Patents

Literature

55results about How to "Effective containment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

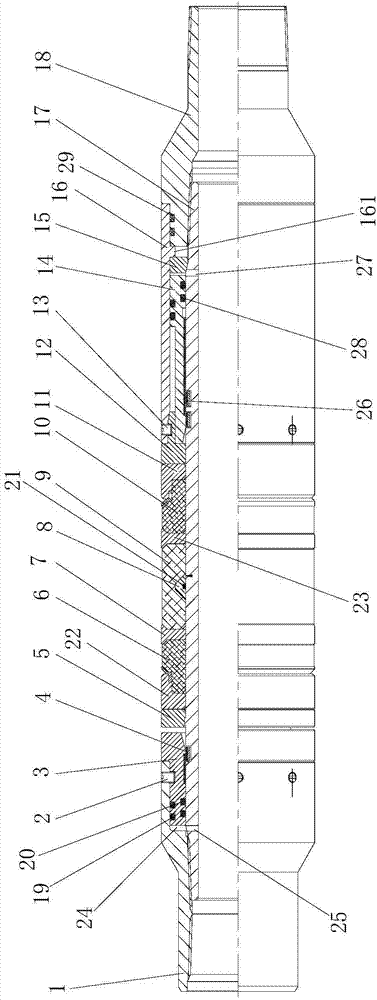

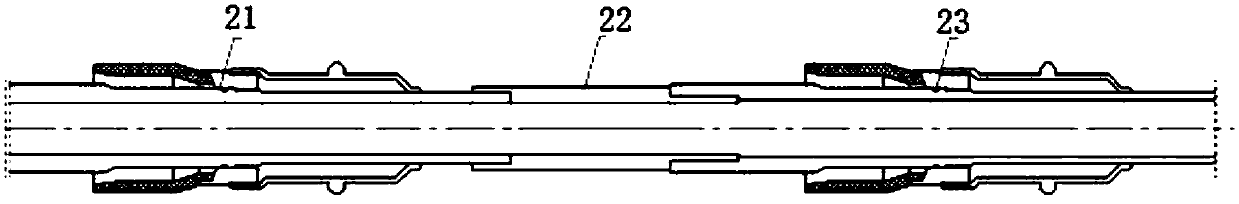

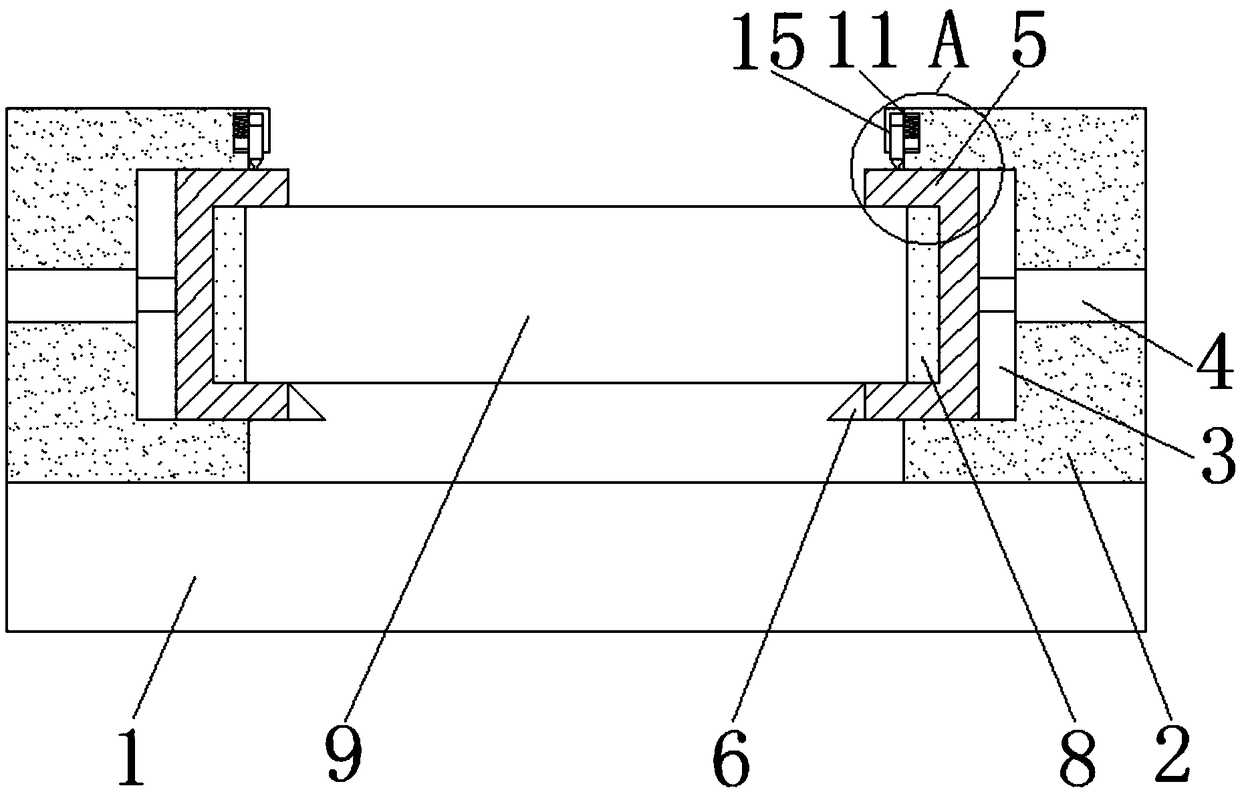

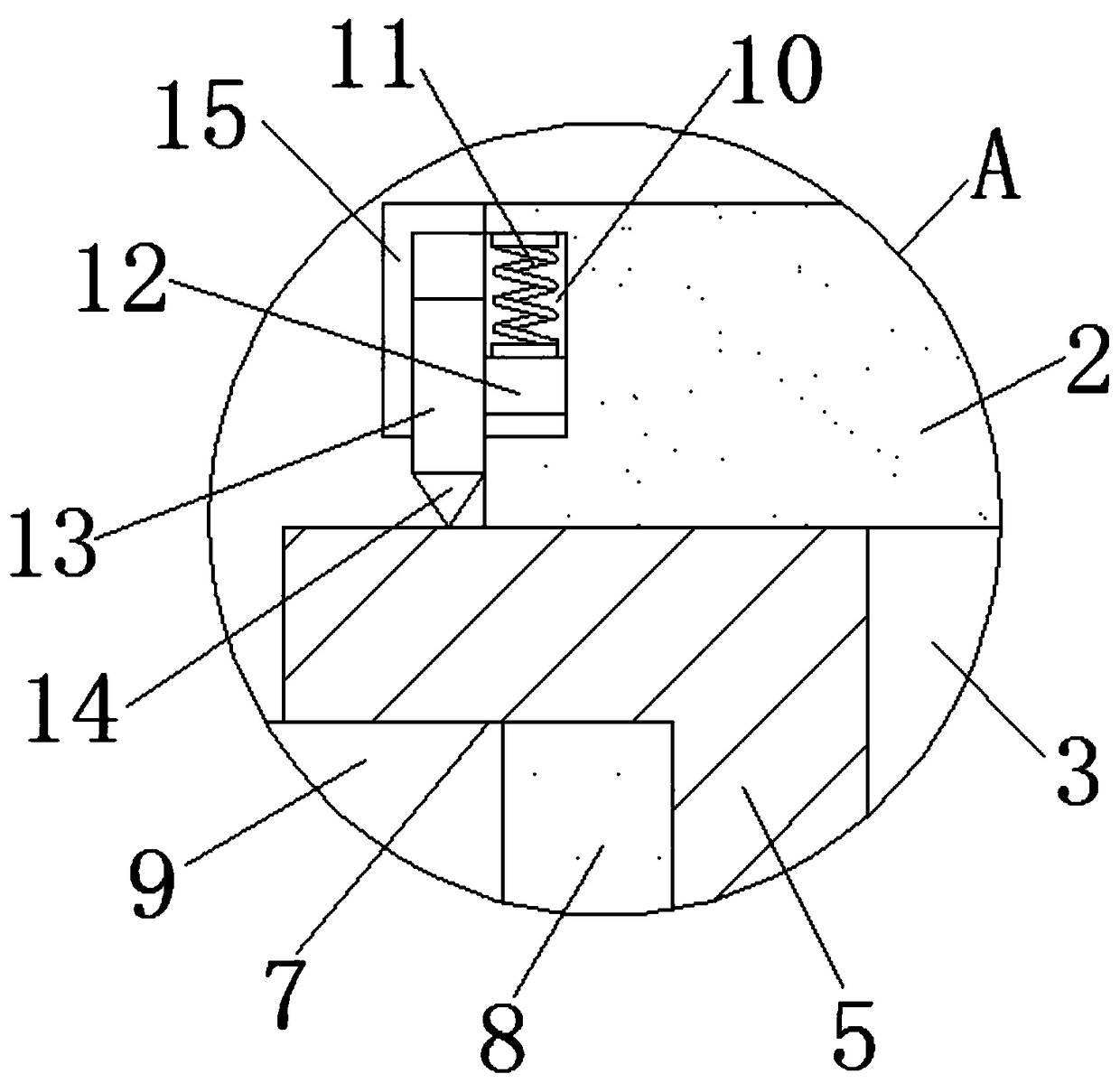

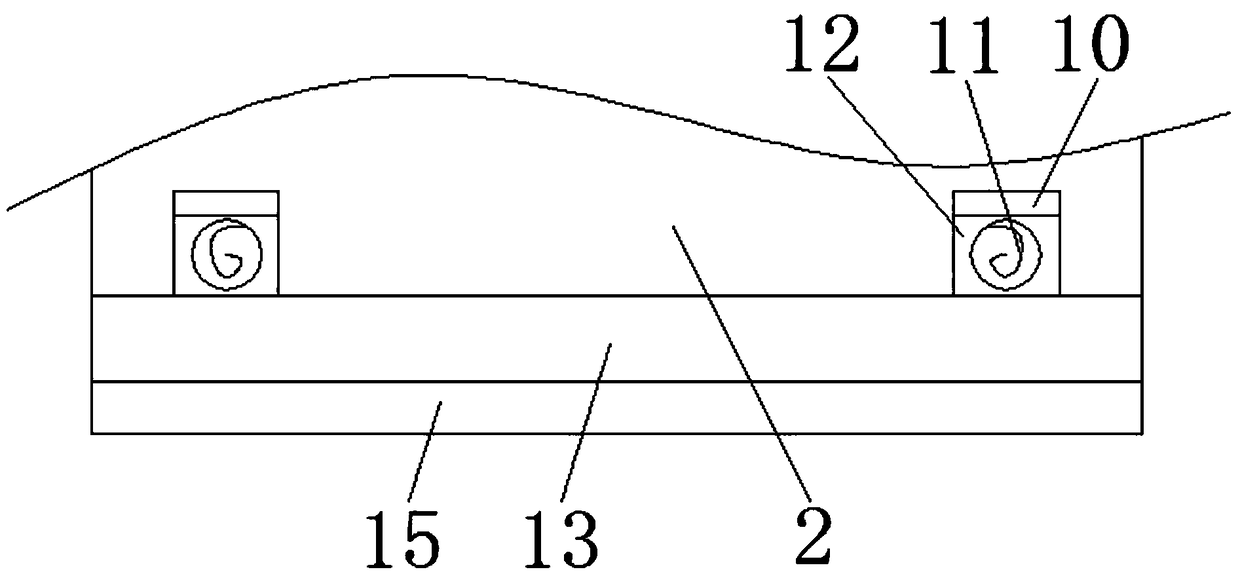

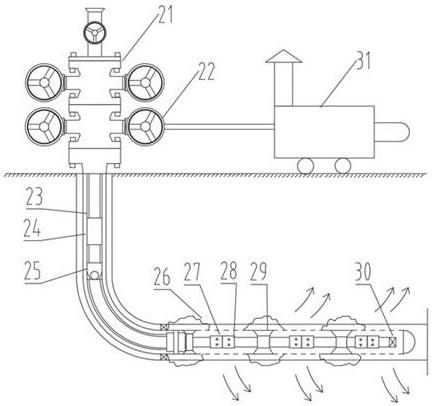

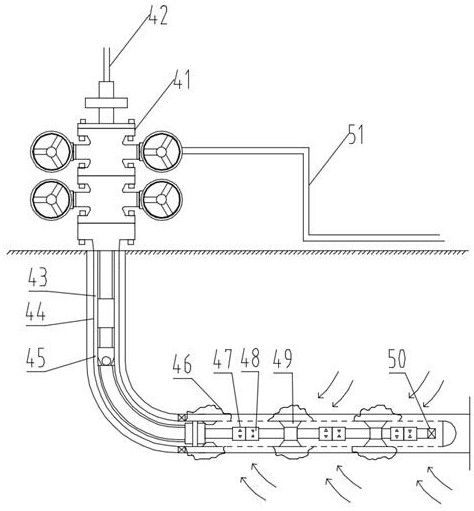

Multi-layer discharge and mining device for multiple seam developed area

InactiveCN102434135AEffective containmentEffective liquid level differenceFluid removalProduction rateEngineering

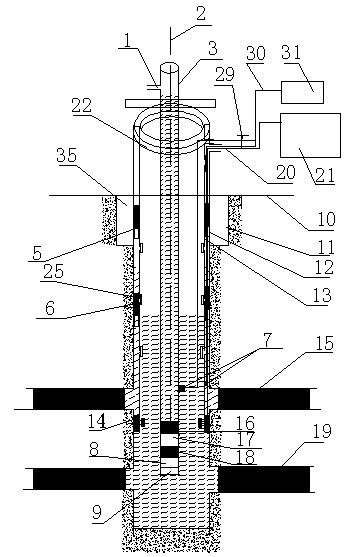

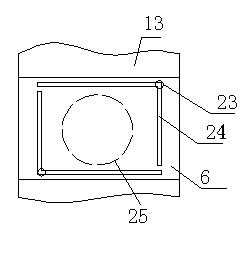

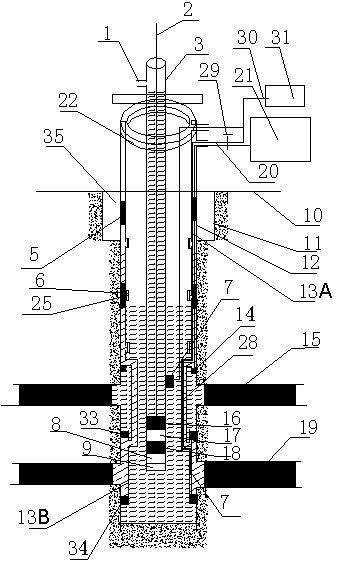

The invention discloses a multi-layer discharge and mining device for a multiple seam developed area, which comprises an additional casing, the outer ring of the upper part of the additional casing is provided with a plugging part, the wall of the additional casing on the lower side of the plugging part is provided with a drain hole, the outer ring of the additional casing on the lower side of the drain hole is provided with a first packer, and the additional casing is provided with an elastic cushion for covering the drain hole. The invention aims at the large difference of stratum liquid feed capacity of multiple seam during the multi-layer discharge and mining of a multiple seam developed area, when the existing discharge and mining device is used to discharge and mine, the pressure is difficult to control, which can cause permeability to be sharply reduced so as to result in large reduction on gas production rate, with the multi-layer discharge and mining device for the multiple seam developed area disclosed by the invention, pressure of the multiple seam can be stably reduced, the reasonable and effective multi-layer discharge and mining can be realized, and the goal of stable and continuous of gas production and high yield can be achieved.

Owner:HENAN POLYTECHNIC UNIV

Integrated garbage treatment and utilization method for effectively controlling dioxin

InactiveCN102145343AInhibitionContainment hazardWaste processingSolid waste disposalRefuse DisposalsPollution

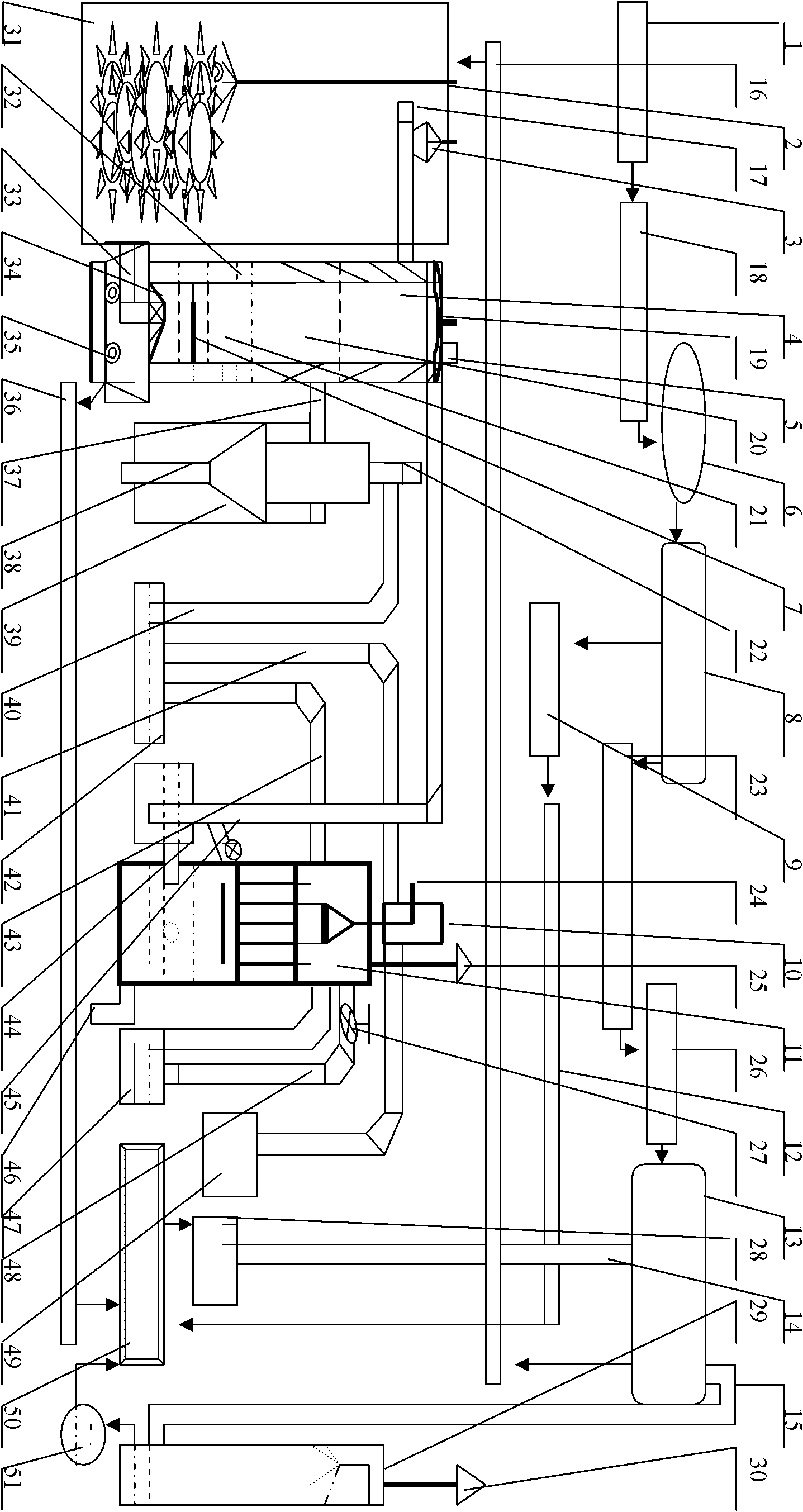

The invention discloses an integrated garbage treatment and utilization method for effectively controlling dioxin, which comprises a garbage sorting, drying and storing method, a garbage dry distillation, pyrolysis and gasification method, an integrated treatment and utilization method for garbage ash and combustible gas and an integrated treatment and utilization method for exhaust gas and wastewater, belonging to the field of environmental protection. The method comprises how to effectively control the dioxin and solve the pollution problem of reducing waste water, exhaust gas, waste residue and the like in the garbage treatment process. The solution comprises the steps of sorting and drying the garbage, turning the garbage into renewable resources like combustible gas, tar and the like through integrated treatment of dry distillation, pyrolysis and gasification, comprehensively utilizing the waste residue and waste water for brick making and emitting the exhaust gas up to the standard after treatment. By adopting the technique for garbage treatment, the generation and damage of the dioxin can be effectively controlled, the emission of no waste water, no waste residue and no wastes can be achieved, and the better effect of complete harmlessness, reduction and recycling approximate to 100% can be realized.

Owner:ZHENGREN ENVIRONMENTAL PROTECTION TECH

Brine cement slurry adapted for salt hole air reserved storeroom

InactiveCN1919963AReliable technologyStrong on-site operabilityMining devicesDrilling compositionSaline waterDefoaming Agents

The invention relates the salt-water cement mud. The mud comprises 100 parts G grade cement, 44-50 parts 15-18% salt-water, 1.2-1.8 parts salt resistance dispersing agent, 3-4 parts salt resistance filtration-reducing agent, and 0.1-0.5 parts defoaming agent. The invention also provides the technology, which has low cost and simple operation and meets other mating technology. The cement has advantages of low temperature fast coagulation, good salt resistance, high-early-strength, preference consistency, low filteration loss and good stability.

