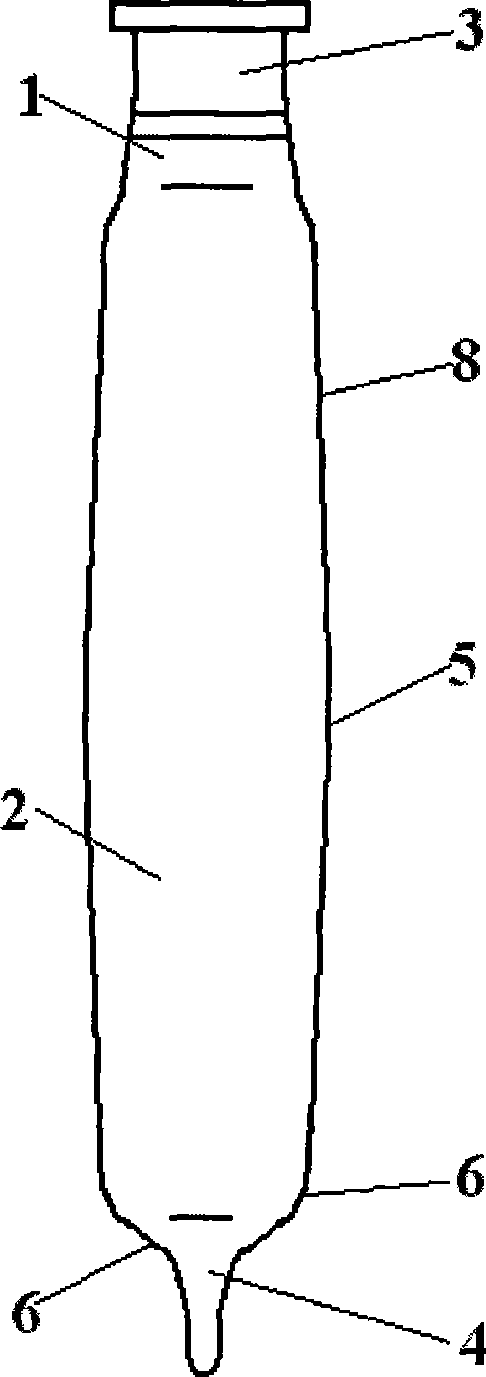

Process and apparatus for producing thick-walled plastic components

InactiveUS20100327470A1Quality improvementLow production costOptical articlesAuxillary shaping apparatusLight guideThick wall

The invention relates to a process for producing plastic components, in particular optical lenses or optical light-guides, wherein plastic melt is injected via a sprue (3, 4, 6, 8) into a cavity (1) of a moulding tool shaping the component and additional plastic melt is after-pressed into the cavity (1) for the purpose of compensating a volume contraction of the injected plastic melt due to cooling. The process is characterised in that the plastic melt located in the sprue (3, 4, 6, 8) is kept flowable by means of energy introduced in the region of the sprue until such time as the molten core of the plastic component has solidified in the course of the after-pressing of plastic melt for the purpose of compensating the volume contraction due to cooling (holding-pressure). The invention further relates to an apparatus for implementing the process.

Owner:BAYER MATERIALSCIENCE AG

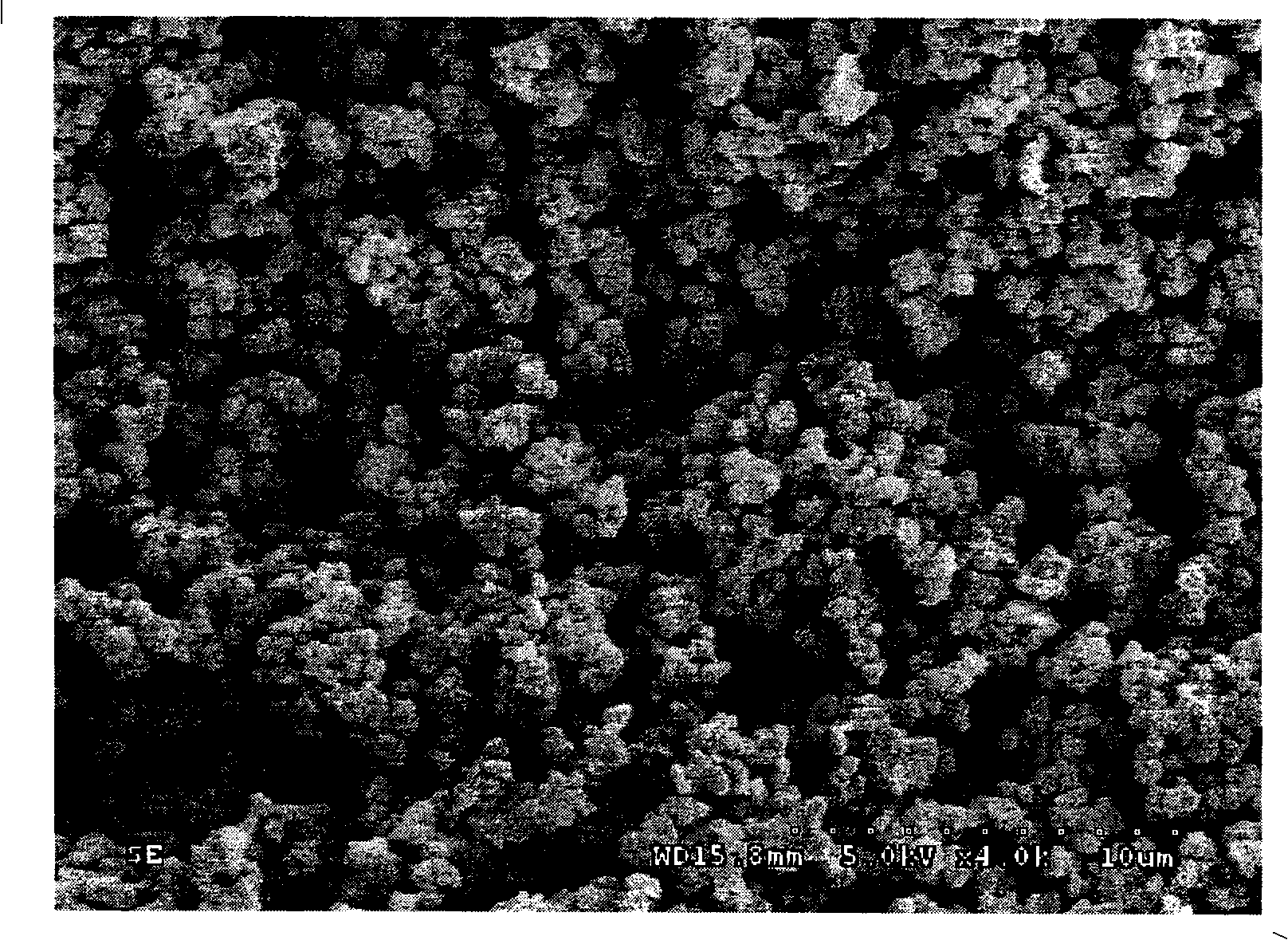

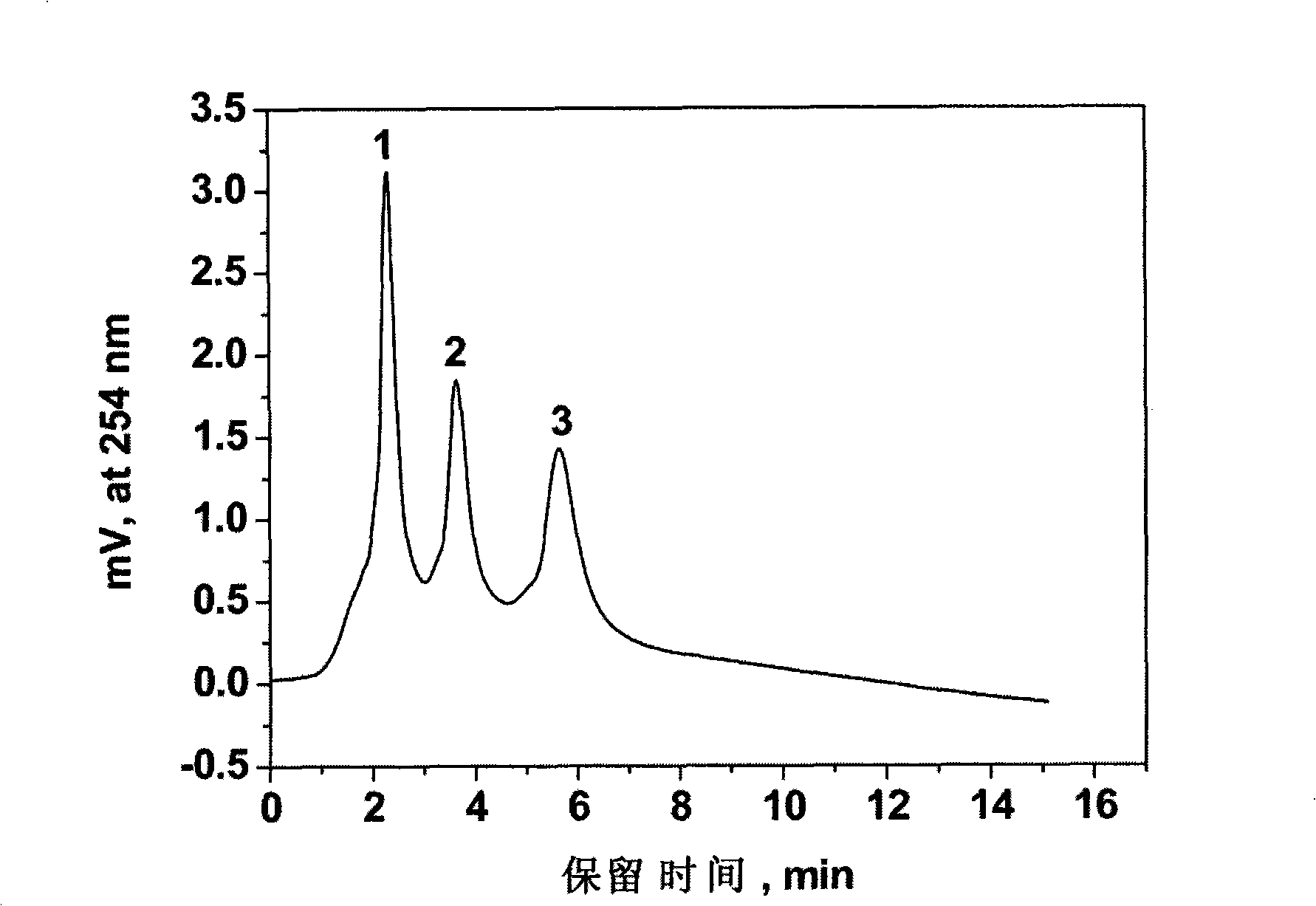

Monolithic column, preparation method and application thereof

InactiveCN101537344AImprove uniformityOptimize volumeOther chemical processesPeptide preparation methodsFunctional monomerFoaming agent

The invention discloses a monolithic column, a preparation method and a application thereof. The preparation method comprises the following steps: 1) polymeric monomer, pore-foaming agent, initiator and cuprous bromide are mixed together and then added with catalyst ligand after being deoxidized; the mixture is put into a chromatographic column tube to react in a sealing way; after the reaction, the chromatographic column tube is connected with a high pressure transfer pump, and the soluble substances such as the pore-foaming agent and the like are rinsed and removed by organic solvent, so that a monolithic column with a three-dimensional continuous skeleton structure is obtained; 2) the mixture of the organic solution, catalyst, catalyst ligand and antioxidant of the functional monomer is injected into the monolithic column, and bromine group remained on the surface of the column body initiates the surface grafting polymerization reaction of vinyl monomer. The method leads polymerization reaction to be carried out at the room temperature, so as to greatly solves the problems of inhomogeneous column body structure, volume contraction and the like caused by high polymerization temperature. Compared with the traditional monolithic column, the obtained monolithic column has obviously different structure, thus being applicable to separating biological macromolecules such as steroid hormone drugs, protein or the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Multi-panel plastic container

ActiveUS8087525B2Reduce internal pressureIncreasing the amount of vacuum uptakeBottlesLarge containersHot liquidsVolume contraction

A container adapted to increase volume contraction and reduce pressure having four panels that are adapted to contract inwardly from vacuum forces created by contraction of container contents. The container has a sidewall including four panels. The four panels are vacuum panels, including vertical transitional walls disposed between and joining the panels and the body is adapted to increase volume contraction and reduce pressure. The panels are adapted to contract inwardly in response to internal negative pressure created during hot-fill processing and subsequent cooling of a hot liquid in the container.

