Patents

Literature

53 results about "Activation action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

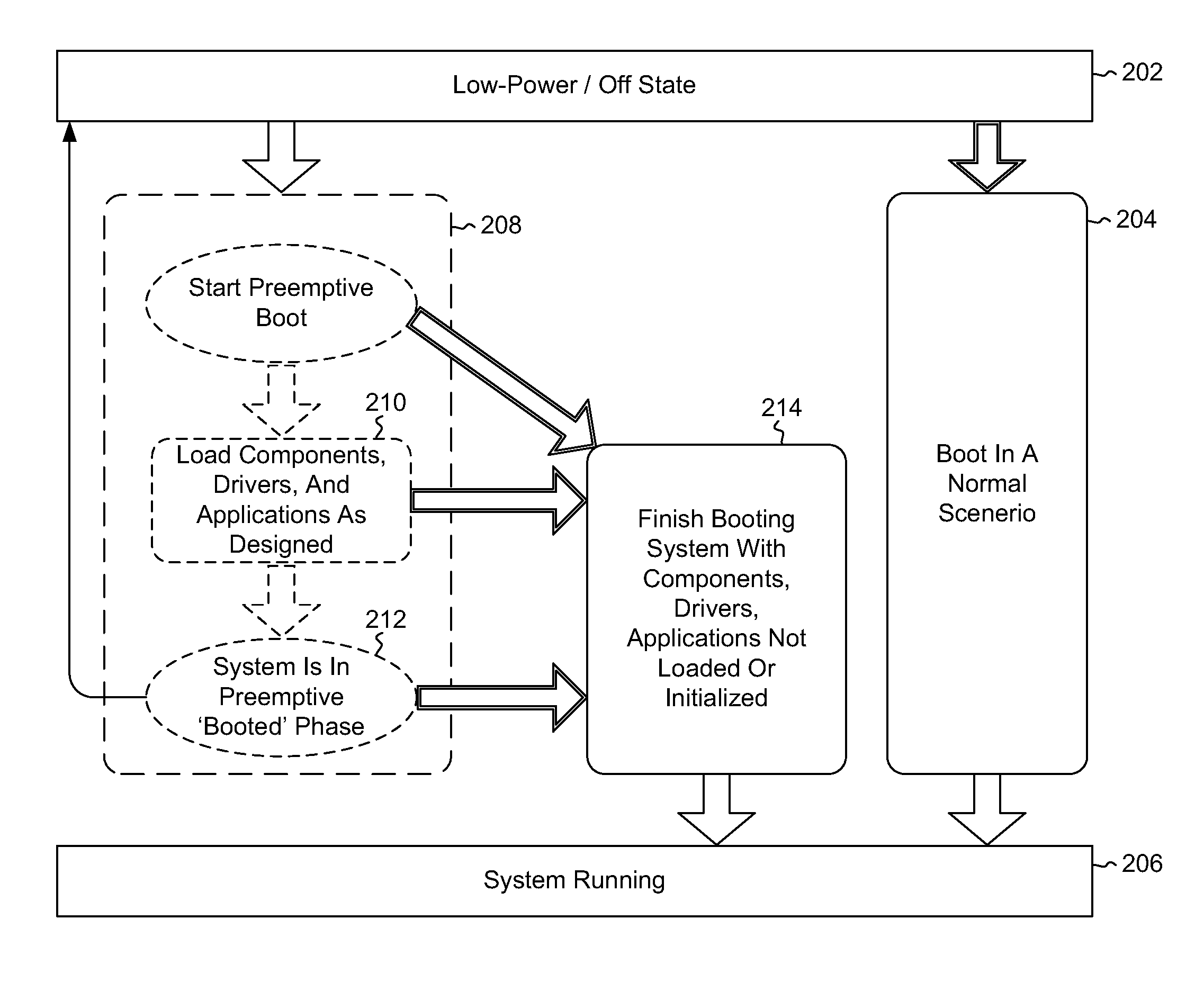

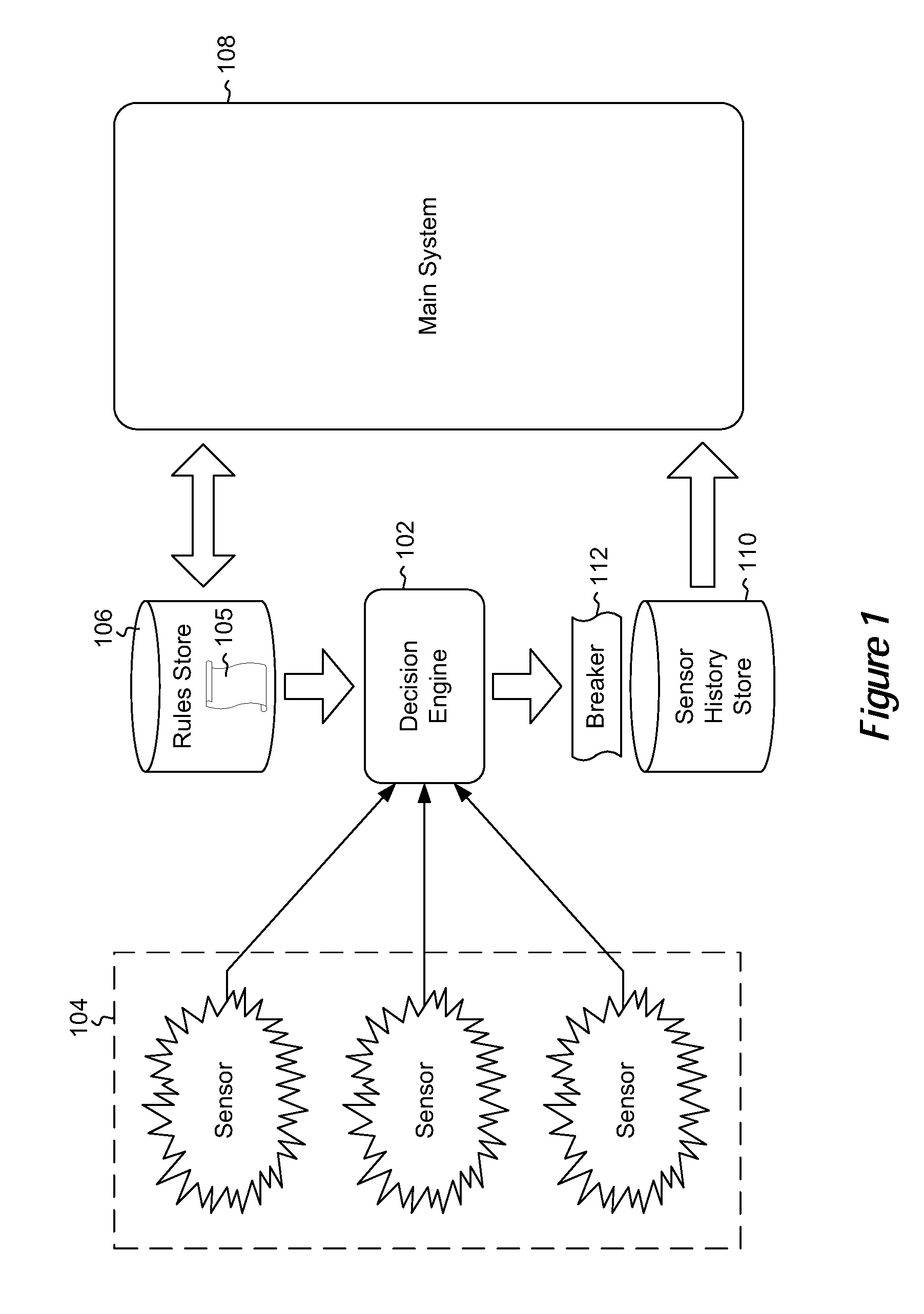

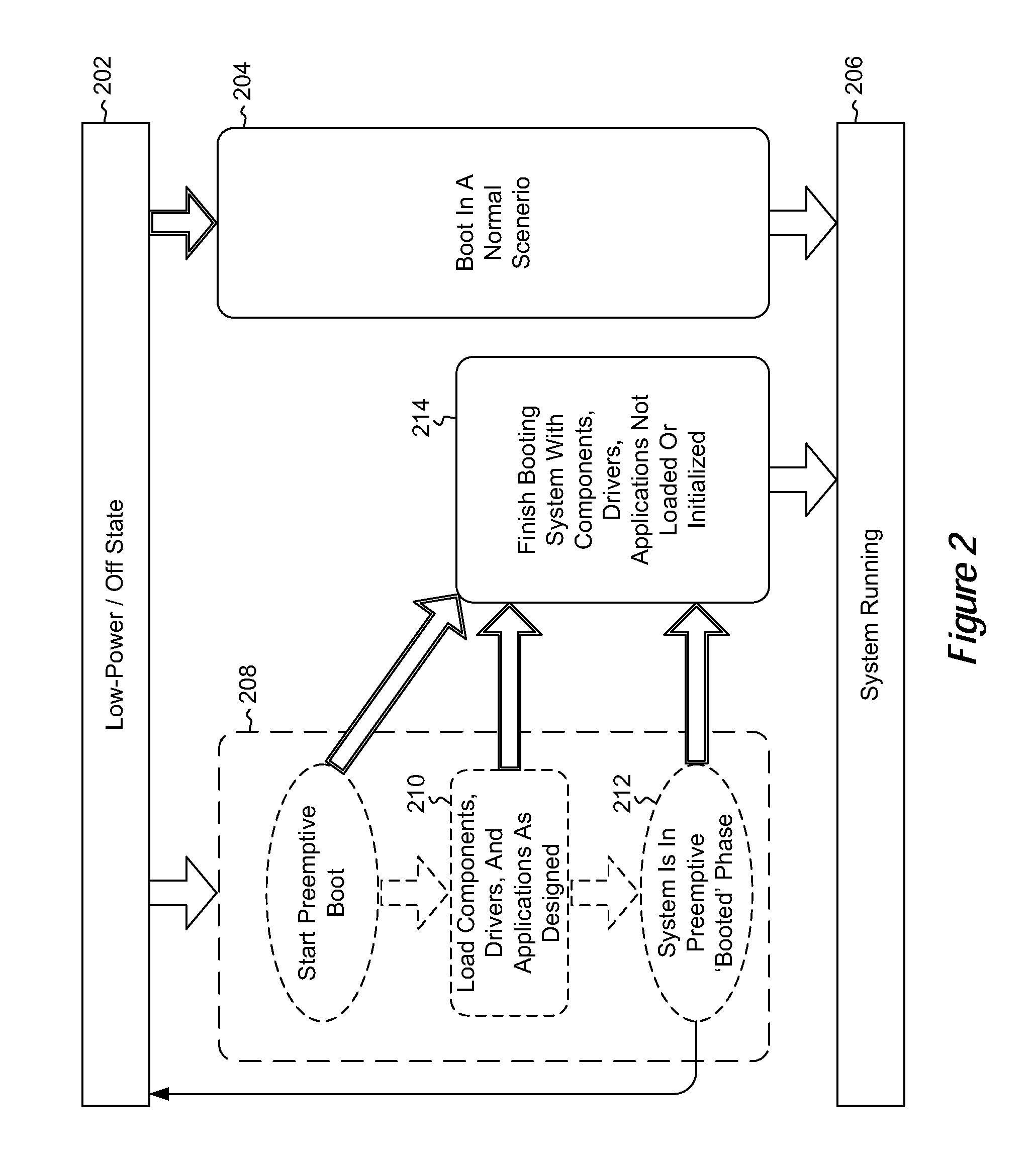

Adaptive sensing for early booting of devices

InactiveUS20130054945A1Well formedDigital computer detailsHardware monitoringActivation actionBiological activation

Automatically performing configuration or activation activities on a device. A method includes collecting at least one of operational or environmental information about a device. The at least one of operational or environmental information about a device is used to determining an anticipated usage of the device. Based on the determined anticipated usage, at least one configuration or activation action is performed putting the device into a normal use state.

Owner:MICROSOFT TECH LICENSING LLC

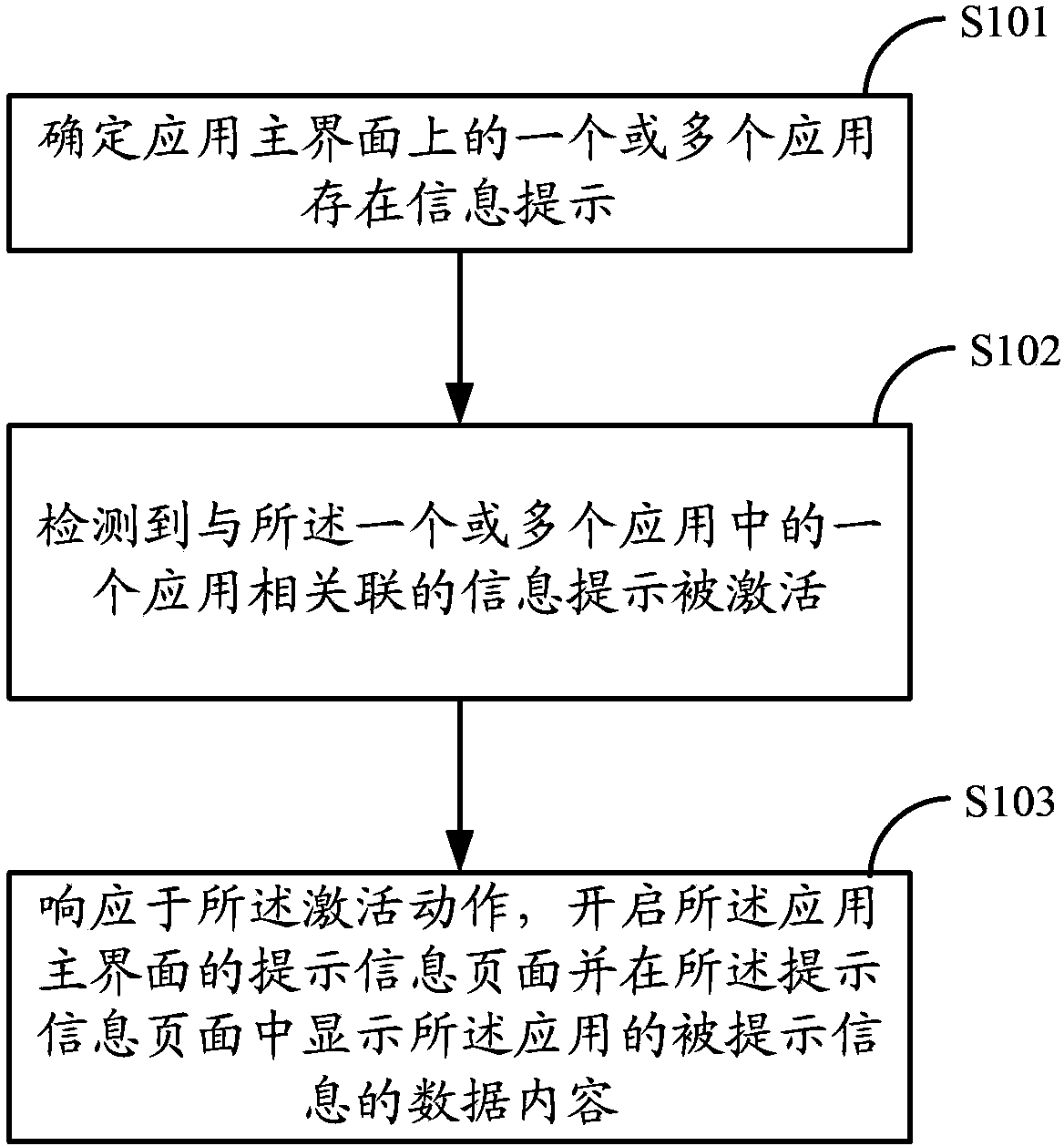

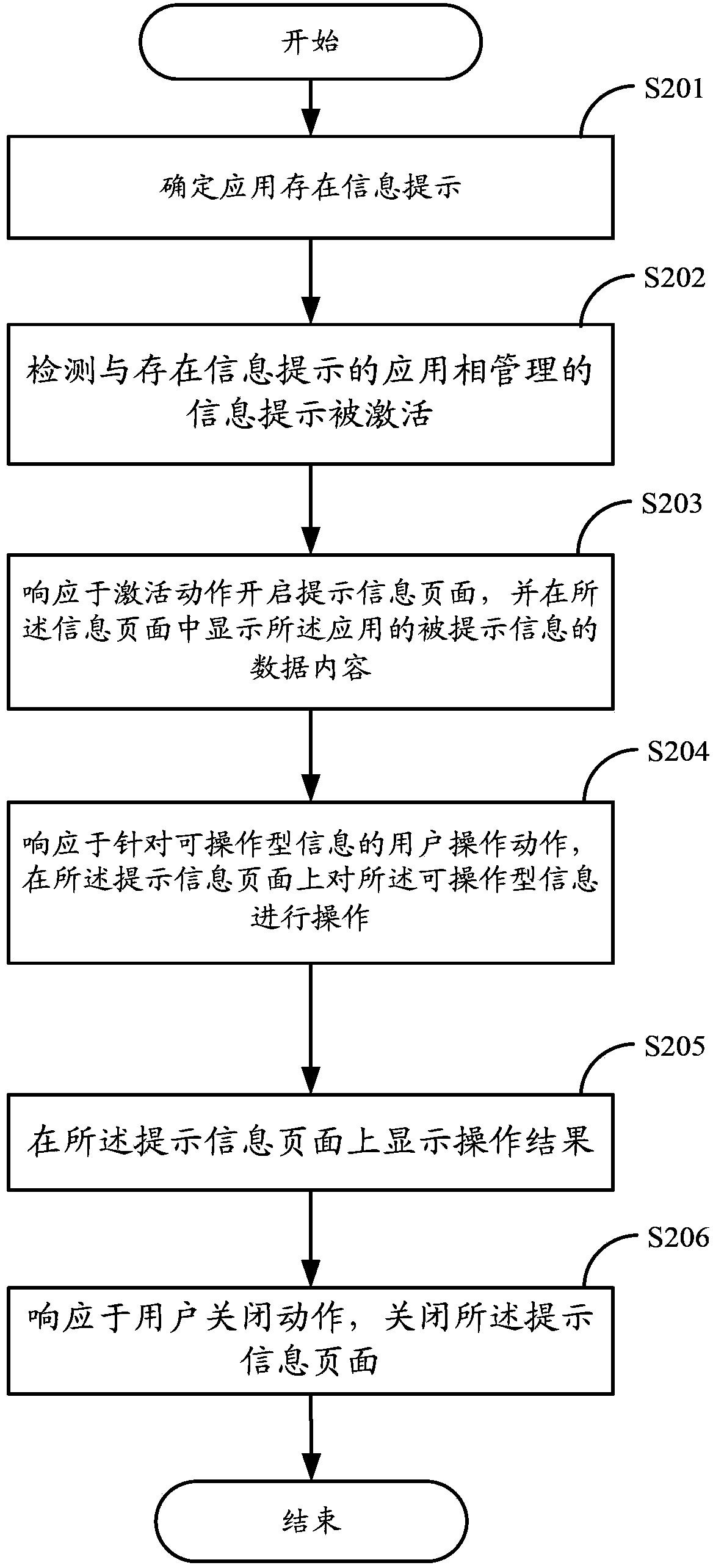

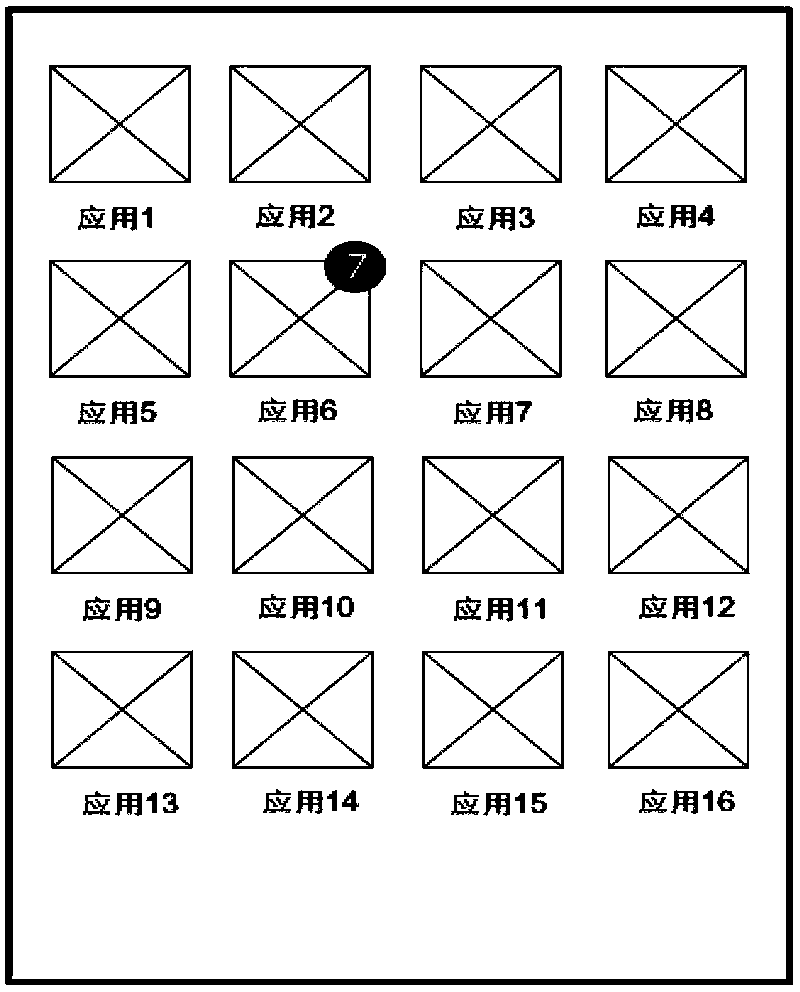

Information processing method and equipment

ActiveCN104077014AEasy to operateImprove experienceInput/output processes for data processingInformation processingActivation action

The invention discloses an information processing method, which comprises the following steps: confirming that information prompts exist in one or a plurality of applications on a main application interface; detecting that an information prompt associated with one application in one or more applications is activated; responding to an activation action; opening a prompted information page of the main application interface; and displaying the data content of the prompted information of the application in the prompted information page. The invention adopts the prompted information page to process information, the prompted information of a corresponding client side / application can be checked and operated without entering the client side / application, so that user operation steps are greatly simplified, and system resources are saved.