Owner:PETROCHINA CO LTD

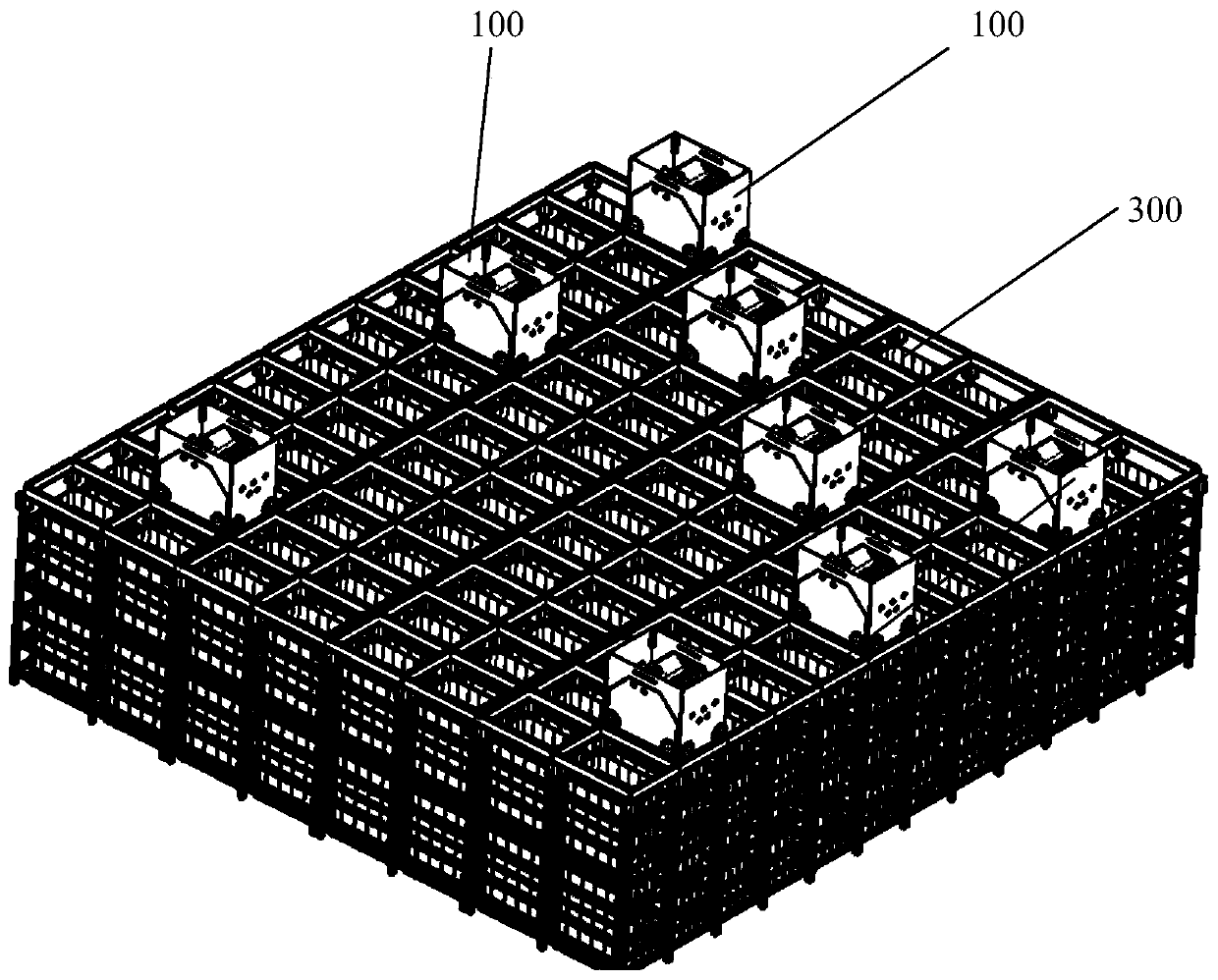

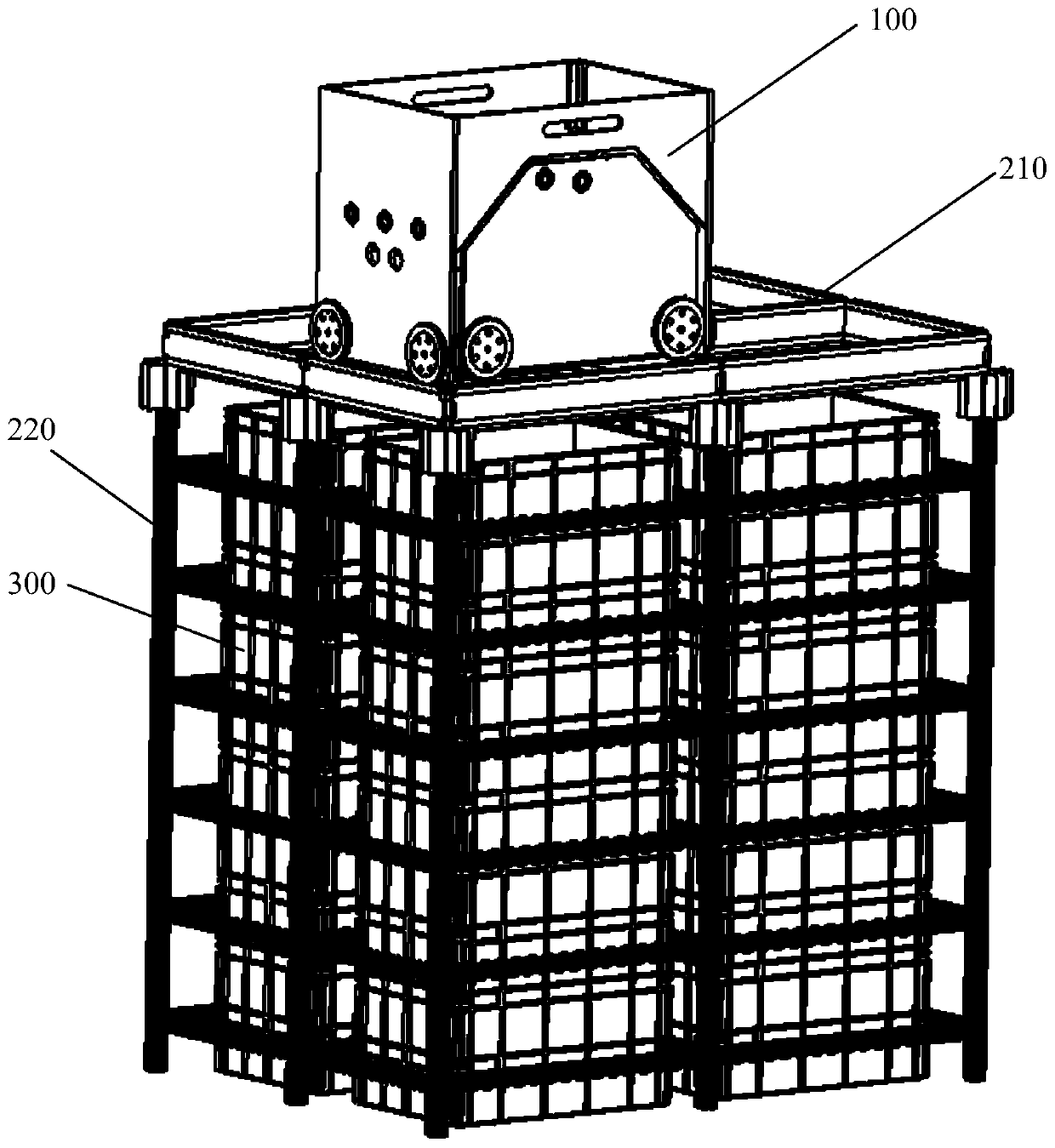

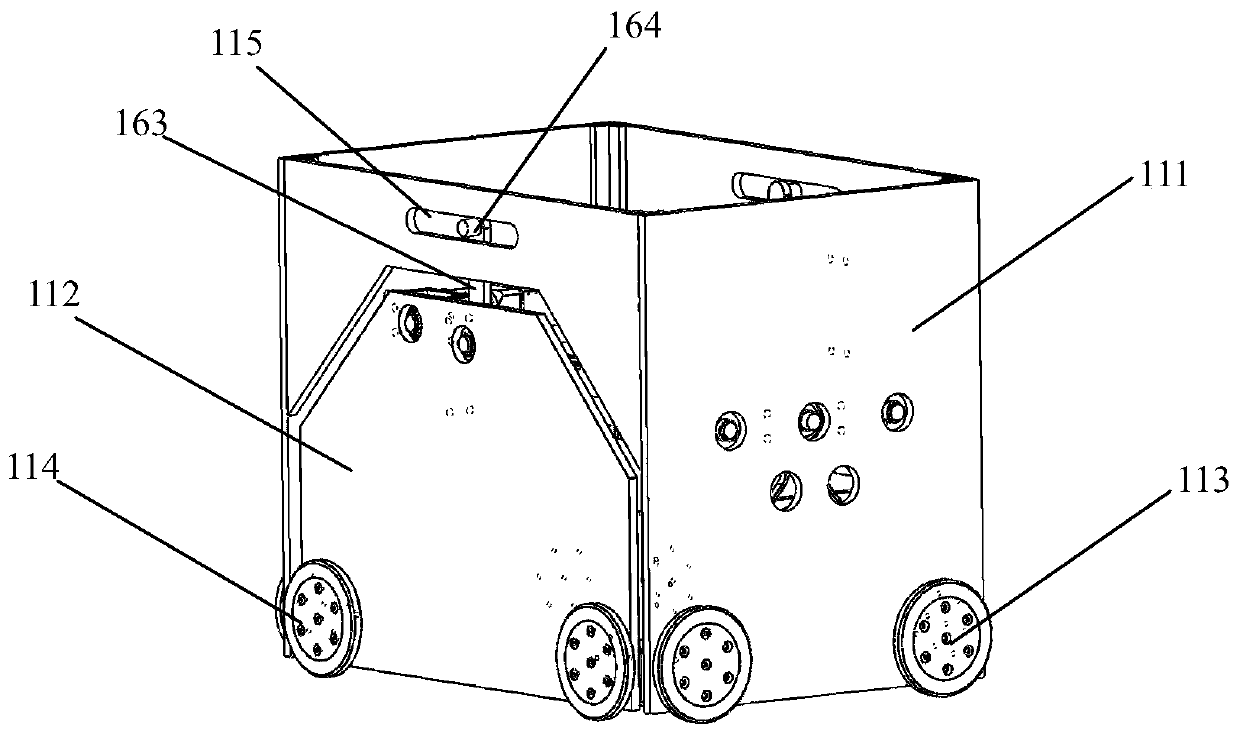

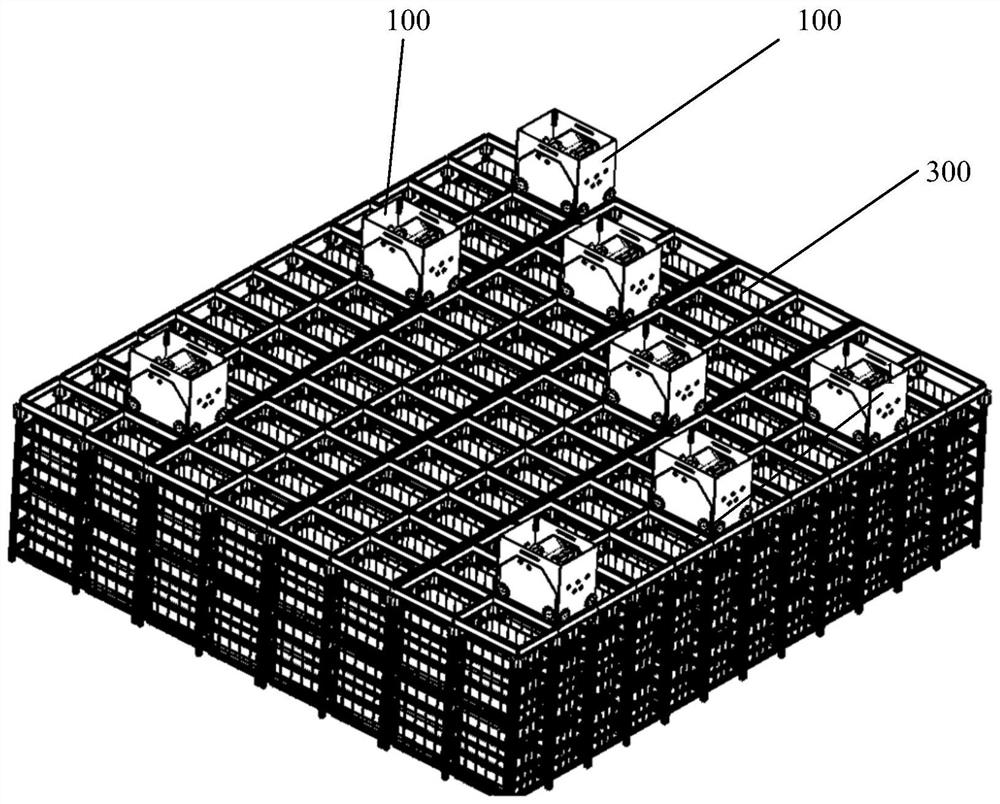

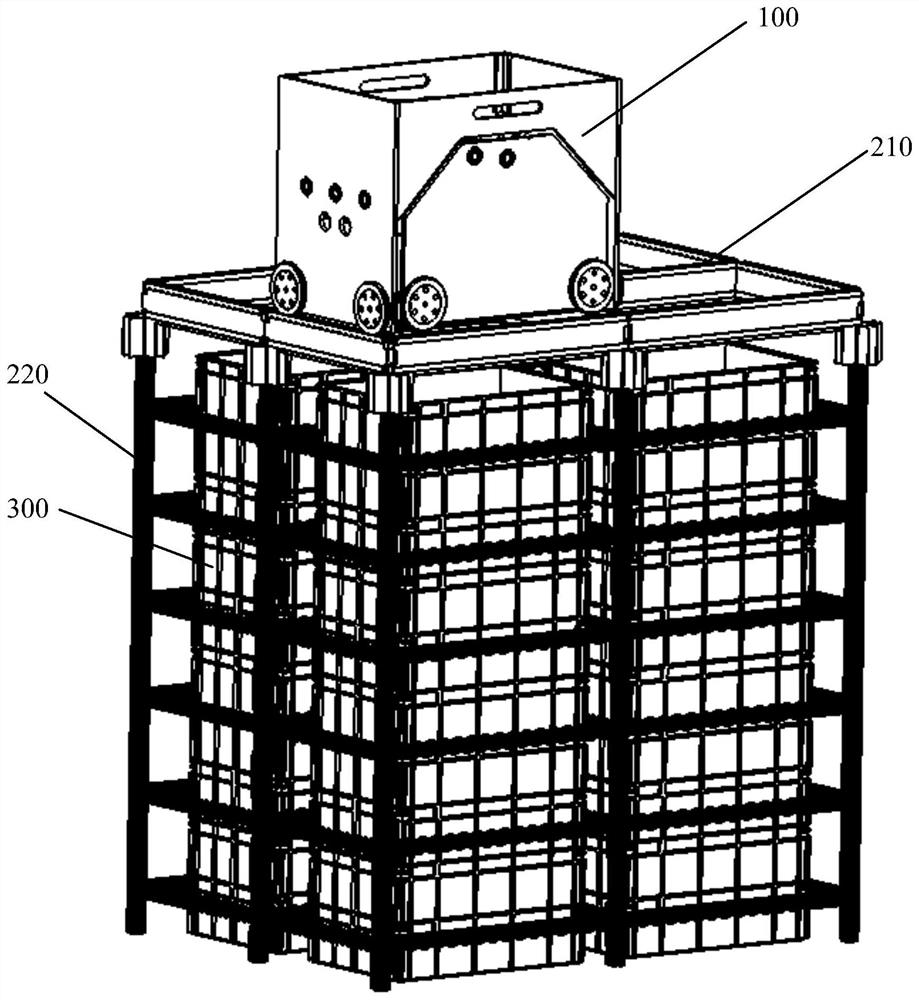

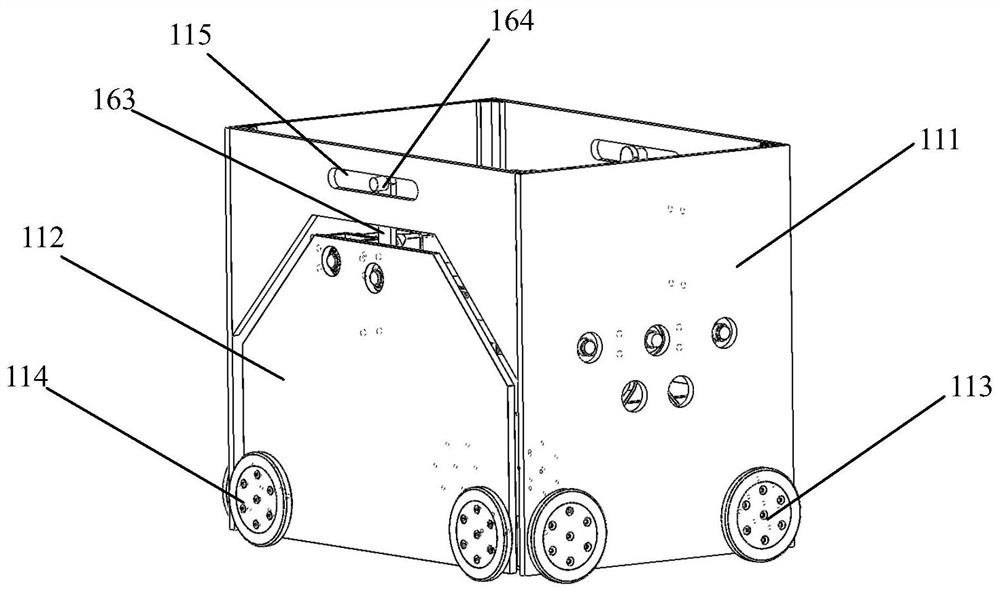

Method and equipment for carrying multi-layer stacked material boxes in storage rack

ActiveCN110329696AImplement pick and place operationsAvoid wastingStorage devicesEngineeringMechanical engineering

Owner:安徽驿星智能物流装备制造有限公司

Bottom water reservoir multi-slug plugging agent and plugging method thereof

ActiveCN111334268AExpand the processing radiusStrong oil-water selectivityDrilling compositionSealing/packingGeotechnical engineeringOil well

The invention provides a bottom water reservoir multi-slug plugging agent and a plugging method thereof. The bottom water reservoir multi-slug plugging agent comprises a foam gel plugging agent, a foam gel plugging agent and a reinforced foam plugging agent, and when the plugging well does not have artificial cracks or / and natural crack development, plugging of a foam gel plugging agent is not needed, after the plugging agents of all the slugs are sequentially injected into the plugging well, a well closing reaction is conducted for 5 d to 7 d, and bottom water reservoir multi-slug plugging iscompleted. The reinforced foam plugging agent is mainly used for plugging cracks, the foam gel plugging agent and the reinforced foam plugging agent have high oil-water selectivity, it is guaranteedthat an oil layer is not damaged on the basis of plugging bottom water, the treatment radius can be increased, a water-resisting layer can be effectively sealed, coning is prevented, and the liquid amount of an oil well during later production can be guaranteed.

