Patents

Literature

158 results about "GLUCOSE LIQUID" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

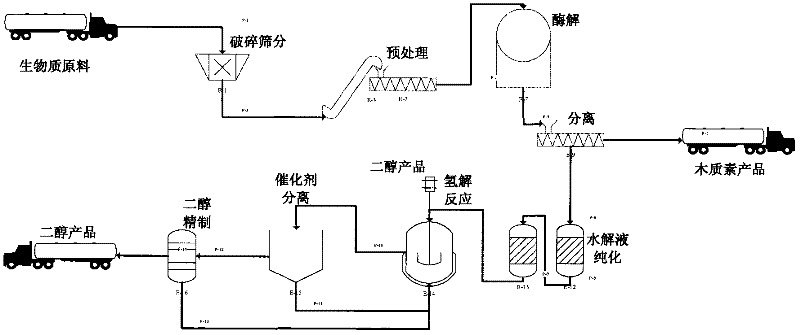

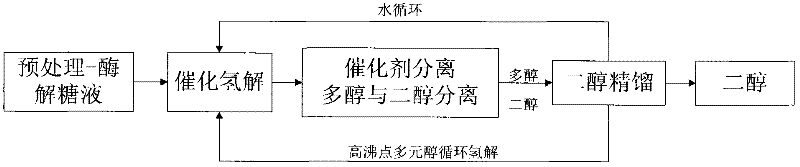

Method for preparing dihydric alcohol from lignocellulosic biomass

ActiveCN102286548AWidely distributedFully distributedOrganic compound preparationHydroxy compound preparationLiquid glucoseFiber

The invention relates to a method for preparing dihydric alcohol from lignocellulosic biomass, which has main steps of: 1, adding alkali liquor, acid liquor or water for pretreatment after lignocellulosic biomass crushing; 2, carrying out enzymolysis and concentrating liquid glucose filtered through enzymolysis after decoloration and ion exchange impurity removal; 3, adding catalysts with hydrogenation hydrogenolysis activity for carrying out hydrogenation hydrogenolysis reaction on the concentrated liquid glucose under the conditions of the pH being 8 to 14, the temperature being 130 to 250 DEG C and hydrogen atmosphere, separating the catalysts, and producing various dibasic alcohol with the carbon number being 2 to 6 after product rectification. The method utilizes the lignocellulosic biomass pretreatment-zymolyting glucose liquid as raw materials, and monosaccharide, soluble polysaccharides and sugar degradation products can respectively react, so both the efficiency and the process controllability can be greatly improved, and products can be independently used through separation and can be directly used for producing unsaturated polyester resin, polyurethane, fuel additives, surface active agents, emulsifying agents, motor vehicle antifreeze fluid and the like without depth separation.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

