Patents

Literature

109 results about "Terminal stage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

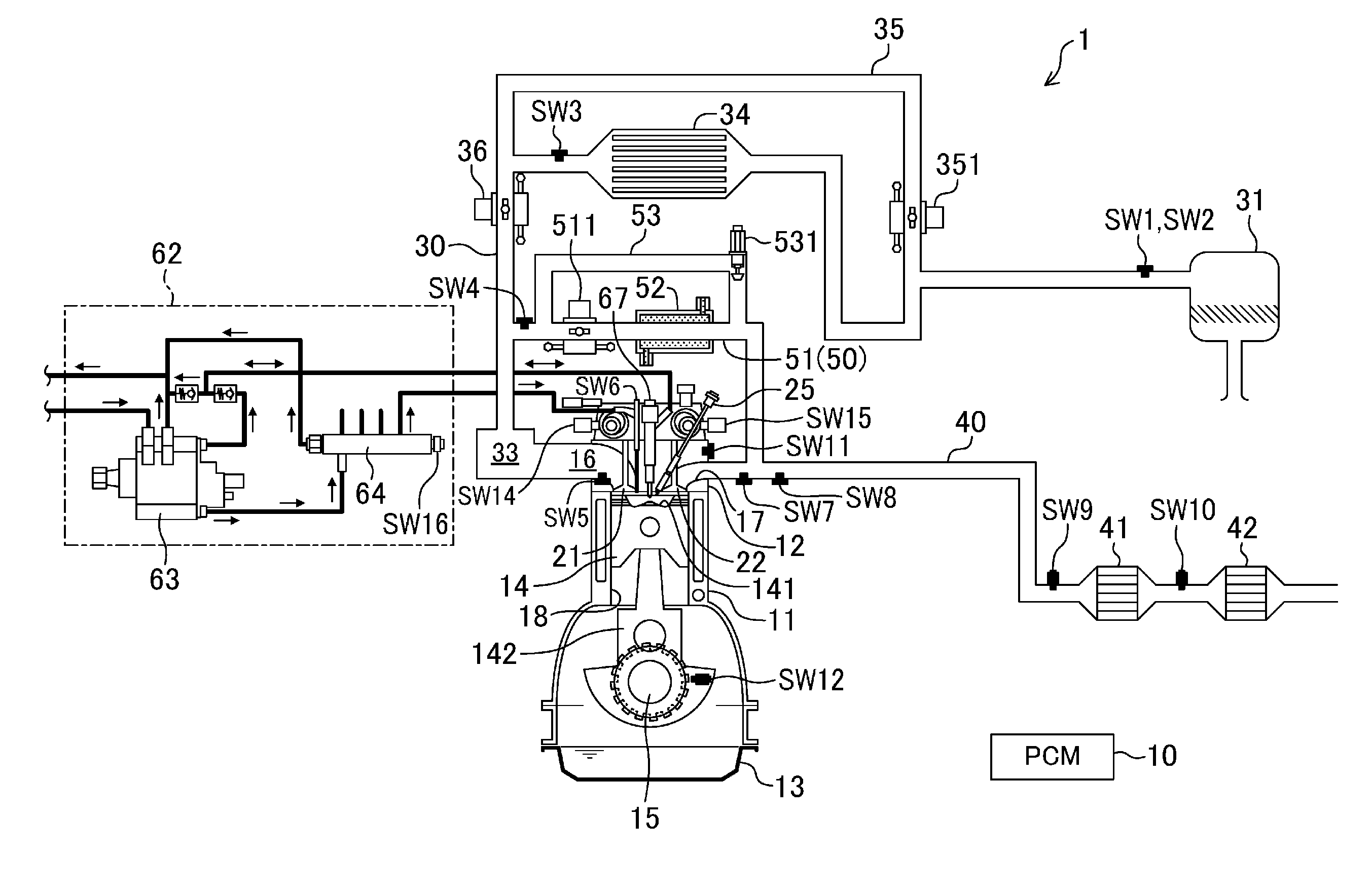

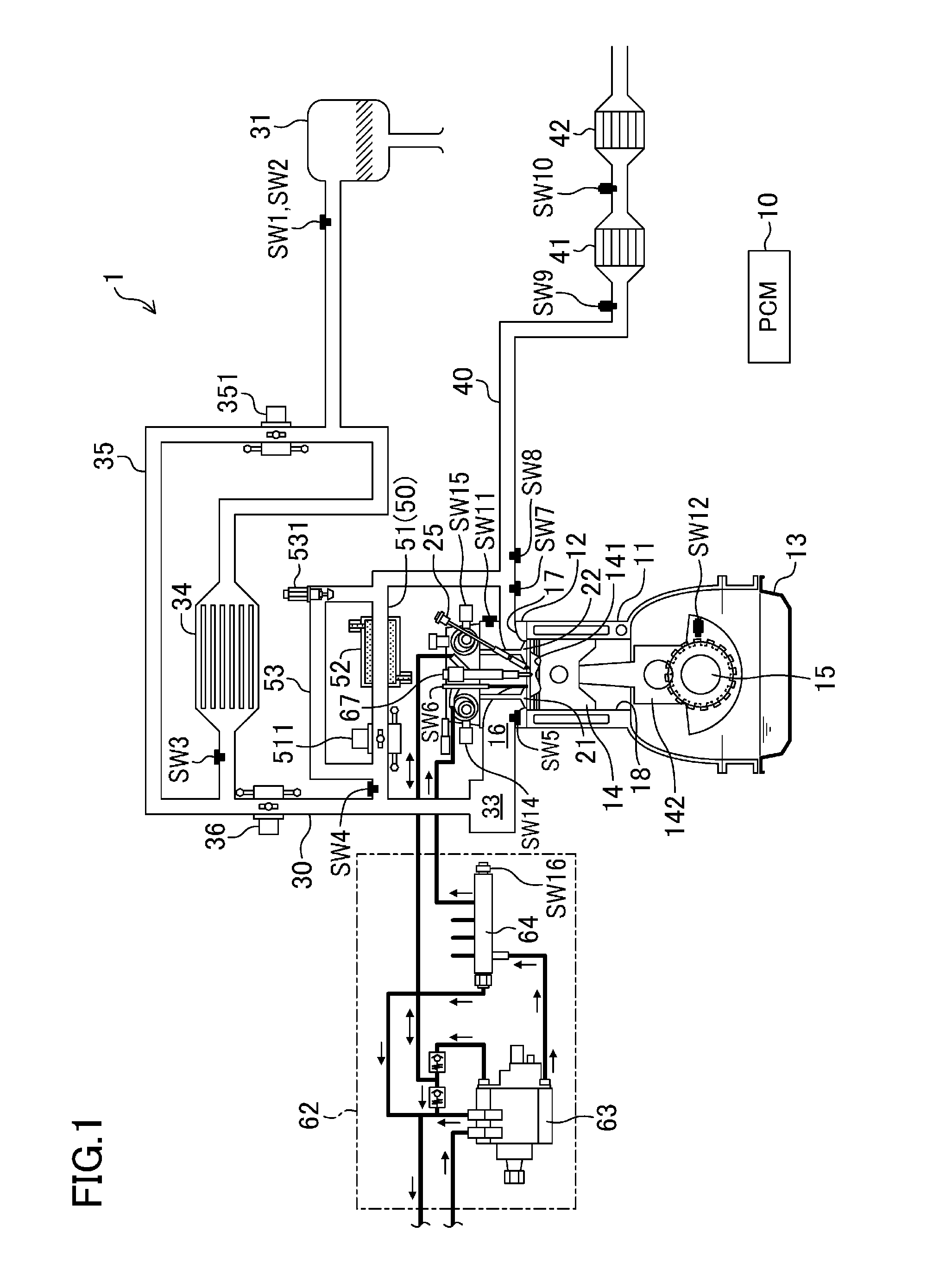

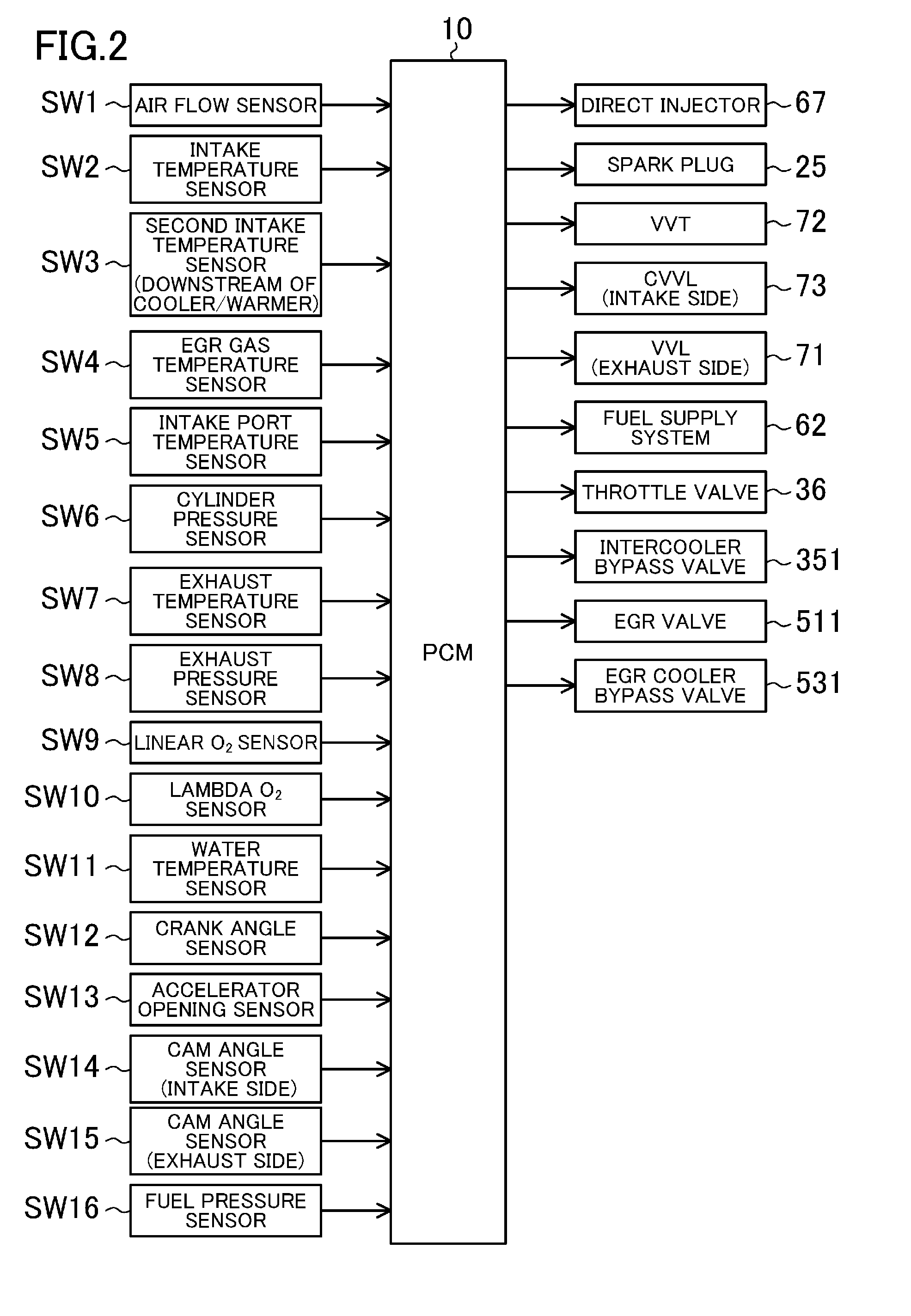

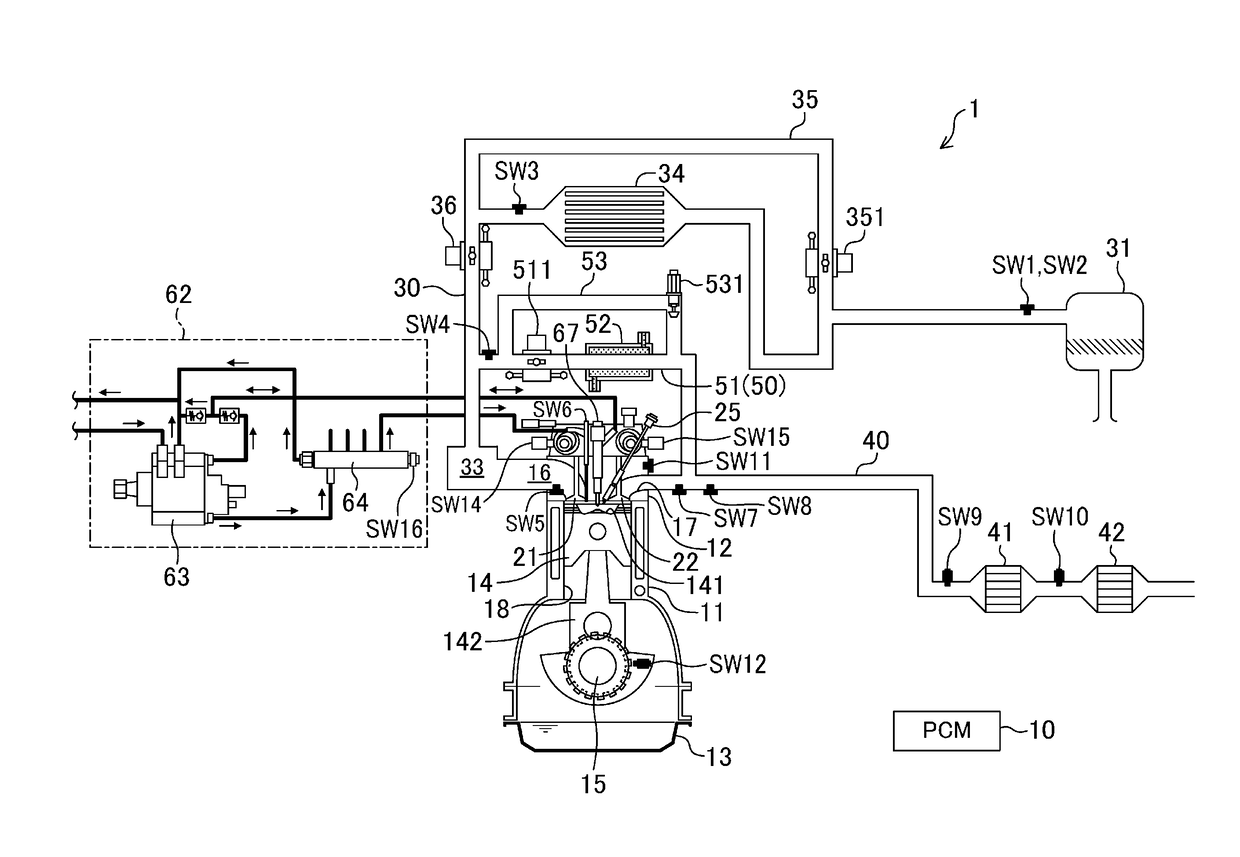

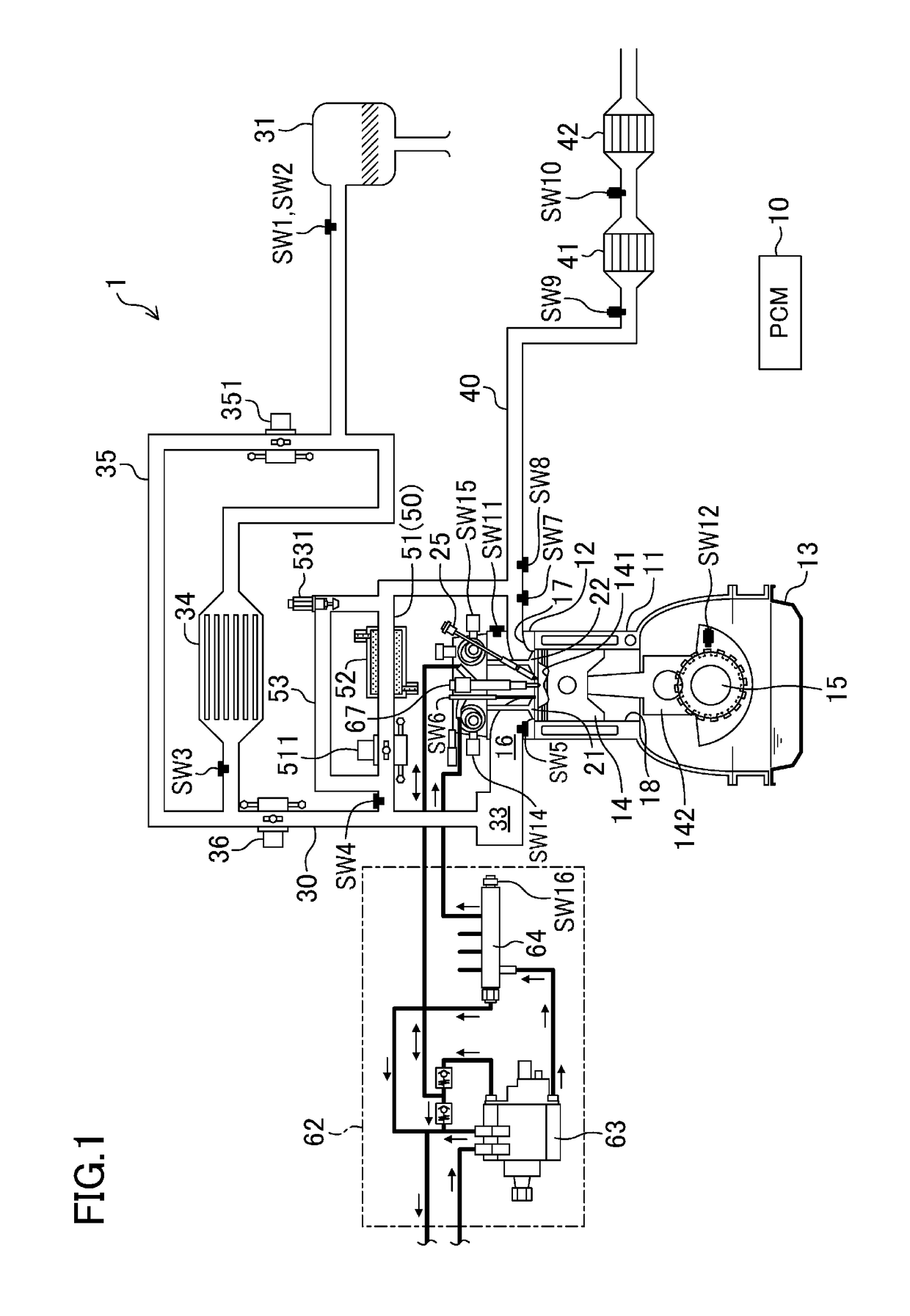

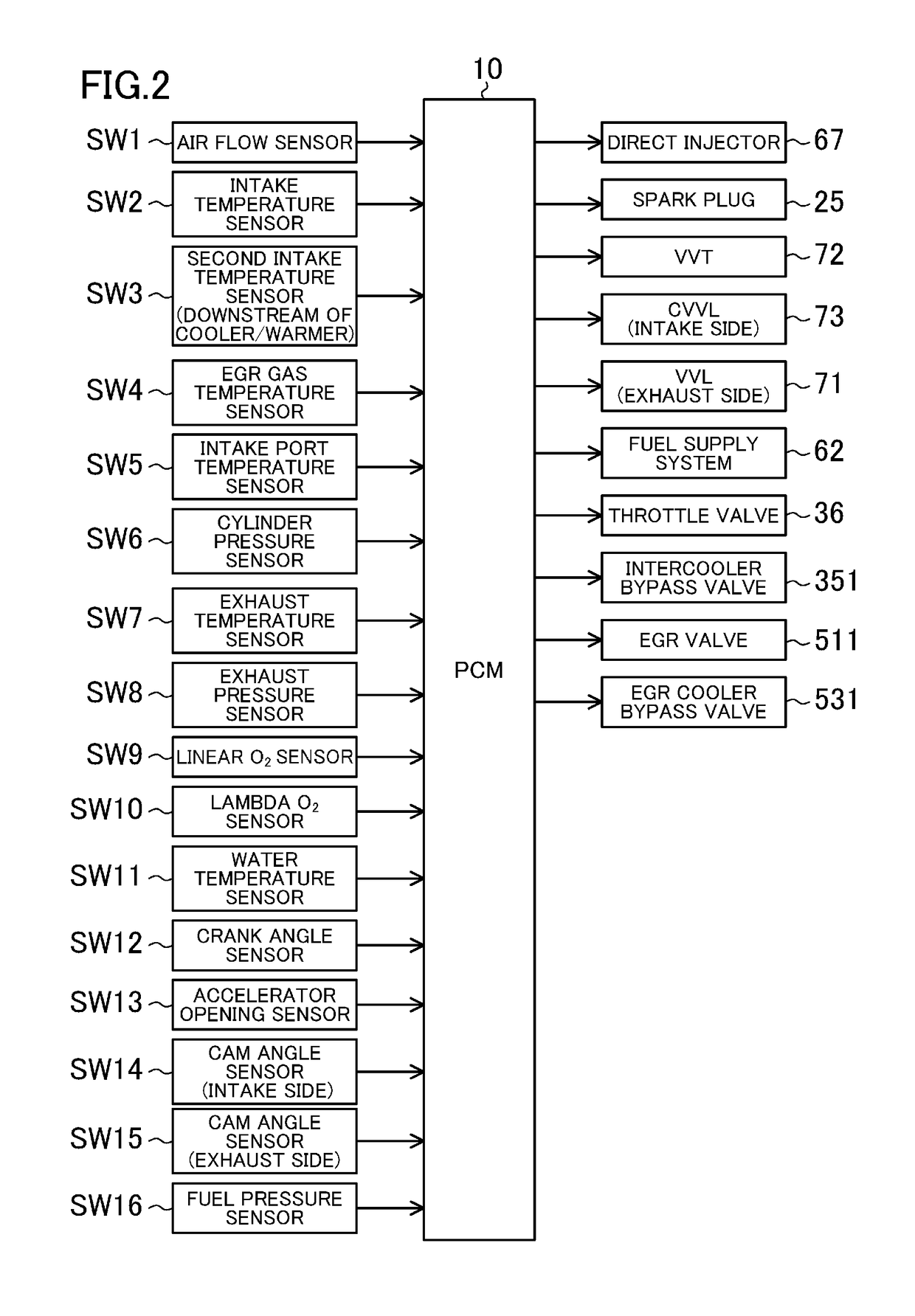

Spark-ignition direct-injection engine

ActiveUS20150114342A1Promote atomizationShorten the overall cycleElectrical controlInternal combustion piston enginesLow loadHigh load

A controller injects fuel into a cylinder at a high fuel pressure of 30 MPa or higher, at least in a period between a terminal stage of a compression stroke and an initial stage of an expansion stroke when an operating mode of an engine body is at least in a first specified sub-range of a low load range, and at least in a second specified sub-range of a high load range. The controller sets an EGR ratio in the first specified sub-range to be higher than an EGR ratio in the second specified sub-range, and advances start of fuel injection in the first specified sub-range to start of fuel injection in the second specified sub-range.