Owner:XI'AN PETROLEUM UNIVERSITY

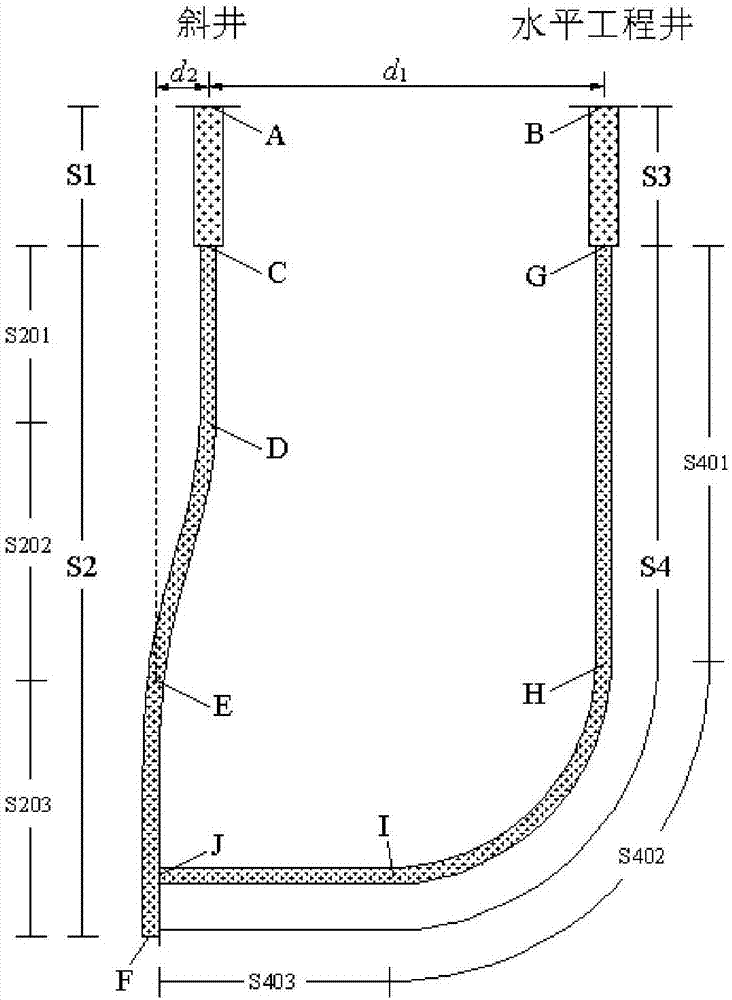

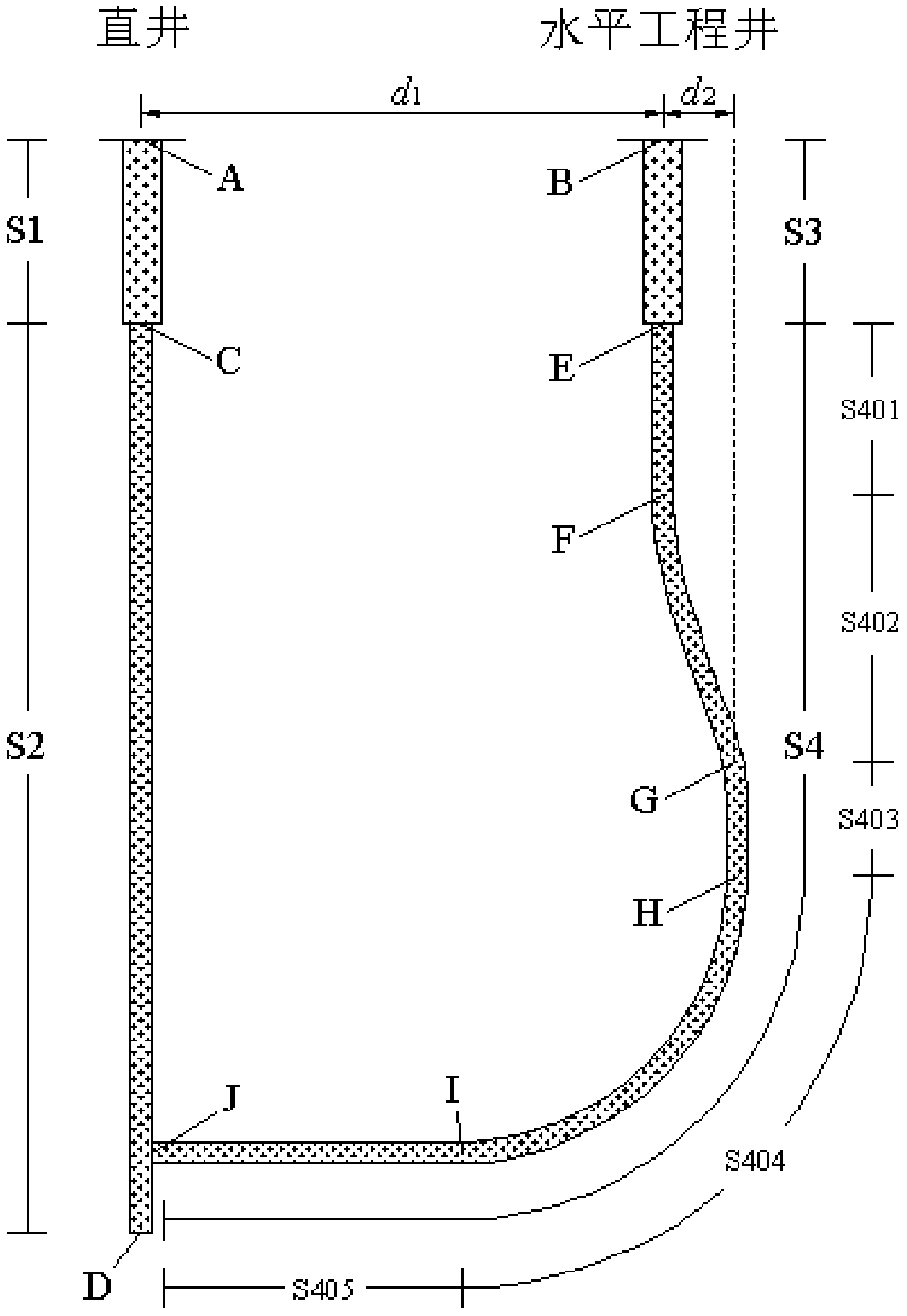

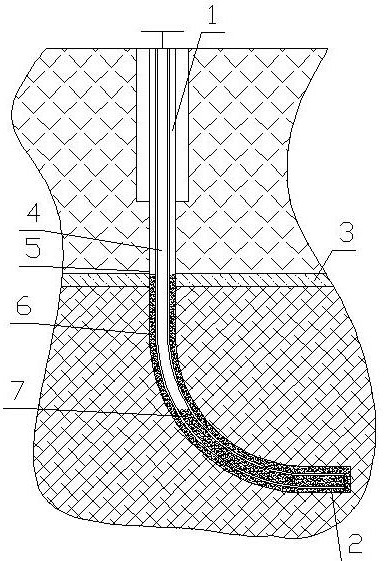

Inclined-well horizontal docking based type geothermal-well hole trajectory and design method thereof

InactiveCN107366531AIncrease docking distanceIncreased docking distanceFluid removalDirectional drillingResource developmentDesign methods

The invention provides an inclined-well horizontal docking based type geothermal-well hole trajectory and a design method thereof. The method includes the steps of 1), according to the size and shape of a construction area, determining positions and coordinates of a wellhead A of an inclined well and a wellhead B of a horizontal engineering well, calculating the distance di between the wellhead A and the wellhead B according to the coordinates of the wellhead A and the wellhead B, and determining the backward migration distance d2 of the hole trajectory according to the distance d1; 2), determining the hole trajectory of the inclined well; 3), determining the hole trajectory of the horizontal engineering well. Backward migration is implemented on the S202 section of the hole trajectory formed in a second inclined well, and the backward migration distance d2 is generated, so that d1+d2 is greater than or equal to 250m; underground communicated docking distance is effectively increased, smooth operation of communication operation of the two wells is ensured, and conditions are created for developing mid-deep water thermal type geothermal resources in narrow sites of a city adopting the horizontal docking type geothermal well technology; the problem about 'taking both heat and water' by an existing hydrothermal type geothermal resource development mode is solved, and the purpose of 'taking water rather than heat' is truly realized.

Owner:陕西省煤田地质集团有限公司

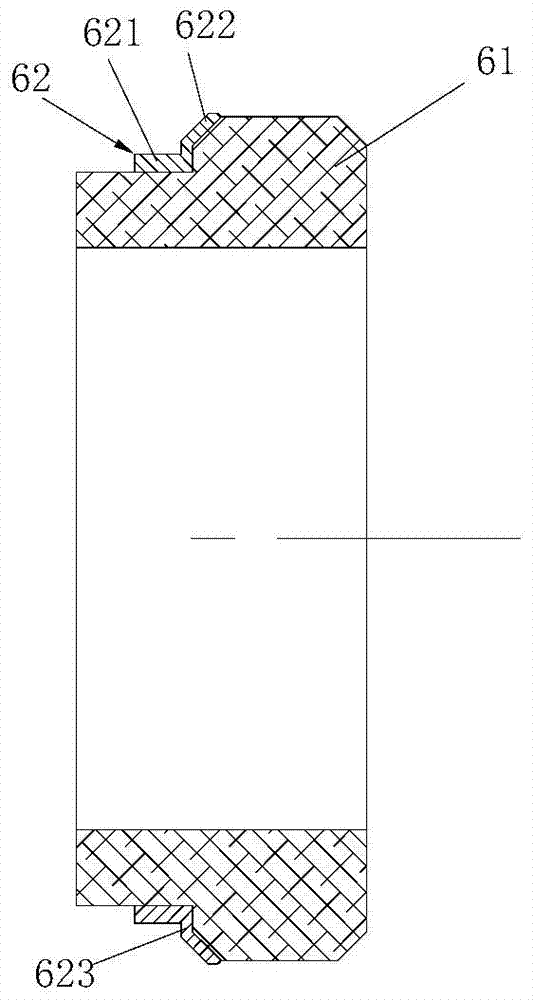

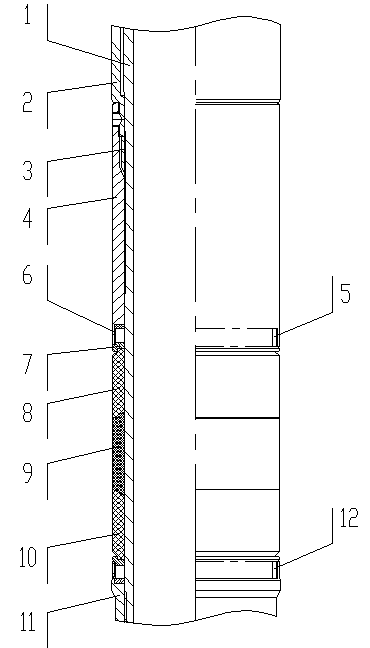

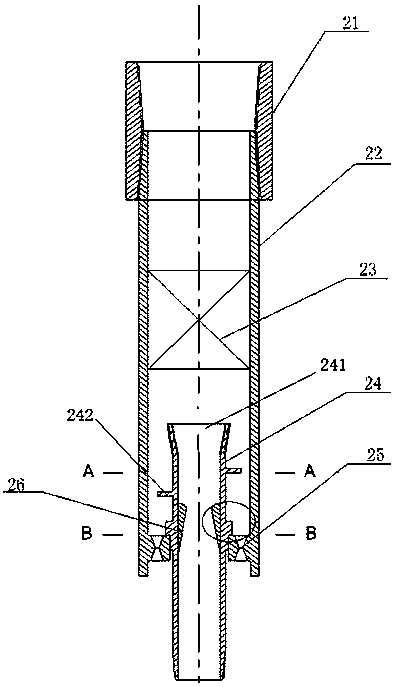

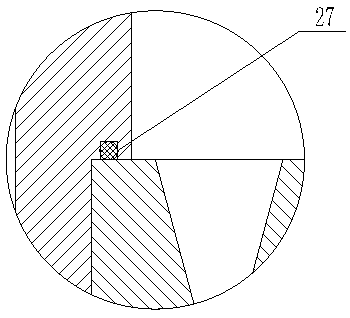

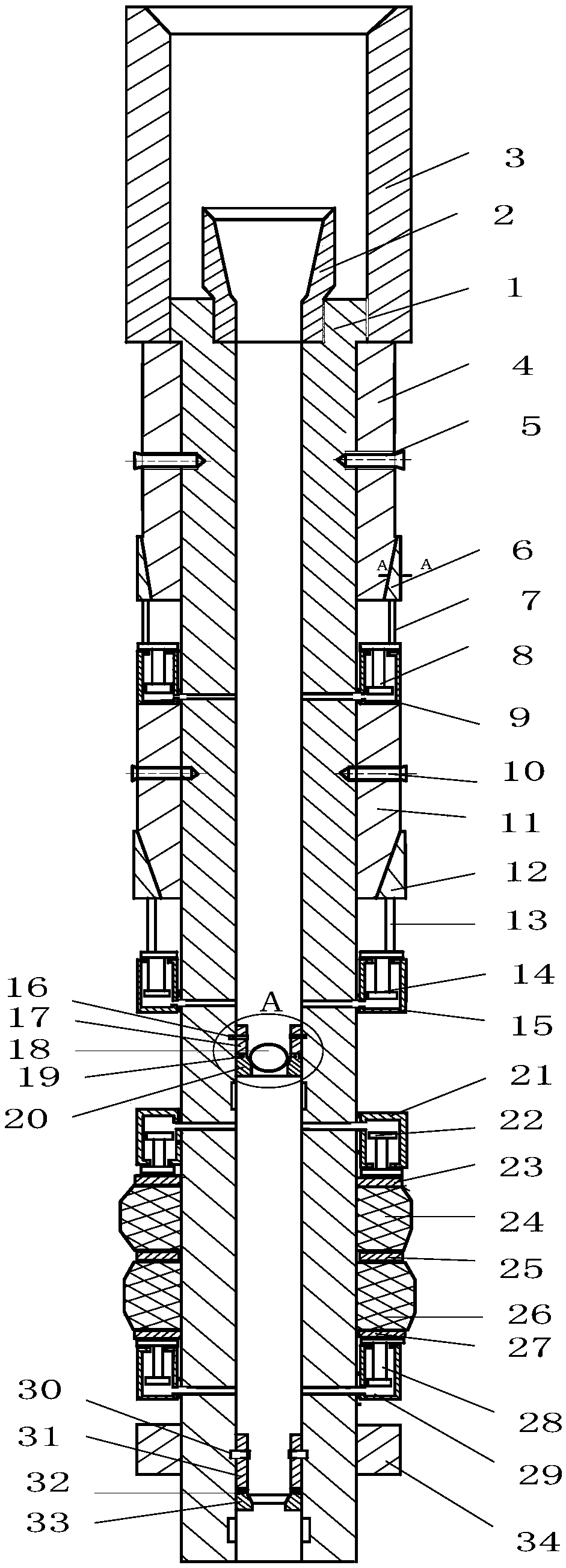

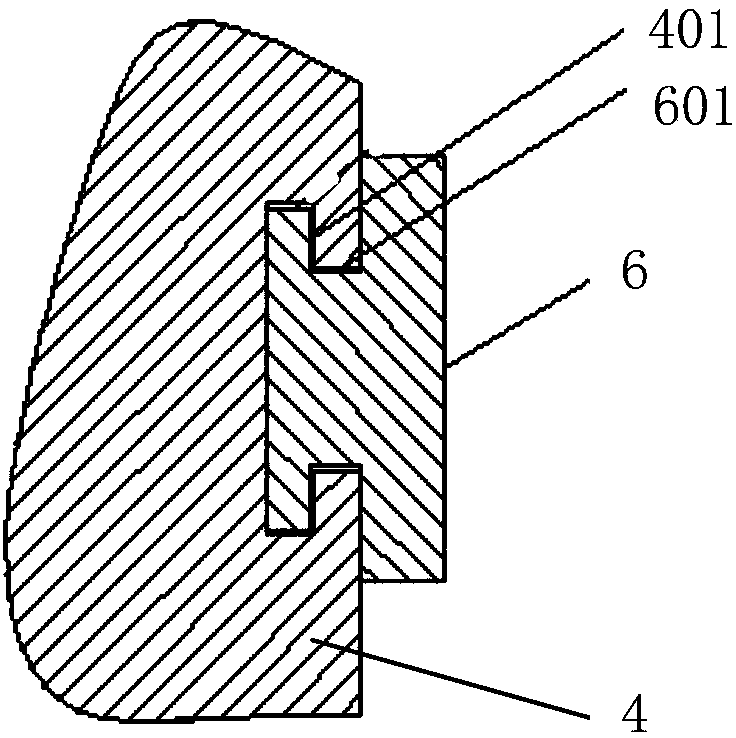

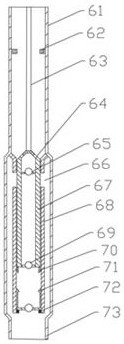

Naked eye packer

ActiveCN103670326AImprove pressure bearing capacityPlay a protective effectSealing/packingPistonPetroleum engineering

The invention discloses a naked eye packer. The naked eye packer comprises a core shaft with an axial through hole, wherein one end of the core shaft is connected with a first joint and the other end is connected with a second joint; a left shearing ring, a limit ring, a first auxiliary rubber cylinder pressing ring, a first auxiliary rubber cylinder, a first packing ring, a main rubber cylinder, a second rubber cylinder, a second rubber cylinder rubber cylinder, a right shearing ring, a piston and a check ring are sequentially sleeved on the core shaft from the first joint; a first pressure transmitting hole and a first slip which correspond to the left shearing ring are formed in the core shaft; a supporting ring is arranged between the main rubber cylinder and the core shaft; an outer sleeve is sleeved on the piston; one end of the outer sleeve is connected with the second joint and the other end is connected with the shearing ring; a second slip corresponding to the piston is arranged on the core shaft; a second pressure transmitting hole is also formed in the core shaft and is positioned between the check ring and the piston. The rubber cylinder is high in loading capacity.

