Continuous production method of edible glucose

A production method and glucose technology, applied in the field of glucose production technology, can solve the problems of low filtration precision, large environmental pollution, and poor quality of filtrate, and achieve the effects of improving utilization rate, simple process, and promoting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

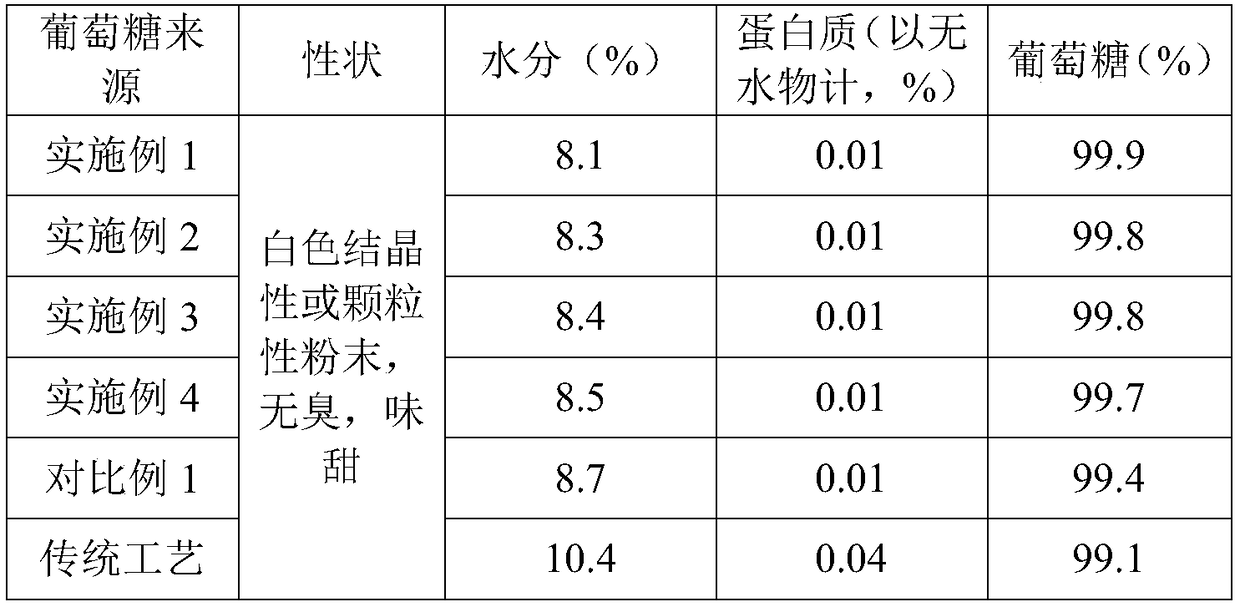

Examples

Embodiment 1

[0030] The continuous production method of food grade glucose provided in this embodiment includes the following steps:

[0031] (1) After the corn is soaked in sulfurous acid solution for 3 days, it is put into a refiner to grind into a thick slurry, and then filtered with a fine sieve to remove impurities, the filtrate is taken into a centrifuge for dehydration, and then placed in a 95 ℃ Corn starch is obtained by drying in a drying box;

[0032] (2) Put the corn starch and purified water obtained in step (1) into the batching tank and mix, add a calcium hydroxide solution with a mass concentration of 0.2%, and heat to 42°C and stir and mix evenly to make the corn starch in the batching tank The pH of the milk is 5.3, and then liquefaction enzyme is added to the corn starch milk to obtain a starch slurry, wherein the beauty of the corn starch milk is 18, and the addition amount of the liquefaction enzyme is that of the corn starch milk 3.5‰ of weight;

[0033] (3) Use a pump to p...

Embodiment 2

[0041] The continuous production method of food grade glucose provided in this embodiment includes the following steps:

[0042] (1) After soaking the corn in sulfurous acid solution for 2 days, put it in a refiner to grind into a thick slurry, then filter with a fine sieve to remove impurities, take the filtrate into a centrifuge for dehydration, and then put it in a 90°C Corn starch is obtained by drying in a drying box;

[0043] (2) Put the corn starch and purified water obtained in step (1) into the batching tank and mix, add a calcium hydroxide solution with a mass concentration of 0.1%, and heat to 40°C and stir and mix evenly to make the corn starch in the batching tank The pH value of the milk is 5.5, and then the liquefaction enzyme is added to the corn starch milk to obtain a starch slurry, wherein the beauty of the corn starch milk is 15, and the addition amount of the liquefaction enzyme is that of the corn starch milk 2‰ of weight;

[0044] (3) Use a pump to pump the s...

Embodiment 3

[0052] The continuous production method of food grade glucose provided in this embodiment includes the following steps:

[0053] (1) After soaking corn in sulfurous acid solution for 4 days, put it in a refiner to grind into a thick slurry, then filter with a fine sieve to remove impurities, take the filtrate into a centrifuge for dehydration, and then put it in a 100 ℃ Corn starch is obtained by drying in a drying box;

[0054] (2) Put the corn starch and purified water obtained in step (1) into the batching tank and mix, add a calcium hydroxide solution with a mass concentration of 0.5%, heat to 45°C, stir and mix evenly to make the corn starch in the batching tank The pH value of the milk is 5.8, and then the liquefaction enzyme is added to the corn starch milk to obtain a starch slurry, wherein the beauty of the corn starch milk is 17, and the amount of the liquefaction enzyme added is that of the corn starch milk 3‰ of weight;

[0055] (3) Use a pump to pump the starch slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com