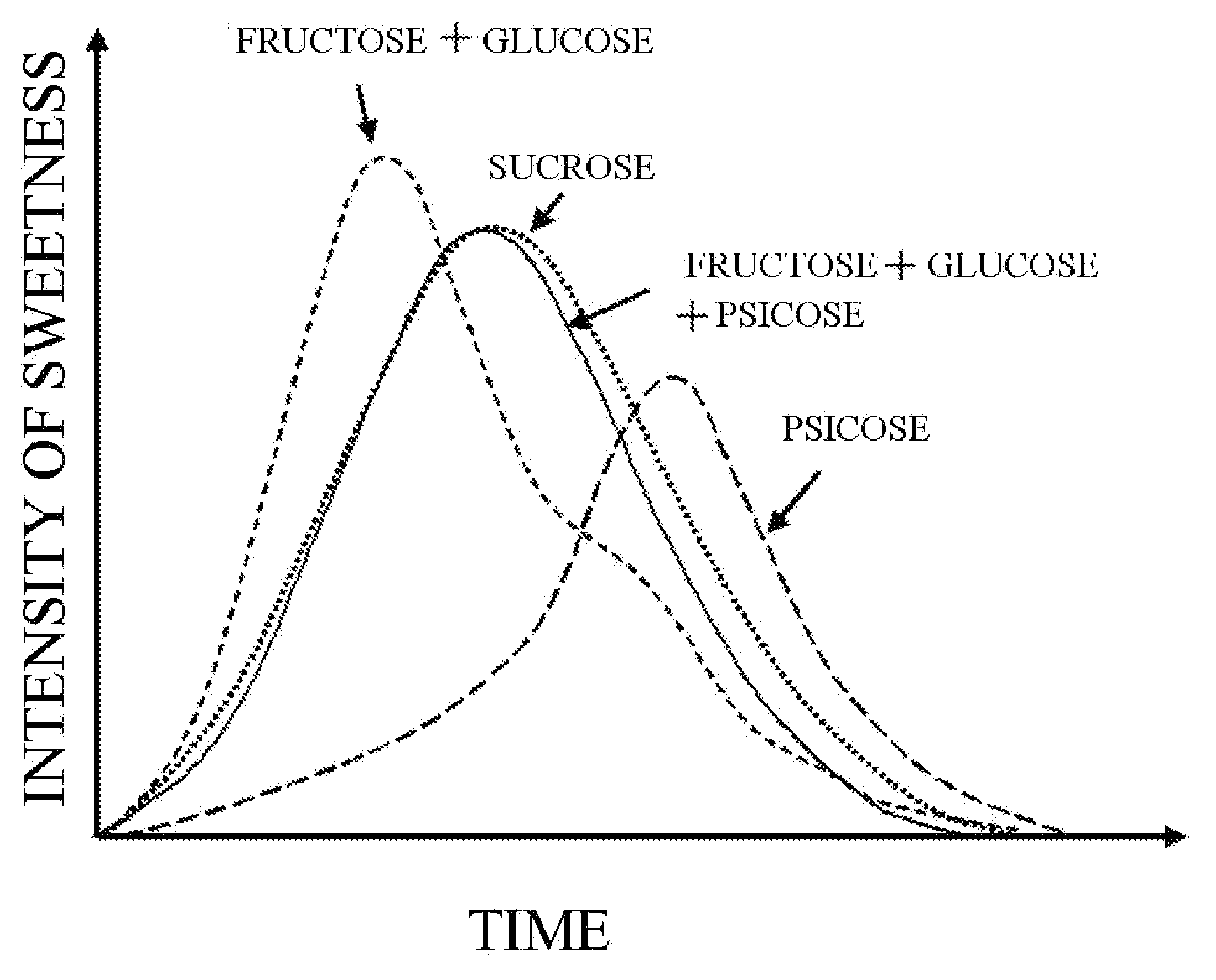

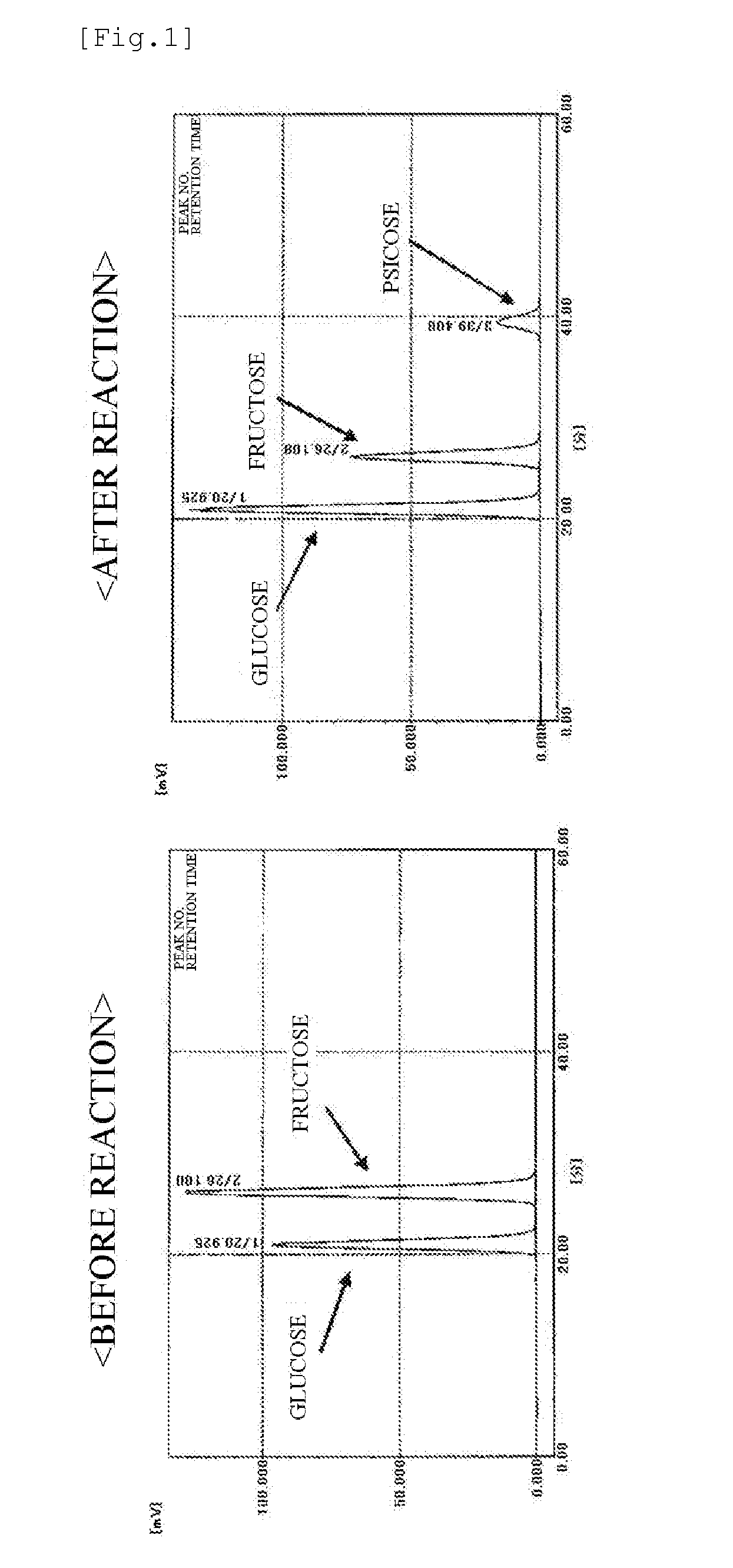

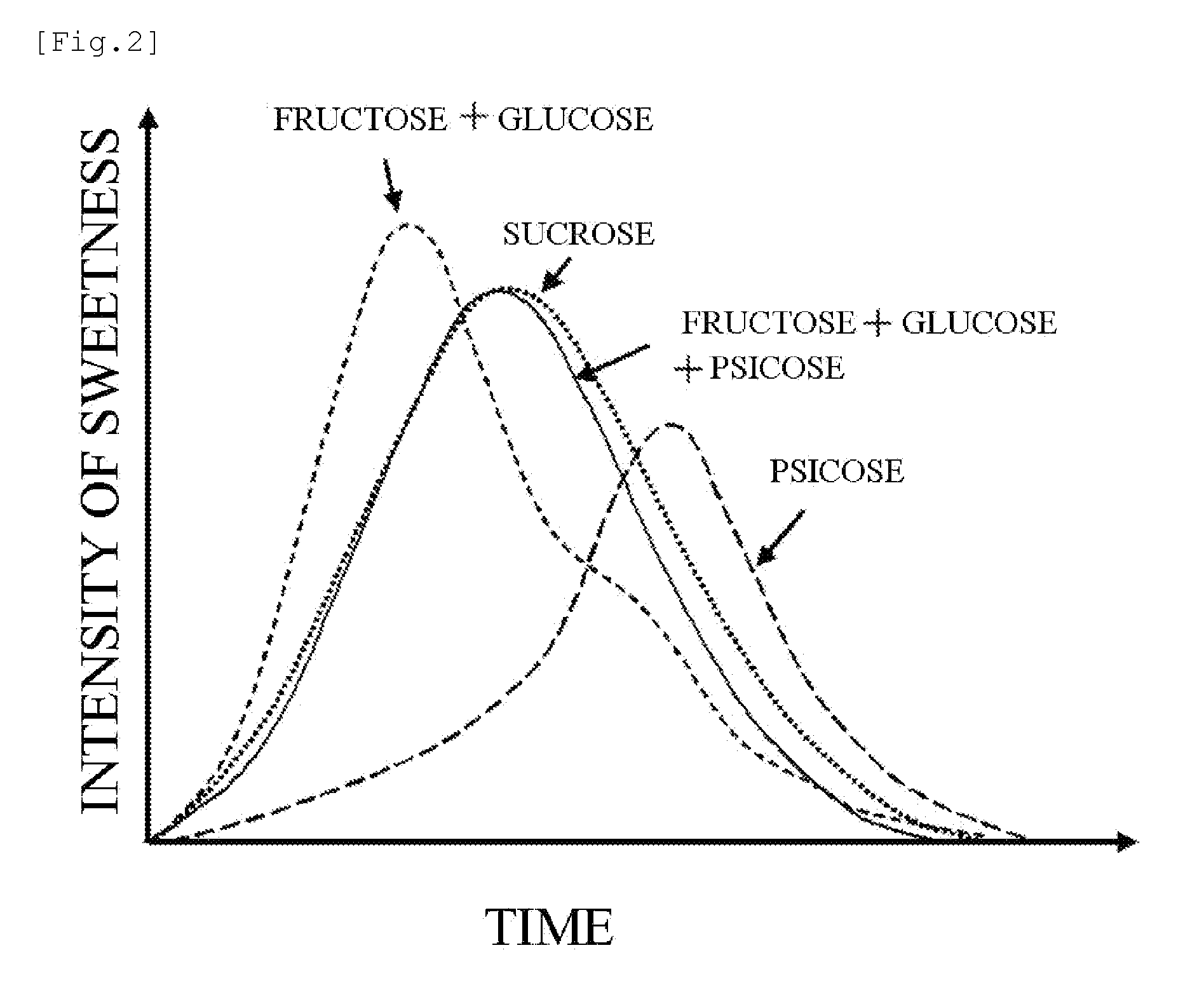

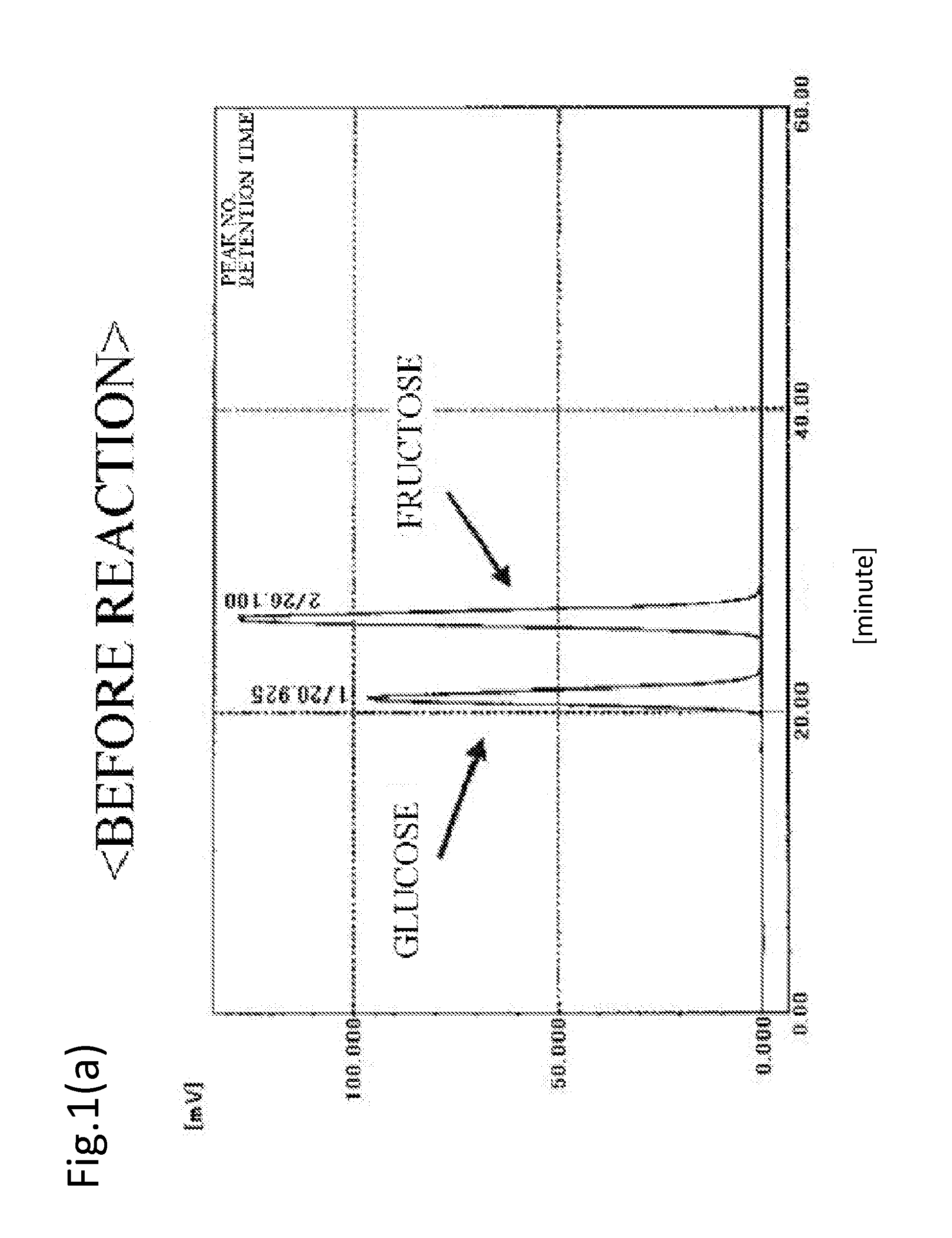

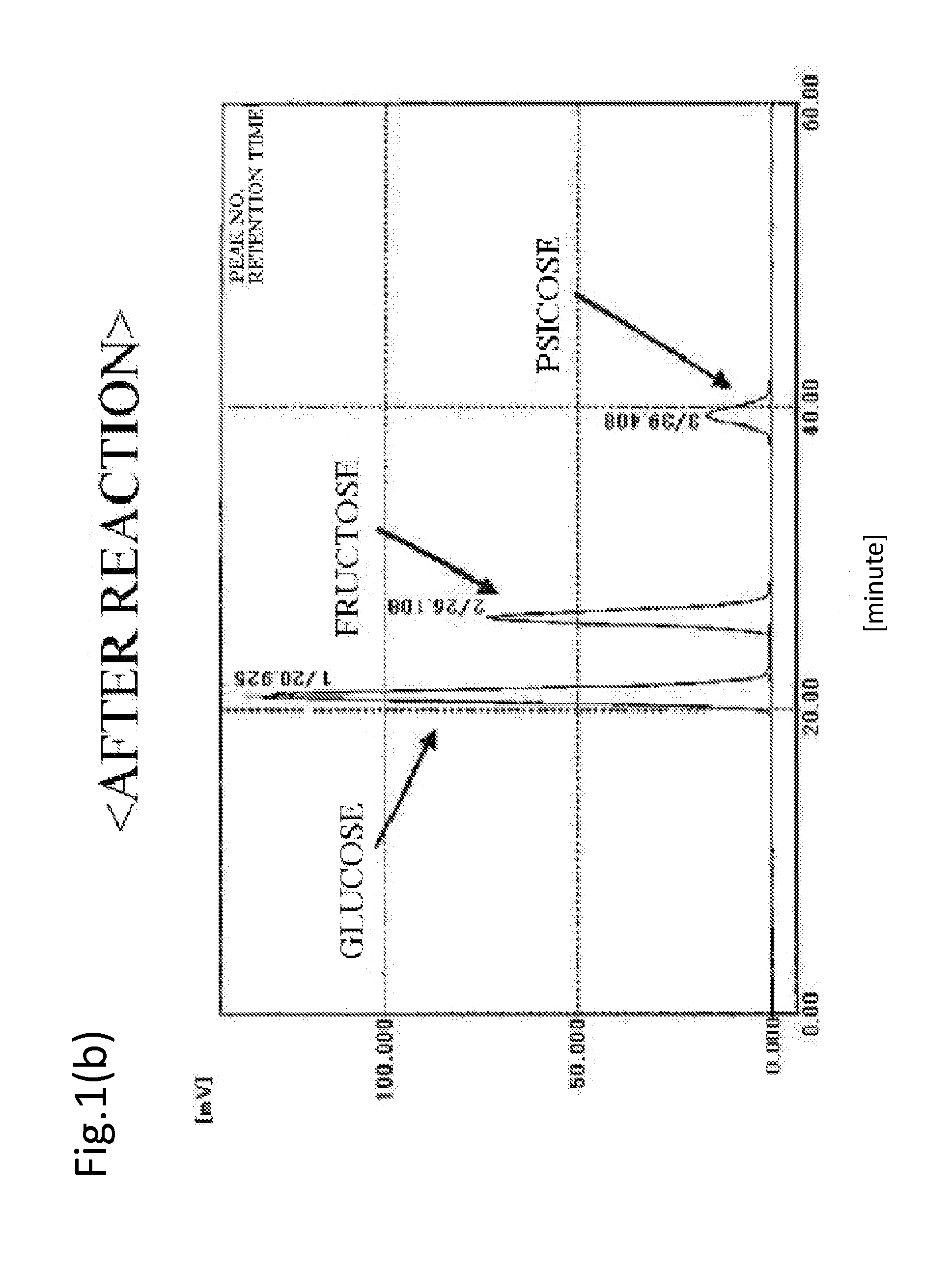

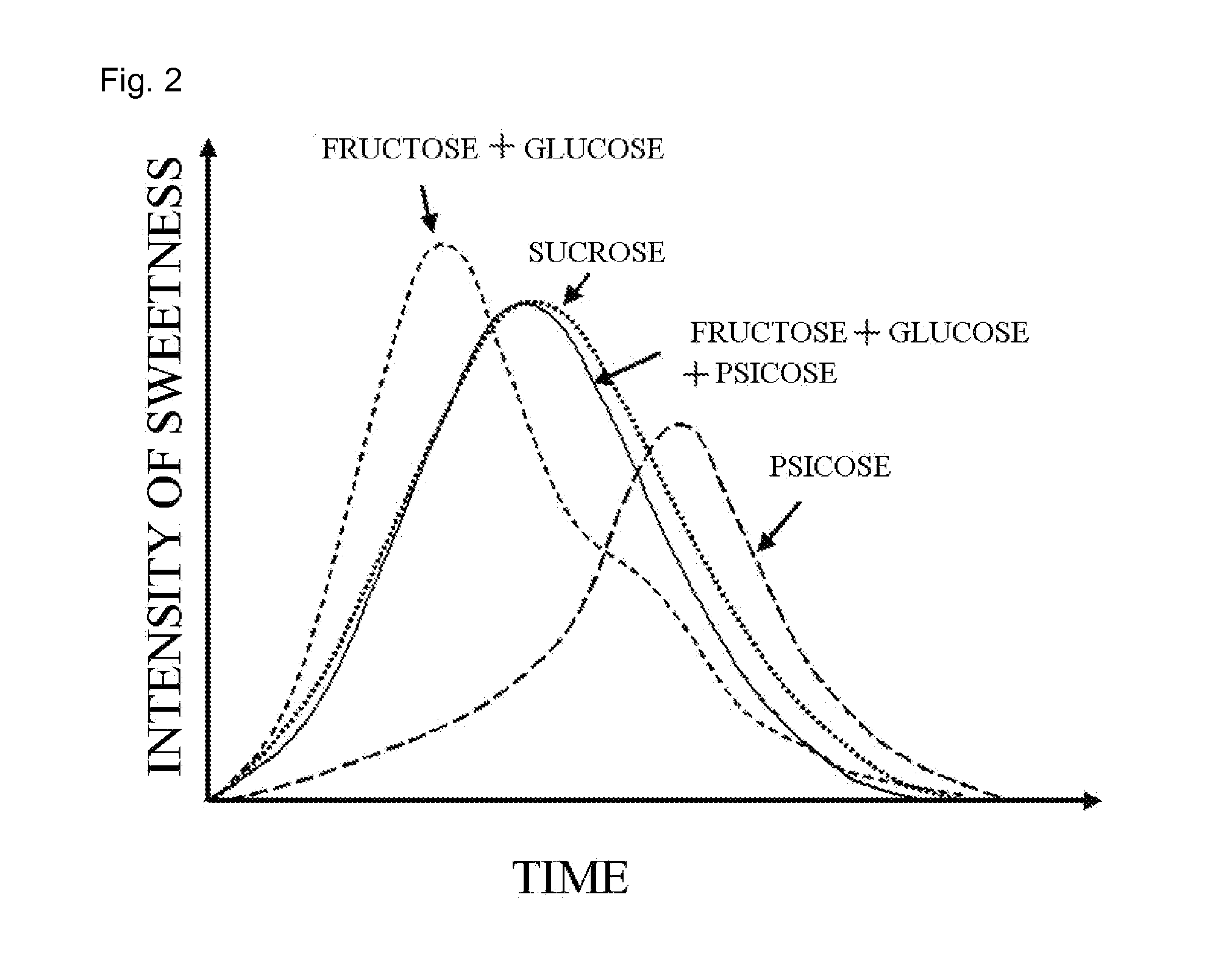

Novel sweetener having sucrose-like taste, method for producing the same, and use of the same

InactiveUS20100204346A1Great tasteLow costOrganic active ingredientsCosmetic preparationsSucroseIsomerase

Problem: To develop a method for producing a novel sweetener containing glucose, fructose, and psicose, which is produced from glucose liquid sugar using an isomerase and an epimerase; use of the novel sweetener as a food or drink material; and a novel sweetener capable of preventing obesity caused by the intake thereof.Means of Resolution: An isomerase and an epimerase are allowed to act on glucose liquid sugar produced in a glucose liquid sugar production plant to thereby produce D-psicose, thereby providing a novel sweetener (product) that maintains the degree and quality of sweetness of a glucose-fructose mixed solution and never causes obesity, a method for producing the same, and use of the same.

Owner:HAYASHIBARA CO LTD +3

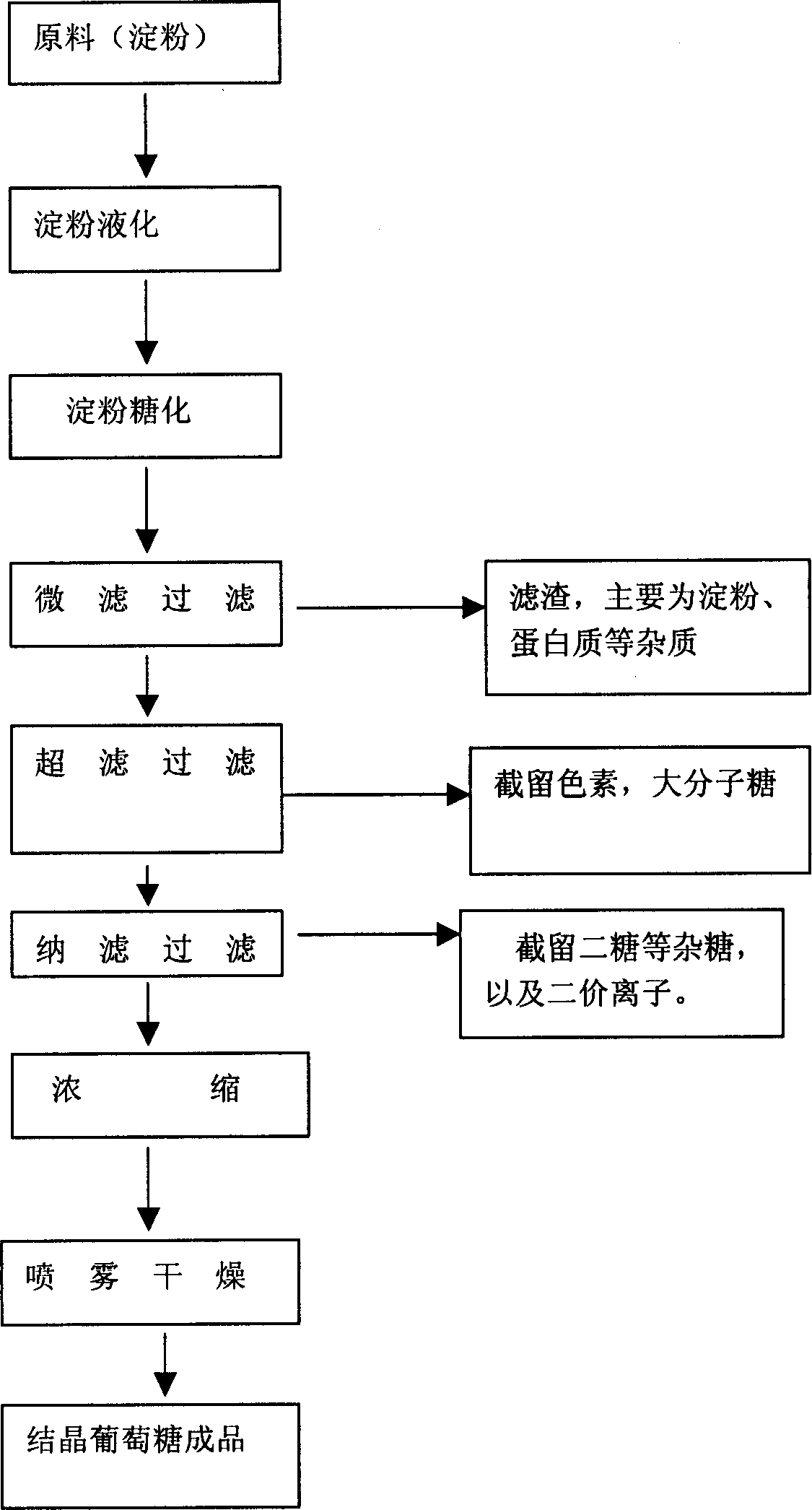

Crystalline glucose producing process based on whole membrane method

ActiveCN1810994AImprove qualityNo pollution in the processInvert sugar productionGlucose productionUltrafiltration

