Oil well cement paste and horizontal well technical casing cementing process

A technology of oil well cement slurry and technical casing, which is applied in the field of oil well cement slurry and horizontal well technical casing cementing technology, and can solve the problems that the brine concentration cannot be guaranteed, the cementing quality is poor, and the plugging effect is small, etc. To achieve the effect of ensuring brine concentration and production life, good cementing quality and reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A kind of oil well cement slurry of this embodiment comprises 1 part of G grade oil well cement, 1.2 parts of saturated brine, 0.02 part of oil well cement expansion agent and 0.002 part of coagulant, according to the ring between the casing and the well wall Empty size, the quality of 1 part of G grade oil well cement is 10 tons, the quality of corresponding 1.2 parts of saturated brine is 12 tons, the quality of 0.02 part of oil well cement expansion agent is 200 kg, and the quality of 0.002 part of coagulant is 20 kg, the oil well cement expansion agent uses montmorillonite, the coagulation accelerator uses calcium chloride, and mixes evenly.

Embodiment 2

[0016] An oil well cement slurry of this embodiment includes 1 part of G grade oil well cement, 1.1 part of saturated brine, 0.018 part of oil well cement expansion agent and 0.0025 part of coagulant. Empty size, the quality of 1 part of G grade oil well cement is 8 tons, the quality of corresponding 1.1 parts of saturated brine is 8.8 tons, the quality of 0.018 part of oil well cement expansion agent is 144 kg, and the quality of 0.0025 part of coagulant is 20 kg, the oil well cement expansion agent uses montmorillonite, the coagulation accelerator uses calcium formate, and mixes evenly.

Embodiment 3

[0018] A kind of oil well cement slurry of this embodiment comprises 1 part of G grade oil well cement, 1.35 parts of saturated brine, 0.03 part of oil well cement expansion agent and 0.003 part of coagulant, according to the ring between casing and well wall Empty size, the quality of 1 part of G grade oil well cement is 20 tons, the quality of corresponding 1.35 parts of saturated brine is 27 tons, the quality of 0.03 part of oil well cement expansion agent is 600 kg, and the quality of 0.003 part of coagulant is 60 kg, the oil well cement expansion agent uses montmorillonite, the coagulation accelerator uses calcium formate, and mixes evenly.

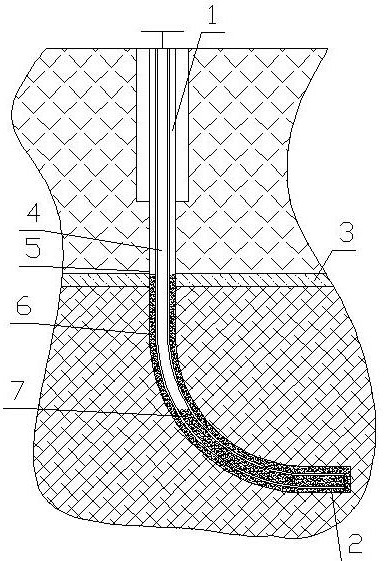

[0019] like figure 1 As shown, the horizontal well technical casing cementing process using any of the above three oil well cement slurries includes the following steps: A) establish a horizontal well 1, and run the technical casing 4 into the wellbore until the level of the horizontal well 1 Section 2, the horizontal section 2 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com