Owner:MAZDA MOTOR CORP

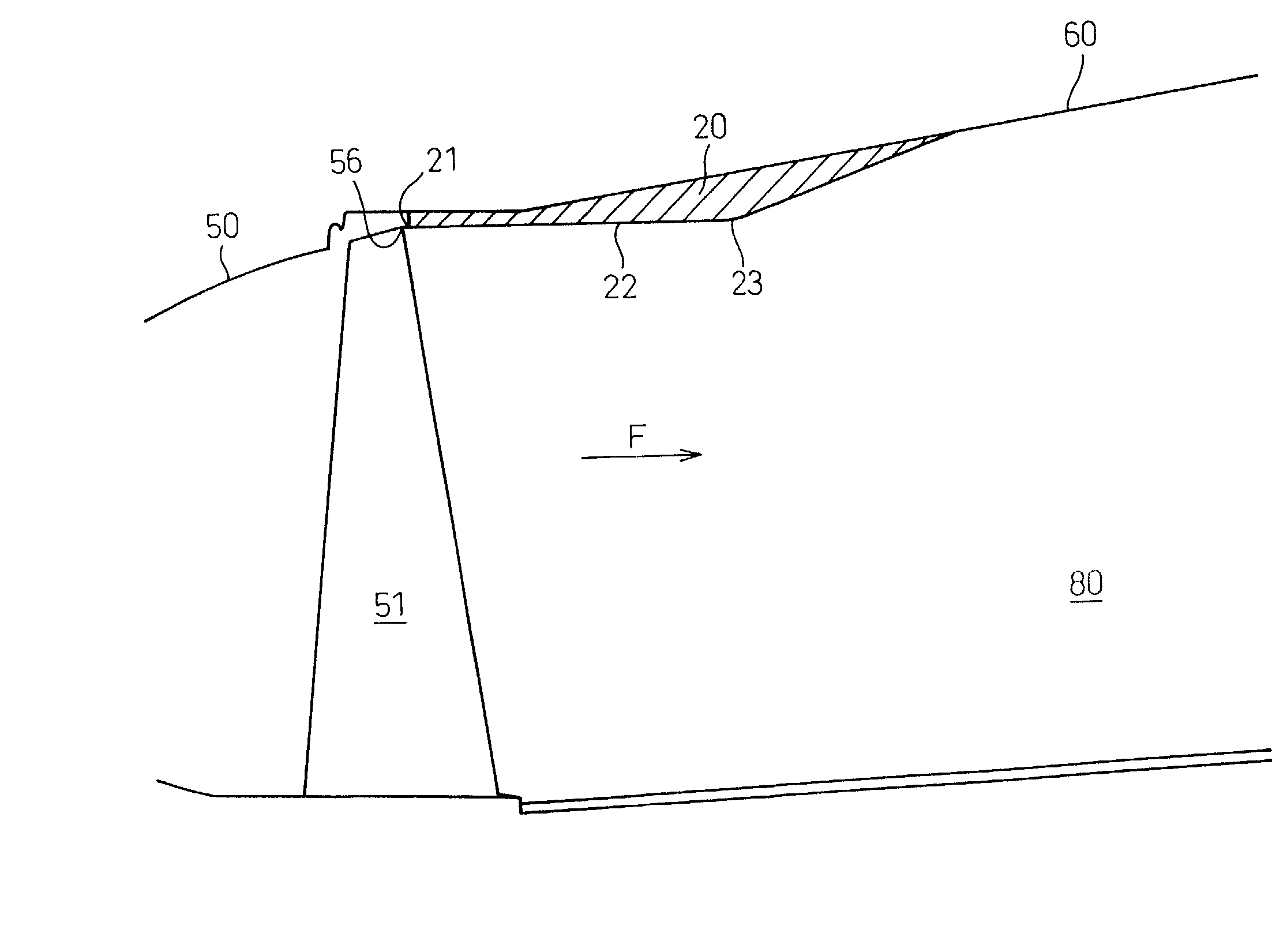

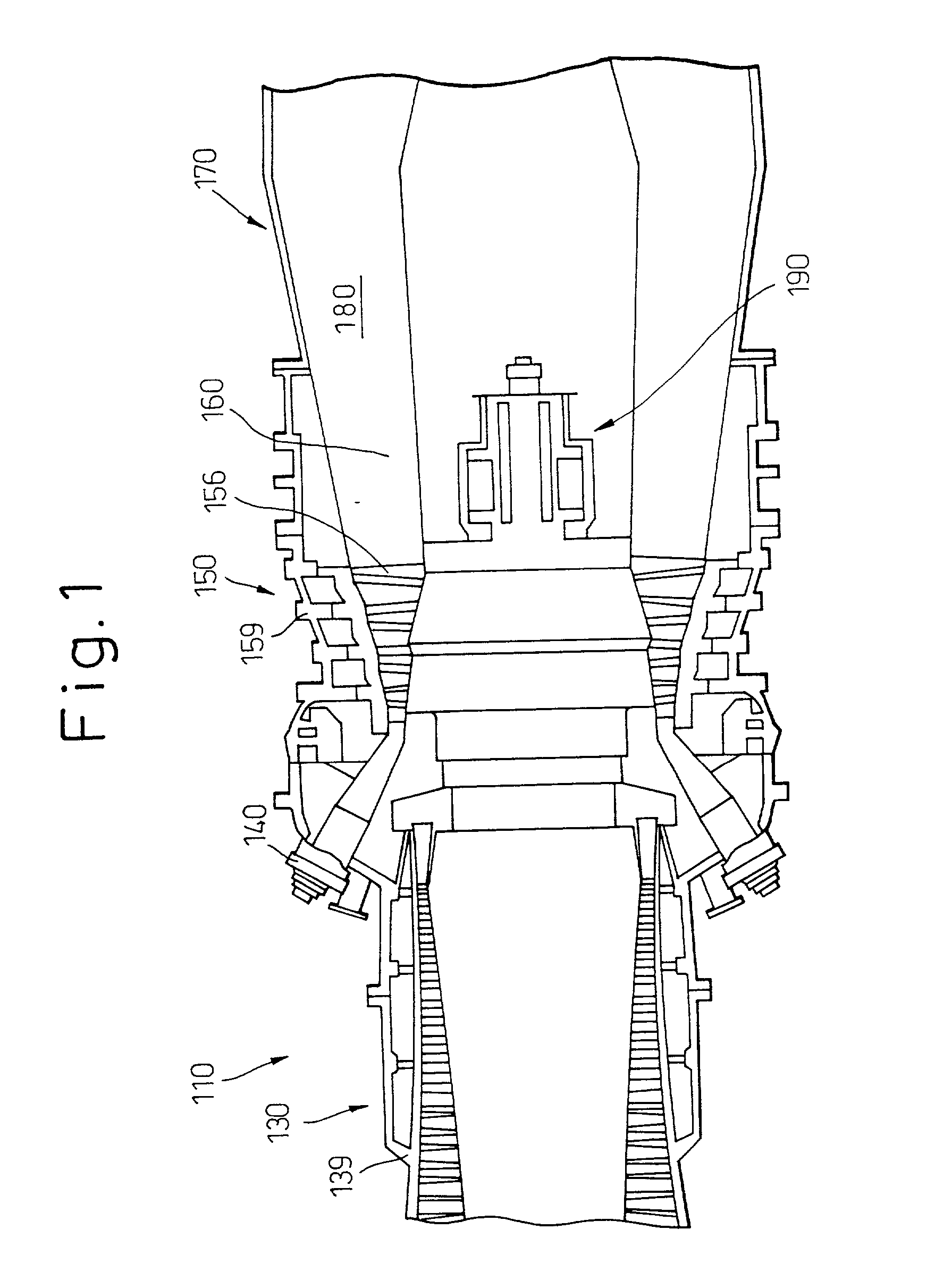

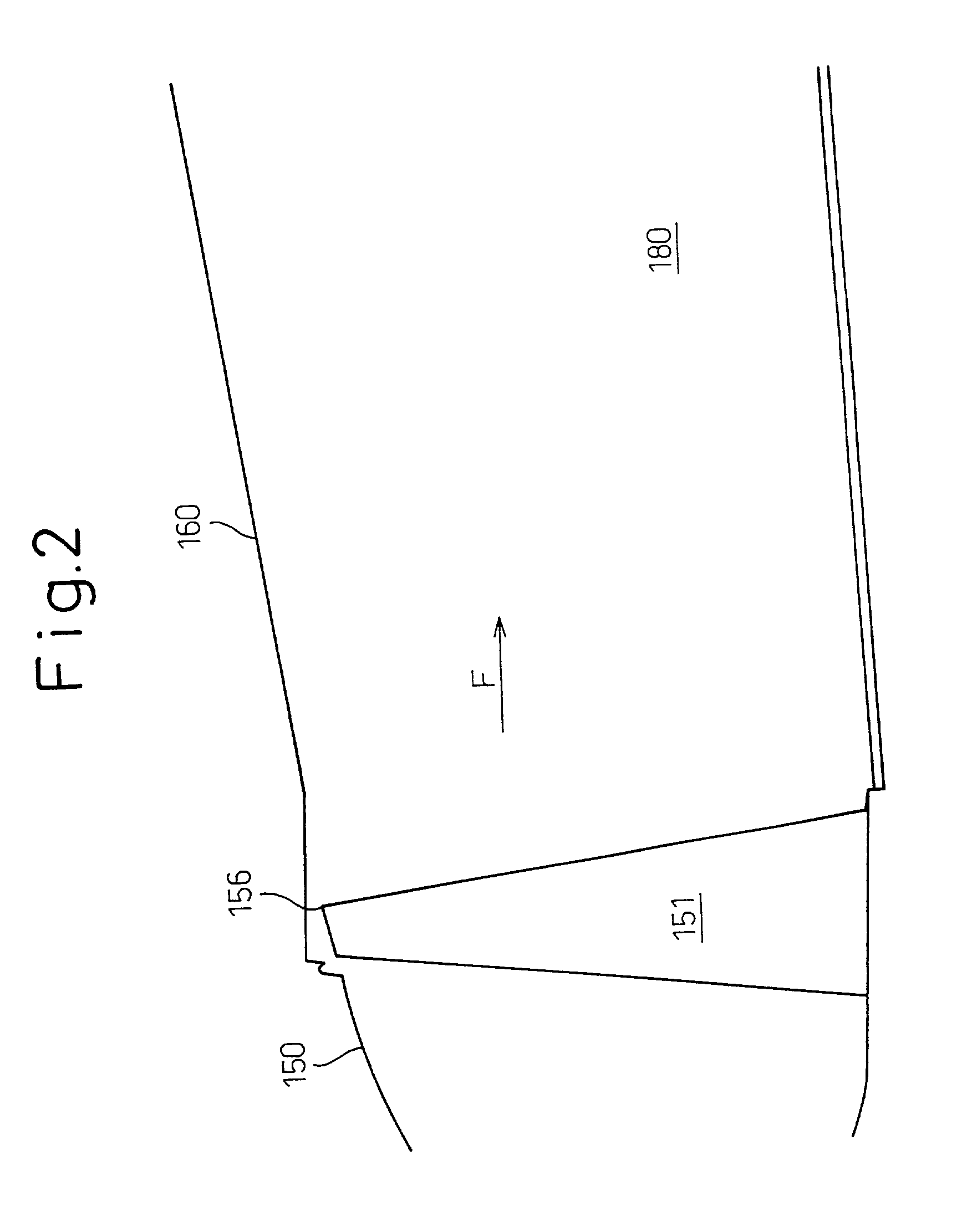

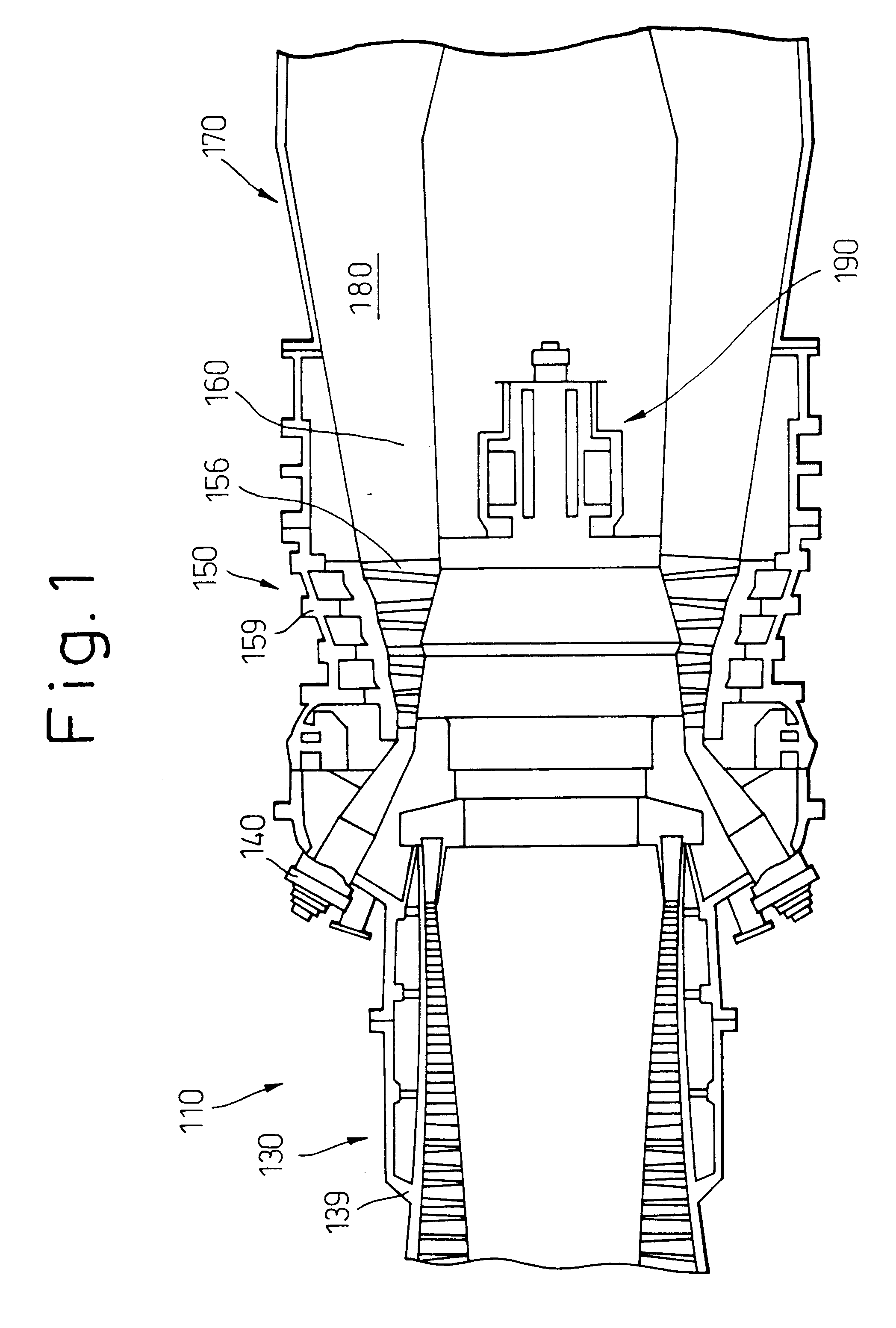

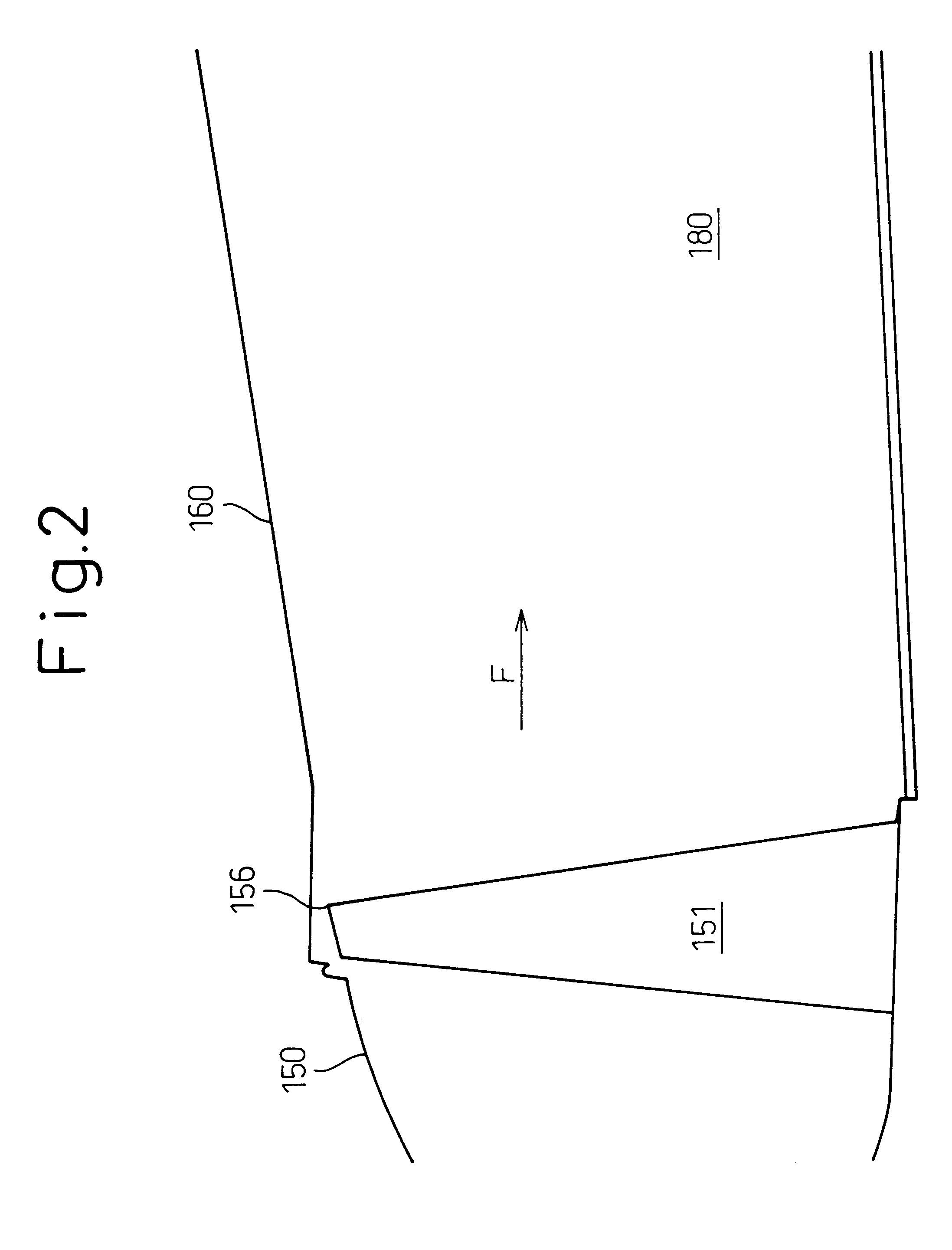

Axial-flow turbine having stepped portion formed in axial-flow turbine passage

InactiveUS20020159886A1Reduce the Mach numberImprove turbine efficiencyPump componentsGas turbine plantsTrailing edgeTurbine

There is provided an axial-flow turbine comprising an exhaust chamber; a turbine including multiple stage rotor blades, said multiple stage rotor blade including terminal stage rotor blades; an annular diffuser located between the turbine and the exhaust chamber; and an annular axial-flow turbine passage defined by the turbine, the diffuser and the exhaust chamber, wherein fluid flows through the axial-flow turbine passage toward the exhaust chamber, and an annular stepped portion which inwardly projects in a radial direction is formed on the portion of an inner wall of the axial-flow turbine passage that is located on the downstream side of a trailing edge of a tip portion of the terminal stage rotor blades provided in the flow direction of the fluid. In the stepped portion, a projecting portion which inwardly projects in a radial direction may be provided.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