Owner:ALIBABA GRP HLDG LTD

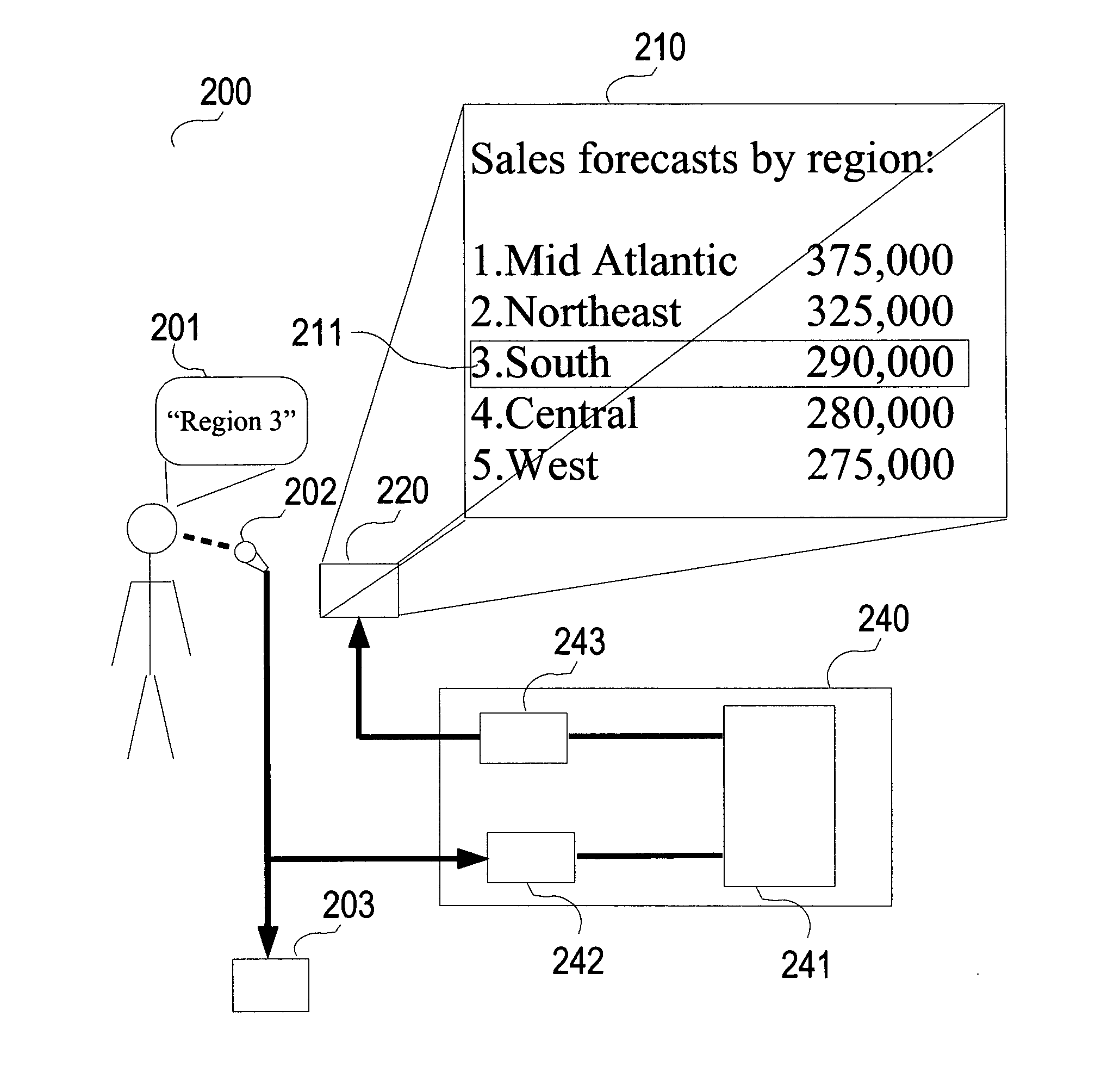

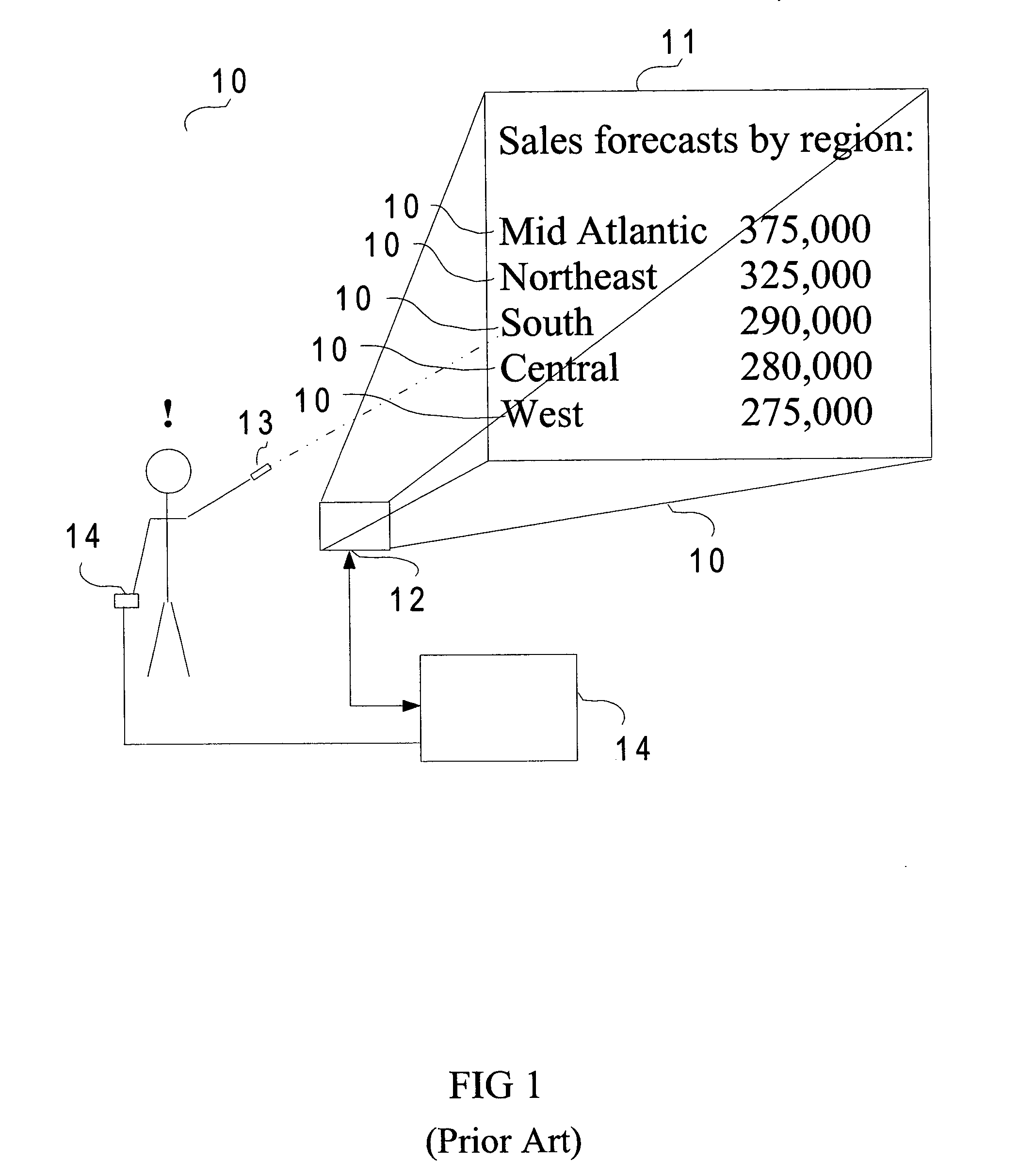

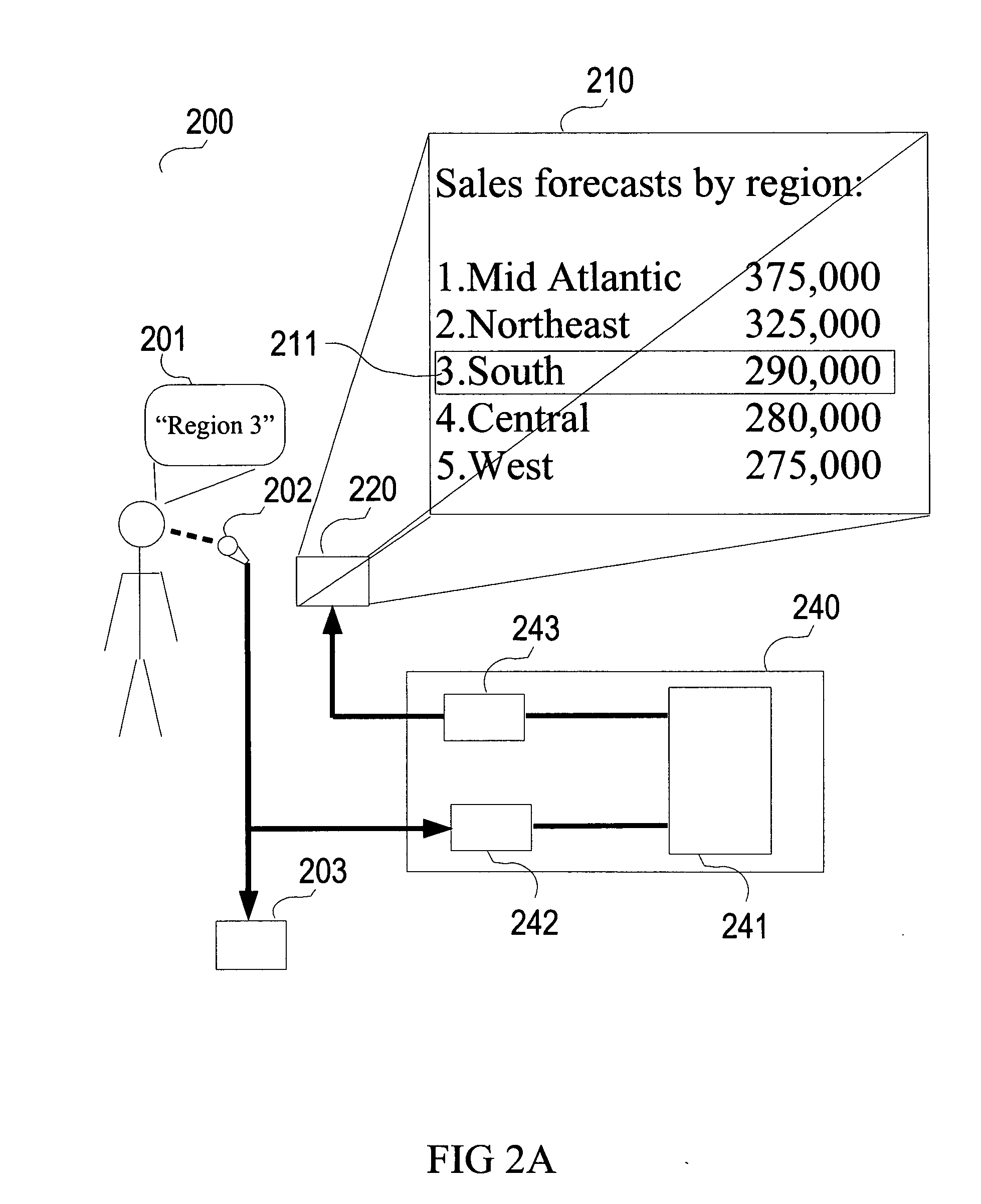

Method and apparatus for highlighting during presentations

A method and apparatus for activating an object for highlighting during a presentation includes recognizing a spoken activation word. An activation link is invoked when the activation word is recognized, and includes an activation action taken. The presentation is prepared by designating a portion for highlighting by association with the activation link, and the activation word. The activation action includes substitution of the designated portion with another object, activating a multimedia object, changing a background color, applying a graphic effect, or the like to the designated portion.

Owner:GATEWAY

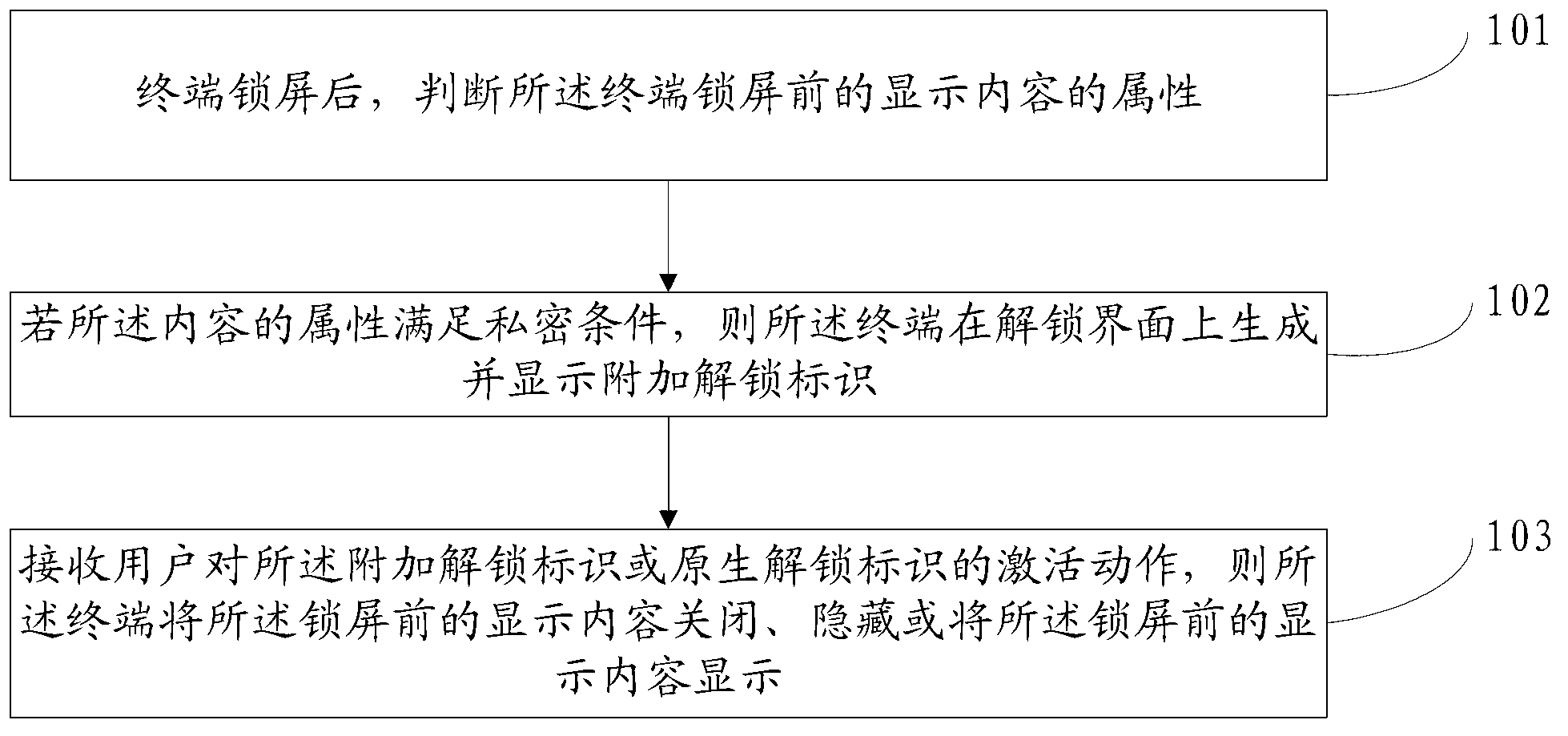

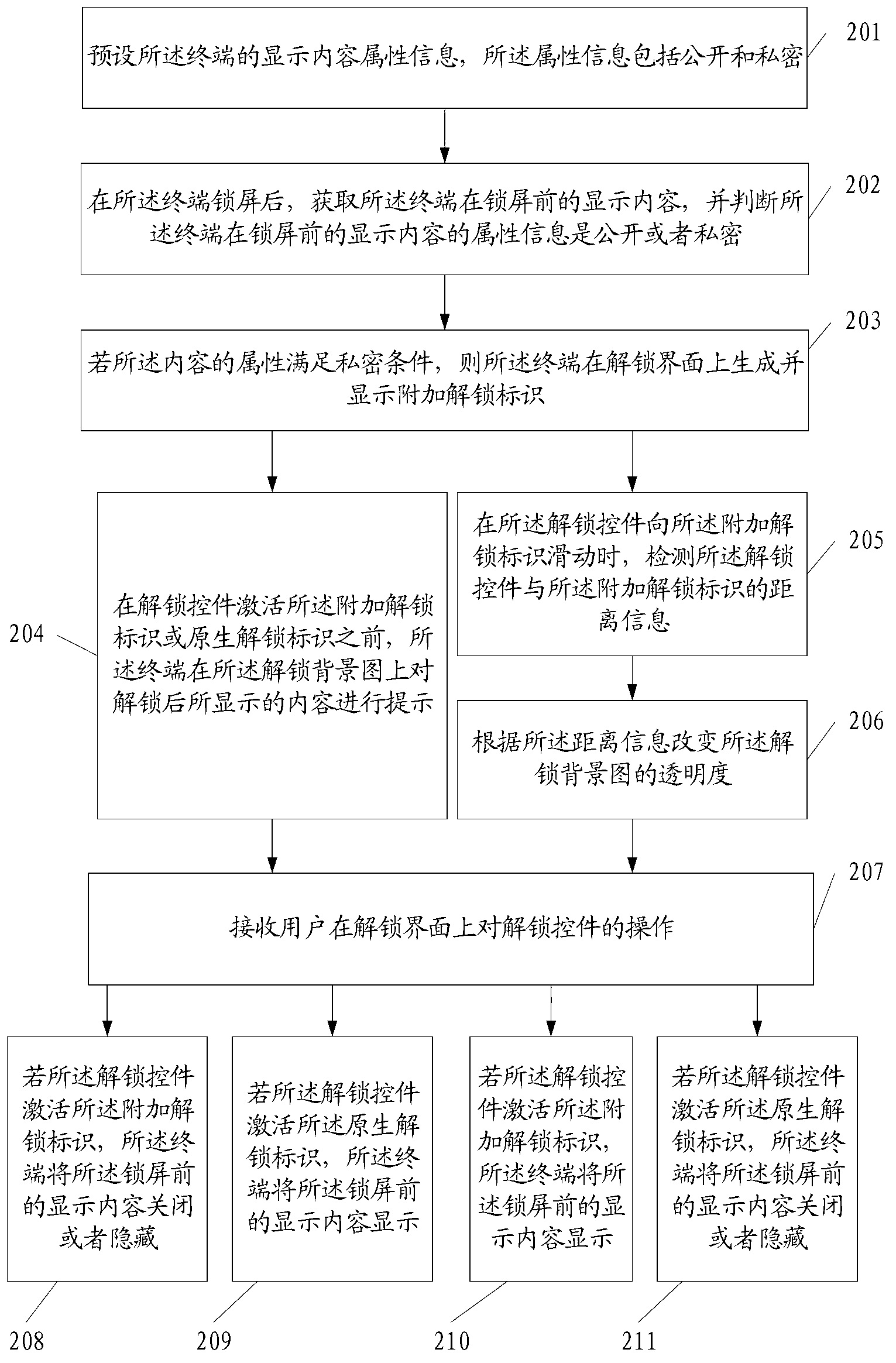

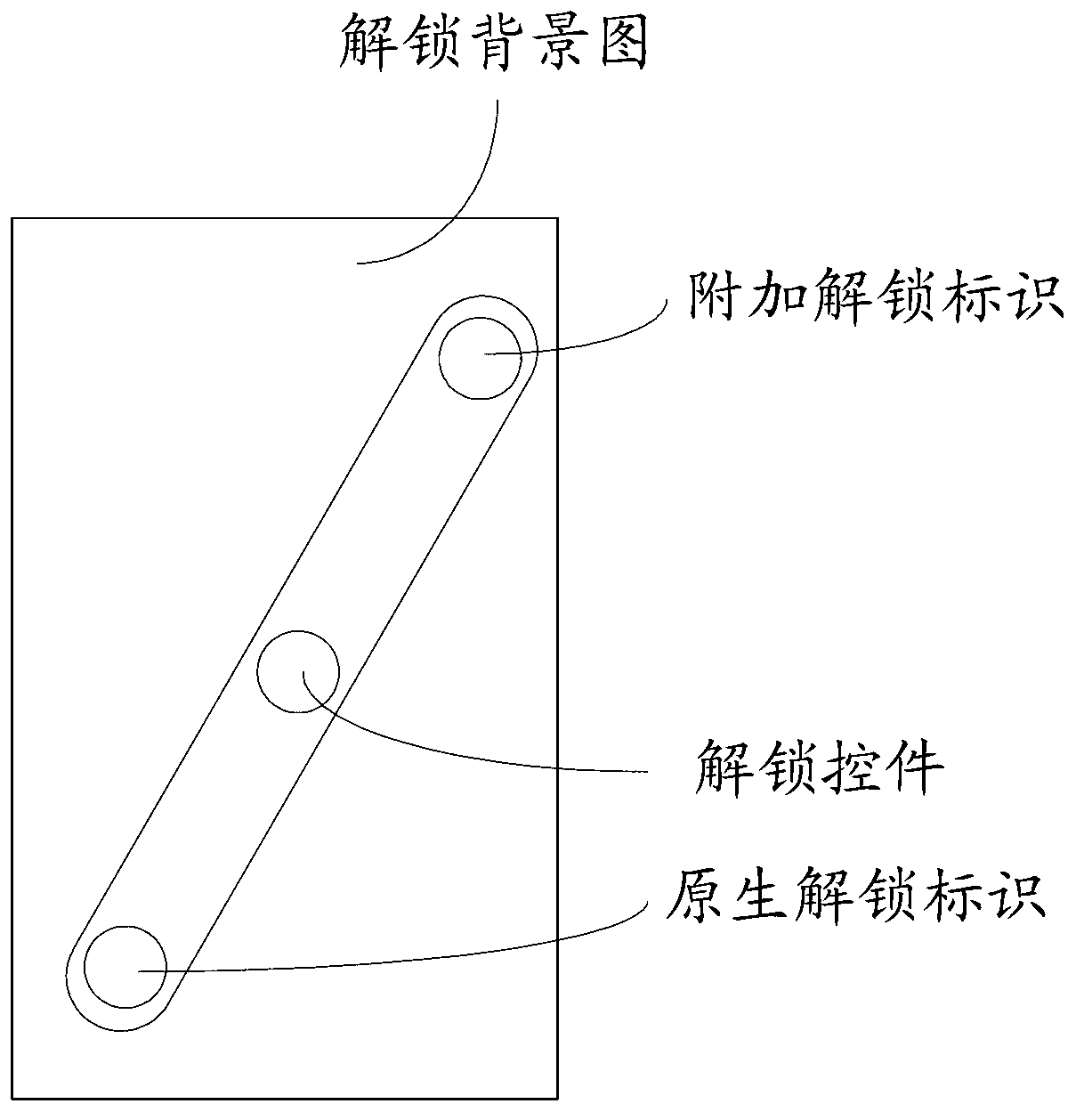

Terminal unlocking method and terminal

InactiveCN103064585AImprove securityInput/output processes for data processingTablet computerActivation action

An embodiment of the invention discloses a terminal unlocking method and a terminal and relates to the technical field of terminals. The terminal unlocking method and the terminal solve the problem that after the terminal is unlocked in the prior art, the terminal continuously displays content before being locked, the display content is easy to divulge, and user's privacy protection of the terminal is poor. The terminal unlocking method includes: after the terminal locks a screen, an attribute of the display content before the terminal locks the screen is judged; if the attribute of the content meets a privacy condition, and the terminal generates and displays an additional unlocking icon on an unlocking interface; and user's activation action on the additional unlocking icon or an original unlocking icon is received, and the terminal closes and hides the display content before the screen is locked or displays the display content before the screen is locked. The terminal unlocking method and the terminal are suitable for terminals of touch screen mobile phones, panel personal computers and the like.

Owner:DONGGUAN YULONG COMM TECH +1

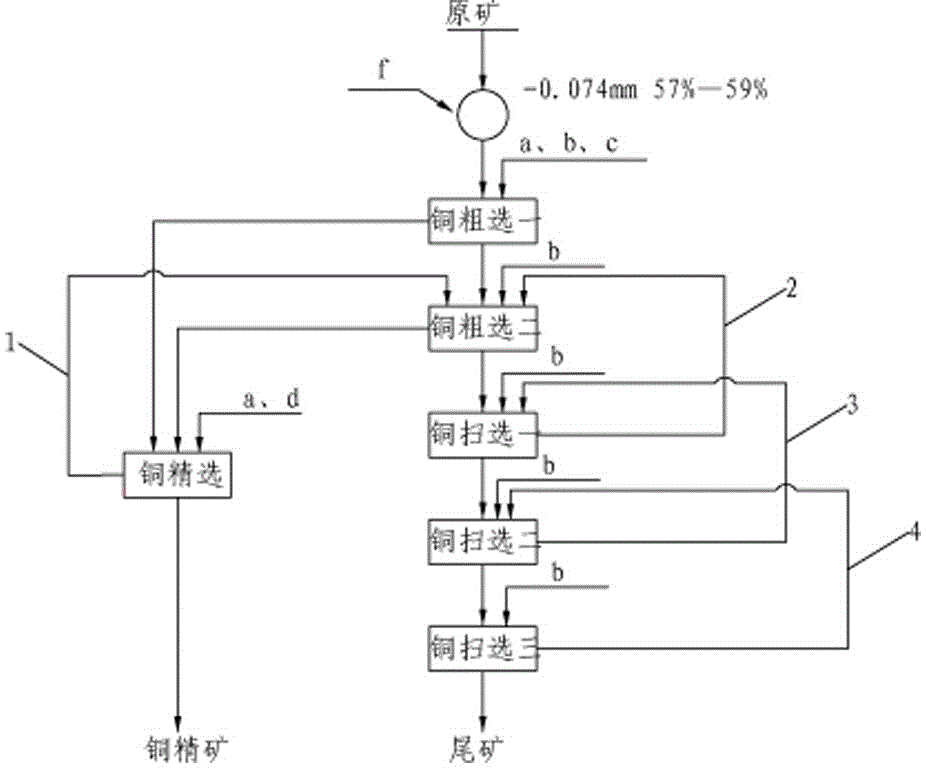

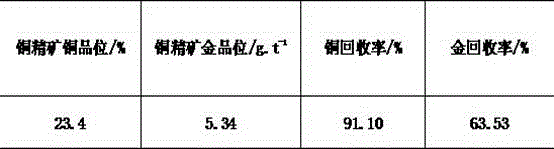

Low-alkalinity flotation separation method for pyrite activated by Cu2+ and chalcocite

The invention discloses a low-alkalinity flotation separation method for pyrite activated by Cu2+ and chalcocite. The method comprises the steps that lime is firstly added in the ore grinding stage so as to keep low alkalinity, a composition of citric acid, sodium sulfite and pyrogallic acid is added as a composite inhibitor in the rougher flotation stage to inhibit the pyrite, copper rougher flotation is achieved under the condition of low alkalinity, then a dispersing agent is added for concentration, inhibition on gangue minerals is intensified, and copper concentrates are obtained. Compared with the traditional manner of inhibiting sulfur through lime, the inhibition effect of the composite inhibitor on the pyrite activated by Cu2+ is remarkable, wherein citric acid is used for removing the activation action of Cu2+ on the pyrite, so that natural floatability of the pyrite is restored, the inhibition effect on the pyrite is intensified through sodium sulfite and pyrogallic acid, meanwhile, the phenomenon of trough moving caused by foam viscosity is eliminated, and the index of the mineral processing technology is improved; and in addition, due to the fact that the flotation pH value is lowered, recycling of associated gold in ore is facilitated.

Owner:ZIJIN MINING GROUP

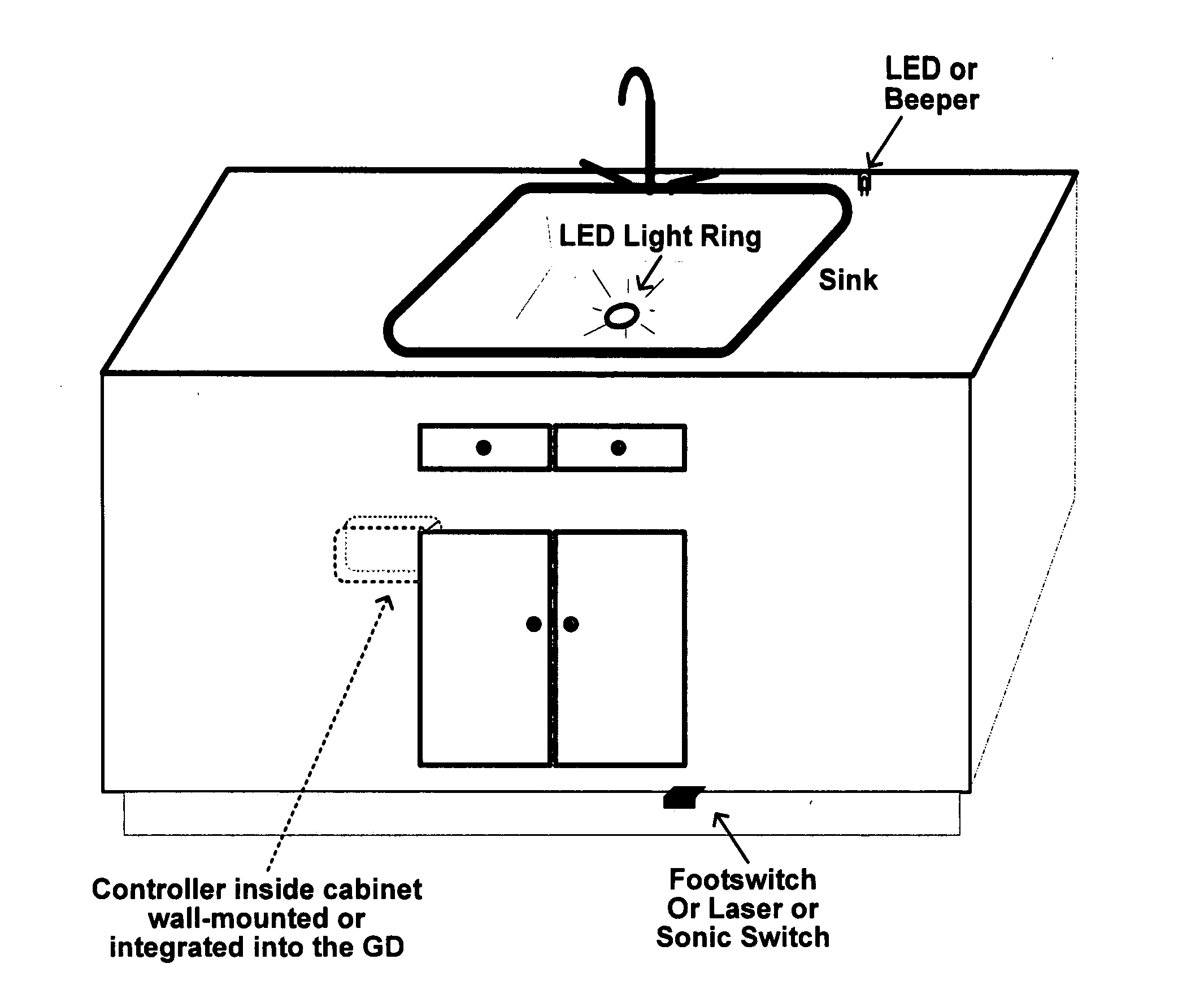

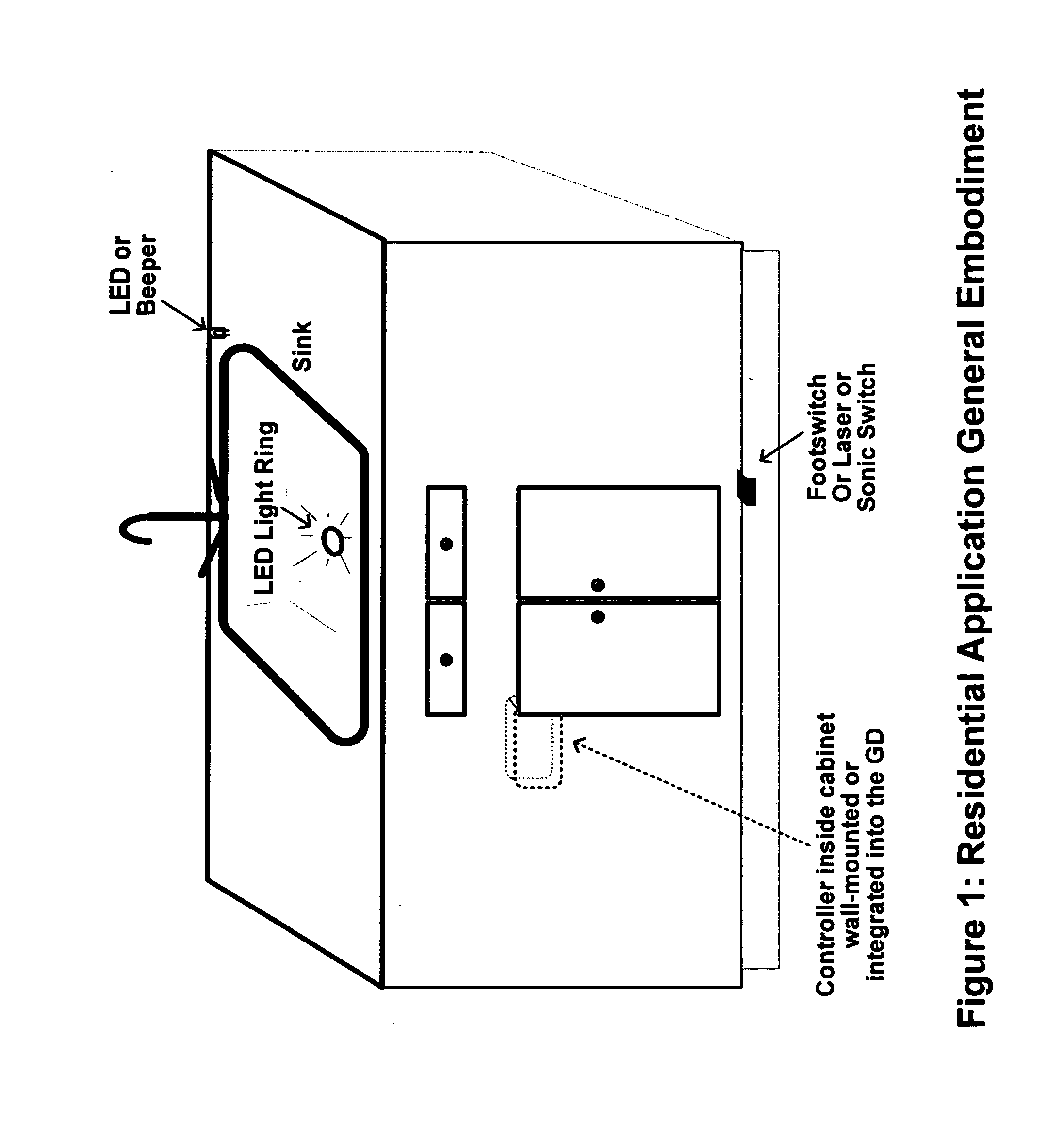

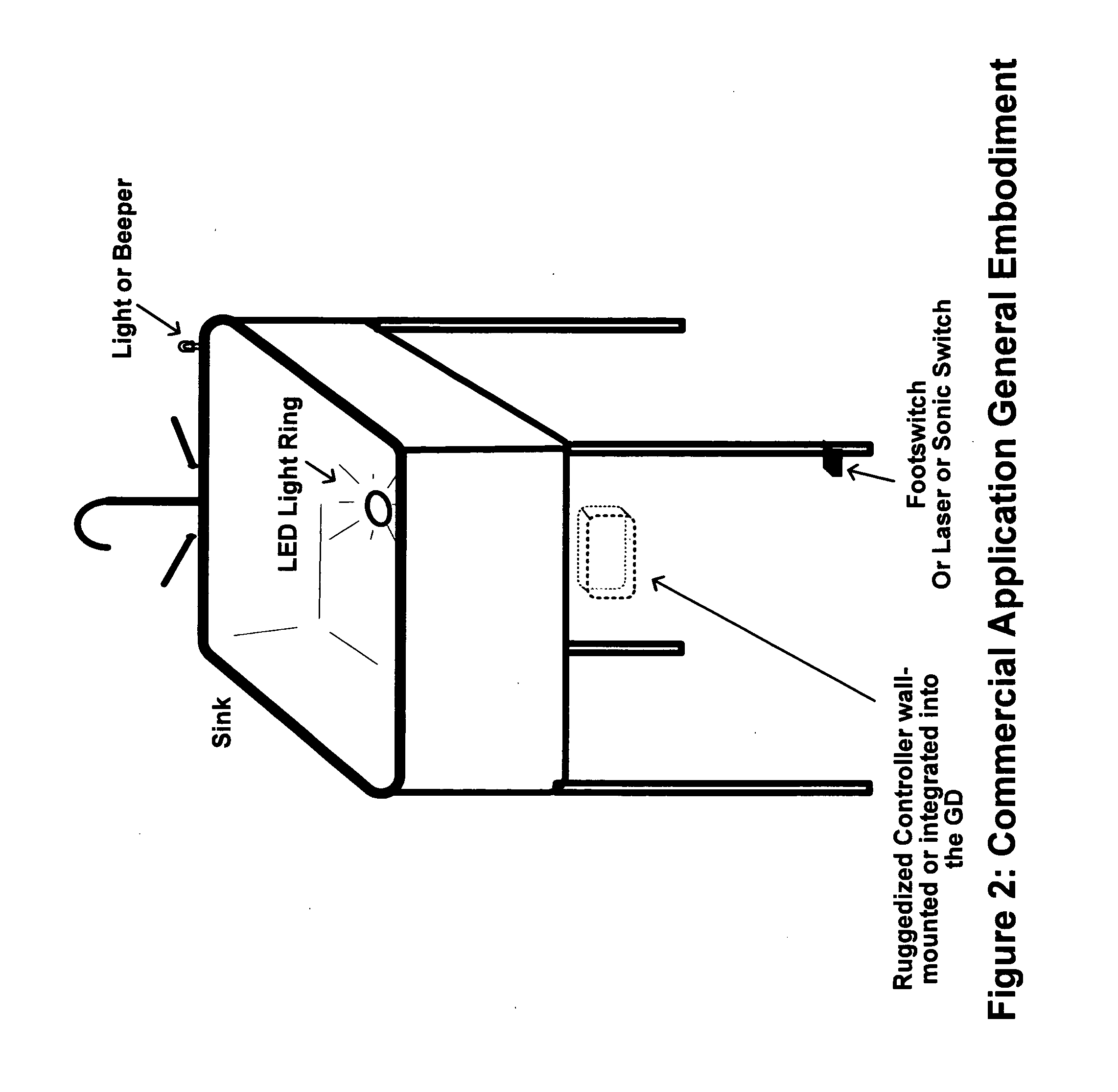

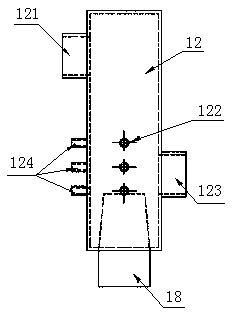

Garbage Disposal Controls System

InactiveUS20150202633A1Ease of use and convenience and safetyLow costControlling membersMechanical apparatusControl systemActivation action

A Garbage Disposal Controls System utility invention that solves the inconvenience problems with using a Garbage Disposal (GD) while also preserving and enhancing safety of the GD for the User. The GD Controls System is applicable to, and provides unique and new functionality to, residential and industrial commercial applications.The invention features are 1) an ability to operate the GD by foot or knee action, 2) an activation delay for safety purposes, delay time being variable and User settable, 3) timed activation of safety devices, 4) a One-Touch capability which controls length of run time, such run time being variable and User settable, 5) automatic water injection during operation, 6) two form factors, which are the Add-On version and the Integrated version.The Garbage Disposal Controls System relies upon micro-controller(or micro-processor) based software that manages sensing and signal interpretation, and carries out sequences of activation actions in timed fashion.

