Cement self-shrinking value test method

A test method and self-shrinking technology, applied in the direction of material inspection products, etc., can solve problems such as unstable bleeding and air bubbles, large errors, and large fluctuations in test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

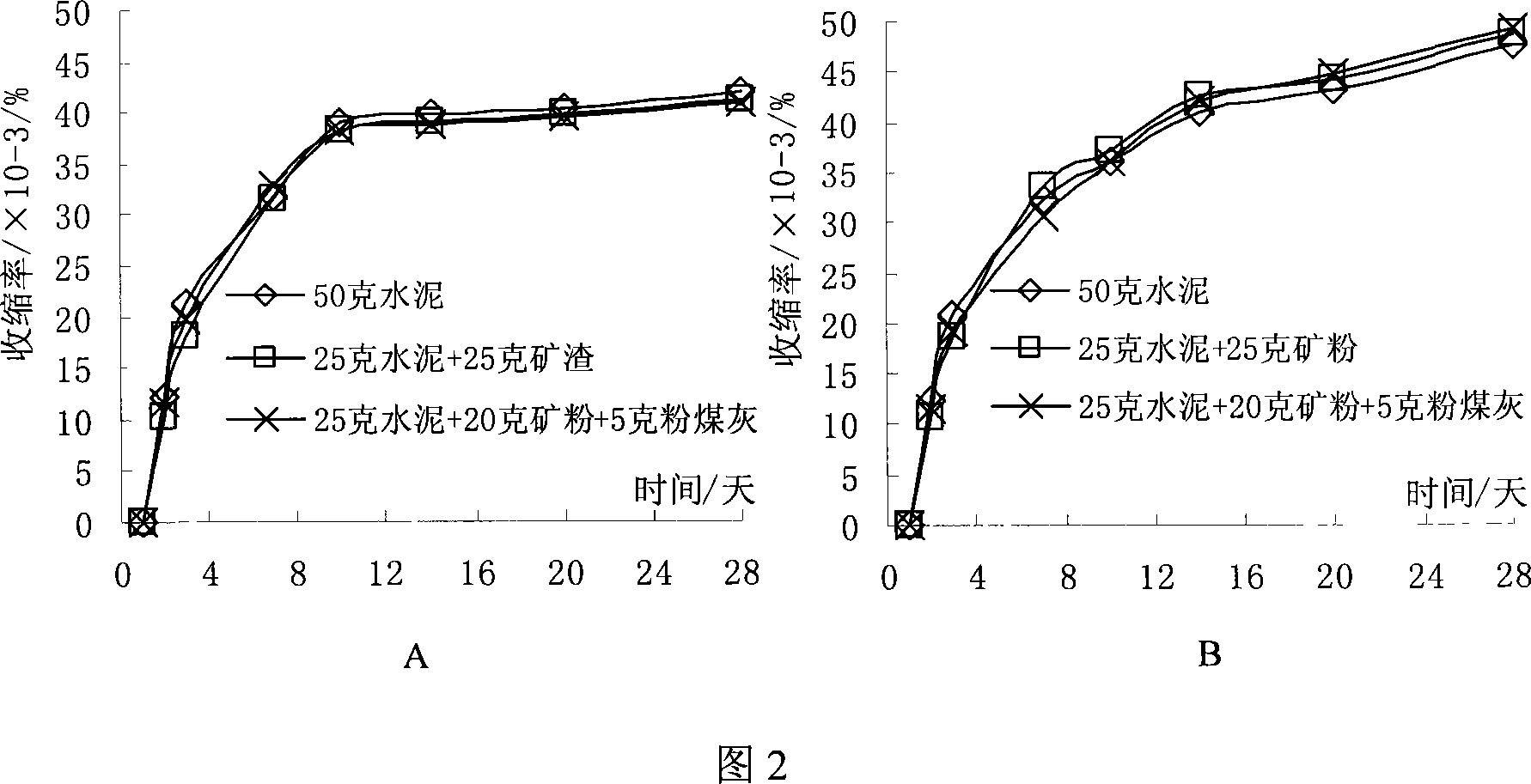

Embodiment 1

[0015] Embodiment 1: the steps are as follows:

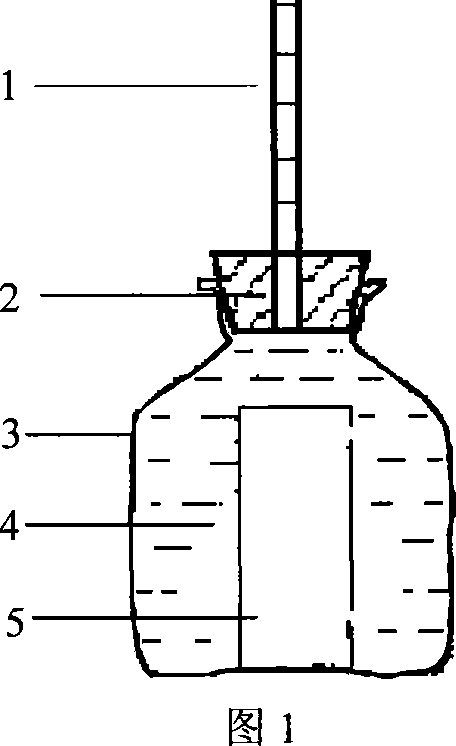

[0016] (1) Take a certain amount of cement or a composite material mixed with cement, fly ash, mineral powder, etc., and prepare cement slurry with water according to the designed ratio. The sample to be tested is prepared by molding in a cylindrical container, and the diameter of the cylinder should enable the hardened cement slurry to be loaded into the jar 3 .

[0017] (2) After the cement paste hardens (generally 12 hours to 24 hours after adding water to the cement), the formwork is removed, and the hardened cement paste is sealed with heated and melted paraffin.

[0018] (3) Put the sealed hardened cement slurry into the jar 3, fill the jar 3 with water, plug the cork 2 tightly, add water to the vector tube 1 to the full scale, and then add a drop of liquid Paraffin or other water-insoluble oily liquids are placed on the surface of the water in the measuring tube to prevent evaporation of water.

[0019] (4) Place the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com