Owner:CO2 PAC

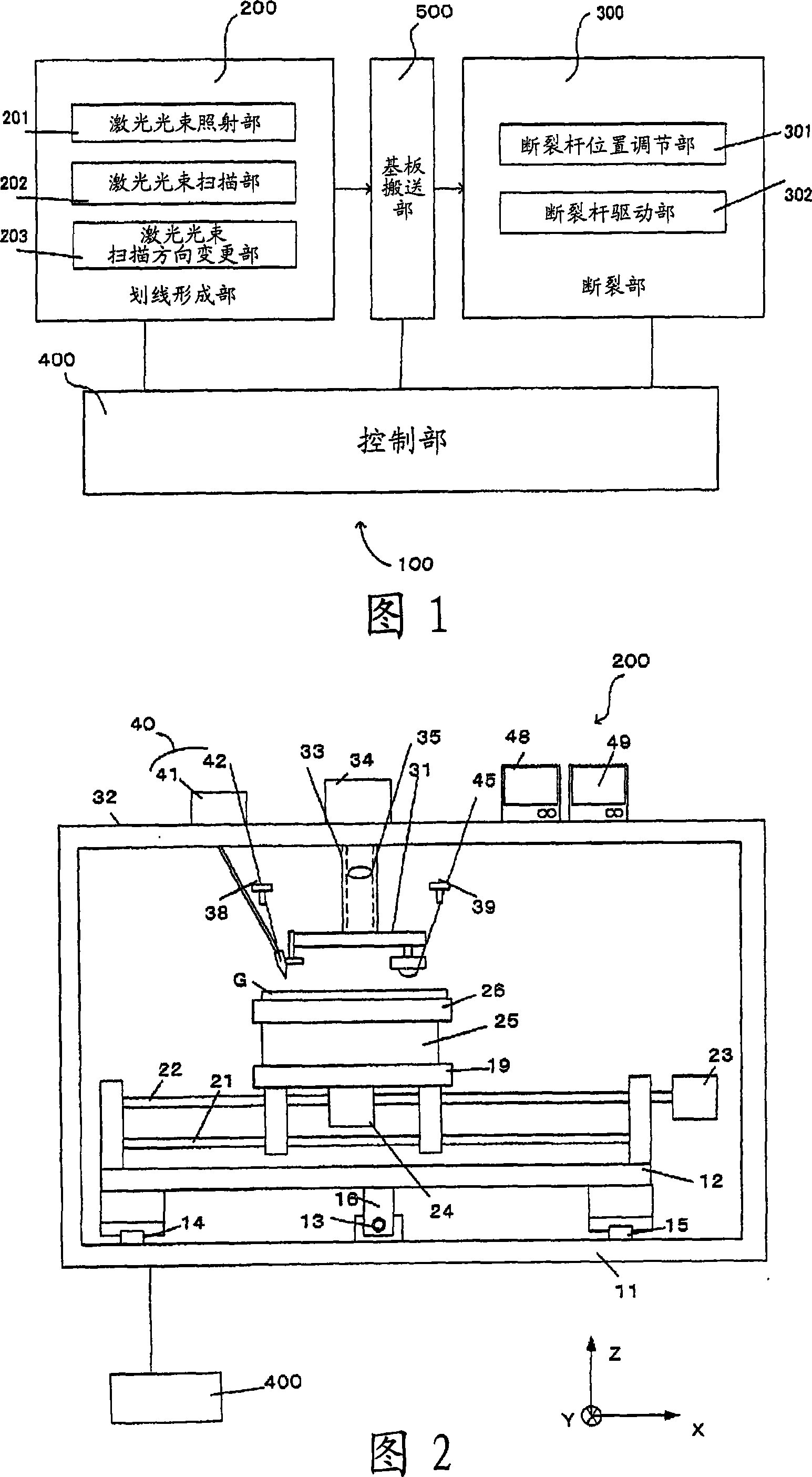

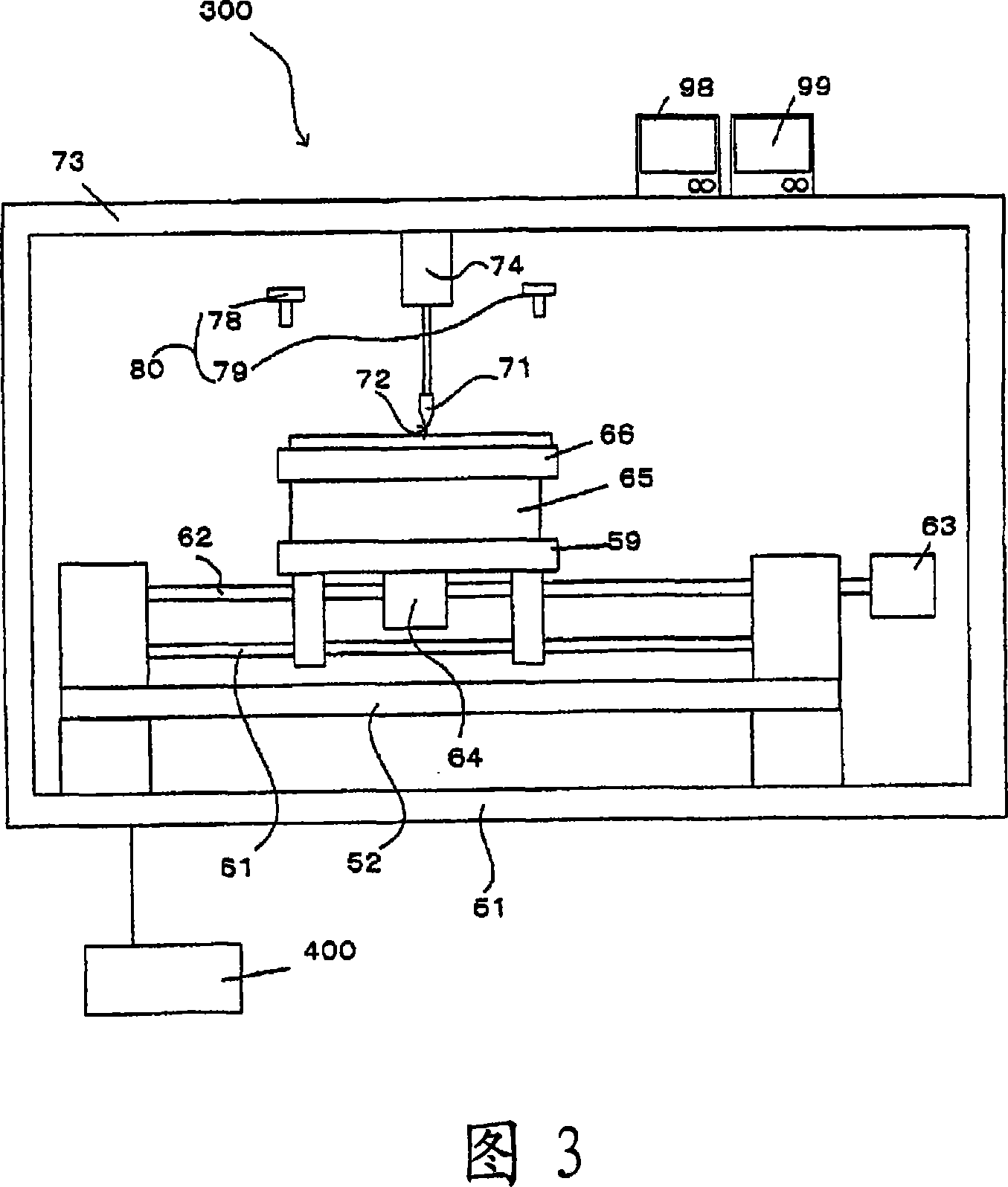

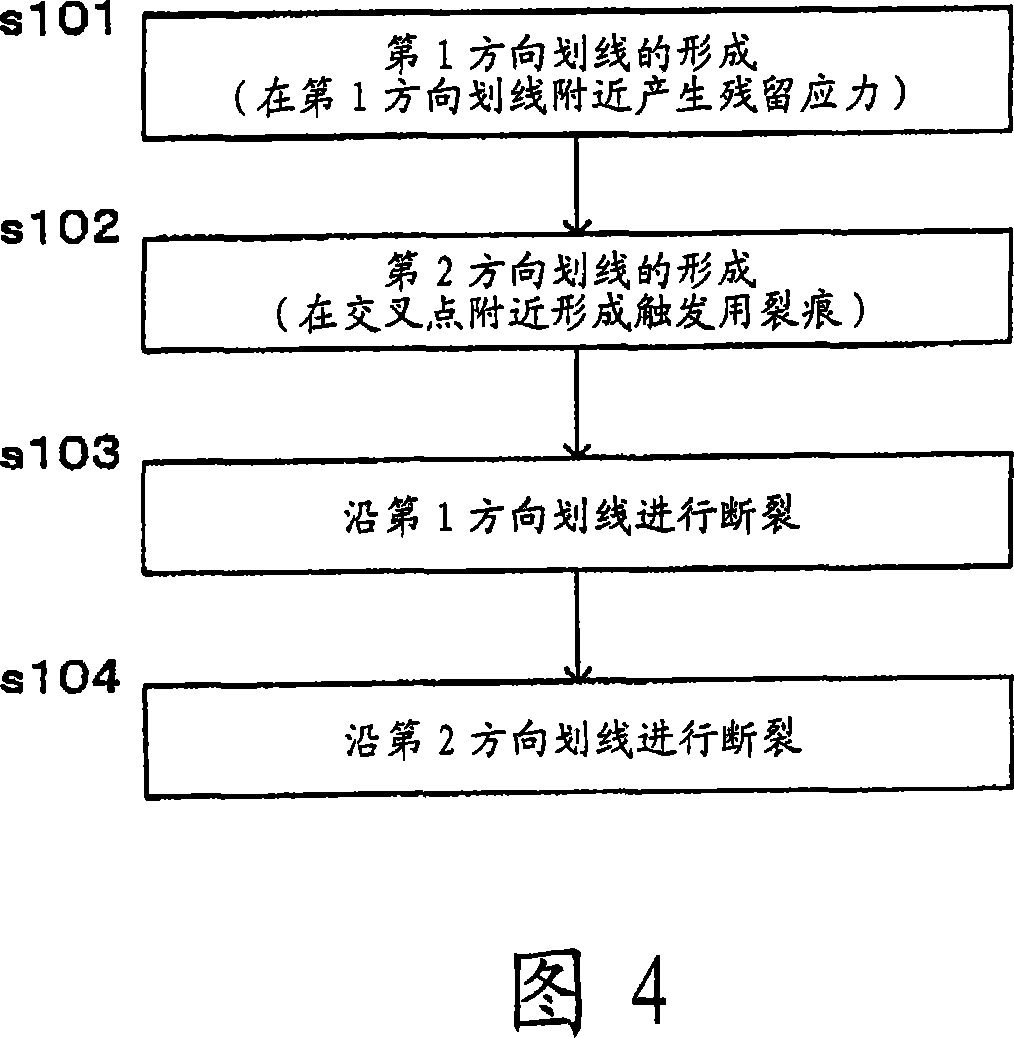

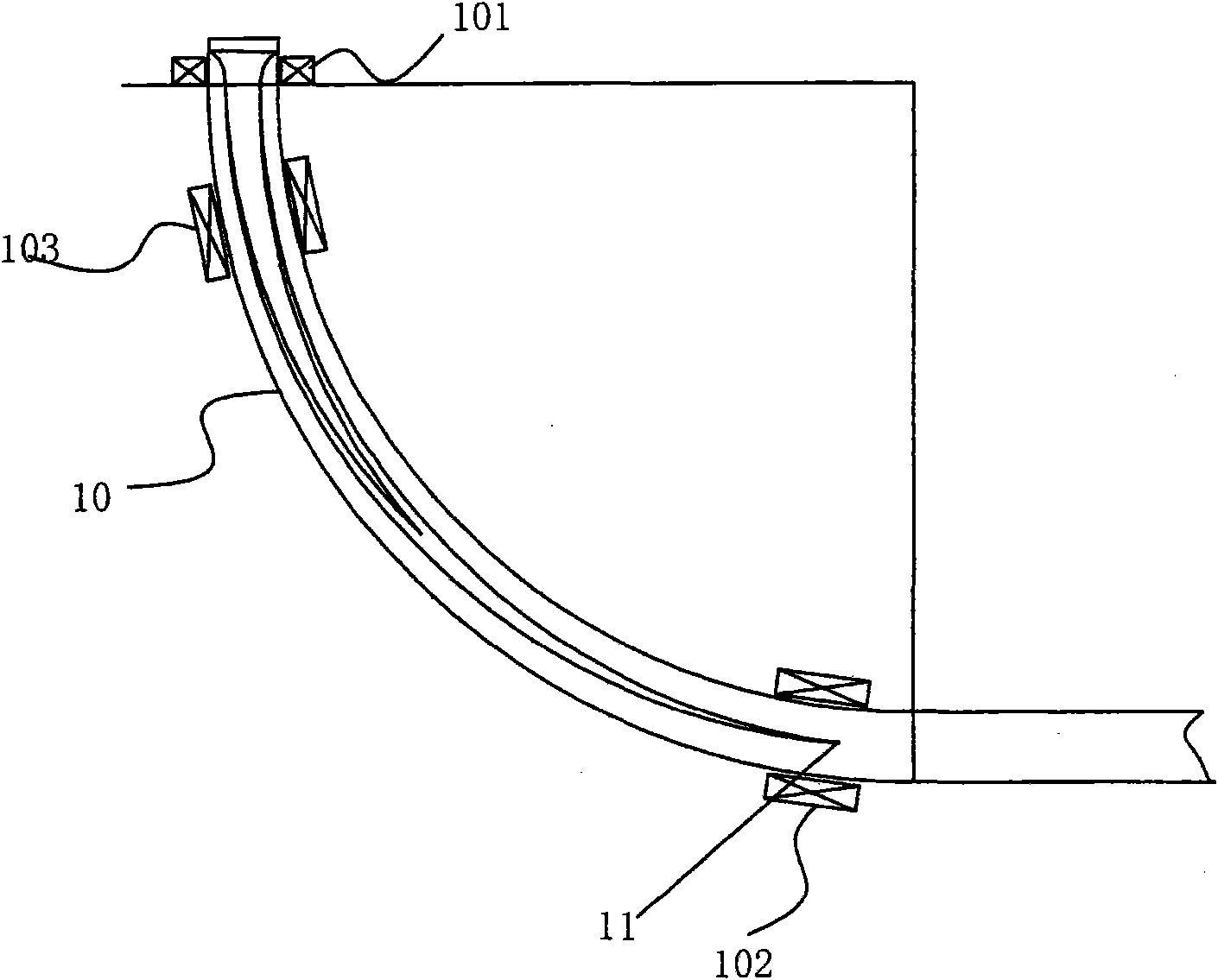

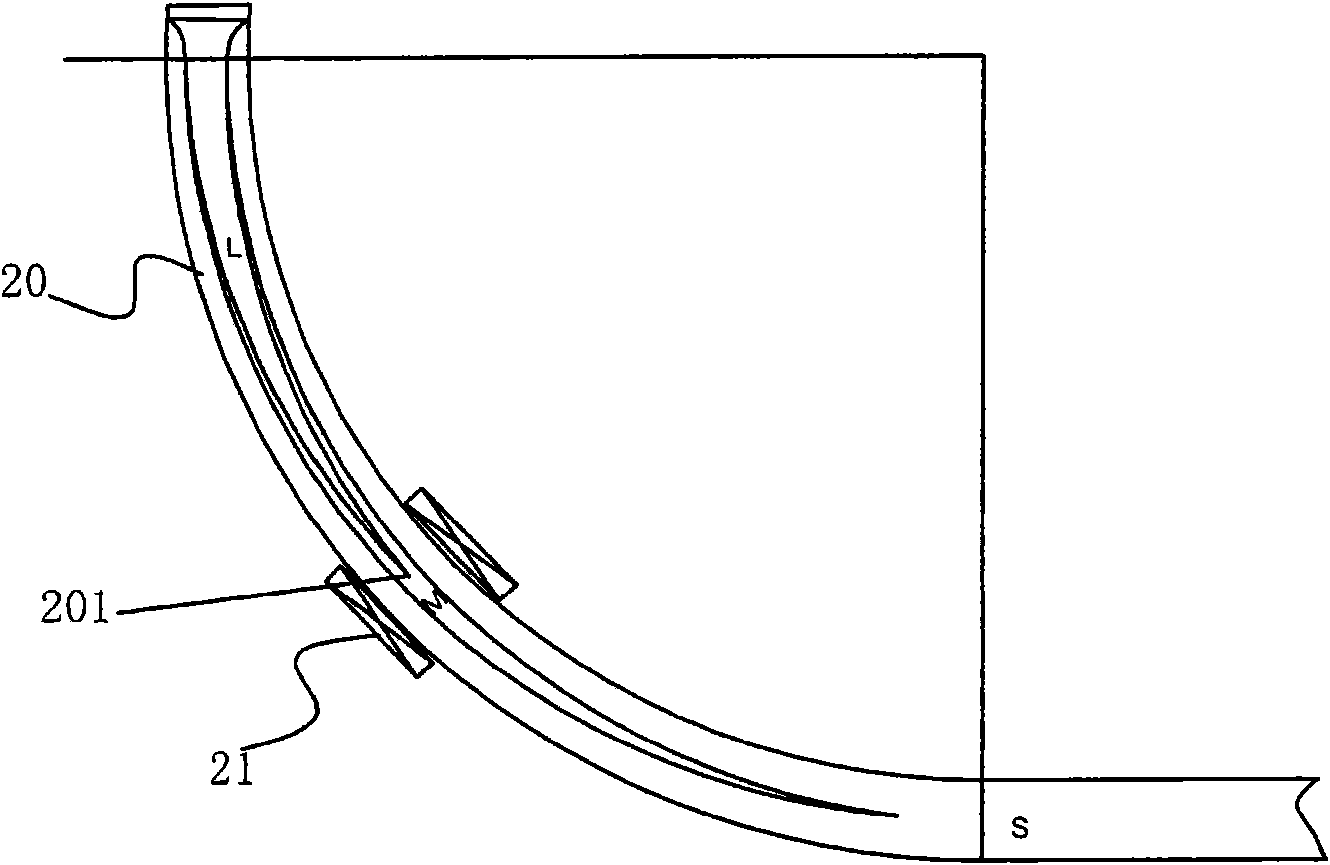

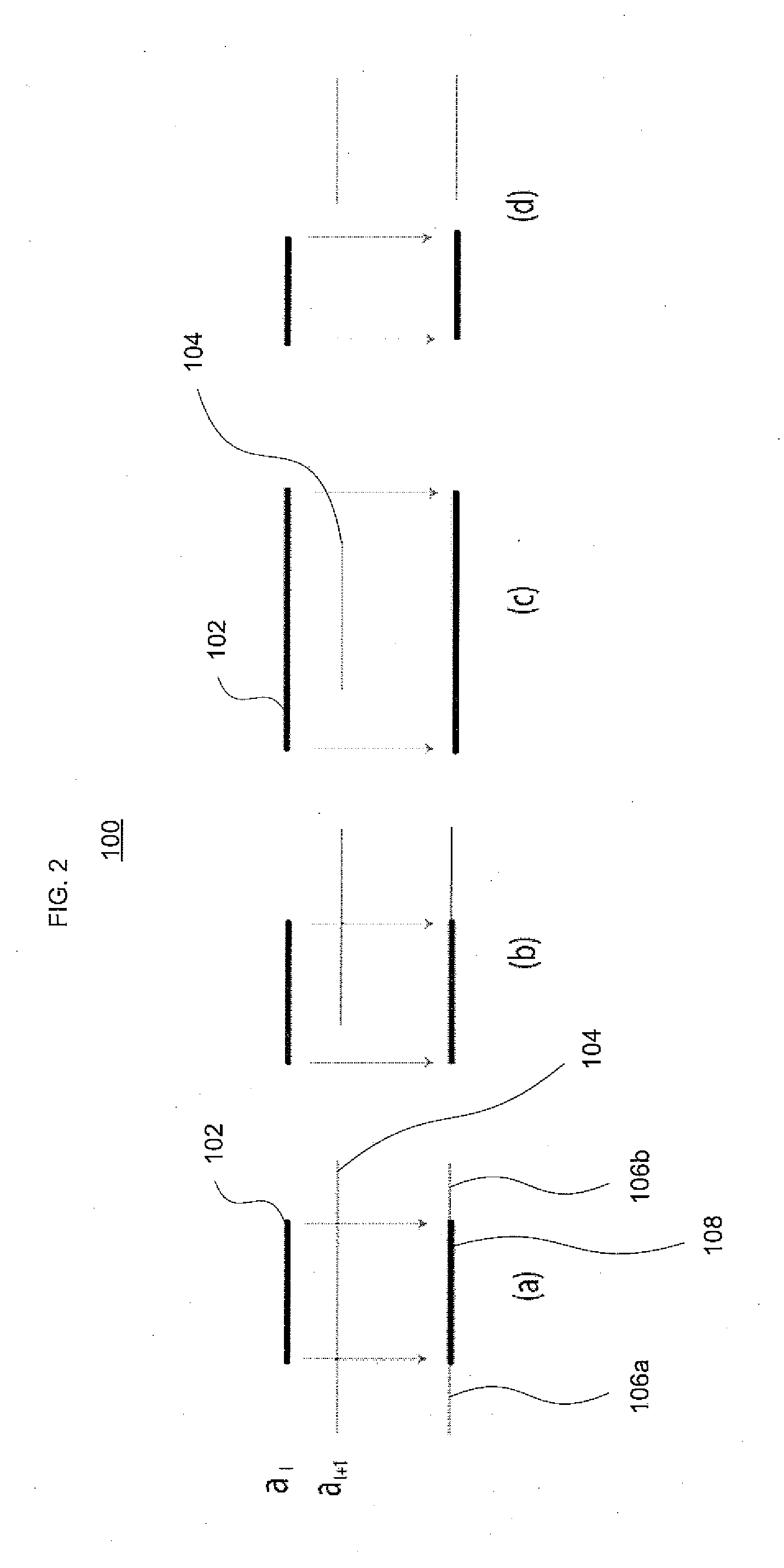

Method for cutting brittle material substrate and substrate cutting system

Owner:MITSUBOSHI DIAMOND IND CO LTD

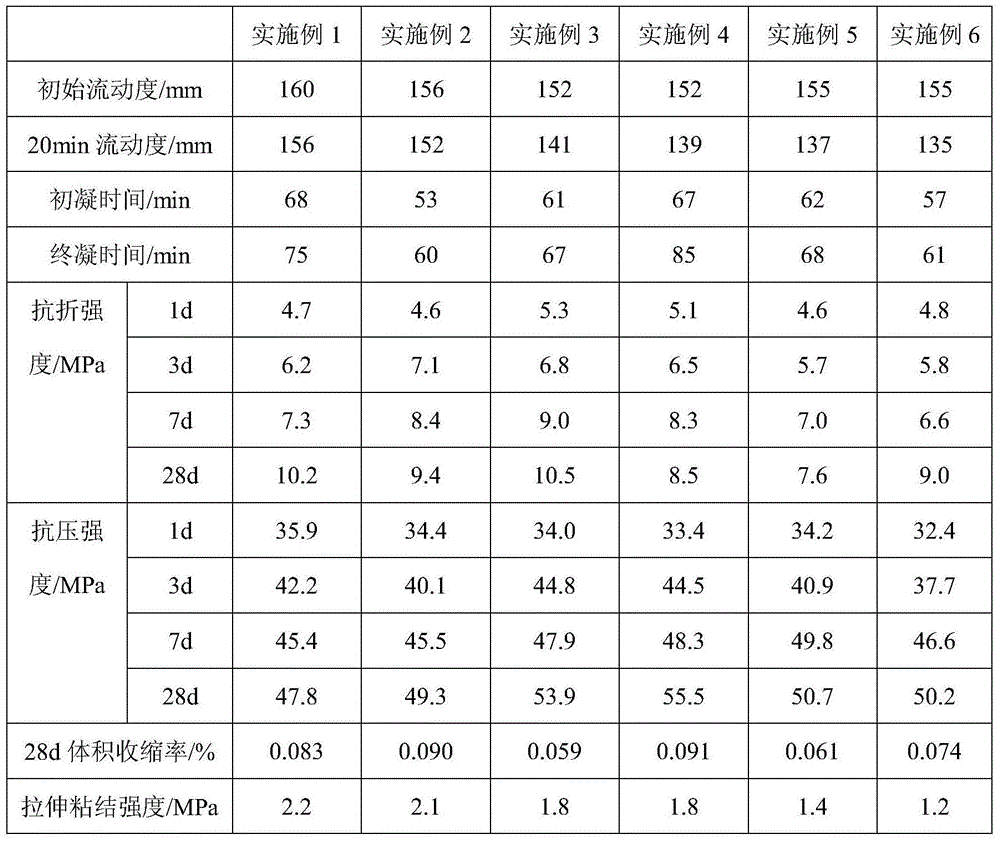

Early-strength type aluminate cement based self-leveling material

The invention relates to an early-strength type aluminate cement based self-leveling material which is characterized by comprising the following raw material components in parts by weight: 300-340 parts of aluminate cement, 40-60 parts of gypsum, 20-60 parts of portland cement, 380-420 parts of quartz