Owner:PERKINS ALAN MARK

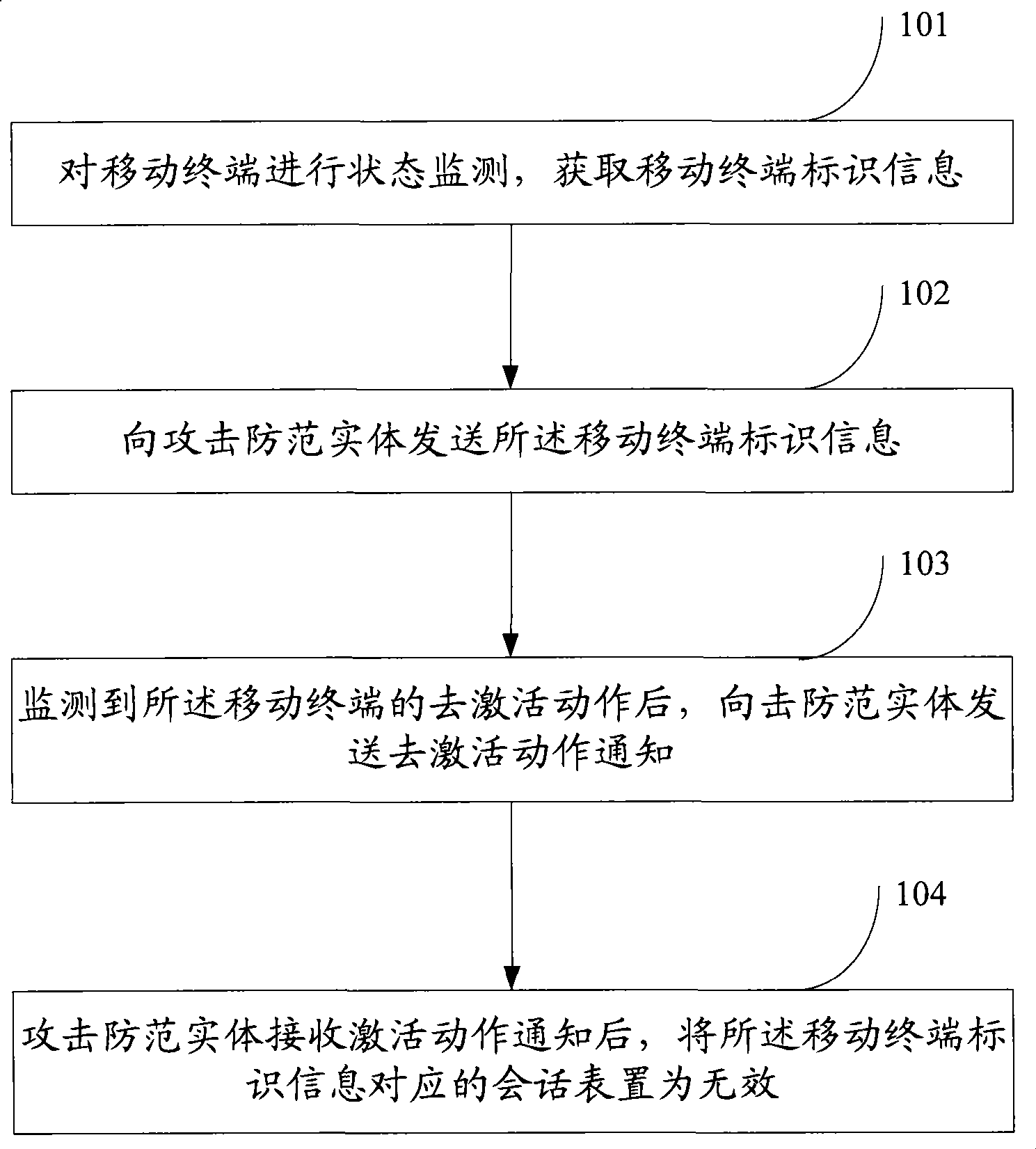

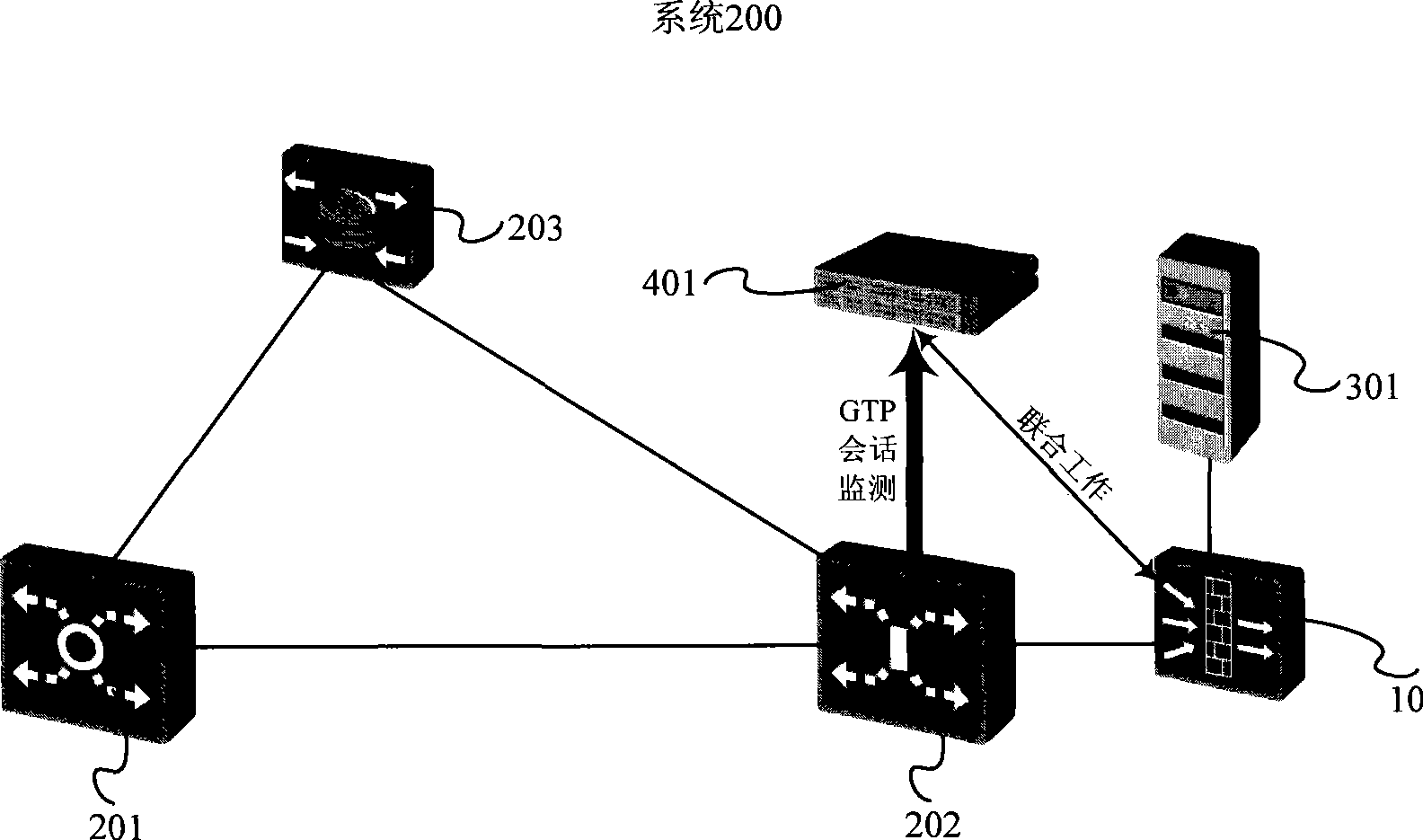

Method and system blocking charging attack

InactiveCN101364906AImplement billing overflow attackEasy to operateRadio/inductive link selection arrangementsData switching networksTelecommunicationsActivation action

The inventive embodiment discloses a method for preventing charging overflow attack. The method comprises the following steps: acquiring the identification information of a mobile station; transmitting the identification information of the mobile station to an entity for preventing the attack; and transmitting a deactivation action message to the entity after monitoring the deactivation action of the mobile station, wherein the deactivation action message is used for informing the entity of setting the session table corresponding to the identification information of the mobile station to invalid. The invention also discloses a system for preventing charging overflow. The method and the system can prevent charging overflow attack under the condition of less system change.

Owner:HUAWEI DIGITAL TECH (CHENGDU) CO LTD

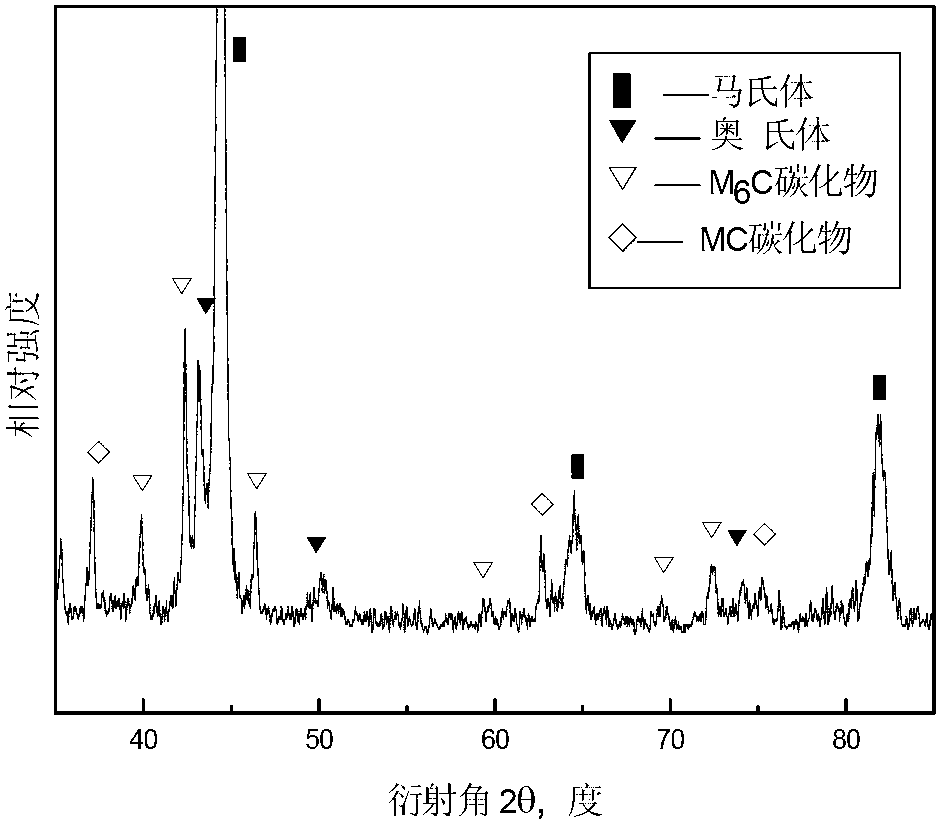

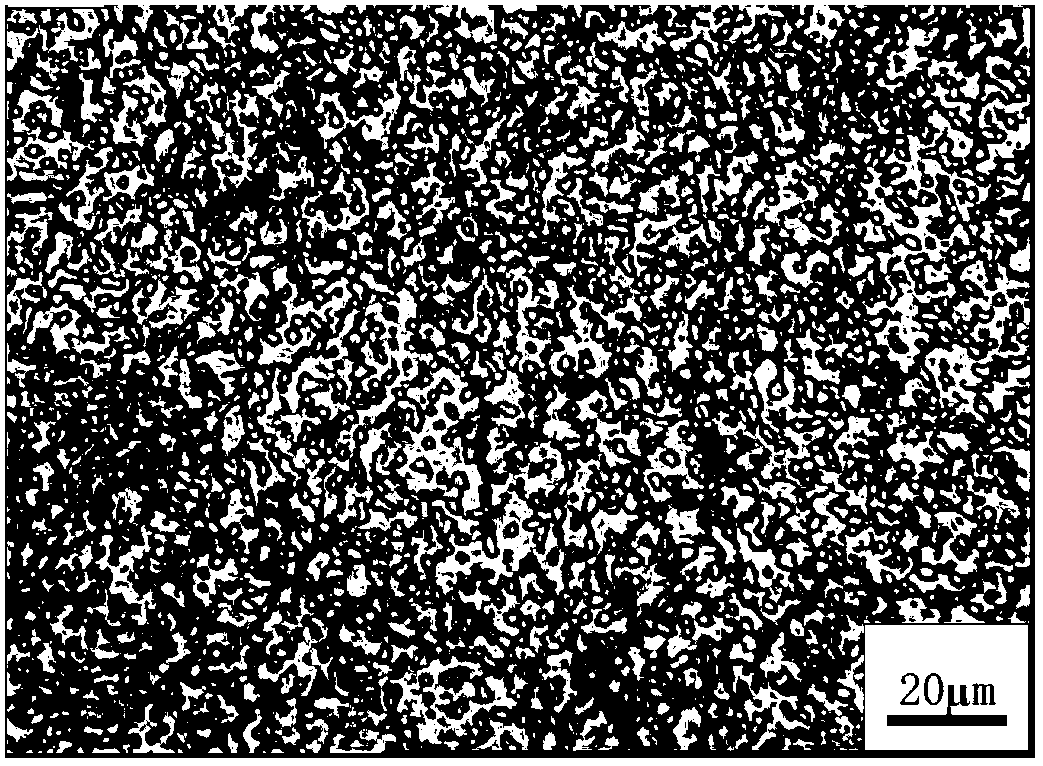

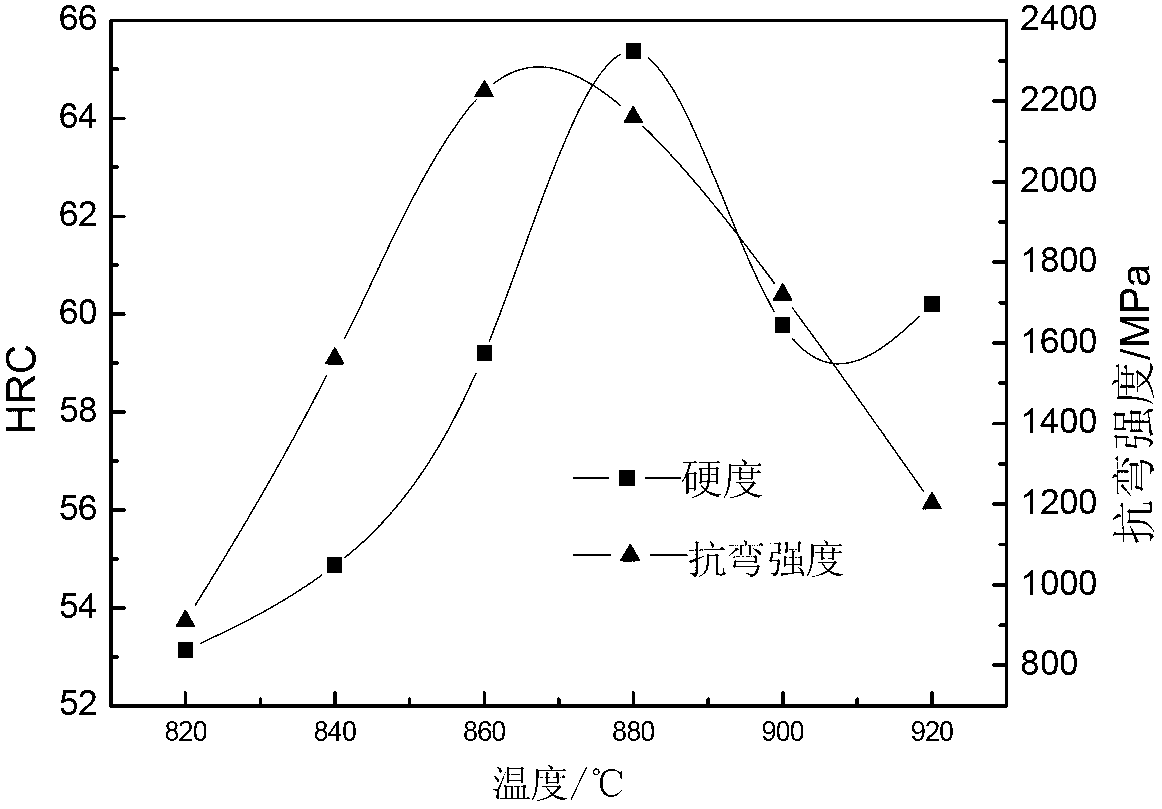

Preparation method of powder high-speed steel material

The invention provides a method for preparing a powder high-speed steel structural member by discharge plasma sintering. In the process of preparing high-speed steel, the addition of carbon powder and the activation action of plasma are utilized to lower the sintering temperature of the high-speed steel, and the activation action of the plasma is utilized to shorten the holding time. The sintering temperature is 870-890 DEG C, the sintering temperature range is 20 DEG C, the sintering time is 10 minutes, and the technique is easy to control. The invention solves the problem of segregation of high-speed steel, refines the crystal grains, and enhances the mechanical properties of the high-speed steel.

Owner:JIANGSU UNIV

Processing method of fermented bean curd by adding eagle tea

InactiveCN104904868AGreat tasteFull of nutritionCheese manufactureFood scienceActivation actionVitamin

The invention relates to a processing method of an eagle tea. The processing method of the fermented bean curd by adding the eagle tea is characterized by comprising the following steps of cleaning fresh eagle tea leaves, crushing the cleaned fresh eagle tea leaves, squeezing the juice from the crushed fresh eagle tea leaves, preparing soybean milk, preparing fermented bean curd and adding juice. According to the production status of the fermented bean curd, in order to improve the quality of the fermented bean curd, through exploration during many years, a brand new processing method of the fermented bean curd is invented. The fresh eagle tea leaves are adopted in the processing method, the eagle tea extract fermented bean curd is prepared through a scientific formula and modernized equipment, and the eagle tea extract fermented bean curd contains rich vitamins, carbohydrate, varied mineral substances and trace elements. The eagle tea extract fermented bean curd has the peculiar fragrance of the fermented bean curd and the peculiar fragrance of the eagle tea and is purely natural, chemical components are not added, the activation action of good microbial populations improves the mouth feel and the taste of the fermented bean curd, and the nutrition is enriched.

Owner:ENSHI PREFECTURE DIYIJIA INTPROP SERVICES CO LTD

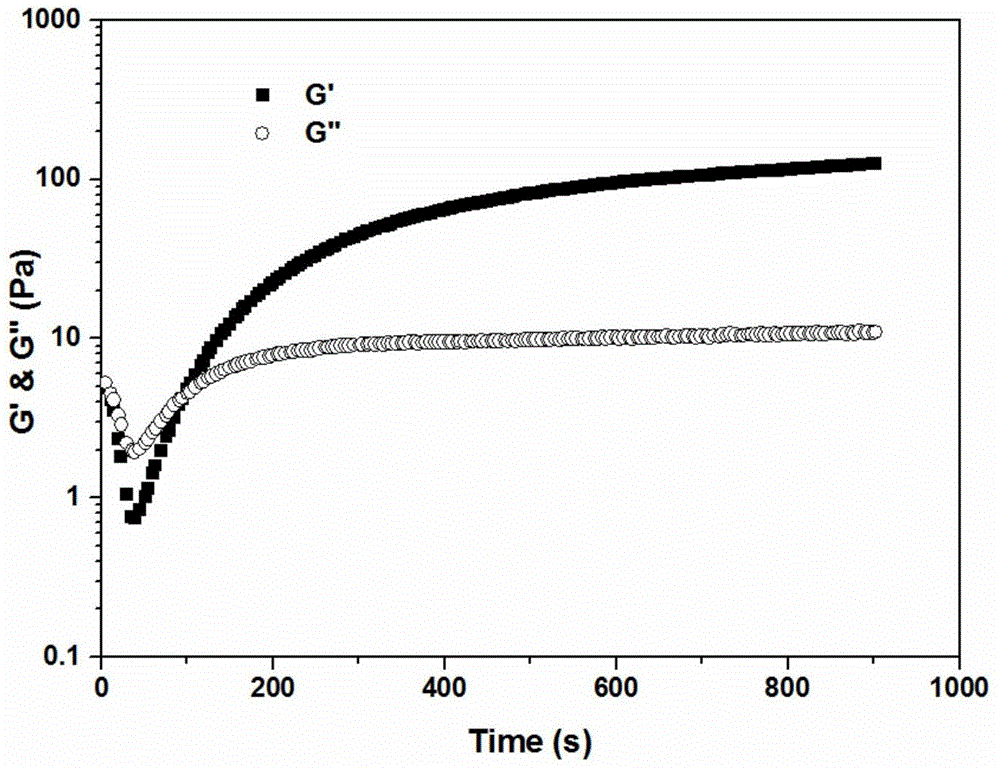

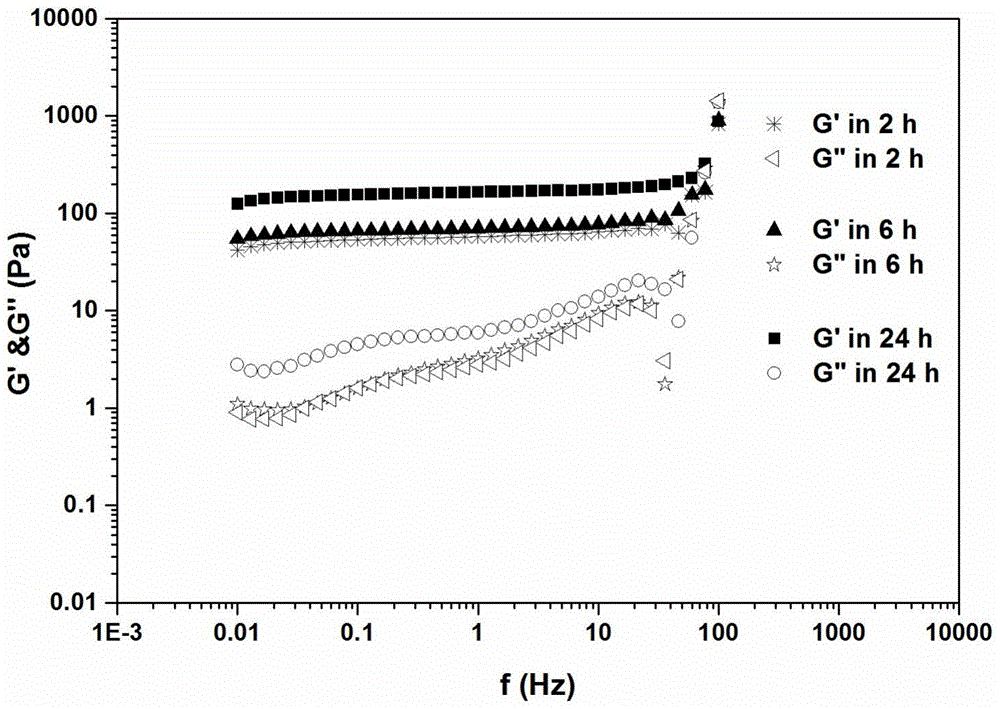

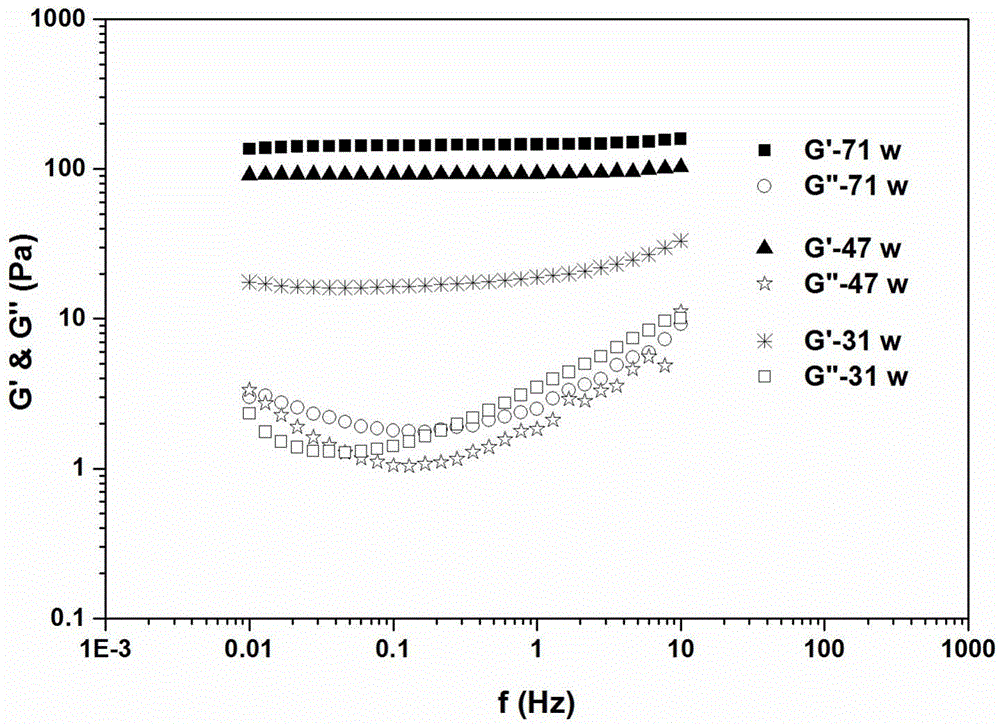

Preparation method of injectable in-situ self-assembled sodium hyaluronate hydrogel