Owner:SANDA FILM SCI & TECH XIAMEN

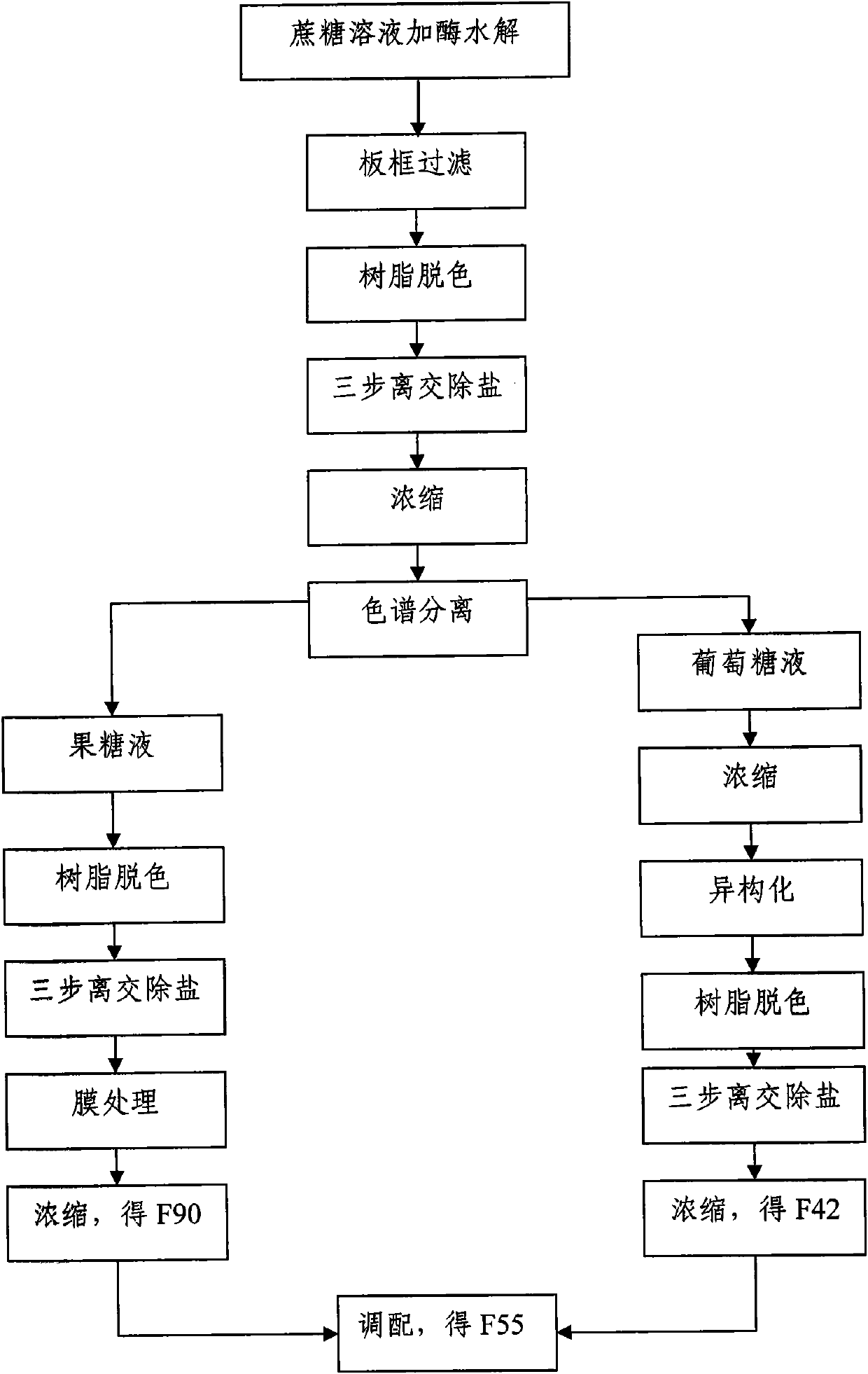

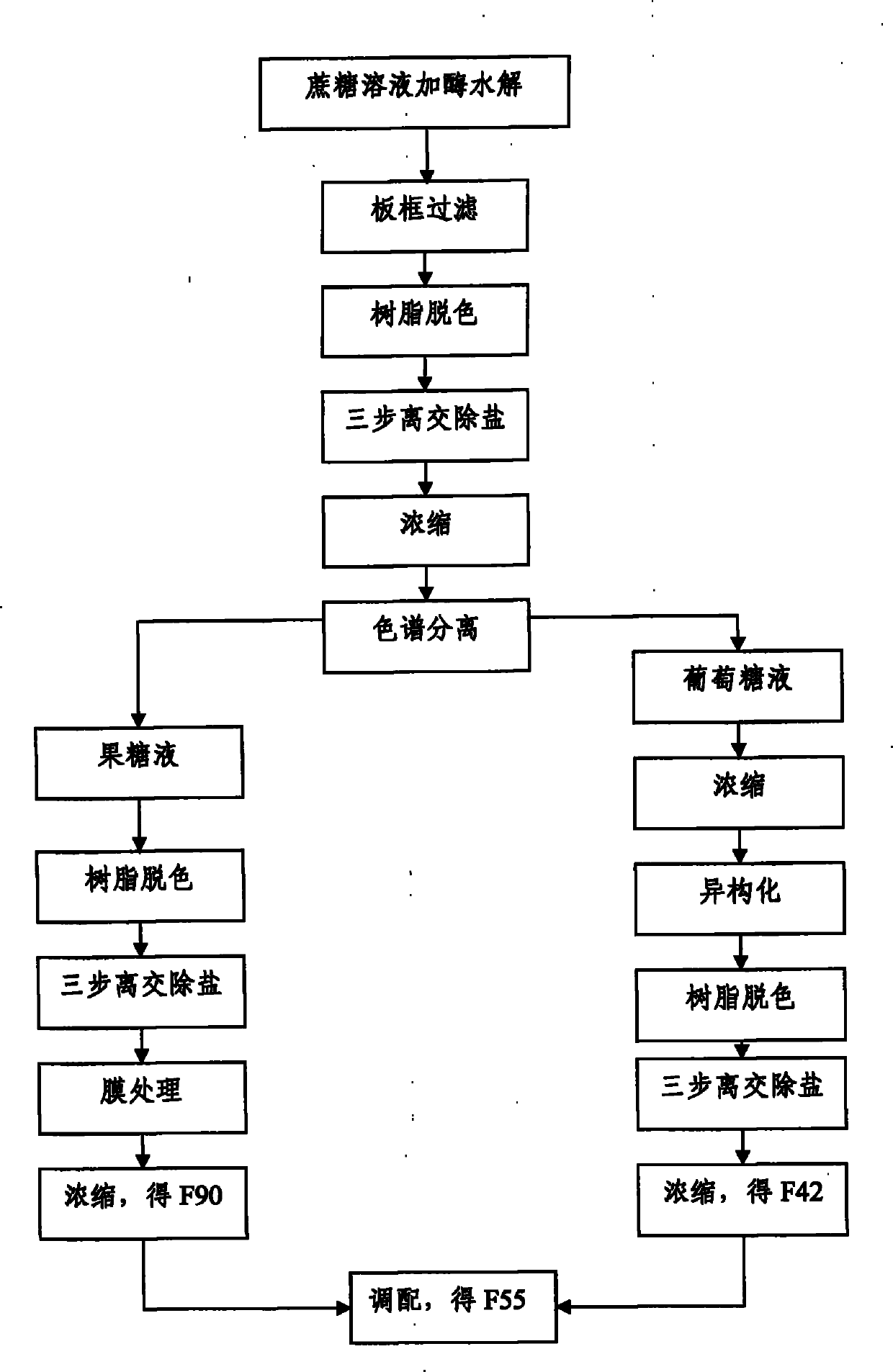

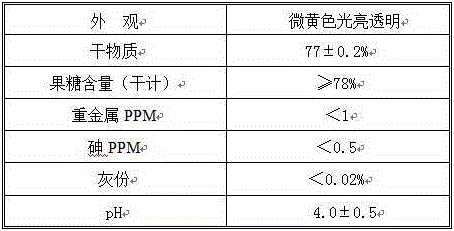

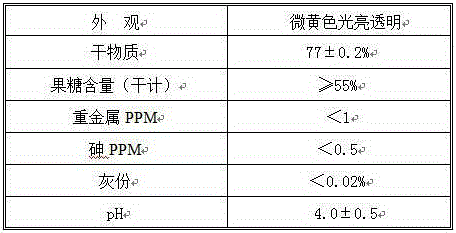

Method for preparing high fructose corn syrup

ActiveCN101766289AHigh purityQuality improvementFood preparationChromatographic separationIsomerization

The invention discloses a method for preparing high fructose corn syrup, comprising the following steps: (1) adding sucrose hydrolase to a sucrose solution for hydrolyzation and carrying out filtration, discoloration, ion-exchange, concentration and chromatographic resolution on the enzymatic hydrolysate to respectively gain high-purity glucose liquid and fructose liquid; (2) carrying out discoloration, ion-exchange, nanofiltration membrane treatment and concentration on the resulting fructose solution to prepare high fructose corn syrup F90; (3) carrying out concentration, isomerization, discoloration, ion-exchange and concentration on the resulting glucose liquid to prepare high fructose corn syrup F42. By adopting the method, sucrose is decomposed by saccharase, fructose purity is increased by resin decolorization and chromatographic resolution, and impurities such as oligosaccharide are removed by a nanofiltration membrane, thus effectively improving the quality of high fructose corn syrup and simultaneously producing sugar liquor with three purities at most to meet different demands.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Method of extracting high-purity glucose from saccharified glucose syrup

InactiveCN1928121AHigh DX valueReduce processGlucose productionGlucose-Fructose SyrupSimulated moving bed

The present invention discloses method of extracting high purity glucose from saccharified glucose syrup, and the method has the advantages of simplicity, high purifying effect, high quality of obtained glucose liquid, etc. The method is that by means of simulating movable bed technology, saccharified glucose syrup is separated to prepare high purity glucose and functional oligose. Specifically, saccharified glucose syrup as material is separated completely into glucose and oligose in a simulating movable bed chromatographic system with water as elutant and at the temperature of 60-80 deg.c, so that the component with rich glucose and the component with rich functional oligose are obtained.

Owner:SHANDONG XIWANG SUGAR

Glucose detection test paper

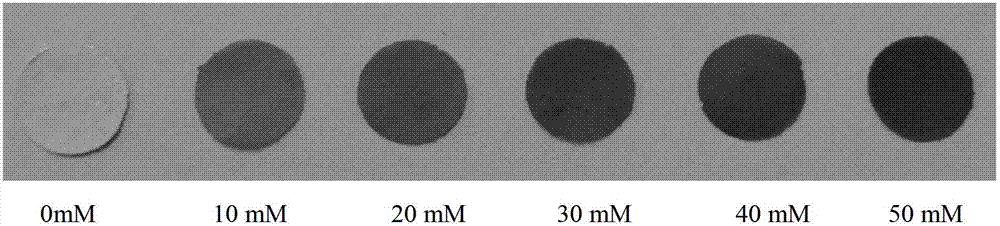

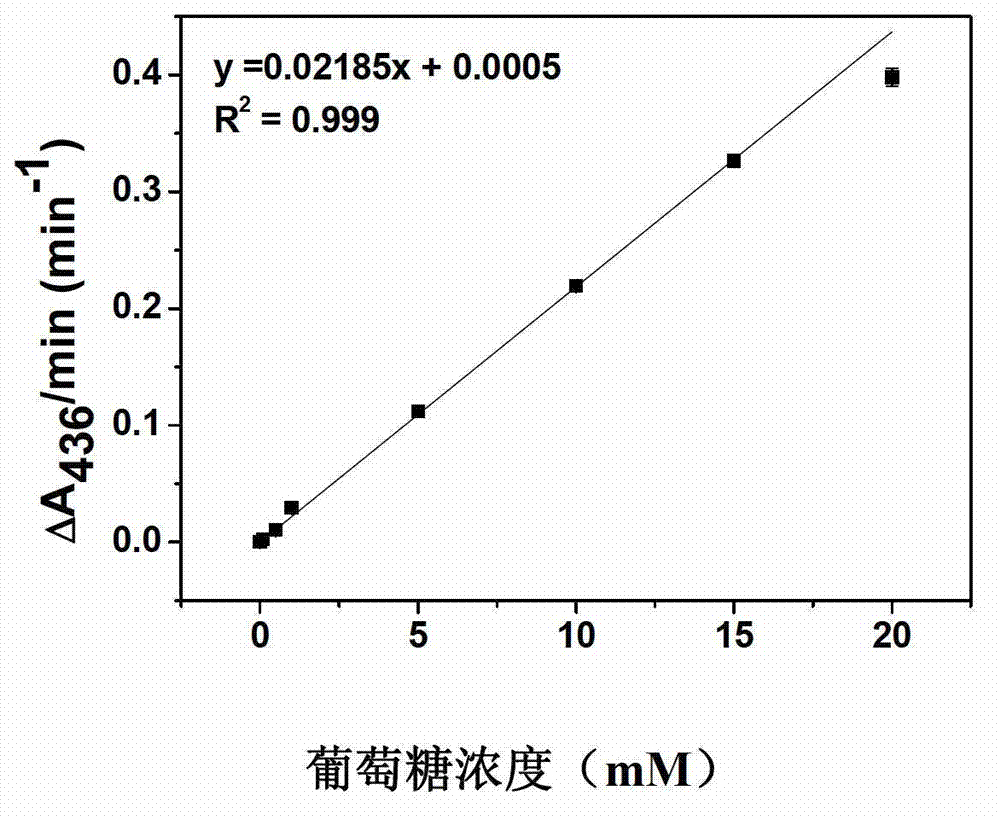

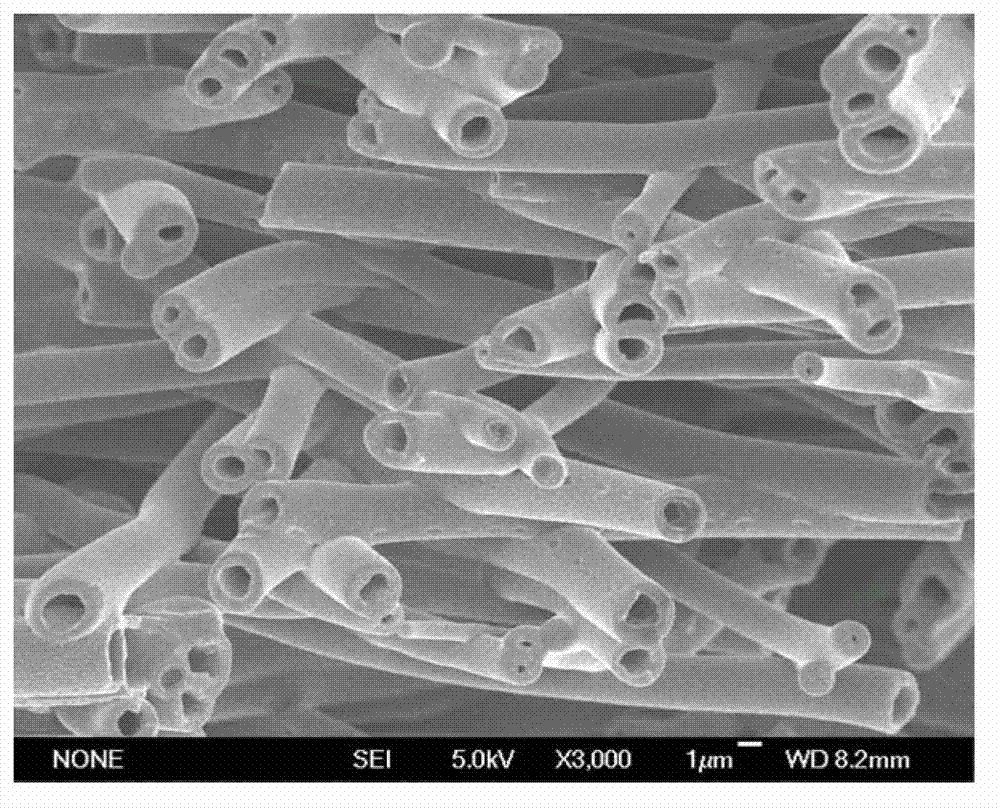

InactiveCN103115919AFast color developmentReduce dosageMaterial analysis by observing effect on chemical indicatorScattering properties measurementsFiberEngineering

The invention provides test paper and a detection method for glucose determination. According to the test paper, glucose oxidase and peroxidase are embedded in a cavity of a polymer, namely hollow nanofibers, in an in-situ manner by using a coaxial co-spinning electrospinning technique, and a color developing agent, namely o-dianisidine, is uniformly distributed on shell layer walls of the hollow nanofibers, and thus the glucose detection test paper with a macroscopic non-woven membrane morphology is obtained. When glucose liquid is dripped on the test paper, glucose is oxidized by the glucose oxidase, hydrogen peroxide is produced, and the colorless o-dianisidine is oxidized to a colored product under the catalysis of the peroxidase, so that the test paper can be subjected to color development, and the quantitative detection on the glucose is carried out through determining the color change of the test paper. A glucose detection reagent based on the hollow nanofibers has the outstanding advantages of simplicity in preparation, small enzyme consumption amount, simplicity and convenient in detection operation, and high storage stability and has an application prospect in the quick and accurate determination of the glucose.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Maize flour low-temperature synchronous saccharification technique by double enzymatical process and its application

InactiveCN101096694AImprove conversion rateImprove utilization efficiencyBiofuelsFermentationAlpha-amylaseSlurry

The invention discloses a low-temperature synchronous saccharifying technique and application of maize flour, which comprises the following steps: blending the maize flour and water; grinding through wet method; making slurry of fine maize flour; modulating the slurry density; adjusting pH value; adding alpha-amylase and saccharifying enzyme into the slurry simultaneously; controlling the saccharifying temperature at 30 deg. c and time; making the glucose liquid synchronously.

