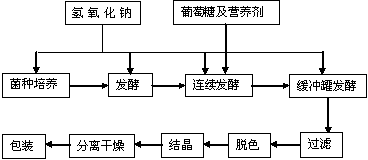

Efficient fermentation production process of sodium gluconate

A technology of sodium gluconate and production process is applied in the field of high-efficiency fermentation production process of sodium gluconate to achieve the effects of saving bacterial culture and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The first step, seed cultivation: Add 2.5kg of glucose, 60g of corn steep liquor, 5.2g of potassium dihydrogen phosphate, 2g of urea, and 2ml of antifoaming agent into a 15L cultivation tank. To 38°C, add 250ml eggplant bottle bacterial suspension, control dissolved oxygen (DO) ≥ 30, cultivate for 15h to obtain seed liquid.

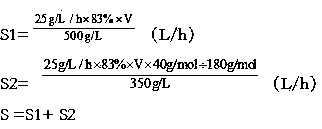

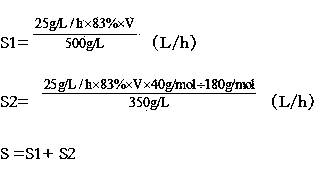

[0024] The second step, fermentation: add 4.0kg of glucose, 2.8g of magnesium sulfate, 1.4g of urea, and 2ml of defoamer to a 50L fermenter, set the volume to 13L, sterilize at 115°C for 15 minutes, then lower it to 38°C, and culture the well The seeds are added to the fermenter in a ratio of 20%, and the pH is adjusted and controlled to 5.4 with 350g / L NaOH to start fermentation.

[0025] The third step, continuous fermentation:

[0026] (1) Ingredients: 14kg of 500g / L glucose, 50g of corn steep liquor, 12.5g of magnesium sulfate, 6.8g of urea, and 1ml of defoamer were added to a 30L feeding tank. To 38 ℃, aseptic transfer to serum bottles for l...

Embodiment 2

[0037] The first step, seed cultivation: Add 2.5kg of glucose, 60g of corn steep liquor, 5.2g of potassium dihydrogen phosphate, 2g of urea, and 2ml of antifoaming agent into a 15L cultivation tank. To 38°C, add 250ml eggplant bottle bacterial suspension, control dissolved oxygen (DO) ≥ 30, cultivate for 15h to obtain seed liquid.

[0038] The second step, fermentation: add 4.0kg of glucose, 2.8g of magnesium sulfate, 1.4g of urea, and 2ml of defoamer to a 50L fermenter, set the volume to 13L, sterilize at 115°C for 15 minutes, then lower it to 38°C, and culture the well The seeds are added to the fermenter in a ratio of 20%, and the pH is adjusted and controlled to 5.4 with 350g / L NaOH to start fermentation.

[0039] The third step, continuous fermentation:

[0040] (1) Ingredients: Add 14kg of 500g / L glucose, 100g of corn steep liquor, 25g of magnesium sulfate, 13.6g of urea, and 2ml of defoamer to a 30L feeder tank, set the volume to 20L, sterilize at 115°C for 30 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com