Owner:TIANJIN ANTON PETROLEUM MACHINERY MFG

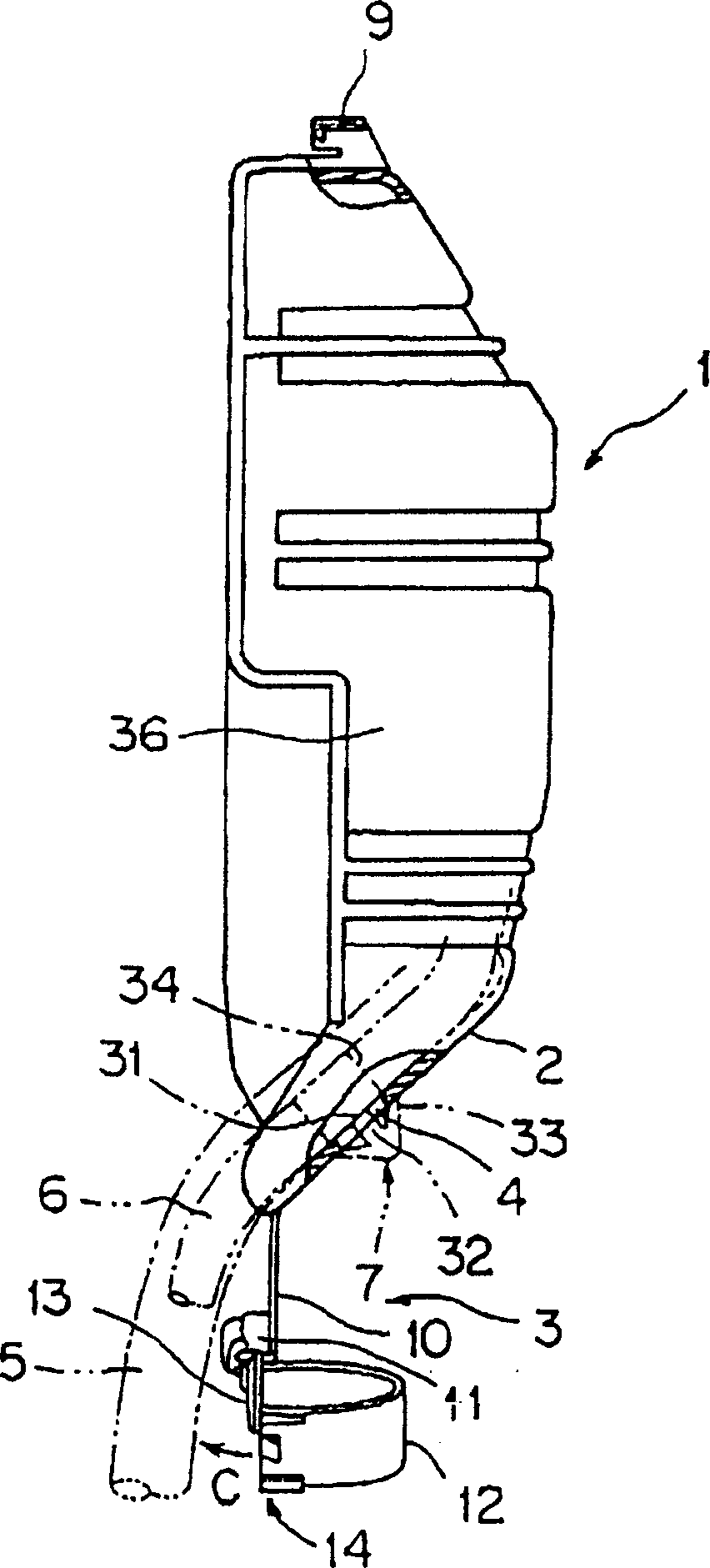

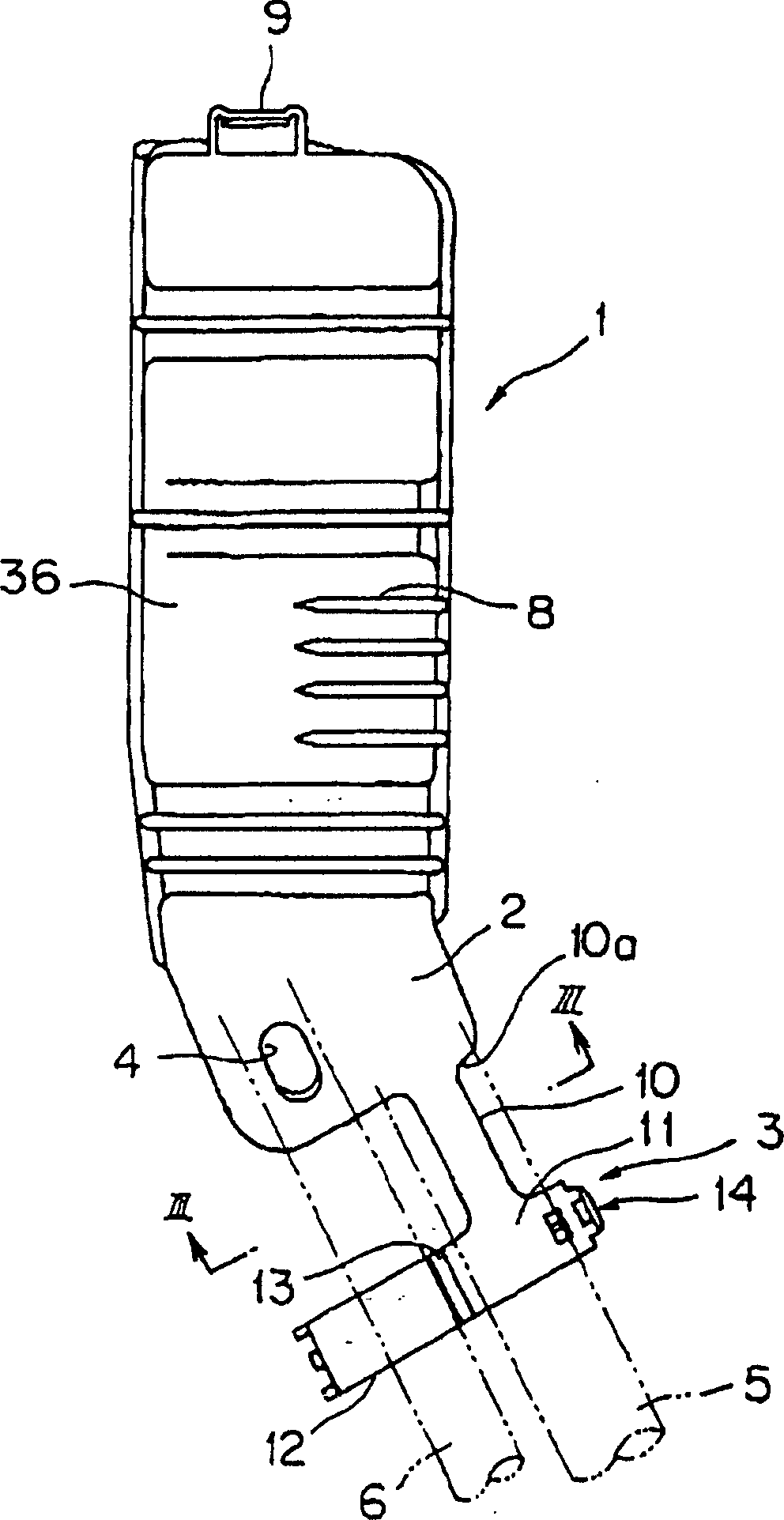

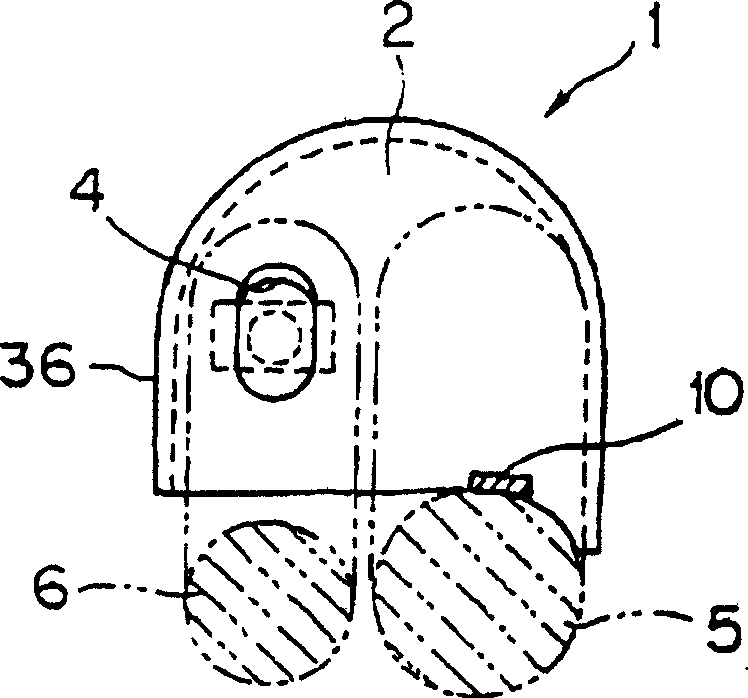

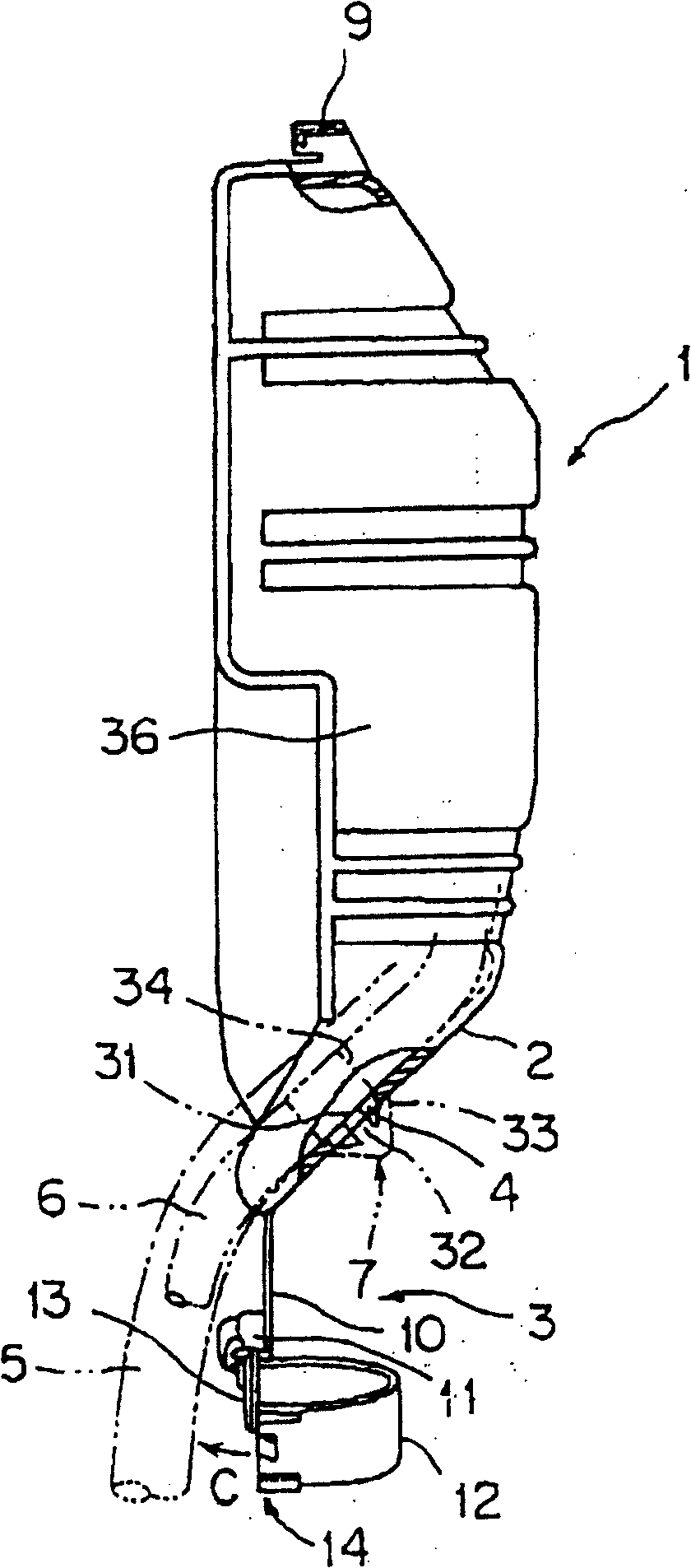

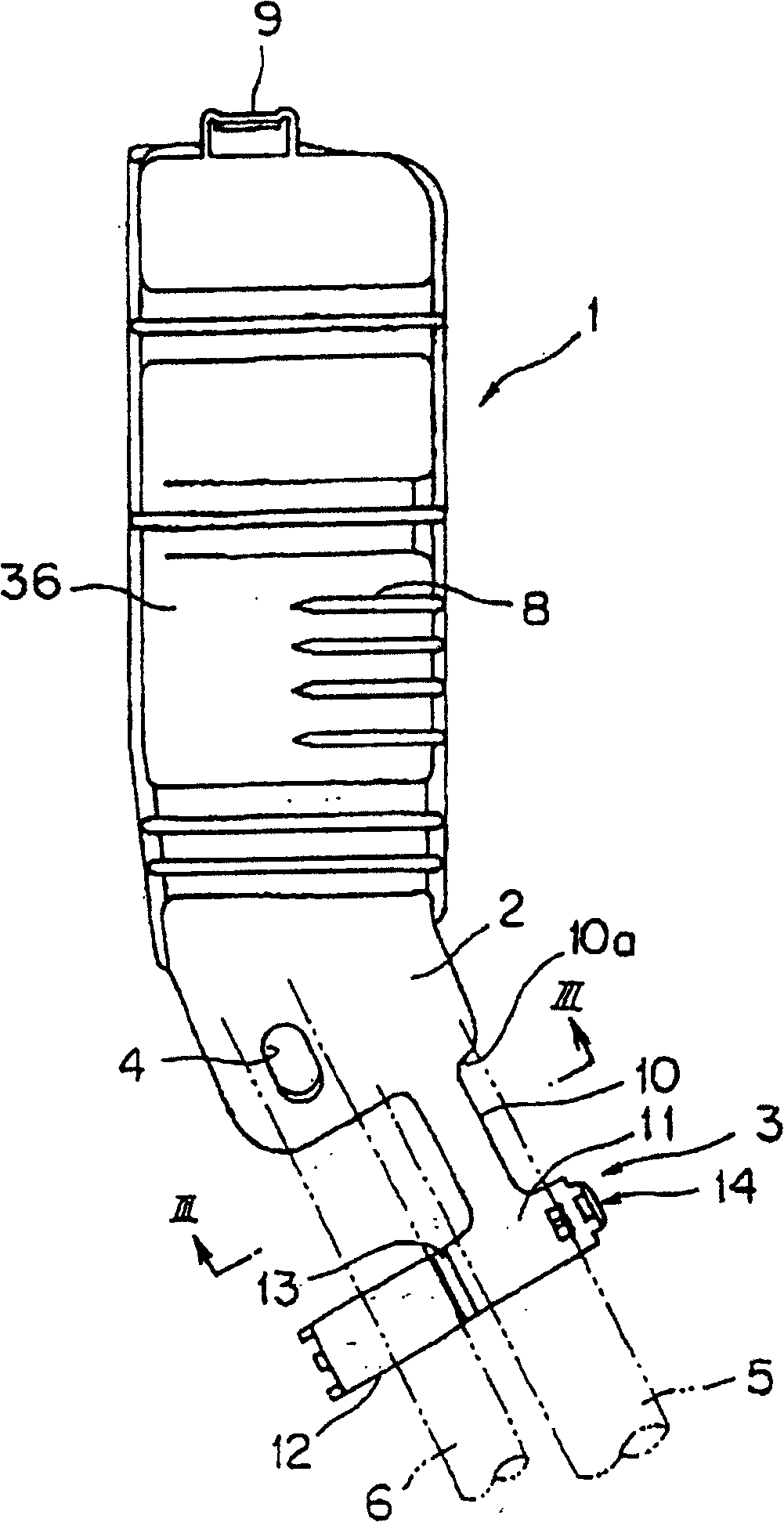

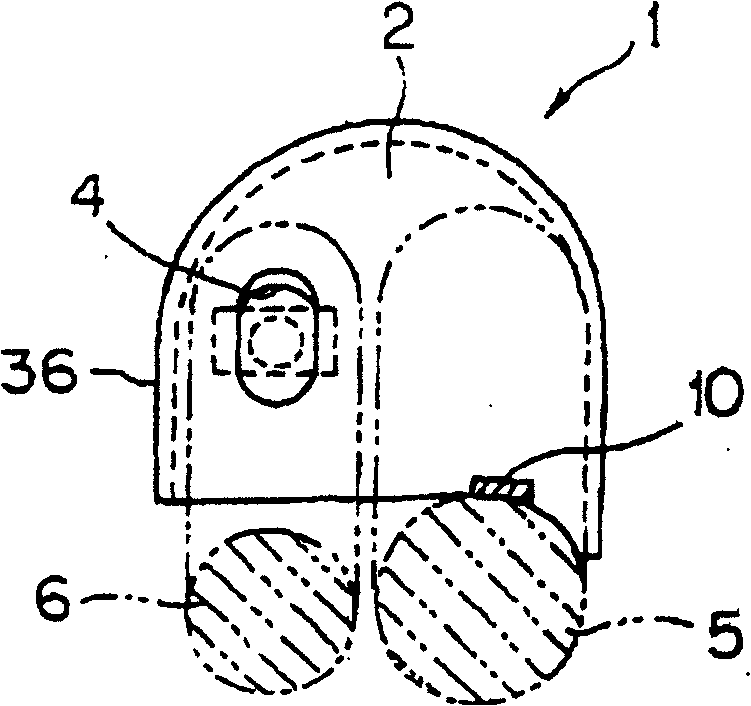

Arrangement for fixing wire harness onto covers of electric connection box and electric connection box thereof

InactiveCN1574532APrevent hold downAvoid wear and tearElectrical apparatus contructional detailsElectrical connectionElectrical bonding

The invention provides a cover arranged at the main body of an electrical connection box, which comprises a wall part for holding a first wiring harness and a second wiring harness connected with the electrical connection box. A first holding part is extended from the wall part in a derivative direction along the first wiring harness; the first wiring harness can be maintained outside of a holding component. The second wiring harness can be maintained at the wall part by a second holding part.

Owner:YAZAKI CORP

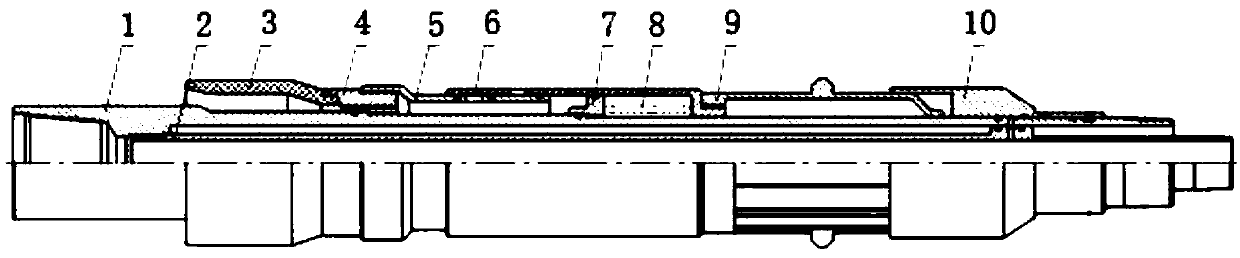

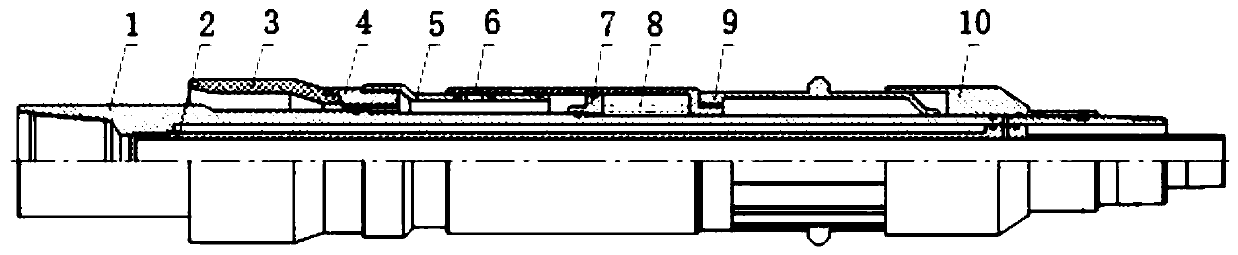

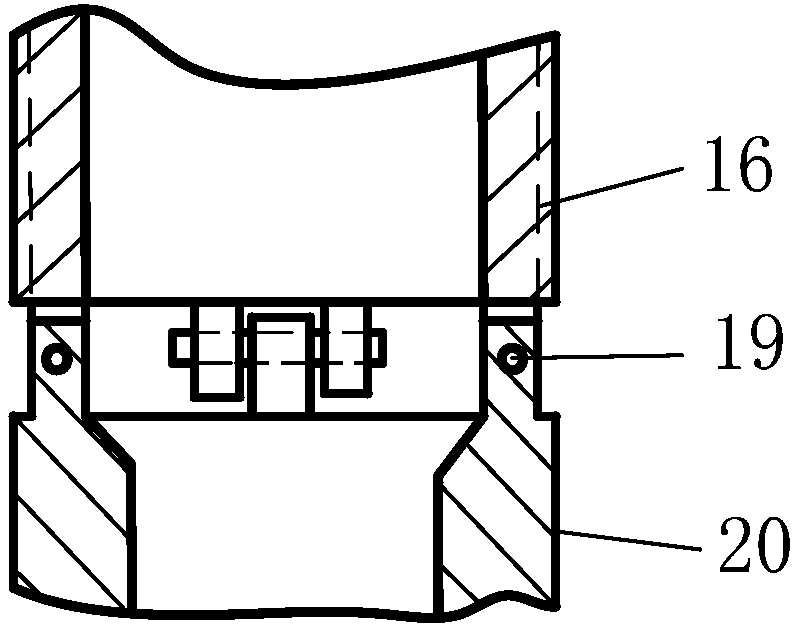

Multilateral well fracturing window sealing tool and process

ActiveCN104373073AEffective containmentAvoid enteringFluid removalSealing/packingEngineeringMechanical engineering

The invention relates to the technical field of oil field multilateral wells, in particular to a multilateral well fracturing window sealing tool and a process. The upper end of a feeding pipe of the device is connected with a feeding pipe joint; an inner center pipe is coated at the outer side of the feeding pipe, and is locked through a hand release locking block; a spherical base is connected to the inner wall of the feeding pipe through a hand release pin, and stops the hand release locking block; the inner wall of the bottom end of the feeding pipe is connected with a stop sleeve; an outer center pipe is coated at the outer side of the inner center pipe, and is locked through a locking block; a unsealing outer cylinder is connected to the outer side of the outer center pipe; and an insertion cylinder is connected to the inner wall of the unsealing outer cylinder through a unsealing pin. The tool realizes effective sealing of a main shaft at the upper part of a window and a non-fracturing multilateral borehole at the lower part to prevent a fluid in the multilateral borehole from entering the main shaft to cause the well control risk.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Packer structure

The invention discloses a packer structure. The packer structure comprises a central tube, a setting barrel, a rubber barrel seat and a rubber barrel, wherein the rubber barrel seat comprises an upper rubber barrel seat and a lower rubber barrel seat; the setting barrel, the upper rubber barrel seat, the rubber barrel and the lower rubber barrel seat are orderly sleeved on the central tube from top to bottom, a self-locking mechanism is arranged between the setting barrel and the upper rubber barrel seat, and two ends of the rubber barrel are respectively provided with an end ring and an expansion ring in order. The packer structure disclosed by the invention is not only small in radial gap, but also capable of effectively packing the great annular gap; meanwhile, the price is low, the well cementation quality is improved, and capacity increasing and revamp are guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Vertical well negative displacement based horizontal butt-joint type geothermal well borehole trajectory and designing method

InactiveCN107605455AIncrease docking distanceIncreased docking distanceFluid removalDirectional drillingOffset distanceResource development

The invention provides a vertical well negative displacement based horizontal butt-joint type geothermal well borehole trajectory and a designing method. The designing method includes the following steps: a first step, determining positions and coordinates of a mouth A of an inclined well and a mouth B of a horizontal engineering well according to the size and the shape of a construction region, calculating a distance d1 between the mouth A and the mouth B according to the coordinates of the mouth A and the mouth B, and determining a negative displacement offset distance d2 of a borehole trajectory of the inclined well according to the distance d1; a second step, determining a borehole trajectory of the vertical well; and a third step, determining a borehole trajectory of the horizontal engineering well. The negative displacement offset distance d2 is generated through construction of a second S402 section of the horizontal engineering well, the d1+d2>=250 m, a downhole communication butt-joint distance is effectively increased, two-well communication working can be smoothly performed, and a condition is created for city narrow places where a horizontal butt-joint geothermal well technology is adopted to develop deep hydrothermal geothermal resources; the problem that the conventional hydrothermal geothermal resource developments take heat and water can be solved, and an objective that heat is taken but water is not taken can be achieved.