Owner:NANJING UNIV OF TECH

Preparation method of micro-nano cuprous oxide particles with controllable morphology and size

InactiveCN104261457AMild responseShape is easy to controlMaterial nanotechnologyCopper oxides/halidesMicro nanoWater baths

The invention discloses a preparation method of micro-nano cuprous oxide particles with controllable morphology and size. The preparation method comprises the following steps: (1) adding a copper sulfate liquid into deionized water, then, adding PVP, mixing with the copper sulfate liquid, then, stirring and performing ultrasonic oscillating to obtain a bright blue liquid; (2) adding a sodium citrate liquid and a sodium carbonate liquid in sequence, and regulating the pH value of the liquid mixture to be greater than 7, wherein the color of the liquid mixture is light blue; (3) standing and then adding the light blue liquid into a glucose liquid, and performing ultrasonic oscillating after mixing so as to uniformly mix the liquid; (4) putting the liquid into a constant-temperature water bath tank to heat to obtain a suspension liquid of cuprous oxide; and (5) centrifuging the suspension liquid by a centrifugal machine after being cleaned with distilled water, and finally drying the particles to obtain the micro-nano cuprous oxide particles. The micro-nano cuprous oxide particles prepared by the preparation method disclosed by the invention have the advantages of environmental friendliness, a controllable particle size, uniform morphology and good dispersion property.

Owner:HARBIN INST OF TECH

Industrial fermentation method of riboflavin

ActiveCN102154426AIncreased industrial fermentation unitsImproving the process conditions of fed-batch fermentationFermentationGLUCOSE LIQUIDCulture mediums

The invention discloses an industrial fermentation method of riboflavin, which comprises the following steps of: filling a seed culture medium into a 10m<3> seed tank, and performing oxic cultivation; and filling a fermentation medium into a 200m<3> fermentation tank for fermentation, mechanically stirring, adding sterilization starch glucose liquid, stopping fermenting till that the glucose is completely consumed or the dissolved oxygen is raised to be 60%, and extracting the riboflavin from the fermentation liquid. After the industrial fermentation method is used, the conventional riboflavin material-supplementing fermentation technology is changed, the low-concentration raw material cultivating bacteria is adopted, the material is quantificationally supplemented according to the changeof the dissolved oxygen of the fermentation solution, the excessive multiplication of the thallus can be effectively controlled, the deviation of the optimum control temperature caused by the excessive supersession can be avoided, the defects of the insufficient ventilation and oxygen supply can be remitted, and the thallus vigor can be kept, so that the indusial fermentation unit of the riboflavin is improved by more than 18g / L, and the yield is increased by 20% compared with the common fermentation.

Owner:GUANGJI PHARMA MENGZHOU

Novel sweetener having sucrose-like taste, method for producing the same, and use of the same

To develop a method for producing a novel sweetener containing glucose, fructose, and psicose, which is produced from glucose liquid sugar using an isomerase and an epimerase; use of the novel sweetener as a food or drink material; and a novel sweetener capable of preventing obesity caused by the intake thereof. An isomerase and an epimerase are allowed to act on glucose liquid sugar produced in a glucose liquid sugar production plant to thereby produce D-psicose, thereby providing a novel sweetener (product) that maintains the degree and quality of sweetness of a glucose-fructose mixed solution and never causes obesity, a method for producing the same, and use of the same.

Owner:MATSUTANI CHEM INDS CO LTD +3

Efficient silkworm breeding method

InactiveCN103931570ASolve the problems of high feeding cost, difficult temperature and humidity control, etc.Improve edibleAnimal husbandryAnimal scienceGLUCOSE LIQUID

The invention discloses an efficient silkworm breeding method. Silkworms are bred in the house of a silkworm breeding family and placed in breeding containers, the indoor temperature and indoor humidity are controlled, and the breeding containers are rectangular dustpans formed by weaving bamboo battens. The method includes the steps of firstly, disinfecting a room and the breeding containers before breeding; secondly, preparing mulberry leaves, namely, selecting the mulberry leaves according to the age of the silkworms and spraying glucose liquid with the concentration of 25% on the mulberry leaves; thirdly, additionally hastening the hatching of the silkworms by adjusting the temperature and humidity; fourthly, gathering newly-hatched silkworms and feeding the silkworms with the mulberry leaves; fifthly, mounting the silkworms at the optimum maturity. By means of the method, labor can be saved, production cost can be reduced, the growth of the silkworms can be accelerated, the constitution of the silkworms can be enhanced, the silkworms can be mounted in advance, the effects of saving cost and improving efficiency are achieved, and the method has practical popularization value.

Owner:陆良县蚕种场

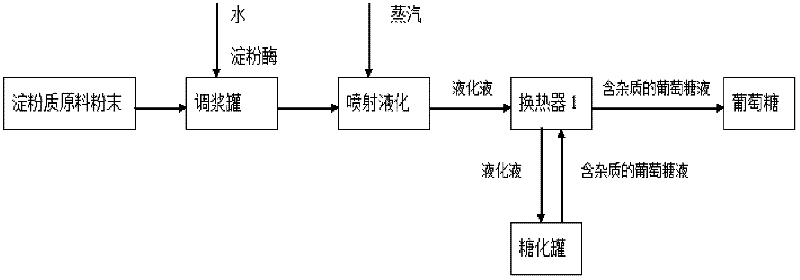

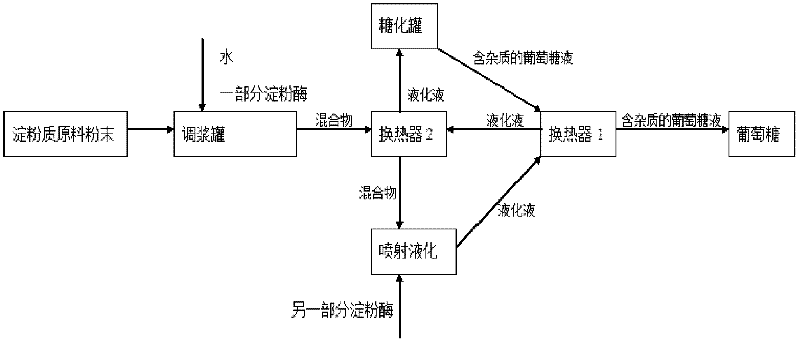

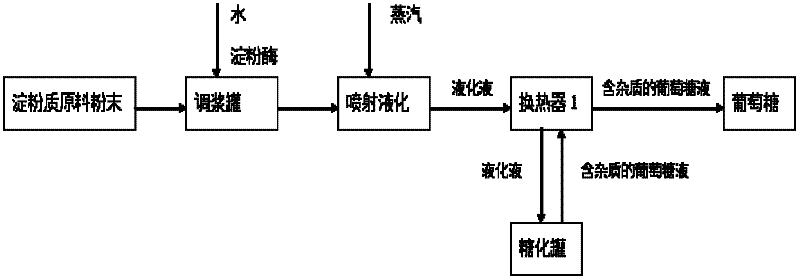

Production method of glucose

The invention provides a production method of glucose. The method comprises steps of: (1) mixing a starchiness raw material powder and water to obtain a starch slurry, mixing the starch slurry with amylase to obtain a mixture, injecting and liquefying the mixture to obtain a liquefied liquid; or mixing the starch slurry with part of the amylase to obtain a mixture, injecting and liquefying the mixture, adding the other part of the amylase to obtain a liquefied liquid; (2) saccharifying the liquefied liquid with existence of glucoamylase to obtain a glucose solution containing impurities; (3) heating and purifying the glucose solution containing impurities to obtain the glucose. Heat for the heating is partly from heat exchange between the liquefied liquid from step (1) and the glucose solution containing impurities to obtain the glucose. According to the above technical scheme, steam needed for heating disinfection of the liquid from saccharification can be omitted to save energy.

Owner:COFCO BIOTECHNOLOGY CO LTD

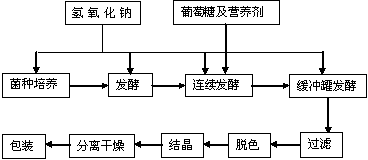

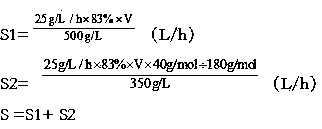

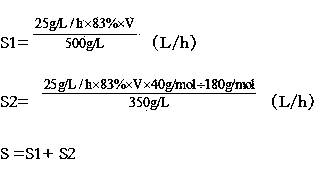

Efficient fermentation production process of sodium gluconate

InactiveCN103898171AShortened cultureShort sterilization timeMicroorganism based processesFermentationBiotechnologyContinuous fermentation

The invention relates to an efficient fermentation production process of a sodium gluconate. The efficient fermentation production process comprises the first step of seed culturing, the second step of inoculated fermentation, the third step of continuous fermentation, the fourth step of filtering, the fifth step of decoloring, the sixth step of crystallization, the seventh of separation and drying and the eighth step of packaging. In the third step, namely, the continuous fermentation step, when the online measured concentration of a sodium gluconate reducing sugar is less than or equal to 50g / L according to the terminal stage of fermentation of the second step, a glucose liquid and a nutrient are automatically replenished by 500g / L, and simultaneously, a fermentation liquor is discharged to a buffer tank from the bottom of a fermentation tank, and meanwhile, NaOH (in a content of 350g / L) is also replenished. The continuous fermentation step of the efficient fermentation production process has the advantages that the glucose liquid and the nutrient are replenished under online automatic control, long-term continuous fermentation of the glucose is realized, the time of seed culture and fermentation liquor sterilization is saved, and the production efficiency is improved.

Owner:山东福洋生物科技股份有限公司

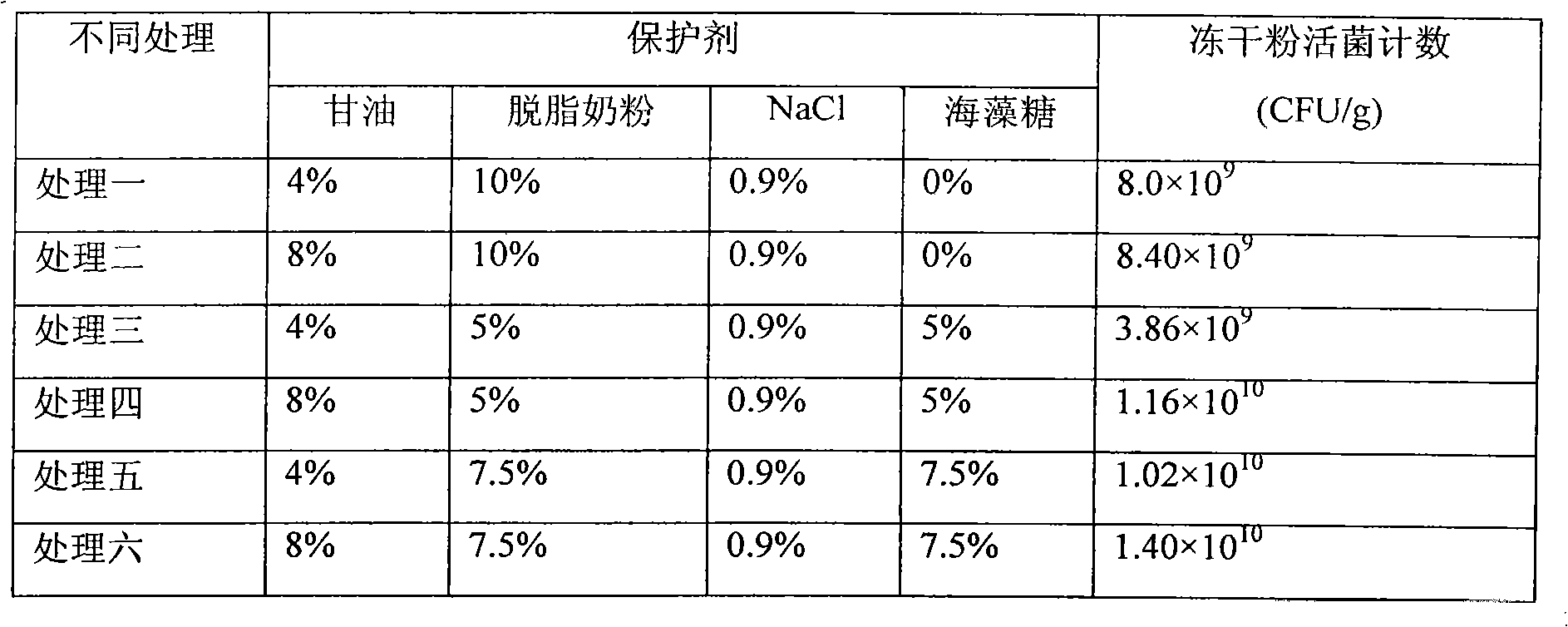

Preparation method of active microbial agent of forage anti-diarrhea yeast

InactiveCN103652320AThe overall impact is smallAvoid damageAnimal feeding stuffAnimal ForagingMicrobial agent

The invention relates to a preparation method of a high-density fermented and freeze-dried active microbial agent of a forage anti-diarrhea yeast, and belongs to the field of an agriculture biotechnology. The method comprises the following steps: inoculating an original starting strain (Saccharomyces boulardii, ATCC MYA-796) into yeast leaching peptone powder glucose liquid culture medium after activating; cultivating at 30 DEG C for 12-16 hours at 200-250rpm as a seed solution; inoculating the seed solution by 10% of inoculation amount, cultivating at 30 DEG C for 12 hours at 800rpm in liquid-expanded yeast leaching peptone powder glucose liquid culture medium, and then feeding 25% glucose for 6 hours, wherein the feeding amount is 20ml / h / L of fermentation liquor; centrifugally collecting thalli and adding protective agents (8% of glycerinum, 7.5% of skim milk powder, 7.5% of mycose and 0.9% of sodium chloride), wherein the mixing ratio of the protective agents to the thalli is 2:1; stewing and balancing for an hour after evenly mixing; pre-cooling at -80 DEG C for 12 hours, and then freeze-drying the thalli in a vacuum freezer dryer; weighing freeze-dried powder to count viable bacteria, wherein the viable bacteria count achieves 1.4*10<10> CFU / g.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

