Curable leaking stoppage spacer fluid and preparation method thereof

A spacer fluid and curing agent technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as failure to reach plugging site construction, limited adjustment of slurry density range, etc., and achieve strong thixotropy and good chemical properties. Good compatibility and rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

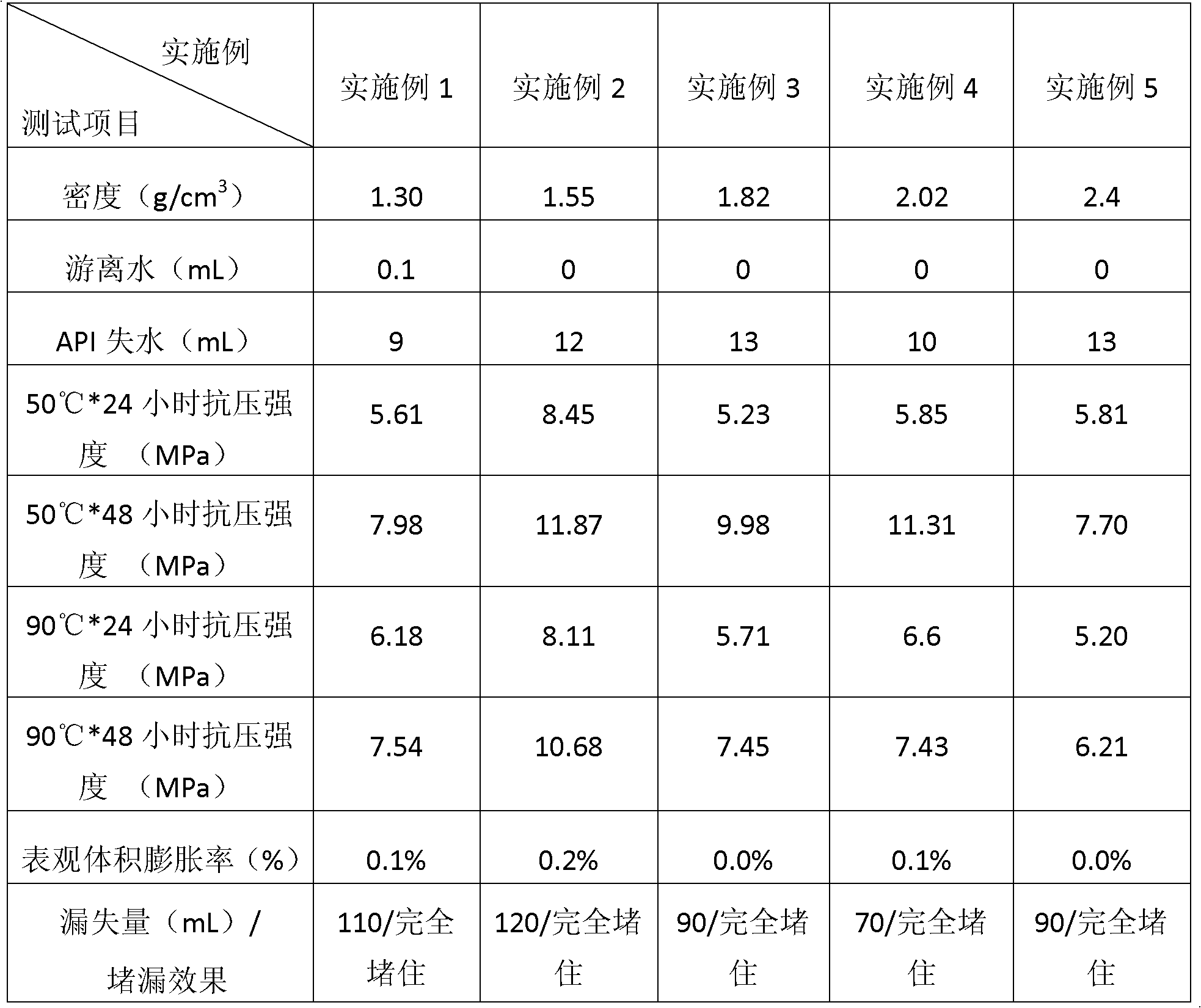

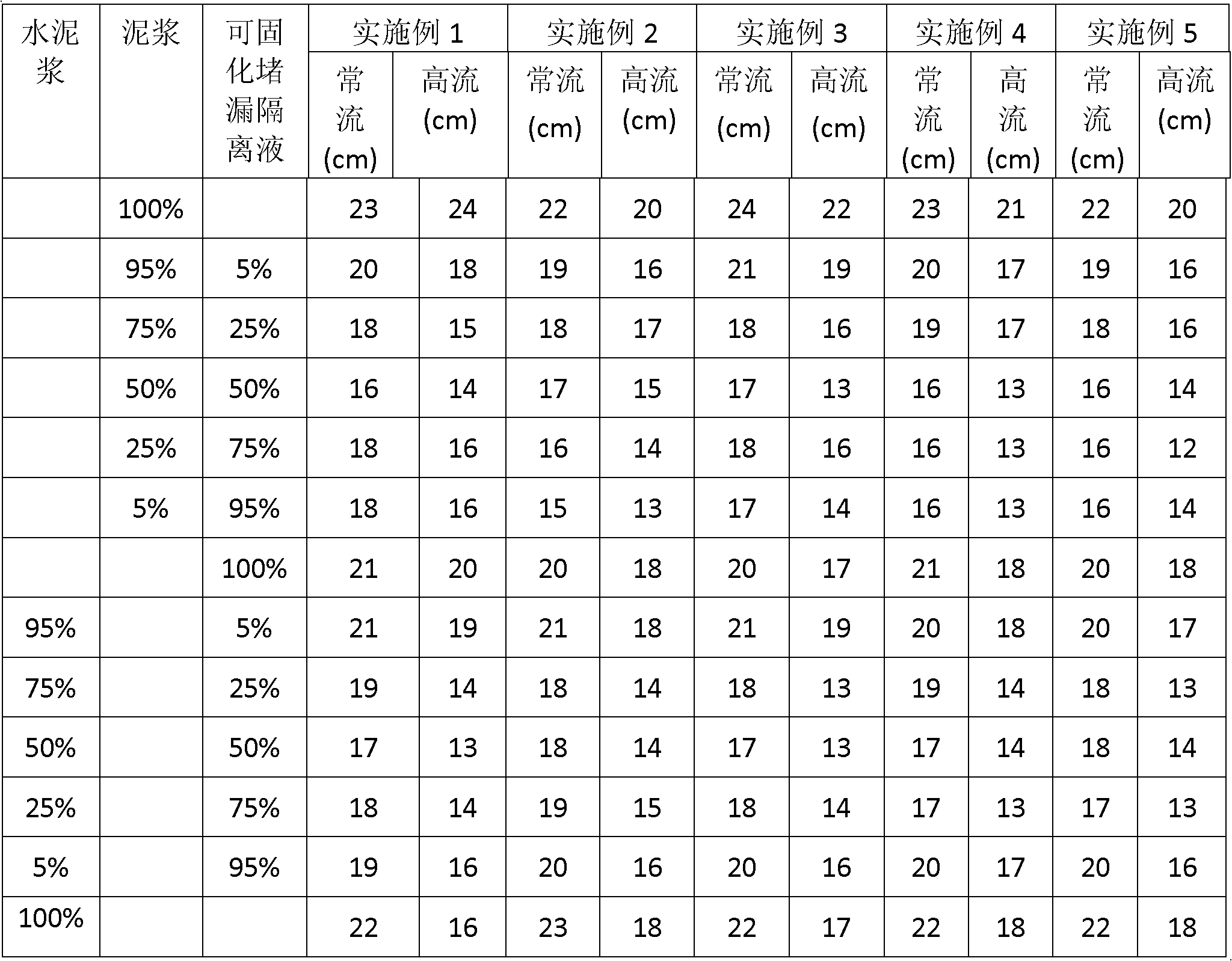

Examples

Embodiment 1

[0023] In 450 parts by weight of fresh water, add 400 parts by weight of S75 grade slag powder, 7.5 parts by weight of GYW-301 clay, 5 parts by weight of calcium-based bentonite, 15 parts by weight of sodium carbonate, 10 parts by weight of sodium hydroxide, and 20 parts by weight of silicic acid Sodium, 30 parts by weight of calcium oxide, stir at low speed for 40 minutes until the raw materials are evenly distributed in fresh water; then add 30 parts by weight of fly ash hollow floating beads, stir at low speed for 20 minutes until the density regulator is evenly dispersed, and can be solidified for plugging and isolation The liquid is prepared.

Embodiment 2