The invention relates to a preparation method of injectable in-situ self-assembled sodium hyaluronate hydrogel. The preparation method comprises that sodium hyaluronate reacts with cystamine to produce a hyaluronic acid derivative under activation action of a coupling reagent 4-(4, 6-dimethoxy-1, 3, 5-triazin-2-yl)-4-methyl morpholinium chloride (DMTMM), the hyaluronic acid derivative is reduced through dithiothreitol (DTT) to produce a hyaluronic acid mercapto derivative, simultaneously, sodium hyaluronate reacts with dopamine under activation action of the coupling reagent DMTMM to produce a catechol functionalized hyaluronic acid derivative and the hyaluronic acid mercapto derivative and the catechol functionalized hyaluronic acid derivative are mixed to form hydrogel without other cross-linking agents.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

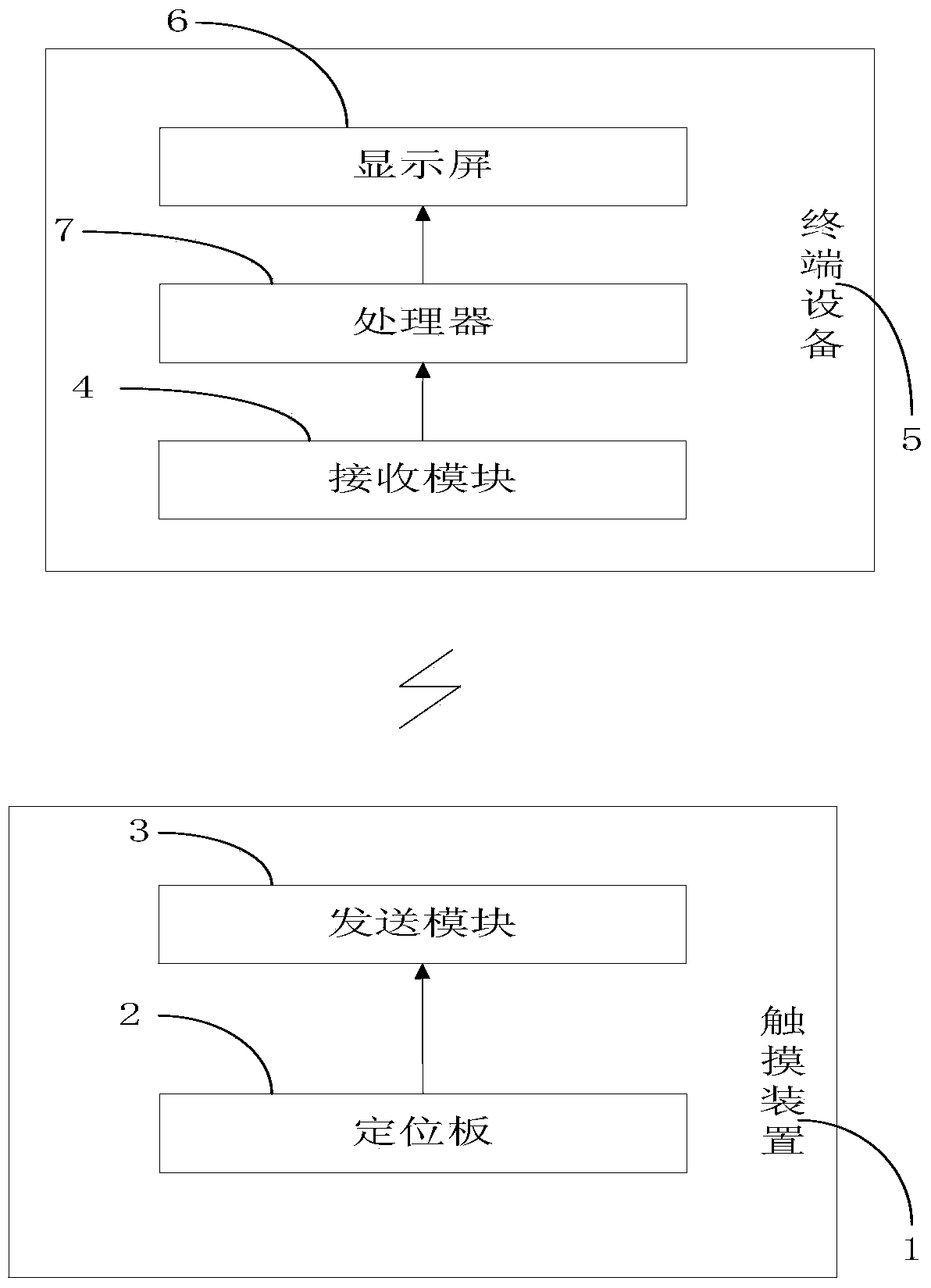

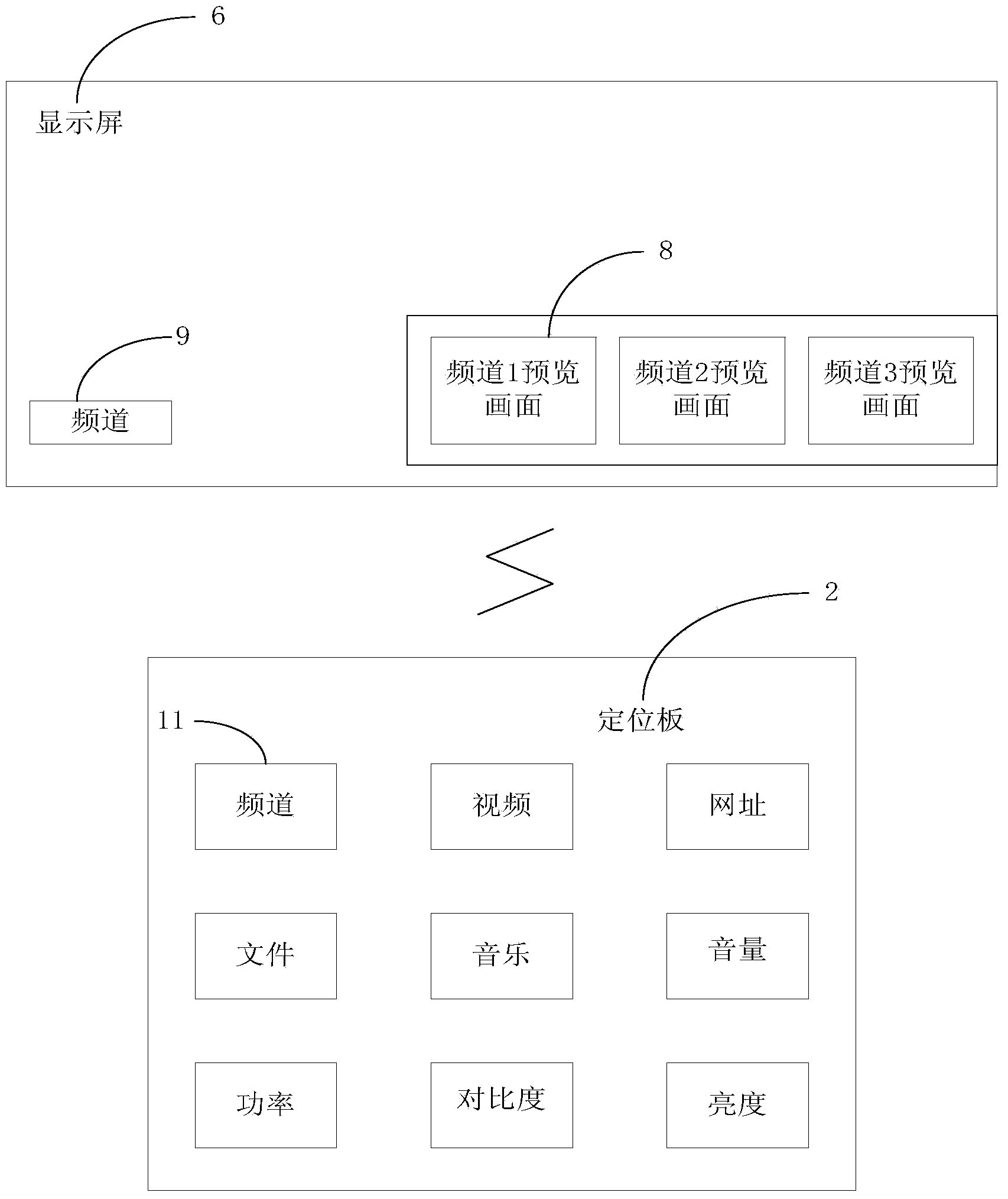

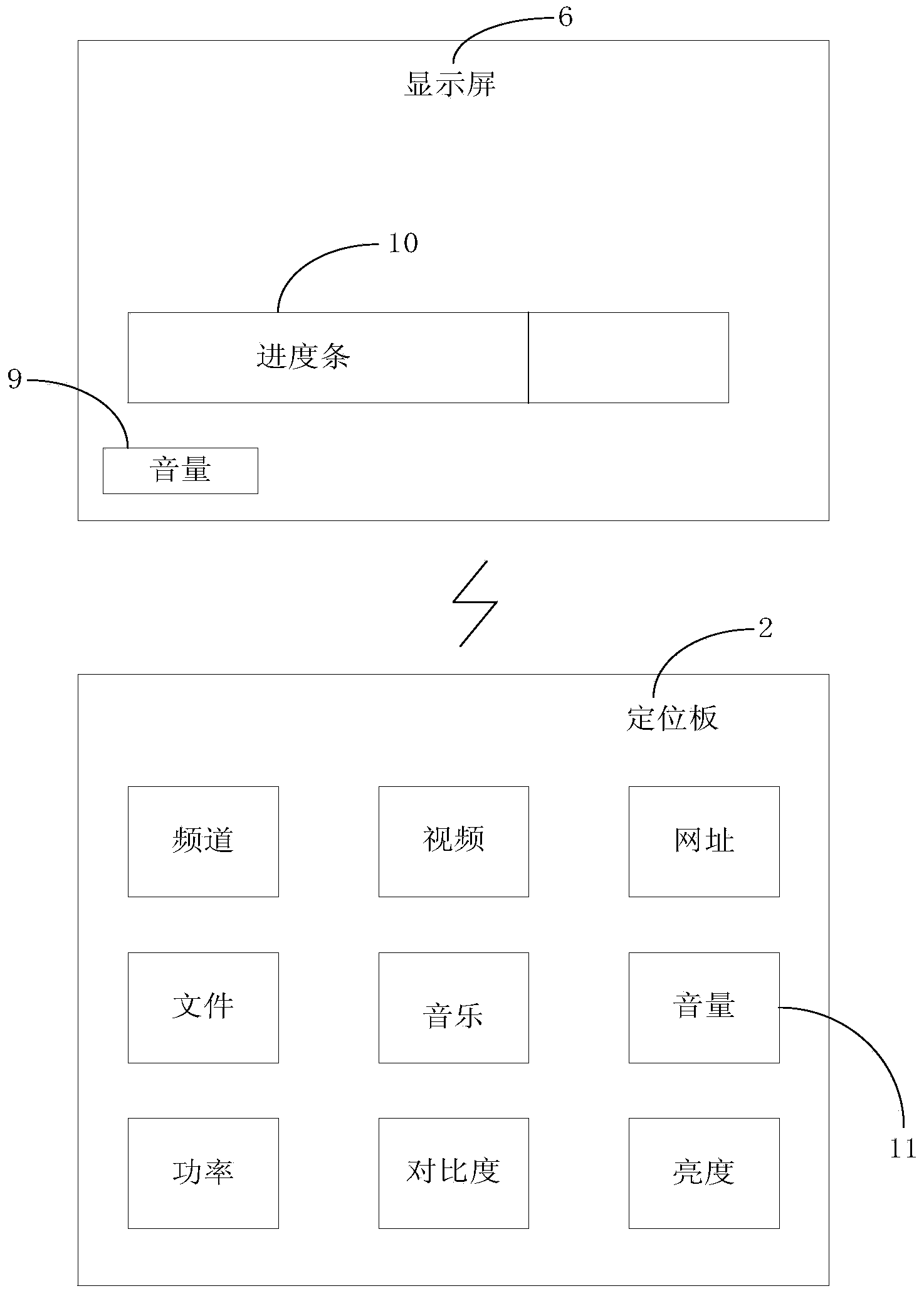

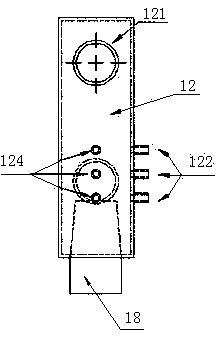

Method and device for controlling terminal device through marker

ActiveCN103731712AAvoid the inconvenience of insufficientImprove securitySelective content distributionInput/output processes for data processingActivation actionTerminal equipment

The invention discloses a method and a device for controlling a terminal device through a marker. The device comprises a touch device (1) and the terminal device (5) building communication with the touch device (1). The touch device (1) comprises a location plate (2). The terminal device (5) comprises a processor (7) and a display screen (6). The location plate (2) is used for detecting action information of the marker on the touch surface with an induction key position (11). The processor (7) activates a controlled object corresponding to an activation key position and enables image-text prompt information corresponding to the controlled object to pop up when used for judging the activation action of the marker to the key position, enables the controlled object to change synchronously with movement of the marker and displays the change of the controlled object through the image-text prompt information when used for judging the selection action of the marker, and executes corresponding operation when used for judging the execution action of the marker to the controlled object. The method and the device have various operation modes and are high in playability.

Owner:张苏渝

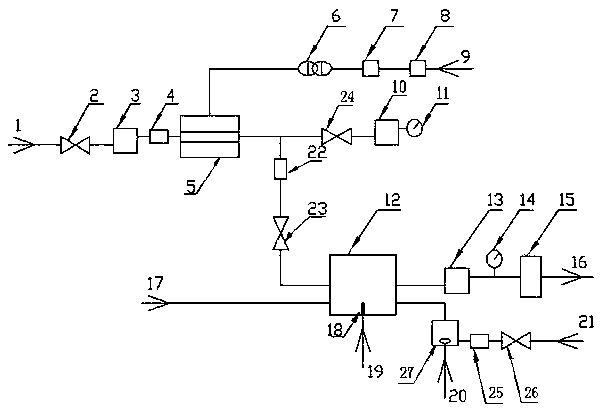

Supersonic wave-ozone-based flue gas desulphurization and denitration device

ActiveCN105363325AAvoid wastingPrevent leakageDispersed particle separationAir quality improvementActivation actionLiquid water

The invention discloses a supersonic wave-ozone-based flue gas desulphurization and denitration device. Air goes through a first valve and then enters a first dryer, the first dryer and a plasma ozone generator are connected by a flowmeter, the plasma ozone generator has two output paths, one path goes through a third valve and then is orderly connected to a second dryer and a first ozone concentration sensor, the other path goes through a second flowmeter and then is orderly connected to a second valve and a flue gas reaction chamber, flue gas is input into the flue gas reaction chamber, an ultrasonic generator is arranged in the flue gas reaction chamber, liquid water orderly goes through a forth valve, a third flowmeter and an ultrasonic oscillator and then is fed into the flue gas reaction chamber, through ultrasonic wave activation action on water and ultrasonic wave mass transfer enhancement effects, when flue gas and ozone go through water mist subjected to ultrasonic treatment and then enter the reaction chamber, gas and water mist in the reaction chamber are subjected to activation under ultrasonic wave action and produce a lot of hydroxyl radicals and other active particles and SO2 and NOX in the flue gas are removed.

Owner:JIANGSU UNIV OF SCI & TECH

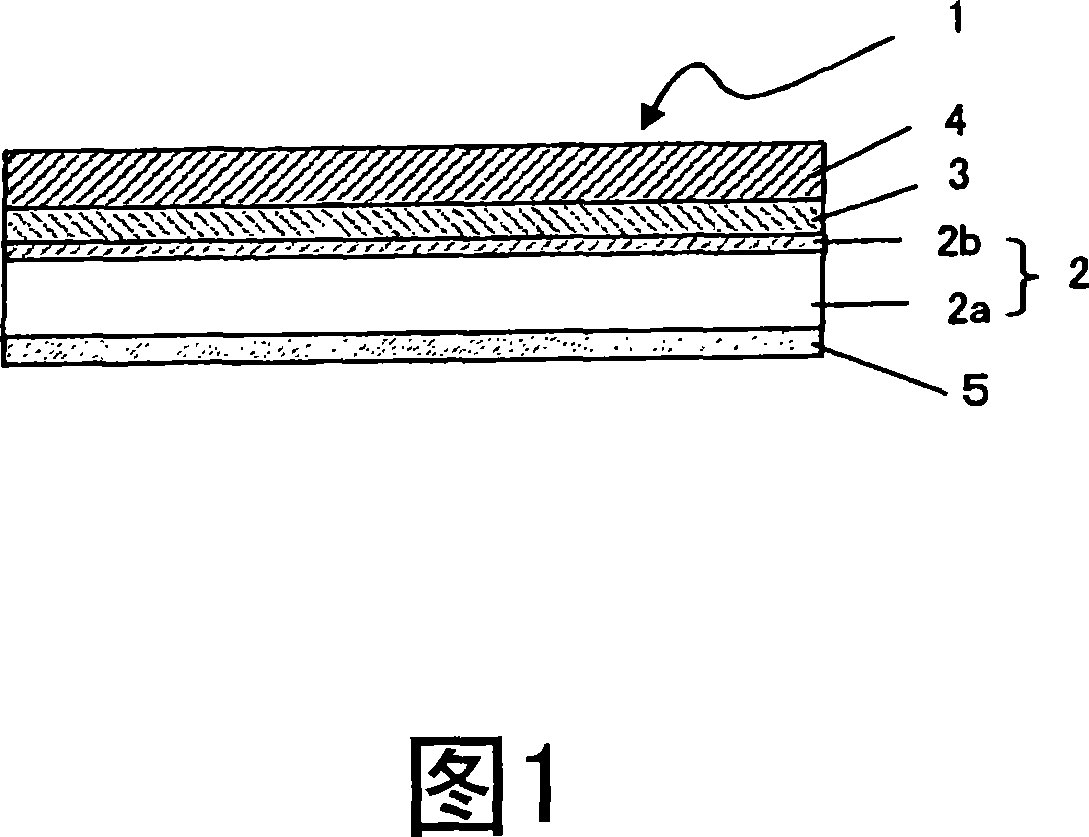

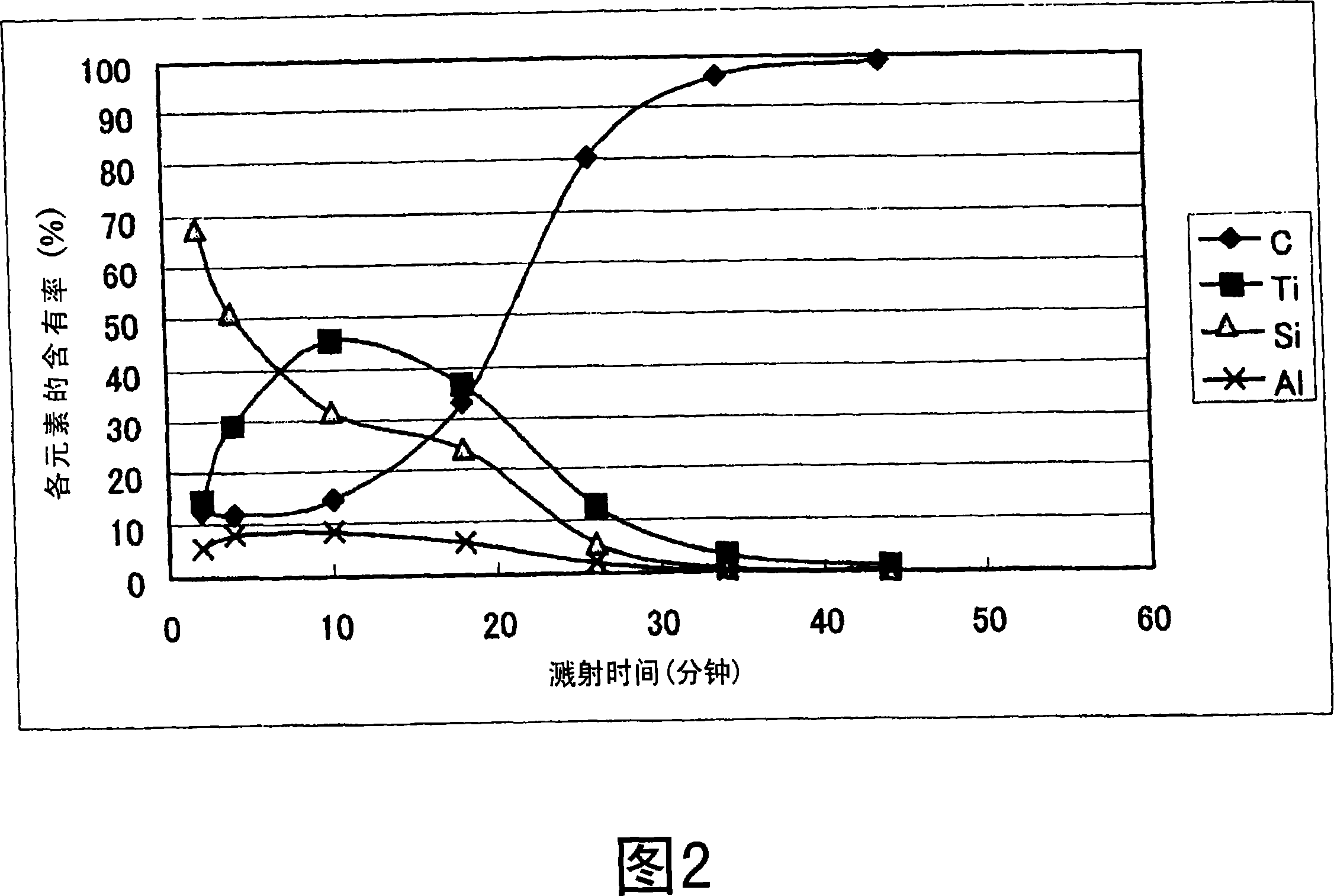

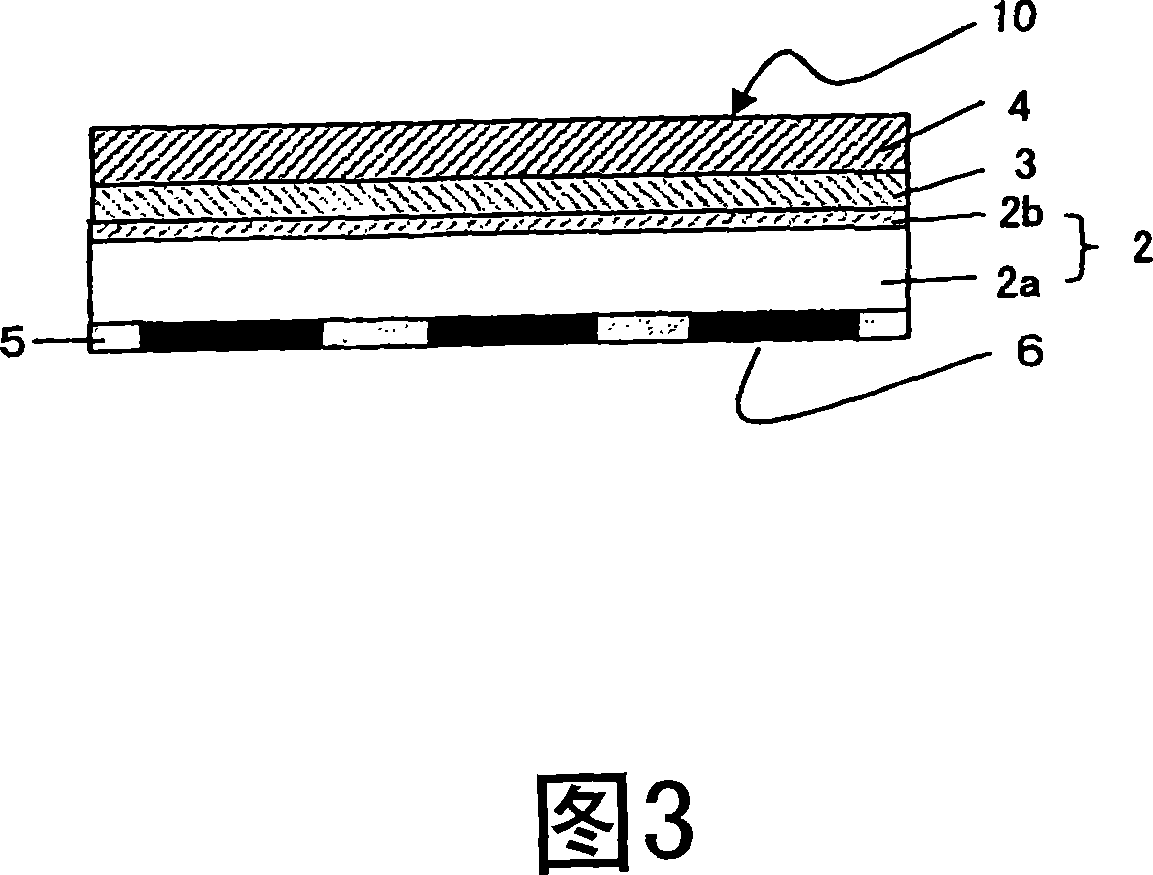

Antifouling printing sheet

InactiveCN101203380ADuplicating/marking methodsSynthetic resin layered productsActivation actionElectrical and Electronics engineering

An antifouling printing sheet characterized by having a hydrophobic antifouling layer formed on one side of a transparent base sheet and a printing surface on the other side, a printed object having a printed antifouling printing sheet, a printed body. The antifouling printing sheet has a self-cleaning capability thanks to a photocatalyst activation action over a long period of time. A printed object and a printed body using the sheet are also provided.