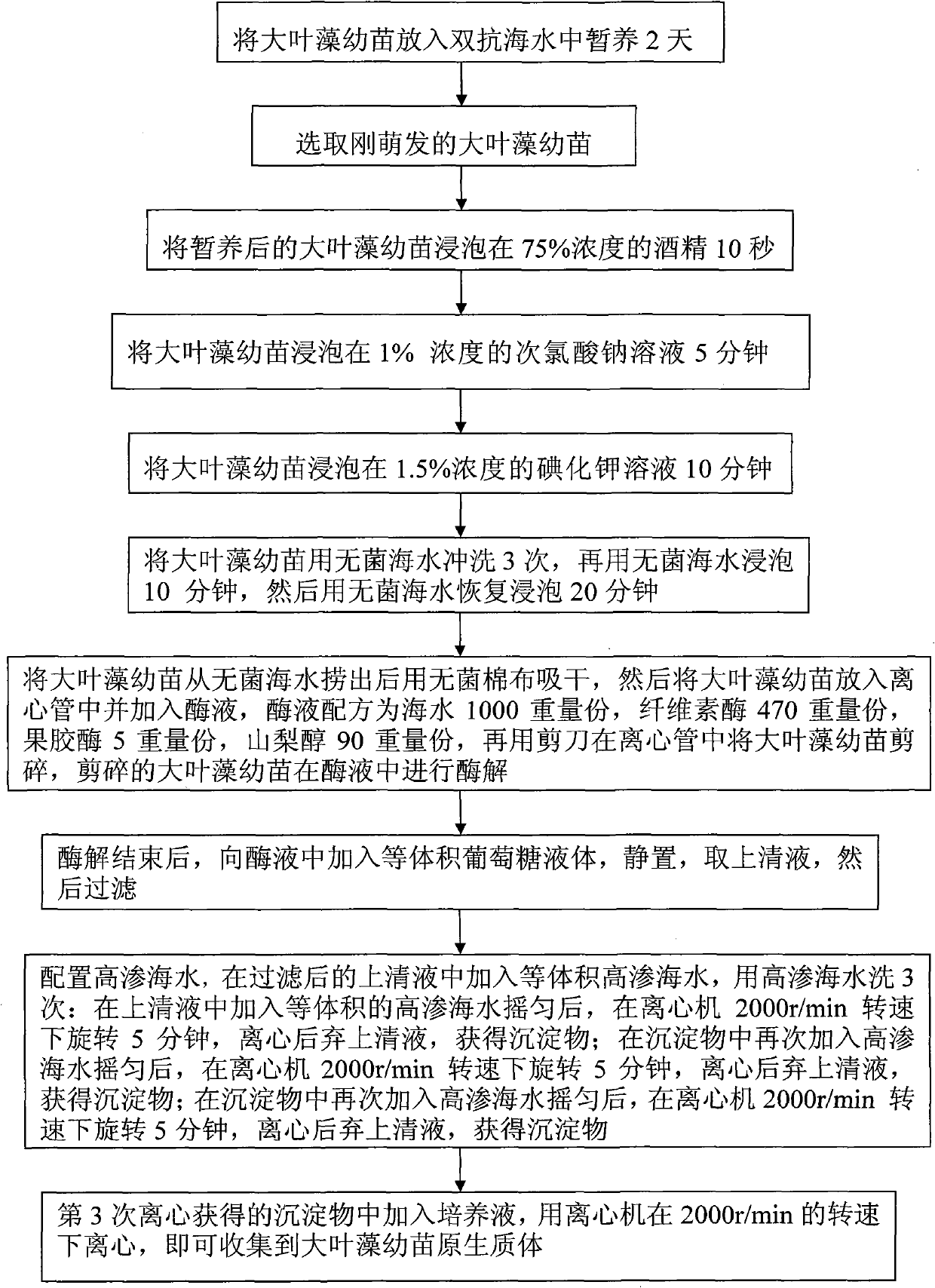

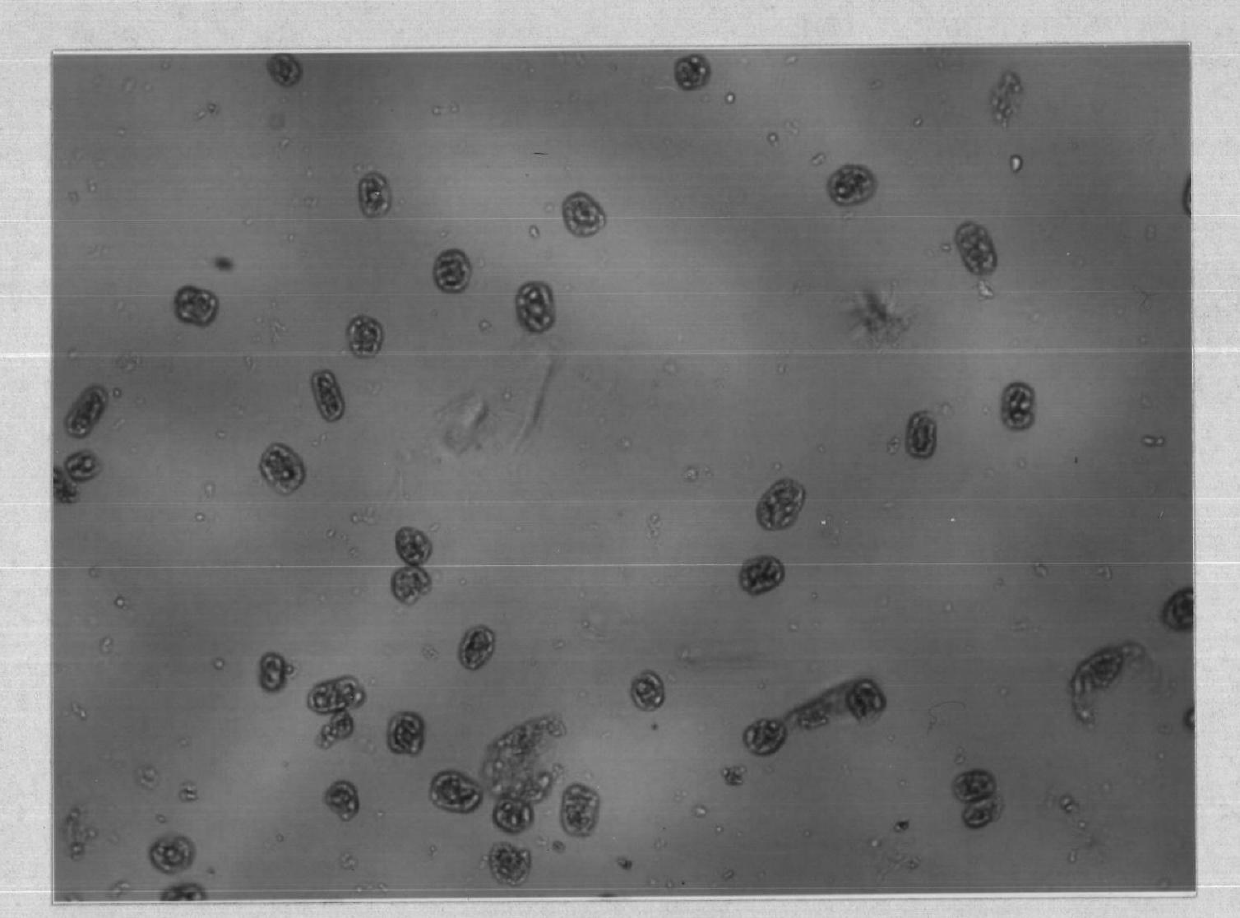

Fabrication method of seagrass seedling protoplast

InactiveCN101768568AIncrease contentProlong the enzymatic digestion timePlant cellsFine lineFiltration

The invention discloses a fabrication method of seagrass seedling protoplast, comprising the following steps: temporarily raise the seagrass seedlings in double-anti sea water, select the seedlings that just sprout and sequentially put them into alcohol with the concentration of 75 percent, sodium hypochlorite solution with the concentration of 1 percent and potassium iodide solution with the concentration of 1.5 percent for disinfection, then wash, soak and restore the seedlings by sterile seawater. Then, the seagrass seedlings are shredded and placed into centrifugal tube with enzyme solution for enzymolysis. After the enzymolysis, glucose liquid is added before filtration. Wash the seedlings thrice with hypertonic sea water and obtain the precipitate after centrifugation. Add medium to the precipitate and obtain the protoplast through centrifugation. The invention can avoid pollution and obtain sterile seagrass seedling protoplast and has laid a solid foundation for the protoplast fusion, genetic transformation, plant regeneration as well as new breeds breeding. Moreover, the invention can also provide technical reserves for seagrass propagation of cell engineering, rapid propagation of fine lines seagrass and improving seagrass genetic engineering.

Owner:SHANDONG ORIENTAL OCEAN SCI TECH

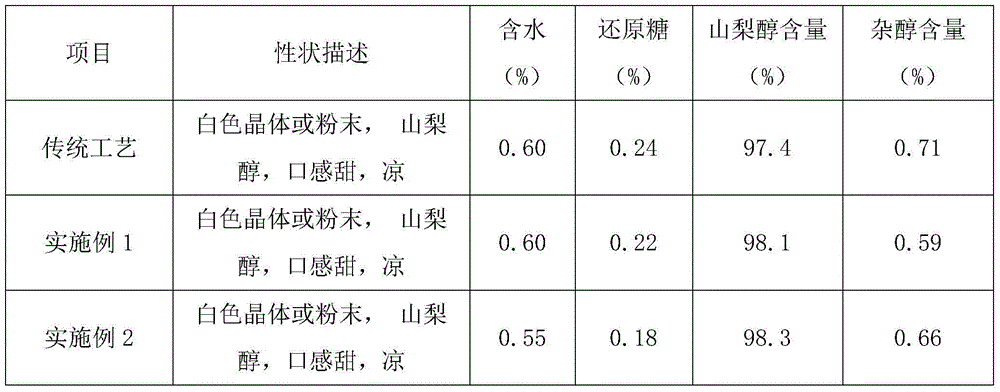

Process for directly producing high-quality sorbitol by taking starch as raw material

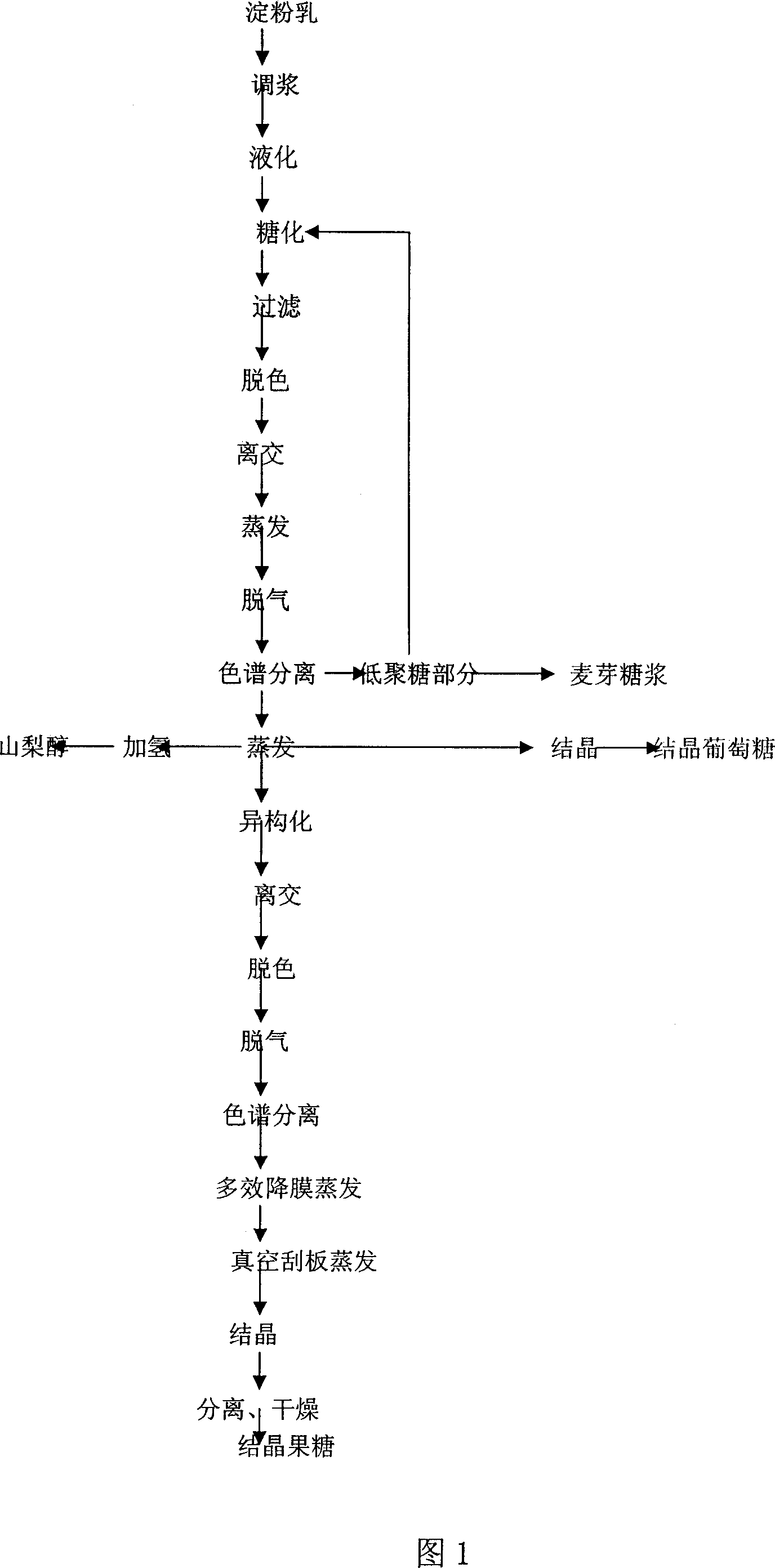

ActiveCN104557463AHigh yieldEasy to produceOrganic compound preparationHydroxy compound preparationChromatographic separationSimulated moving bed

The invention discloses a process for directly producing high-quality sorbitol by taking starch as a raw material. The process comprises the following steps: by taking the starch as the raw material, performing size mixing, liquefaction, saccharification, decoloration, ion exchange and chromatographic separation to collect glucose liquid fraction; then, performing continuous hydrogenation on the glucose liquid fraction by evaporating and concentrating to convert a glucose liquid into a sorbitol liquid; finally, refining, concentrating, mixing and crystallizing, crushing and drying the sorbitol liquid, so as to obtain the high-quality sorbitol, wherein process water is added into starch to perform size mixing, baume degree of the starch milk subjected to the size mixing is 15-20 and the pH value of the starch milk is 4.0-6.0; during liquefaction, the addition amount of liquifying enzyme is 0.30-0.40kg / t dry starch, a spray temperature ranges from 105 DEG C to 145 DEG C and a liquefaction pH value is 5.0-6.0; during saccharification, the addition amount of saccharifying enzyme is 0.35-0.45kg / t dry base, the temperature is kept with intermittent agitation for not less than 48 hours at 50-70 DEG C; during the chromatographic separation, a simulated moving bed chromatographic separation system is adopted, water is taken as an eluent, the separation temperature is controlled to range from 40 DEG C to 80 DEG C, and separation pressure is 0.2 Mpa to 0.5 Mpa. According to the process for directly producing high-quality sorbitol by taking starch as the raw material, the product quality is improved, the production process is simplified, the production efficiency is improved and the production consumption is reduced.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