[0025] In 450 parts by weight of fresh water, add 600 parts by weight of S75 grade slag powder, 7.5 parts by weight of GYW-301 clay, 5 parts by weight of sodium bentonite, 15 parts by weight of sodium carbonate, 10 parts by weight of sodium hydroxide, and 20 parts by weight of silicic acid Sodium, 30 parts by weight of calcium oxide, stir at low speed for 40 minutes until the raw materials are evenly distributed in fresh water; then add 40 parts by weight of fly ash hollow floating beads, stir at low speed for 20 minutes until the density regulator is evenly dispersed, and can be solidified for plugging and isolation The liquid is prepared.

Embodiment 3

[0027] In 450 parts by weight of fresh water, add 500 parts by weight of S75 grade slag powder, 7.5 parts by weight of GYW-301 clay, 5 parts by weight of sodium bentonite, 15 parts by weight of sodium carbonate, 10 parts by weight of sodium hydroxide, and 20 parts by weight of silicic acid Sodium, 25 parts by weight of calcium oxide, stir at low speed for 40 minutes until the raw materials are evenly distributed in fresh water; then add 40 parts by weight of fly ash hollow floating beads, stir at low speed for 20 minutes until the density regulator is evenly dispersed, and can be solidified for plugging and isolation The liquid is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com