sand, 180-220 parts of a heavy calcium carbonate powder, 8-20 parts of a redispersible emulsion powder, 2-2.4 parts of a water reducing agent, 0.15-0.25 part of a water-retaining agent, 1.5-2.5 parts of a defoaming agent, and 0-0.4 part of a retarder, wherein the water-material mass ratio is 0.18-0.19. The self-leveling material has the characteristics of good fluidity, high surface flatness, good stability, fast condensation hardening speed, high early strength, small volume shrinkage rate and the like, and can be used as a ground leveling material and a grouting repairing material.

Owner:NANJING UNIV OF TECH

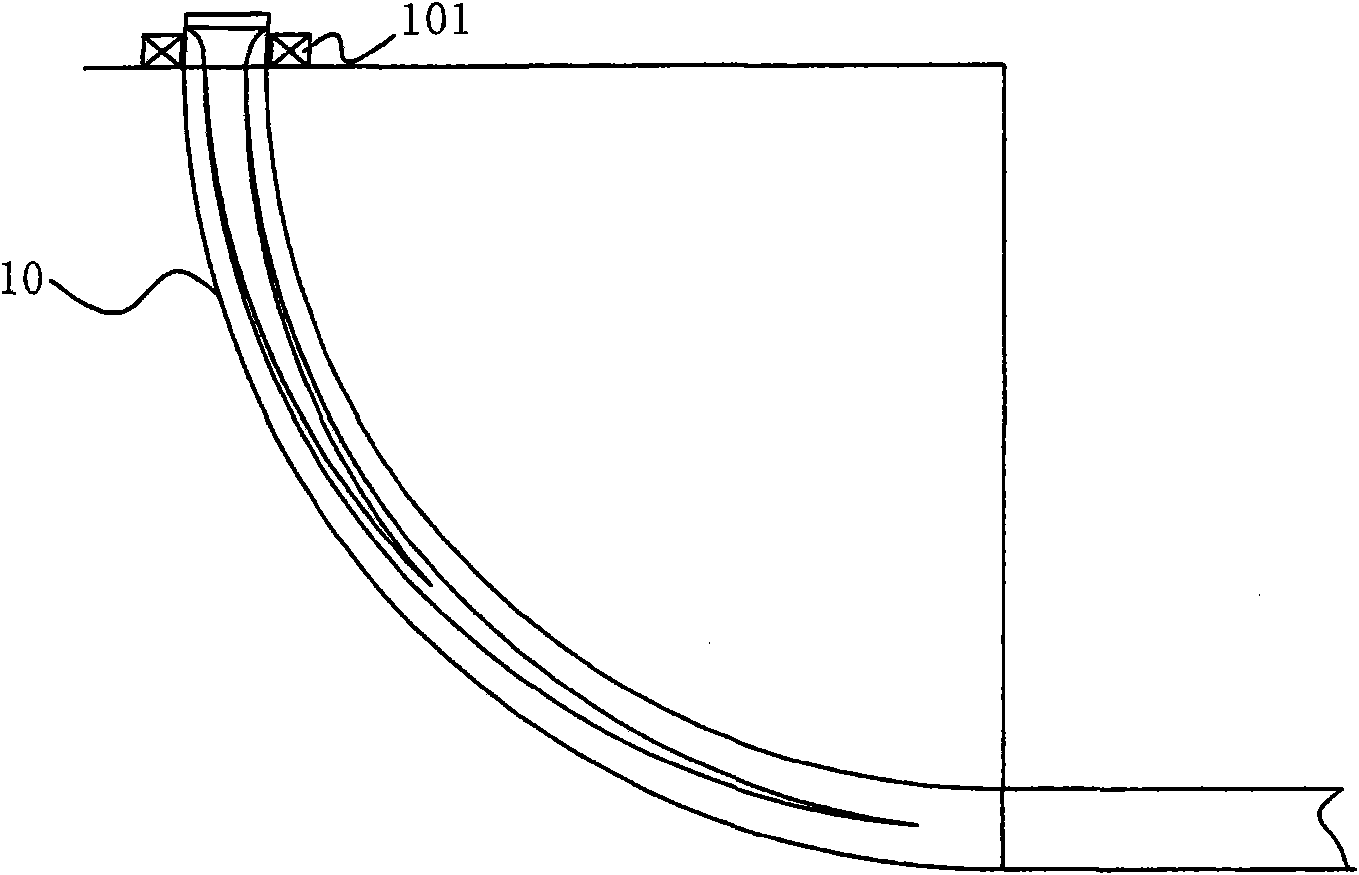

Method for improving internal organization of casting blank of continuous casting machine and electromagnetic stirring device