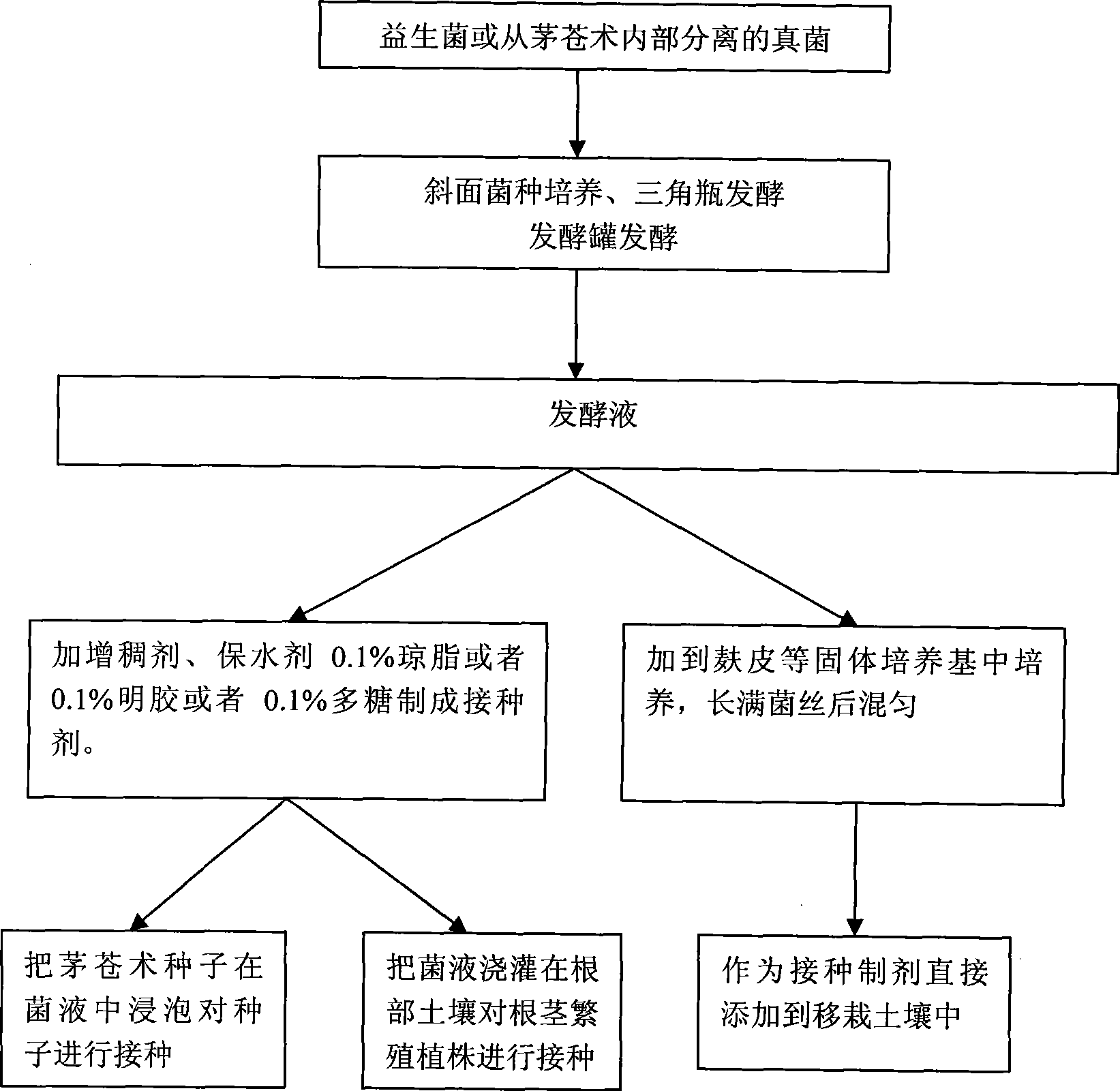

Method for producing novel lance atractylodes rhizome inoculation agent

InactiveCN101444230AShorten the production cycleSimple production processBiocideFungiPlant rootsGLUCOSE LIQUID

The invention relates to the field of agricultural seeds, in particular to a method for producing a lance atractylodes rhizome inoculation agent from lance atractylodes rhizome endophytic fungus or probiotic bacteria. The method specifically comprises the following steps: activating the lance atractylodes rhizome endophytic fungus or the probiotic bacteria; adding a small quantity of thickening agents or water retention agents after the lance atractylodes rhizome endophytic fungus or the probiotic bacteria are cultivated on a culture medium containing potato immersion liquid, lance atractylodes rhizome immersion liquid and glucose liquid or a solid medium containing lance atractylodes rhizome straws; and soaking lance atractylodes rhizome seeds and transplanting soaking roots or adding the seeds to rhizoplane soil directly. The inoculation agent is not easily influenced by the environment during the production and has short production period, simple production process, production time, easy control of output and remarkable action. The method adopting the soaking seeds, soaking plant roots or pouring and directly adding the seeds in soil ensures that the inoculation agent acts on plants and has the advantages of simple method, easy operation, less consumption, low cost and good effect.

Owner:NANJING NORMAL UNIVERSITY +1

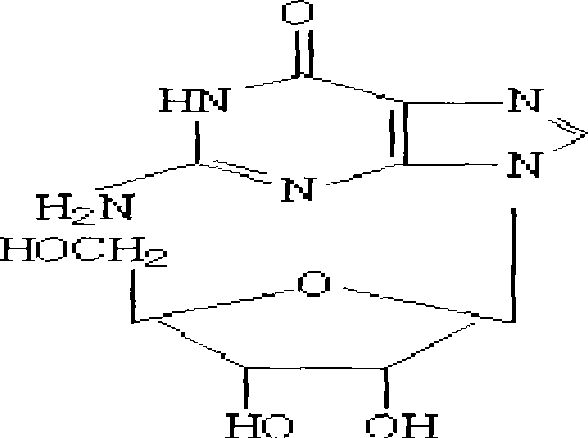

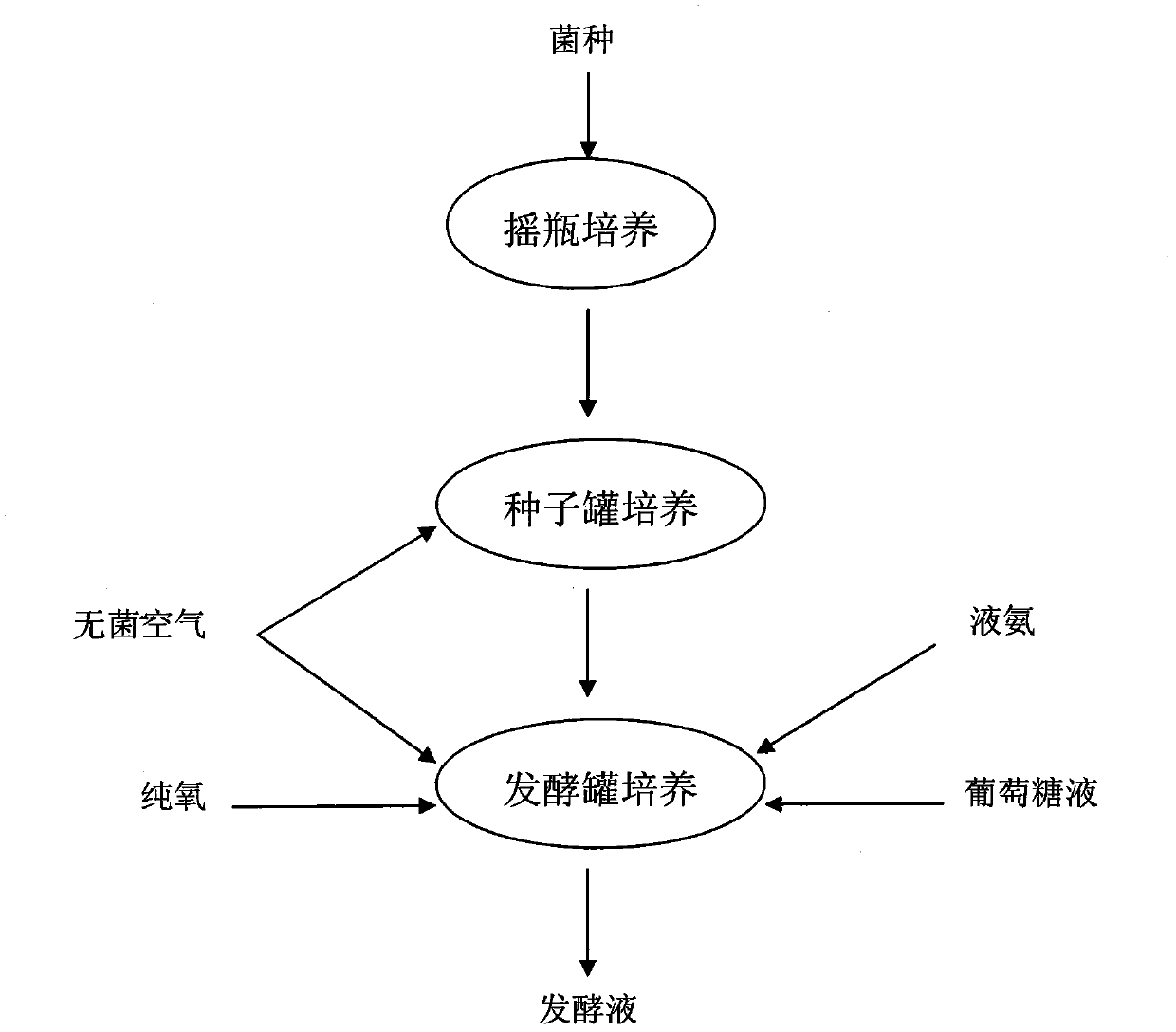

Production method of guanine nucleosides

InactiveCN101487036AGenetic stabilitySynchronous productivity is highMicroorganism based processesFermentationUltrafiltrationMicrofiltration membrane

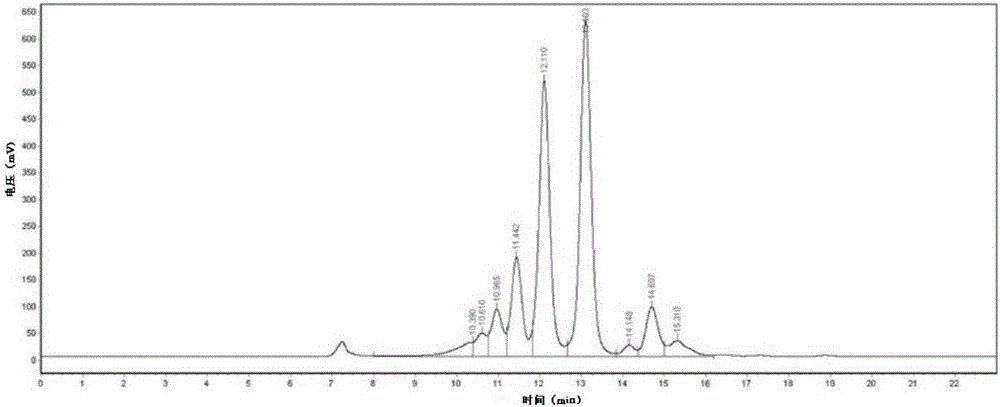

The invention discloses a guanosine production method, which consists of four major technical processes including fluid strain cultivation in a shaking bottle, production of glucose solution, production of guanosine fermented fluid and extraction and refinement of guanosine, adopts a preserved strain TA208-IMPD with genetic stability, prepares the glucose solution by steeping, pulping, liquefying, filter pressing and saccharifying cracked grains, adopts new techniques including flow feeding of the glucose solution in a fermentation process, and produces qualified guanosine through microfiltration membrane sterilization, crude guanosine crystallization, ultrafiltration membrane decoloring and impurity removing, separating and parching of the guanosine fermented fluid. The guanosine production method overcomes the disadvantages of traditional new techniques that have behindhand culture techniques, lower guanosine yield of the strain, long fermentation period, lower transformation ratio and lower synthesized extraction yield, and the like, achieves high synchronized production efficiency and guanosine production level of the strain, stable glucose solution product and high guanosine fermented production level, and can reach the guanosine product purity of over 99 percent and the yield of over 80 percent.

Owner:湖南赛康德生物科技有限公司

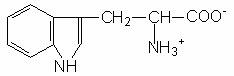

Method for producing L-tryptophan

ActiveCN101914584AIncreased acid production levelsImprove conversion rateOrganic chemistryMicroorganism based processesSaccharic acidGLUCOSE LIQUID

The invention discloses a method for producing L-tryptophan, which comprises the following steps of: performing primary culture and shaking culture on corynebacterium glutamicum strains to obtain shaking liquid strains; preparing glucose liquid from corn serving as a raw material by steps of soaking, pulping, liquefying, saccharifying and the like, wherein the glucose liquid is used as a carbon source of a culture medium and adds sugar for fermentation flow; performing secondary culture on the shaking liquid strains to obtain secondary strains, and performing fermentation culture on the secondary strains to obtain L-tryptophan fermentation liquid; and extracting and refining the L-tryptophan fermentation liquid to obtain the L-tryptophan. The acid yield of the strains can reach 40g / L at most by controlling the composition of the culture medium and the fermentation conditions; the glucose liquid is produced by using the corn, so the production cost is low; the fluctuation of the glucose content of the culture medium is low and the saccharic acid conversion rate of a fermentation acid production level box is improved by continuously adding the glucose liquid; and the extracting and refining process flows are reasonable, the purity of the L-tryptophan product can reach over 99 percent, and the yield reaches over 75 percent.

Owner:SHANDONG YANGCHENG BIOLOGY TECH CO LTD

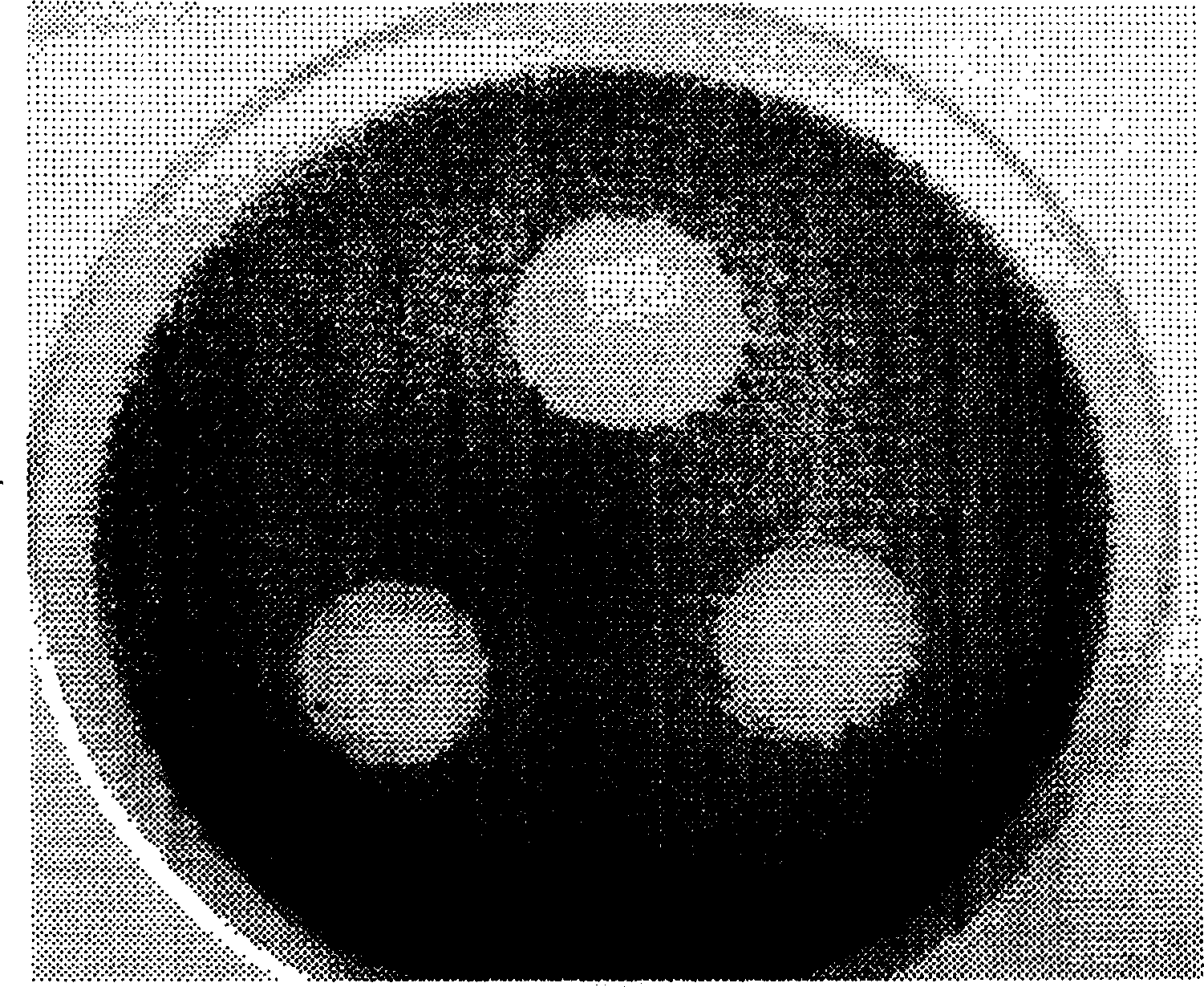

Wild rice stem smut fungus strain capable of producing anti-fungus antibiotic and its use

The present invention discloses a kind of Ustilago esculenta strain UEZC1 capable of producing antifungal antibiotic and its use. The Ustilago esculenta strain UEZC1 features that the teleutospore is germinated on potato glucose liquid culture medium to form basidium promycelium with 1-4 basidiospore promycelia, and the basidiospore after falling off further grow to form fusiform short hypha for inserting basidiospore. The present invention can produce antifungal antibiotic, and may be used in developing and producing medical and agricultural antifungal antibiotic.

