Supersonic wave-ozone-based flue gas desulphurization and denitration device

A desulfurization and denitrification, ultrasonic technology, applied in the direction of air quality improvement, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of large power consumption, less electronics, large floor space, etc., to reduce operating costs and operating costs , no pressure loss, low operating costs

Active Publication Date: 2016-03-02

JIANGSU UNIV OF SCI & TECH

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this technology consumes a lot of power (accounting for about 3% of the power generation), and the energy intensity of pulsed corona discharge is about 1 times higher than that of DC corona discharge, but the average electron energy in the channel is only 2-3eV, and only a hundred A few percent of the electrons are used for the formation of hydroxyl groups and their oxidative desulfurization and denitrification reactions. The pulse width is 10 μs, and the pulse time duty cycle is too small, which is 10-3 to 10-2, so that the electron density in the discharge space is too low, and electrons can be used Less, the ionization duty cycle is too low, which is 10-5~10-4, which also makes the electron concentration in the discharge field extremely low

At the same time, the manufacturing technology of nanosecond pulse power supply is very difficult, which greatly hinders the application of plasma pulse corona discharge in industry

However, the electron beam method has low energy utilization rate, expensive electron gun, short service life of electron gun and target window, complex equipment structure, large floor area, X-ray shielding and protection problems are not easy to solve, and at the same time, it needs to increase the huge amount of equipment that needs to be cooled first and then heated up. heat exchanger etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

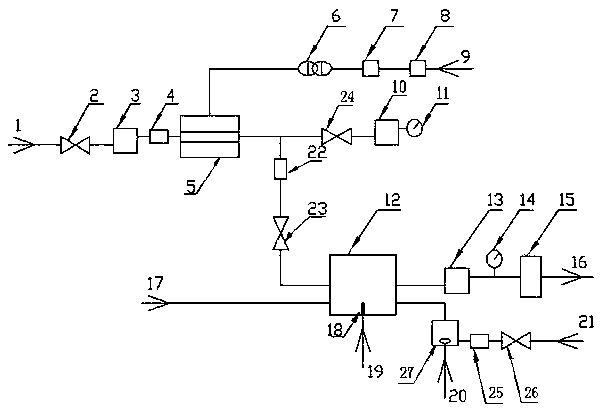

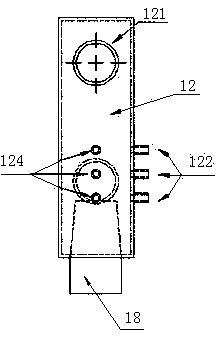

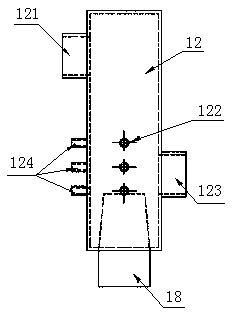

The invention discloses a supersonic wave-ozone-based flue gas desulphurization and denitration device. Air goes through a first valve and then enters a first dryer, the first dryer and a plasma ozone generator are connected by a flowmeter, the plasma ozone generator has two output paths, one path goes through a third valve and then is orderly connected to a second dryer and a first ozone concentration sensor, the other path goes through a second flowmeter and then is orderly connected to a second valve and a flue gas reaction chamber, flue gas is input into the flue gas reaction chamber, an ultrasonic generator is arranged in the flue gas reaction chamber, liquid water orderly goes through a forth valve, a third flowmeter and an ultrasonic oscillator and then is fed into the flue gas reaction chamber, through ultrasonic wave activation action on water and ultrasonic wave mass transfer enhancement effects, when flue gas and ozone go through water mist subjected to ultrasonic treatment and then enter the reaction chamber, gas and water mist in the reaction chamber are subjected to activation under ultrasonic wave action and produce a lot of hydroxyl radicals and other active particles and SO2 and NOX in the flue gas are removed.

Description

technical field The invention belongs to the field of flue gas treatment, in particular to the field of flue gas treatment produced by diesel engine combustion in a ship power system, and relates to a diesel engine flue gas desulfurization and denitrification device. Background technique The diesel engine is in an irreplaceable position in the ship power system, but due to the short formation time, uneven concentration distribution, high temperature and high maximum combustion pressure of the mixed gas generated during the operation of the diesel engine, in the process of diesel combustion, in addition to the normal In addition to the combustion products, a large amount of harmful substances will be produced, which need to be desulfurized and denitrified. In the current desulfurization and denitrification of marine diesel engines, the most mature denitrification technology is selective catalytic reduction (SCR), which refers to the use of reducing agents (such as NH3, liqui...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/74B01D53/60

CPCY02A50/20

Inventor 陈宁

Owner JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com