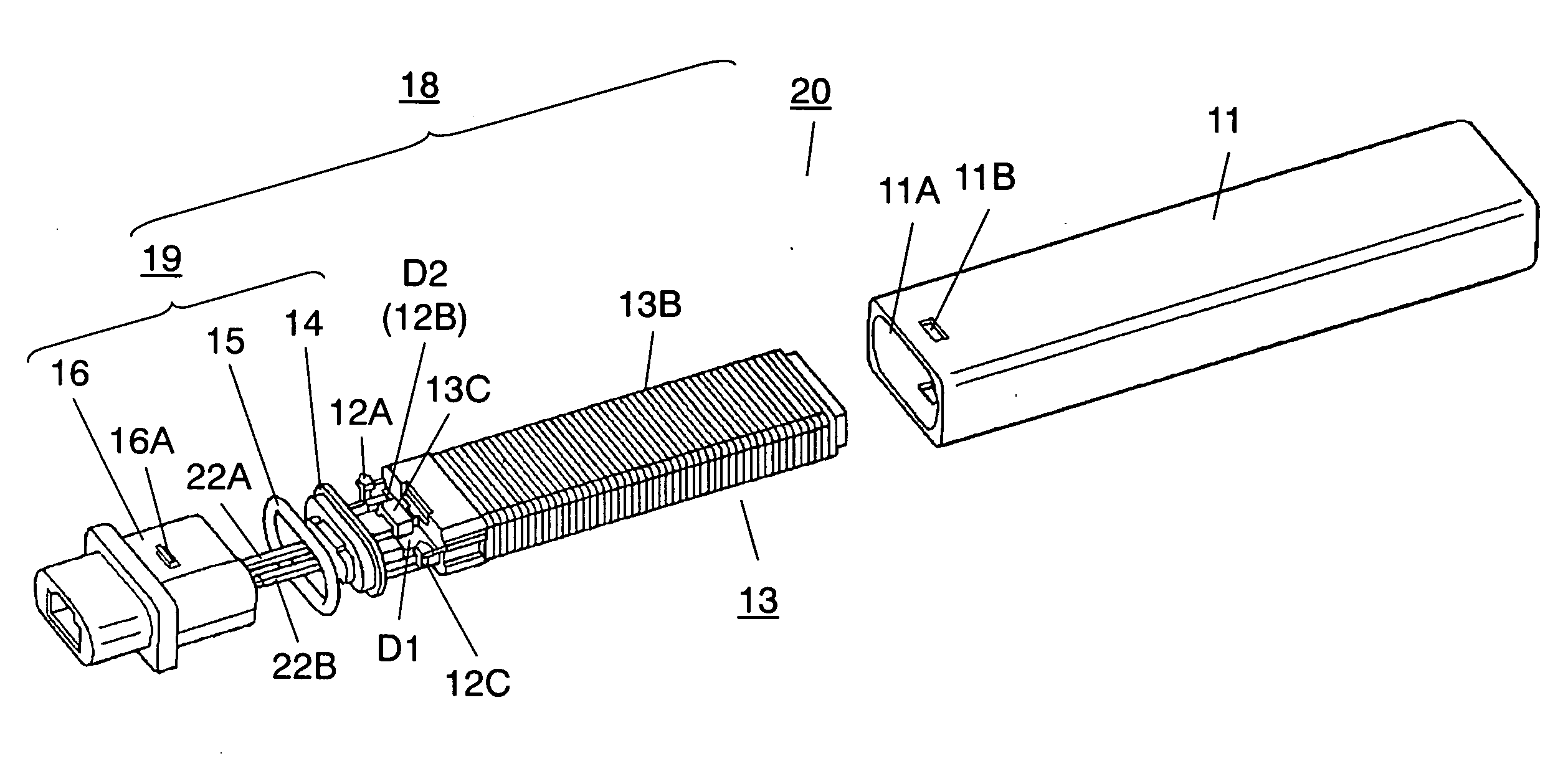

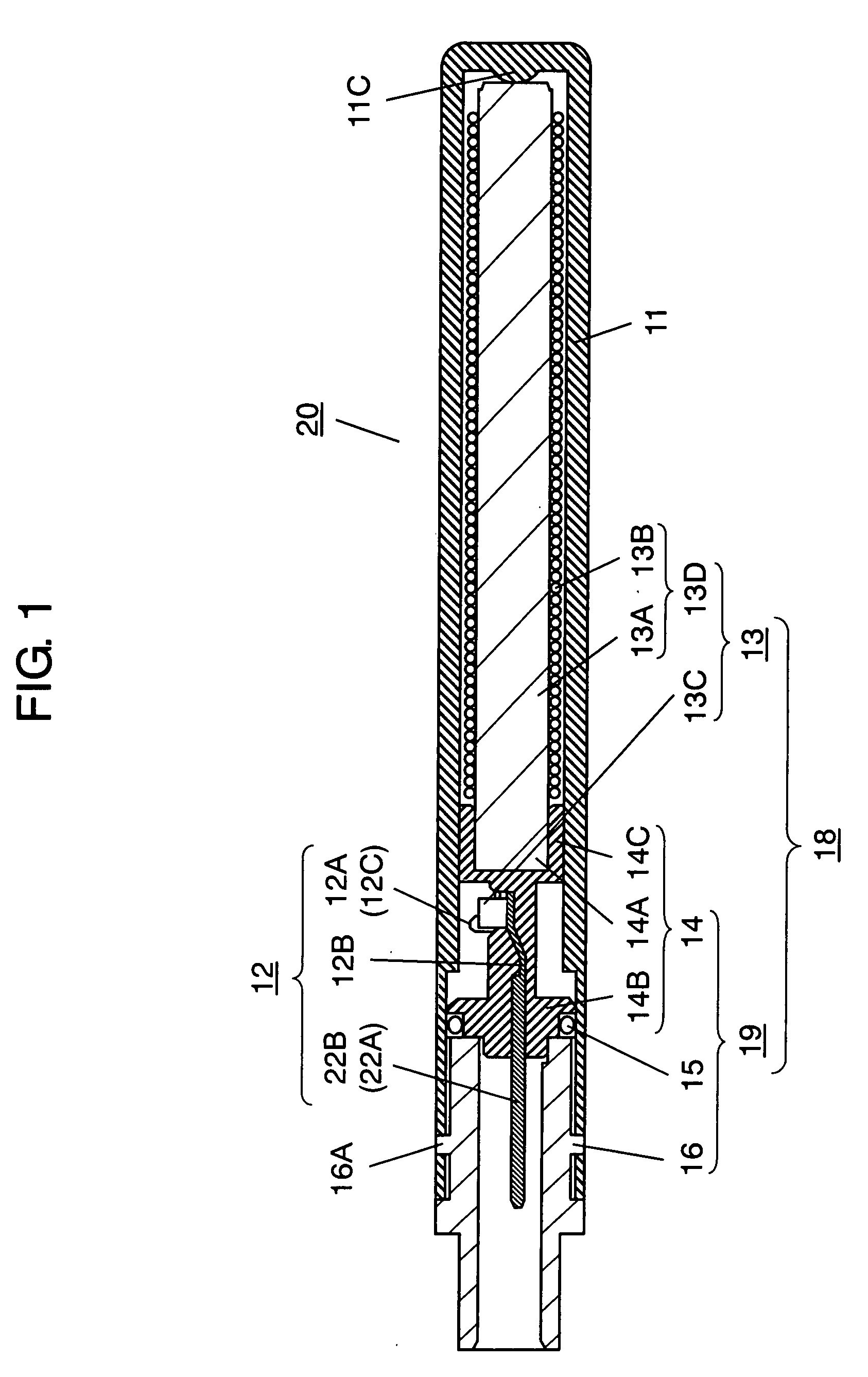

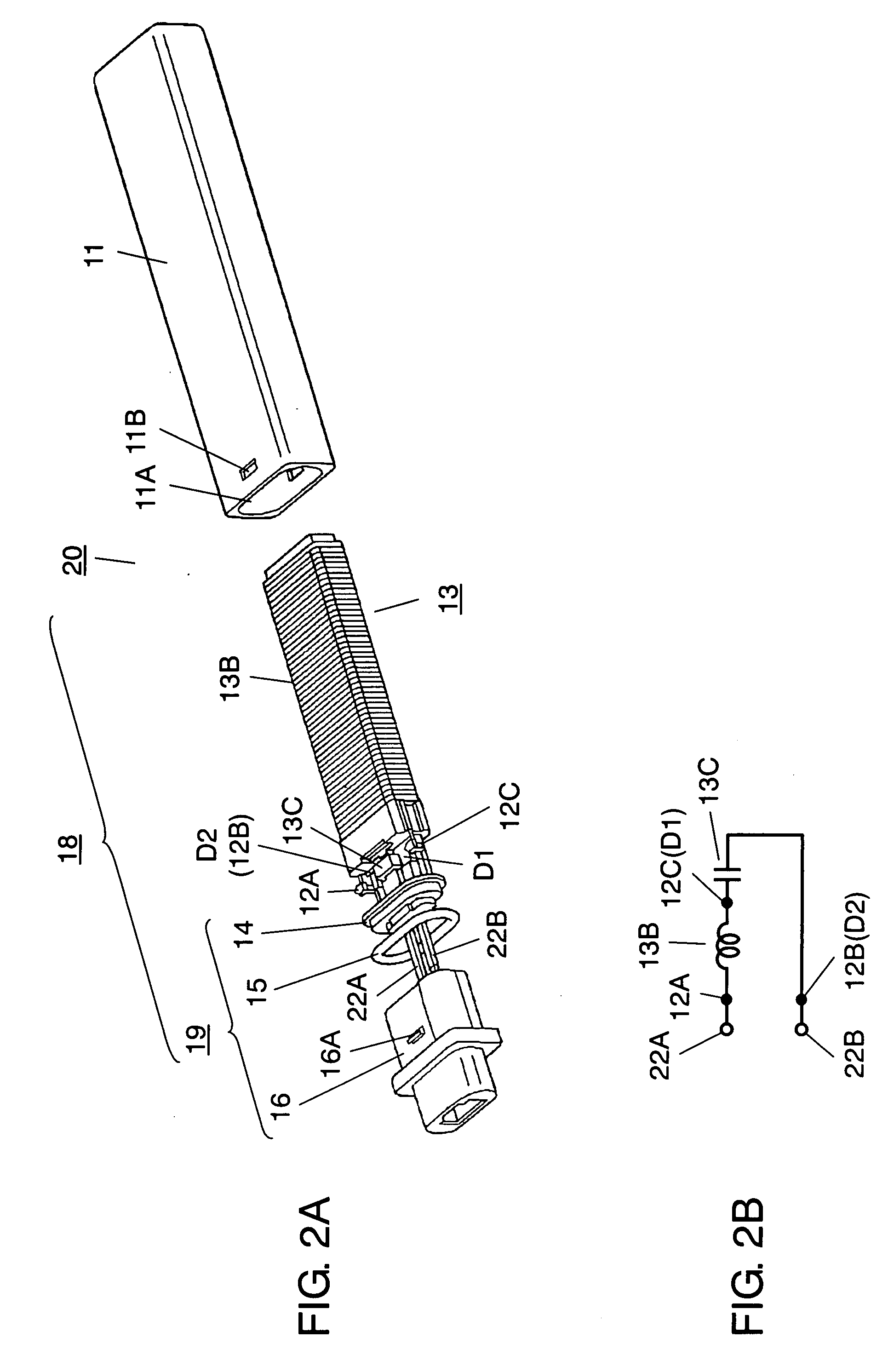

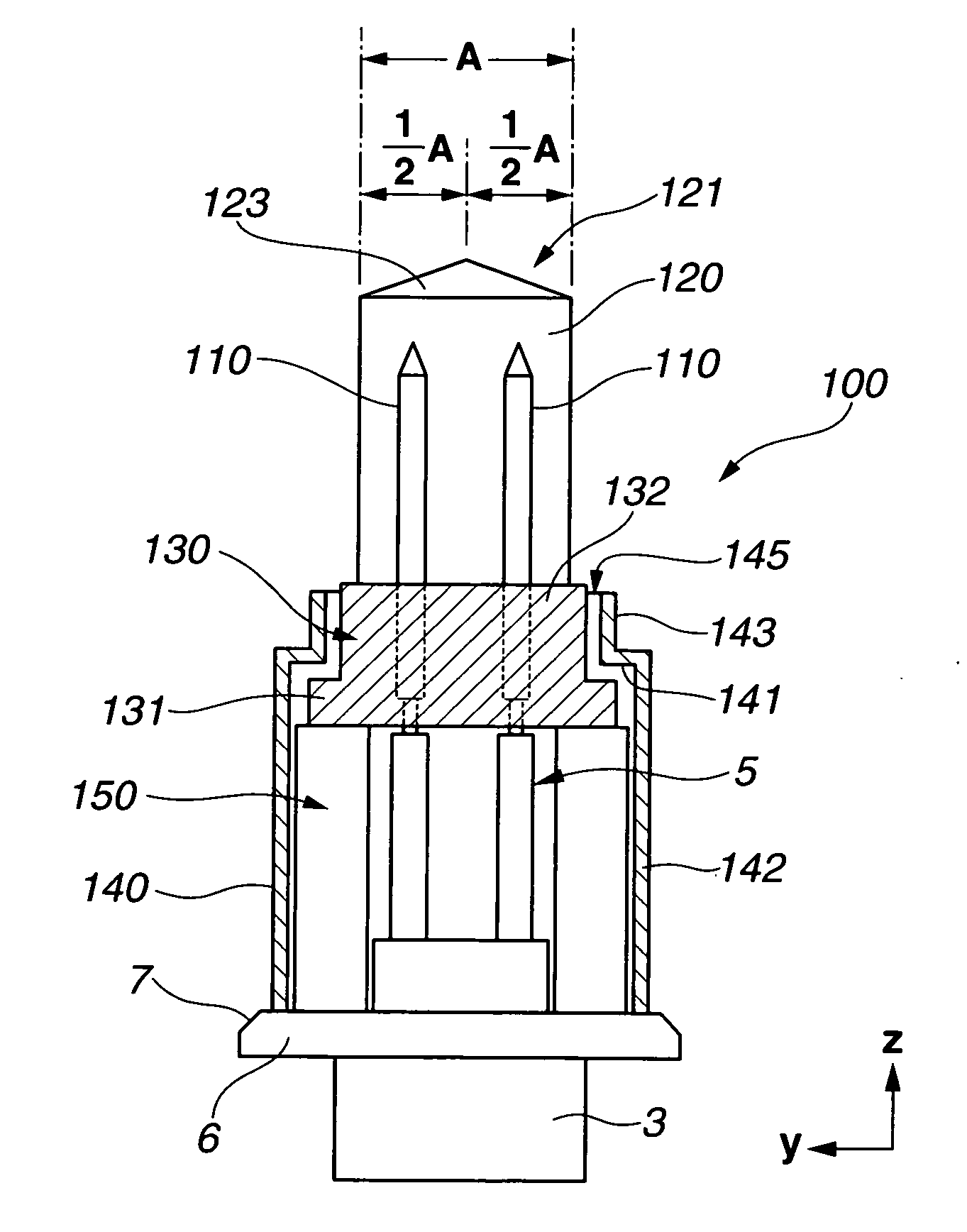

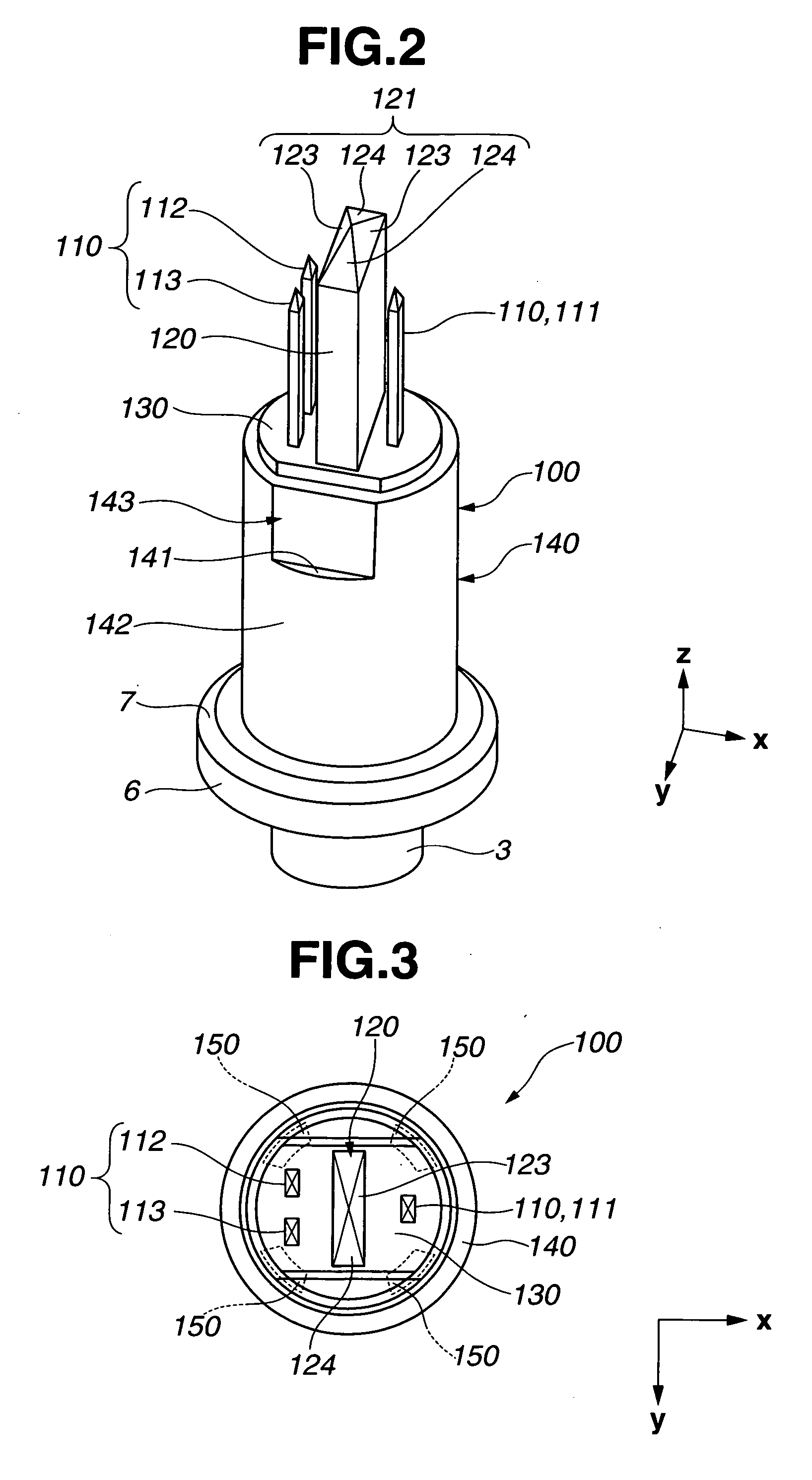

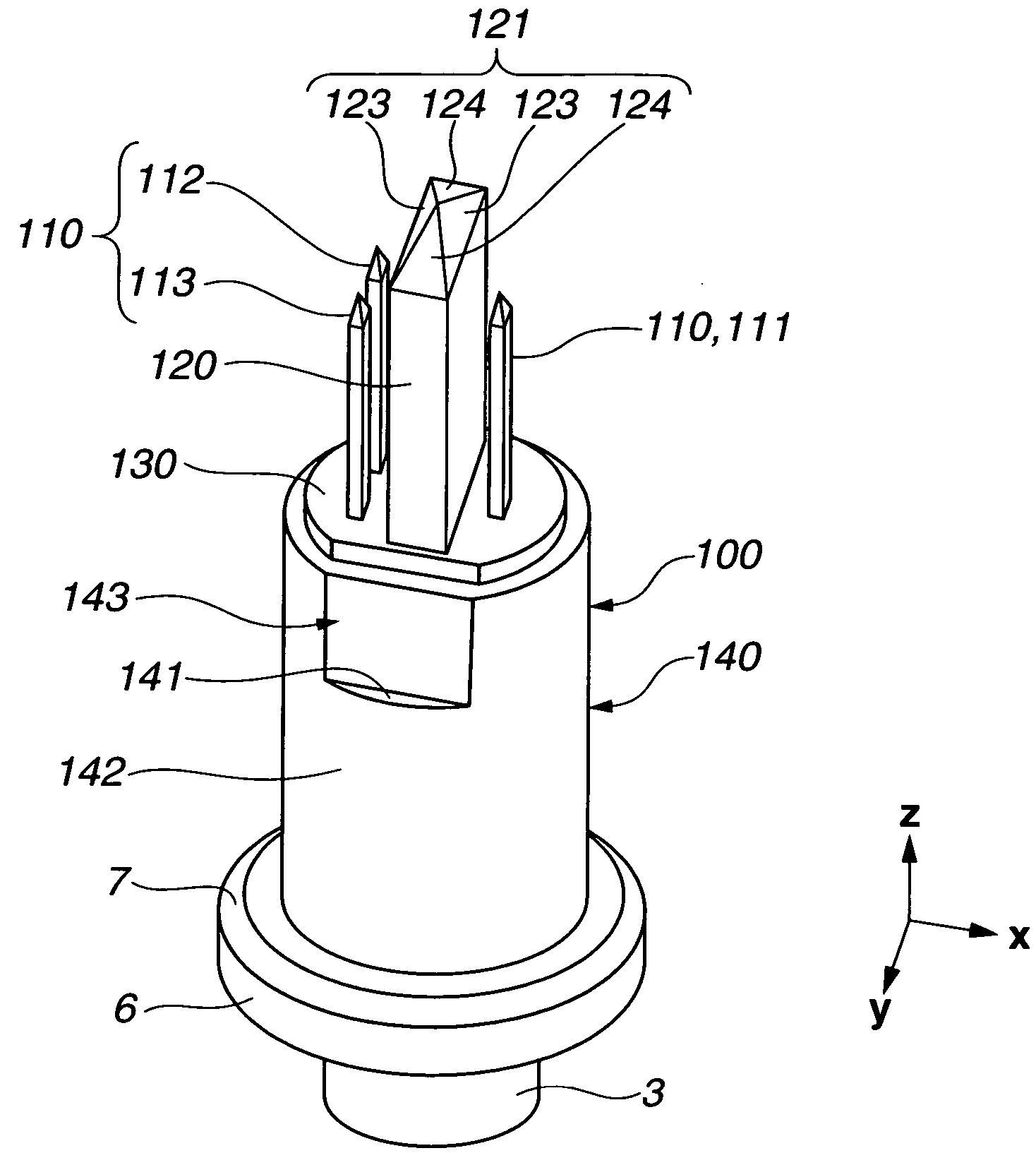

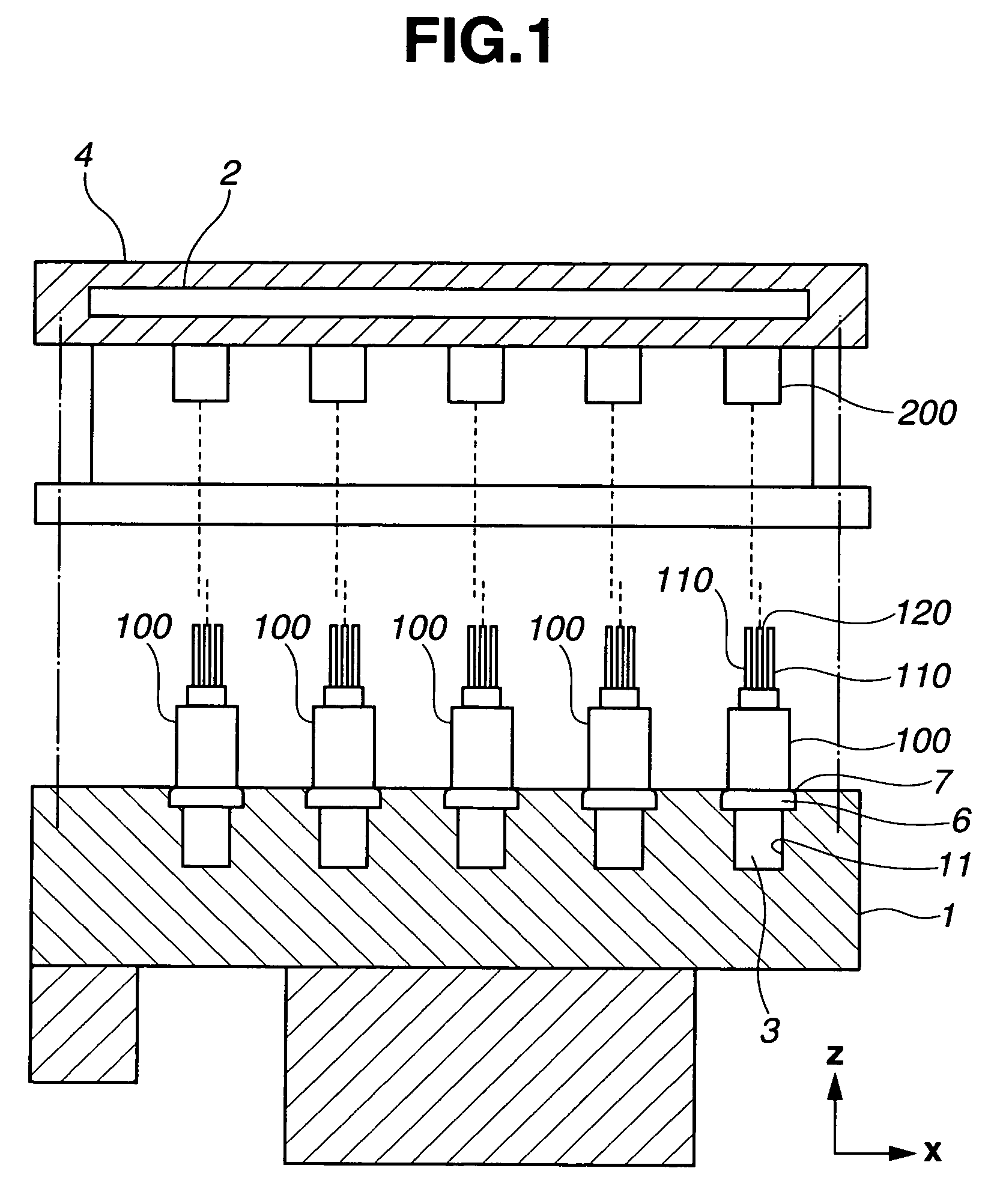

Atenna device

InactiveUS20080030423A1Loop antennas with ferromagnetic coreAntenna supports/mountingsElectrical and Electronics engineeringTerminal stage

The present invention provides an antenna device that is easy to manufacture by doing away with the wiring section. The antenna device includes an antenna member housed inside a nearly tubular case and a terminal body electrically connected to the antenna member for taking out electrical signal to outside, and the antenna member is sealed inside the case. The antenna device also has a housing for sealing the antenna member inside the case for engaging with a connector to be coupled, and a plugging member having an O-ring and a terminal stage fit into a nearly integral unit.

Owner:PANASONIC CORP

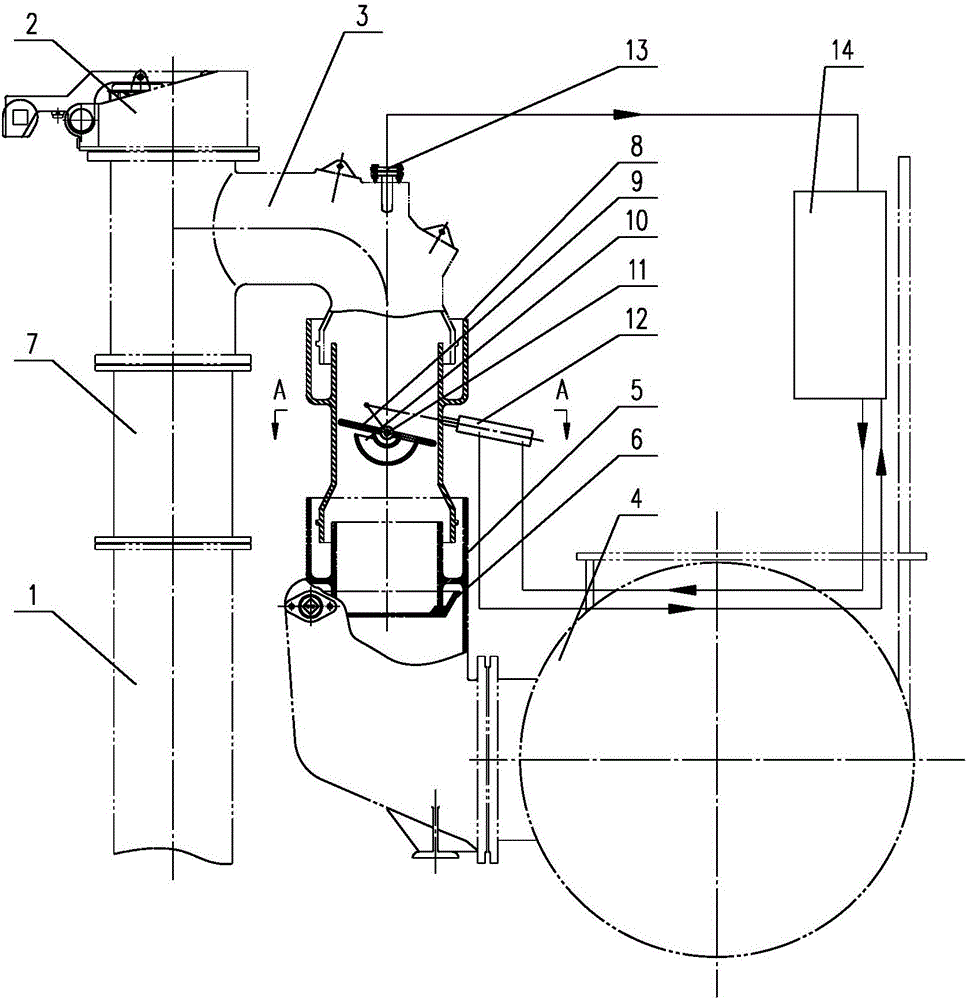

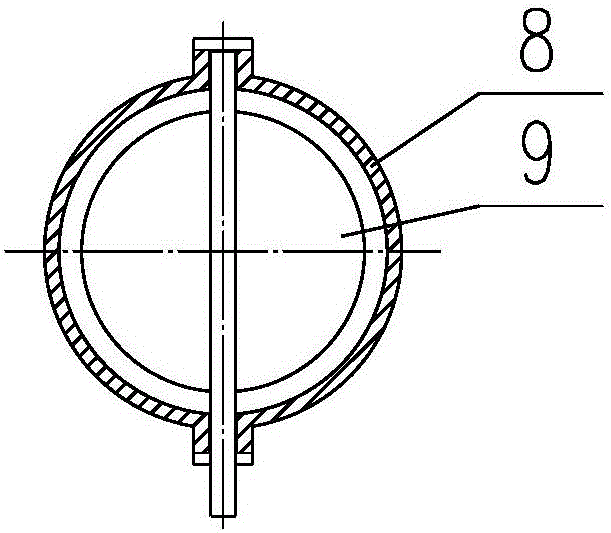

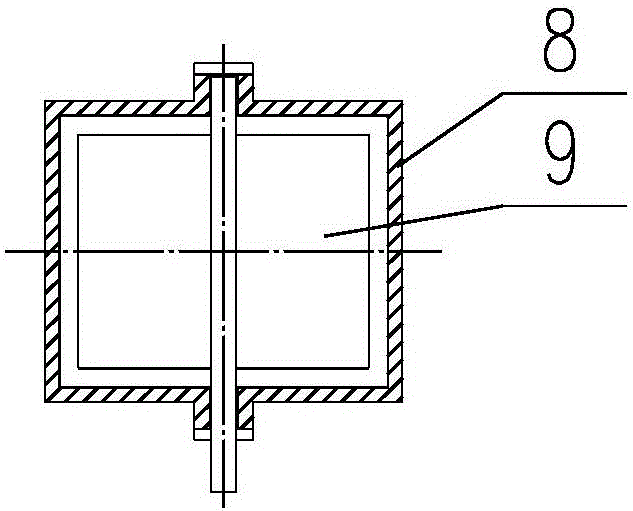

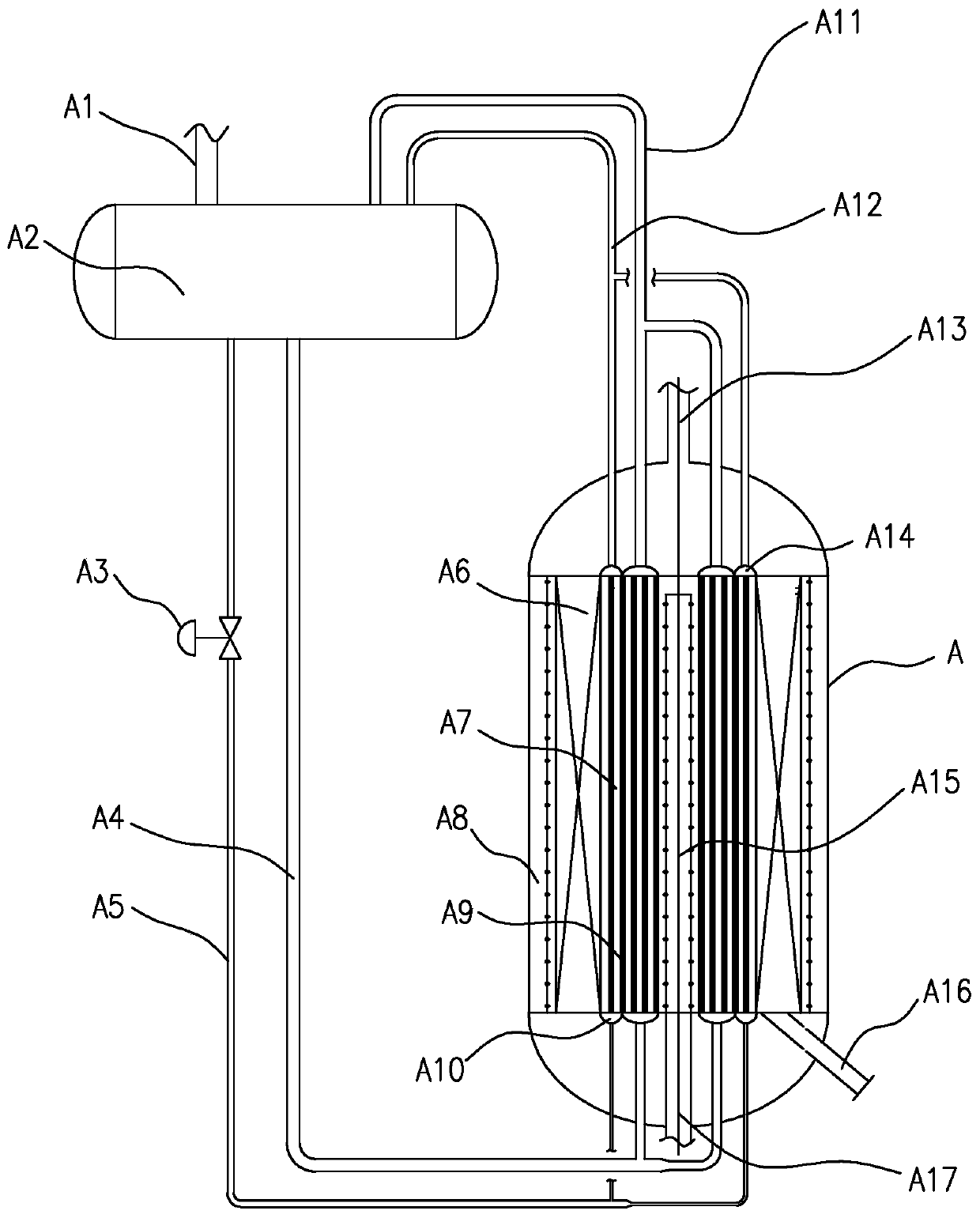

Device and method for pressure regulation of coke oven carbonization chamber

ActiveCN106147803AEasy to implementDoes not take up circulation spaceCoke oven safety devicesControl systemCarbonization

The invention relates to a device and method for pressure regulation of a coke oven carbonization chamber. The regulation device comprises a water-sealed valve and a throttle. The throttle is composed of a casing, an overturning plate, an overflow channel and a rotating shaft. The casing is fixed between an axle tube and a water-sealed valve body. The overturning plate is installed in the casing through the rotating shaft, the rotating shaft is driven by an execution mechanism and can drive the overturning plate to rotate; and the overflow channel is arranged at the bottom of the overturning plate to be used for forming an ammonia water water seal and performing overflow of ammonia water. The axle tube is provided with a pressure measurement device. The pressure measurement device and the execution mechanism are connected with a control system. The structural form of combining the throttle and the water-sealed valve is adopted, the throttle overturning plate is utilized to regulate pressure of the carbonization chamber, the water seal of the water-sealed valve is utilized to cut off raw gas during coke pushing, finally the goals that smoke is prevented from escaping during coal charging into a coke oven and during a coking period, negative pressure of the carbonization chamber during a coking terminal stage is avoided and air is prevented from leaking into the carbonization chamber to damage coke by fire and damage an oven body are achieved. The device is simple in structure, easy to implement and particularly suitable for modification of an existing coke oven gas gathering system.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

