Early-strength type aluminate cement based self-leveling material

A technology of aluminate cement and Portland cement, applied in the field of early-strength aluminate cement-based self-leveling materials, can solve the problems of false setting, shortened operation time, adulteration and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

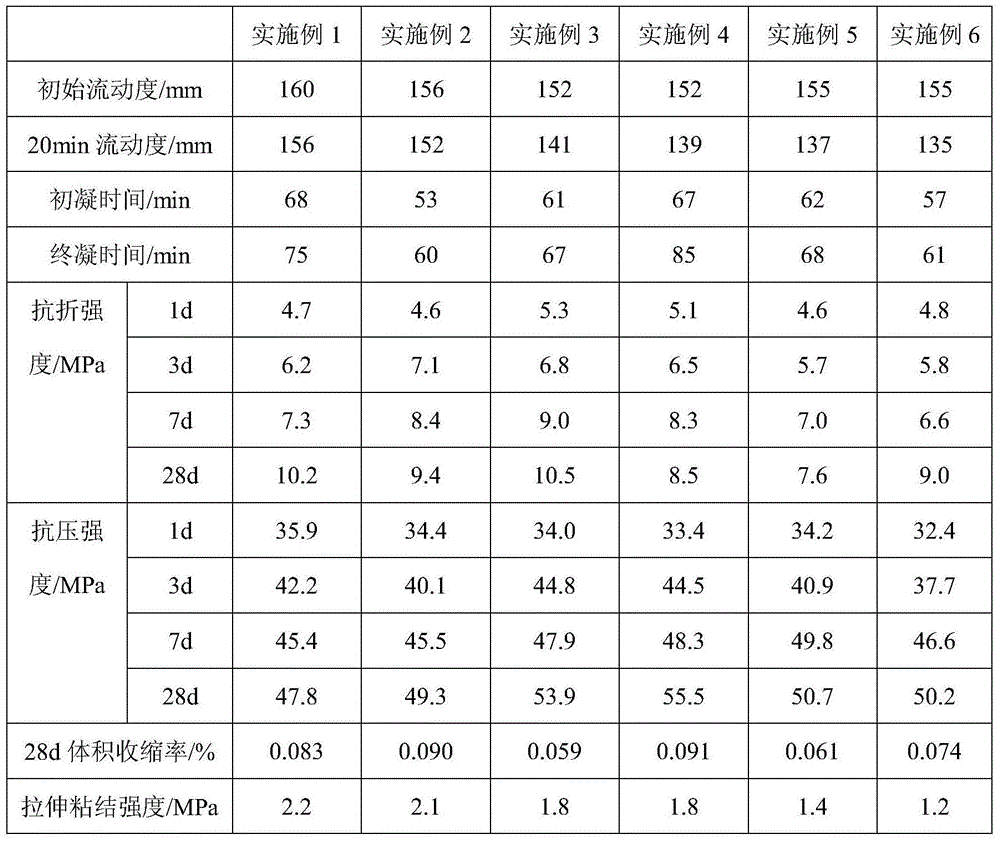

Examples

Embodiment 1

[0014] In terms of mass, the mix ratio is as follows: 340 parts of CA50 aluminate cement, 40 parts of α-hemihydrate gypsum, 20 parts of PⅡ52.5 Portland cement, 150 parts of 40-60 mesh quartz sand, 60-120 mesh quartz sand 230 parts, 400 mesh heavy calcium powder 220 parts, "Wake" 8 parts of 5044N redispersible latex powder, 2 parts of HY polycarboxylate powder superplasticizer, 1.5 parts of P803 powder defoamer, 0.25 parts of hydroxypropyl methylcellulose ether water retaining agent (viscosity of 80000mpa.s), and the mass ratio of water to material is 0.18. Mortar preparation and performance testing are carried out according to JC / T985-2005 "cement-based self-leveling mortar for ground" industry standard.

Embodiment 2

[0016] In terms of mass, the mix ratio is as follows: 340 parts of CA50 aluminate cement, 40 parts of β-hemihydrate gypsum, 20 parts of PⅡ52.5 Portland cement, 190 parts of 40-60 mesh quartz sand, 60-120 mesh quartz sand 190 parts, 400 mesh heavy calcium powder 220 parts, "Wake" 8 parts of 5044N redispersible latex powder, 2 parts of HY polycarboxylate powder superplasticizer, 1.5 parts of P803 powder defoamer, 0.25 parts of hydroxypropyl methylcellulose ether water retaining agent (viscosity of 80000mpa.s), and the mass ratio of water to material is 0.185. Mortar preparation and performance testing are carried out according to JC / T985-2005 "cement-based self-leveling mortar for ground" industry standard.

Embodiment 3

[0018] In terms of mass, the mix ratio is as follows: 320 parts of CA50 aluminate cement, 60 parts of α-hemihydrate gypsum, 20 parts of PⅡ52.5 Portland cement, 200 parts of 40-60 mesh quartz sand, 60-120 mesh quartz sand 200 parts, 400 mesh heavy calcium powder 200 parts, "Wake" 12 parts of 5044N redispersible latex powder, 2 parts of HY polycarboxylate powder superplasticizer, 1.5 parts of P803 powder defoamer, 0.2 parts of hydroxypropyl methylcellulose ether water retaining agent (viscosity of 80000mpa.s), and the mass ratio of water to material is 0.18. Mortar preparation and performance testing are carried out according to JC / T985-2005 "cement-based self-leveling mortar for ground" industry standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com