Owner:UBE NITTO KASEI CO LTD

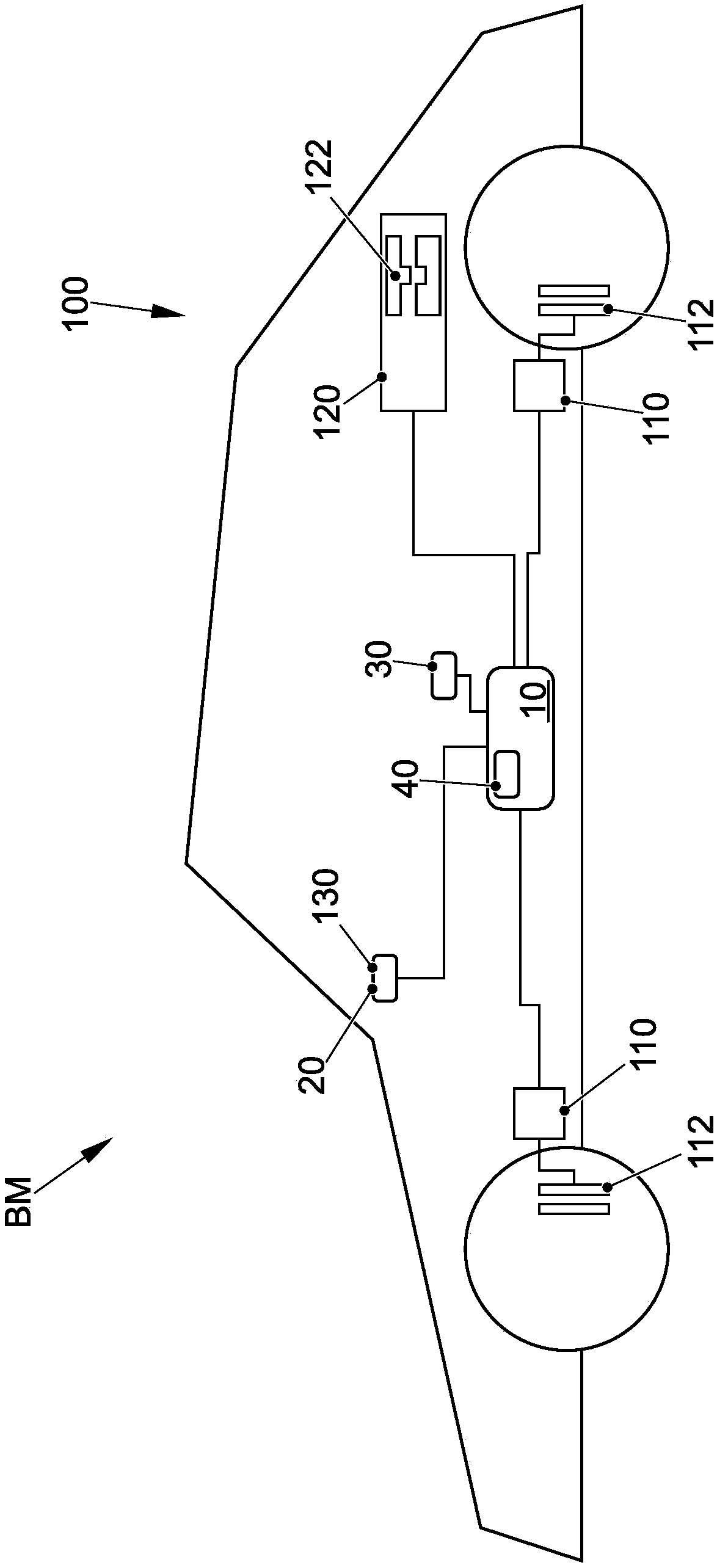

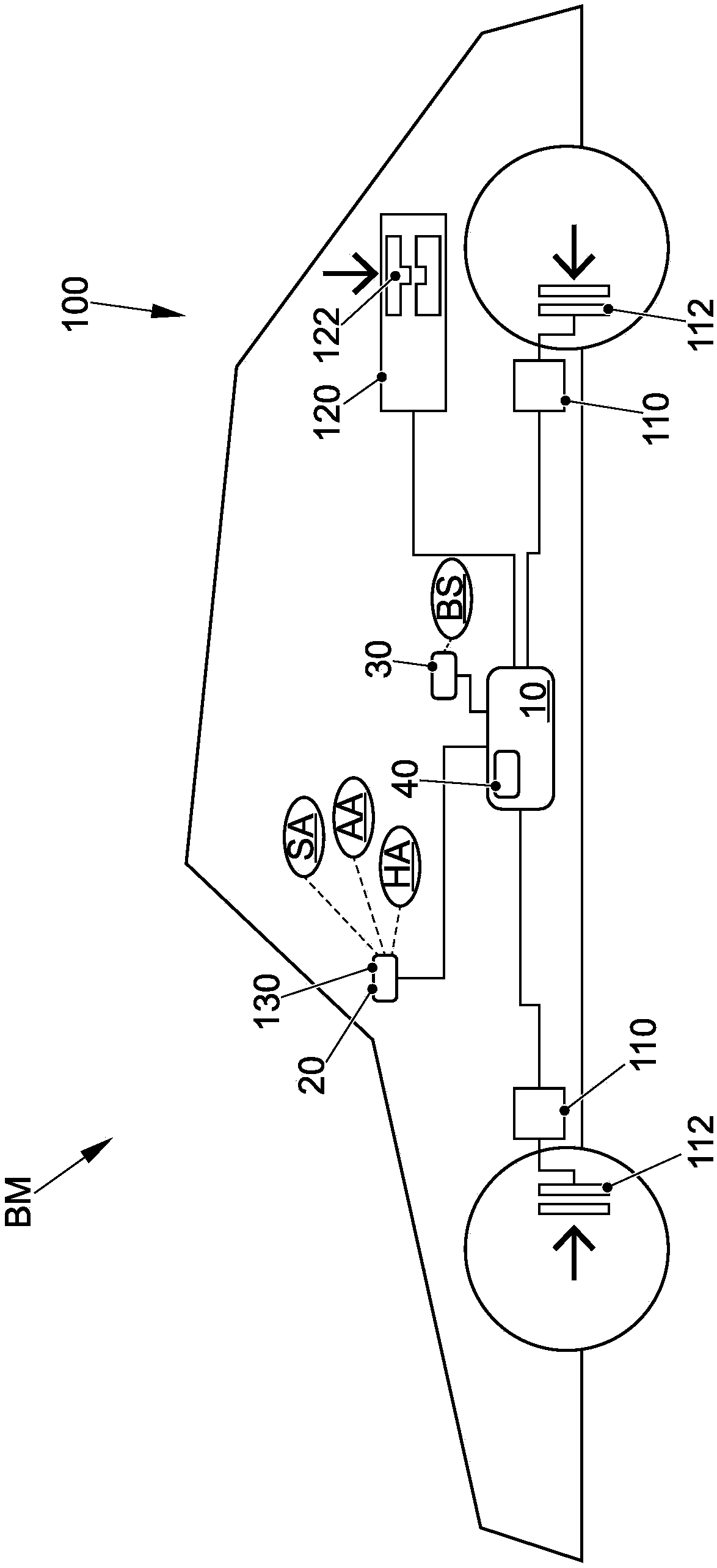

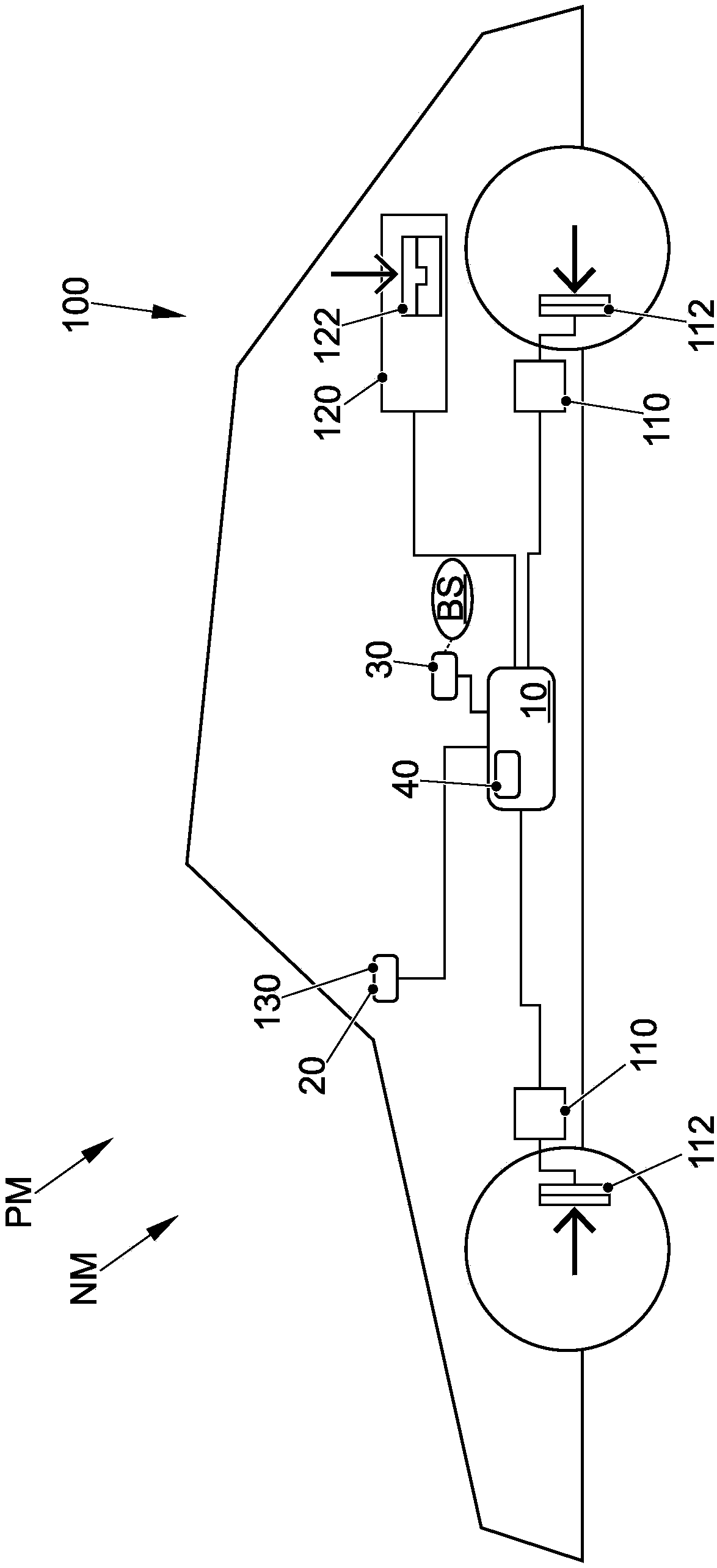

Method for controlling a parking mode of a vehicle

ActiveCN108327726AReduce complexityImprove securityAutomatic initiationsGearing controlActivation actionParking brake

A method for controlling a parking mode (PM) for a vehicle (100) includes detecting an activation action (AA) of a user of the vehicle (100), determining a movement status (BS) of the vehicle (100), and activating a parking mode (PM) for the vehicle (100) by closing a parking brake (112) of a brake device (110) of the vehicle (100) and by engaging a gearshift lock (122) of a transmission (120) ofthe vehicle (100).

Owner:DR ING H C F PORSCHE AG

High efficiency method for making fruit and vegetable juice by high static pressure in combination with bio-enzyme catalysis

The invention discloses a high efficiency method for making fruit and vegetable juice by high static pressure in combination with bio-enzyme catalysis, belonging to the technical field of food processing. The method comprises the steps of: adding pectase to fruit and vegetable pulp, applying a pressure of between 200 and 400MPa at a temperature of between 30 and 55 DEG C, and processing for 30 to 60 minutes to obtain the fruit and vegetable juice. The method of the invention, by means of the activation action of high static pressure on exogenous enzyme, improves the activity of pectase, raises the efficiency of hydrolyzing pectin and cellulose through bio-enzyme catalysis, reduces the viscosity of fruit pulp and reaches the purpose of improving juice yield; and compared with traditional processes, the method of the invention can reduce the use of exogenous bio-enzyme in a juice making process by over 40%, or shorten the bio-enzymolysis time by over 30% and has excellent social and economical benefits when being applied to actual production.

Owner:CHINA AGRI UNIV

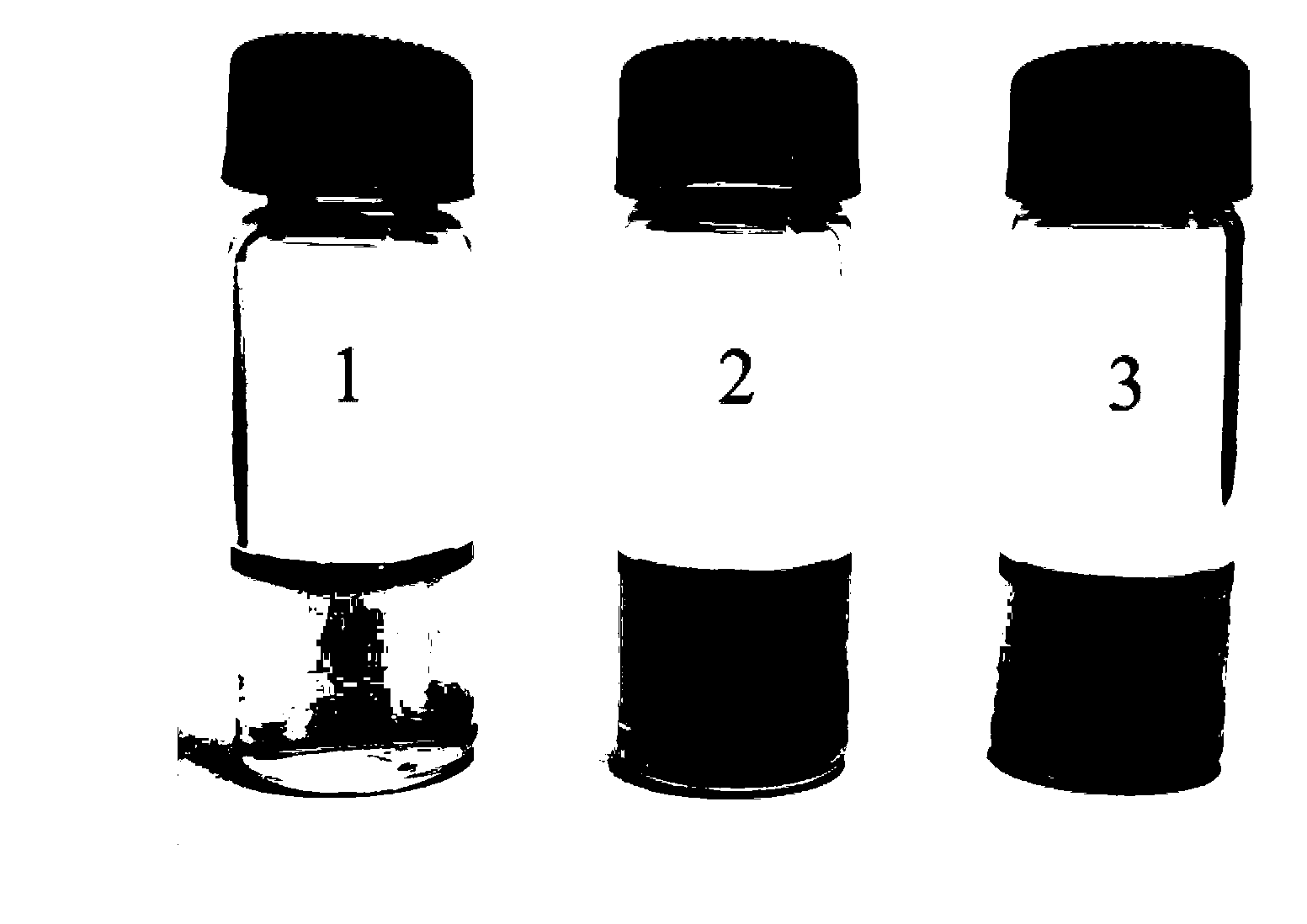

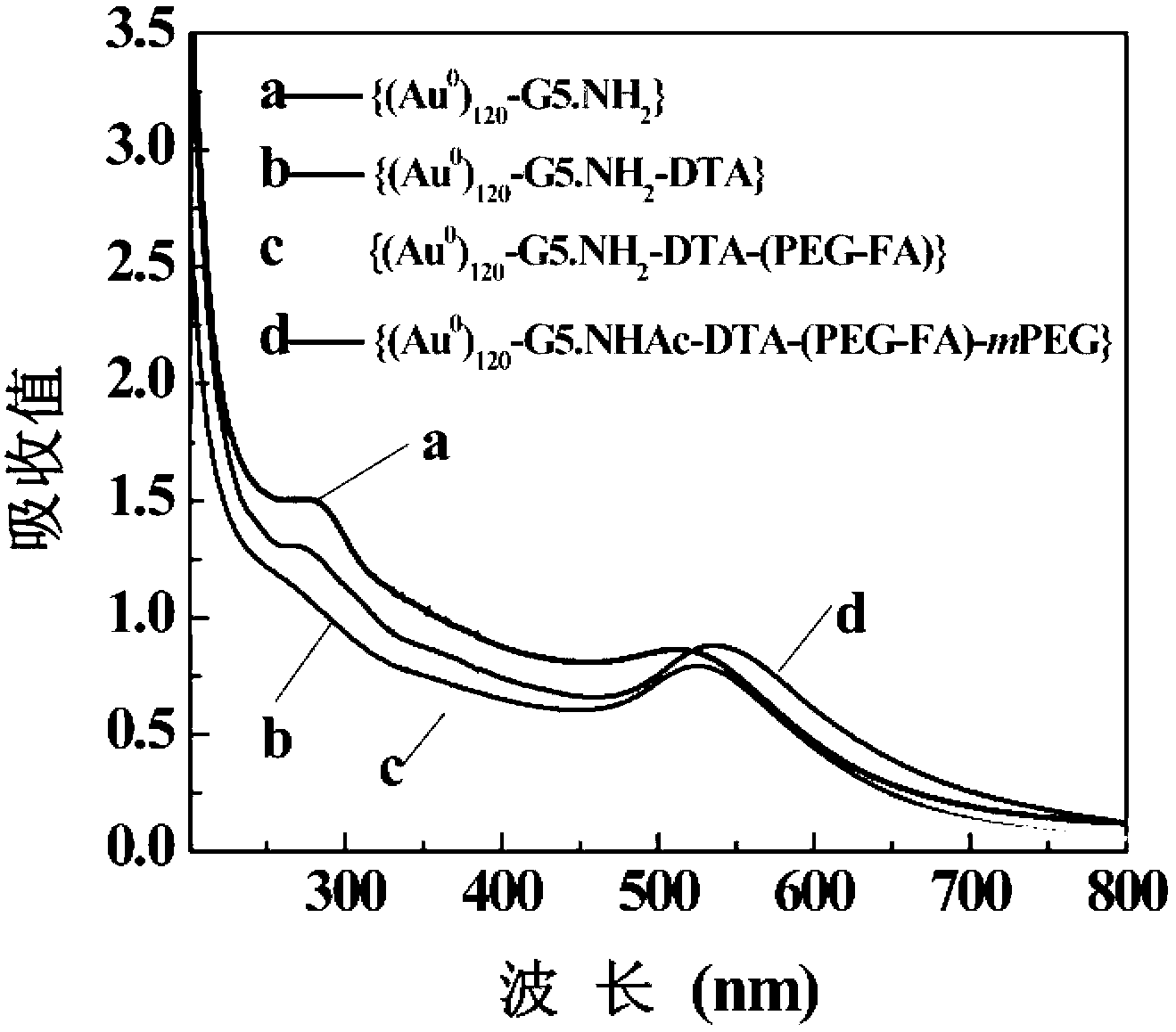

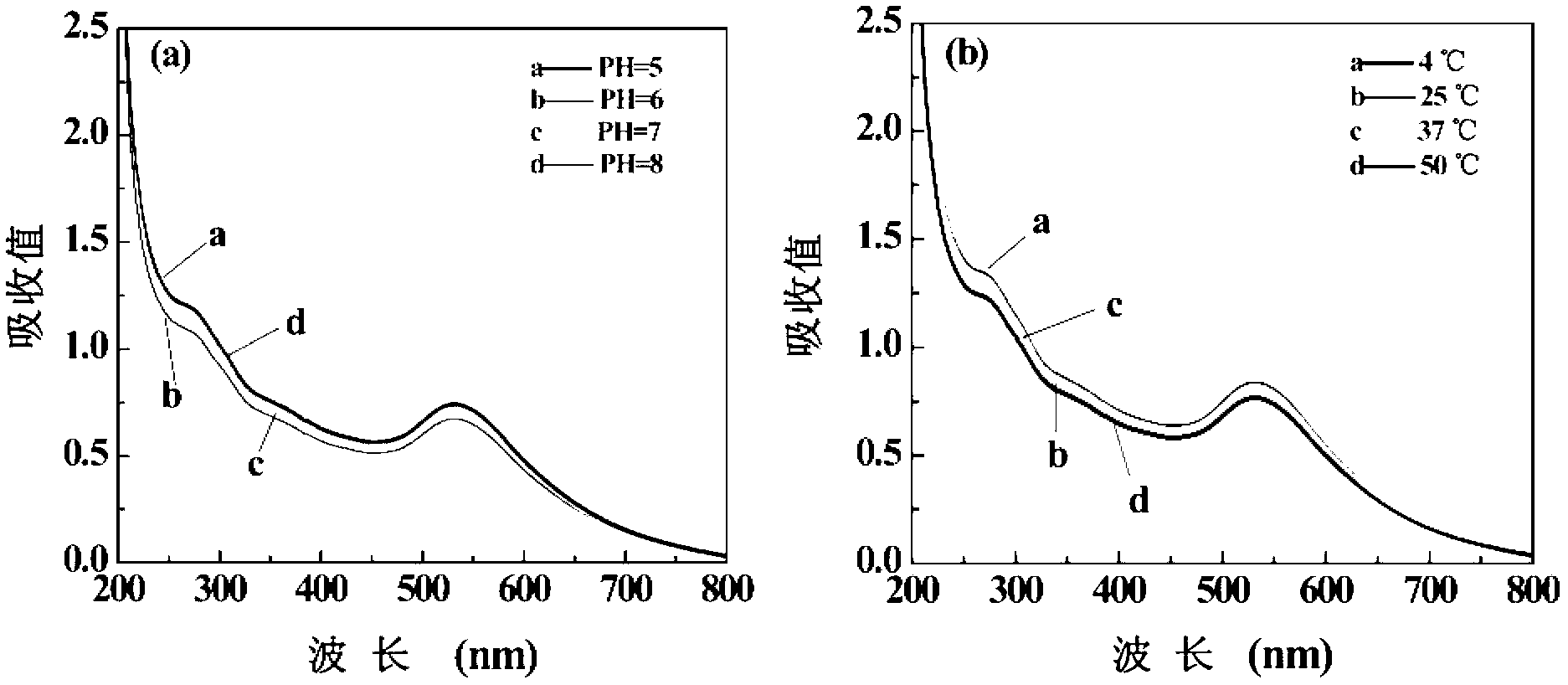

Preparation of diatrizoic-acid-modified double-element target CT (Computed Tomography) contrast agent containing gold and iodine

InactiveCN102698295AGood biocompatibilityGood water solubilityX-ray constrast preparationsSolubilityAcetic anhydride

The invention relates to a preparation method of a diatrizoic-acid-modified double-element target CT (Computed Tomography) contrast agent containing gold and iodine. The preparation method comprises the following steps of: (1) adopting a fifth-generation polyamide-amine dendroid macromolecule as a template, adopting a gradual reduction method to load higher-content gold nanoparticles and forming Au NPs; (2) connecting small-molecular diatrizoic-acid containing the iodine onto the amino group of the surface of the dendroid macromolecule by EDC activation action to obtain the nano compound containing gold and iodine simultaneously; and (3) connecting carboxylic polyethylene glycol-folic acid and methoxy polyethylene glycol onto the surface of the nano compound in the step (2) sequentially by EDC activation action, and finally under the existence of triethylamine, acetylizing all the remained amino groups on the surface of the dendroid macromolecule by using acetic anhydride, dialyzing, and freeze-drying to obtain the diatrizoic-acid-modified double-element target CT contrast agent containing the gold and the iodine. The preparation method is simple in operation, mild in condition and easy in operation; and the CT contrast agent is good in imaging effect and has the advantages of good water solubility and biocompatibility.

Owner:DONGHUA UNIV

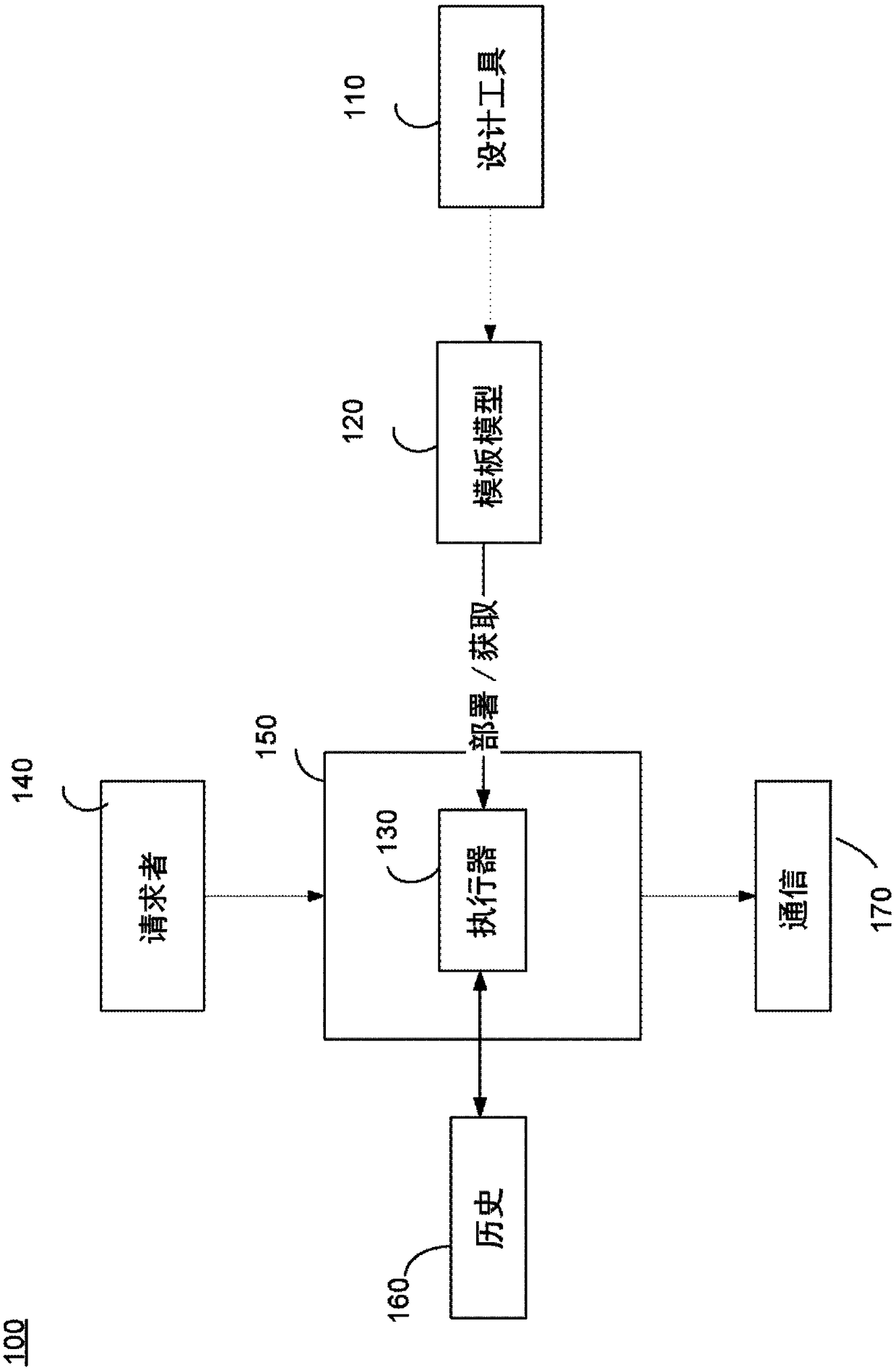

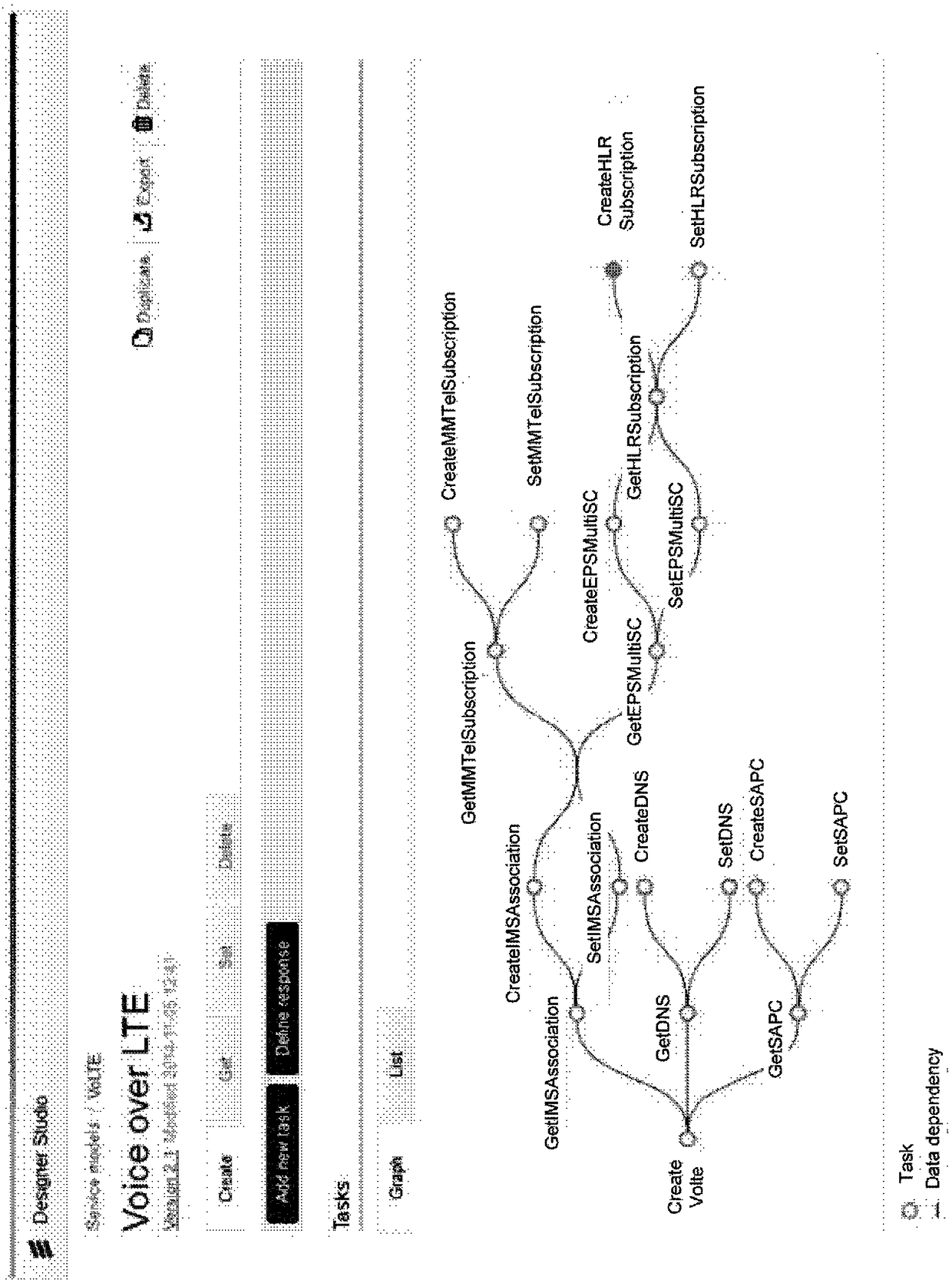

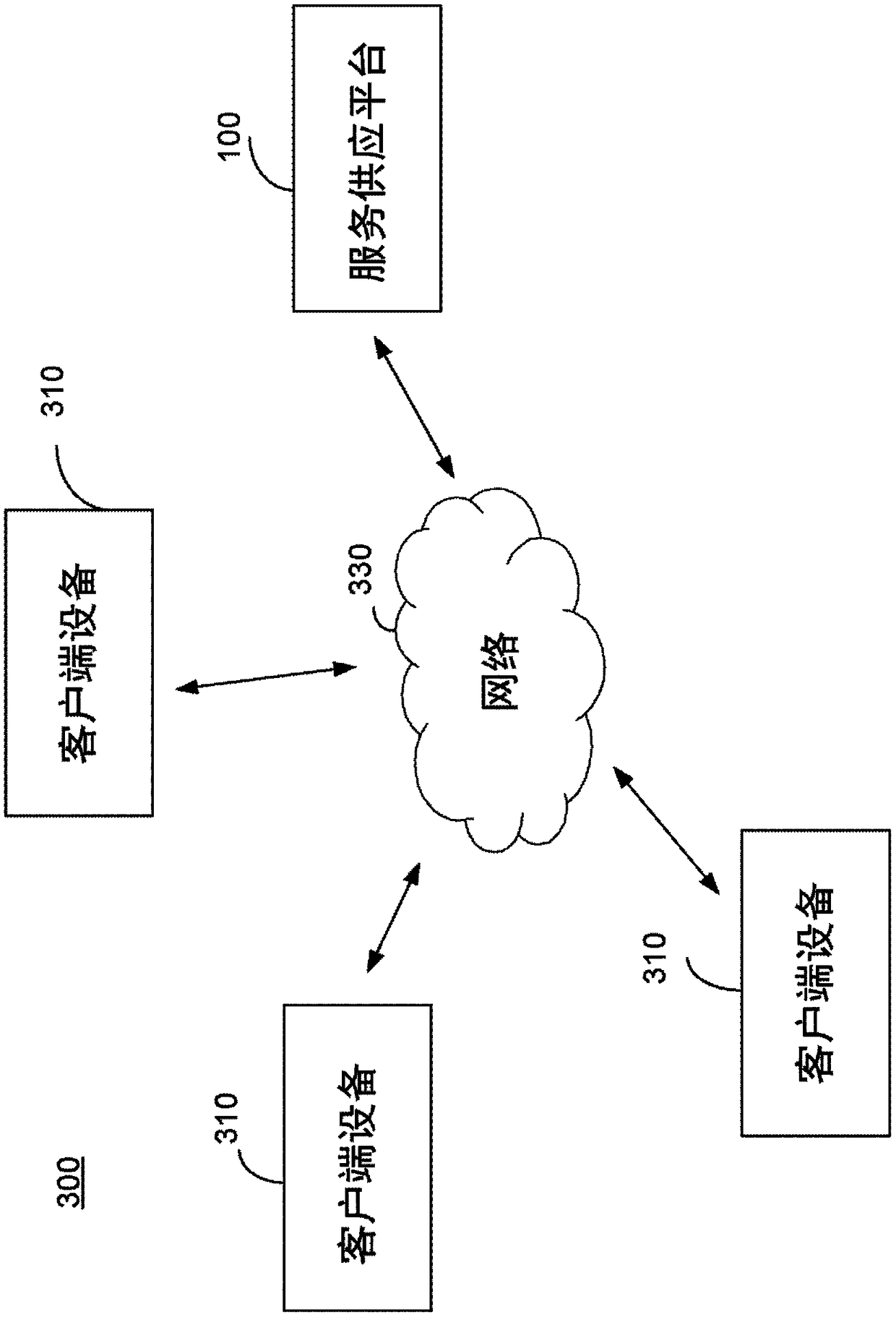

Method and apparatus for declarative action orchestration

InactiveCN108292207ARemove restrictionsVersion controlSoftware designActivation actionTheoretical computer science

