A step-by-step rubber cup packer that can be dragged under pressure and its application method

A leather cup packer and dragging technology under pressure, applied in the directions of sealing/isolation, earthwork drilling, wellbore/well components, etc. The effect of reducing the probability of wear and meeting the requirements of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

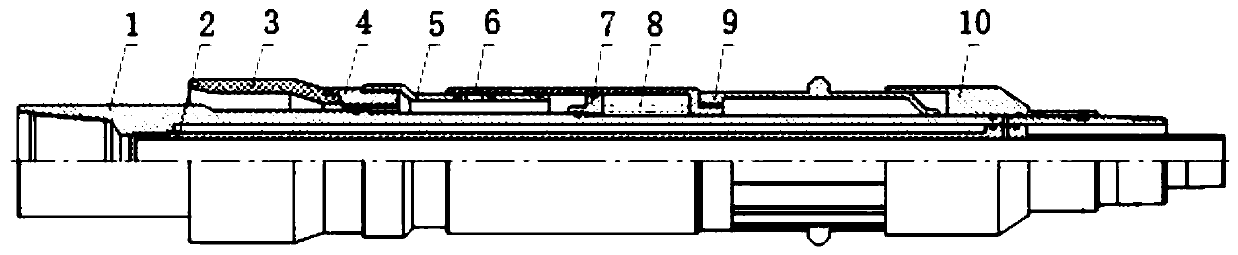

[0029] refer to figure 1 , the pressure-dragging stepping cup packer of the present invention includes a hollow main shaft 1 and a mandrel 2 installed inside the main shaft 1 for pressure transmission, and the outer diameter of the main shaft 1 is threaded The cup seat 4 and the cup 3 directly vulcanized on the cup seat 4, the rear part of the cup seat 4 is connected with the pressure relief nipple 5, and the seal seat 7 is installed at the rear of the pressure relief nipple 5 And the return spring 8, the outer side of the sealing seat 7 and the return spring 8 is equipped with a sliding sleeve 6 sealingly matched with the pressure relief joint 5, the sliding sleeve 6 is connected to the elastic claw 9, and the elastic claw 9 The pressure sleeve 10 connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com