Owner:陕西省煤田地质集团有限公司

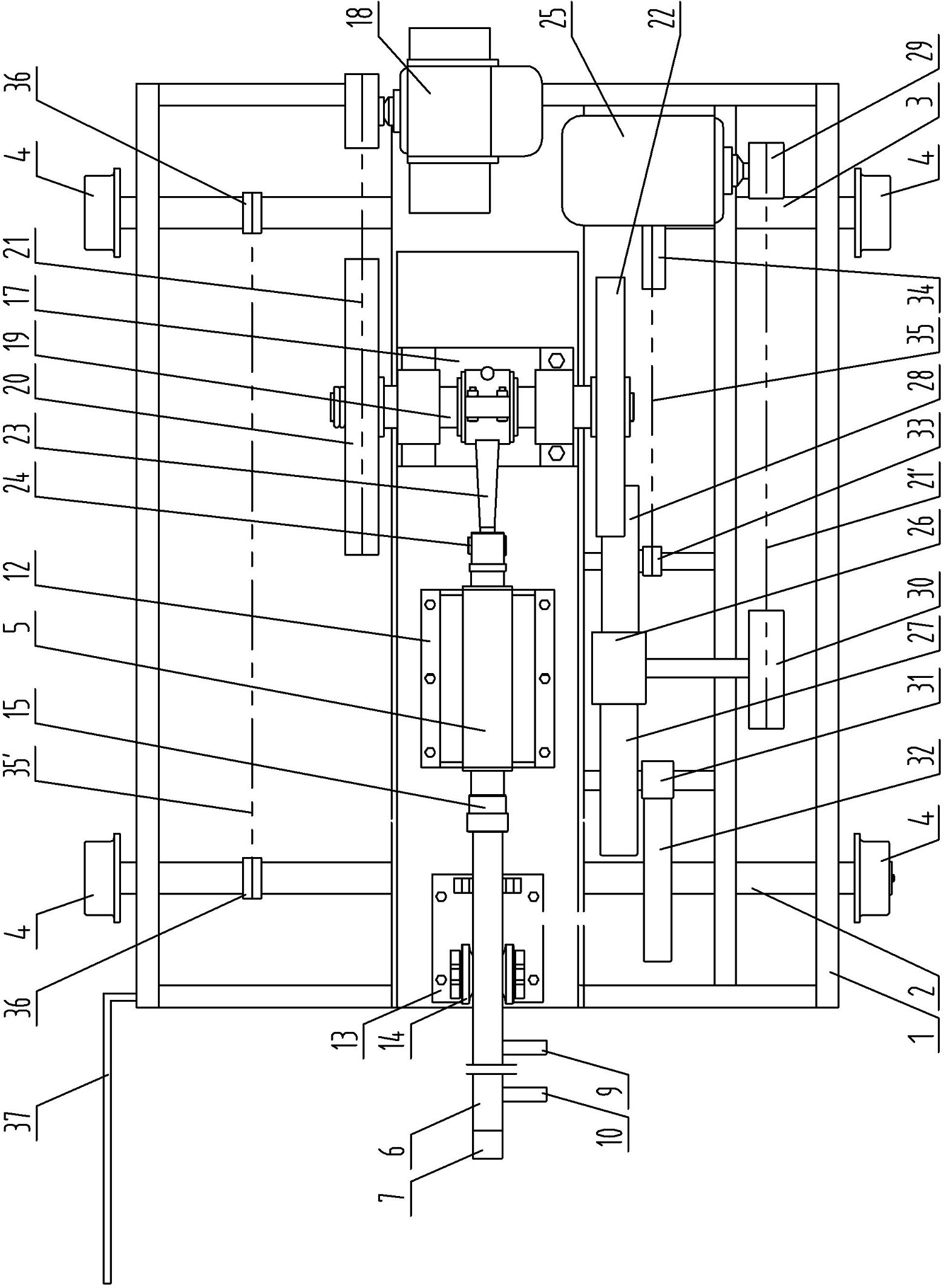

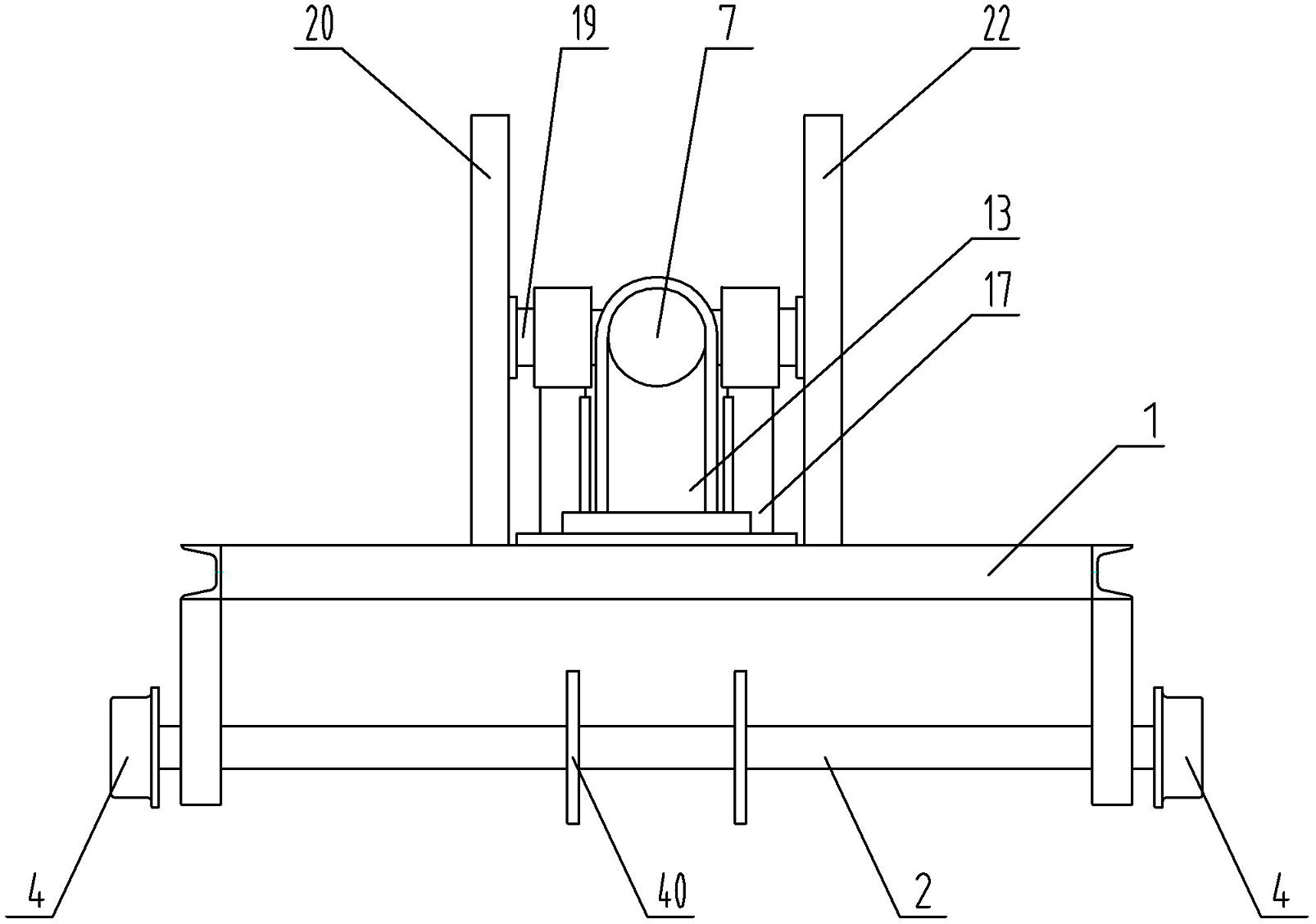

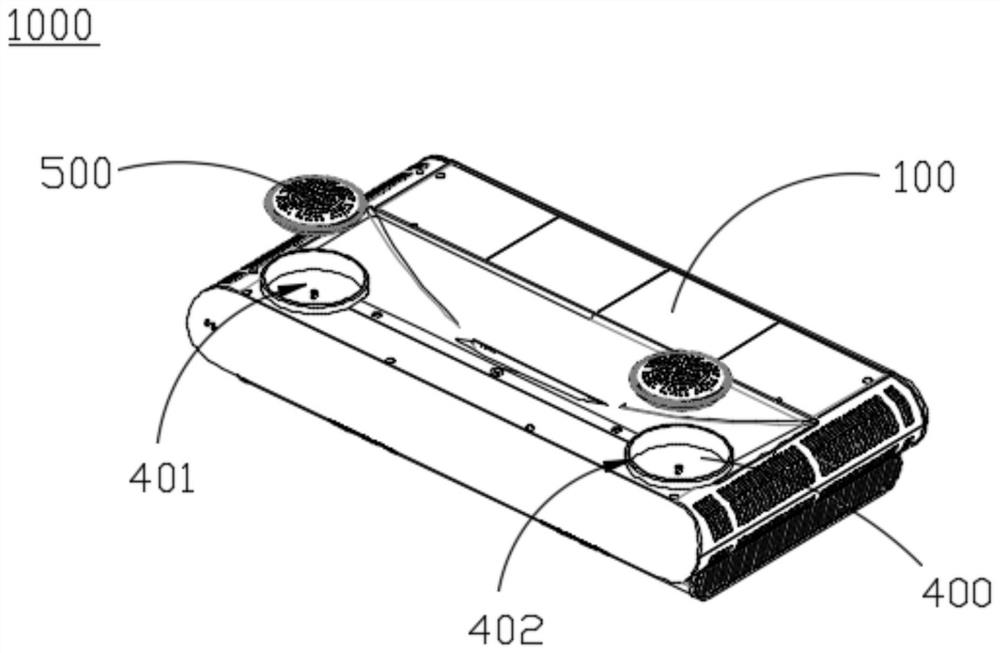

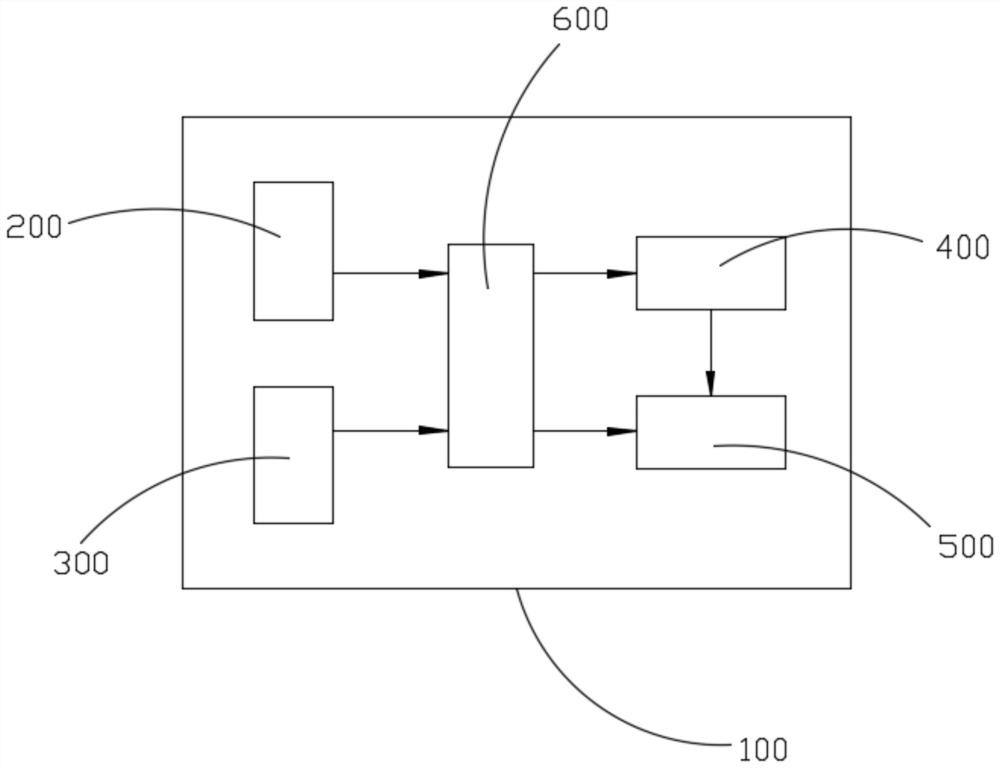

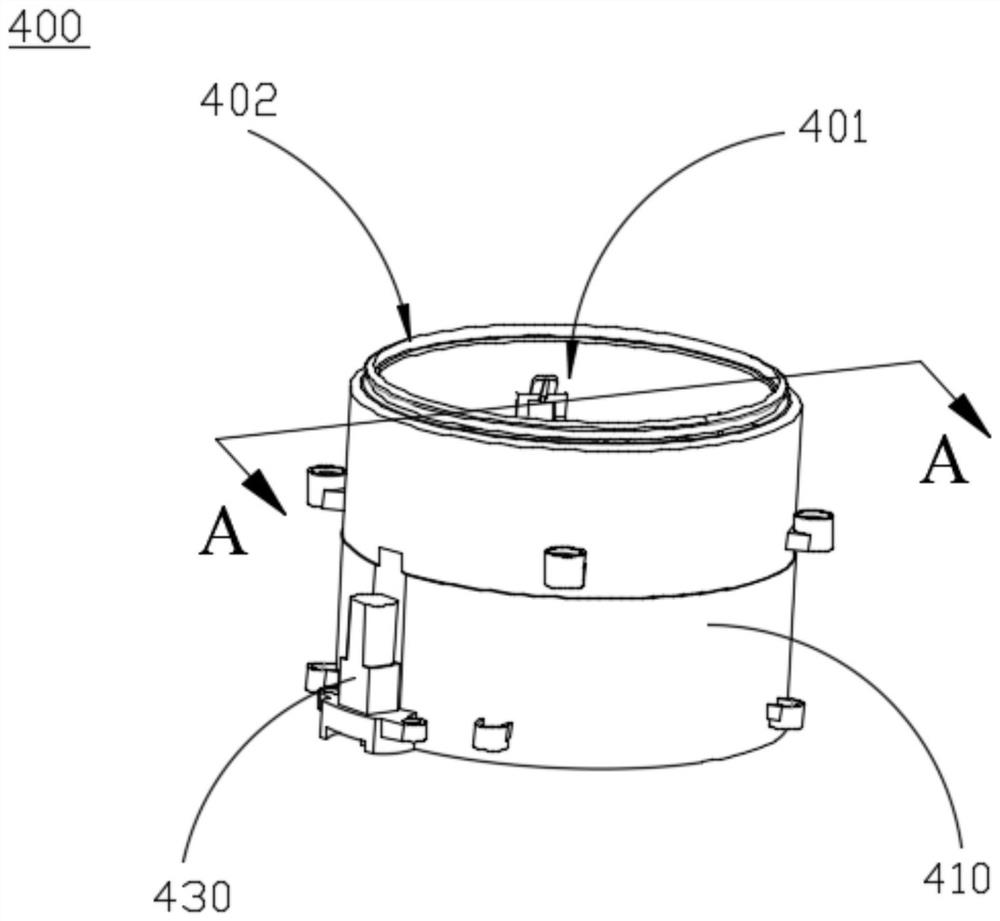

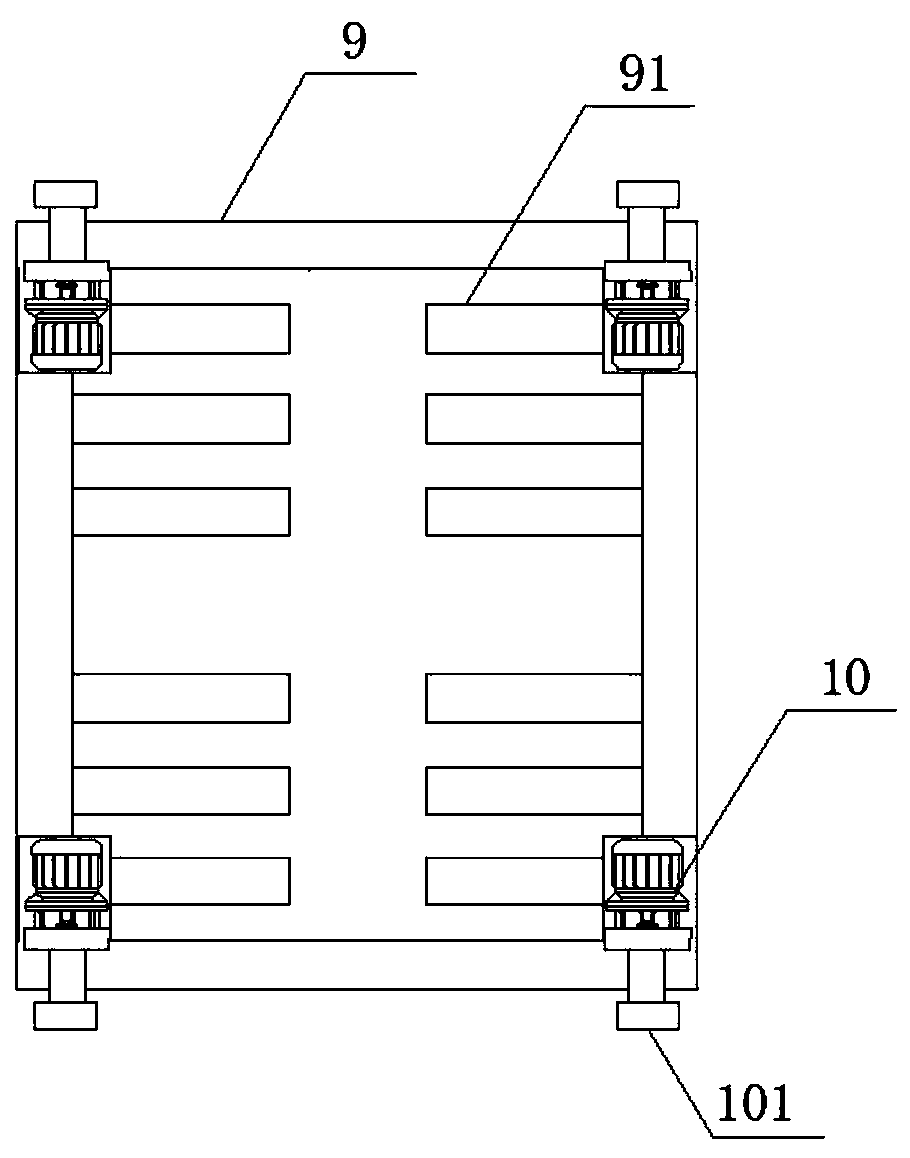

a handling equipment

ActiveCN110329696BImplement pick and place operationsAvoid wastingStorage devicesProcess engineeringMechanical engineering

The invention discloses a method for transporting multi-layer stacked material boxes in a storage shelf, wherein the material boxes are directly stacked up and down in the shelf to avoid the waste of space caused by storage cabinets in the prior art; and for the material boxes directly stacked in the shelf , using the handling equipment to "pull up and place the material box down in the shelf" for up and down moving handling. As for the handling or placement of material boxes that are not at the top, auxiliary handling equipment is provided to assist in the operation, so as to realize the pick-and-place operation of material boxes in different positions. The invention also provides a handling device used in the handling method, which can realize the functions of pulling up and placing the material box down in the shelf.