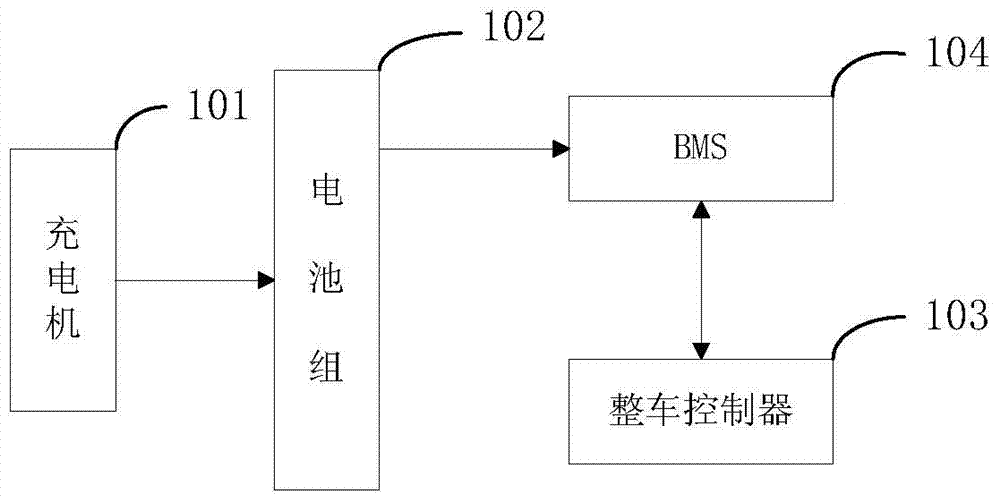

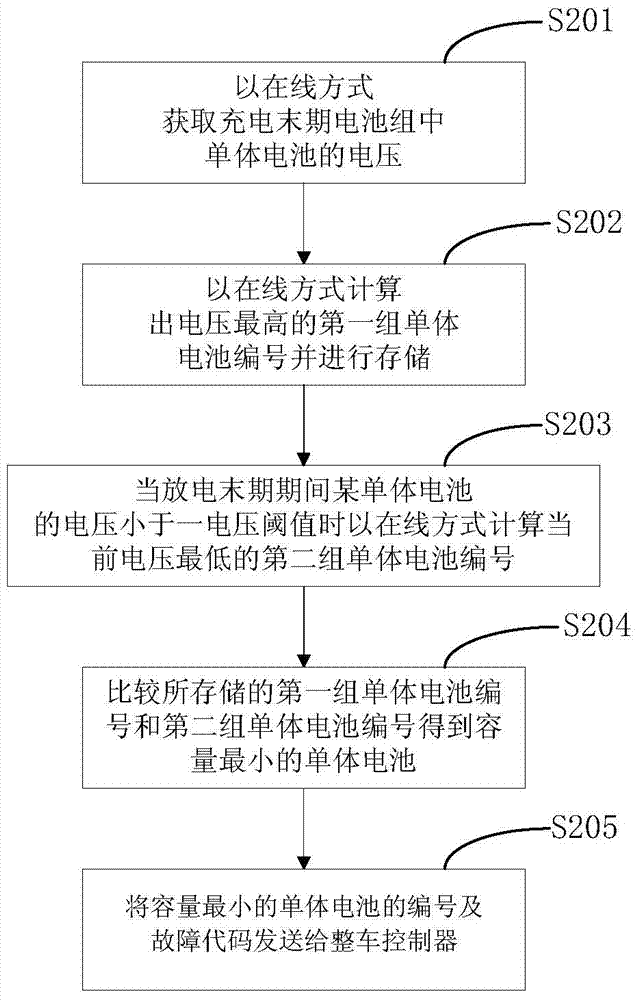

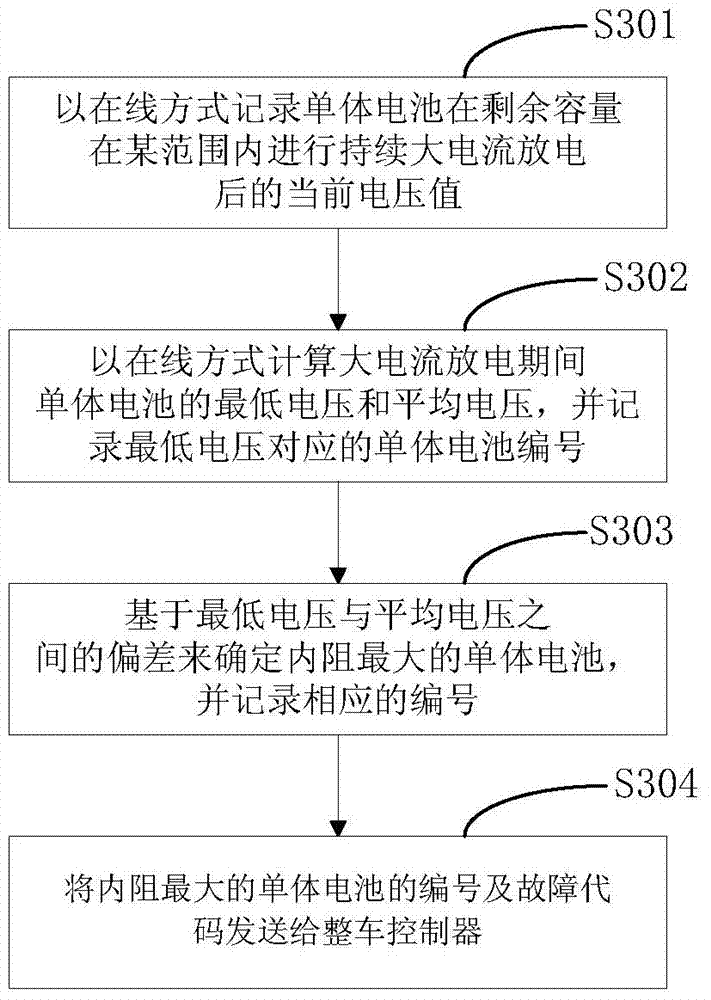

Method for judging health degree of batteries

The invention provides a method for judging the health degree of batteries. The method includes the first step of obtaining the voltage of battery cells in a battery pack at the terminal stage of charging in an online real-time mode; the second step of calculating the serial numbers of the first group of battery cells with the highest voltage in an online real-time mode and storing the serial numbers; the third step of calculating the serial numbers of the second group of battery cells with the lowest voltage at the current in an online real-time mode when the voltage of certain battery cells is smaller than a voltage threshold value at the terminal stage of discharging; the fourth step of comparing the stored serial numbers of the first group of battery cells and the serial numbers of the second group of battery cells, and determining the battery cells with the same serial numbers in the serial numbers of the first group of battery cells and the serial numbers of the second group of battery cells to be the battery cells with the smallest capacity relative to other battery cells. According to the method, the online dynamic judging of the health degree of the batteries when a vehicle runs can be achieved, early warning can be carried out when the health degree of the batteries is too low, the overuse of the batteries is avoided, and the batteries can be used safely and reliably.

Owner:HUNAN CSR TIMES ELECTRIC VEHICLE

Spark-ignition direct-injection engine

ActiveUS9932883B2Promote atomizationShorten the overall cycleElectrical controlInternal combustion piston enginesFuel injectionTerminal stage

A controller injects fuel into a cylinder at a high fuel pressure of 30 MPa or higher, at least in a period between a terminal stage of a compression stroke and an initial stage of an expansion stroke when an operating mode of an engine body is at least in a first specified sub-range of a low load range, and at least in a second specified sub-range of a high load range. The controller sets an EGR ratio in the first specified sub-range to be higher than an EGR ratio in the second specified sub-range, and advances start of fuel injection in the first specified sub-range to start of fuel injection in the second specified sub-range.