It is provided a method, an Activation Node, a computer program and a computer program product for orchestration of activation actions. The solution provides for avoiding an imperative way of specifying the logic and manually defining its level of parallelism. The Activation node is adapted to deploy or fetch a specification, the specification mapping dependencies between a data model for an activation request to a data model of lower layer resources, to be used for orchestrating execution of the activation actions; receive an activation request; match the activation request with a specific flow of activation actions to be executed in in accordance with the specification; and execute the execute logic of the flow of activation actions ordered based on the dependencies between the data models.

Owner:TELEFON AB LM ERICSSON (PUBL)

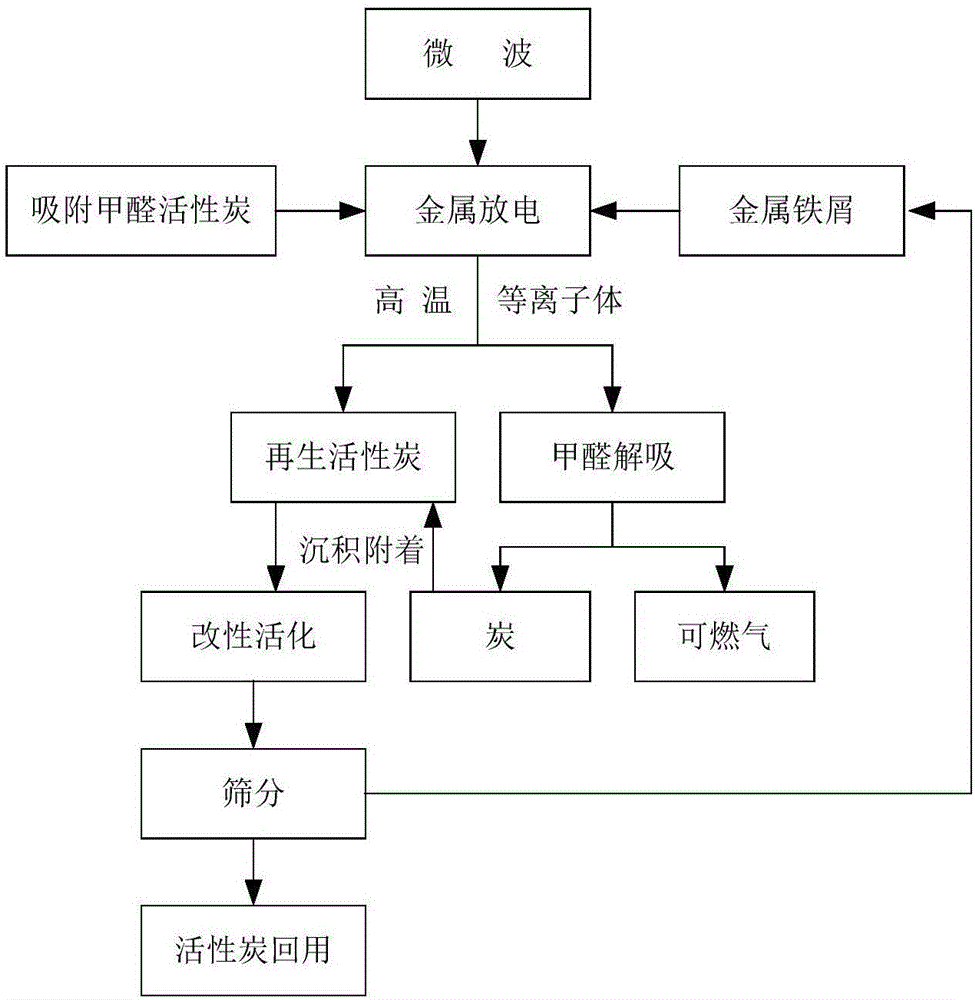

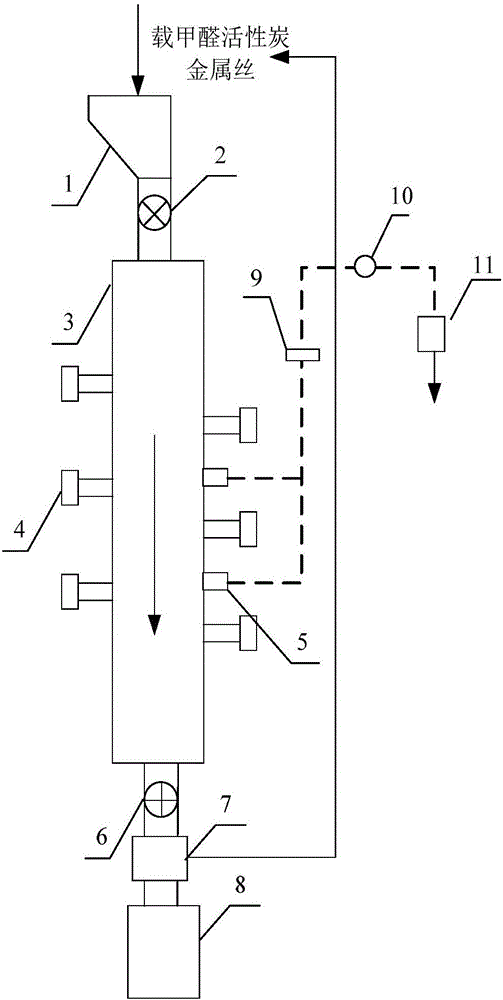

Method and device of simultaneously carrying out formaldehyde loaded activated carbon regeneration and desorbed gas quenching

InactiveCN106732488AIncrease regeneration rateReduce processing stepsOther chemical processesCombustible gas purificationActivated carbonChemical reaction

The invention discloses a method and a device of simultaneously carrying out formaldehyde loaded activated carbon regeneration and desorbed gas quenching. Metal powder or a metal wire is placed in a regeneration device, and formaldehyde loaded activated carbon regeneration and desorbed gas quenching are realized simultaneously by utilizing microwave-induced metal discharge. The method and the device have two advantages that firstly, a heat effect of microwave-induced metal discharge: a great quantity of heat is released within a short time to enable the ambient temperature to rise at high speed, and the regeneration rate of activated carbon can be increased; and a plasma phenomenon: plasmas have the certain catalysis to chemical reaction, but are excited and generated by metal discharge, so that degradation and desorption of generated formaldehyde are accelerated, amorphous carbon is generated to be adhered to and deposited in the surface interface of the regenerative activated carbon, and modified activation action is exerted on the regenerative activated carbon; and secondly, from the angles of economy and the regeneration device, activated carbon regeneration and desorbed gas quenching are simultaneously carried out in the same device, the step of processing desorbed gas after regeneration is saved, and thus the regeneration cost is saved.

Owner:魏汝涵

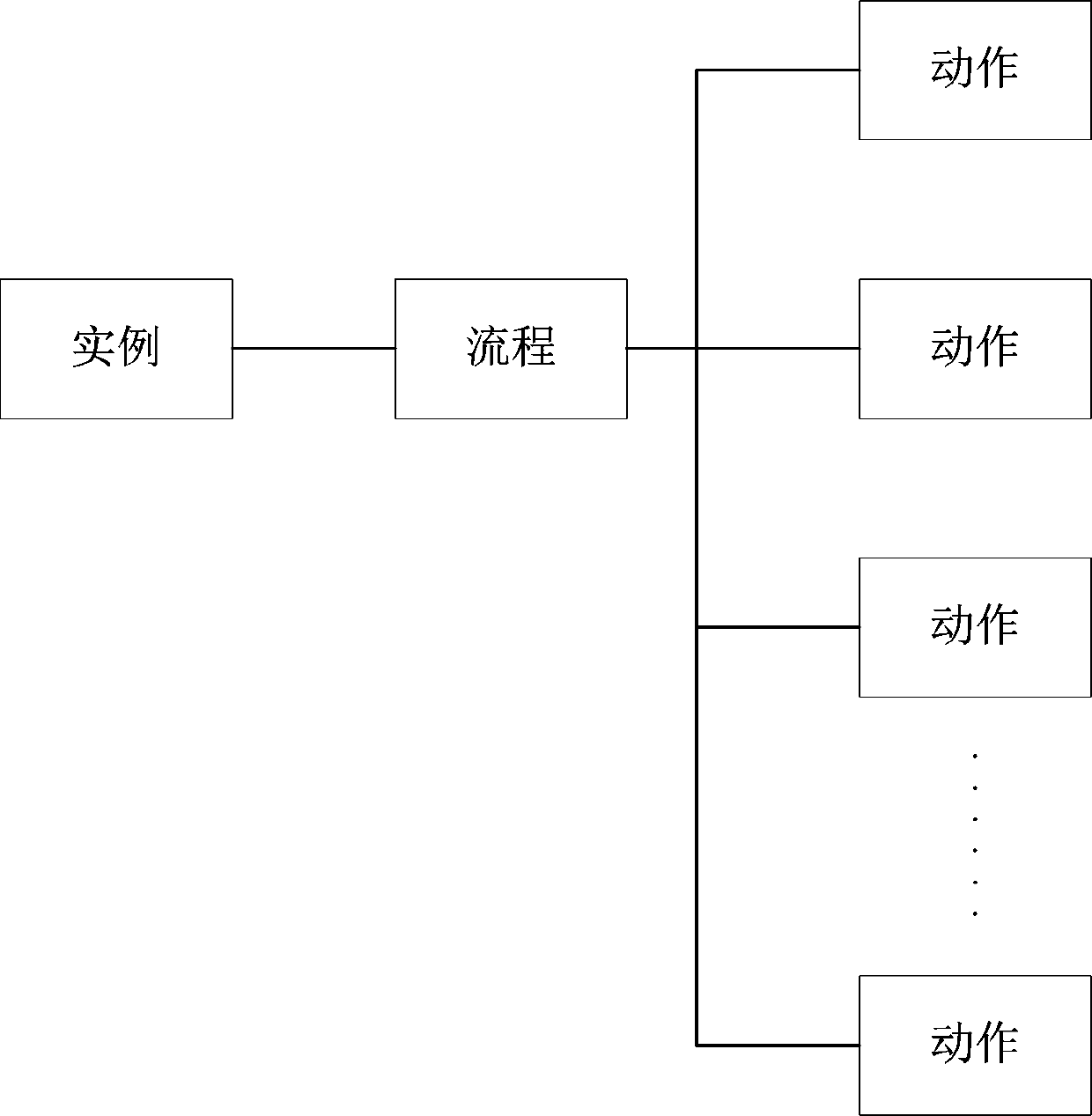

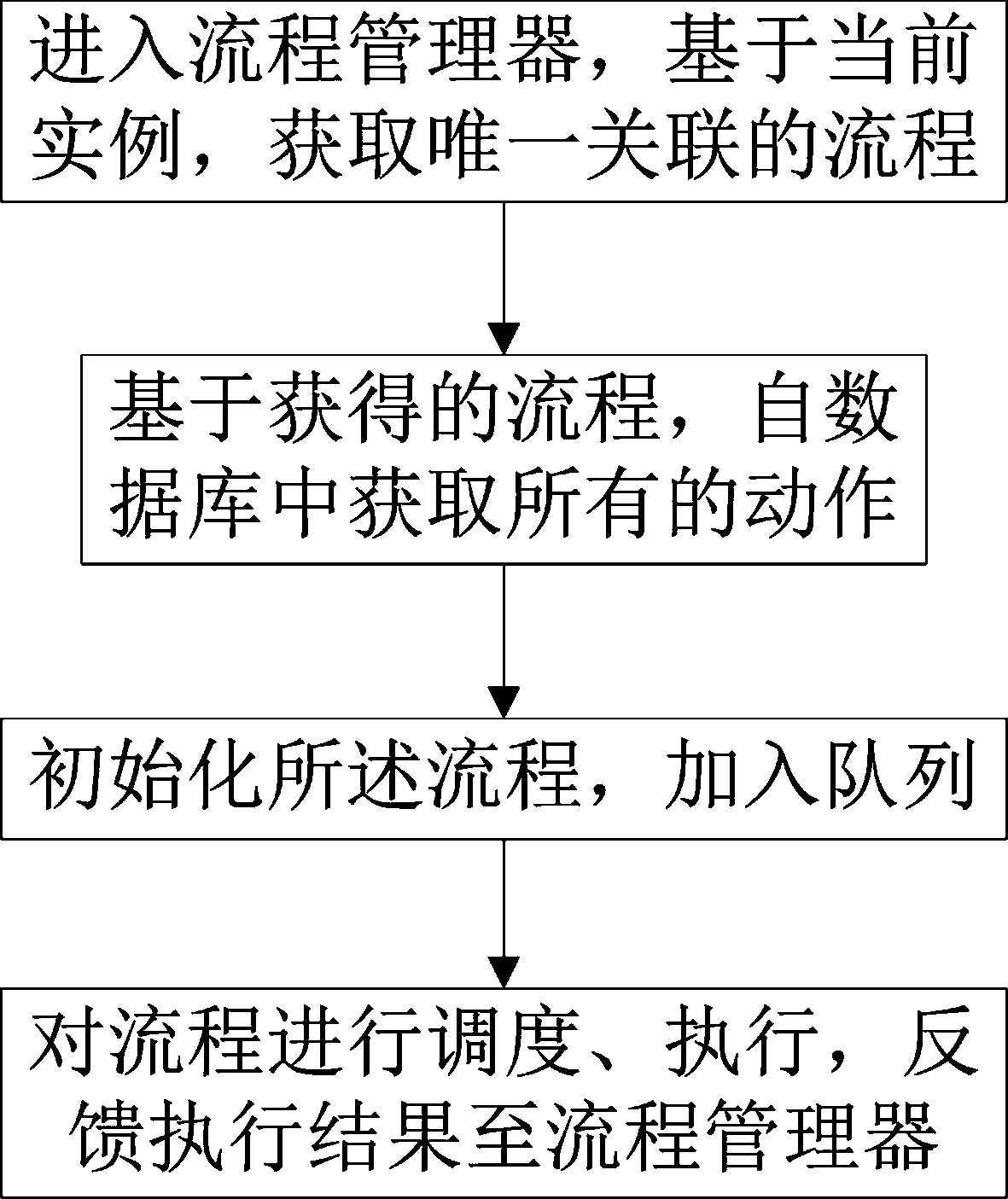

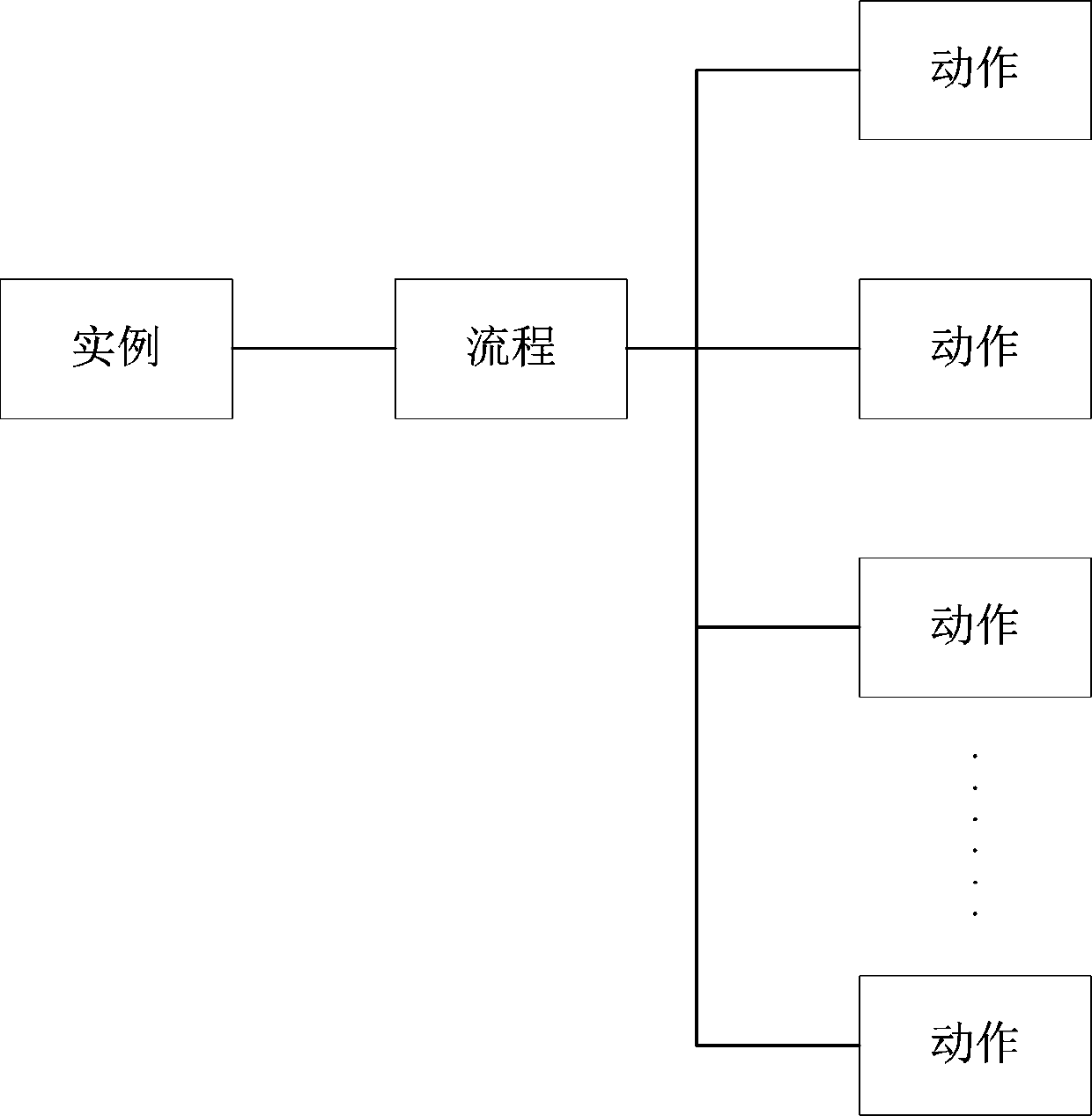

Process arrangement engine and control method thereof

PendingCN111124636AImplement schedulingSolve scheduling problemsProgram initiation/switchingActivation actionProcessing

The invention relates to a process arrangement engine and a control method thereof. An engine is constructed in a mode that an instance uniquely corresponds to a flow and the flow corresponds to one or more actions. When the instance is generated, the uniquely-associated flow is obtained, all the actions are obtained from a database based on the instance, the flow is initialized and then added into a queue, the flow is scheduled and executed, and finally an execution result is fed back to a flow manager. The invention supports custom activation action sets and execution sequences, supports custom processing of returned results, can check and modify activation arrangement and arrangement modification strategies of products through interfaces, takes effect in real time, and embeds product activation services into scheduling tasks to realize scheduling. A real-time effective strategy in process arrangement is solved, so that a program is more flexible, can be executed according to specific steps, is more suitable for various different complex scenes, does not need to modify codes for repackaging, only needs to modify a database, is compatible with various application scenes, and is clearer in service and more convenient to maintain.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

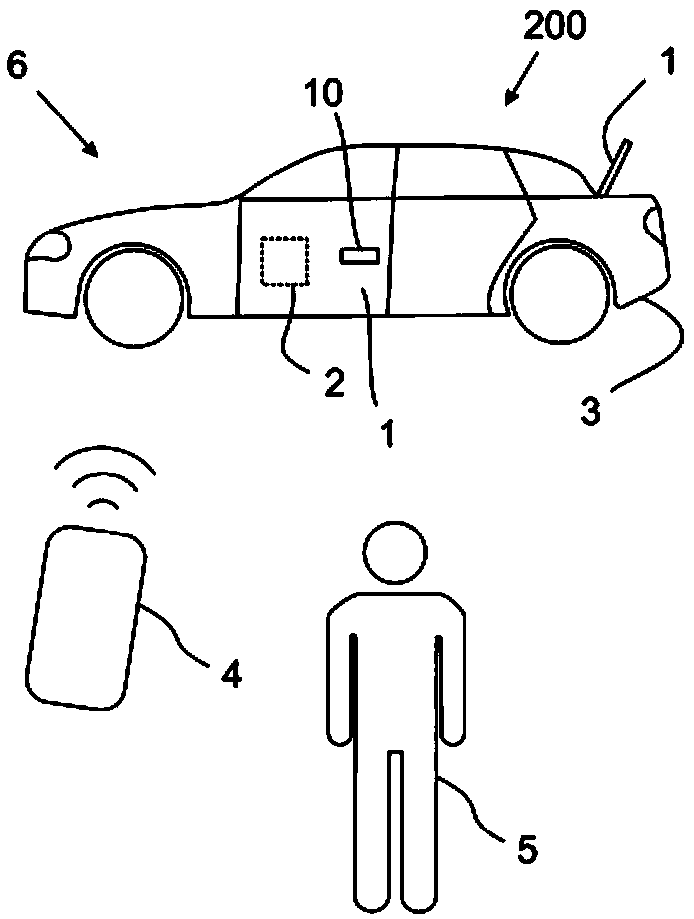

Access system for a vehicle

The invention relates to an access system (200) for a vehicle (3), in particular for activating an electric lock (2) of the vehicle (3), comprising: at least one actuation sensor (30), through which afirst inductance detection (110) for detection an activation action is feasible, at least one information sensor (35), through which a second inductance detection (120) can be carried out, so that additional information on the activation action can be determined, whereby the detection of the activation action is credible.