Owner:安徽驿星智能物流装备制造有限公司

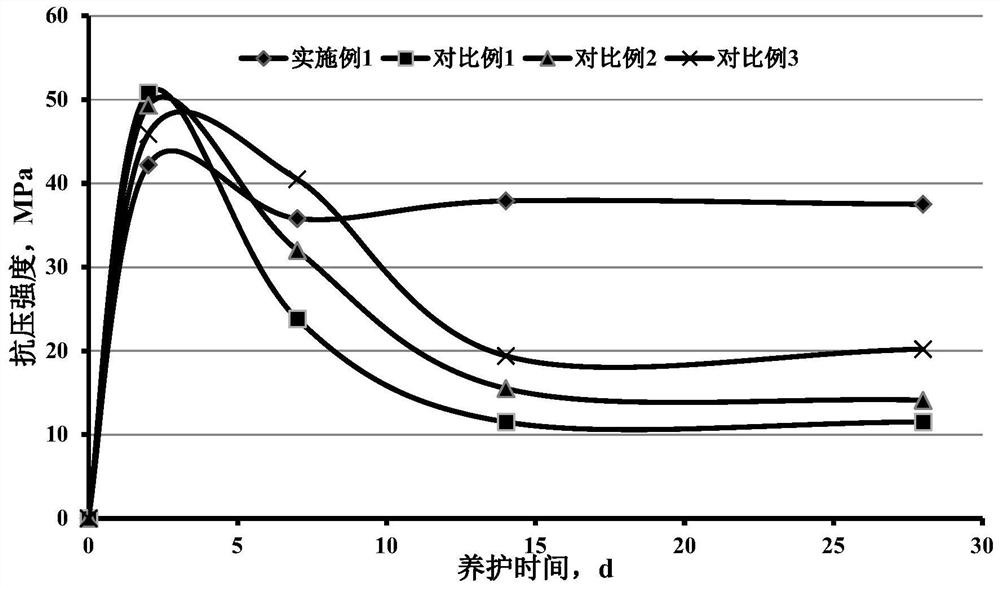

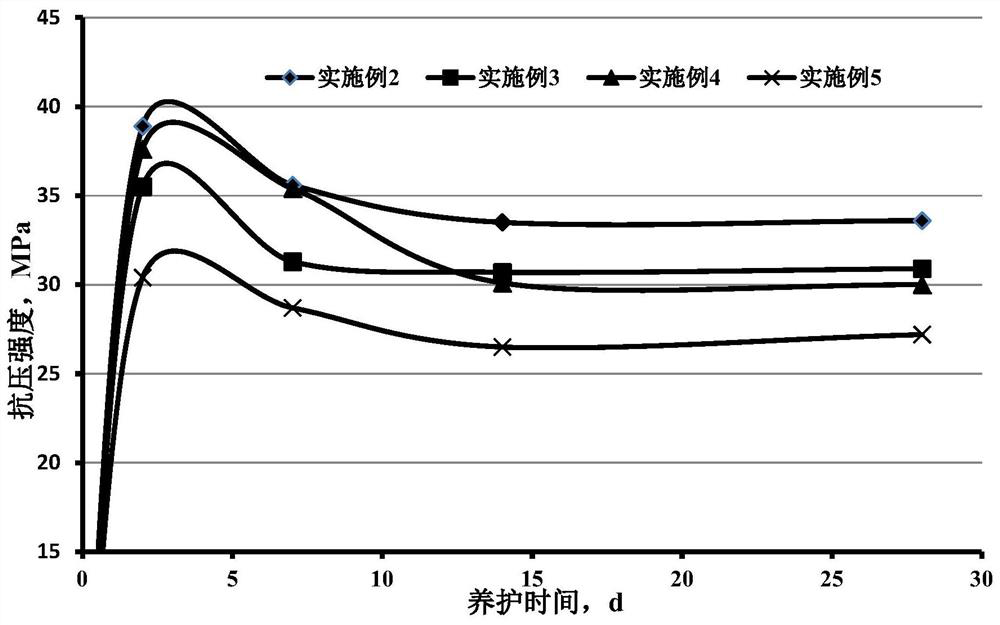

Anti-leakage cement paste for well cementation

InactiveCN110002798AWell mixedImprove stabilityDrilling compositionDifferential pressureHigh probability

The invention discloses anti-leakage cement paste for well cementation and belongs to the technical field of well cementation of an oil-gas well. The anti-leakage cement paste is prepared from components as follows: water, oil well cement, bridging particles, quartz sand, silica fume and a cement admixture, wherein the oil well cement has the particle size of 10 mu m to 30 mu m; the particle sizeof the bridging particles is 1 / 2-2 / 3 of the average hole diameter or the average crack width of target stratum; the quartz sand has the particle size of 180 mu m to 425 mu m; the silica fume has the particle size of 0.1 mu m to 0.3 mu m. According to the anti-leakage cement paste, bridge blinding is formed through reasonable gradation of particle materials of different particle sizes, porous stratum with high probability of leakage and inductive crack stratum caused under the action of differential pressure are effectively blocked the pressure bearing capability is high, and well leakage in the well cementation process can be effectively prevented. Cement formed after the anti-leakage cement paste is thickened has high compressive strength and interfacial cementation strength, and effective blocking of an oil and water layer can be realized.

Owner:PETROCHINA CO LTD

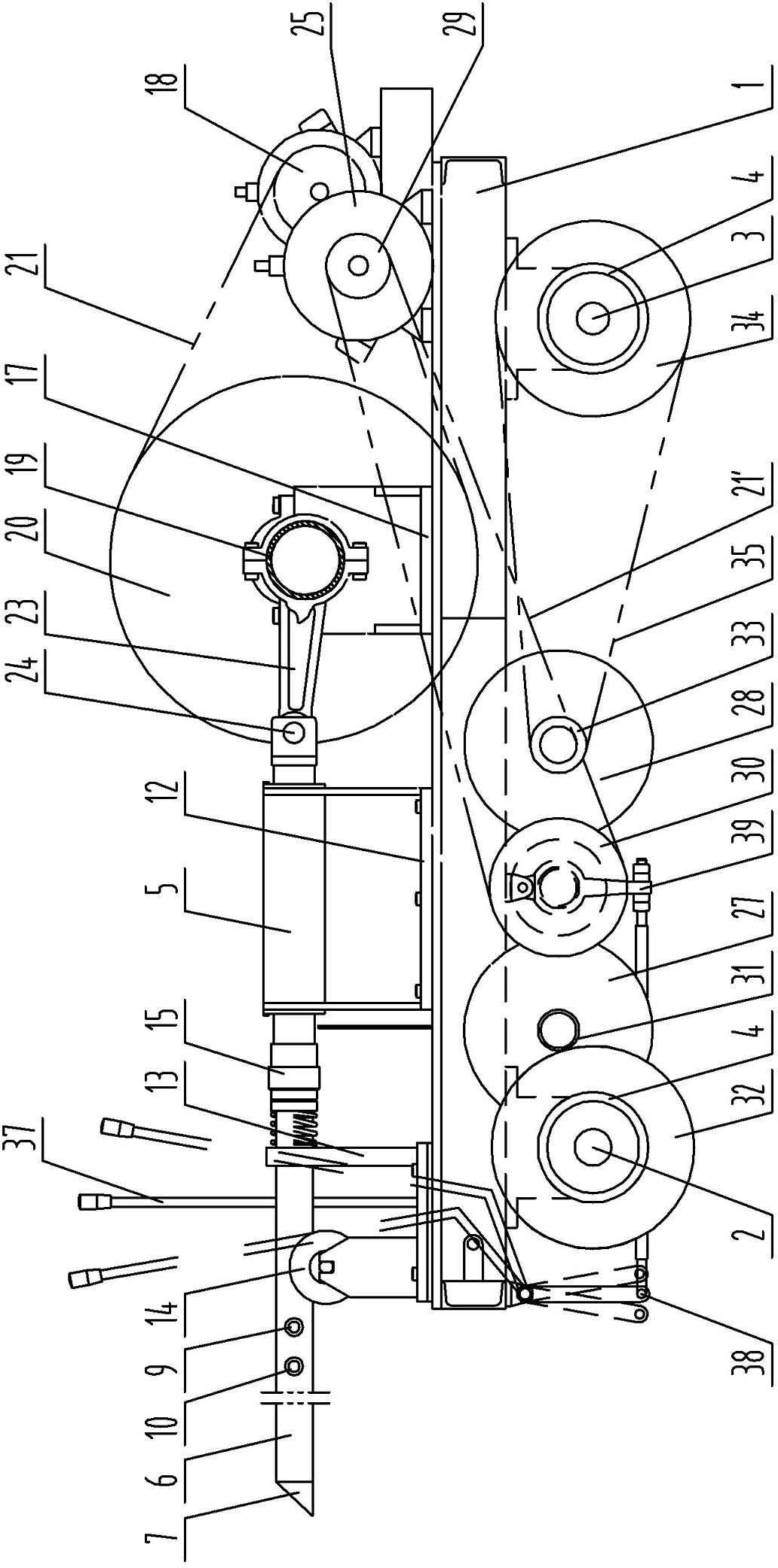

Device for rapidly treating ring formation of rotary kiln and method

The invention belongs to the technical field of rotary kilns for metallurgy, building materials, chemical engineering and refractory materials, and particularly relates to a device for rapidly treating ring formation of a rotary kiln and a method. The device comprises a kiln car, an impact bar, an impact bar support device, an impact bar driving device, a kiln car driving device and an operating device, the impact bar, the impact bar support device and the impact bar driving device are arranged on the kiln car, the kiln car consists of a frame, a front axle, a rear axle and wheels mounted on two sides of the front axle and the rear axle, a hollow shovel rod is movably connected to the front end of the impact bar and fixed onto the kiln car by a shovel rod support device, a shovel head is fixed to the front end of the shovel rod, a cooling water pipe is fixedly sleeved in the shovel rod, a water inlet of the cooling water pipe is fixed to the rear end of the shovel rod, a water outlet pipe is additionally fixedly disposed at the rear end of the shovel rod and communicated with the inside of the shovel rod, and an annular plug is disposed between the inner wall of the shovel rod on the rear side of the water outlet pipe and the outer wall of the cooling water pipe. Impact force for automatically removing rings is high, the device is high in efficiency, low in service cost and convenient in operation, simultaneously, energy consumption can be reduced, sintering conversion rate of materials is improved, yield of the rotary kiln is increased, economic benefit is remarkable, and the device is suitable for popularization and implementation.

Owner:GONGYI XIAOYI JINLI MECHANICAL EQUIP MFG FACTORY

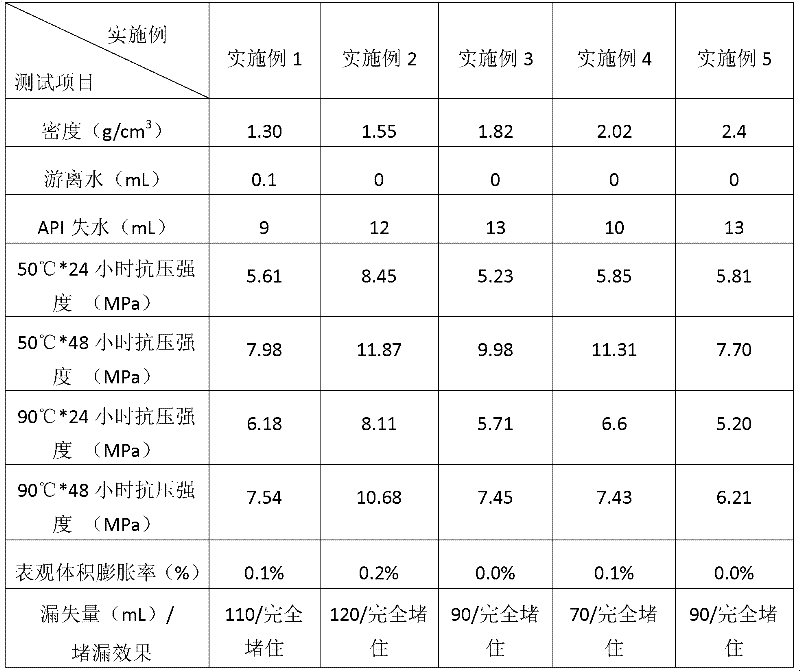

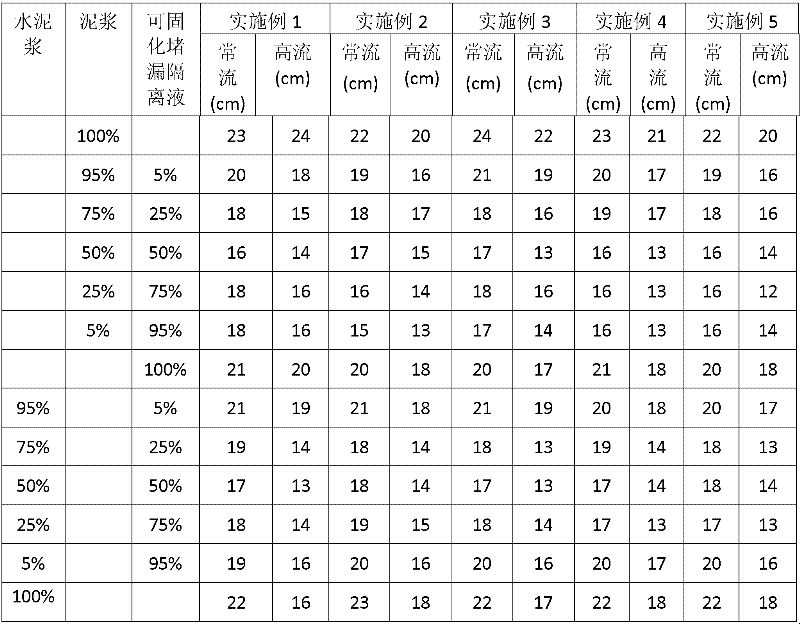

Curable leaking stoppage spacer fluid and preparation method thereof

ActiveCN101857799BExcellent curabilityGood chemical compatibilityDrilling compositionSodium BentoniteMicrosphere

The invention relates to a curable leaking stoppage spacer fluid and a preparation method thereof. The spacer fluid comprises the following components according to parts by weight: 450 parts of fresh water, 400-600 parts of curing agent, 3-10 parts of stabilizing agent, 2-20 parts of suspending agent, 10-40 parts of activating agent, 10-60 parts of activating auxiliary agent and 10-700 parts of density regulator, wherein the curing agent is slag powder; the stabilizing agent is clay; the suspending agent is sodium bentonite or calcium bentonite; the activating agent is the mixture of sodium hydroxide and sodium carbonate; the activating auxiliary agent is the mixture of sodium silicate and calcium oxide; and the density regulator can be iron ore powder for well cementation or coal ash hollow microsphere. After the curable leaking stoppage spacer fluid is cured, the lamination capability can reach more than 5MPa, the spacer fluid shows good chemical compatibility with mud and cement paste and good curing performance between 30-130 DEG C; after the spacer fluid is cured, the appearance of a formed cured body has non volume contraction; therefore, the spacer fluid can effectively pack a stratum dropping passage and provides guarantees for the follow-up operation of oil and gas wells.

Owner:SOUTHWEST PETROLEUM UNIV

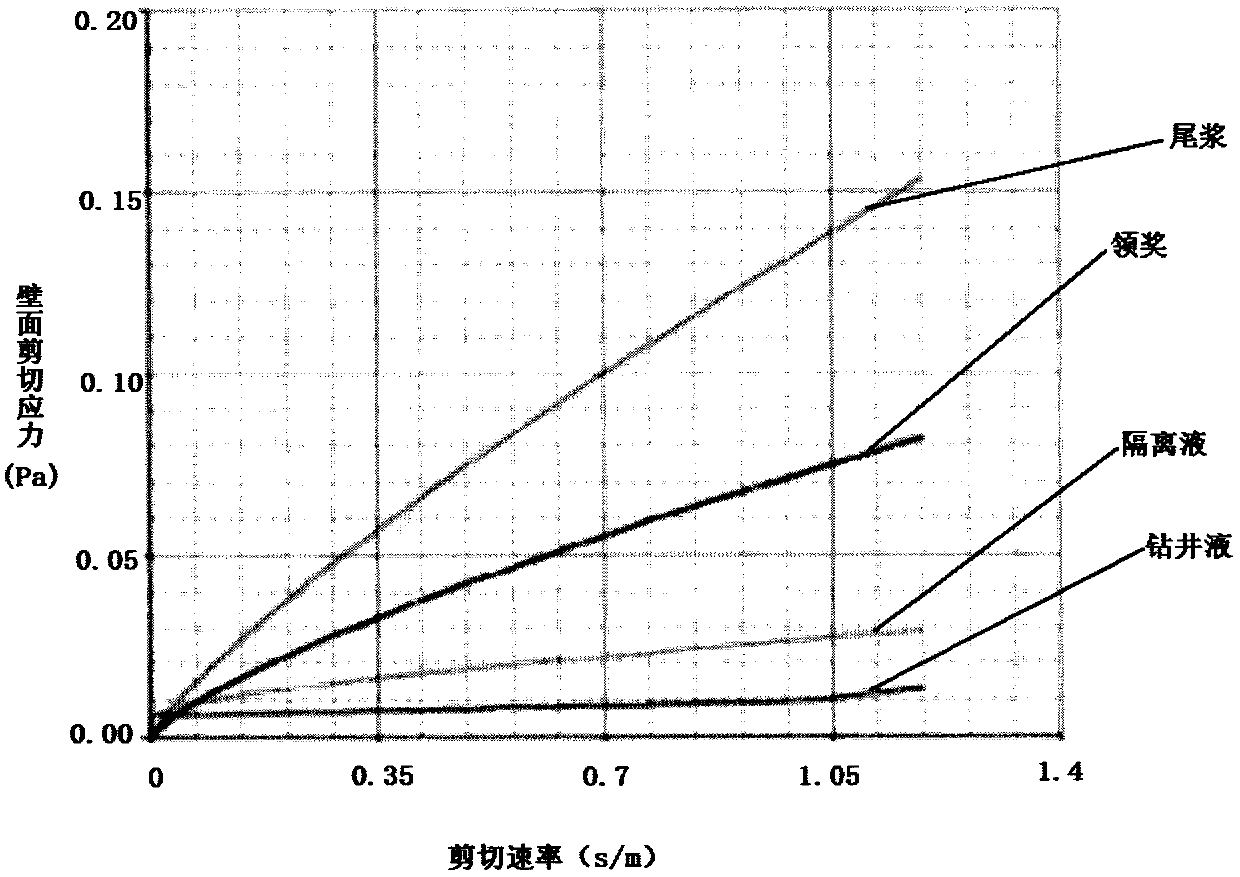

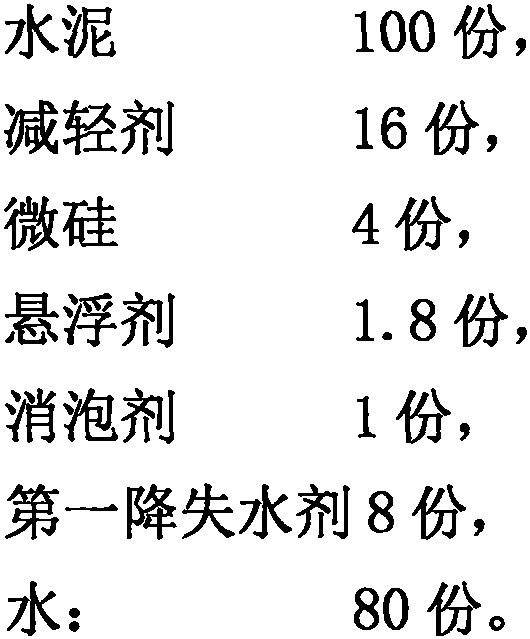

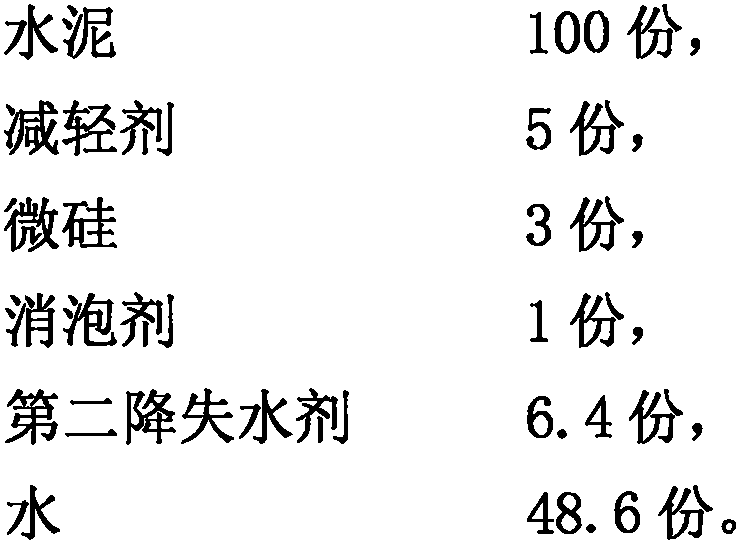

Technique for cement pouring in well cementing engineering

InactiveCN110939405AImprove bonding qualityEffective containmentDrilling compositionSealing/packingPressure stabilizationHorizontal wells

The invention discloses a technique for cement pouring in well cementing engineering. The technique comprises the steps that a casing is put into a well mouth; a spacer fluid with a density of 1.30sgis poured by pumping into the casing; a lower rubber plug is put down; head slurry and tail slurry are successively poured by pumping into the casing, wherein the head slurry is cement paste with a density of 1.45sg and the tail slurry is cement paste with a density of 1.75sg; an upper rubber plug is put down; a drilling liquid with a density under 1.18sg is poured from the casing for alternation,so the spacer fluid, the head slurry and the tail slurry can return upwards to a preset height in an annular space between outside of the casing and a well wall, wherein an annular returning speed ofthe spacer fluid, the head slurry and the tail slurry in the annular space is not lower than 0.21s / m; and the upper rubber plug is used for press collision and pressure stabilization, unloading is conducted, cementing is waited, and construction is finished. The technique disclosed by the invention has the beneficial effects that wall face shear stress theoretical conditions can be satisfied between the tail slurry, the head slurry and the spacer fluid at the same time; when a centralizing degree of the horizontal well casing with a large slope cannot reach standards, cement slurry displacement efficiency can be effectively increased; and gluing quality between cement and a stratum can be improved, and effective sealing can be realized.