Owner:MAZDA MOTOR CORP

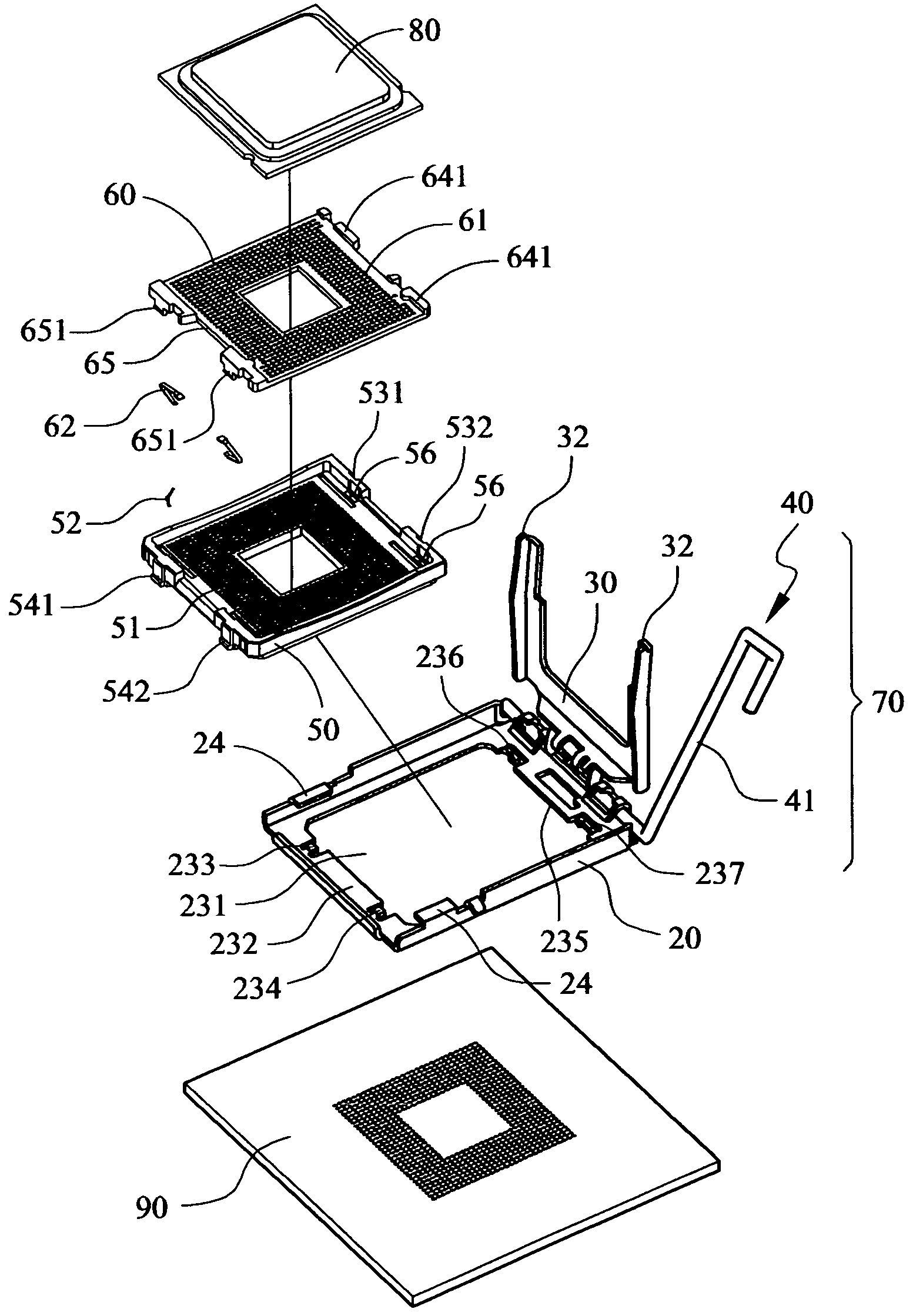

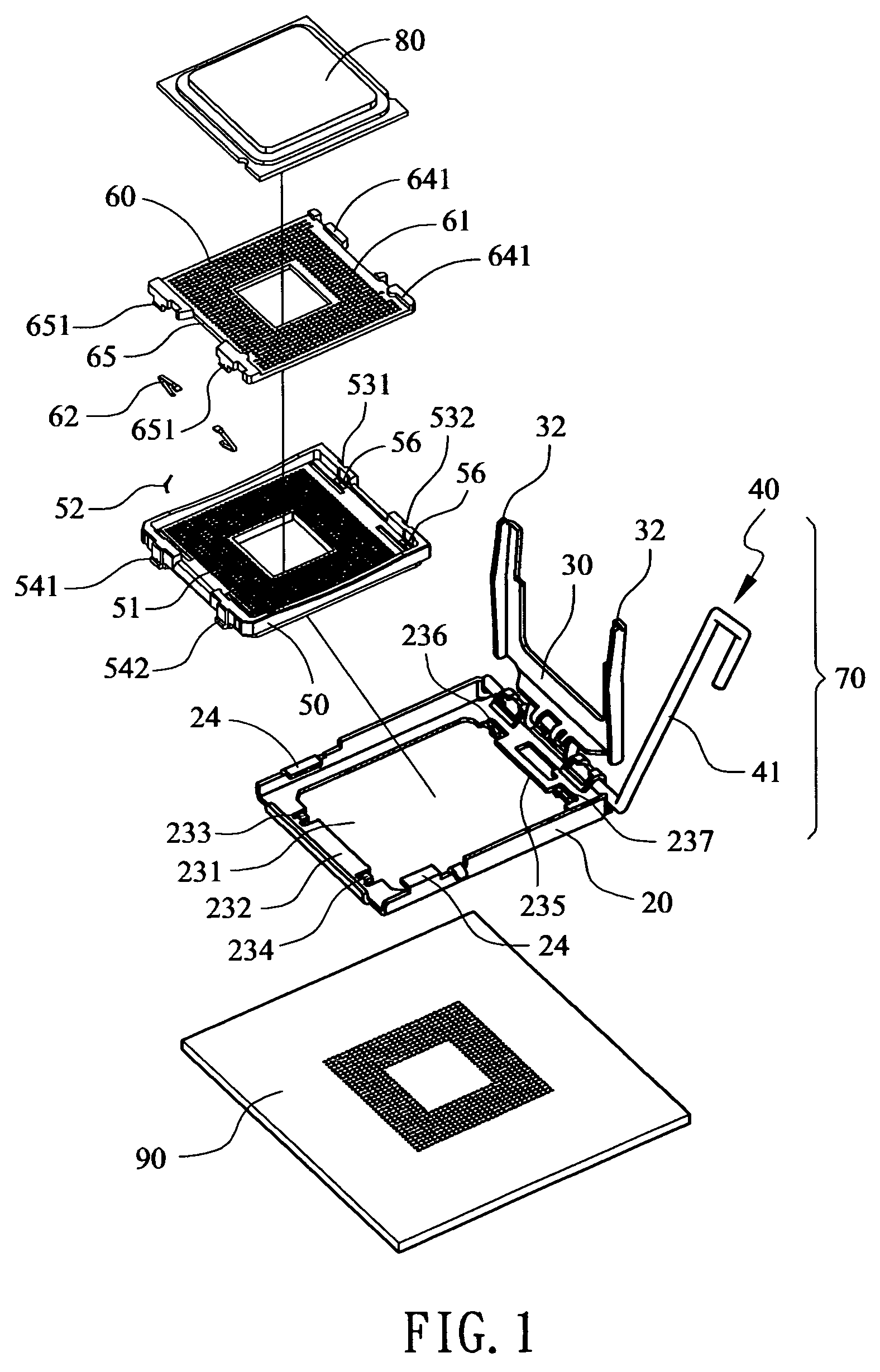

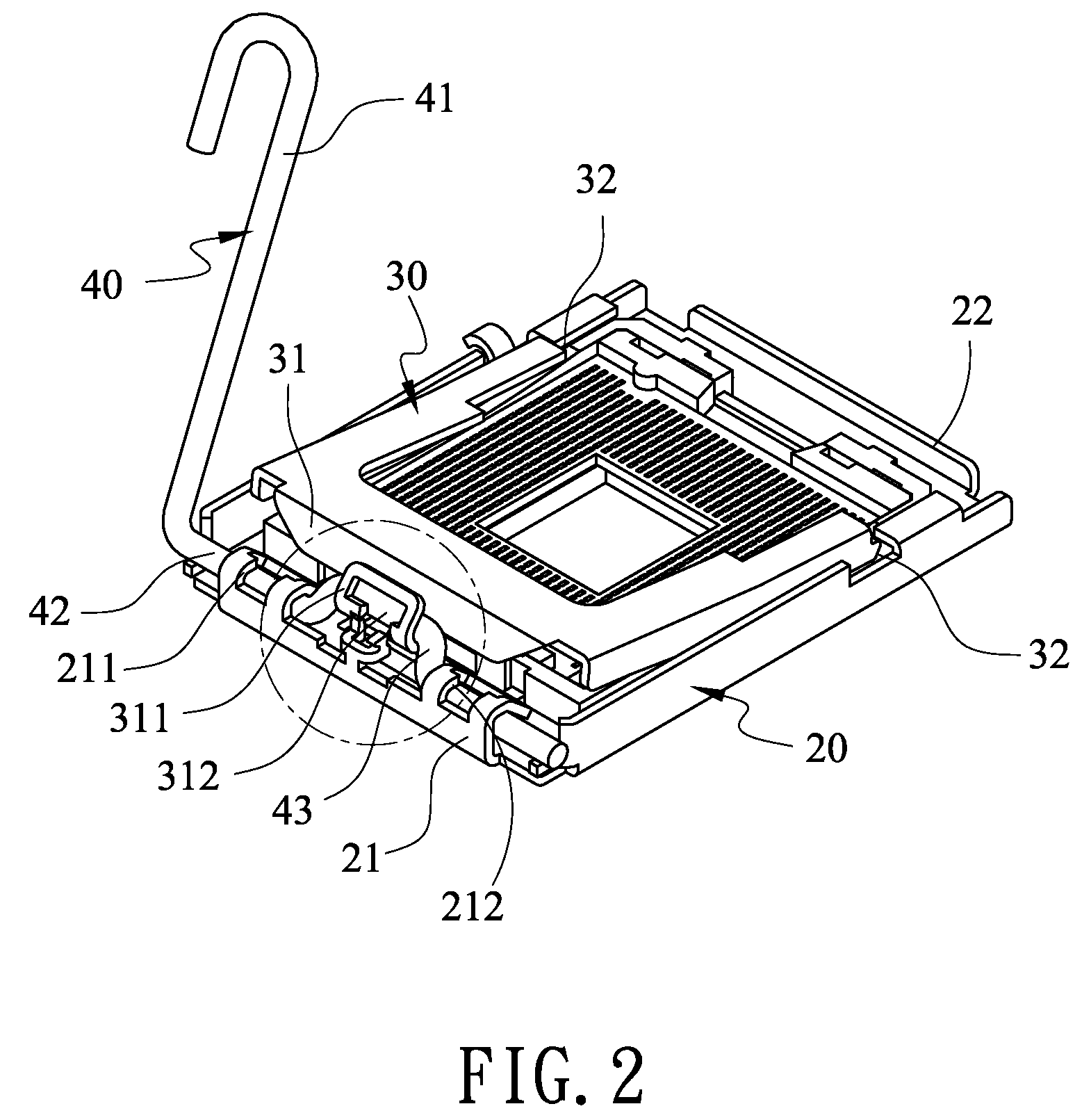

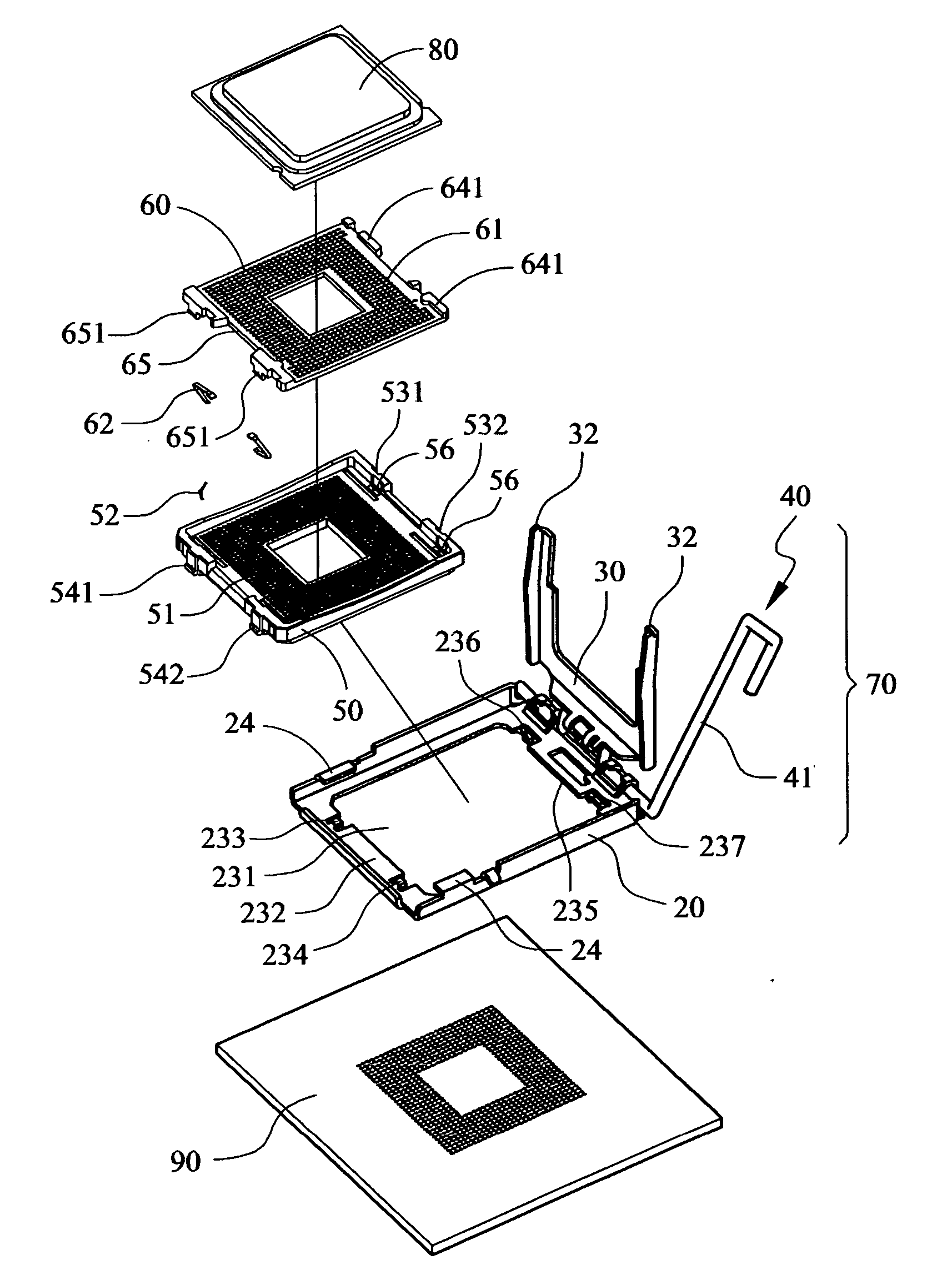

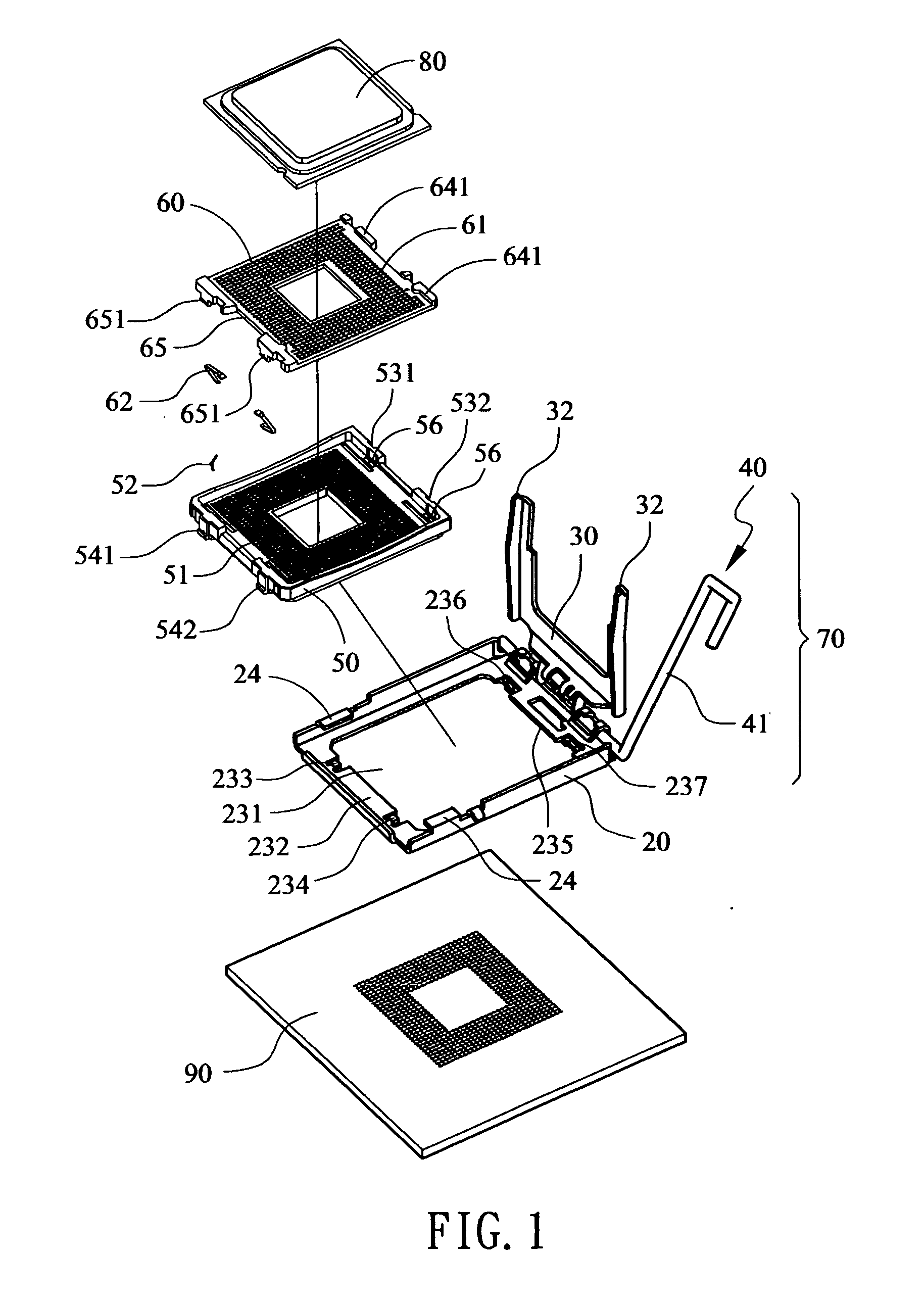

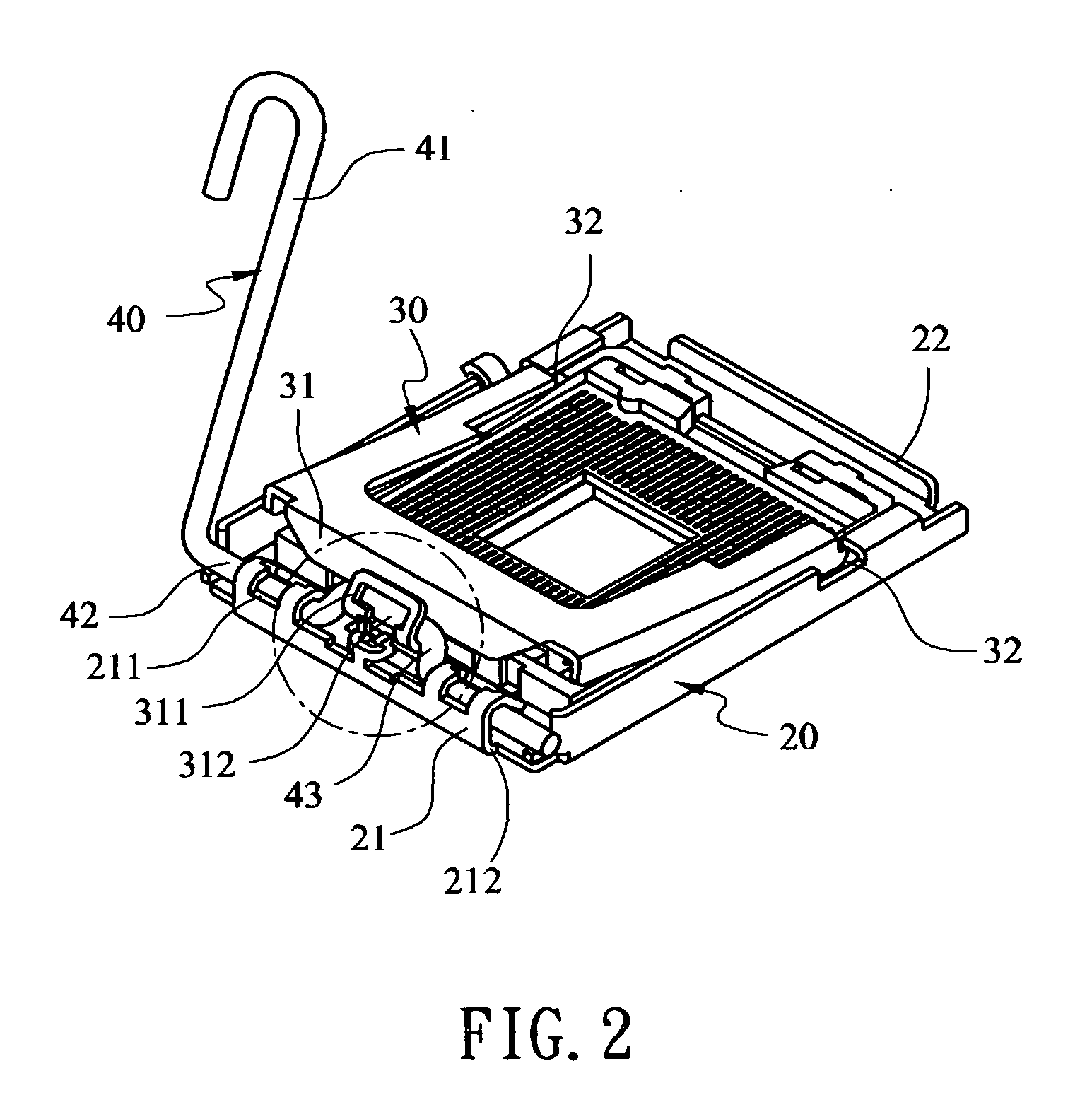

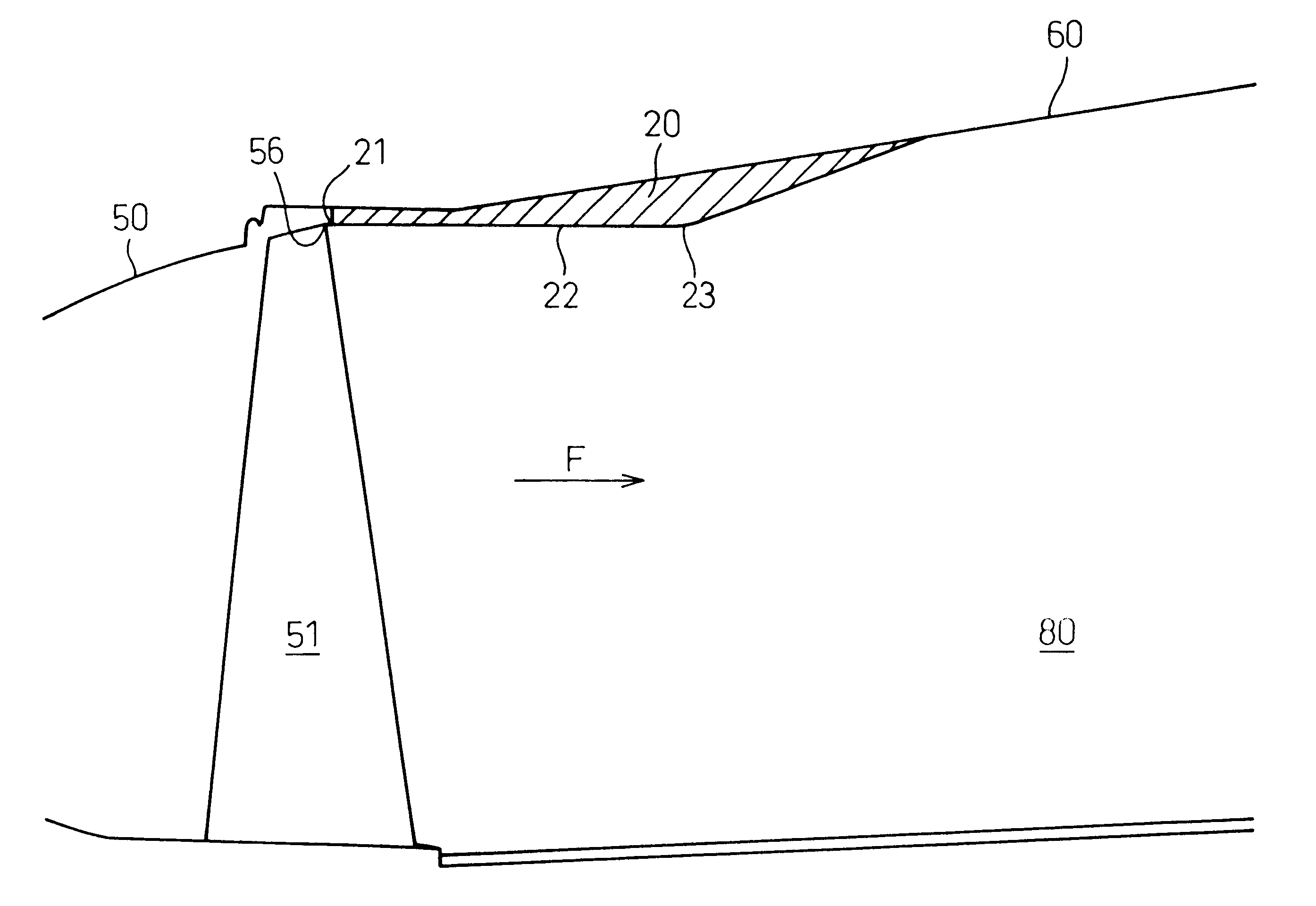

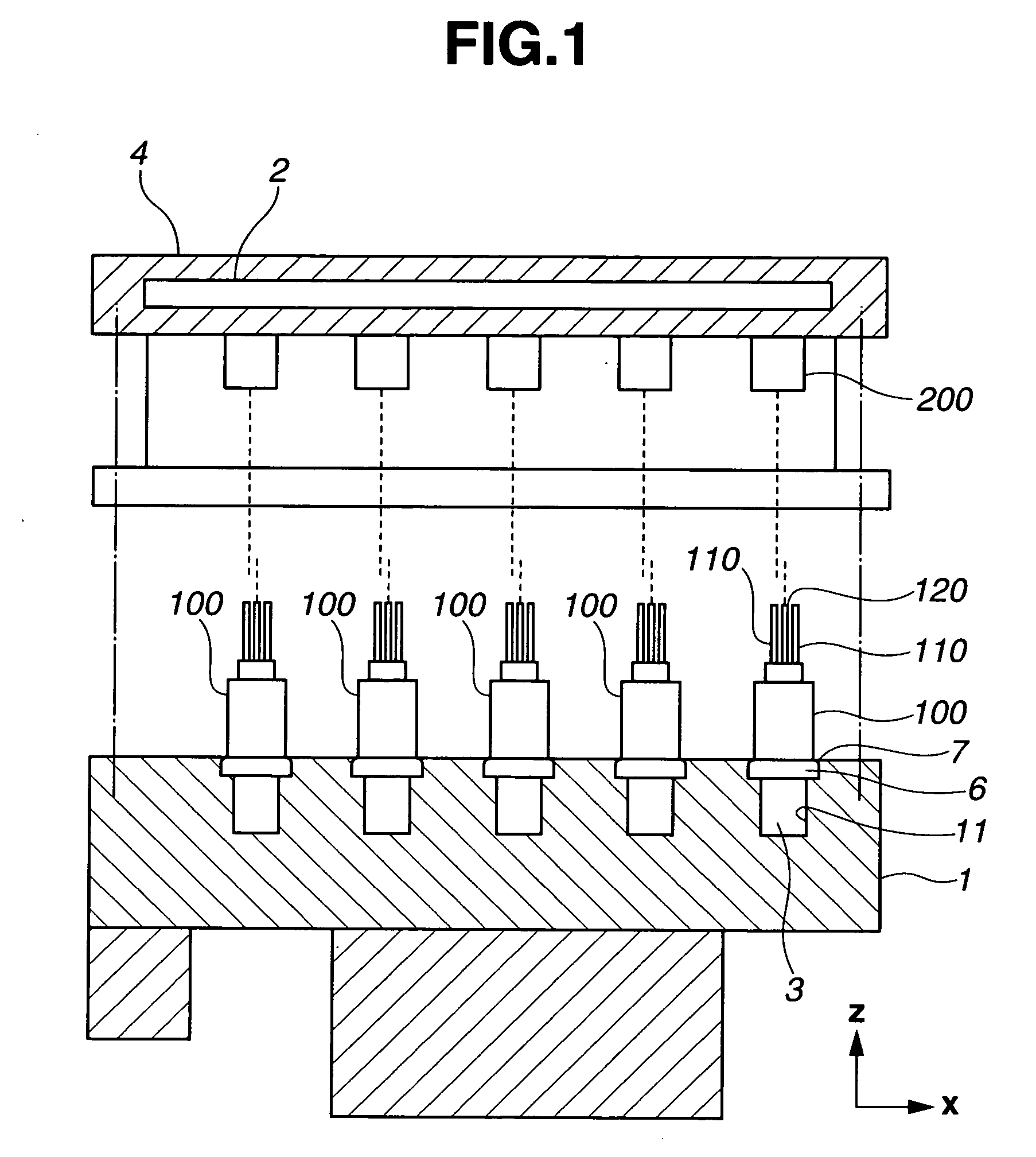

Land grid array integrated circuit connector

InactiveUS7247043B2Sufficient pressureEasy to operateEngagement/disengagement of coupling partsElectrical apparatus contructional detailsSolder ballEngineering

A land grid array integrated circuit (LGA IC) connector uses a pressing rod assembly linked with a cover for opening / closing operation. The LGA IC connector includes a first tooth and a second tooth driven by a first post and a second post of a positioning section to enhance the rotation angle thereof. A sufficient pressure can be provided with smaller operation angle of the pressing rod and cover, thus facilitating operation. A protection board is assembled to the terminal stage and then arranged on a frame. A V-shaped spring element is provided between the protection board and the terminal stage such that the protection board is higher than the terminal to protect the terminal. The terminal can be protected from deformation. In the present invention, the terminal is received in the terminal hole and the annular cone at terminal tail can clamp the solder ball.

Owner:LAI KUANG CHIH

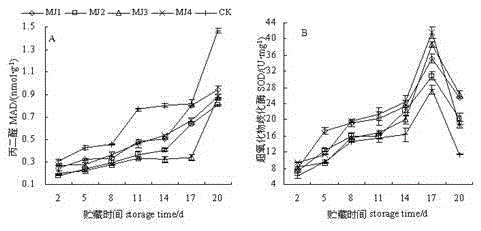

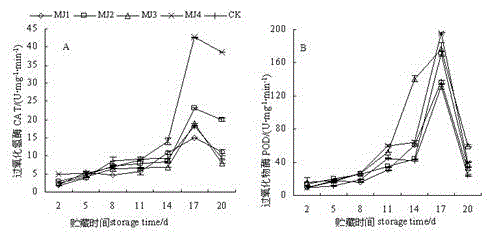

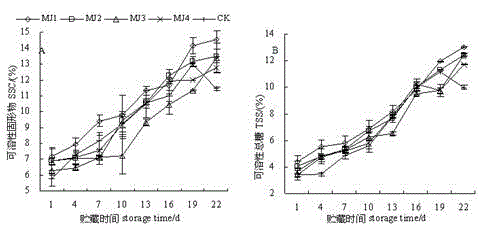

Novel method and protective film agent for preventing and controlling soft rot of actinidia and preparation method for protective film agent

InactiveCN105660267AImprove disease resistanceImprove storage effectBiocideFungicidesTectorial membraneNatural barrier

The invention discloses a novel method and a protective film agent for preventing and controlling soft rot of actinidia and a preparation method for the protective film agent. The chitosan composite protective film agent is adopted in the method. The protective film agent comprises the following components in percentage by mass: 2.5-7.5% of chitosan, 0.5-2.5% of calcium salt, 1.5-3.5% of a film former, 0.5-1.5% of an antibacterial substance and the balance of water. The fruit surface is sprayed with a 25-100-fold solution of the protective film agent in the field during the early stage of pathogen infection of the soft rot of the actinidia or the germination stage, young fruit stage and strong fruit terminal stage of the actinidia, so that a layer of natural barrier is formed on the fruit surface for protecting the actinidia from being infected with pathogenic microorganisms. The protective film agent for the actinidia is high in stability and can effectively improve the nutritional quality and the eating quality of the actinidia.

Owner:GUIZHOU UNIV

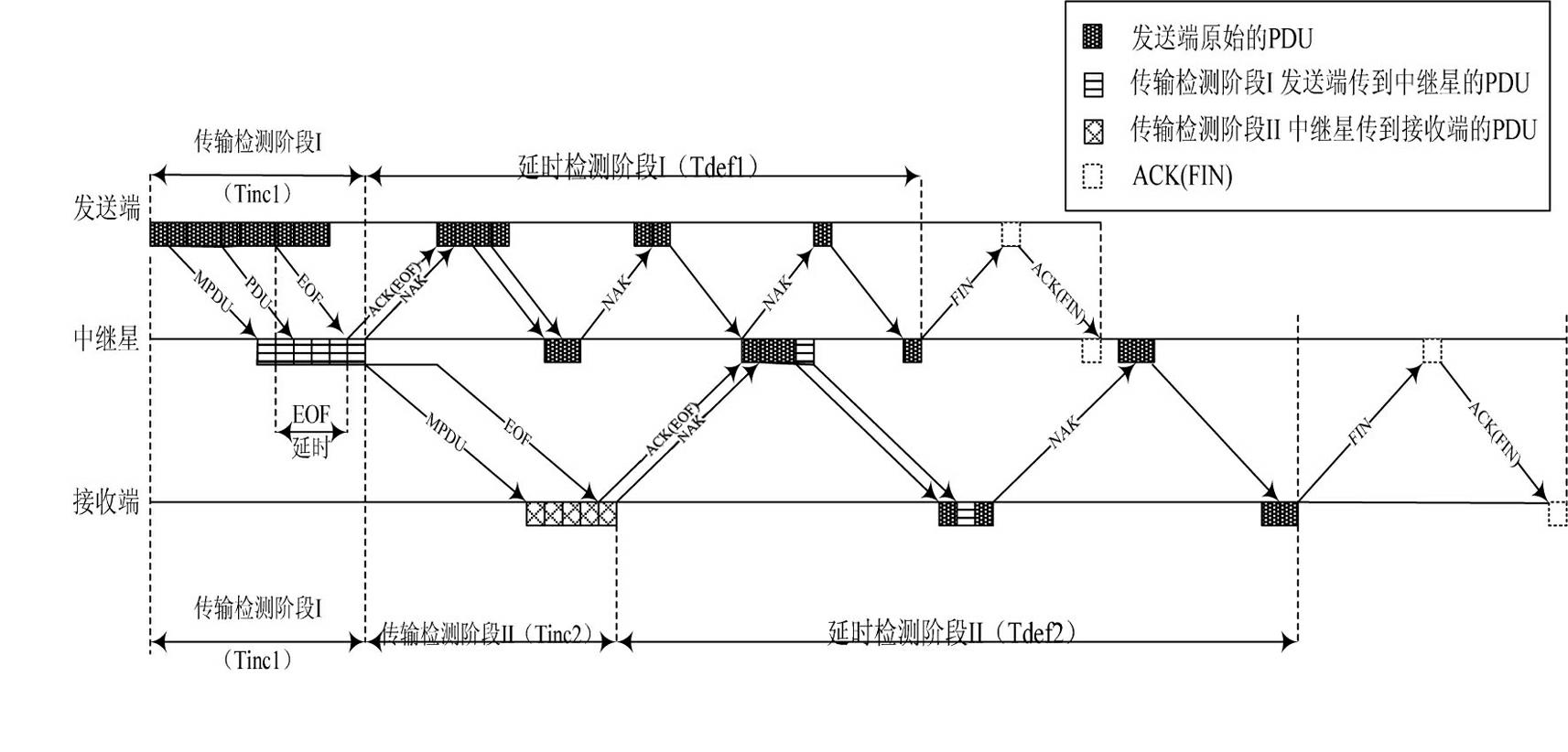

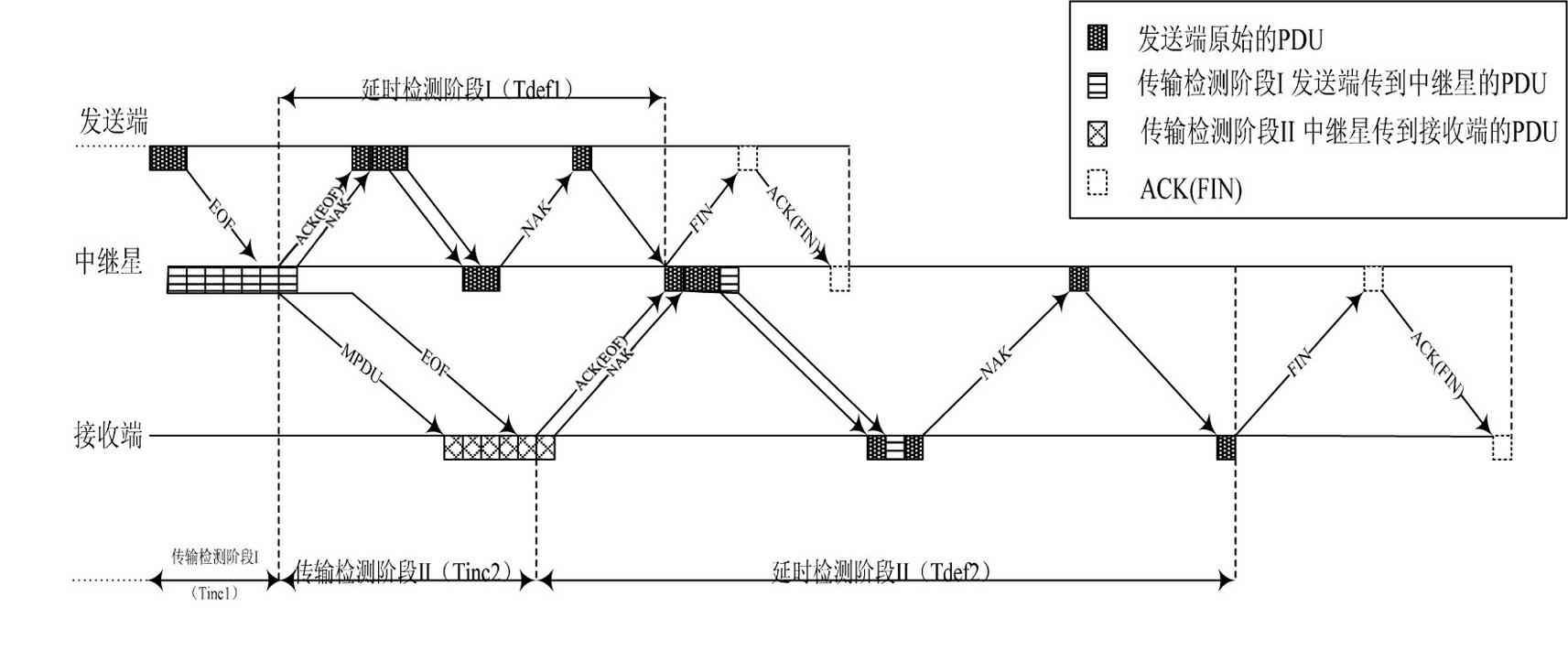

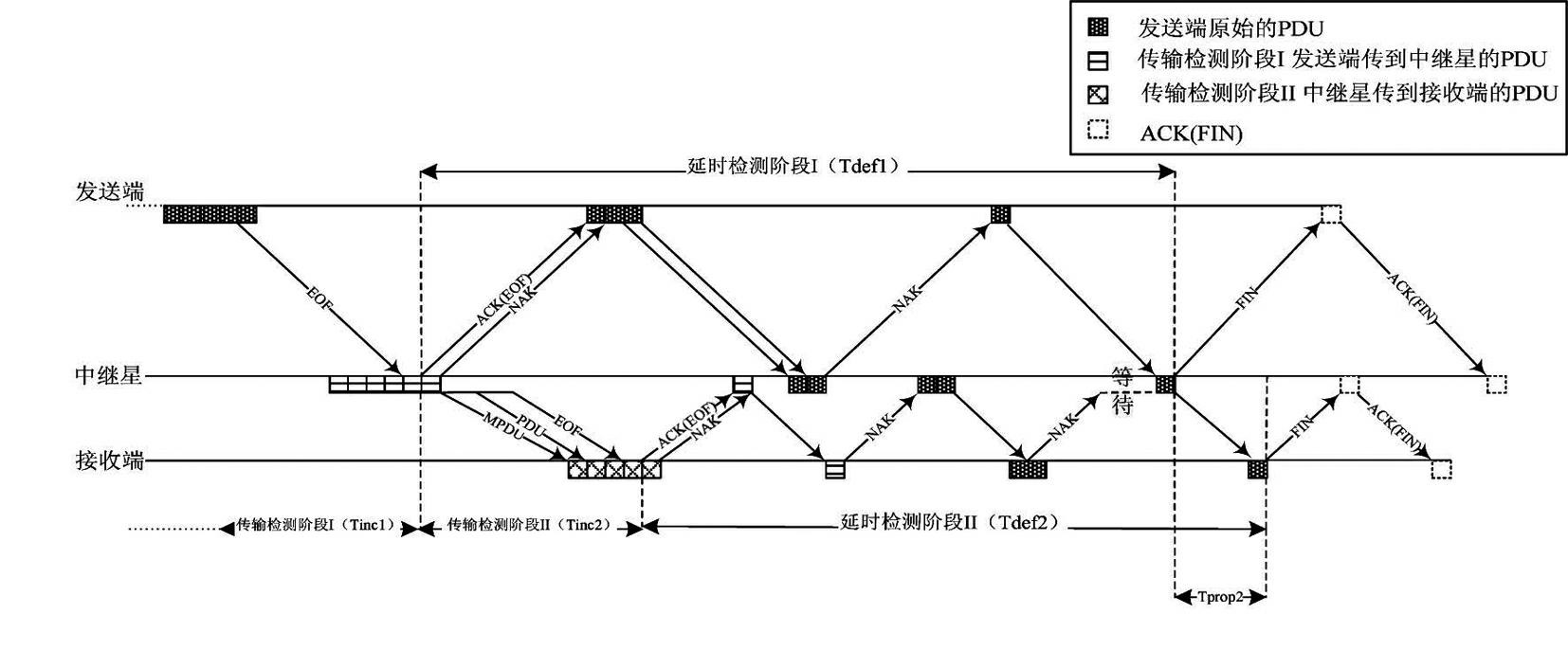

Deep space file transfer method based on relay store-forward

ActiveCN102694632AError prevention/detection by using return channelSpace environmentStore and forward

The invention provides a deep space file transfer method based on relay store-forward, used for transmitting a file to a receiving terminal from a transmitting terminal by virtue of a relay satellite. The deep space file transfer method based on relay store-forward comprises a transmitting terminal-to- relay satellite stage and a relay satellite-to-receiving terminal stage... According to the deep space file transfer method based on relay store-forward disclosed by the invention, in a high-error-rate deep space environment, gain of a delay negative acknowledgement type CFDP (ccsds file delivery protocol) based on the relay store-forward is increased by dozens to hundreds of astronomical units compared with the traditional point-to-point direct transfer protocol scheme, relay amplification forward protocol scheme and relay decoding forward protocol scheme in the aspect of transmission delay index.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

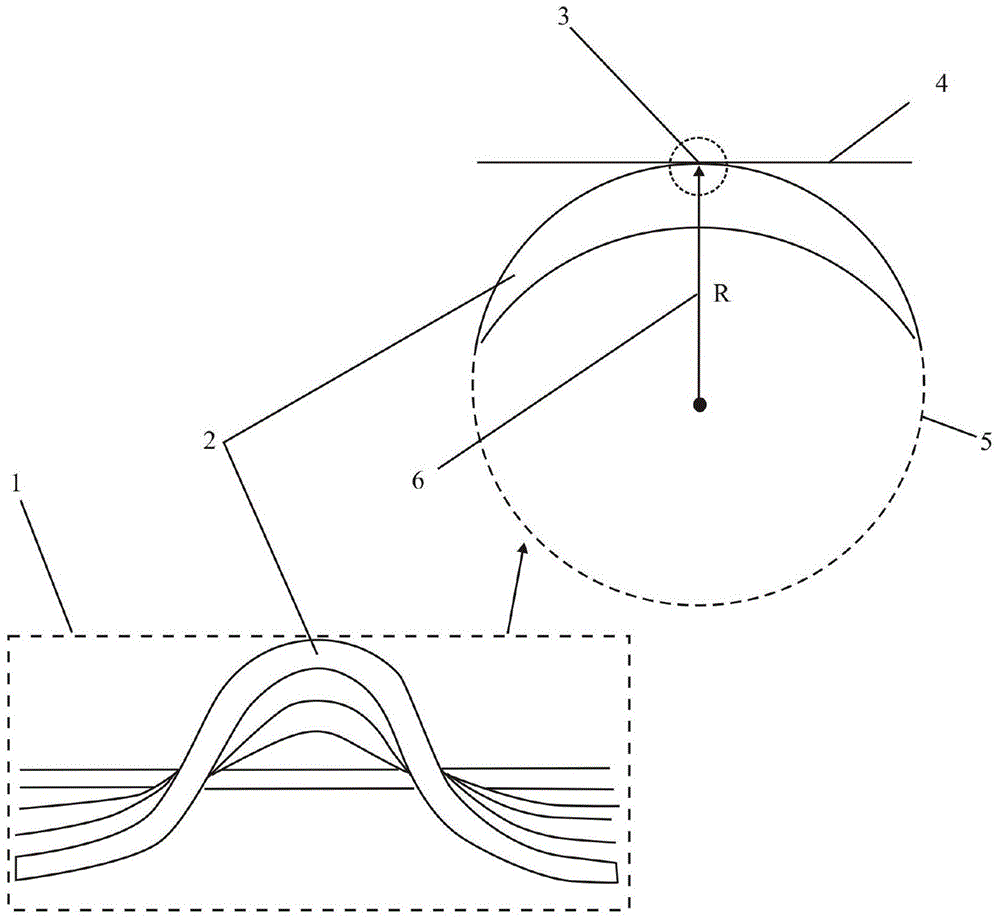

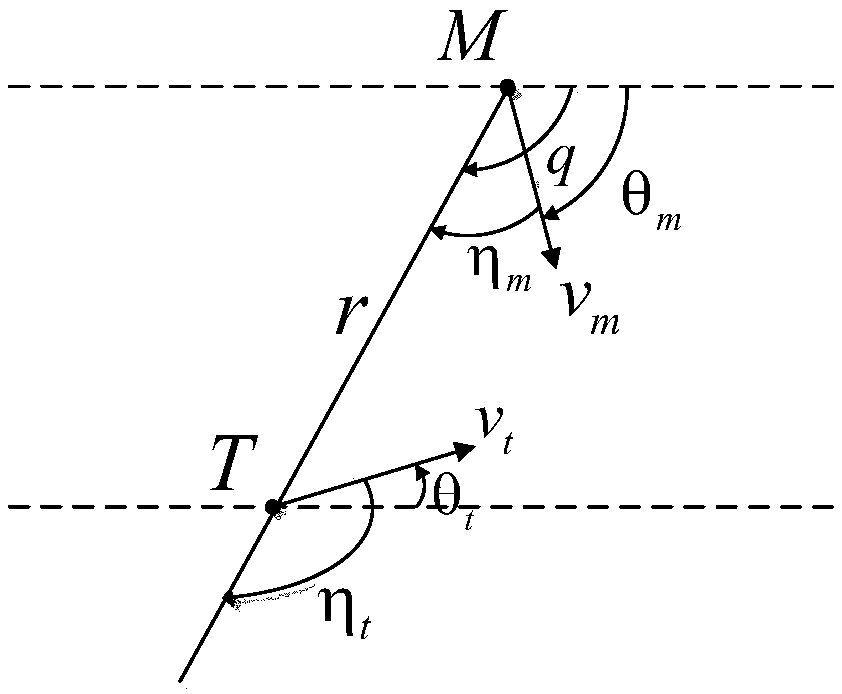

Underground deep-buried meander point dam sand body historical reconstruction method

ActiveCN104453877AAnatomical results are reasonableGeometric CADWater resource protectionStructure recognitionStructure of the Earth

The invention discloses an underground deep-buried meander point dam sand body historical reconstruction method. A preliminary-stage riverway flow line and terminal-stage riverway flow line enveloping method is adopted, and combined with a sand body thickness diagram, a point dam is recognized; through extraction of the point dam lateral deposition body scale, the tendency, the inclination and lateral deposition body spacing parameter in a research region, a point dam building structure recognition key parameter database is built, through a skeleton section, fine dissection is conducted on the meander riverway sand body of a stratigraphic unit, riverway flow lines are obtained, then the riverway flow lines are sequentially recovered and arranged according to the development sequence, and the riverway sedimentary evolution history is represented. The underground deep-buried meander point dam sand body historical reconstruction method has the advantages that the sand body building structure dissection result for riverway historical process rebuilding is made to be more reasonable and closer to the actual underground situation.