The invention provides a method for improving the internal organization of a casting blank of a continuous casting machine and an electromagnetic stirring device, wherein the method is as follows: atthe tail end of a continuous casting bank liquid core on a secondary cooling zone of the continuous casting machine, carrying out electromagnetic stirring and generating forward and reverse alternantspiral rotating force which causes molten steel to rotate and flow along the casting direction of the continuous casting machine and appends static pressure to a solid-liquid phase zone of the tail end of the liquid core. The method and the electromagnetic stirring device of the invention can provide enough molten steel for supplying the volume contraction during the solidification of the liquid core and eliminating shrinkage cavity and loose, thus increasing the quality of the continuous blank.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

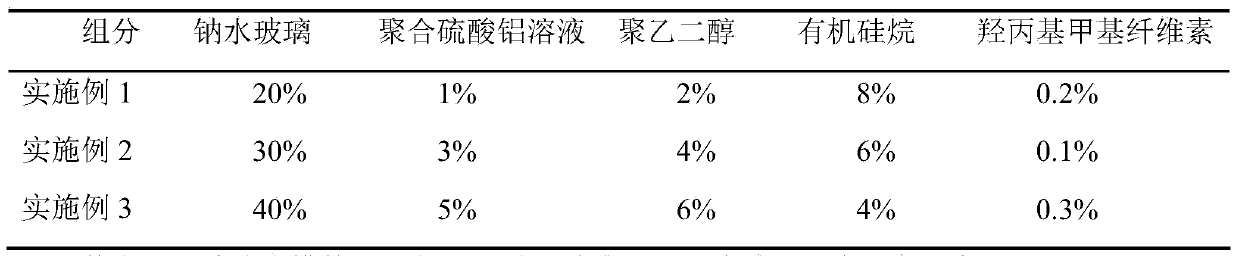

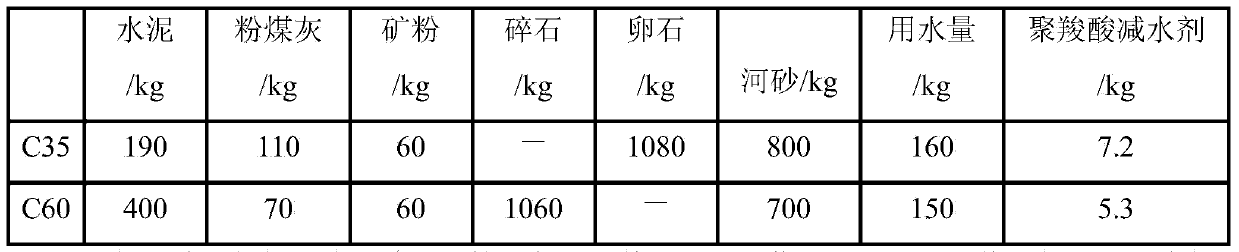

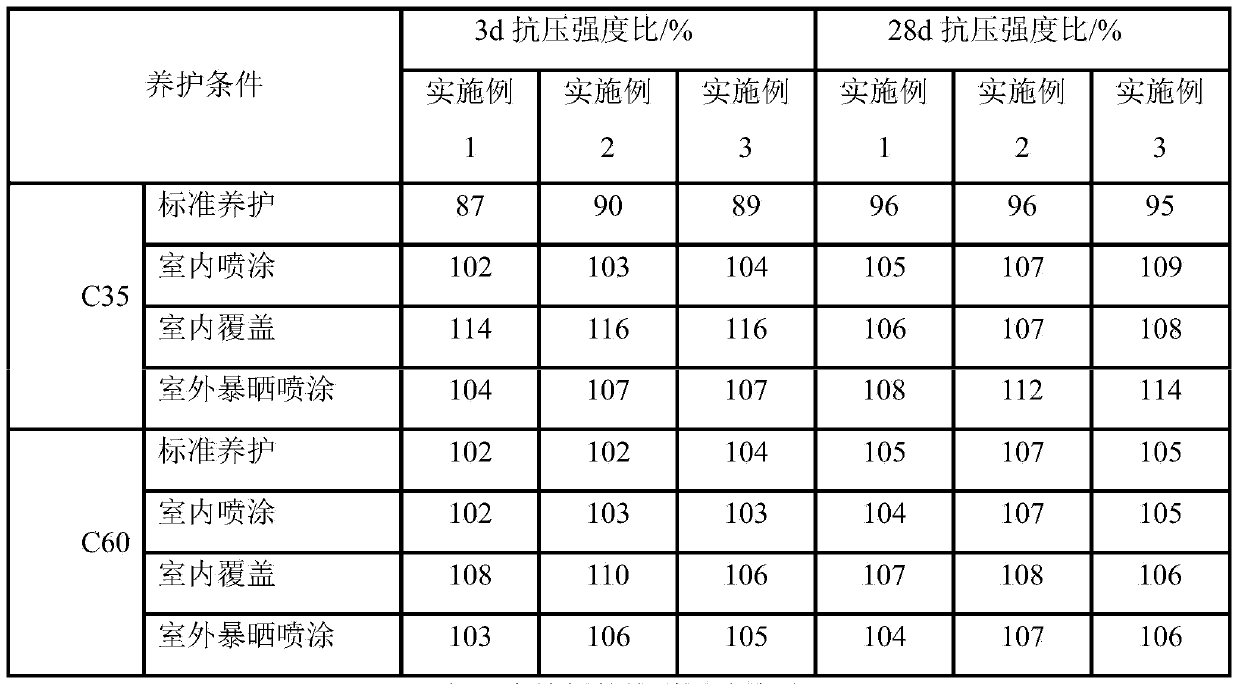

Concrete curing compound and preparation method thereof

The invention belongs to the field of a concrete admixture, and particularly relates to a concrete curing compound. The concrete curing compound is prepared from the following functional components by weight percent: 20-40% of water glass, 1-5% of polyaluminium sulfate, 2-8% of polyethylene glycol, 4-8% of organosilane, 0.1-0.3% of hydroxypropyl methyl cellulose and the balance of water. The concrete curing compound is low in cost, does not contain poisonous and harmful elements, has dual properties of compact and hard inorganic curing agent layer and an organic curing agent with good water-retention rate, enters into the concrete to promote hydration reaction by infiltration and diffusion action, has a compact surface structure, simultaneously can be crossly linked and combined with a hydration product and a surface layer silicon oxygen bond, and forms a rigid hydrophobic membrane layer. A concrete surface pore is plugged to prevent moisture evaporation, and plays the roles of penetration, maintenance, water conservation and autotrophic nutrition. The concrete curing compound is sprayed on the concrete surface, so that the concrete compression strength and the crack resistance can be effectively improved, and volume contraction is reduced.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

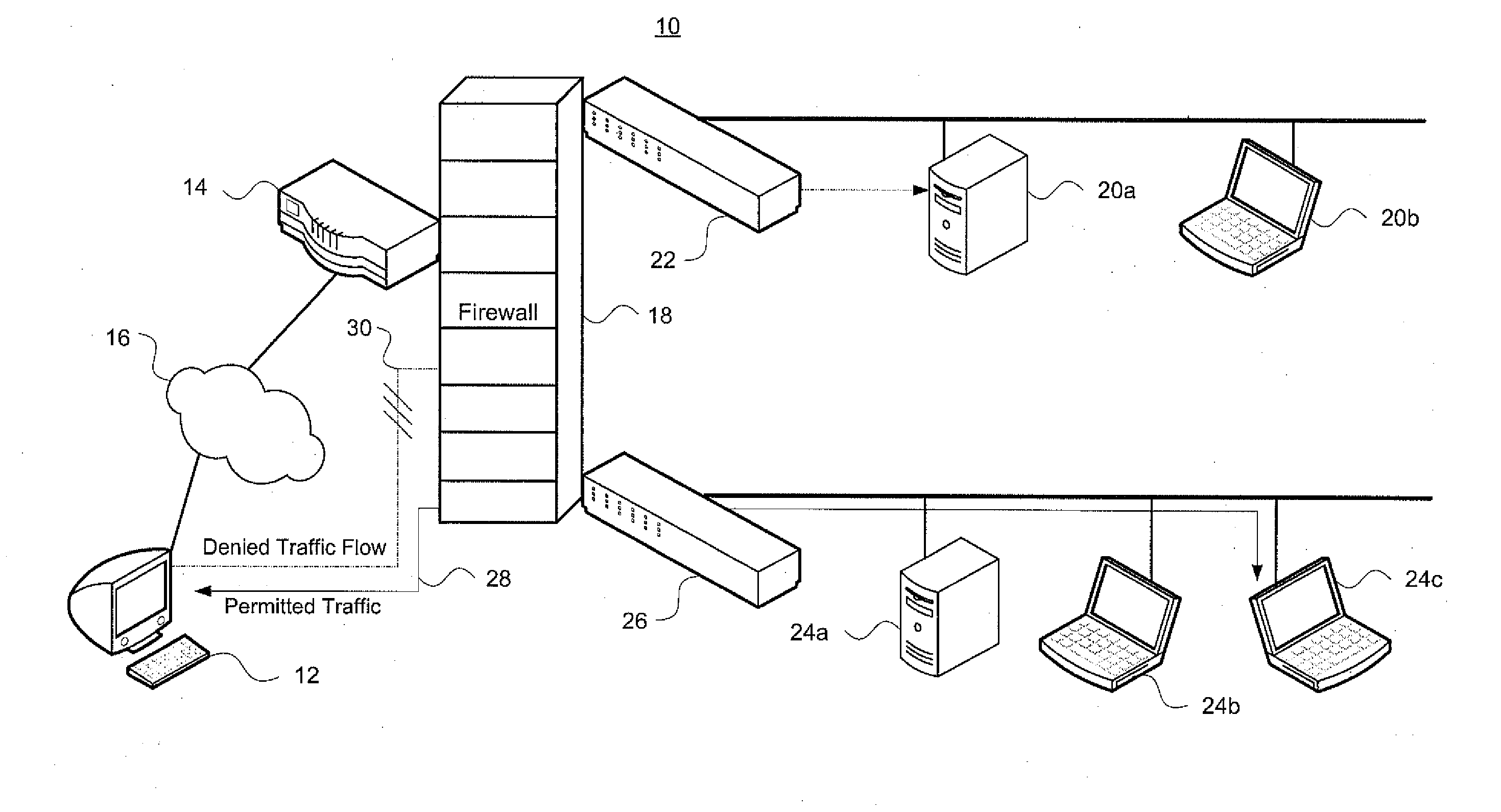

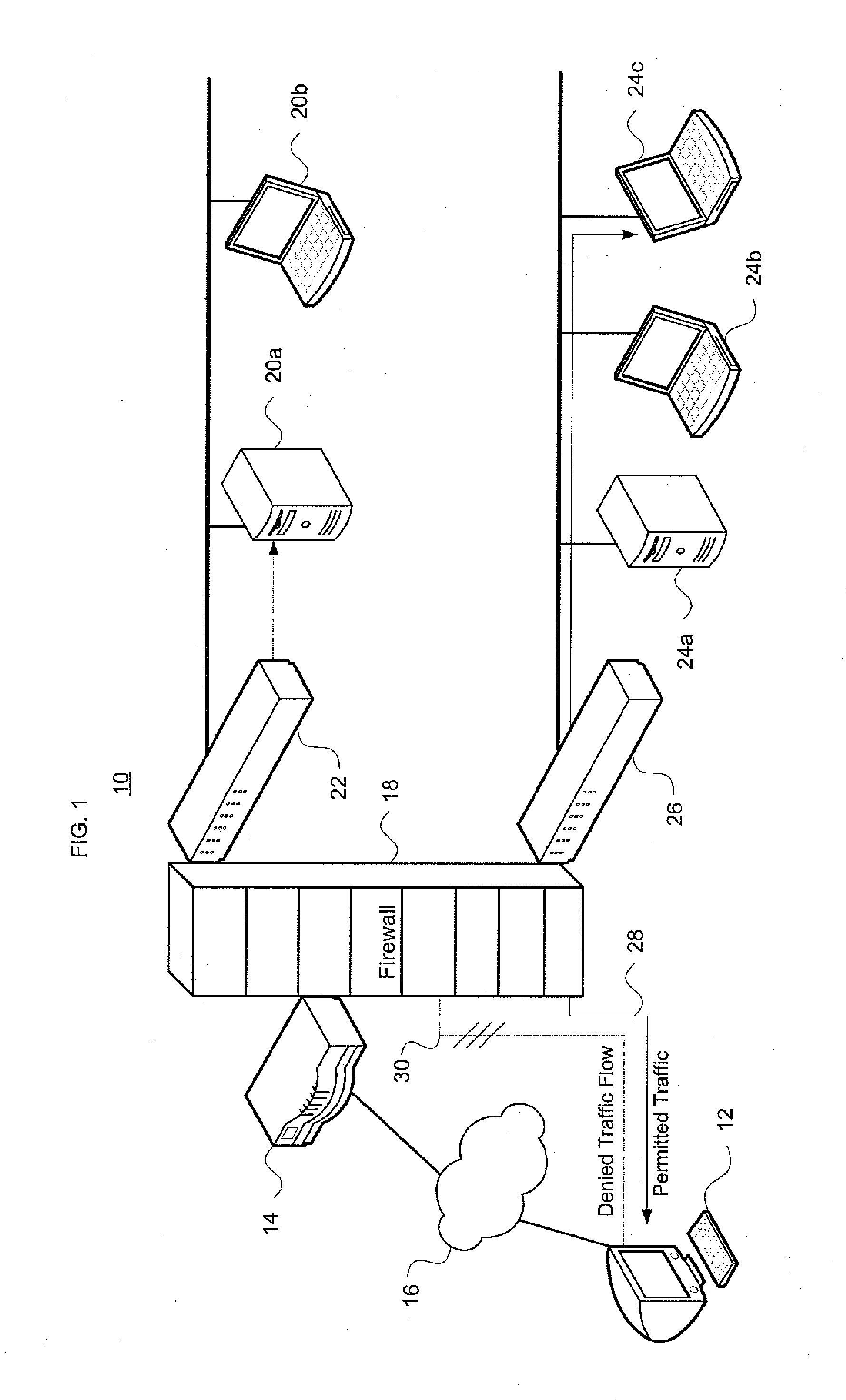

Redundancy detection and resolution and partial order dependency quantification in access control lists

ActiveUS20100199344A1Computer security arrangementsMultiple digital computer combinationsDatabaseAccess control list

Aspects of the invention pertain to analyzing and modifying access control lists that are used in computer networks. Access control lists may have many individual entries that indicate whether information can be passed between certain devices in a computer network. The access control lists may include redundant or conflicting entries. An aspect of the invention converts an order-dependent control list into an order-free equivalent. Redundant entries are identified and removed without adversely affecting the access control list. Redundancy may be identified by evaluating the volume contraction ratio, which is the ratio of the volume of spin-off entries to specific original entry in the access control list. This ratio reflects the extent of order-dependent impact on that entry in a given access control list.

