Turbulence self-cleaning reduced pressure pipeline exchange water heater

A water heater and self-cleaning technology, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of small range, increased stress of heat exchangers, and easy formation of scale, so as to increase the resistance Effect of aging strength, improvement of heat exchange efficiency, and prevention of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

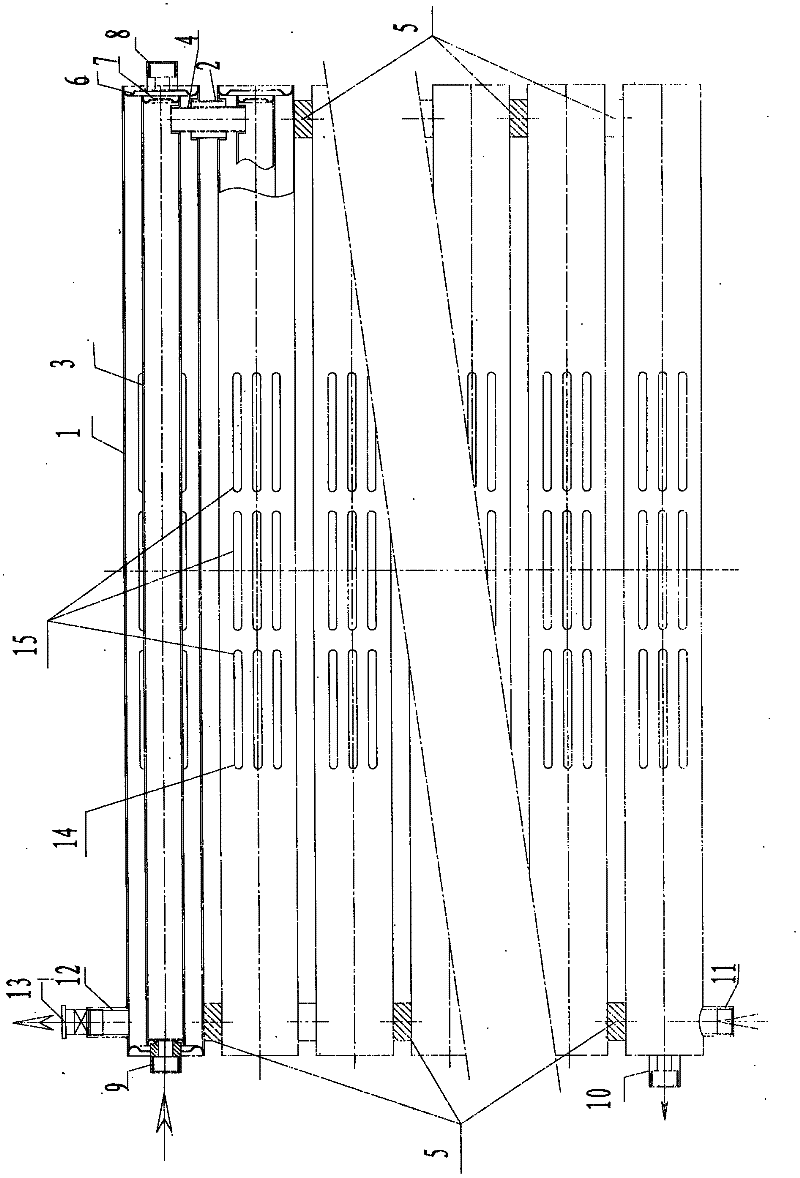

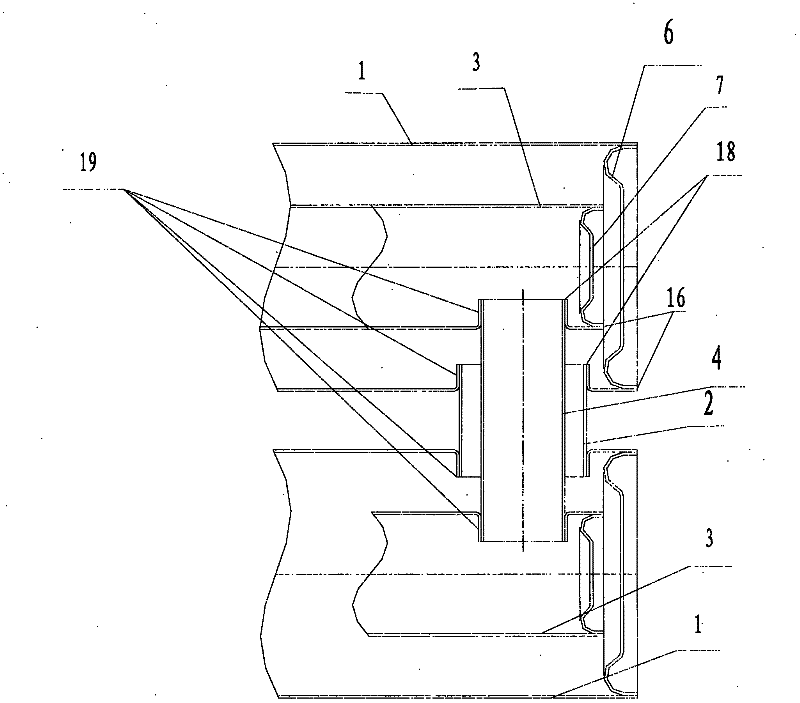

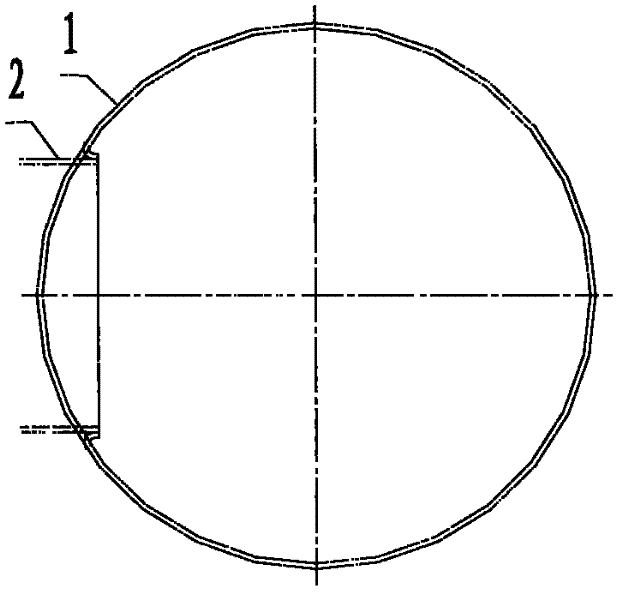

[0016] The present invention as Figure 1 to Figure 4 As shown, the turbulent flow self-cleaning pipe water heater for reducing internal pressure includes several serially connected running water stretching heat pipes 1, heat pipe connecting parts 2, heating pipes 3, inner pipe connecting parts 4, and connecting parts 5 , Inner circular arc head 6, Small inner circular arc head 7, Air release valve 8, Heating inlet inner wire connector 9, Heating outlet inner wire connector 10, Tap water inlet inner wire connector 11, Tap water outlet inner wire Composed of wire joint 12 and pressure relief valve 13, it is characterized in that the two ends of the plurality of tap water stretched heat pipes 1 are connected with the heat pipe connecting piece 2, the inner pipe connecting piece 4, the connecting piece 5, and welded in series to form a rectangular shape. , can be placed horizontally or vertically, and the stretched heat pipe 1, heating pipe 3, connecting piece 2, and inner pipe c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com