Owner:BEIJING BAOWO PETROLEUM TECH

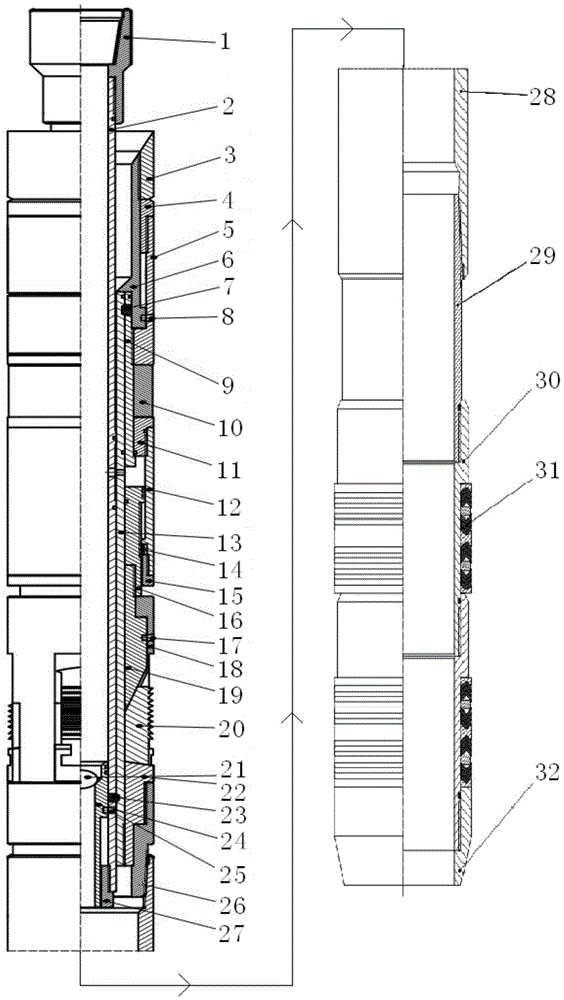

Stepping type cup packer capable of achieving dragging under pressure and using method

ActiveCN107701145AReduce wearSatisfy the operating requirements of annular space under pressureSealing/packingCouplingPressure balance

The invention discloses a stepping type cup packer capable of achieving dragging under pressure and a using method. The packer comprises a main shaft and a core shaft arranged in the main shaft, a cupseat and a cup directly vulcanized to the cup seat are arranged on the outer diameter of the main shaft, and the rear portion of the cup seat is connected with a pressure relief short section. The rear portion of the pressure relief short section is provided with a seal seat and a rest spring, a sliding sleeve constituting a matching pair with the pressure relief short section is arranged on theouter sides of the seal seat and the reset spring and connected with an elastic claw, and a pressing sleeve connected with the main shaft is mounted on the outer side of the elastic claw. Pressure conducting holes capable of conducting the pressure into the pressing sleeve are formed in the core shaft and the main shaft correspondingly. The using method of the stepping type cup packer has the advantages that the cup can be subjected to coupling through a sleeve pipe under the pressure balance state, the abrasion probability of the cup at the coupling position is effectively reduced, and the sliding sleeve moves downwards to automatically recover to the state that the sliding sleeve and the pressure relief short section are sealed after the cup is subjected to coupling through the sleeve pipe; and through stepping type matching using of the two sets of cup packers, the operation requirement of on-site annulus bearing can be met, an oil sleeve annulus is effectively packed, and the operation danger and the construction cost are reduced.

Owner:CNOOC ENERGY TECH & SERVICES

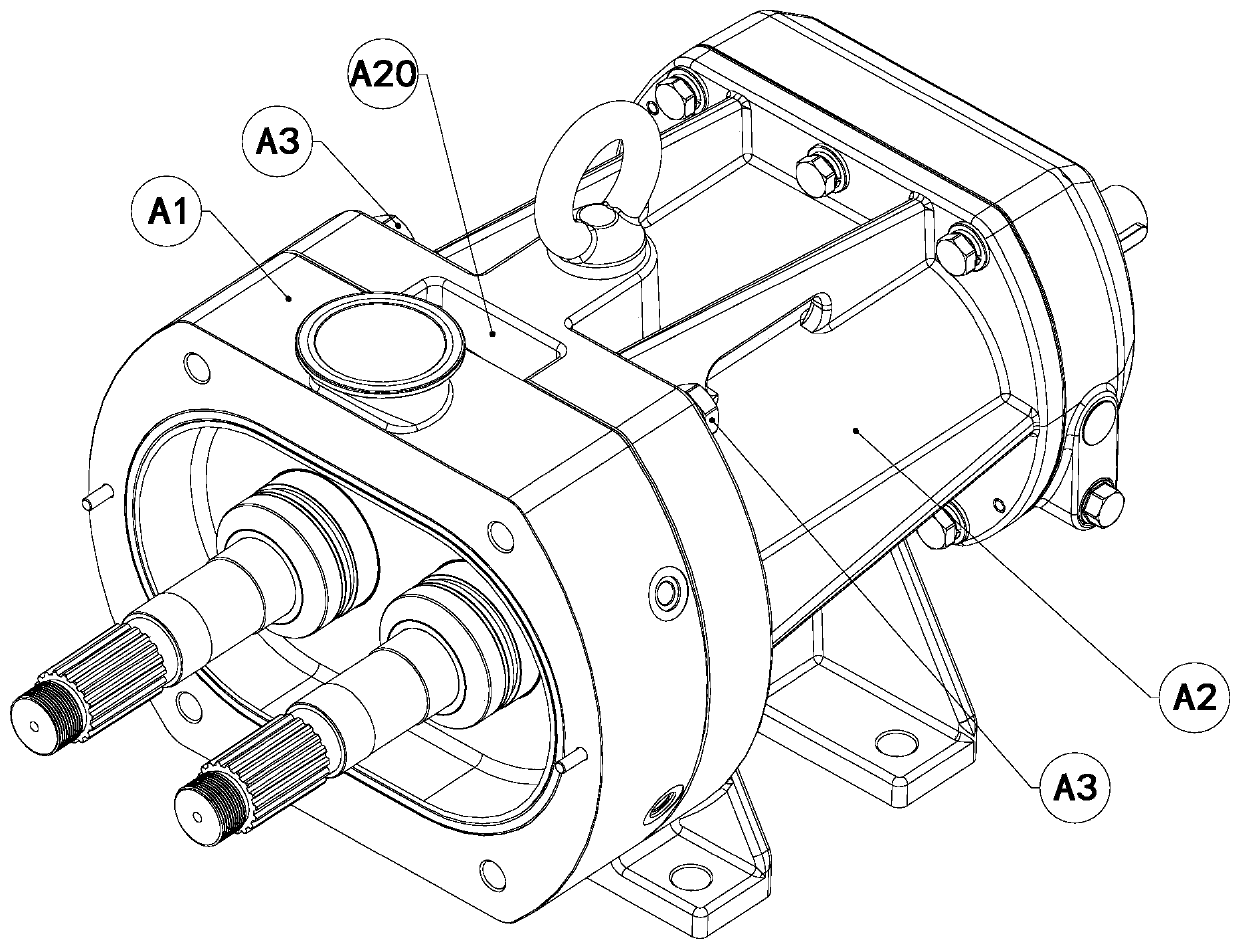

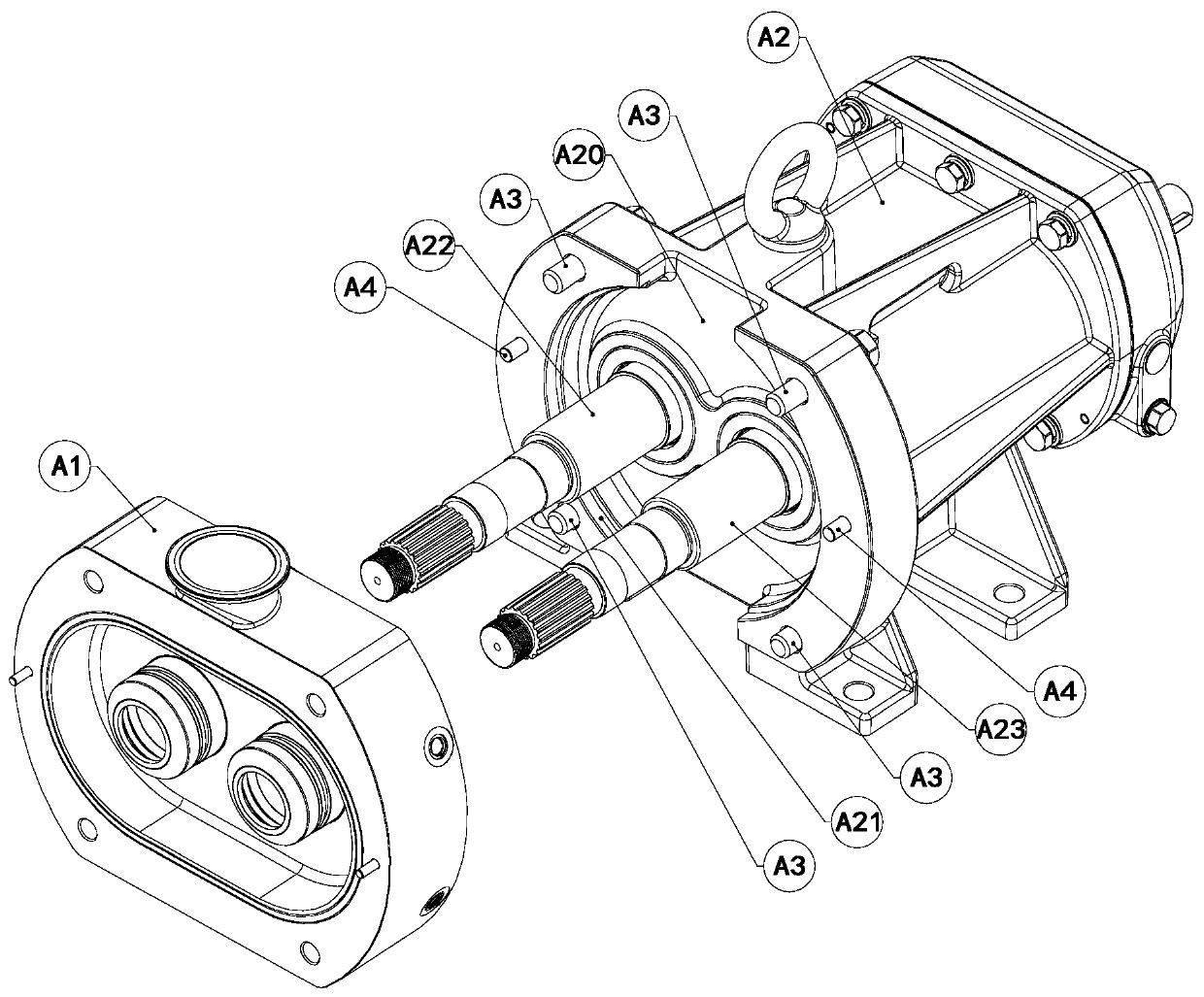

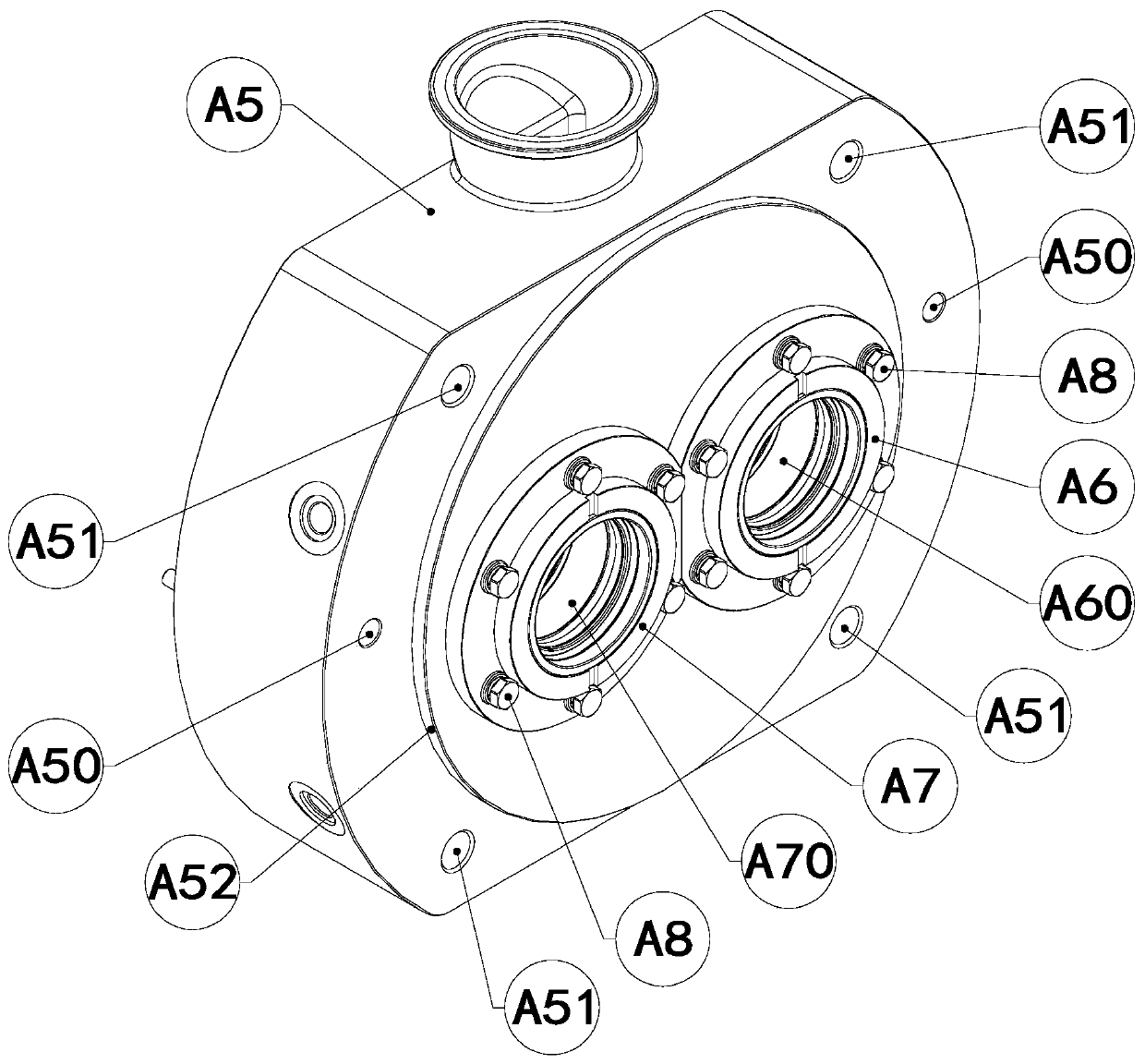

Isolation sealing device of viscous fluid conveyor

InactiveCN110067748AImprove isolation and sealing effectPrevent leakageEngine sealsBearing componentsPressure differenceMechanical engineering

The invention discloses an isolation sealing device of a viscous fluid conveyor, and aims to provide the viscous fluid conveyor with a good isolation sealing performance. The invention provides the technical scheme point that the isolation sealing device of the viscous fluid conveyor comprises a sealing assembly and a bearing box arranged at one end of the sealing assembly, wherein a left shaft neck and a right shaft neck symmetrical to each other are arranged at one end, close to the sealing assembly, of the bearing box; a left sealing component provided with a left shaft neck sealing surfaceand a right sealing component provided with a right shaft neck sealing surface are symmetrically arranged on the sealing assembly; the left shaft neck passes through the left shaft neck sealing surface; the right shaft neck passes through the right shaft neck sealing surface; the sealing assembly and the bearing box form an isolation chamber during installation; one end, far away from the bearingbox, of a sealing seat is a conveying chamber; and a pressure difference is formed between the conveying chamber and the isolation chamber. According to the isolation sealing device of the viscous fluid conveyor provided by the invention, the isolation chamber is arranged between the conveying chamber and the bearing box, and a pressure difference is formed between the isolation chamber and eachspace of the device, so that liquid in each component can be only unidirectionally leaked into the isolation chamber, and an isolation sealing performance is improved.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

Convenient-to-clean mold fixing device for machining of mold

ActiveCN109227170AEasy to cleanShorten the timePositioning apparatusMetal-working holdersMachiningScrap

The invention relates to the technical field of machining of molds and discloses a convenient-to-clean mold fixing device for machining of a mold. The mold fixing device comprises a fixing base, fixing blocks are fixedly connected to the upper surface of the fixing base, two device slots are formed in the outer walls of the opposite faces of the two fixing blocks, electric retractable rods are fixedly connected in the fixing blocks, and one end of each electric retractable rod extends into the corresponding device slot. According to the convenient-to-clean mold fixing device for machining of the mold, through arrangement of scrapers on the lower surfaces of cutter head mounting blocks, when the electric retractable rods are retracted, the upper surfaces of clamping blocks can be effectively cleaned under the action of the scrapers, and scraps splashed on the outer walls of the clamping blocks during machining of the mold can be effectively scraped off, so that the fixing device is moreconvenient to clean, the time for cleaning the fixing device is shortened, and machining is accelerated.

Owner:TAIZHOU SANJIN DIE CASTING

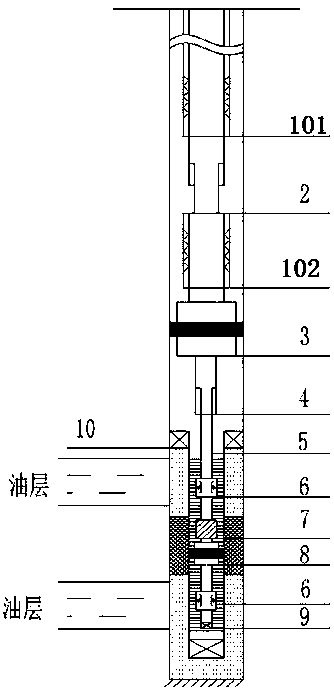

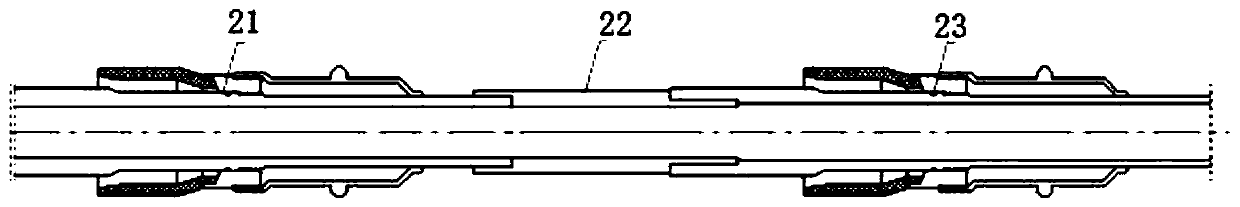

Separate layer steam injection pipe column of thermal recovery straight inclined shaft in general sand preventing condition and method

ActiveCN110195579AImprove injection drynessImprove the use effectFluid removalSealing/packingSpray nozzleDensity difference

The invention discloses a separate layer steam injection pipe column of a thermal recovery straight inclined shaft in a general sand preventing condition and a method. The separate layer steam injection pipe column comprises a top packer, an underground thermal expansion compensator and at least two flow regulators which are successively connected onto an oil pipe from top to bottom. The at leasttwo flow regulators separately correspond to different oil layers, and an interlayer packer is arranged between every two flow regulators; the upper end of the interlayer packer is connected to a liquid phase separator in a screw thread manner, each liquid phase separator comprises an outer pipe and an inner pipe, rotational flow blades are arranged on the inner wall of the outer pipe, the upper half section of the inner pipe enters the outer pipe, the inner pipe is located below the rotational flow blades, axial liquid phase nozzles are also arranged on the inner wall of the outer pipe, the liquid phase nozzles are located in an annulus formed by the outer pipe and the inner pipe, and gas phase critical flow nozzles are arranged on the inner wall of the inner pipe. By means of a density difference between gas and liquid phases, liquid phase separation of a certain thickness is established between the sand-preventing pipe column and a casing, so that upper and lower oil layers are packed effectively in the general sand preventing condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

A step-by-step rubber cup packer that can be dragged under pressure and its application method

ActiveCN107701145BReduce wearAutomatically restore the sealing stateSealing/packingPressure.driveCoupling

The invention discloses a stepping type cup packer capable of achieving dragging under pressure and a using method. The packer comprises a main shaft and a core shaft arranged in the main shaft, a cupseat and a cup directly vulcanized to the cup seat are arranged on the outer diameter of the main shaft, and the rear portion of the cup seat is connected with a pressure relief short section. The rear portion of the pressure relief short section is provided with a seal seat and a rest spring, a sliding sleeve constituting a matching pair with the pressure relief short section is arranged on theouter sides of the seal seat and the reset spring and connected with an elastic claw, and a pressing sleeve connected with the main shaft is mounted on the outer side of the elastic claw. Pressure conducting holes capable of conducting the pressure into the pressing sleeve are formed in the core shaft and the main shaft correspondingly. The using method of the stepping type cup packer has the advantages that the cup can be subjected to coupling through a sleeve pipe under the pressure balance state, the abrasion probability of the cup at the coupling position is effectively reduced, and the sliding sleeve moves downwards to automatically recover to the state that the sliding sleeve and the pressure relief short section are sealed after the cup is subjected to coupling through the sleeve pipe; and through stepping type matching using of the two sets of cup packers, the operation requirement of on-site annulus bearing can be met, an oil sleeve annulus is effectively packed, and the operation danger and the construction cost are reduced.