Owner:PERSPECTA LABS INC

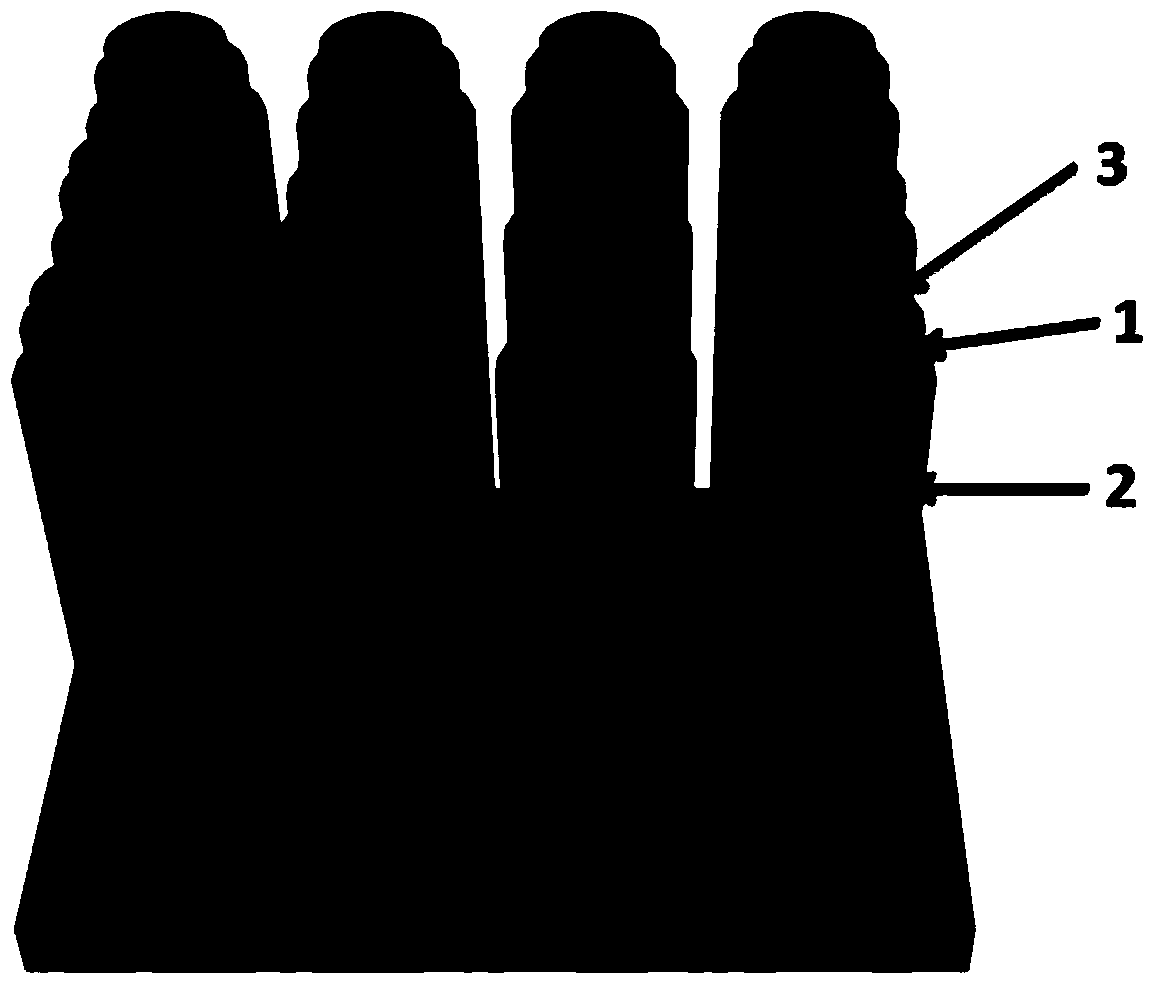

Polypyrrole-titanium dioxide or titanium nitride-polyaniline coaxial three-layer nanotube array composite material, and preparation method and application thereof

ActiveCN104112603AImprove cycle lifeFully contactedMaterial nanotechnologyHybrid capacitor electrodesCapacitancePolypyrrole

The invention provides a coaxial three-layer nanotube array composite material. The coaxial three-layer nanotube array composite material comprises a titanium dioxide or titanium nitride nanotube array frame, a polypyrrole nanotube formed through polymeric deposition at the outer wall surface of the frame, and a polyaniline nanotube formed through polymeric deposition at the inner wall surface of the frame. The invention also provides a preparation method of the coaxial three-layer nanotube array composite material and an electrochemical energy storage application of the coaxial three-layer nanotube array composite material. The composite material is prepared by taking a titanium dioxide or titanium nitride nanotube as the frame, the frame is of a hollow structure, has uniform tube spacing and can absorb volume contraction and expansion caused when a conductive polymer is charged and discharged, and the circulating life of an electrode material is prolonged; the multi-gap hollow tubular structure enables polyaniline and polypyrrole to be fully contacted with a doping agent electrolyte, such that ion diffusion and charge transfer are facilitated; and the composite material comprises P-type doped characteristic polypyrrole and n-type doped characteristic polypyrrole at the same time and fully utilizes anions and cations in a solution so as to obtain a super capacitor electrode material with high specific capacitance and good circulating stability.

Owner:SOUTHEAST UNIV

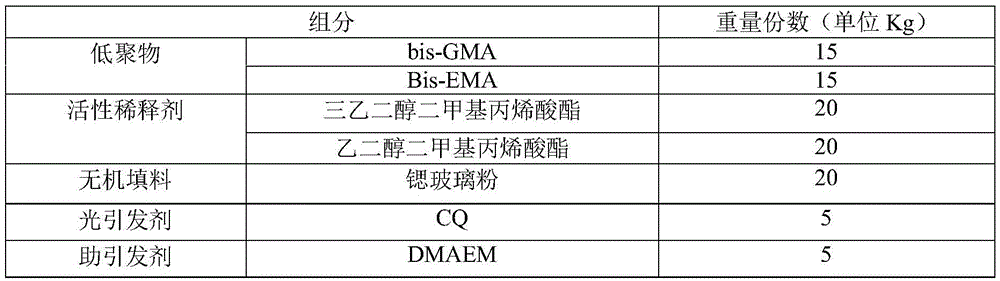

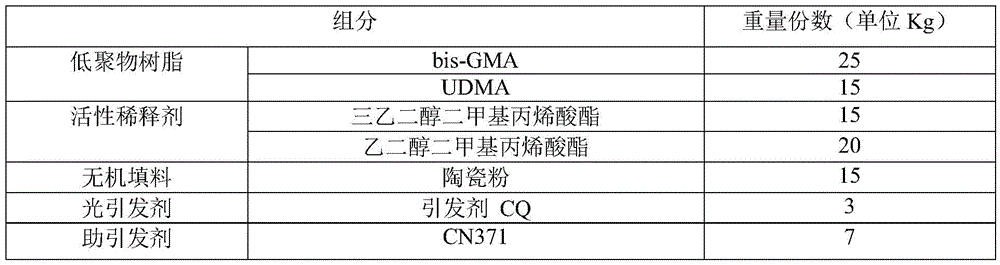

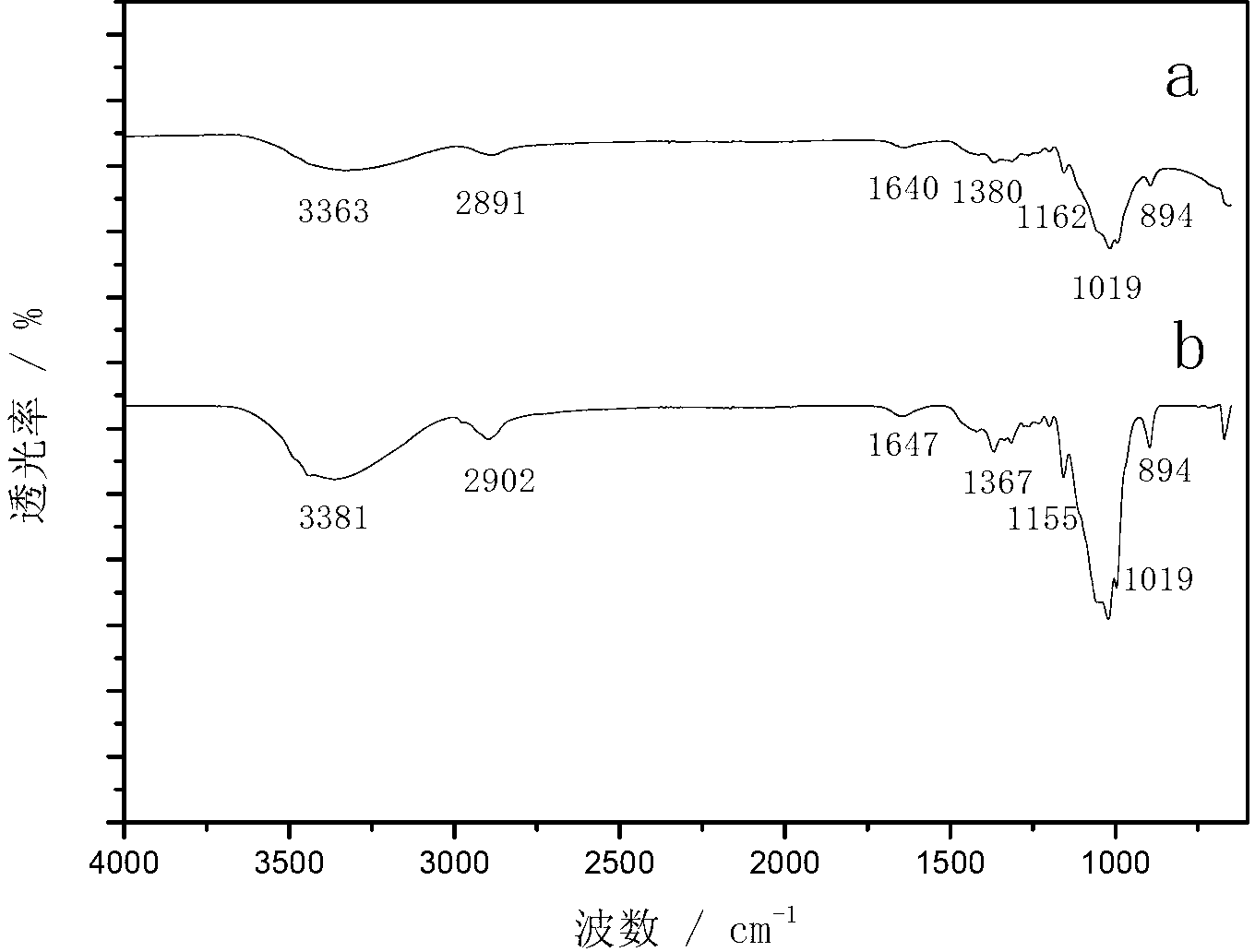

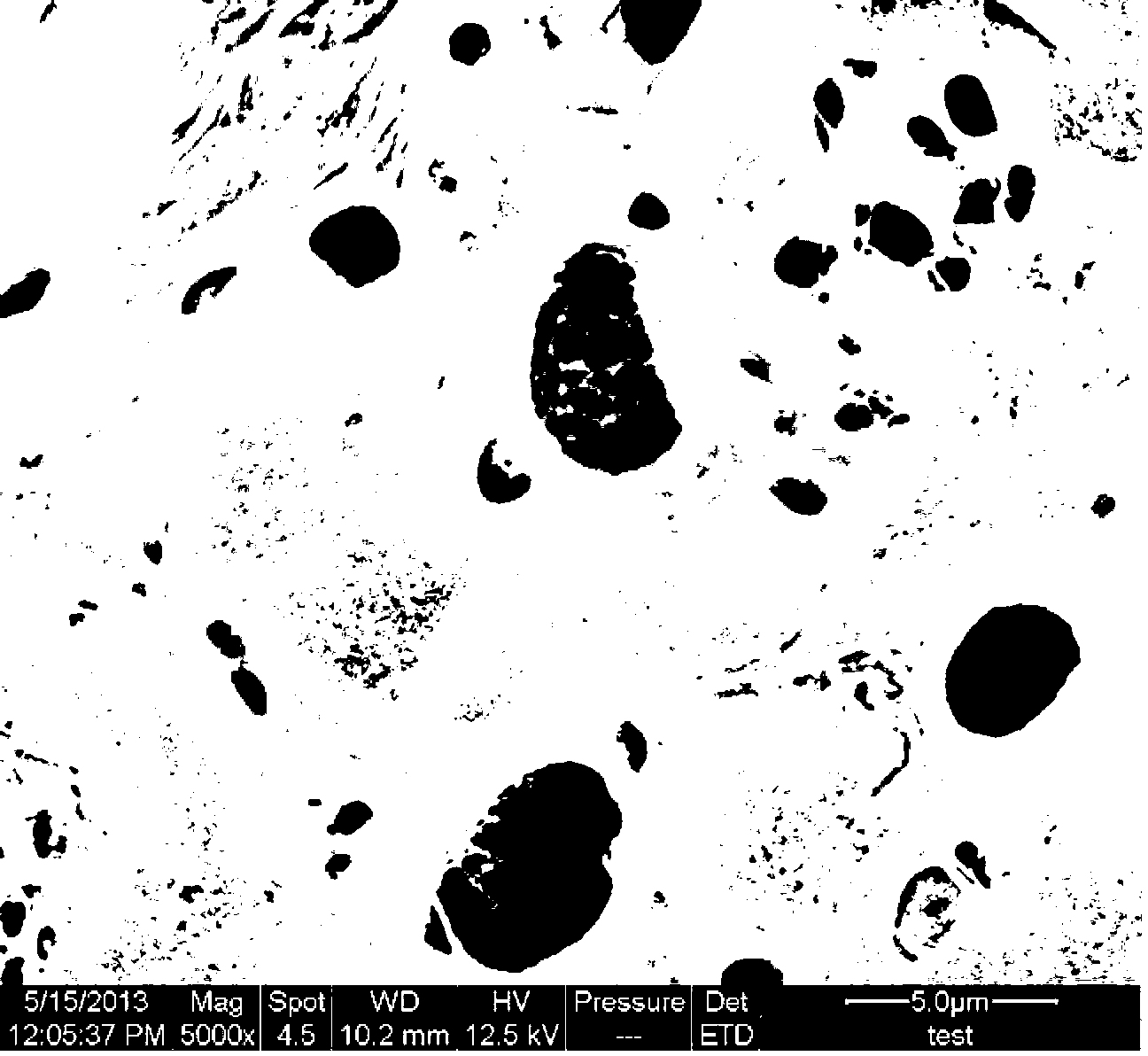

Visible light cured dental restorative composition and preparation method thereof