Owner:北京福瑞宝能源科技有限公司

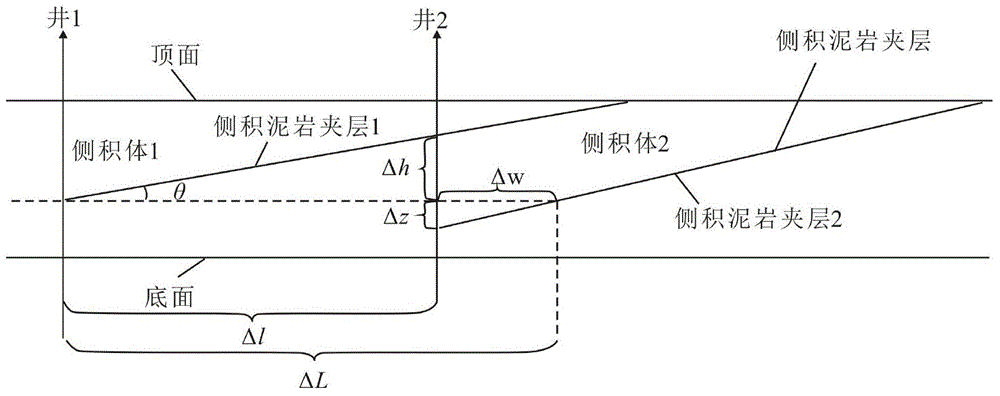

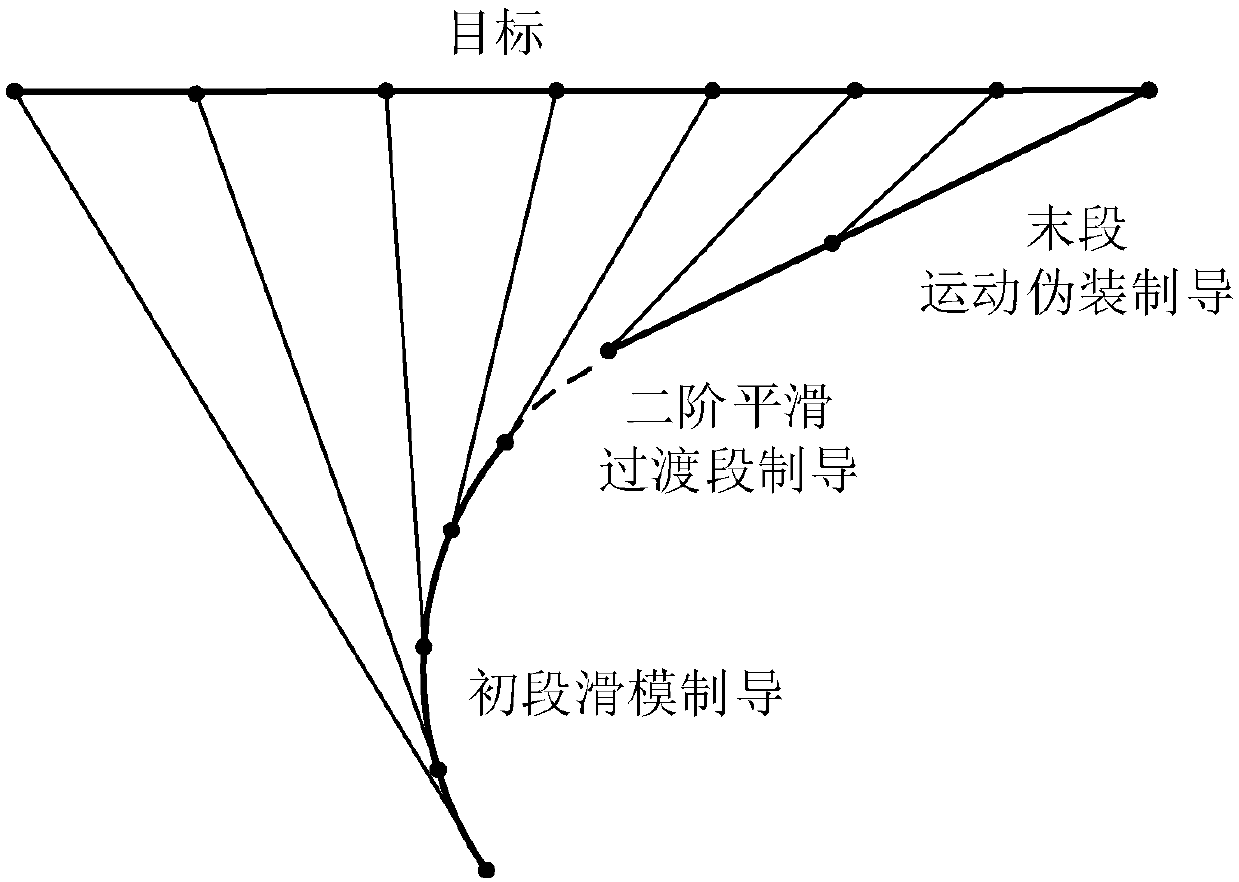

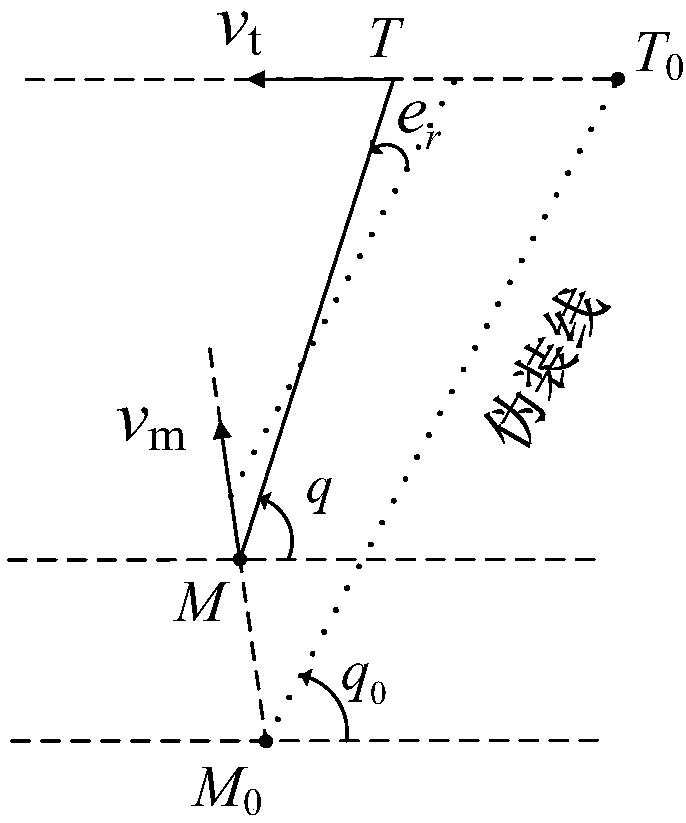

Vision sensing-based bionic staged composite terminal guidance method

The invention relates to a vision sensing-based bionic staged composite terminal guidance method, which belongs to the technical field of guidance. A staged tracking strategy of turning intercepting to tail chasing when a dragonfly tracks a fruit fly is simulated, a sliding mode guidance law of controlling a target parallax angle is used in an early stage of guidance to quickly adjust the flying direction of an aerocraft, and the aerocraft quickly enters a tail chasing state; in a terminal stage of guidance, a motion camouflage guidance law with a focus located at infinity is used to guide theaerocraft to track the target, and in a transition stage between the early stage and the terminal stage, a two-step slip intersection law is used. According to the terminal guidance method disclosedin the invention, when a micro aerocraft which depends on a vision sensor to detect a target intercepts a quick moving target, the required overload is smaller in comparison with the traditional guidance method, the target is closer to the visual field center of the vision detector, and the target can be ensured to be hard to escape from the visual field of the vision detector during the guidanceprocess.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

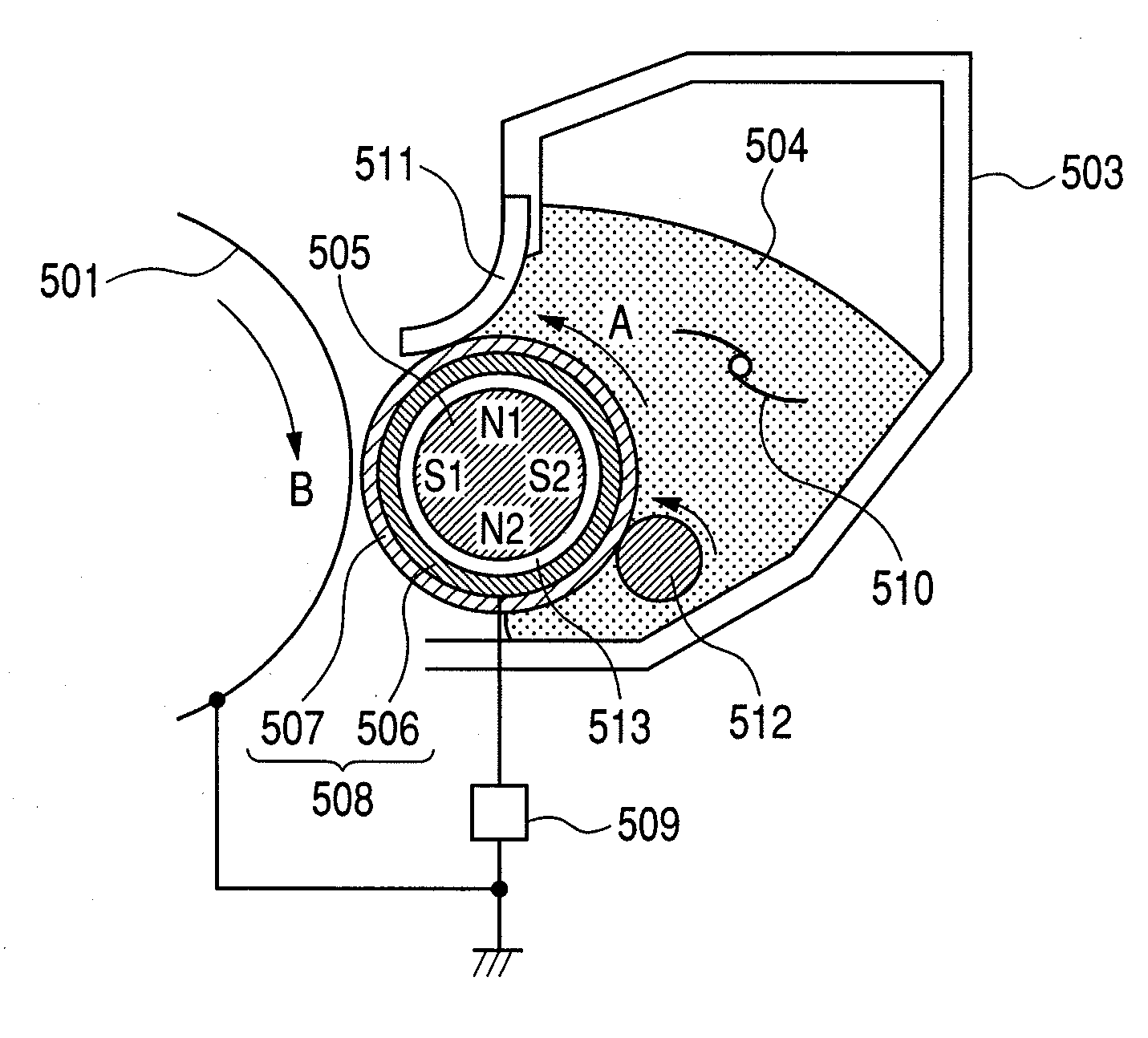

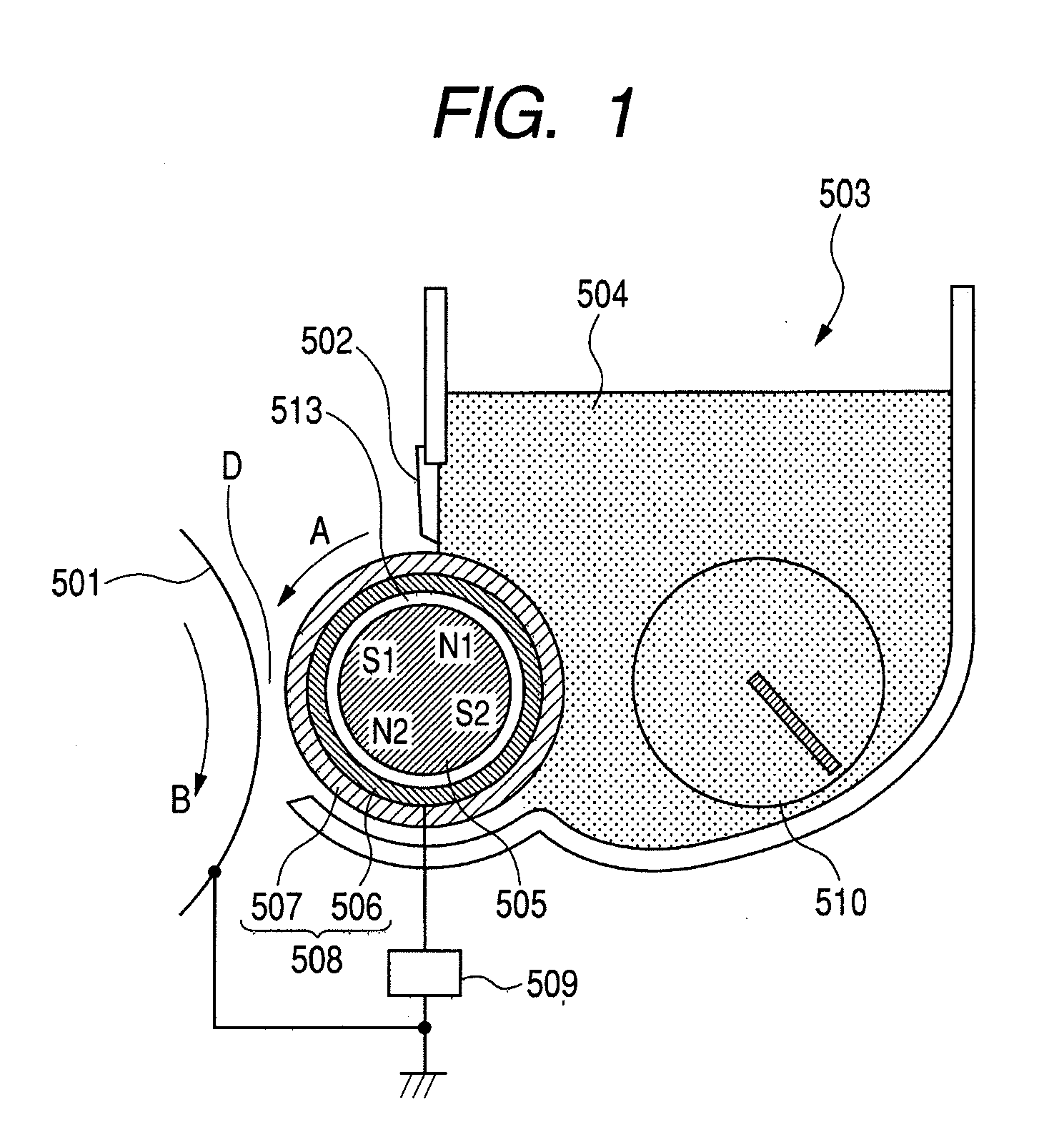

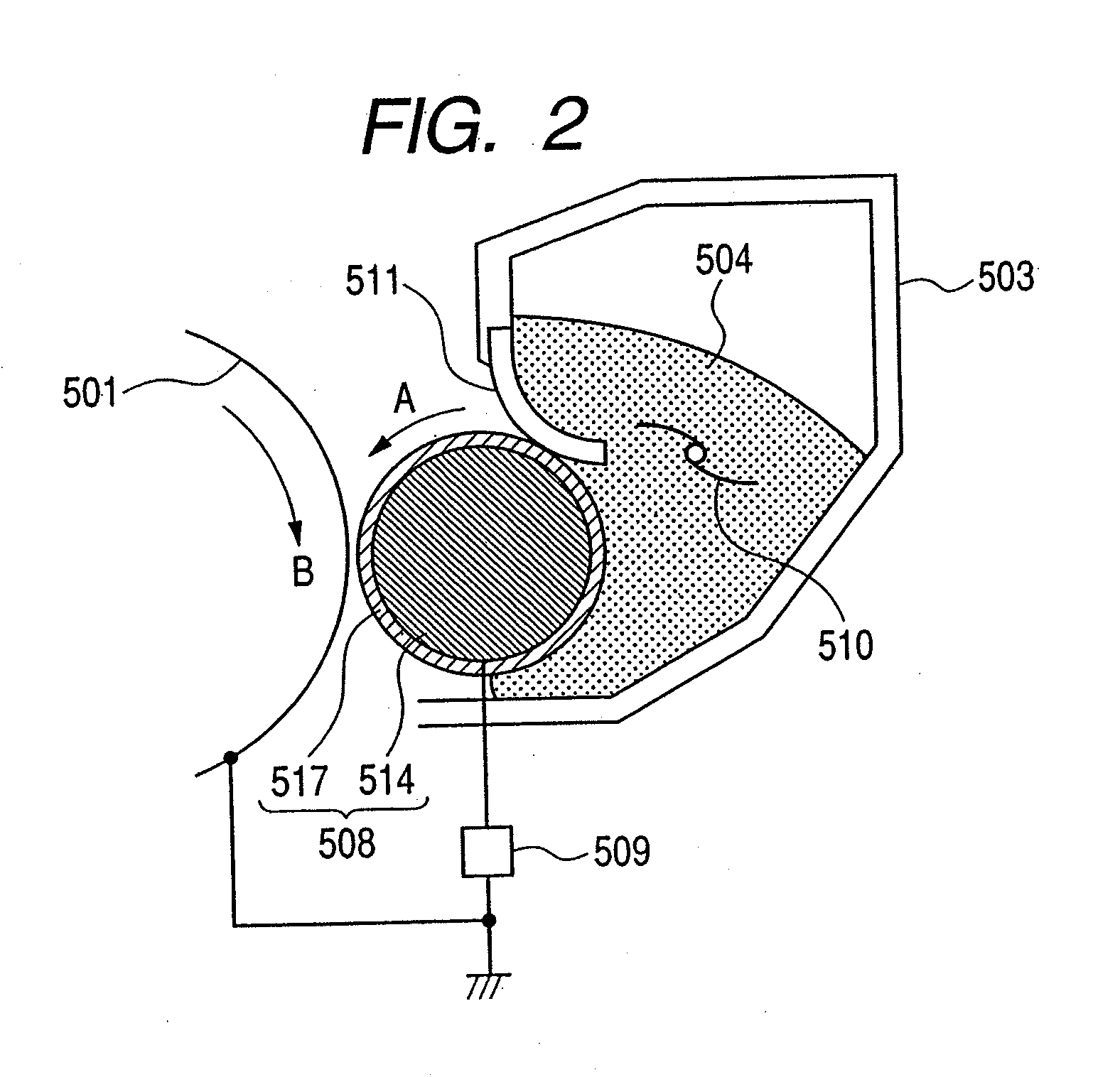

Developer bearing member and process for producing same, development apparatus and development method

ActiveUS20100028792A1Suppress overchargeIncrease the viscosity of the solutionConductive layers on insulating-supportsDevelopersPhosphonium saltResin coating

A developer bearing member is provided which can charge a toner stably and uniformly during the period from the initial stage to the terminal stage of extensive operation even in various environments. The developer bearing member includes a substrate and an electrically conductive resin coating layer formed on the surface thereof. The electrically conductive resin coating layer is formed from a resin composition containing a phenolic resin having in its structure at least one of an —NH2 group, an ═NH group and an —NH— linkage, a quaternary phosphonium salt and electrically conductive fine particles and the resin composition contains 1 part by mass or more and 60 parts by mass or less of the quaternary phosphonium salt with respect to 100 parts by mass of the phenolic resin.

Owner:CANON KK

Land grid array integrated circuit connector

InactiveUS20060286827A1Increase frictionAccurate contact positionEngagement/disengagement of coupling partsElectrical apparatus contructional detailsSolder ballLand grid array

A land grid array integrated circuit (LGA IC) connector uses a pressing rod assembly linked with a cover for opening / closing operation. The LGA IC connector includes a first tooth and a second tooth driven by a first post and a second post of a positioning section to enhance the rotation angle thereof. A sufficient pressure can be provided with smaller operation angle of the pressing rod and cover, thus facilitating operation. A protection board is assembled to the terminal stage and then arranged on a frame. A V-shaped spring element is provided between the protection board and the terminal stage such that the protection board is higher than the terminal to protect the terminal. The terminal can be protected from deformation. In the present invention, the terminal is received in the terminal hole and the annular cone at terminal tail can clamp the solder ball.

Owner:LAI KUANG CHIH

Axial-flow turbine having stepped portion formed in axial-flow turbine passage

InactiveUS6733238B2Improve efficiencyReduce total pressure lossPump componentsGas turbine plantsTrailing edgeTurbine

There is provided an axial-flow turbine comprising an exhaust chamber; a turbine including multiple stage rotor blades, said multiple stage rotor blade including terminal stage rotor blades; an annular diffuser located between the turbine and the exhaust chamber; and an annular axial-flow turbine passage defined by the turbine, the diffuser and the exhaust chamber, wherein fluid flows through the axial-flow turbine passage toward the exhaust chamber, and an annular stepped portion which inwardly projects in a radial direction is formed on the portion of an inner wall of the axial-flow turbine passage that is located on the downstream side of a trailing edge of a tip portion of the terminal stage rotor blades provided in the flow direction of the fluid. In the stepped portion, a projecting portion which inwardly projects in a radial direction may be provided.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Superheated steam and cold air combined drying method for abalones or sea cucumbers

ActiveCN103404941ADehydration fastImprove drying efficiencyFood preservationBound waterAdditive ingredient

The invention discloses a superheated steam and cold air combined drying method for abalones or sea cucumbers. The method comprises: firstly employing a superheated steam drying technology to dry abalones or sea cucumbers quickly to remove part of moisture from the material; when the moisture content of the material is reduced to 37.5%-41.2%, entering a second stage, and using a cold air drying technology to remove the residual bound water from the material. The method provided in the invention avoids damage of the high temperature steam at the terminal stage of superheated steam drying to the organizational structure and nutritional ingredients of aquatic products, and also solves the problems of slow cold air drying speed, long time and the like. At the same time, at the early stage of a drying process, abalones or sea cucumbers can shrink uniformly, dehydrate rapidly, have good quality, and are free of crusting, hardening cracking, excessive shrinkage, distortion and other undesirable phenomena caused by hot air drying.

Owner:FUJIAN AGRI & FORESTRY UNIV

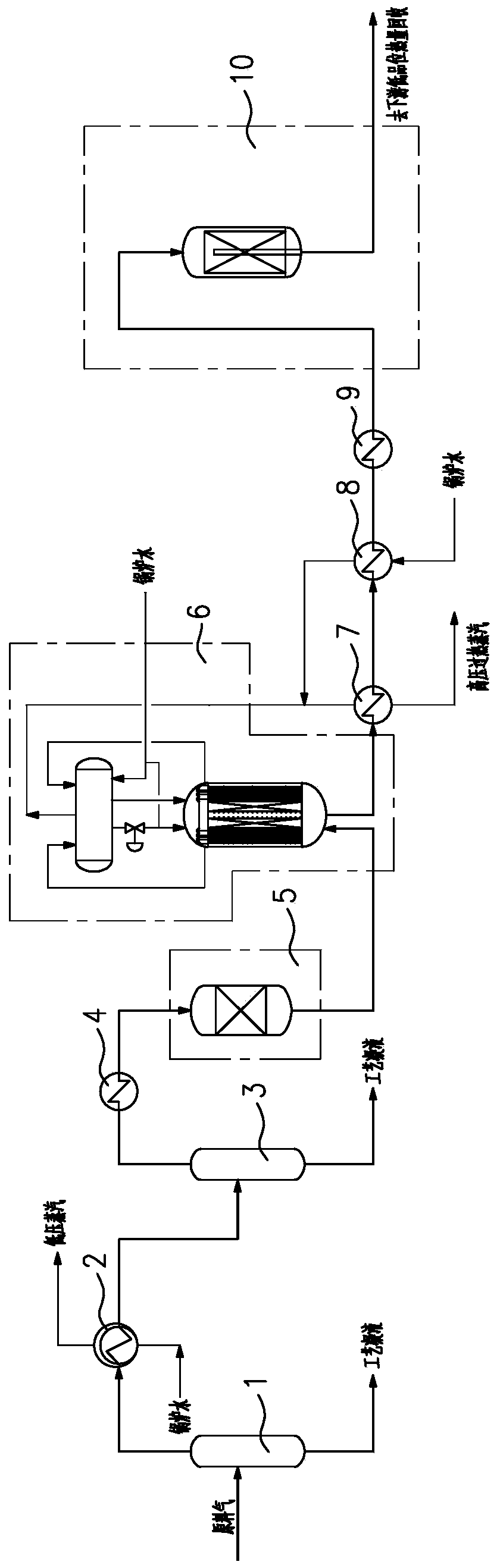

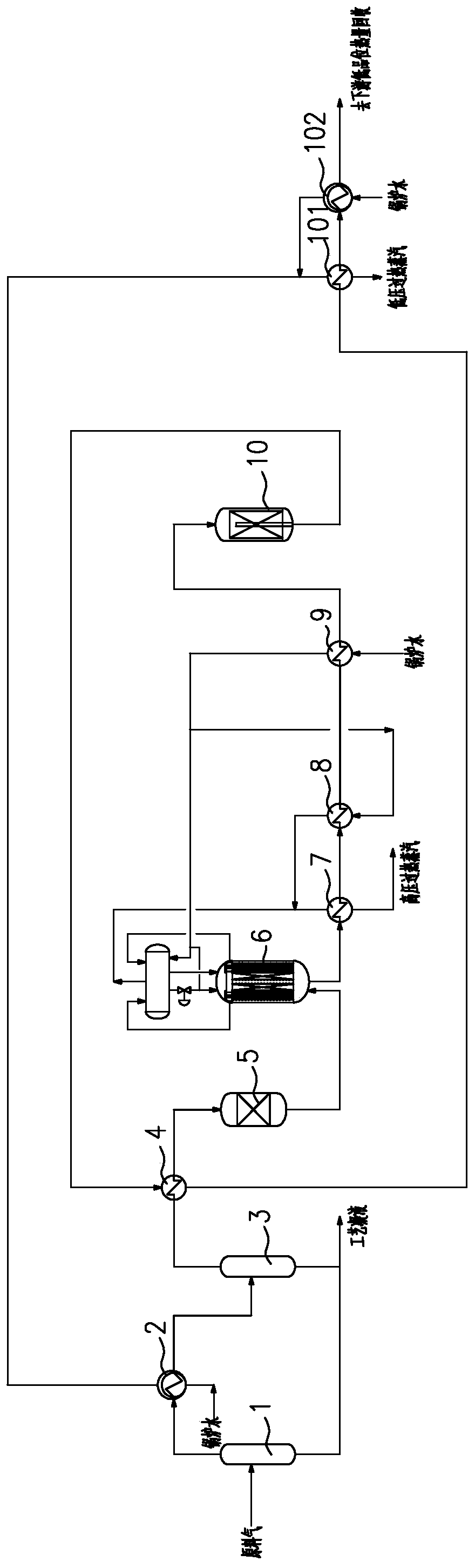

High-concentration carbon monoxide controllable semi-isothermy conversion process for carbonyl synthesis

ActiveCN110550602AAddress reactivitySolve the problem of difficult temperature controlHydrogenEnergy inputHigh concentrationHigh carbon

The invention relates to a high-concentration carbon monoxide controllable semi-isothermy conversion process for carbonyl synthesis. The application range is wide, and raw materials with the volume content of a carbon monoxide dry basis being 30-90% and with the volume ratio of water / extra-dry gas being 0.1-1.6 are adopted; the technological process is short, the number of equipment is small, control is easy, and the investment and operation costs are low; by arranging a controllable semi-isothermy saturated steam generation system with a control valve, the temperature of shift gas can be quickly and effectively adjusted, the steam generating pressure is not affected, the problems that a gas conversion reaction of the raw materials with the high carbon monoxide content is prone to overtemperature and difficult temperature control are solved, the grade of byproduct saturated steam is increased to the largest extent, and the yield of low-pressure saturated steam with low utilization value is decreased; high-pressure saturated steam can be overheated, arranging of an external overheating furnace or heat combination with other devices is not needed, and thus the investment and operation difficulty is lowered; and as for the working condition that the temperature needs to be increased at the terminal stage of a catalyst, only the opening degree of the control valve needs to be appropriately adjusted, and thus operation is convenient.