Owner:HUF HULSBECK & FURST GMBH & CO KG

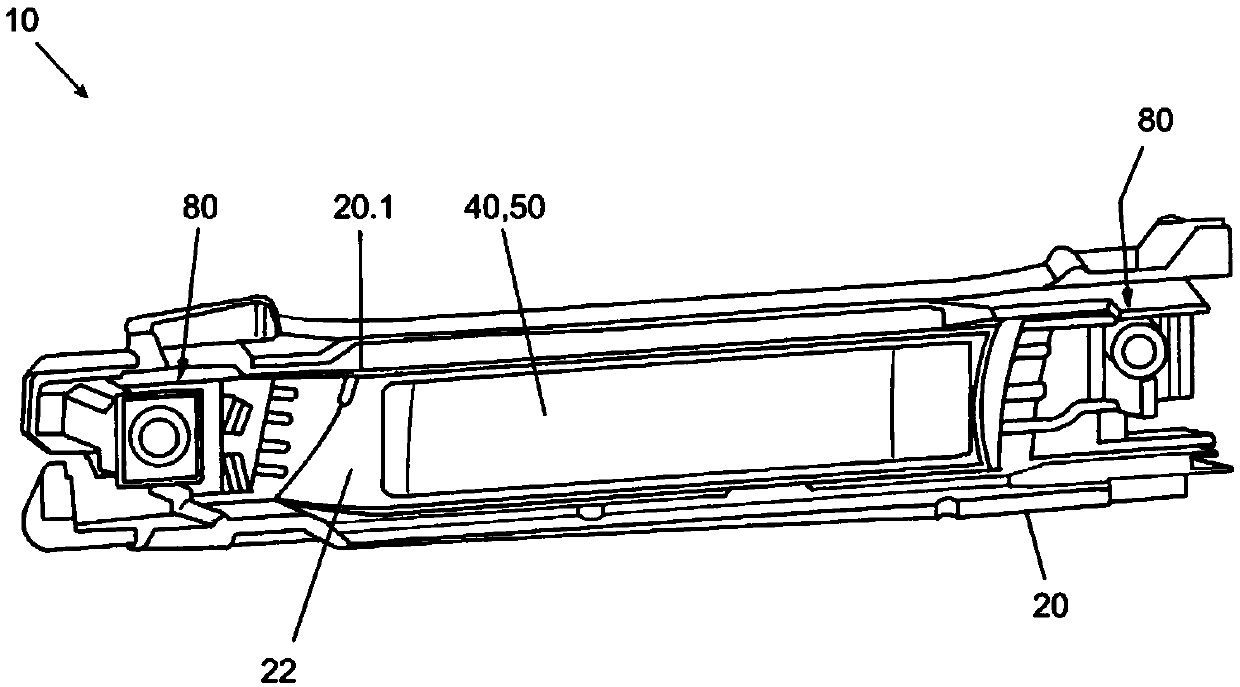

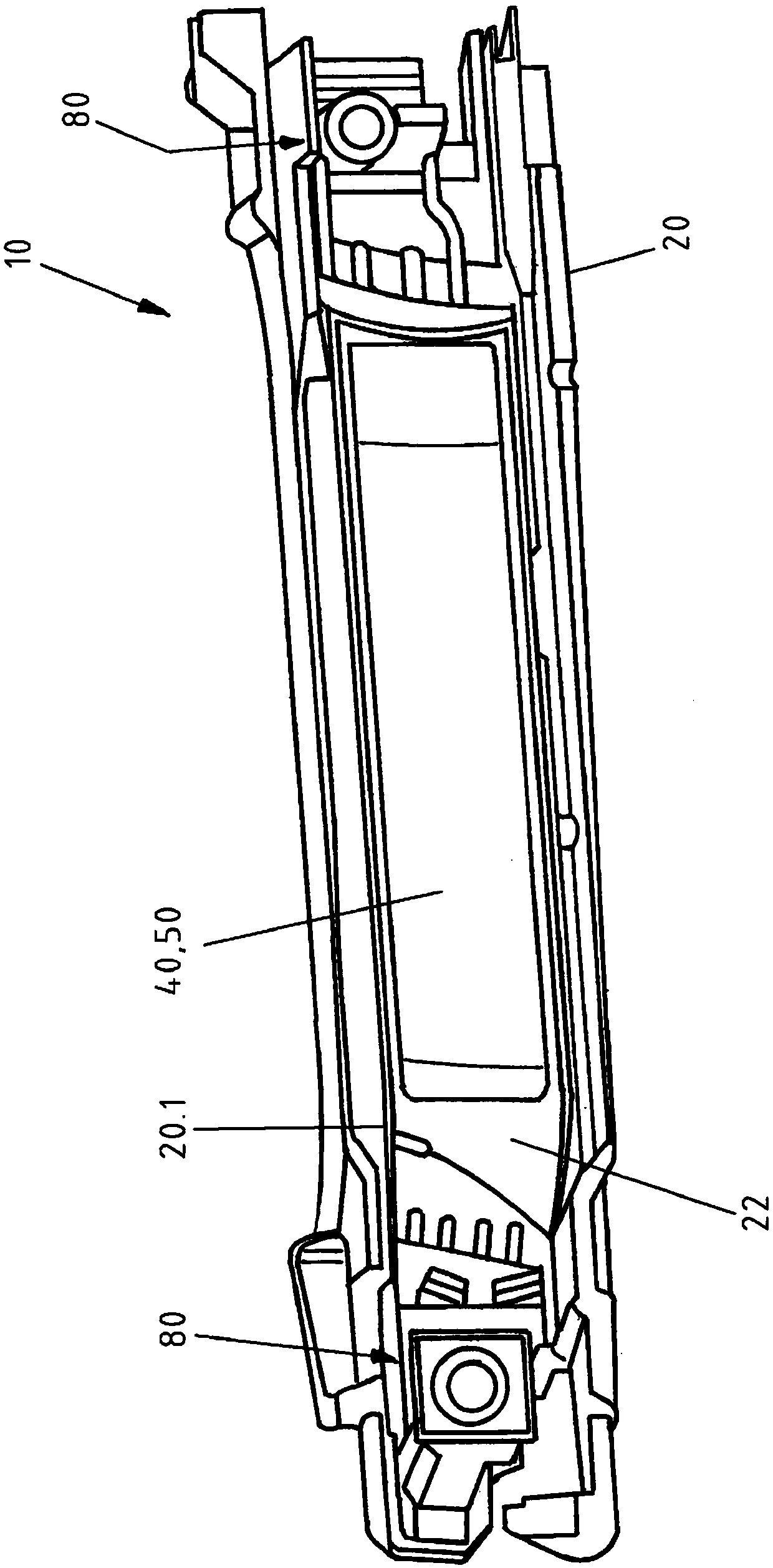

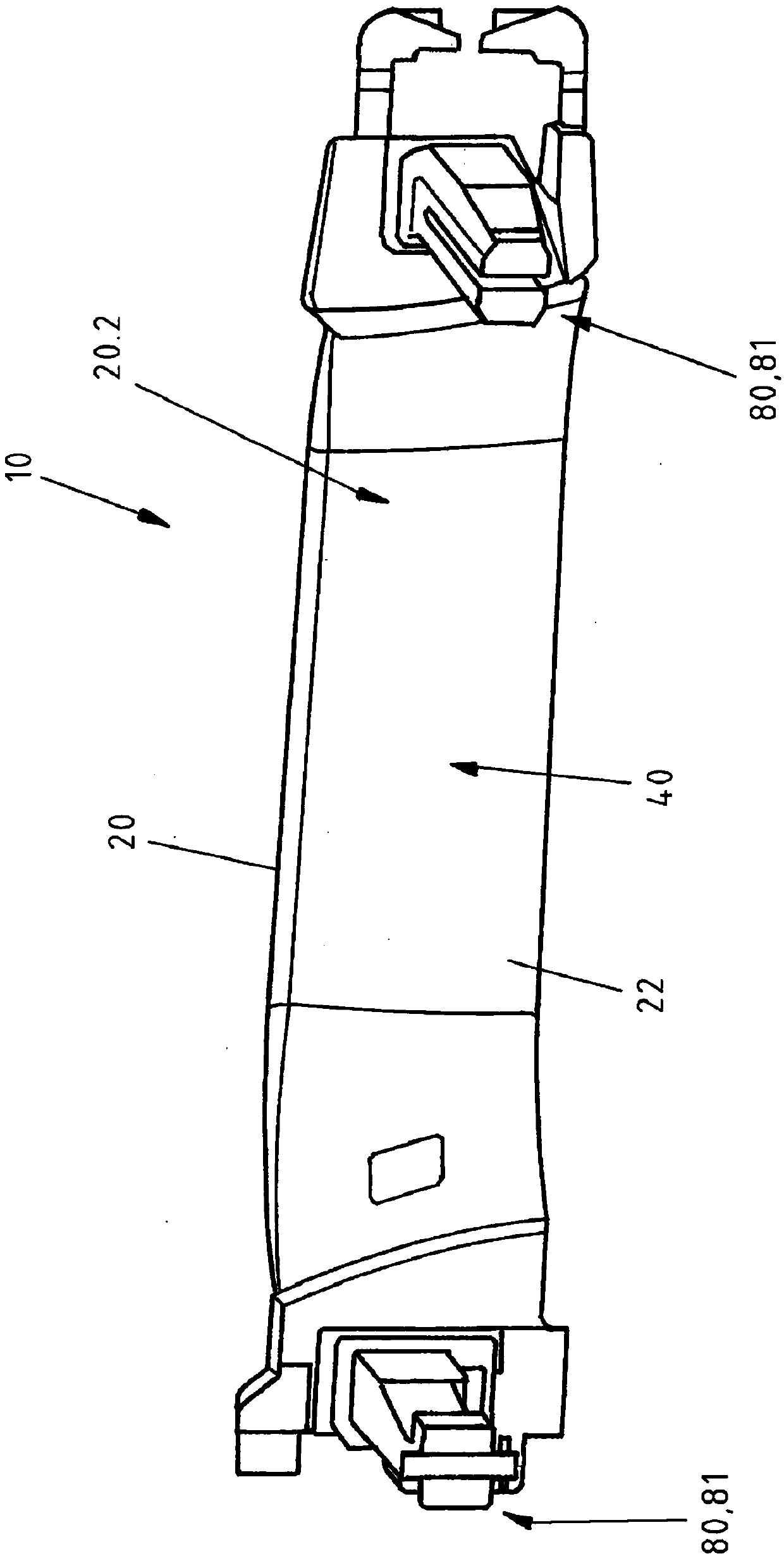

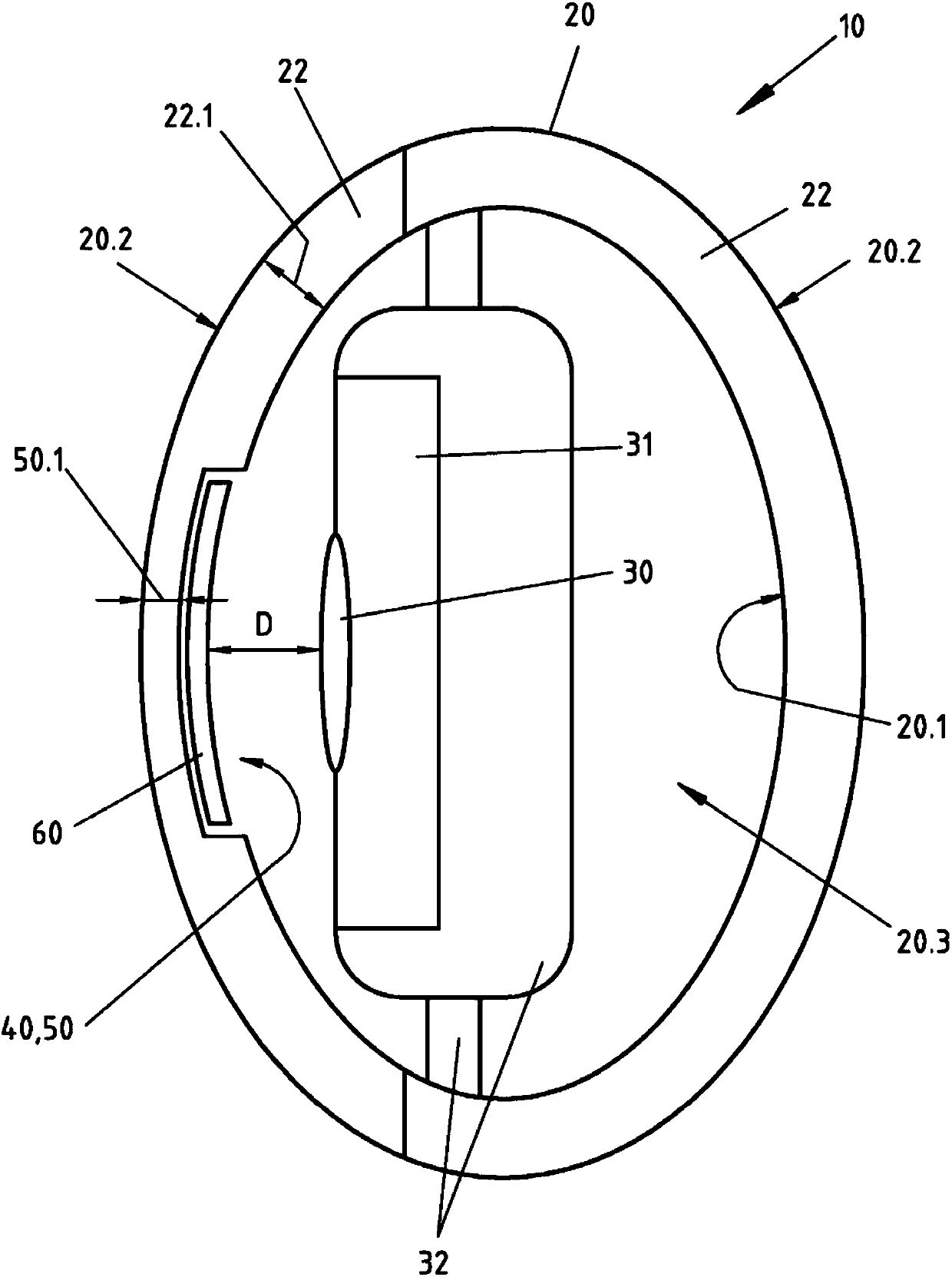

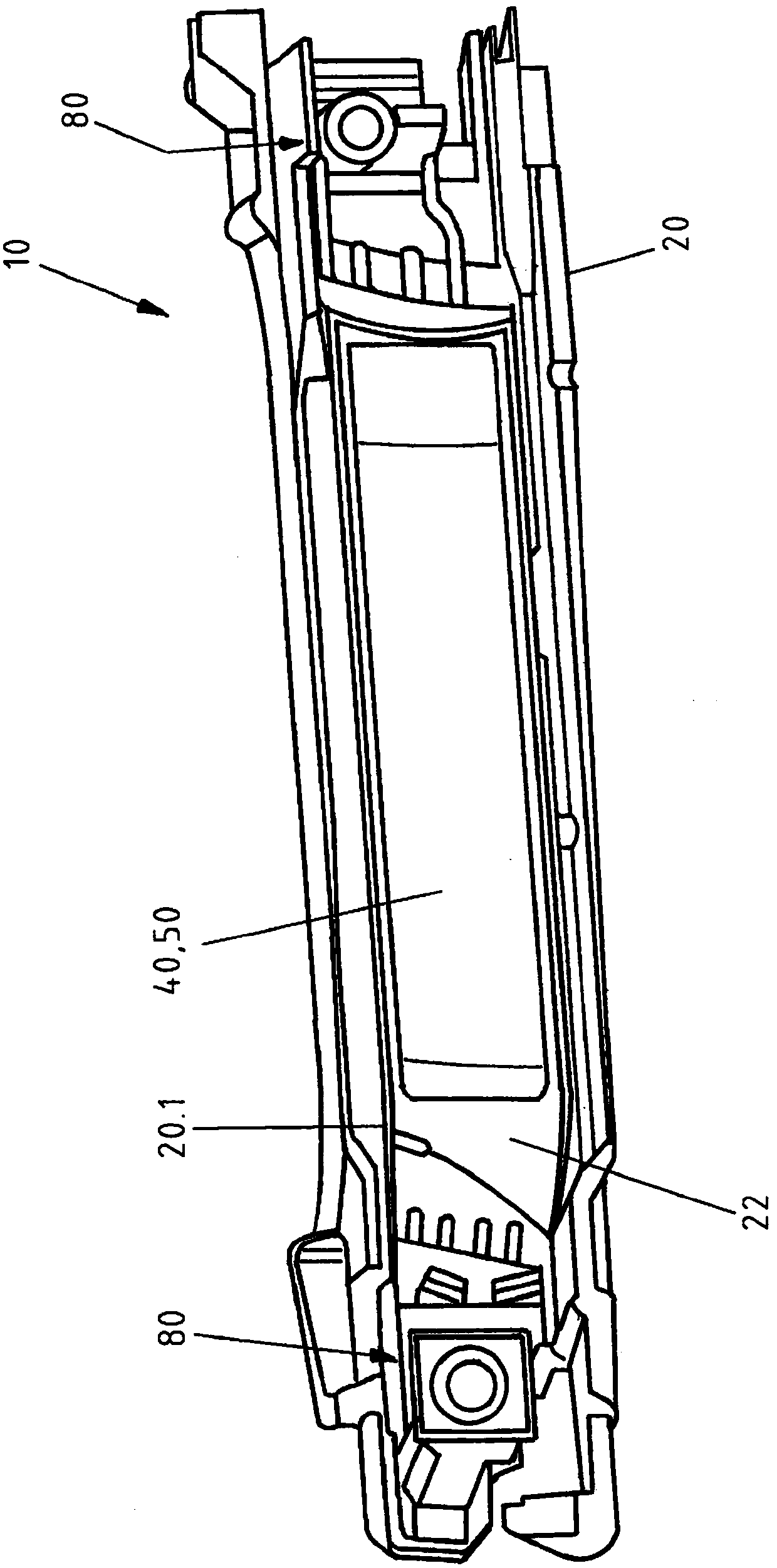

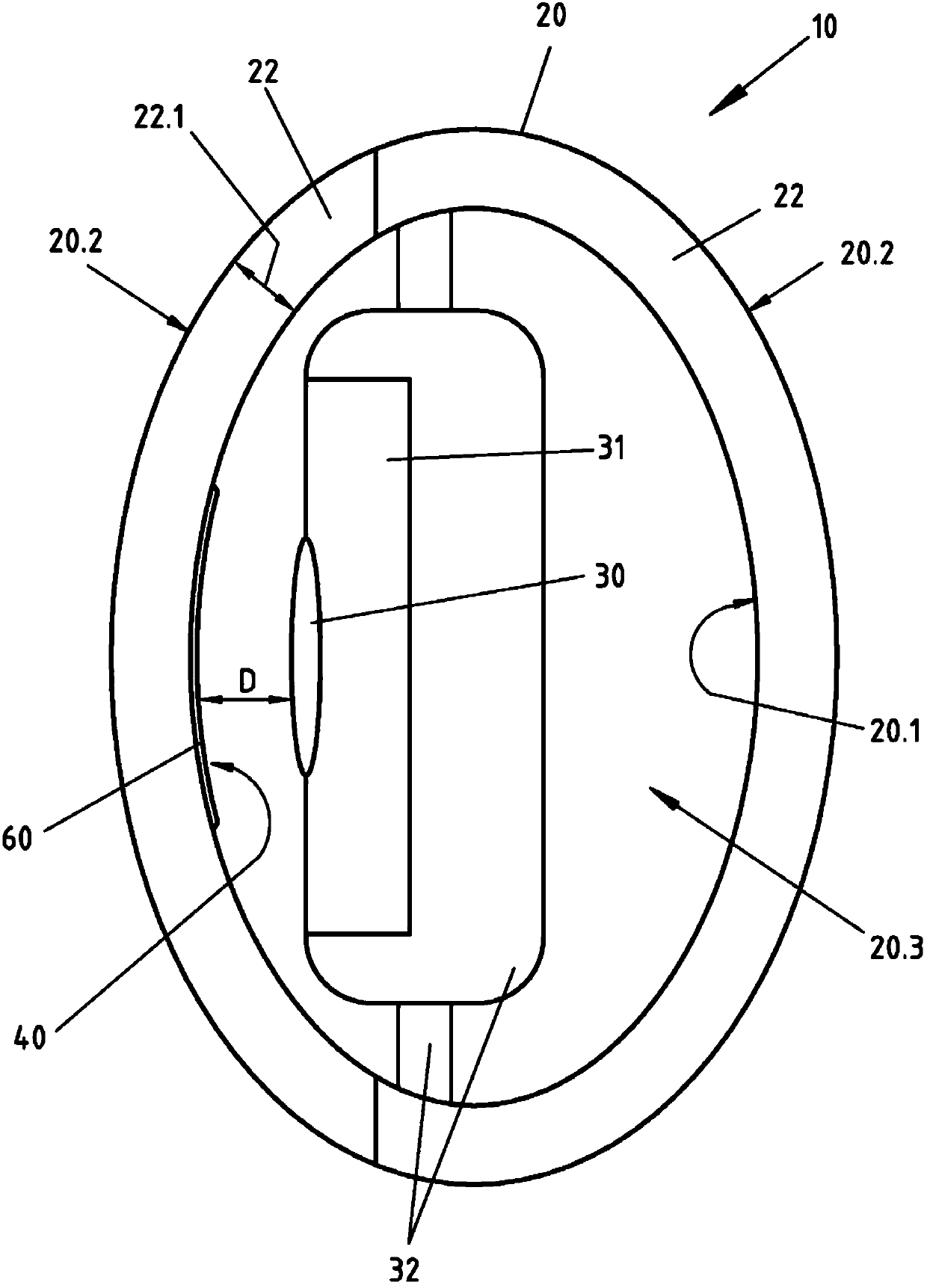

Exterior door handle for a vehicle

ActiveCN107849866AProbe activation actionWing handlesWing knobsActivation actionStructural engineering

The invention relates to an exterior door handle (10) for a vehicle (3), in particular for activating an electric lock (2) of the vehicle (3), comprising: - a door handle base (20) having a wall (22),said door handle base (20) being designed such that a user (5) can carry out an activation action on the door handle base (20) in a deformation zone (40); - at least one inductive activation means (60) arranged in the deformation zone (40); and - at least one sensor device (30), which is arranged inside the door handle base (20) and serves in particular for measuring the inductance on the activation means (60). The door handle base (20) is designed to be elastically deformable at least in the deformation zone (40), and the sensor device (30) is spaced apart from the activation means (60) suchthat the deformation of the door handle base (20) can be detected by measuring the inductance.

Owner:HUF HULSBECK & FURST GMBH & CO KG

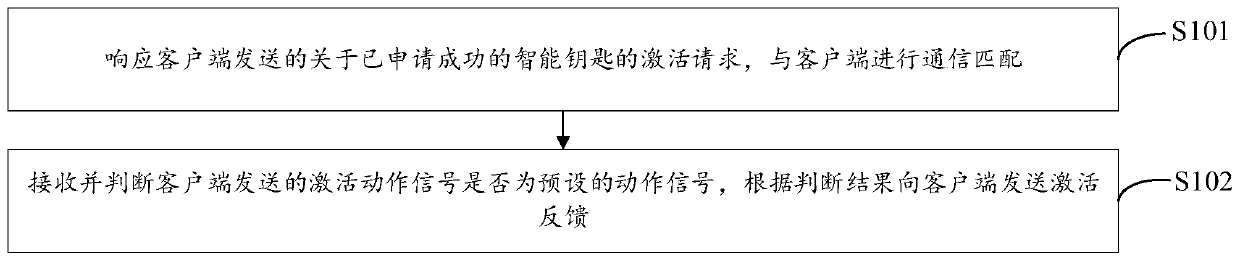

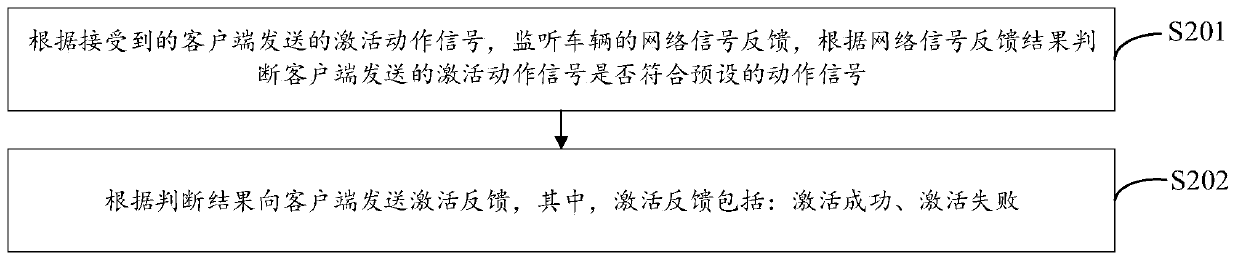

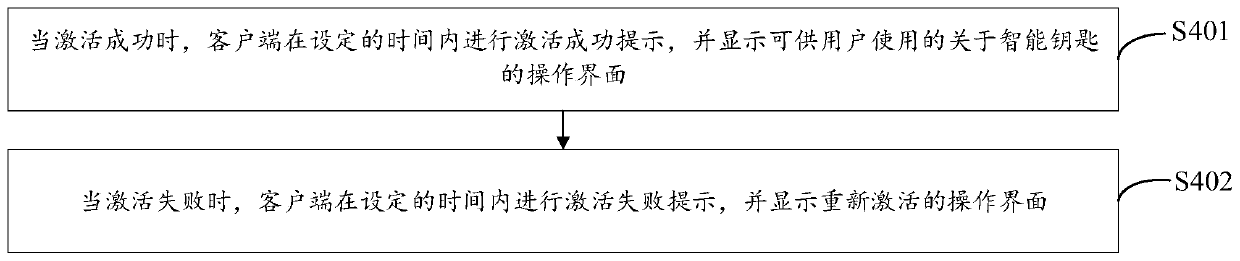

Intelligent key activation method and system, control device and client

InactiveCN110164004AAchieve activationAchieve matchingAnti-theft devicesIndividual entry/exit registersActivation methodActivation action

The invention discloses an intelligent key activation method and system, a control device and a client, and belongs to the technical field of vehicles. The method comprises the steps of carrying out communication matching with the client in response to an activation request, about a successfully applied intelligent key, sent by the client; and receiving and judging whether an activation action signal sent by the client is a preset action signal or not, and sending activation feedback to the client according to the judging result. According to the method, the activation of the intelligent keysis realized through judging whether activation action signals accord with preset action signals or not, and the matching of the intelligent keys can be realized without the information such as the serial numbers of intelligent key controllers and the identification codes of vehicles, so that the whole process is short in time, low in cost and high in safety; and time and frequency are set in the activation process, so that the safety of the intelligent keys in the activation process can be further improved.

Owner:DFSK MOTOR LTD CHONGQING BRANCH CO

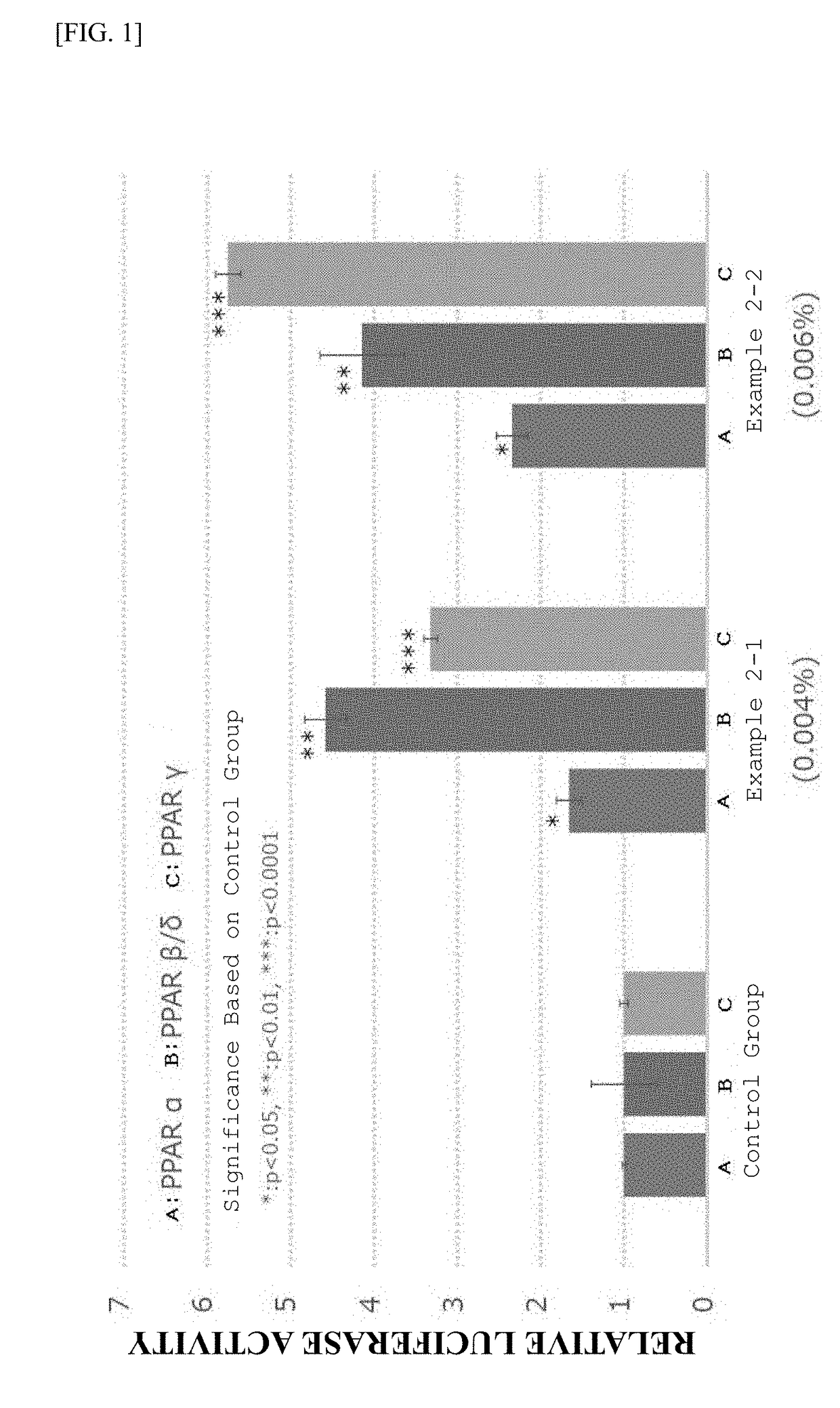

Moringa extract

ActiveUS20180318367A1Useful physiological functionImprove securityOrganic active ingredientsSenses disorderDiseaseSide effect

A moringa extract containing a benzyl glucosinolate in a content of 6% by mass or more, calculated as a dry solid content of the extract, wherein the extract does not substantially contain an alkaloid. The moringa extract of the present invention for solving a first aspect is useful in the field of foodstuff or the like. Also, the PPAR activator of the present invention for solving a second aspect has excellent PPAR activation action, and has no disadvantages in side effects, so that it can be ingested for long term, which can be preferably used in foodstuff and the like. Therefore, the PPAR activator of the present invention for solving a second aspect can be expected to be used as a food, a supplement or a medicament not only for prevention of disease such as insulin resistance, hyperinsulinism, Type 2 diabetes, hypertension, hyperlipidemia, arterial sclerosis and obesity, but also for fatigue recovery or endurance improvement by improving basal metabolism. In addition, a benzyl glucosinolate-containing composition for solving a third aspect is useful in the field of foodstuff or the like.