InactiveCN105456039ALong operating timeEasy to useImpression capsDentistry preparationsUltravioletResin-Based Composite

Owner:JIANGSU SHENGYING NEW MATERIAL

Preparation method for spherical cellulose aerogel

The invention provides a preparation method for a spherical cellulose aerogel, which relates to a preparation method for an aerogel. The objective of the invention is to overcome the problems that the phenomena of structure collapse and volume contraction of a conventional cellulose aerogel frequently occur and the specific surface area of an obtained aerogel is small. The method comprises the following steps: 1, putting vegetable fiber in a mixed solution of urea and NaOH and carrying out stirring after refrigeration for formation of a solution so as to obtain a vegetable fiber / alkaline urea solution; 2, mixing trichloromethane with ethyl acetate and then adding glacial acetic acid so as to obtain an organic solution; 3, titrating the vegetable fiber / alkaline urea solution into the organic solution of glacial acetic acid and carrying out ageing so as to obtain a gel; 4, putting the gel into a glacial acetic acid solution for solidification; and 5, replacing a hydrogel successively with absolute ethyl alcohol and tert-butyl alcohol and carrying out refrigeration and freeze-drying so as to obtain the aerogel. According to the invention, the phenomena of structure collapse and volume contraction of an aerogel in the process of drying are overcome, and the prepared cellulose aerogel has low density and a specific surface area of more than 240 m<2> / g.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

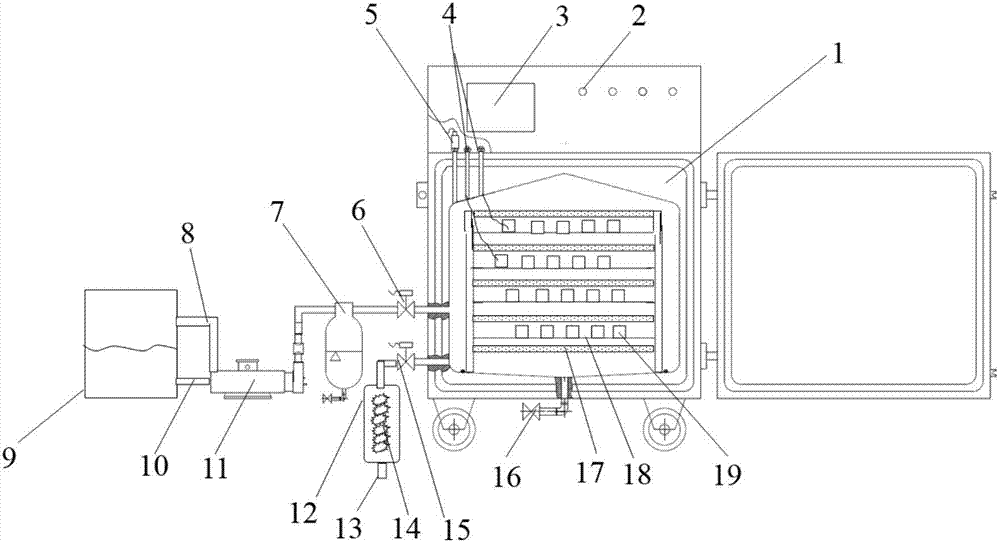

Method and device for drying poria cocos through vacuum pulsation

ActiveCN107166897AAvoid crackingAvoid breakingLighting support devicesDrying solid materials without heatControl systemPulp and paper industry

The invention belongs to the technical field of agricultural product processing and relates to a nutrition-loss-free poria cocos processing method and equipment, in particular to a method and device for drying poria cocos through vacuum pulsation. According to the method, a vacuum drying mode is adopted for drying diced poria cocos, and the situation that due to the fact that internal and external humidity gradients are uneven, volume contraction is uneven, so that materials are cracked or broken is avoided. By means of the method and device for drying the poria cocos through vacuum pulsation, under the pulsation condition that the pressure inside a drying chamber (1) is continuous, microcosmic pore channels of the diced poria cocos (19) can be expanded and contracted ceaselessly and furthermore made to communicate with one another; and volume contraction, generated in the drying process, of the diced poria cocos can be effectively promoted, and high material strength is maintained. The device comprises a vacuum system, an auxiliary hot air drying system, a heating system and a control system. By means of the device, intelligent adjustment of the temperature and the vacuum degree can be effectively achieved; the diced poria cocos can be dried quickly and evenly; and the dried diced poria cocos (19) is high in compactness and not prone to breakage.

Owner:CHINA AGRI UNIV

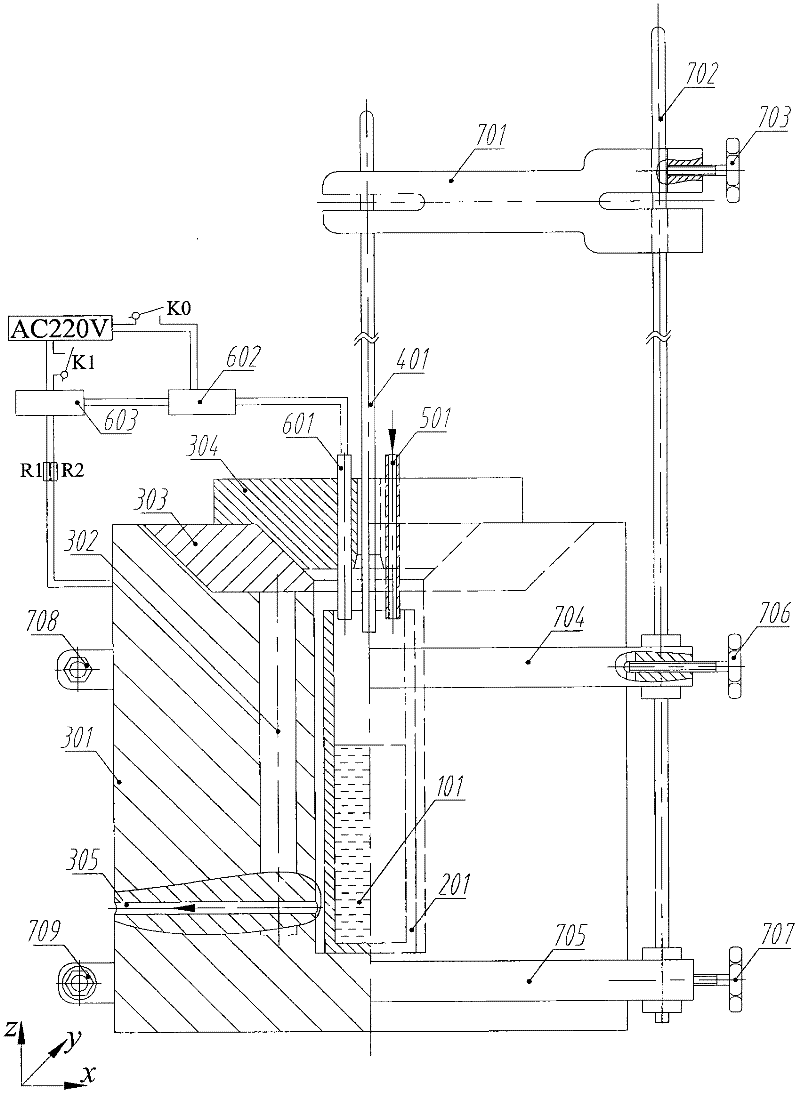

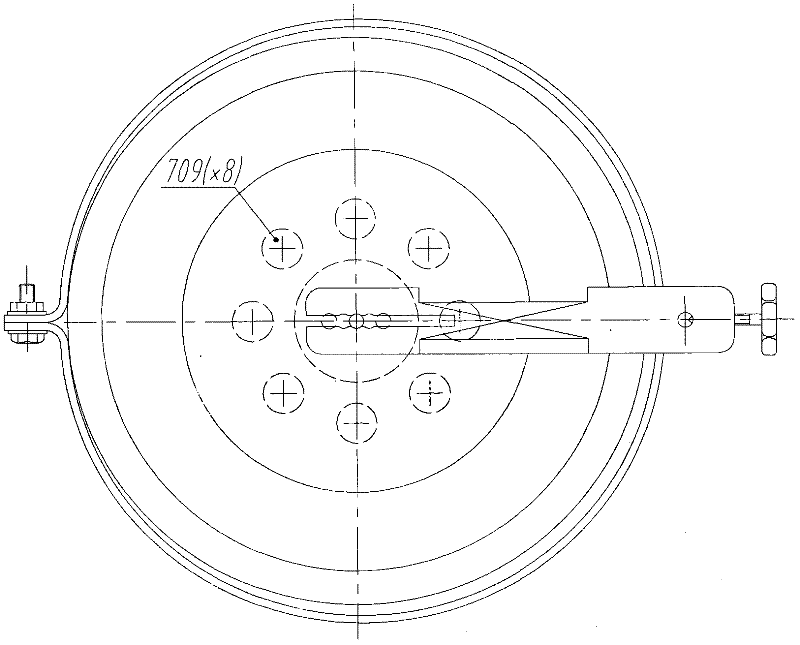

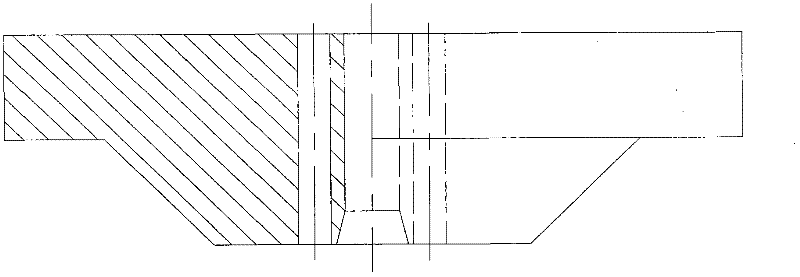

Measuring device and method of melting volume expansion ratio/molten state density of material

InactiveCN102507373AMeasuring Volume ExpansionMeasured value of molten state densityMaterial thermal coefficient of expansionSpecific gravity measurementMolten stateShielding gas

The invention discloses a measuring device and a method of melting volume expansion ratio / molten state density of a material, the device is characterized in that a sample chamber is positioned in an electrically heated sample seat; a thermocouple, a PID intelligent temperature controller and a relay are used for coordinately controlling a heating temperature and a heat preservation period; and a probe is fixed on a clamping mechanism and is capable of integrally and freely moving in a z direction along a guide rod. The method comprises the steps of: vertically putting the sample chamber holing samples with a known mass in the sample seat, covering a top cover, guaranteeing the probe to be vertical to the bottom surface of the sample chamber through a correcting device, filling a shielding gas, turning on a temperature display switch, setting a heating parameter and heating; closing the shielding gas after the sample is completely molten, stretching the probe in the sample chamber to measure a liquid level, and stopping the heating procedure to finish one measurement process; repeatedly measuring to obtain an average liquid level, figuring out a melting volume expansion ratio (a negative value refers to melting volume shrinkage) and a molten state density of the sample according to a formula.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