Owner:CNOOC ENERGY TECH & SERVICES

Projector

ActiveCN112153523AExpansion of sound field spaceEffective containmentPicture reproducers using projection devicesFrequency/directions obtaining arrangementsEngineeringMechanical engineering

The invention provides a projector which comprises a shell, a power supply assembly, an audio assembly, a magnetic levitation control base and a first loudspeaker box, the power supply assembly, the audio assembly, the magnetic levitation control base and the first loudspeaker box are arranged in the shell, a containing space is formed in the magnetic levitation control base, the containing spaceis communicated with the exterior of the shell to form an opening, and the first loudspeaker box is contained in the containing space; the power supply assembly is electrically connected with the magnetic levitation control base to transmit current to the magnetic levitation control base, the magnetic levitation control base is powered on to control the first loudspeaker box to be magnetically levitated and enable the first loudspeaker box to move out of the shell through the opening, and the audio assembly is in communication connection with the first loudspeaker box to transmit audio signalsto the first loudspeaker box. According to the projector provided by the invention, the magnetic levitation control base and the first sound box are arranged in the shell, and the magnetic levitationcontrol base is electrified to control the first sound box to be magnetically levitated and enable the first sound box to move to the outside of the shell through the opening, so that the sound fieldspace range of the first sound box can be further expanded; and the first sound box can be effectively accommodated.

Owner:SHENZHEN HUOLE TECH DEV CO LTD

Preparation method of high-strength heat-resistant oil field well cementation rubber plug

The invention discloses a preparation method of a high-strength heat-resistant oil field well cementation rubber plug. The oil field well cementation rubber plug is prepared from, by weight, 20-30 parts of 65-mesh rubber powder, 12-15 parts of butadiene styrene rubber, 10-30 parts of silica gel, 15-25 parts of silica powder, 5-8 parts of floating beads, 3-10 parts of argil, 12-15 parts of calcium carbonate, 1-3 parts of white carbon black, 1-5 parts of an anti-aging agent, 1.5-4 parts of an anti-scorching agent, 2-6 parts of a plasticizing agent and 3-9 parts of a softening agent. The overall strength, high temperature resistance and heat resistance of the rubber plug can be greatly improved, the adsorption capacity, acid and alkali resisting and corrosion resisting capacity, high temperature resistance, mechanical strength, insulating property, heat stability and chemical stability of the rubber plug can be greatly improved, steel tubes for oil field well cementation can be protected and prevented from being damaged by external factors, and thus smooth oil field well cementation can be promoted.

Owner:枣阳市恒泰化工有限公司

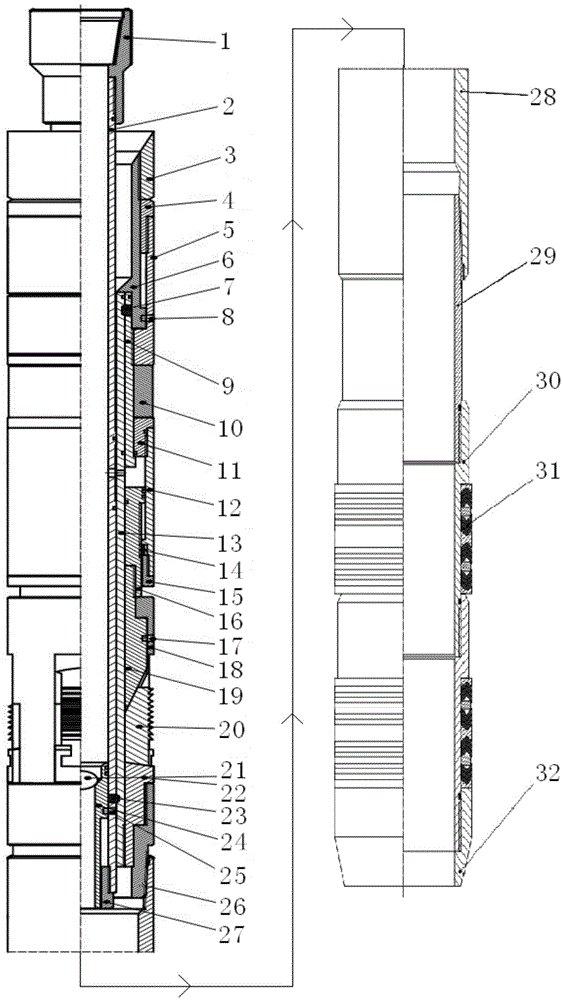

Single-ball-type hydraulic drilling liner hanger

ActiveCN108060907AGuaranteed success rateProtection from damageSealing/packingHydraulic cylinderPressure transmission

The invention discloses a single-ball-type hydraulic drilling liner hanger. The single-ball-type hydraulic drilling liner hanger comprises an external casing pipe, at least two sit hanging mechanisms,a blocking mechanism, a plurality of hydraulic transmission mechanisms, a first pitching pressure building mechanism and a second pitching pressure building mechanism, wherein the at least two sit hang mechanisms and the blocking mechanism are arranged on the outer wall of the external casing pipe, the multiple hydraulic transmission mechanisms are arranged below each sit hanging mechanism and below and above the blocking mechanism, and the first pitching pressure building mechanism and the second pitching pressure building mechanism are arranged on the inner side of the external casing pipe.A plurality of pressure transmission hole sets communicating with an inner cavity of a hydraulic cylinder of each hydraulic transmission mechanism are formed in the side wall of the external casing pipe, and thus the sit hanging mechanisms and the blocking mechanism can be arranged on the well wall in a sit hanging or blocking mode under the effect of hydraulic pressure. The first pitching pressure building mechanism is located on the part, between the sit hanging mechanisms and the blocking mechanism, of the inner wall of the external casing pipe, and the second pitching pressure building mechanism is located on the part, below the blocking mechanism, of the inner wall of the external casing pipe. The device can correspondingly utilize the two pitching pressure building mechanisms to prevent the problems of late sit hanging and blocking or improper timing from happening, the sit hanging effect is improved effectively, and the success rate of sit hanging and effective blocking are ensured.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A Fracturing Window Isolation Tool and Technology for a Branch Well

ActiveCN104373073BEffective containmentAvoid enteringFluid removalSealing/packingMain branchProcess window

The invention relates to the technical field of oil field branch wells, in particular to a branch well fracturing window sealing tool and technology. The upper end of the feeding pipe of the device is connected with the feeding pipe joint, and the outer side of the feeding pipe is fitted with an inner center pipe and locked by a locking block. The ball seat is connected to the inner wall of the feeding pipe through a locking pin and blocks the locking block. The inner wall of the bottom end of the feeding pipe is connected with a stopper, the outer side of the inner central tube is fitted with an outer central tube and locked by a locking block, the unsealed outer cylinder is connected to the outside of the outer central tube, and the return inserting cylinder is connected to the inner wall of the unsealed outer cylinder by an unsealed pin . The invention realizes the effective isolation of the main wellbore at the upper part of the window and the unfractured branch wellbore at the lower part, and prevents the well control risk caused by the fluid in the branch wellbore entering the main wellbore.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Oil well cement paste and horizontal well technical casing cementing process

The invention discloses oil well cement paste. The oil well cement paste comprises 1 part of oil well cement, 1.1 to 1.35 parts of saturated salt water, 0.018 to 0.03 part of oil well cement expandingagent and 0.002 to 0.003 part of coagulation accelerator. The horizontal well intermediate casing cementing process comprises the following steps that: A) a horizontal well is established, and an intermediate casing is installed into the borehole of the horizontal well until reaching the horizontal section of the horizontal well; B) oil well cement paste is injected into an annulus between the intermediate casing and the well wall of the horizontal well, and then first displacement operation is performed so as to make the oil well cement paste enter a salt bed top plate and the annulus between the intermediate casing below the salt bed top plate and the well wall, and part of the oil well cement paste is left in the intermediate casing; when the thixotropy of the cement paste is enhancedbefore the initial setting of the cement paste, second-time displacement operation is conducted, when the initial setting thixotropy of the cement paste is worst, third-time displacement operation isconducted, a part of the oil well cement paste left in the intermediate casing is ejected out every time, and a part of the cement paste is left in the intermediate casing; and C) solidification is performed. According to the method, gaps between the cement and the borehole can be greatly reduced, pressure maintaining and coagulation promoting can be completed, a light salt brine channel can be effectively sealed and isolated, well cementation quality is good, the water permeation of the salt bed top plate is prevented, and the brine concentration and the production life of a well group are guaranteed.

Owner:四川盐业地质钻井大队

Arrangement for fixing wire harness onto covers of electric connection box and electric connection box thereof

InactiveCN100428600CEffective containmentPrevent accidental openingElectrical apparatus contructional detailsElectrical connectionElectrical bonding

The invention provides a cover arranged at the main body of an electrical connection box, which comprises a wall part for holding a first wiring harness and a second wiring harness connected with the electrical connection box. A first holding part is extended from the wall part in a derivative direction along the first wiring harness; the first wiring harness can be maintained outside of a holding component. The second wiring harness can be maintained at the wall part by a second holding part.

Owner:YAZAKI CORP

A thermal recovery well forced segmented injection-production string and its method

ActiveCN110094191BReduce replacementReduce cold damageFlexible member pumpsFluid removalThermodynamicsHorizontal wells

The invention discloses a forced segmented injection-production pipe string and a method for a thermal recovery well. The injection-production pipe string includes a steam injection and oil production integrated pump sequentially connected to the oil pipe from top to bottom, a self-regulating uniform steam injection device, a self-regulating The oil well liquid inlet device and the steam injection pipe string plug, the self-adjusting uniform steam injection device and the self-adjusting oil well liquid inlet device are taken as a group, and the number is set in at least two groups, and the self-adjusting uniform steam injection device, self-adjusting The oil well liquid inlet device corresponds to the same section of injection-production layer at the same time, and the oil pipe is also connected with a steam injection expansion packer, which is sealed on the inner wall of the thermochemical sealing rubber plug in the casing. The number of vapor expansion packers and thermochemical sealing plugs is consistent and at least three are set, and each thermochemical sealing plug can force the injection-production layer to be segmented. It can overcome problems such as uneven production, steam channeling and high water cut caused by heterogeneity in the process of steam injection and production in horizontal wells, thereby improving the overall recovery rate and economic benefits of the oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

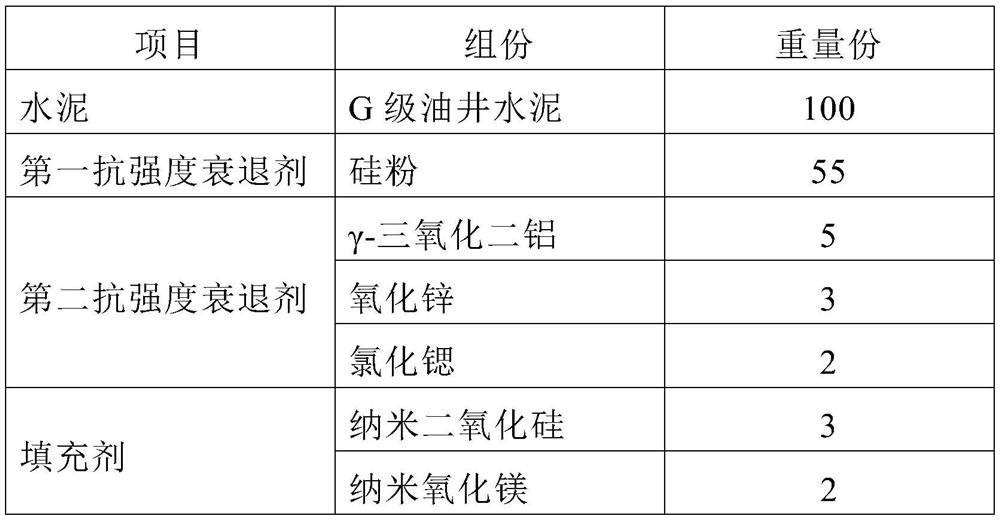

A cementing cement for ultra-high temperature deep wells and its preparation method and application

ActiveCN110563428BExtend your lifeImprove thermal stabilityDrilling compositionZinc hydroxideAluminium hydroxide

Owner:PETROCHINA CO LTD

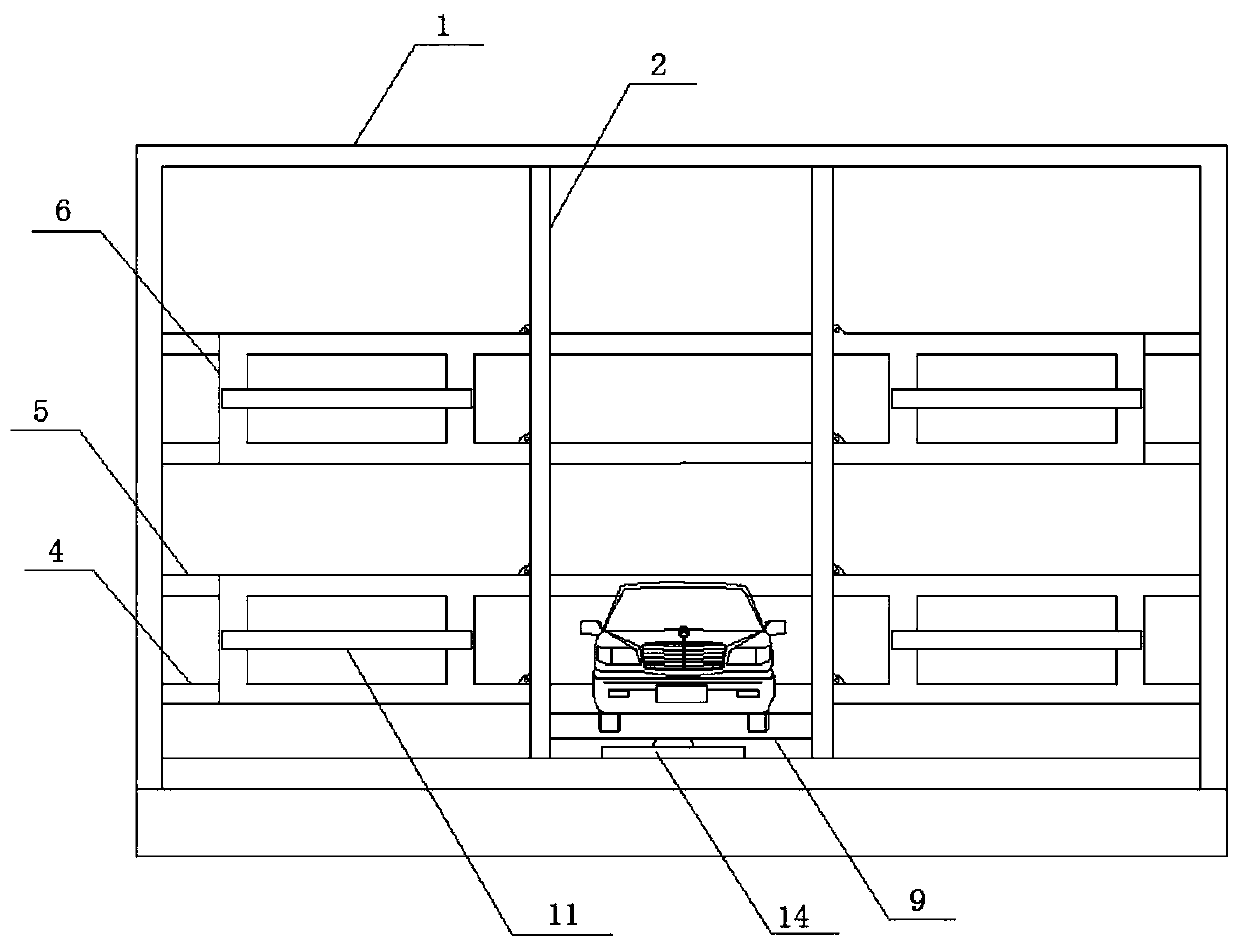

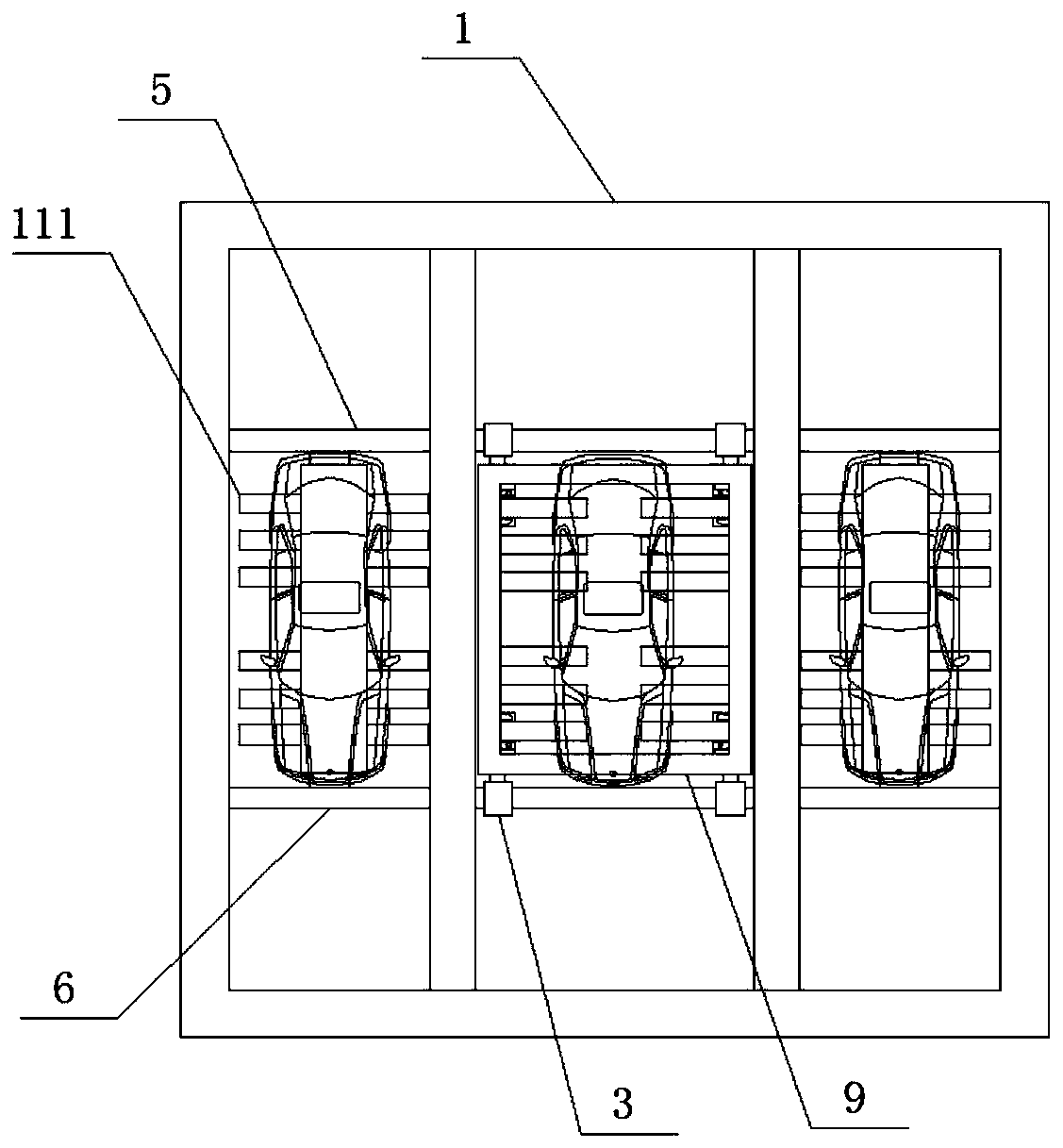

A convenient double-deck lift and traverse parking device with enhanced fixing effect

The invention discloses convenient dual-layer lifting-and-translation parking equipment with a reinforced fixing effect. The convenient dual-layer lifting-and-translation parking equipment comprises aparking garage main body, symmetric fixed rods are arranged at the two sides of the parking garage main body, a first vehicle carrying plate vertical slide rod is arranged at one side of each fixed rod, the two ends of each first vehicle carrying plate vertical slide rod are fixedly connected with the parking garage main body, a vehicle carrying plate return slide rod is arranged at one side of the bottom of each first vehicle carrying plate vertical slide rod, and a vehicle carrying plate parking slide rod is arranged at the top of each vehicle carrying plate return slide rod and is parked at one side of the corresponding first vehicle carrying plate vertical slide rod. Through the fixed rods which are arranged on the side faces, it is prevented that steel balls are installed in the front portion for stabilizing, and parking is facilitated; meanwhile, through the arrangement of a photoelectric detection device, full automation of a mobile vehicle carrying plate in the motion processis achieved, and errors brought by manual operation is reduced; meanwhile, the convenient dual-layer lifting-and-translation parking equipment is simple in structure, convenient to operate, and safe to use, and effective accommodation of the space usage of a garage is achieved.

Owner:ANHUI LOCKU INTELLIGENT PARKING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com