Owner:SINOPEC NINGBO ENG +2

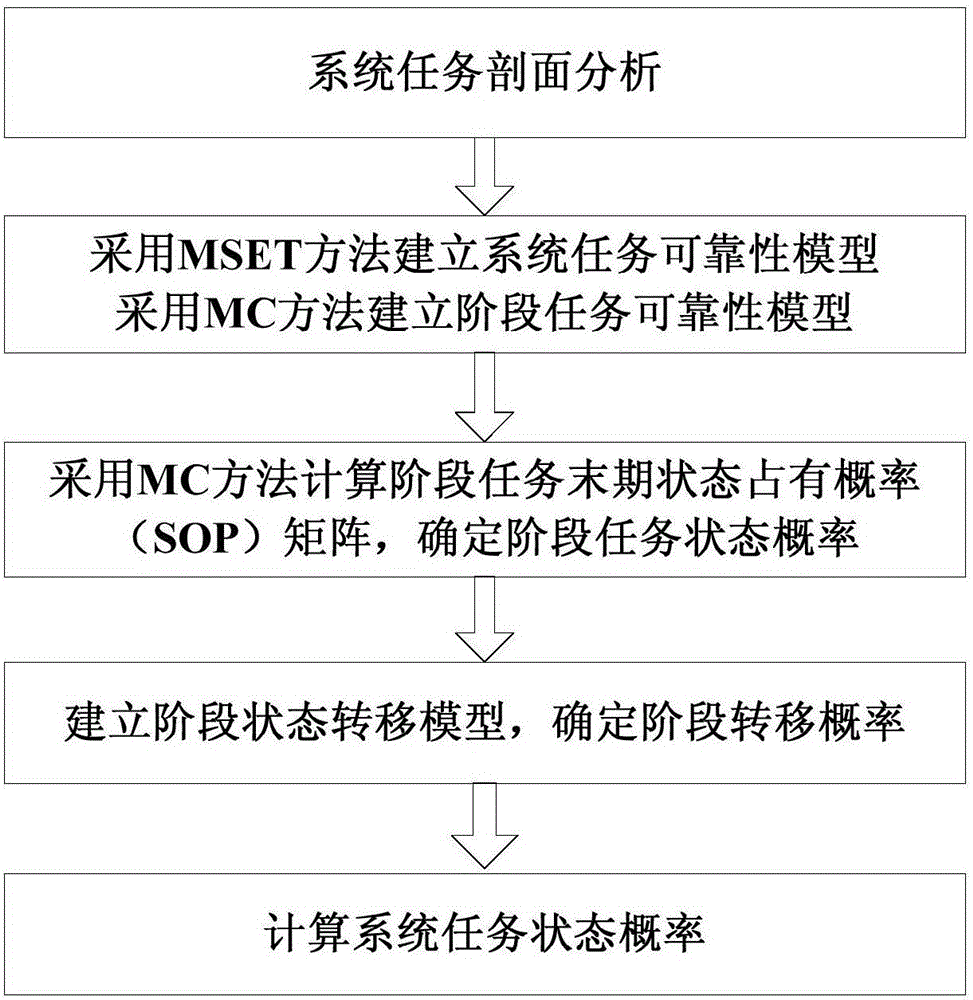

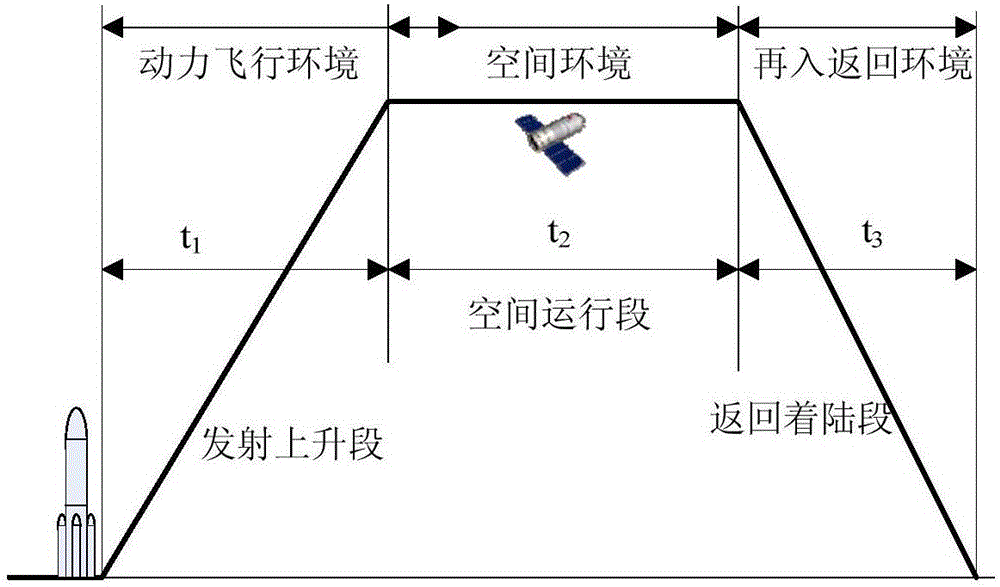

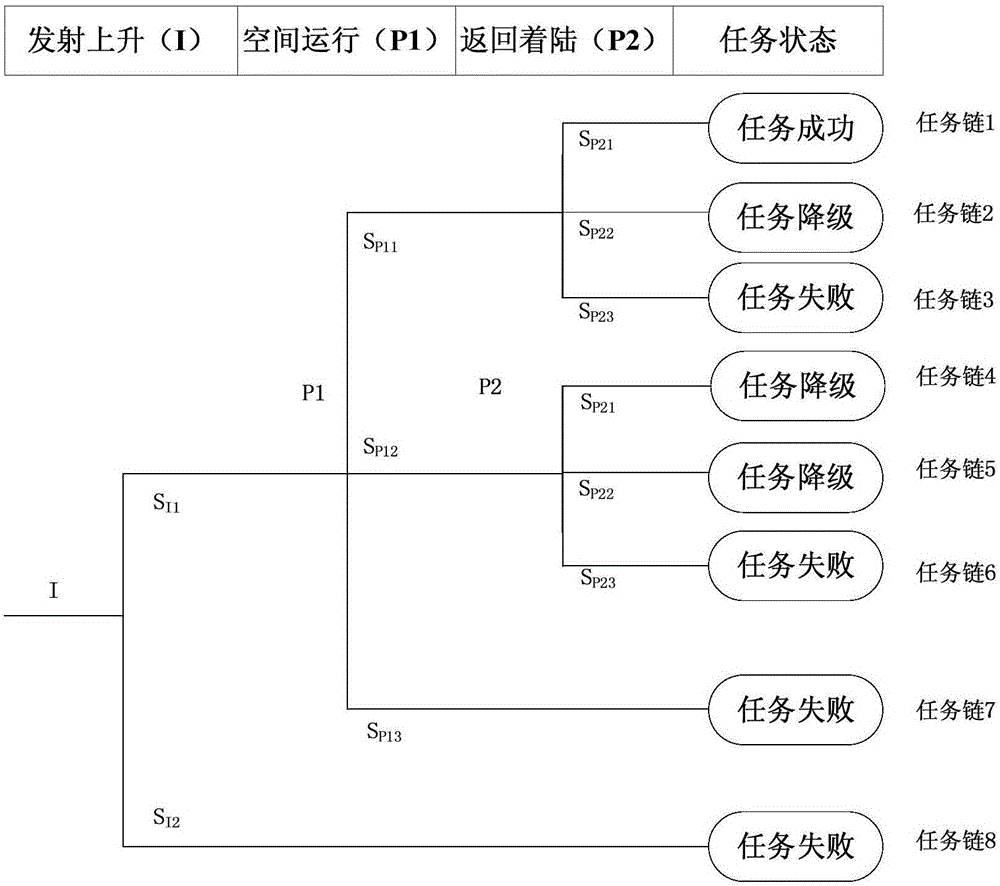

Feature-based space multi-phase mission system reliability modeling method

InactiveCN106650023AMeet the needs of reliability modeling workSolve the problem of insufficient description ability of polymorphic featuresGeometric CADDesign optimisation/simulationReliability (characteristic)Modelling methods

The invention relates to a feature-based space multi-phase mission system reliability modeling method. The method comprises the steps of (1) analyzing a mission profile of a space multi-phase mission system, determining a system reliability feature, and defining a phase mission state and a system mission state; (2) proposing a space multi-phase mission system reliability modeling method, building a system mission reliability model by adopting a multi-state event tree (MSET) method, and building a phase mission reliability model by adopting a Markov chain (MC) method; (3) calculating a state occupation probability (SOP) matrix in a terminal stage of phase mission, and determining a phase mission state probability; (4) building a phase state transfer model, and determining a phase transfer probability; and (5) calculating a system mission state probability. According to the method, the mission reliability feature of the space multi-phase mission system can be accurately described, so that the built mission reliability model is more accurate.