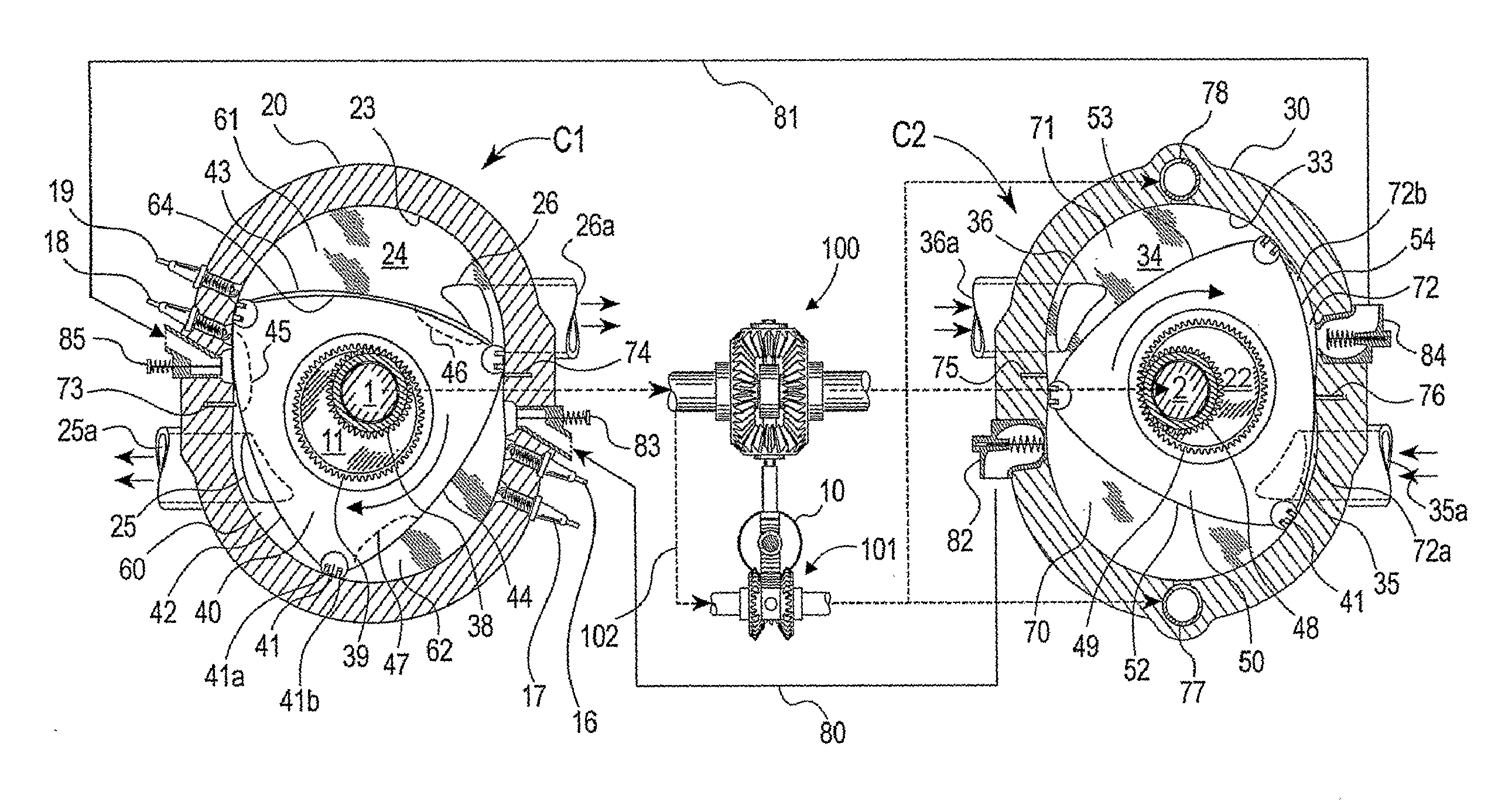

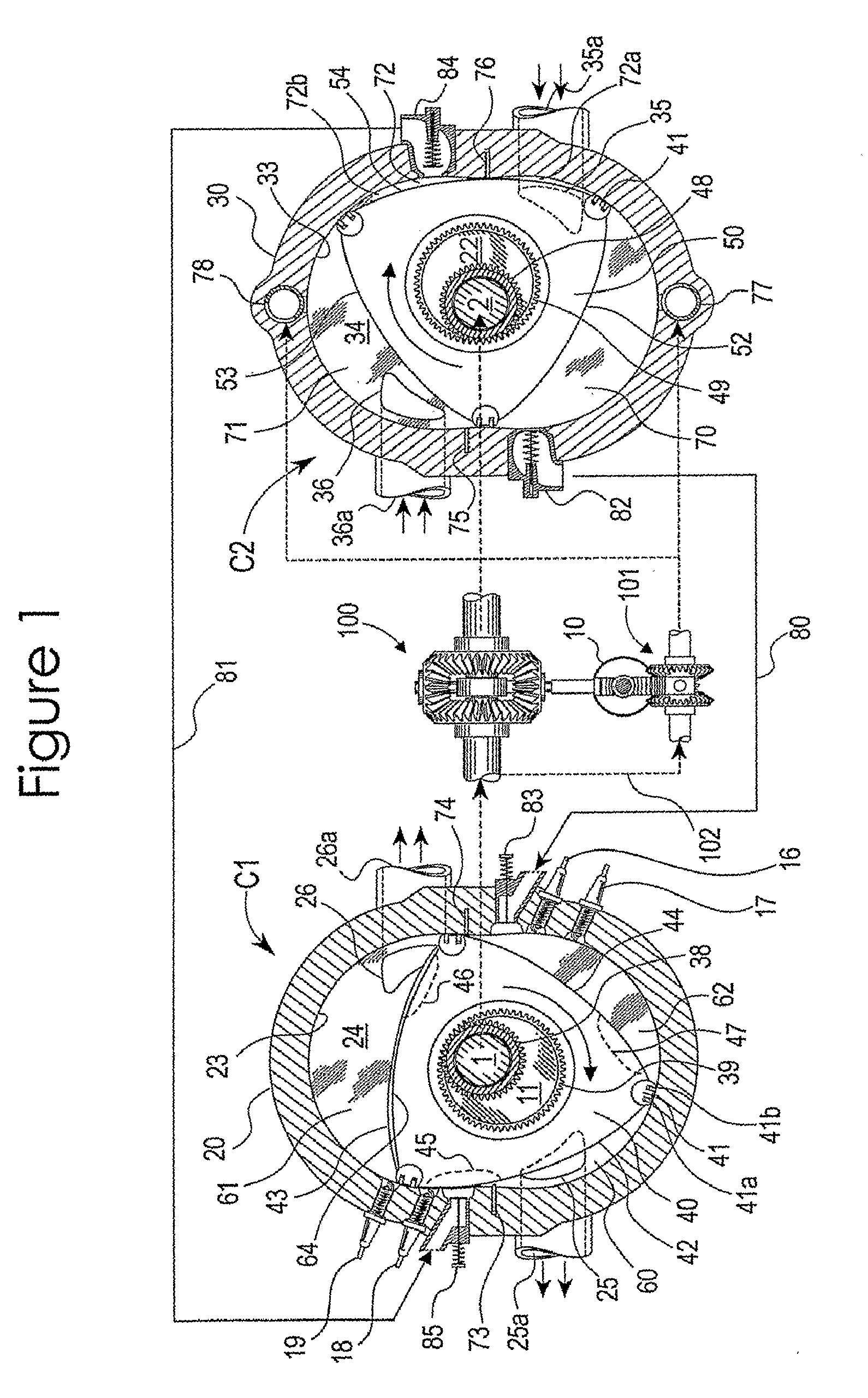

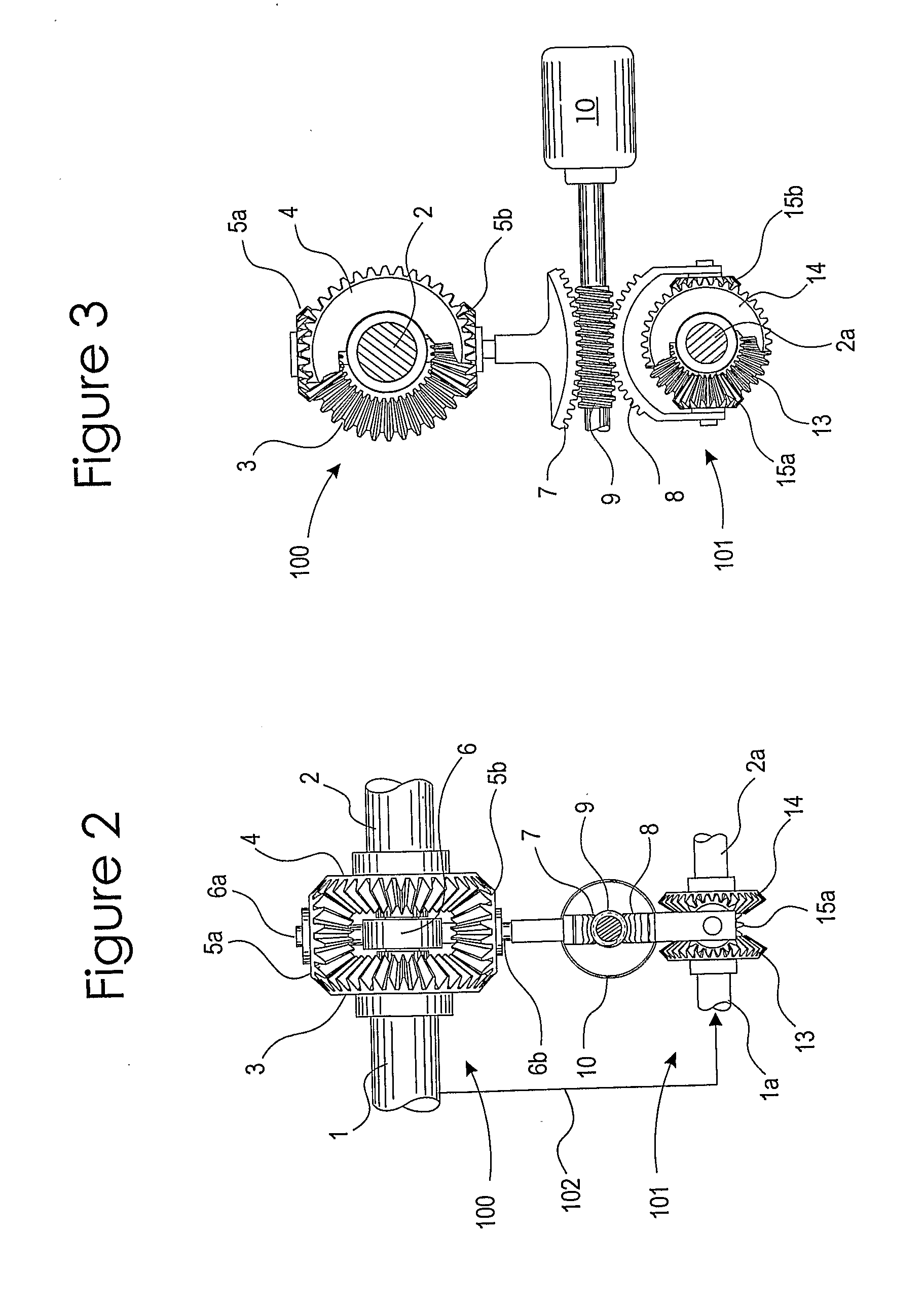

Split Cycle Variable Capacity Rotary Spark Ignition Engine

InactiveUS20100116241A1Improve sealingLess internal stressAnalogue computers for vehiclesElectrical controlCombustion chamberMechanical engineering

A split-cycle variable capacity rotary spark ignition engine system having at least a first rotary configuration (C1) including repetitively volume variable working chambers [60, 61, 62] for carrying out the combustion-expansion and exhaust phases and at least a second rotary configuration (C2) including repetitively volume variable working chambers (70, 71, 72) for carrying out the intake and compression phases of a four phase engine cycle. Dividing seal means (73, 74 of C1, 75, 76 of C2) for periodically dividing each of successive working chambers into a volume enlarging leading portion and a volume contracting trailing portion. Discharge valve means for varying compression chamber capacity through discharging fraction of trapped intake gas from compression chambers. A first phase altering arrangement is provided for varying the phase relation between the first rotary configuration (C1) and the second rotary configuration (C2). A second phase altering arrangement varies phase relation between the discharge valve means and corresponding compression chambers. The first rotary configuration (C1) having variable capacity combustion chambers operatively synchronize with the variable capacity compression chambers of the second rotary configuration (C2) so that accomplish nearly full-load-like combustion environment through a substantially wide engine operating range.

Owner:SETH

Method for determining plastic volume shrinkage of cement paste

ActiveCN103558364AEffectively determine the change law of plastic volume shrinkageEffectively guide the performance evaluation of anti-gas channelingMaterial testing goodsCondensation processStress working

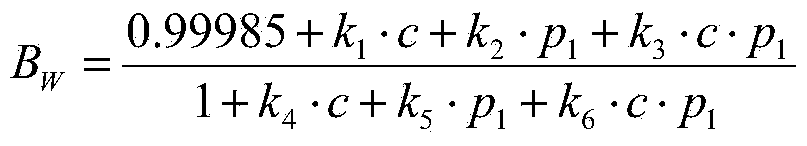

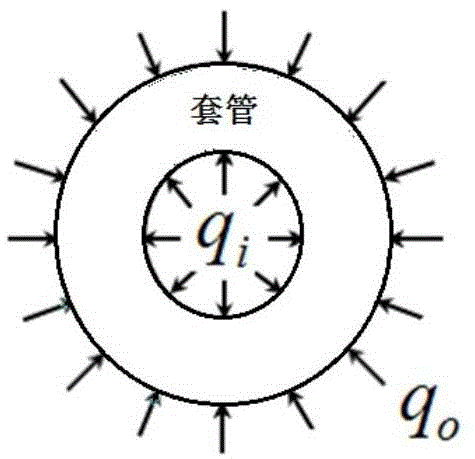

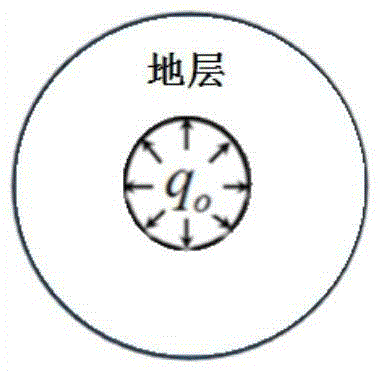

The invention discloses a method for determining the plastic volume shrinkage of cement paste. The method sequentially comprises the following steps of (1) acquiring relevant size parameters of a casing and a well; (2) acquiring relevant mechanical parameters of the casing and stratum rock; (3) determining relevant working condition parameters of an oil-gas well; (4) calculating a reservoir pressure and an initial fluid column pressure of the cement paste; (5) calculating an isothermal compressibility of the cement paste; (6) preparing the cement paste, performing a weight loss experiment, and determining the final setting time; (7) determining a pore pressure descending curve under the actual working condition according to the similarity comparison principle; and (8) calculating the plastic volume shrinkage of the cement paste. A plastic volume shrinkage mathematic model of the cement paste comprehensively considers the actual stress working conditions of the underground casing and the stratum and the weight loss performance of the cement paste, is simple in principle and simple in operation, is capable of effectively determining the plastic volume shrinkage change principle of the cement paste in a condensation process, and provides a scientific method for determining the plastic volume shrinkage of the cement paste.

