Naked eye packer

A packer and open hole technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve problems such as reservoir isolation, no protection measures, and reduced pressure bearing capacity, and achieve Increased pressure bearing capacity, ingenious structural design, and high pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

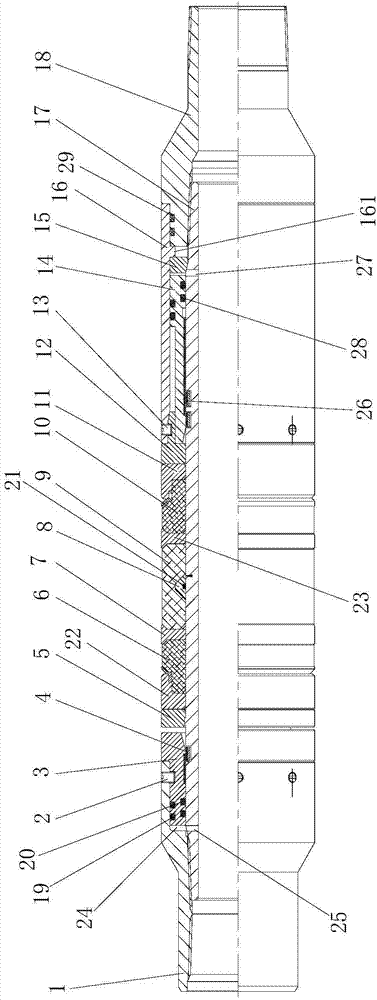

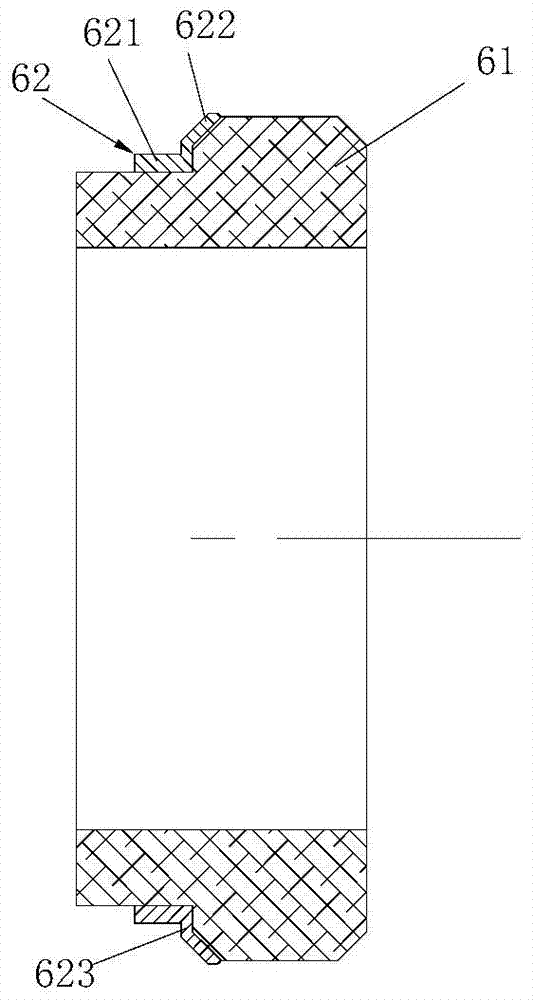

[0022] figure 1 It is a half-sectional view of the structure of the open hole packer of the present invention. figure 2 It is a schematic structural diagram of the first auxiliary rubber cartridge in the present invention. Such as figure 1 with figure 2 As shown, the open hole packer includes: a mandrel 17 with an axial through hole, one end of the mandrel 17 is connected to the first joint 1, the other end of the mandrel 17 is connected to the second joint 18, and the first joint 18 is connected to the mandrel 17. 1 to the second joint 18 are sequentially socketed with the left shear ring 3, the limit ring 5, the first auxiliary rubber cylinder pressure ring 22, the first auxiliary rubber cylinder 6, the first spacer ring 7, the main rubber cylinder 9, the second spacer Ring 23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com