Owner:GUIZHOU UNIV +1

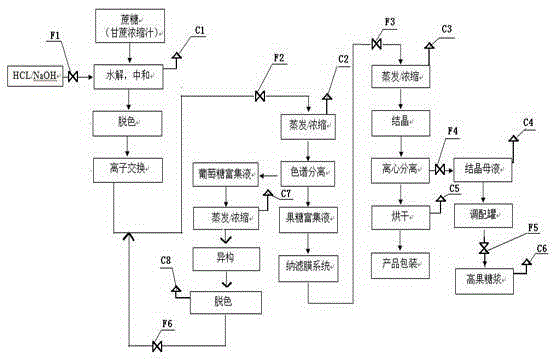

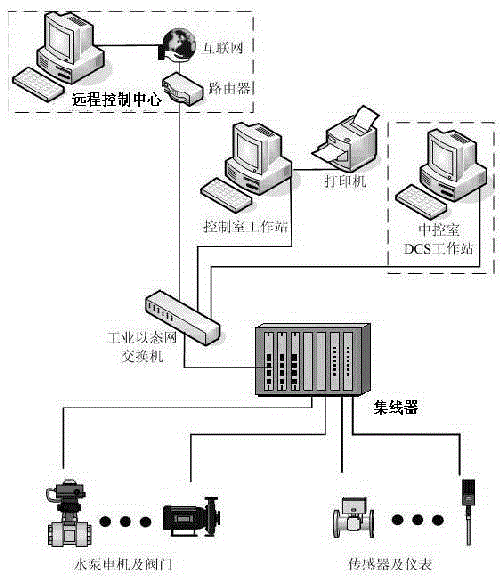

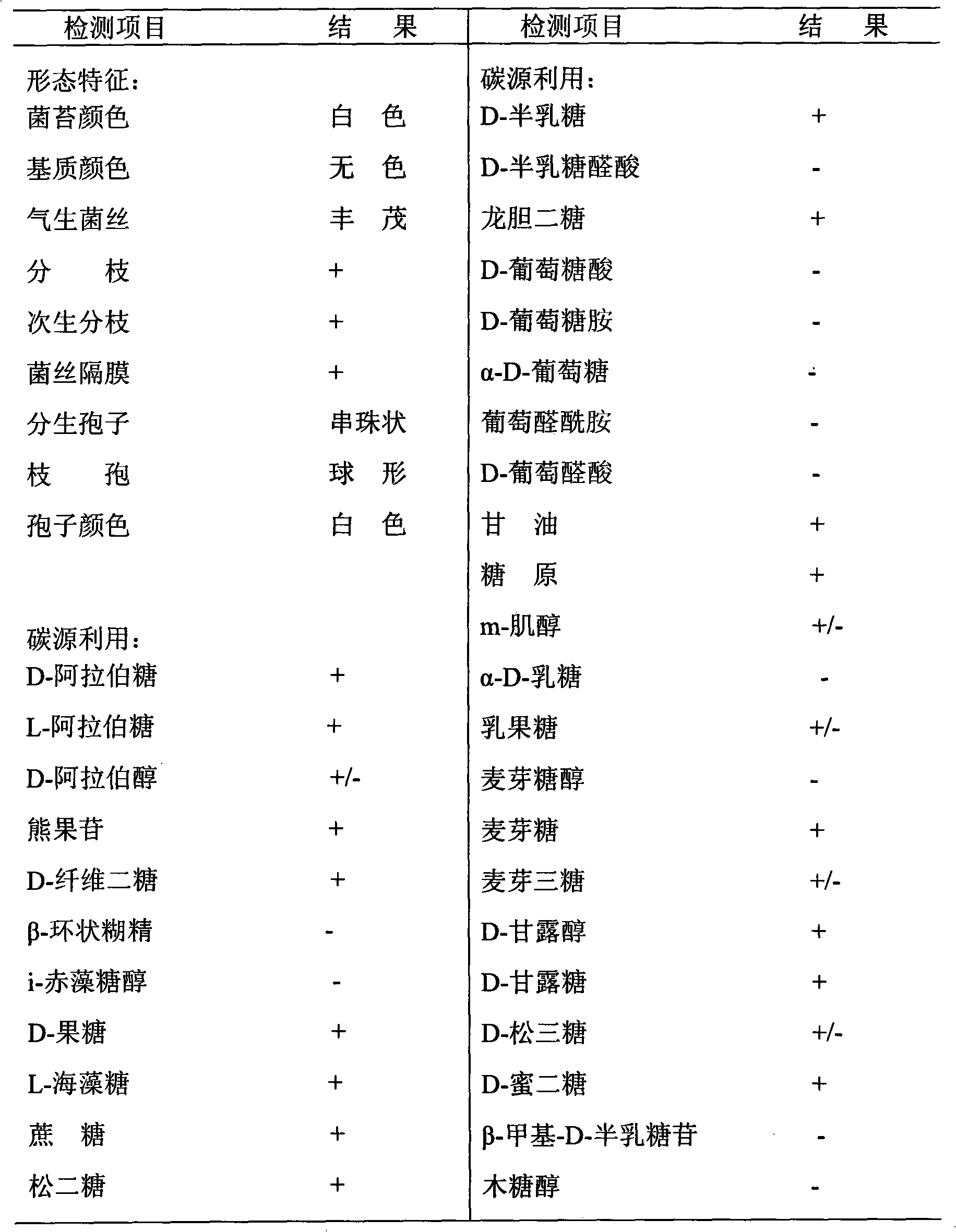

DCS control system for producing anhydrous crystalline fructose by using sugarcanes as raw materials

ActiveCN105242652ASignificant progressIncrease fructose contentFructose productionTotal factory controlAutomatic controlControl cell

The invention relates to a DCS control system for producing anhydrous crystalline fructose by using sugarcanes as raw materials. According to the system, a pH control unit is set in a hydrolysis neutralization process of sugarcane juice concentration; a conductivity control unit is set in a continuous ion exchange stage of high fructose corn syrup; a flow rate, concentration and temperature control unit is set in a concentrating process after fructose and glucose ion exchange separation; a flow rate, liquid level, concentration and temperature control unit is set in a fructose concentrating, crystallization and drying processes; and a flow rate, liquid level, concentration and temperature control unit is arranged in a glucose recovery process. According to the control units, sensors are arranged in equipment; control valves are arranged at feeding openings and discharging openings; and the sensors are connected with an industrial Ethernet switch through lines and are further connected with a control room workstation and a central control room DCS workstation respectively, and are connected with a remote control center through the Internet. With the DCS control system of the invention adopted, and equipment devices and process parameters in each process are controlled comprehensively and automatically and are reasonably matched, and equipment input and production cost are greatly reduced, and the primary yield of industrially-produced crystalline fructose products can be up to 50%.

Owner:广西普霖生物科技有限公司

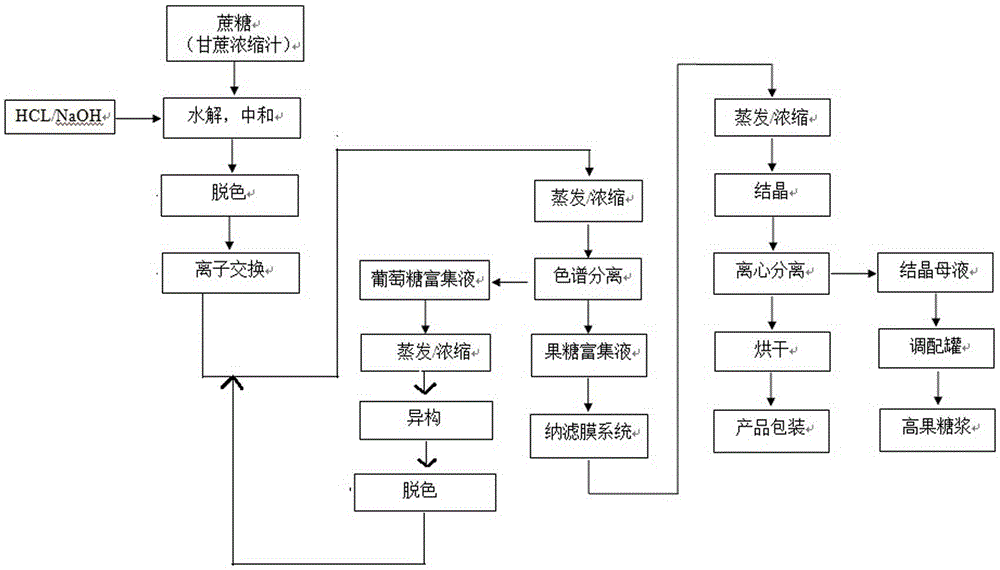

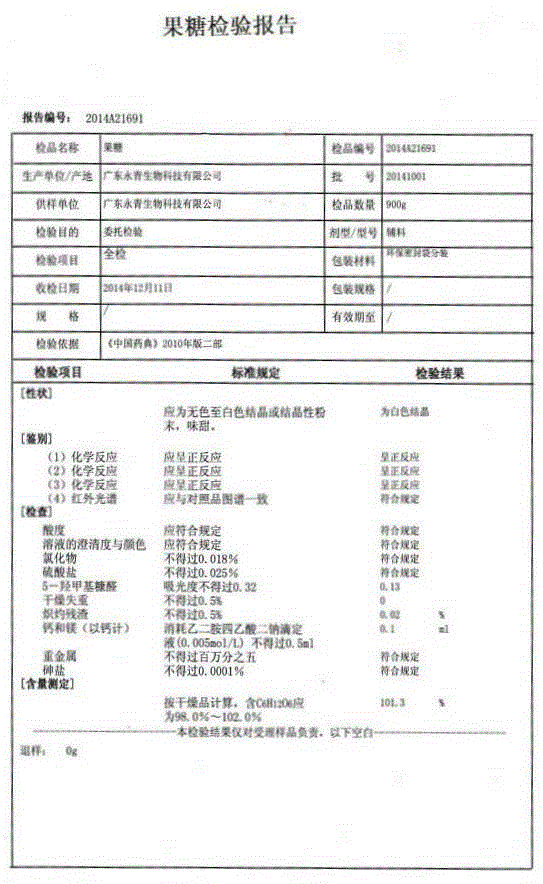

Method for preparing medicinal waterless crystallized fructose by taking sugarcane as raw material

PendingCN105331751AIncrease fructose contentIncreased spawn chanceFructose productionInvert sugar productionBiotechnologyHigh-fructose corn syrup

A method for preparing medicinal waterless crystallized fructose by taking sugarcane as raw material is disclosed. The technological process of the method comprises the following steps: performing cane juice squeezing concentration, preparing high fructose corn syrup, refining high fructose corn syrup, separating refined high fructose corn syrup, crystallizing fructose and recovering a glucose solution. In the method, the equipment and technological parameters of all procedures are comprehensively optimizes and reasonable matched, the method is suitable for industrialized production demand, equipment investment and production cost are substantially reduced, the once yield of the industrialized produced crystallized fructose product is up to 50%, the technology content of fructose production is improved, and the situation that fructose market severely depends on imported high-quality medicinal fructose and technology equipment thereof is solved.

Owner:姜蓉生

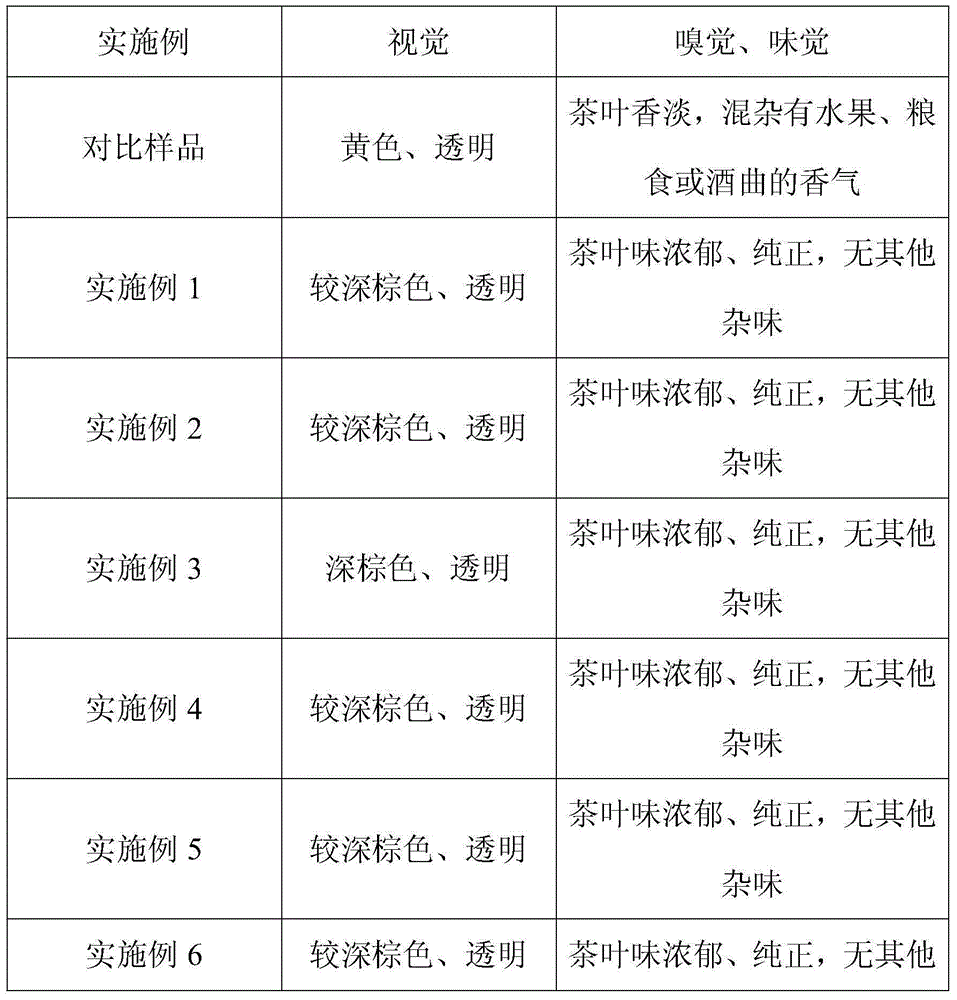

Method for manufacturing tea leaf wine

ActiveCN105087272AStrong tea flavorRelease fullyAlcoholic beverage preparationMicroorganism based processesWarm waterRoom temperature

The invention relates to a method for manufacturing tea leaf wine. The method includes steps of 1, preparing fermentation raw materials, to be more specific, soaking tea leaves, then drying the tea leaves, cooking the tea leaves in a water-insulation manner and then cooling the tea leaves until the temperatures of the tea leaves reach the room temperature so as to obtain the fermentation raw materials; 2, preparing seed liquid, to be more specific, feeding brewer's yeast in glucose liquid and shaking and cultivating the brewer's yeast and the glucose liquid to obtain the active seed liquid; 3, carrying out stacking heat insulation, to be more specific, adding the seed liquid into the fermentation raw materials, and then adding accessory sugar into the fermentation raw materials to carry out stacking heat insulation; 4, adding warm water into the fermentation raw materials and fermenting the fermentation raw materials to obtain fermentation products; 5, distilling the fermentation products after the fermentation raw materials are completely fermented so as to obtain the tea leaf wine. The method has the advantages that shortcomings of insufficient fermentation due to the fact that fermentation temperatures are difficult to reach and tea leaves individually used in existing processes cannot continue being fermented and adulterated tea aroma due to the fact that additional fermentation raw materials such as grains and fruits are required to be added into the tea leaves to solve the problem of insufficient fermentation can be overcome by the aid of the method; processes for fermenting the raw materials for the tea leaf wine can be assuredly smoothly carried out without additional fermentation raw materials such as grains and fruits, and the tea leaf wine manufactured by the aid of the method has strong and unadulterated tea aroma.