Owner:TAIYO KAGAKU CO LTD

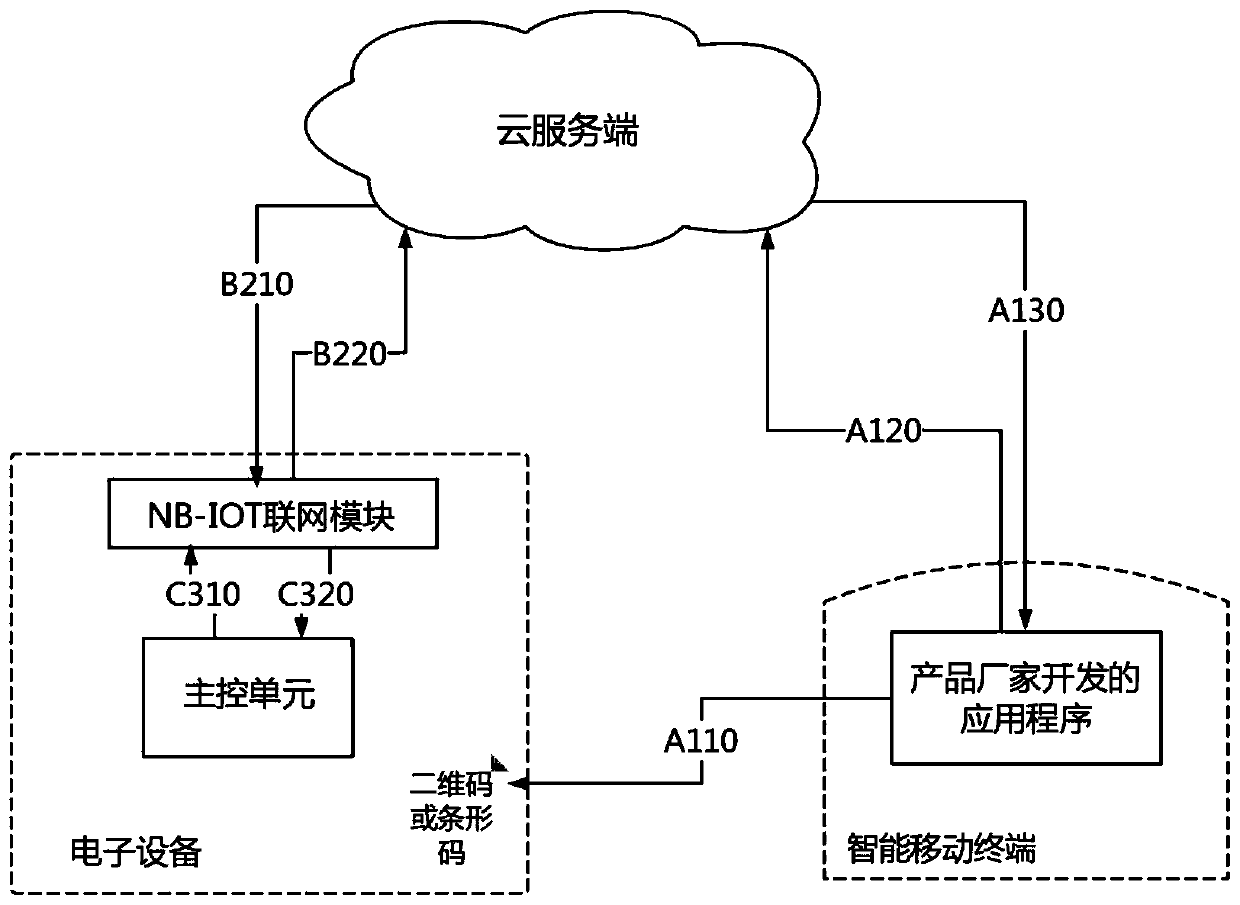

Equipment anti-counterfeiting and activation method and device

InactiveCN110135858AAvoid Activation SituationsGuard against plagiarismCo-operative working arrangementsTransmissionActivation methodActivation action

The invention relates to an equipment anti-counterfeiting and activating method, which comprises the following steps of: S1, scanning an identification code on equipment by using a mobile terminal, obtaining identification information of the equipment, and sending the identification information to a cloud server; S2, after receiving the identification information, enabling the cloud server to check the authenticity and activation of the equipment, and return a corresponding check result to the mobile terminal; S3, if the verification result of the equipment in the step S2 is a genuine productand is not activated, enabling the mobile terminal to trigger an activation action to the cloud server; and S4, enabling the cloud server to generate an activation code according to the identificationcode of the device and send the activation code to the device, and enabling the device to unlock the device after receiving the activation code to complete activation of the device. According to themethod, the anti-counterfeiting and activation method and technology can be effectively prevented from being plagiarized by other manufacturers, and the situation that the method provided by the invention can be applied to activate the copycat product is avoided. The risk of technical leakage is avoided.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

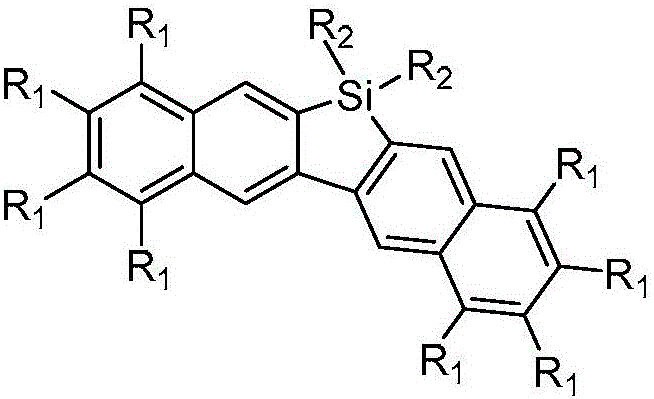

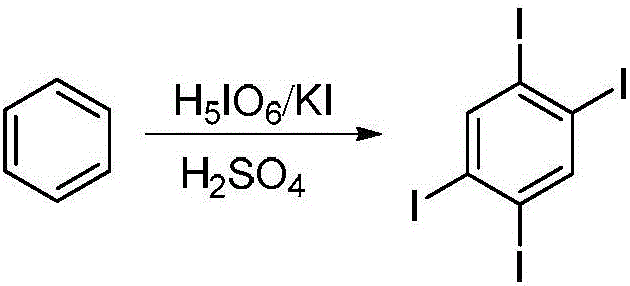

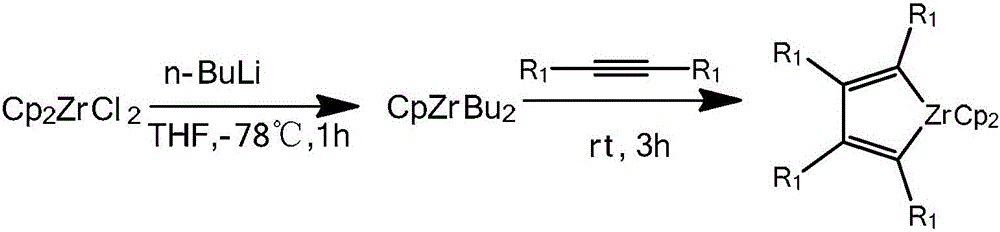

Dinaphthosilole organic photoelectric functional material and synthesis method thereof

InactiveCN106543215ASimple methodHigh stereoselectivitySilicon organic compoundsLuminescent compositionsSynthesis methodsActivation action

The invention discloses a dinaphthosilole organic photoelectric functional material. The functional material is synthesized mainly through the following steps: synthesizing a zirconium heterocycle performing water-free and oxygen-free reaction on bis-substituted internal alkyne under the catalytic action of a metallocene zirconium complex; under the catalytic action of cuprous chloride, reacting with tetraiodo-benzene to generate diiodo-naphthalene; synthesizing a dinaphthalene under the lithiation action of n-butyllithium; and finally synthesizing the dinaphthosilole photoelectric material under the lithiation action of tert-butyllithium. In the synthesis process, the method for preparing the diiodo-naphthalene through coupling reaction of heterocyclopentadiene and polyarylated iodide is simple and high in yield; through the activation action of the n-butyllithium, the dinaphthalene can be synthesized from the bimolecular diiodo-naphthalene; and the metallocene zirconium complex is used as a homogeneous olefin polymerization catalyst, so that the catalytic activity and the olefin polymerization stereoselectivity are high. The synthesized dinaphthosilole is of great use in the fields of conductive high-polymer materials, liquid crystal materials and biological active substances.

Owner:TIANJIN UNIV

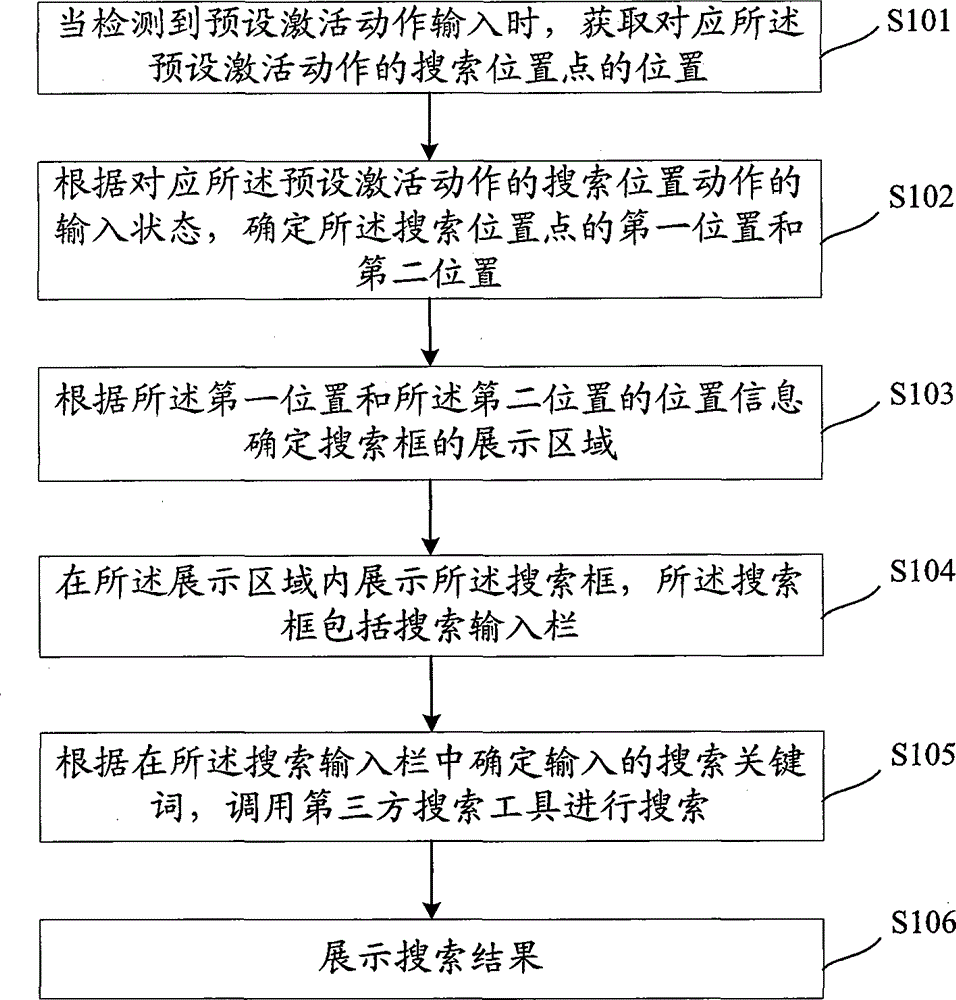

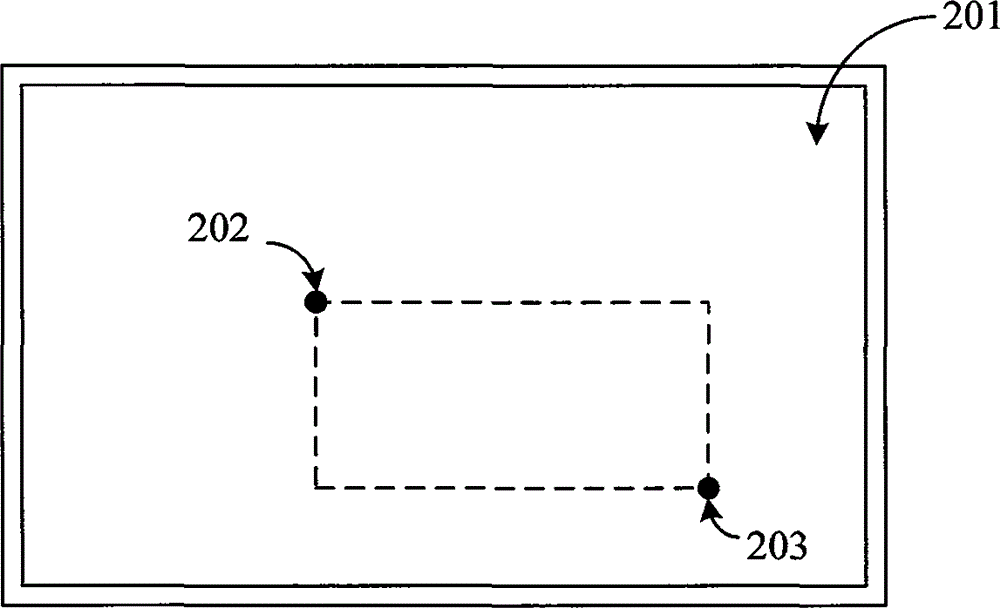

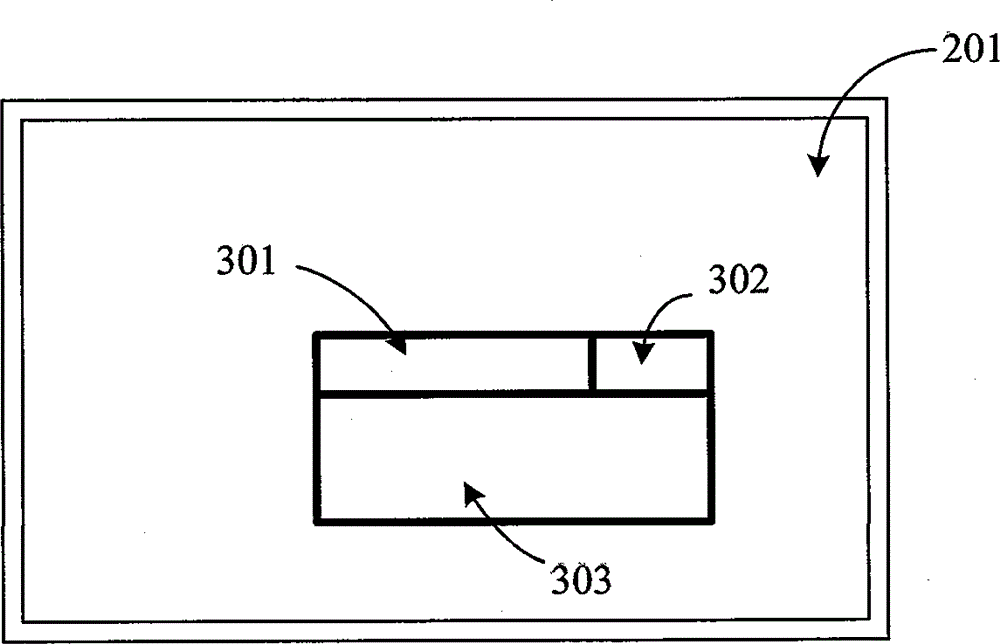

Fast search method and device

InactiveCN104484334AAffect response speedImprove experienceSpecial data processing applicationsInput/output processes for data processingThird partyActivation action

An embodiment of the invention discloses a fast search method and device. When preset activation action input is detected, the position of a search point corresponding to preset activation action is acquired, a first position and a second position of the search point are determined according to input states of search position action corresponding to the preset activation action, a display area of a search box is determined according to position information of the first position and the second position, the search box is displayed in the display area and comprises a search input field, a third-party search tool is called for search according to inputted search keywords determined in the search input field, and search results are displayed. By the aid of the self-defined search box, a user can directly perform search operation on a currently running software interface without switching to a system desktop, search speed is increased, the response speed of search cannot be affected by additional processing burden on a system, and user experience degree is improved.

Owner:高唱

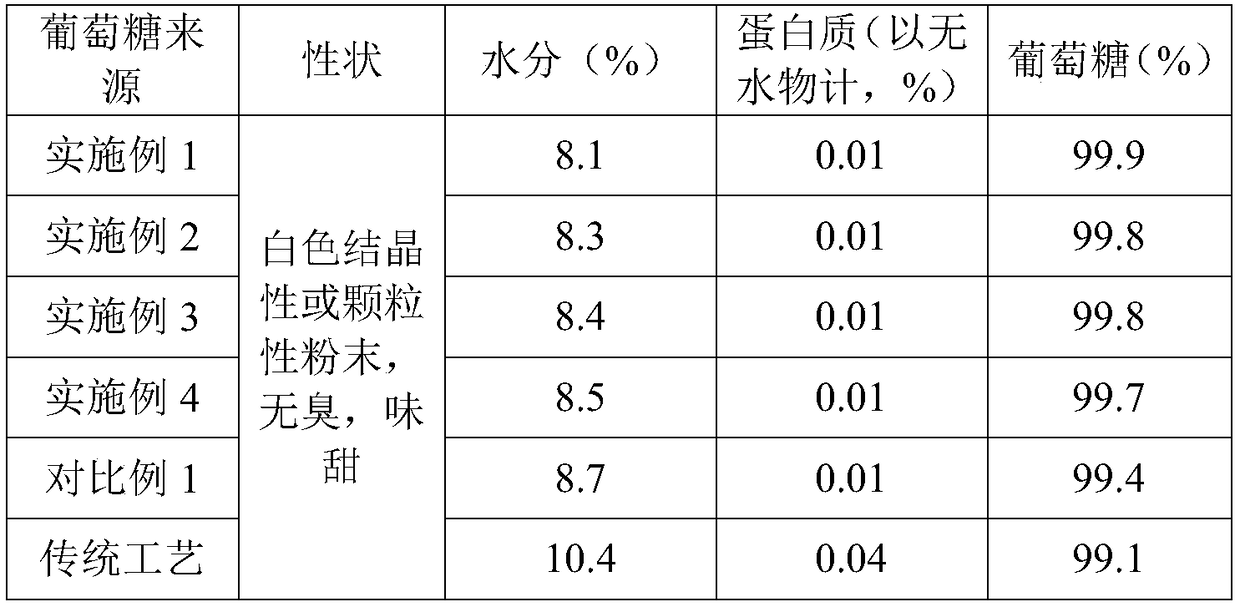

Continuous production method of edible glucose

PendingCN109234330AIncrease profitPromote degradationFermentationGlucose productionUltrafiltrationActivation action

The invention discloses a continuous production method of edible grade glucose. The method utilizes secondary spraying and other processes to prepare high-purity glucose from corn starch milk. The addition amount of liquefaction enzyme and saccharification enzyme in the process is small and the process is simple. As that corn is soak in the ferrous sulfite, the corn can be sterilized, the degradation of the starch in the corn can be promote, and the subsequent glucose production can be promoted to a certain extent; The method also adopts calcium hydroxide solution to adjust pH value of starchsolution before liquefaction and saccharification, and utilizes activation action of calcium ion on liquefaction enzyme to achieve the effect of promoting decomposition of starch, thereby improving utilization rate of corn starch milk; and the invention also adopts calcium hydroxide solution to regulate pH value of starch solution before liquefaction and saccharification to promote decomposition of starch; The invention adopts activated carbon and ultrafiltration membrane to carry out secondary decolorization treatment on glucose solution, and also adopts attapulgite rod to carry out secondarydecolorization treatment on glucose solution. Bacterial cellulose microspheres adsorb proteins, fats and small inorganic salts in glucose solution.

Owner:珠海市麦可美生物技术有限公司

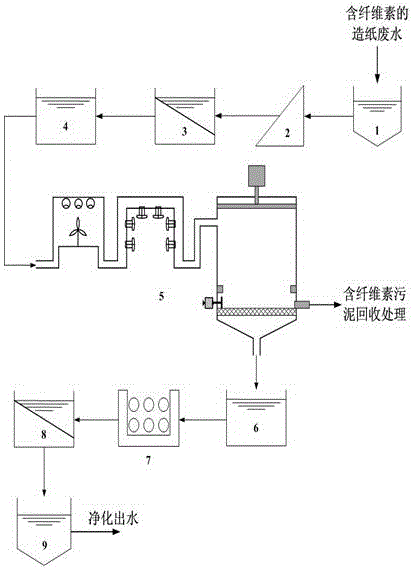

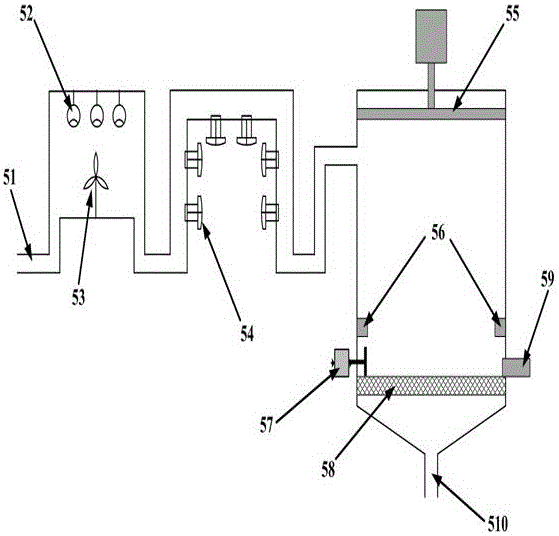

Treatment method for removing cellulose from papermaking wastewater

ActiveCN106007230AEfficient removalHas flocculation propertiesTreatment using aerobic processesWater/sewage treatment with mechanical oscillationsCross-linkCellulose

The invention discloses a treatment method for removing cellulose from papermaking wastewater. The wastewater is treated through a water collection well, a coarse screen, a primary sedimentation tank, a pH value regulation tank, an ultrasonic catalytic crosslinking and cellulose filter-pressing separation system, an aeration tank, a biological oxidation filter tank, a secondary sedimentation tank and a water purification tank sequentially. By innovatively taking the advantage that cellulose has a characteristic of crosslinking reaction in existence of certain weak acid substances, citric acid is selected as a crosslinking agent, and trisodium citrate is selected as a catalyst; the citric acid and the trisodium citrate are added into papermaking wastewater containing a great quantity of natural celluloses to realize well mixing, and then the citric acid and the natural celluloses are in cyclic anhydride-esterification reaction under catalytic activation action of ultrasonic to generate a cellulose gel substance with a space chemical cross-linked structure. The cellulose gel substance is insoluble in water and has a flocculation characteristic, and accordingly simultaneous removal of COD and celluloses in the papermaking wastewater is realized.

Owner:淄博语嫣丹青纸业有限公司

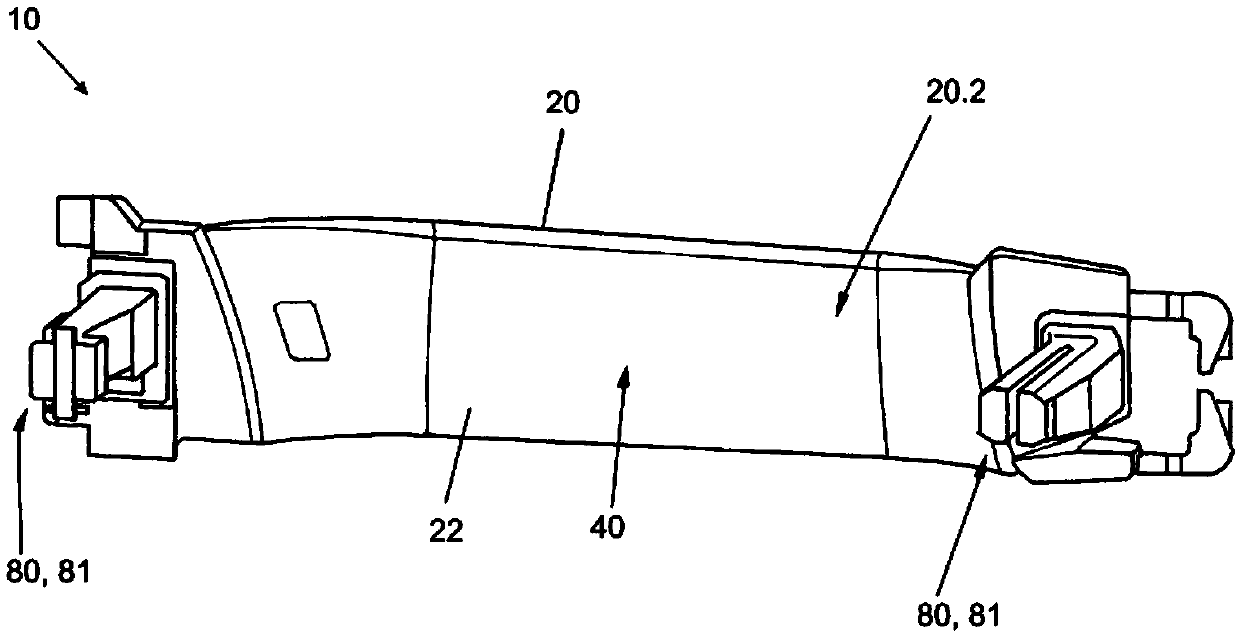

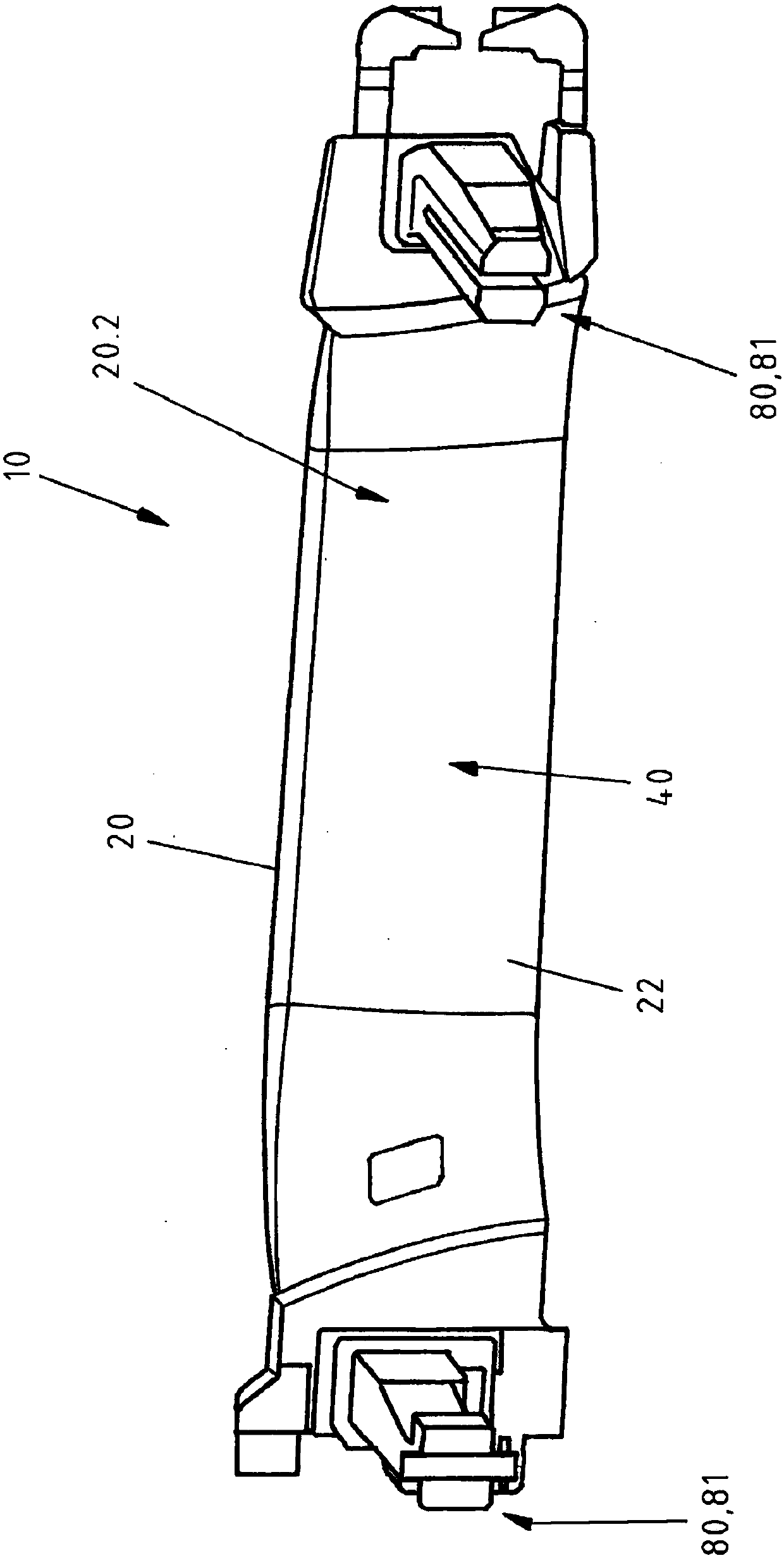

Exterior door handle for a vehicle

ActiveCN107849875AProbe activation actionWing handlesWing knobsActivation actionStructural engineering

The invention relates to an exterior door handle (10) for a vehicle (3), in particular for activating an electric lock (2) of the vehicle (3), comprising: a door handle base (20) having a wall (22), said door handle base (20) being designed such that a user (5) can carry out an activation action on the door handle base (20) in a deformation zone (40); at least one in particular inductive activation means (60) arranged in the deformation zone (40); and at least one sensor device (30), which is arranged inside the door handle base (20) and serves in particular for measuring the inductance on theactivation means (60), the door handle base (20) being designed to be elastically deformable at least in the deformation zone (40).

Owner:HUF HULSBECK & FURST GMBH & CO KG

Ginger juice fermented bean curd and preparation method thereof

InactiveCN102754700AGreat tasteImprove technical indicatorsCheese manufactureFood scienceActivation actionGingerol

The invention relates to ginger juice fermented bean curd which is prepared by comprising the following steps: in the preparation process of fermented bean curd, adding 20wt% of fresh ginger juice into raw soybean milk, and evenly mixing to make the fermented bean curd. The fermented bean curd prepared by adopting fresh ginger and through scientific formula and modern equipment contains abundant protein of soybean and massive vitamins, carbohydrate and various mineral substances and trace elements in the ginger. The ginger juice fermented bean curd has special incense of fermented bean curd and vegetables, has activation action of excellent flora, has increased mouthfeeling taste, and is abundant in intuition.

Owner:HUAINAN BAGONGSHAN XINGXING BEAN PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com