Owner:SOUTHWEST PETROLEUM UNIV

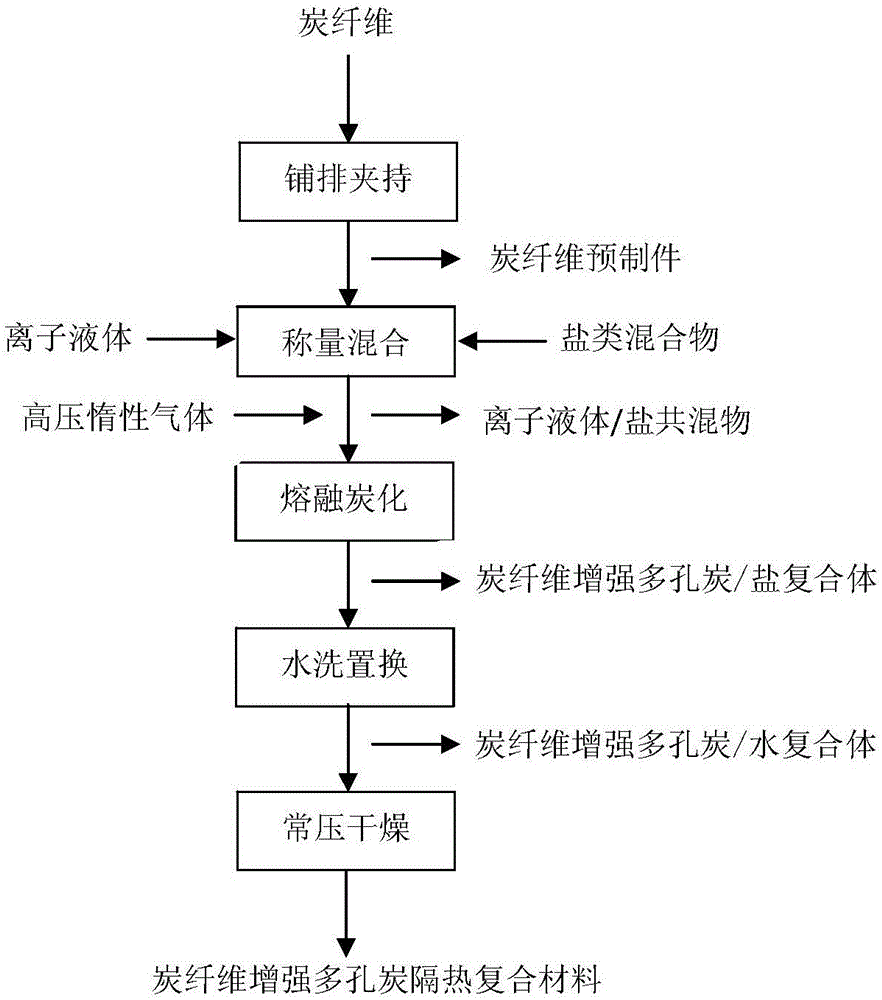

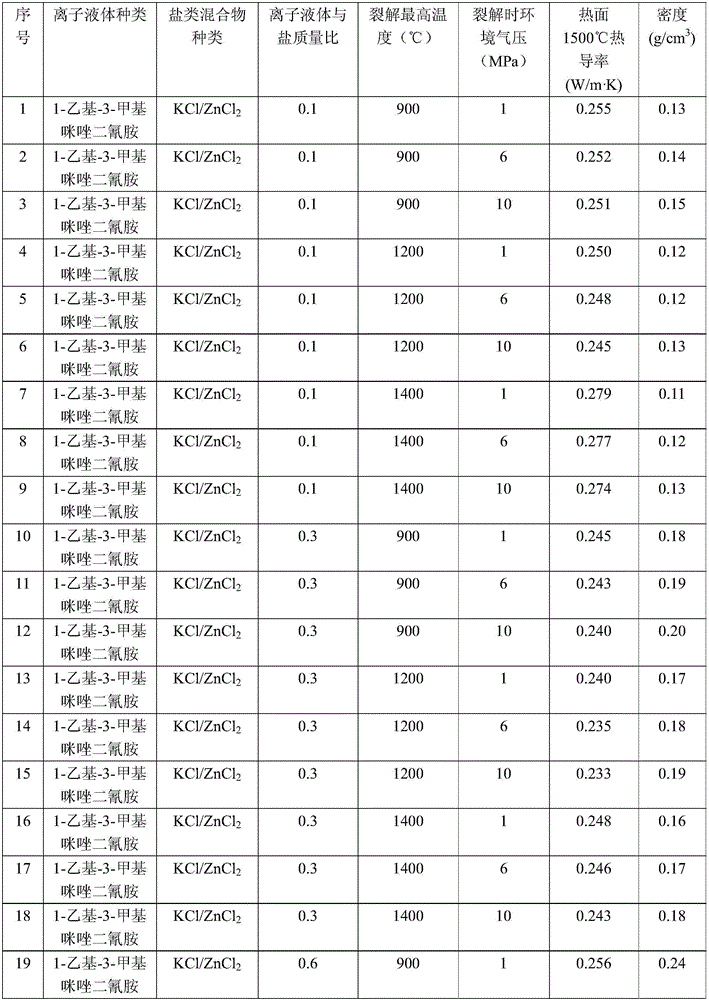

Preparation method of porous carbon heat-insulating composite material

The invention discloses a preparation method of a porous carbon heat-insulating composite material and aims to solve the problem that existing porous carbon heat-insulating composite material preparation methods are long in process period, serious in volume shrinkage during carbonization and large in potential safety hazard. The preparation method includes: using ion liquid as a carbon precursor, an eutectic-salt mixture as a pore foaming agent and an inorganic carbon fiber prefabricated member as enhancosome; grinding and mixing the ion liquid and eutectic-salt mixture; increasing temperature for fusion under protection of high-pressure inert gas; mixing with the carbon fiber prefabricated member; continuing increasing temperature to enable the ion liquid to be carbonized into porous carbon to obtain a carbon fiber enhanced porous carbon / salt complex; subjecting the carbon fiber enhanced porous carbon / salt complex to cooling, water washing and drying to obtain the carbon fiber enhanced porous carbon heat-insulating composite material. The preparation method is simple in process, short in period, small in potential safety hazard and environment-friendly, and the carbon fiber enhanced porous carbon heat-insulating composite material prepared by the method is low in heat conductivity, good in heat-insulating performance, free of surface cracking and more conducive to preparing special-shaped components.

Owner:NAT UNIV OF DEFENSE TECH

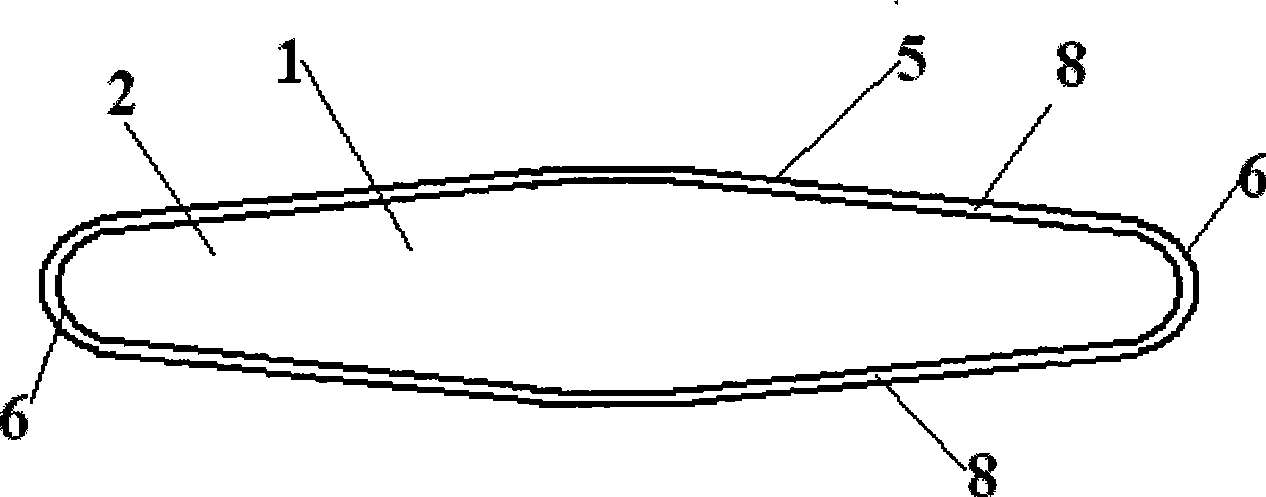

Medical infusion soft bag and method for producing the same, and shaping method

The invention discloses a medical soft infusion bag, which comprises an infusion bag body as well as an infusion bag mouth and a suspension structure which are connected with both ends of the infusion bag body respectively, wherein the infusion bag body is made of flexible plastic and is flat under the state of filling a liquid medicine, that is, the width of the infusion bag body is larger than the thickness of the infusion bag body on the cross section of a connecting line between the infusion bag mouth and the suspension structure. The invention also provides a method for manufacturing the soft infusion bag and a shaping method after the filling of the liquid medicine. The bag body of the soft infusion bag is an integrity formed by injecting, stretching and blowing, has no connecting surfaces, does not need high-temperature hot-pressing plastic packaging, has no leakage caused by uncompacted plastic packaging of edges, has no pollution problem of air return to the liquid medicine, improves the safety of the infusion due to the fact that the phenomenon of blood backflow of vein blood is not generated, and can obtain best effects of the sterilization of the liquid medicine and the shaping of the soft infusion bag. The medical soft infusion bag has the advantages that the medical soft infusion bag has a reasonable structure and convenient use, has small volume shrinkage after the use, is easy to treat, has high performance-price ratio of raw materials, and reduces cost.

Owner:ANHUI DOUBLE CRANE PHARMA

Dental composite restorative material and method of restoring a tooth

A composite material is provided which, while having an unusually high filler content may be extruded from a dental syringe and remains easily adaptable in the dental cavity. When materials of the present invention are cured, dental restorations are provided which have unusually high surface hardness and yield strength, as well as a low volume shrinkage on curing. This is achieved by use of a mixture of filler particles with a specific size, size range, and size relationship. Such a combination of properties makes the material of the present invention particularly useful for restoring cavities in posterior teeth.

Owner:DENTSPLY DETREY GMBH

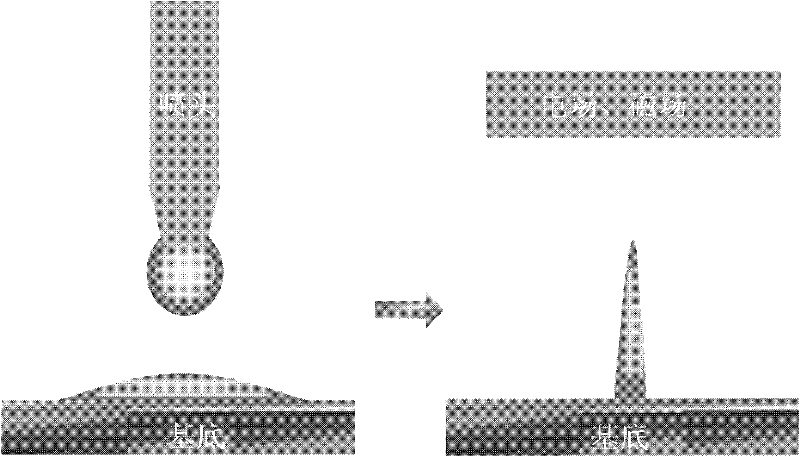

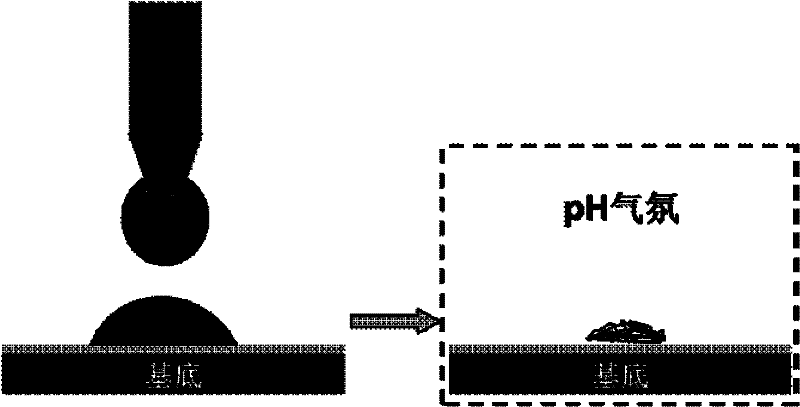

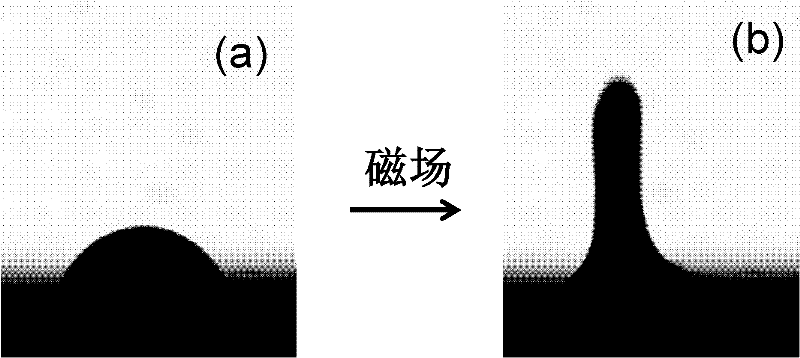

Method for improving resolution of inkjet printing by inducing de-infiltration of ink droplets based on external stimulus

The invention belongs to the technical field of inkjet printing and relates to a method for improving the printing resolution by inducing de-infiltration of ink droplets based on external stimulus. The method comprises the following steps: firstly dispersing inorganic particles or a polymer with external stimulus response in an appropriate substrate to get ink with the external stimulus responsiveness, then spraying the ink with the external stimulus responsiveness through an inkjet printing device, enabling the ink droplets to generate shape change and volume contraction or only generate thevolume contraction due to induction of the external stimulus before curing so as to generate de-infiltration on the substrate, further reducing the deposition area of the ink droplets on the substrate, appropriately curing the ink droplets, and finally improving the printing resolution of inkjet printed contents. The method for improving the printing resolution of the inkjet printed contents is simple to operate, has the characteristics of low cost, no special requirements on equipment, greatly improved resolution and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com