Owner:陈克春

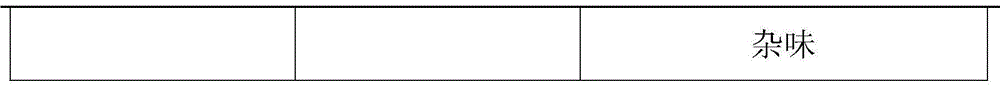

Aspergillus candidus for producing taxol and method for preparing taxol from same

The invention relates to Aspergillus candidus which is separated from Taxus x media and is used for producing taxol. Under the condition of shaking culture at the temperature of 25 DEG C and with the rotating speed of 180 rpm, a wild strain Aspergillus candidus HUST-RBB3 is fermented for 10 days in 300 mL of potato glucose liquid culture medium to obtain the taxol with a concentration of about 120 mu g / L, and is a wild strain with higher taxol yield under unoptimized culture conditions which has been reported at present. Under preliminarily optimized fermentation conditions, the fermentation of the Aspergillus candidus HUST-RBB3 can produce the taxol with a concentration of about 497.3 mu g / L. The production of the taxol through the fermentation of the strain has the advantages of short production period, easy strain breeding and preservation and the like. The invention provides a novel strain and corresponding fermentation production technology for producing the taxol by utilizing microbial fermentation.

Owner:HUAZHONG UNIV OF SCI & TECH

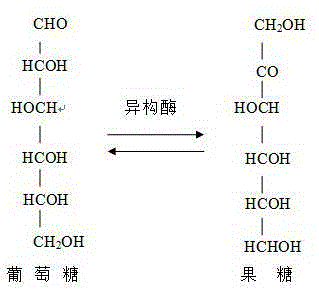

Isomerization method for glucose in fructose production process

InactiveCN105255961AHigh yieldEasy to separate and purifyFermentationHigh-fructose corn syrupIsomerization

An isomerization method for glucose in a fructose production process is characterized by comprising technological steps as follows: a glucose rich liquid obtained in a high fructose corn syrup separation process is subjected to evaporation and concentration firstly and then is isomerized, the glucose liquid is subjected to follow-up treatment after isomerization, and 42% of fructose is recovered finally. The glucose rich liquid after evaporation and concentration is subjected to isomeric transformation with glucose isomerase, about 42% of fructose is recovered, and accordingly, the yield of finished products is increased.

Owner:邓和超 +1

Fermentation production method of L-tryptophan

InactiveCN105087703ASuitable for large-scale fermentation productionReduce manufacturing costFermentationEscherichia coliBatch fermentation

The invention discloses a fermentation production method of L-tryptophan. The method is characterized in that the escherichia coli gene engineering bacteria with the preservation number of CICC 10303 are used as the fermentation strains, cassava is used as raw material to produce glucose liquid serving as the carbon source in fermentation medium and fed-batch sugar liquor, and fed-batch fermentation is performed under certain conditions to produce the L-tryptophan. The method has the advantages that L-tryptophan yield reaches 40g / L by controlling fermentation medium components and fermentation conditions, production cost is lowered greatly by using the cassava to prepare the glucose liquid, the glucose content in the fermentation medium is basically kept constant by continuously feeding the glucose liquid so as to increase fermentation acid production level and glucose-acid conversion rate, and the method is applicable to large-scale L-tryptophan production.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Method for improving yield of L-threonine produced by fermentation

InactiveCN102181502AHigh yieldReduce manufacturing costMicroorganism based processesFermentationBiotechnologyEscherichia coli

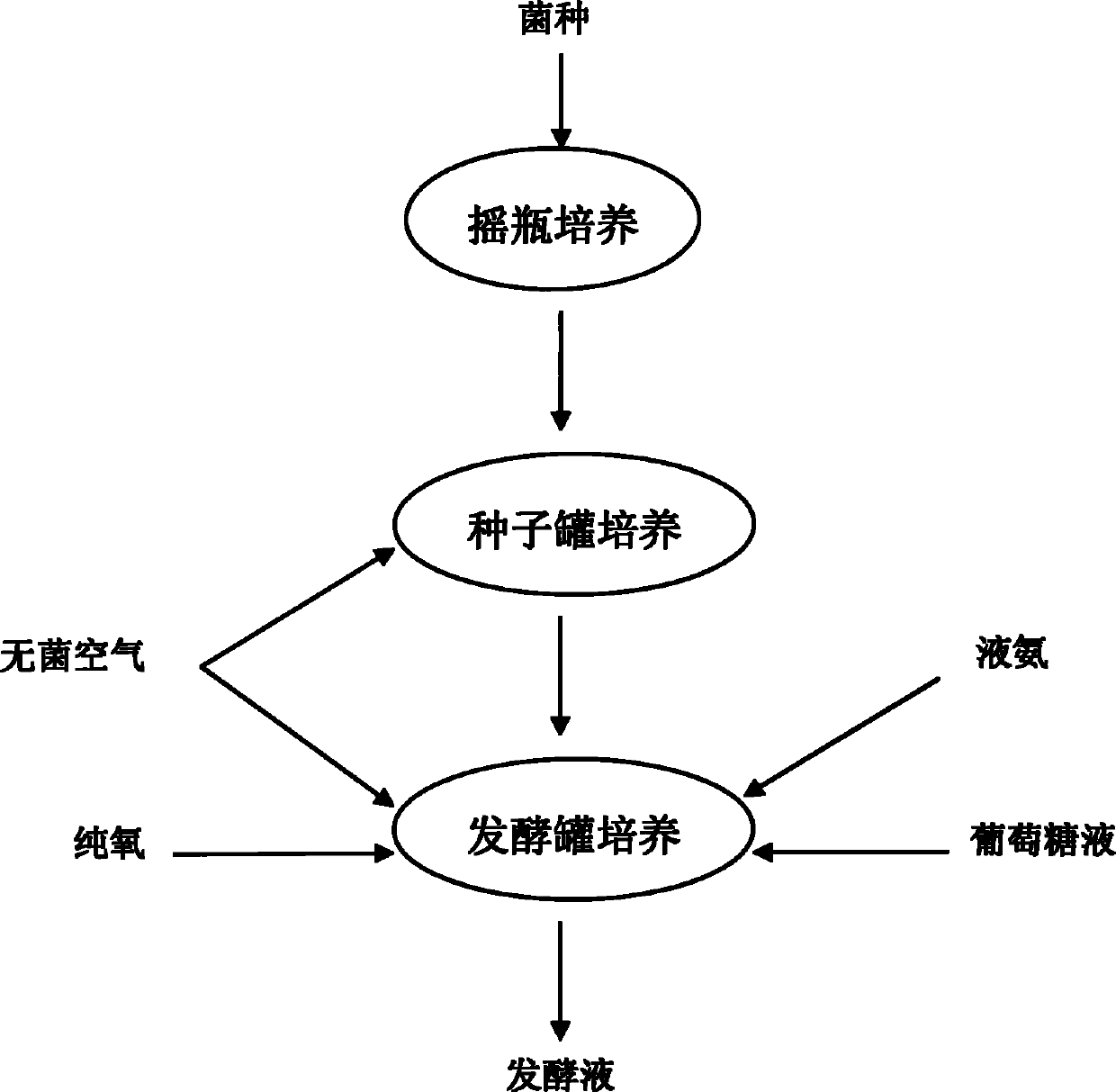

The invention discloses a method for improving yield of L-threonine produced by fermentation, comprising the following steps: obtaining the L-threonine by adopting escherichia coli engineering bacteria through shaking culture, seeding tank amplification culture and fermentation tank culture, wherein, in the fermentation culture process: pure oxygen is utilized to replace partial compressed air to provide sterile air for threonine fermentation; the pH value is controlled to be 7.0-7.2 through adding liquid ammonia; and the residual sugar concentration is controlled to be 0.1-0.5% through adding glucose liquid the mass concentration of which is 600g / L-800g / L. In the method provided by the invention, under the condition of not adding any extra equipment, partial compressed air is replaced through adding the pure oxygen periodically, thus improving the dissolved oxygen level in the fermentation process, and greatly improving the yield and the transformation ratio of the L-threonine. The whole process has simple operational process and lower production cost, and is suitable for industrial production.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

Factory-like production method of silkworm cordyceps

The invention provides a factory-like production method of silkworm cordyceps. The method is characterized by comprising the steps as follows: separating fruiting bodies of cordyceps militaris, sterilizing and washing the fruiting bodies, putting the fruiting bodies on a slant culture medium, and placing the slant culture medium in an incubator for culture; placing a PDA (potato dextrose agar) culture medium in a shake flask, placing white mycelia in the shake flask for shake culture, inoculating the white mycelia on a rice culture medium, after the white mycelia grow over the rice culture medium, taking out the mycelia, adding a glucose liquid, mashing the mycelia, and obtaining a nutrition fungus suspension as an inoculation fluid; stabbing and injecting pleopod parts of silkworm larvae with a medical injector sucked with the inoculation liquid to obtain the inoculated silkworm larvae, obliquely placing the silkworm larvae on the sterilized rice culture medium, performing light-shielding variable-temperature culture on the silkworm larvae firstly, and performing light culture after white hyphae grow over the larvae; and collecting the silkworm cordyceps. The factory-like production method is simple in technology, the mass production can be realized, and the silkworm cordyceps with shapes similar to natural cordyceps sinensis and medium values basically identical with the cordyceps sinensis can be produced.

Owner:钱国琛

Beverage special caramel pigment and preparation method thereof

ActiveCN104544461AImprove resource utilizationLow 4-methylimidazole contentFood preparationChromatographic separationGlucose preparations

The invention discloses a method for preparing beverage special caramel pigment. The method comprises the following steps: (1) performing chromatographic separation; (2) exchanging ions: cooling a glucose AD liquid prepared in step (1) to 45-50 DEG C, and then enabling the glucose AD liquid to pass through ion exchange resins in the following sequence: a strongly acidic cation resin, a weakly alkaline anion resin, the strongly acidic cation resin and the weakly alkaline anion resin; (3) concentrating; (4) isomerising; (5) mixing to obtain a mixture; (6) decolorizing and filtering; (7) exchanging ions; (8) concentrating; (9) heating to boiling; (10) adding ammonium sulfite; (12) refining: adding dietary alkali into the caramel pigment prepared in step (11) to adjust the pH value of the liquid caramel to 4.5-5.5, and then further filtering and refining to obtain finished caramel. According to the invention, a glucose mother liquid excreted after crystalline glucose separation is adopted as a raw material, which turns wastes to treasures and improves the resource utilization rate during glucose preparation through comprehensively utilizing the resources.

Owner:河南飞天生物科技股份有限公司

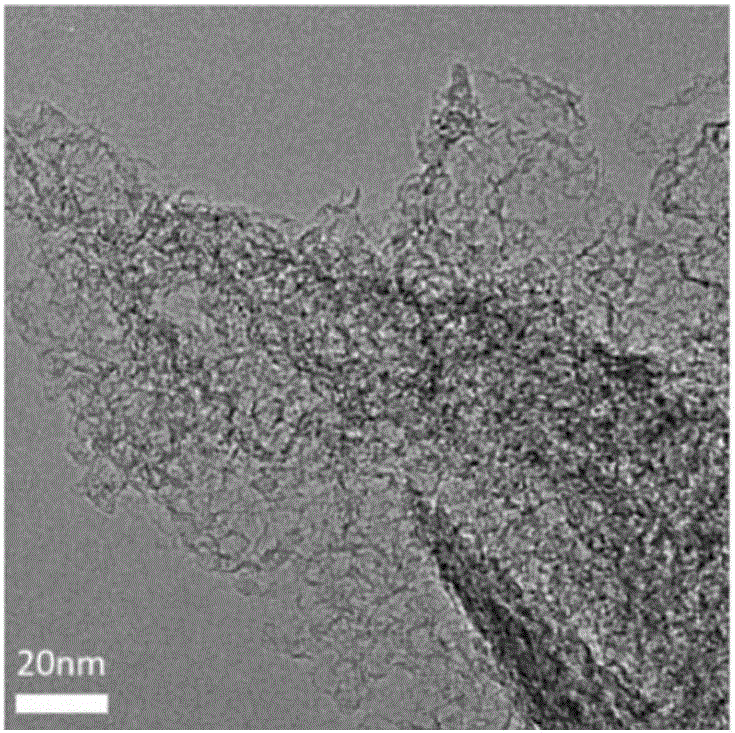

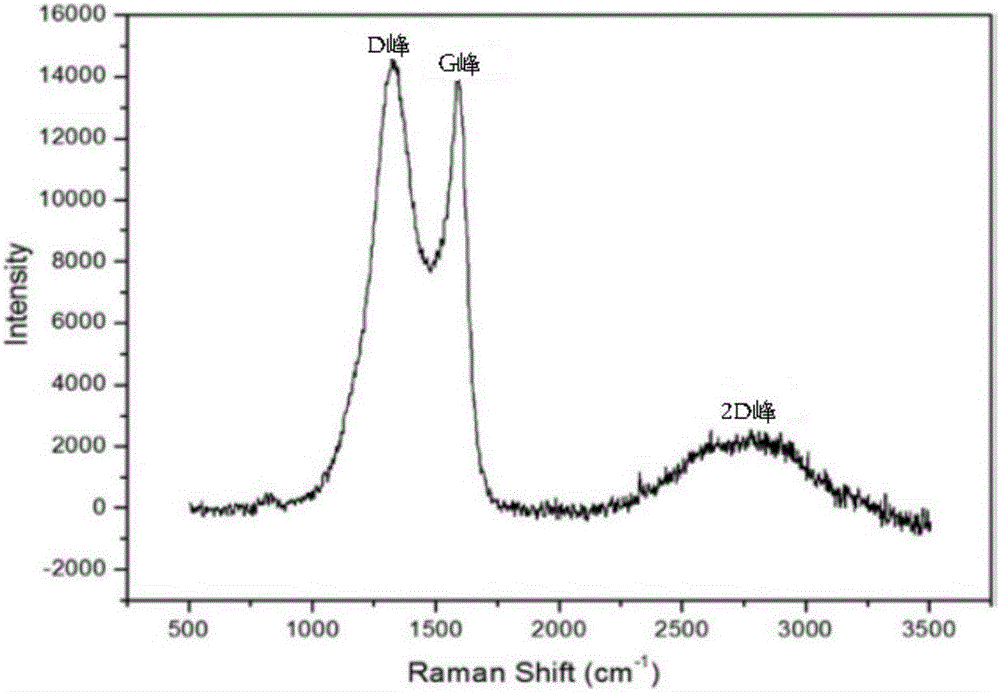

Xylooligosaccharide, dietary fiber and three-dimensional graphene preparation method based on biomass straws

The invention belongs to the field of biological engineering, and provides a xylooligosaccharide, dietary fiber and three-dimensional graphene preparation method based on biomass straws. The preparation method comprises the following steps: conducting primary digestion and multi-stage screw pressing on the biomass straws so as to obtain primary digestion residues and coarse glucose liquid, and enzymatically hydrolyzing, clarifying, decolorizing, concentrating and drying the coarse glucose liquid so as to obtain xylooligosaccharide; conducting secondary digestion and multi-section double-roll extrusion on the primary digestion residues so as to obtain secondary digestion residues and black liquid, and conducting high-pressure homogenizing, mixed enzyme treatment and concentrating and drying on the secondary digestion residues so as to obtain dietary fibers; and conducting purifying, concentrating and drying, pre-carbonizing treatment, deoxidizing treatment, rinsing, drying and high-temperature carbonizing on the black liquid so as to obtain the three-dimensional graphene. The method provided by the invention achieves the full and efficient utilization of the straws, and the finished products (the xylooligosaccharide, the dietary fibers and the three-dimensional graphene) are good in quality. The method, which is free from the discharge of waste gas, waste liquid and residue, is safe and environment-friendly. The method provided by the invention can reduce production cost and improve a production effect, therefore the method is applicable to large-scale industrial production.

Owner:张冰青

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com