Soft sealing fluororubber valve seat and production process thereof

A technology of fluorine rubber valve seat and production process, which is applied in the field of soft sealing fluorine rubber valve seat and its production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

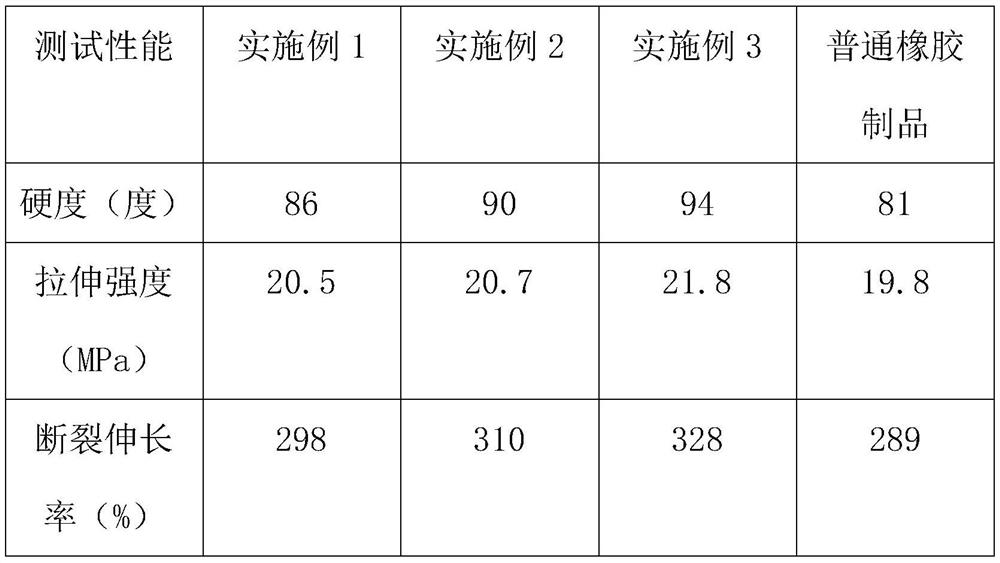

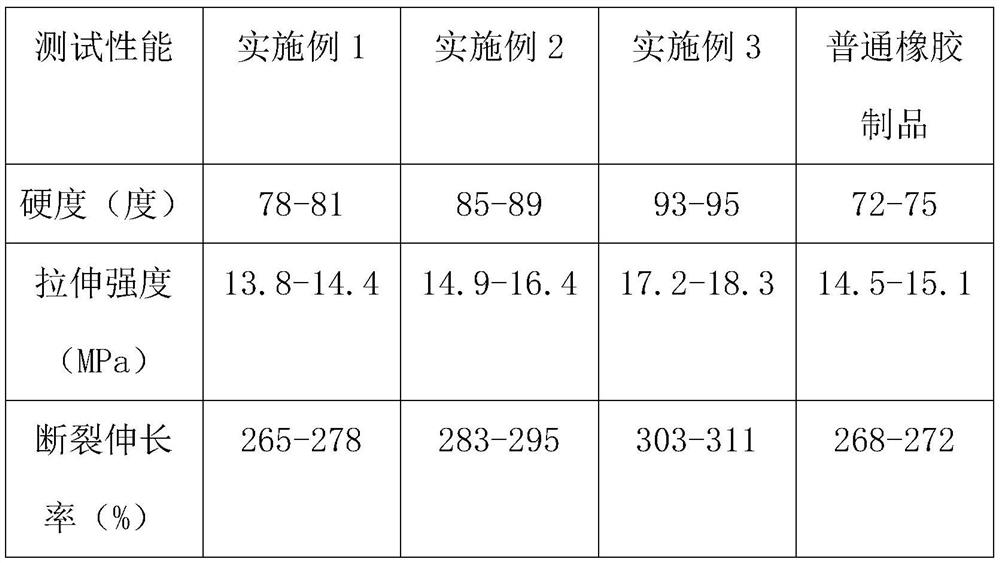

Examples

Embodiment 1

[0056] The formula of the soft-sealed fluorine rubber valve seat includes the following ingredients in parts by weight:

[0057] Type A fluorine rubber 50 parts

[0058] Type B fluorine rubber 25 parts

[0059] 25 parts of powdered carbon fiber

[0060] 5 parts of cross-linking active agent

[0061] Calcium hydroxide 5 parts

[0062] Vulcanizing agent 0.1 parts

[0063] AF vulcanization accelerator 1 part

[0064] 0.1 parts of BPP vulcanization accelerator

[0065] Palm wax 0.1 parts

[0066] Viscosity improver 0.1 part.

Embodiment 2

[0068] The formula of the soft-sealed fluorine rubber valve seat includes the following ingredients in parts by weight: 60 parts of A-type fluorine rubber

[0069] Type B fluorine rubber 32 parts

[0070] 32 parts of powdered carbon fiber

[0071] 13 parts of cross-linking active agent

[0072] Calcium hydroxide 8 parts

[0073] 1.5 parts of vulcanizing agent

[0074] AF vulcanization accelerator 5 parts

[0075] 1.5 parts of BPP vulcanization accelerator

[0076] 0.5 parts of brown wax

[0077] Viscosity improver 0.5 part.

Embodiment 3

[0079] The formula of the soft-sealed fluorine rubber valve seat includes the following ingredients in parts by weight:

[0080] Type A fluorine rubber 70 parts

[0081] Type B fluorine rubber 40 parts

[0082] 40 parts of powdered carbon fiber

[0083] 20 parts of cross-linking active agent

[0084] Calcium hydroxide 10 parts

[0085] 3 parts vulcanizing agent

[0086] AF vulcanization accelerator 10 parts

[0087] 3 parts of BPP vulcanization accelerator

[0088] 1 part brown wax

[0089] Viscosity improver 0.1-1 part.

[0090] In view of the above-mentioned examples 1-3, the present invention also proposes a production process of a soft-sealed fluorine rubber valve seat. According to the formula, each component is added to the internal mixer for mixing for 15-25 minutes. After mixing, open the internal mixing The machine transports the mixed material to the open mill to release the flakes, to be processed;

[0091] Carry out the first vulcanization heating molding,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com