Owner:CHINA AEROSPACE STANDARDIZATION INST

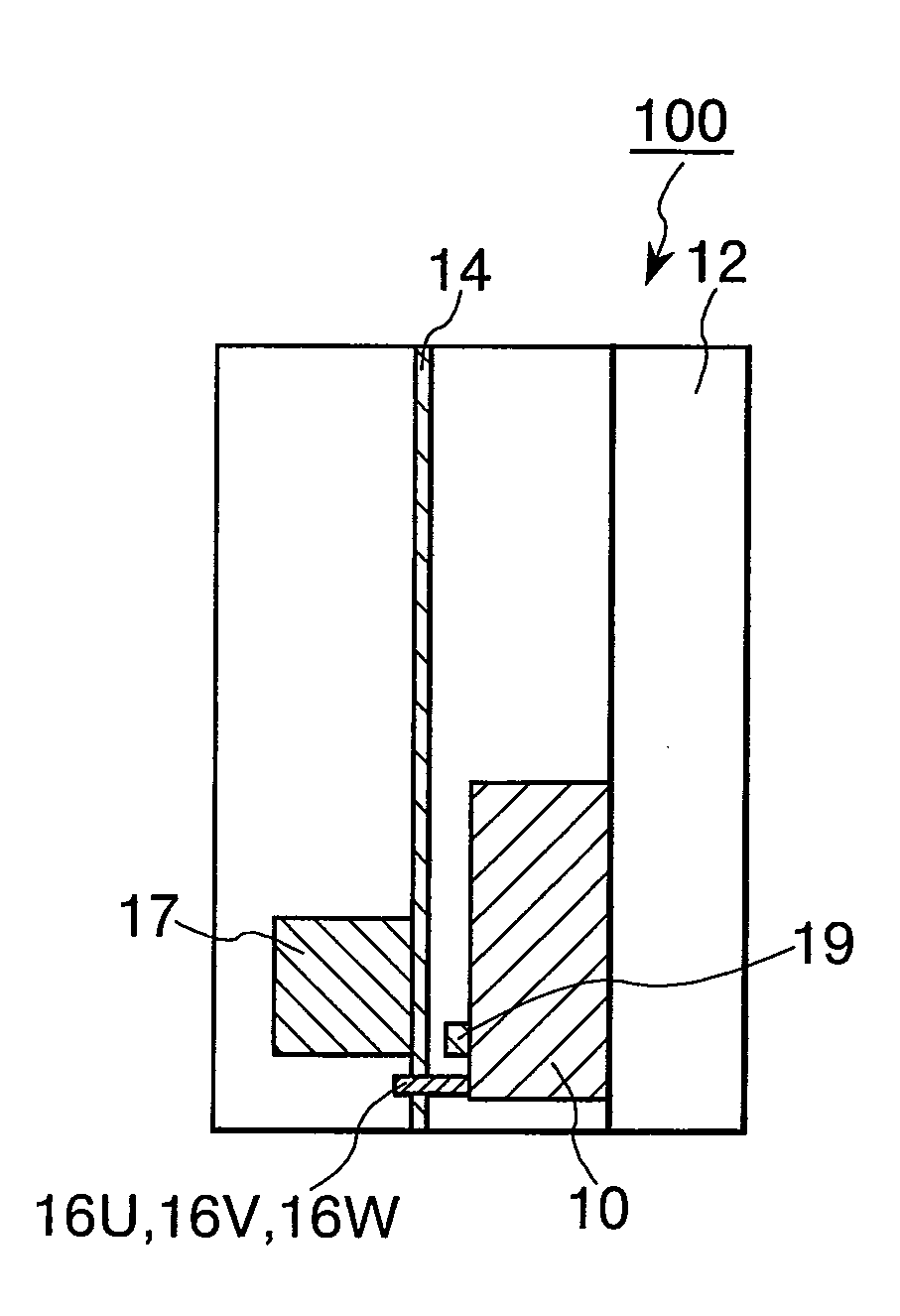

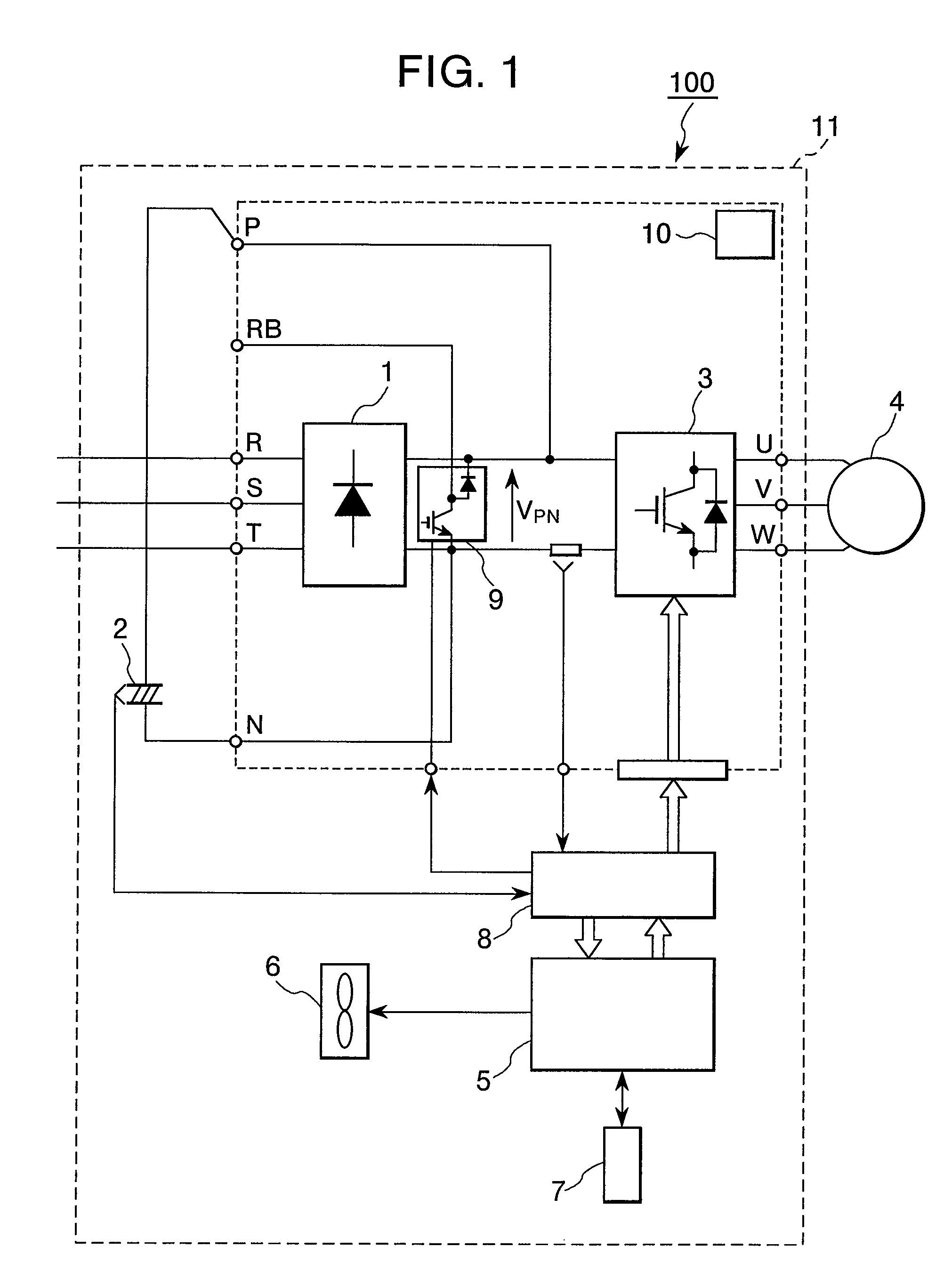

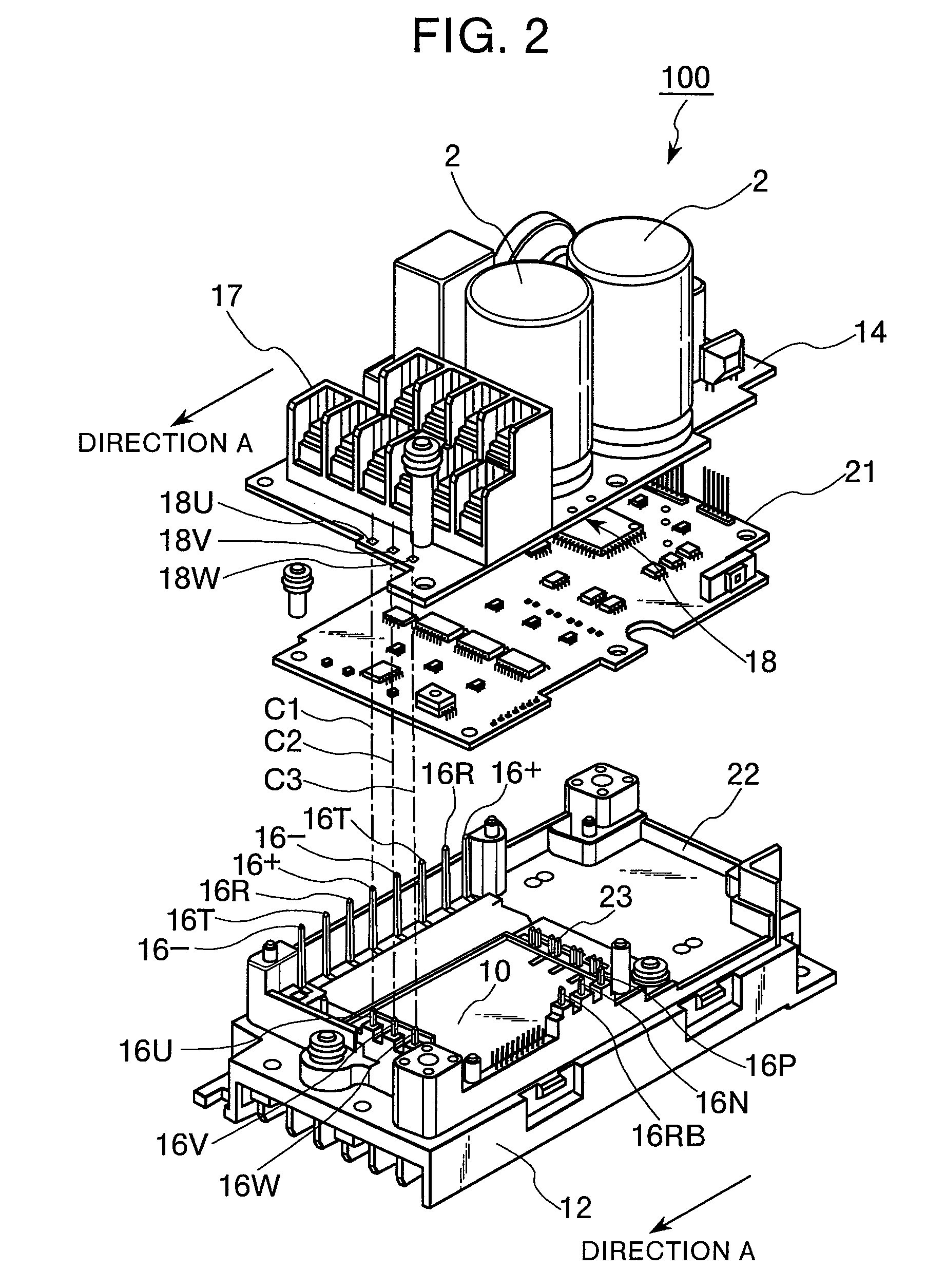

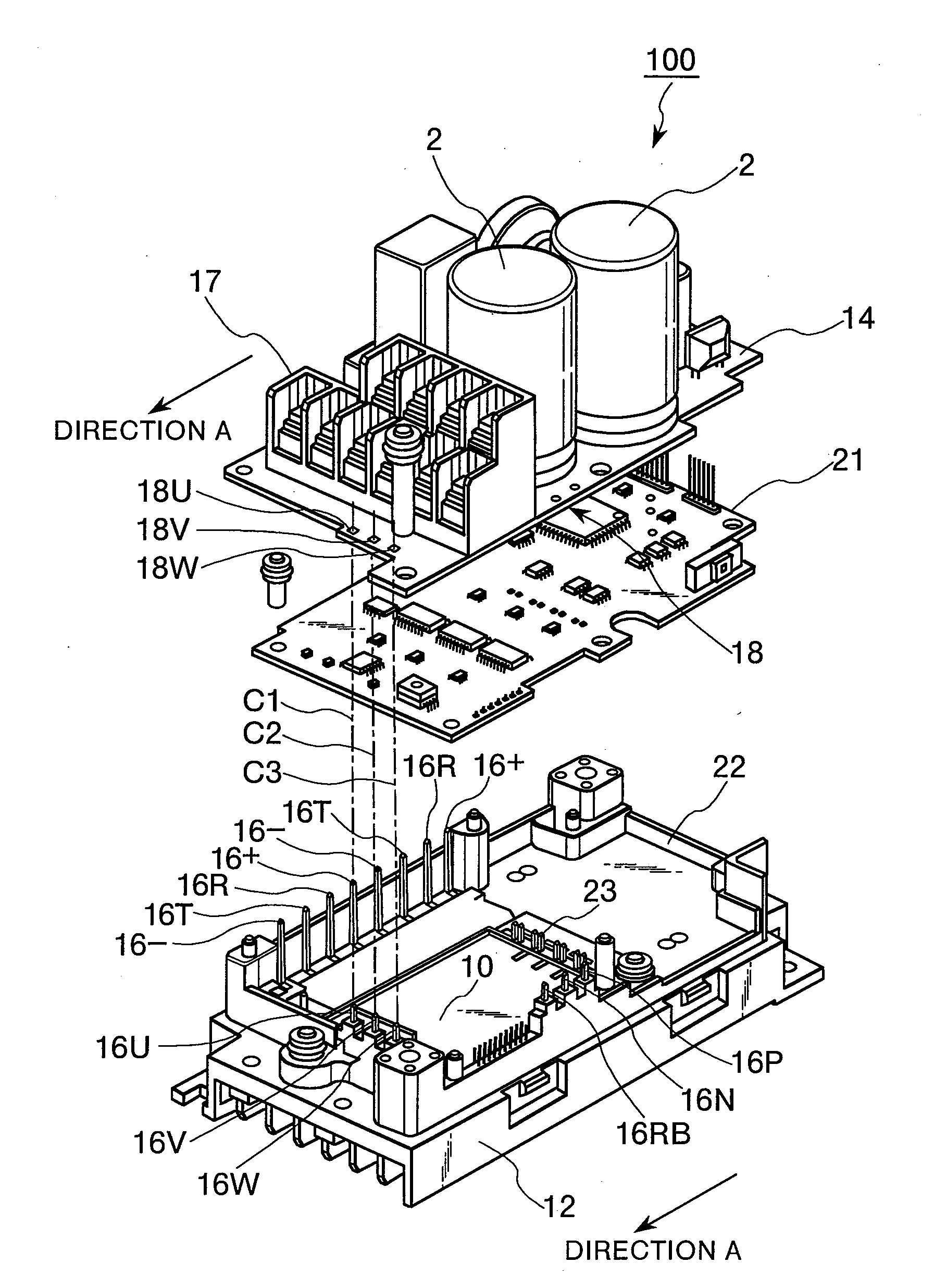

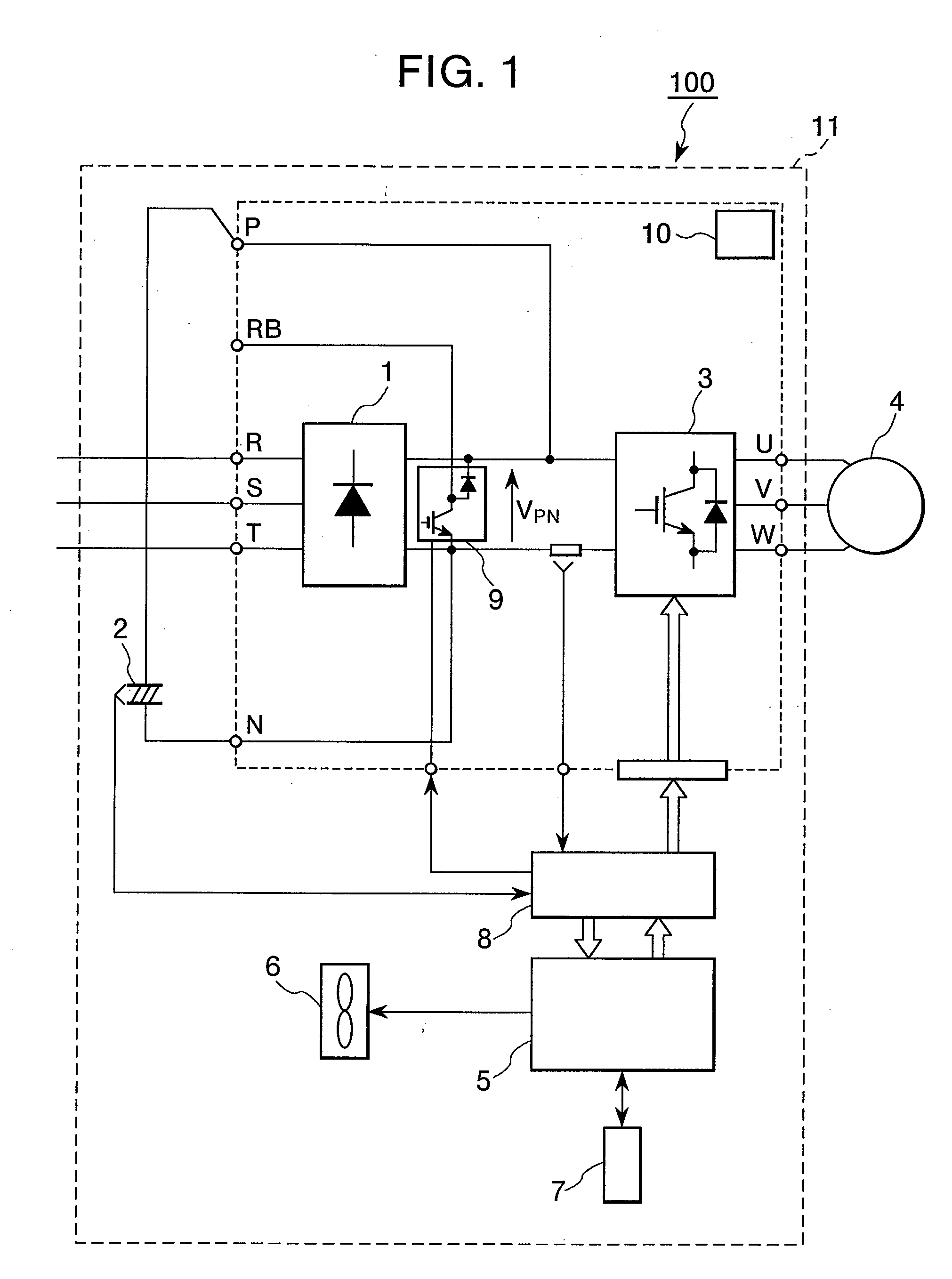

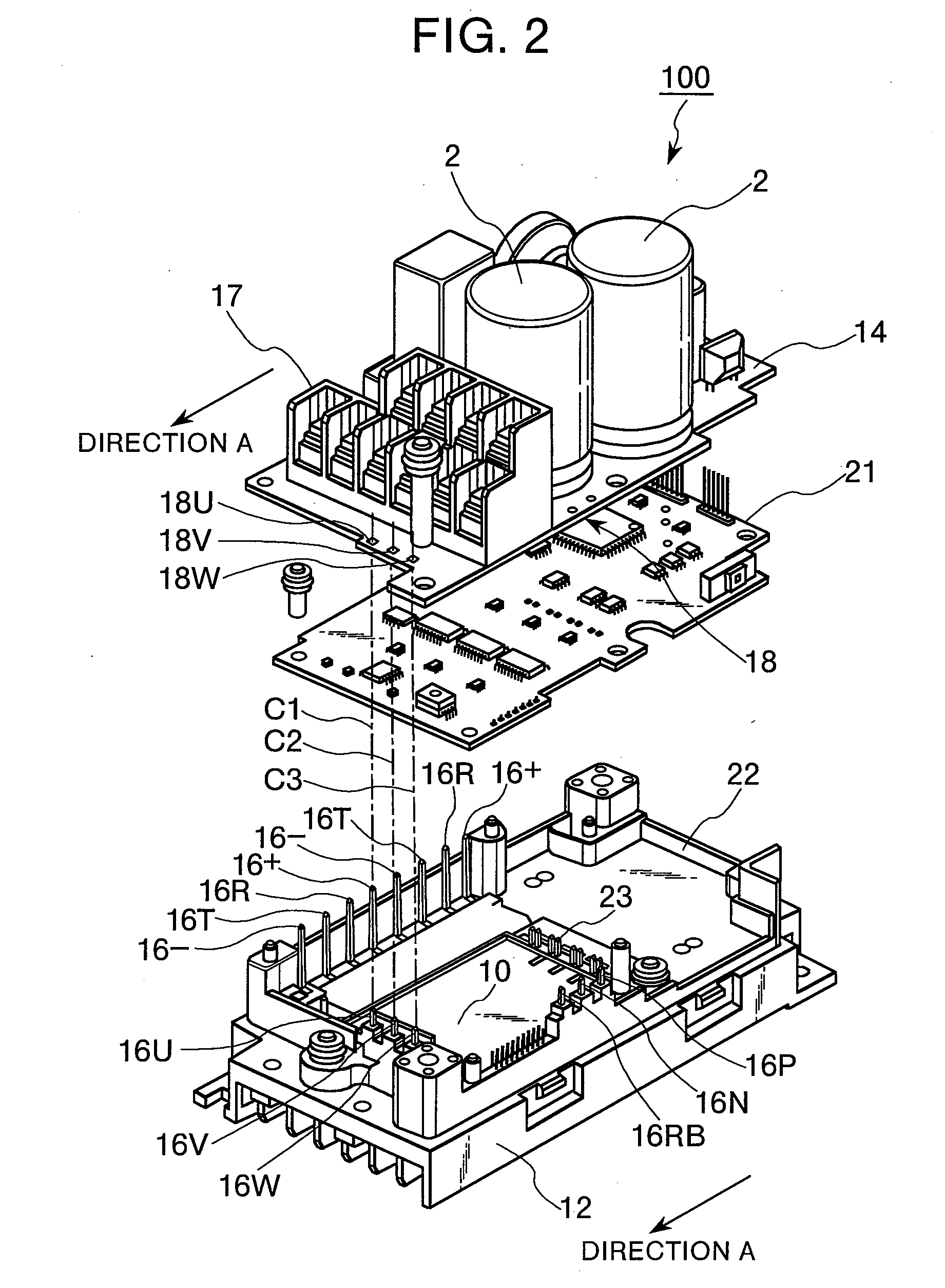

Power transducer

ActiveUS8385078B2Small sizeReduce power levelConversion constructional detailsCircuit arrangements on support structuresPower sensorTransducer

A power transducer is downsized by reducing the size of a power source board and highly reliable. The power source board is provided in the power transducer and for a large-current circuit. The power transducer includes a power semiconductor module having lead terminals. Of the lead terminals provided for the power semiconductor module and connected with the main circuit board, predetermined one or ones of the lead terminals is or are connected with the main circuit board in the vicinity of a main circuit terminal stage and at a position or positions lower than the main circuit terminal stage. Alternatively, predetermined one or ones of the lead terminals is or are connected with the main circuit board at a position or positions lower than a position at which the main circuit terminal stage is provided.

Owner:HITACHI IND EQUIP SYST CO LTD

Connection terminal and a connection terminal assembly and method for assembling the connection terminal

InactiveUS20070032113A1Precise positioningLow costIncorrect coupling preventionElectrical connectionEngineering

A connection terminal includes a housing, a case fixed to the housing, a terminal stage installed inside the case and having a first terminal and a guide portion, the first terminal and the guide portion projecting parallel to each other from one end of the terminal stage in the same direction, a connected member facing the case and having a second terminal to which the first terminal is fitted and connected for establishment of electrical connection, and a recessed portion to which the guide portion is fitted. The terminal stage is movable at least in a direction orthogonal to a direction of the connection between the first and second terminals while being installed inside the case. The first and second terminals are fitted to each other after the guide portion is fitted to the recessed portion.

Owner:HITACHI LTD

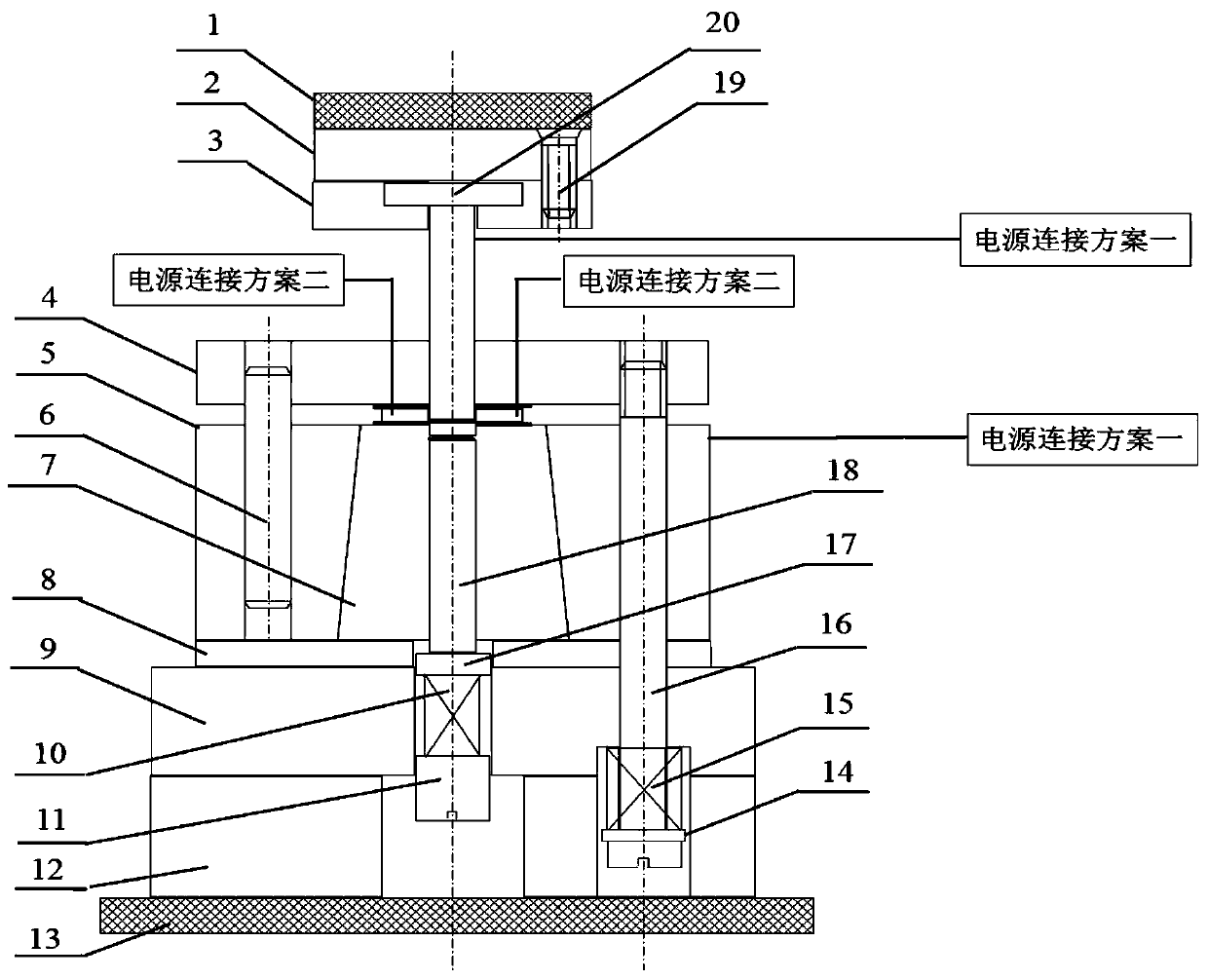

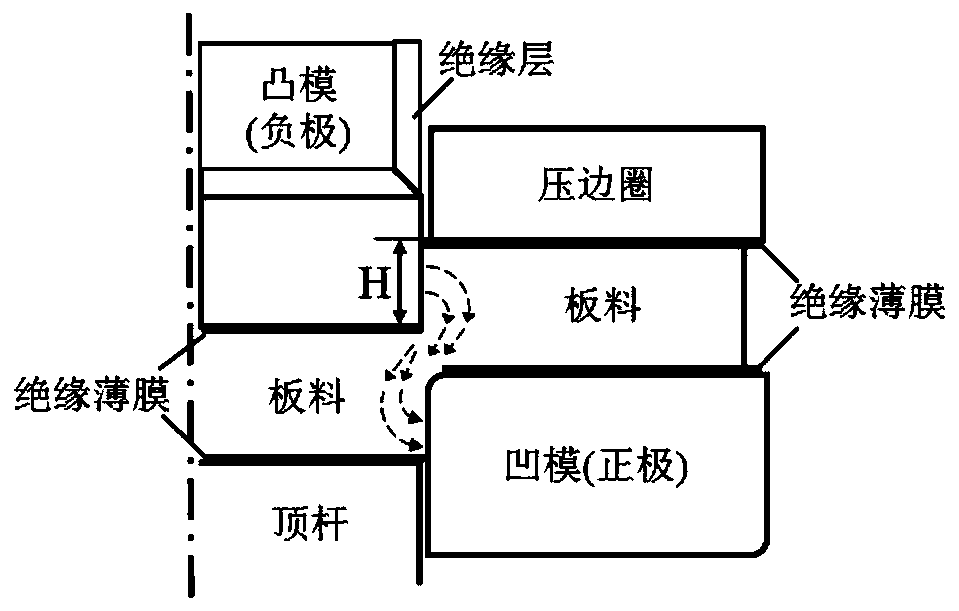

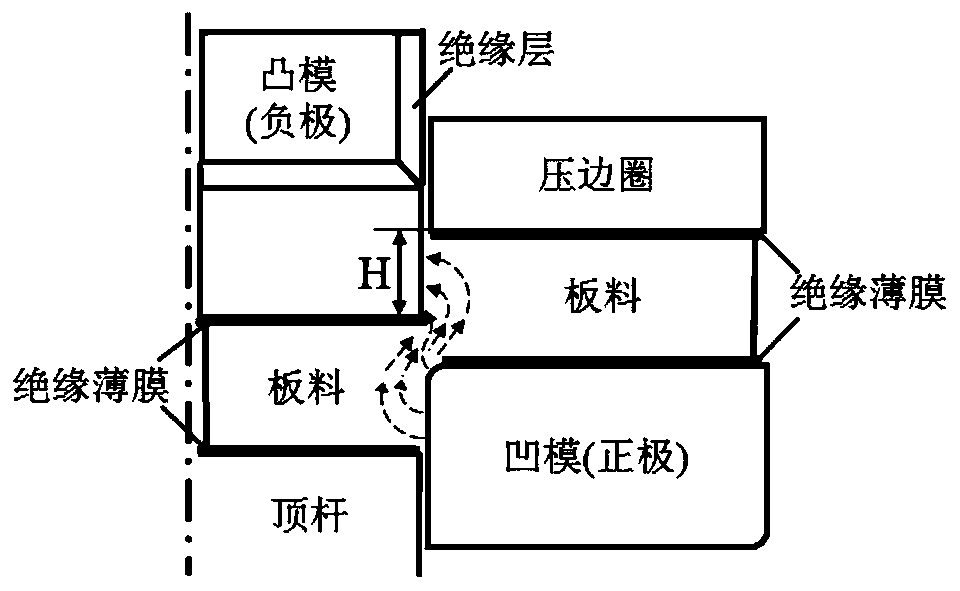

Current loading method used during pulse current auxiliary precision blanking machining

ActiveCN110369600AImprove toughnessImprove featuresShaping toolsMetal working apparatusMetallic materialsElectrocaloric effect

Currents act on metal, and an electric heating effect and electrically induced plasticity are achieved, wherein a high-frequency pulse current effect has the capacity of healing metal plastic strain damage. Electrically induced plasticity and electric heating softening effects are introduced into the precision blanking technology, and the precision blanking difficulty of high-strength steel platesis reduced. Metal materials are heated to expand through the electric heating effect, the defect that in the blanking medium-terminal stage, hydrostatic pressure stress of shear zones of the metal materials is reduced rapidly is relieved, and the capacity of restraining production-extension of holes of the shear zones is improved. By means of a good-time and proper pulse current acting manner anda loading method, current energy is intensively injected in good time at high density aiming at local zones, where the holes and micro-cracks are easily generated in the blanking process, of the shear zones, strain damage is repaired, the situation that the micro-cracks are further developed into macro-cracks, and a rough tear zone on a precision blanking section is finally formed is avoided, anda higher possibility is provided for enabling precision blanking to be more widely applied to high-strength type materials.

Owner:AIR FORCE UNIV PLA +1

Power transducer

ActiveUS20100079956A1Small sizeImprove reliabilityCircuit arrangements on support structuresConversion constructional detailsPower sensorTransducer

A power transducer is downsized by reducing the size of a power source board and highly reliable. The power source board is provided in the power transducer and for a large-current circuit. The power transducer includes a power semiconductor module having lead terminals. Of the lead terminals provided for the power semiconductor module and connected with the main circuit board, predetermined one or ones of the lead terminals is or are connected with the main circuit board in the vicinity of a main circuit terminal stage and at a position or positions lower than the main circuit terminal stage. Alternatively, predetermined one or ones of the lead terminals is or are connected with the main circuit board at a position or positions lower than a position at which the main circuit terminal stage is provided.

Owner:HITACHI IND EQUIP SYST CO LTD

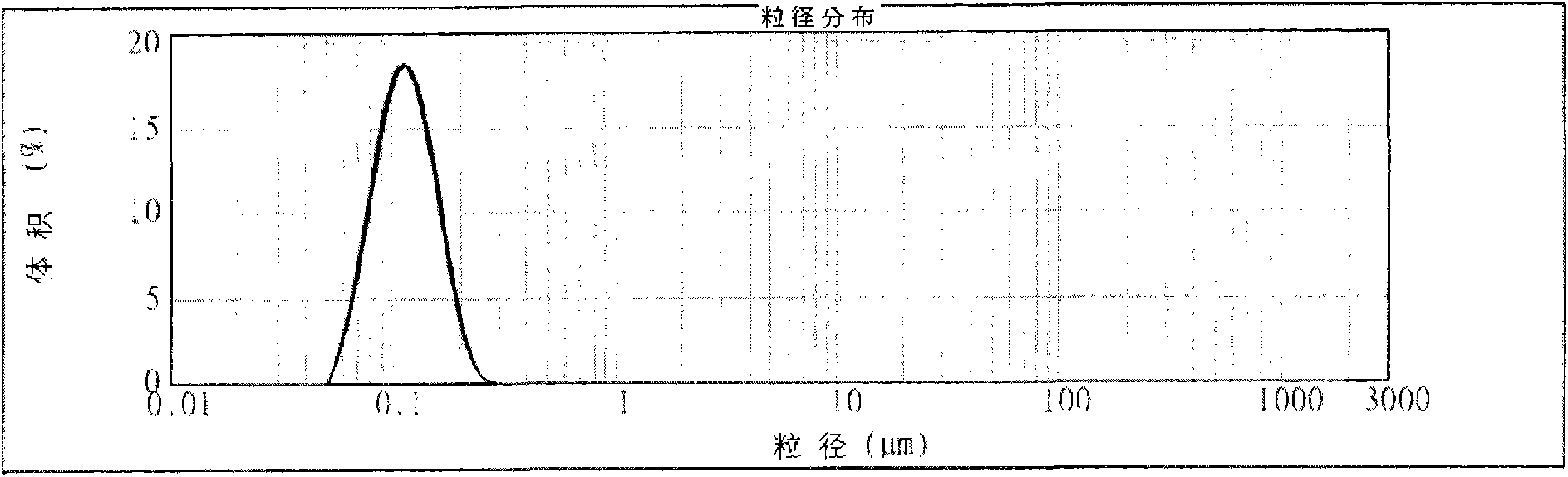

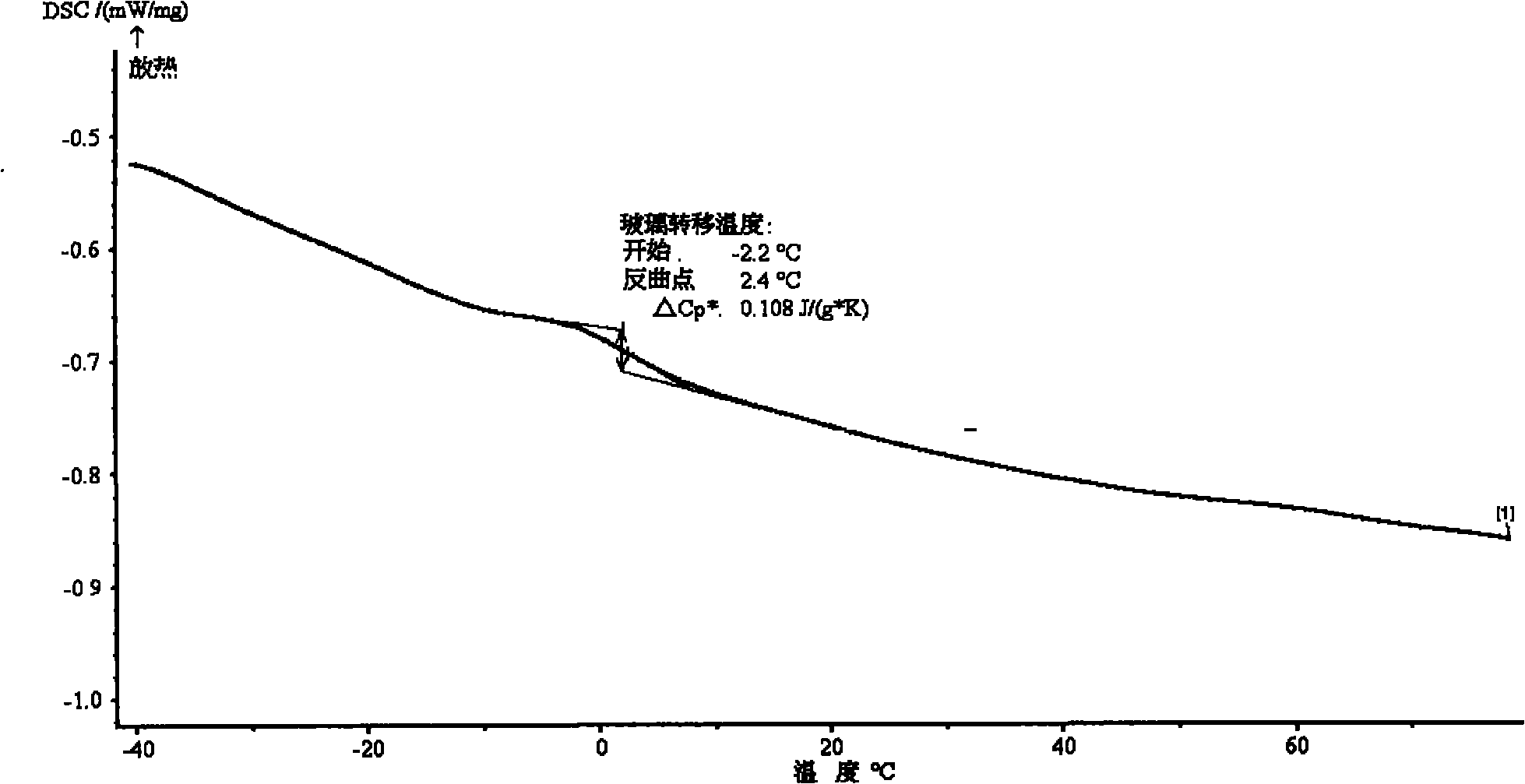

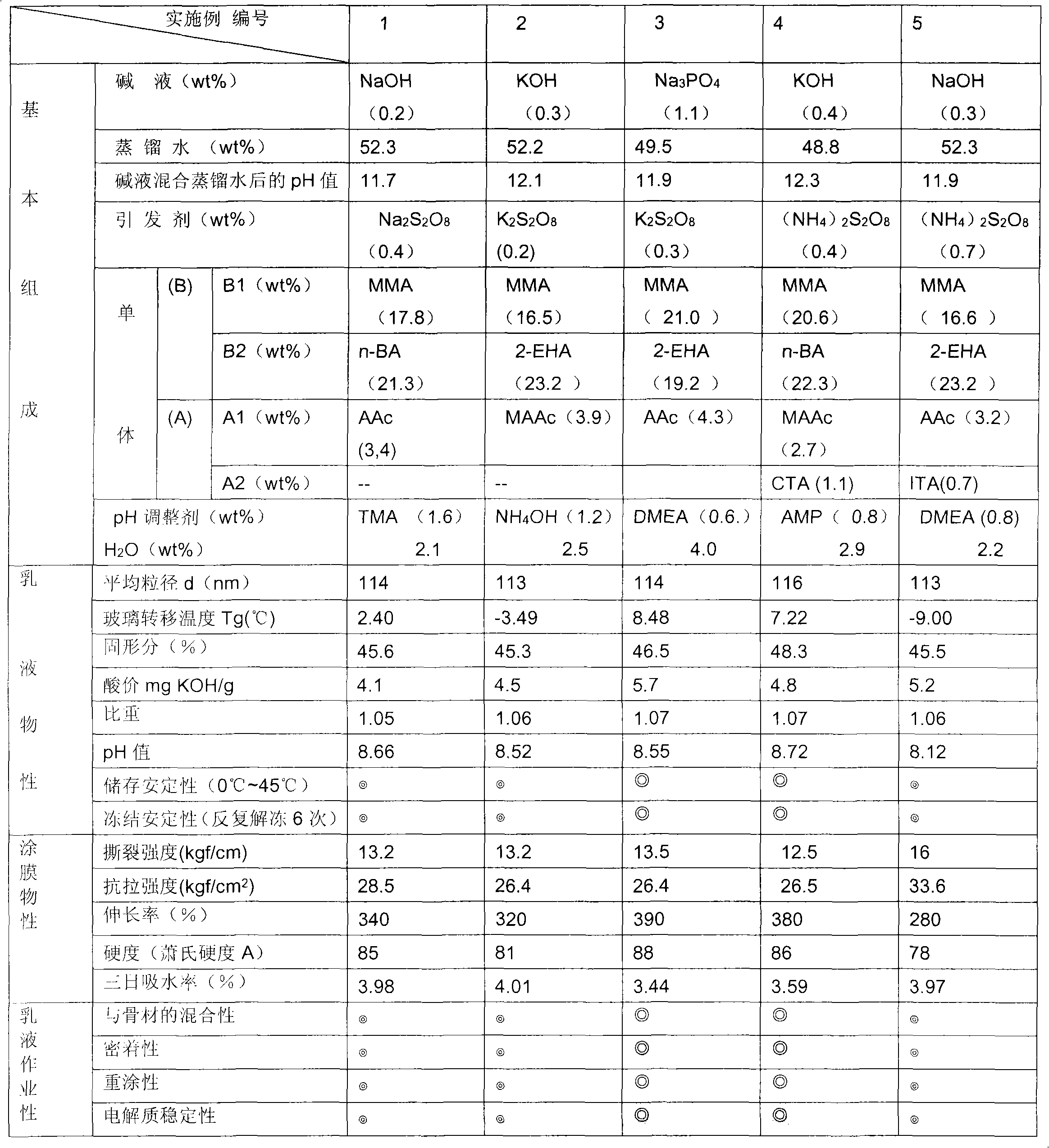

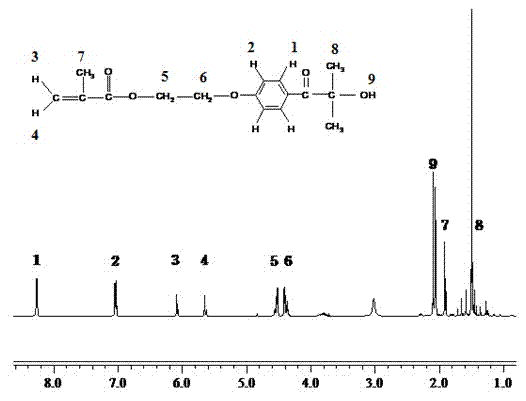

Emulsifier-free acrylic ester emulsion polymerization method

The invention relates to an emulsifier-free acrylic ester emulsion polymerization method. For a reaction system comprising 40-60 wt% of purified water, 2-9 wt% of a carboxylic acid monomer (A) with a polymerizable functional group of a carbon-carbon double bond and 40-50 wt% of a methyl acrylicylester monomer or an acrylic ester monomer ( B ), 0.2-2.0 wt% of an inorganic alkali liquid is adopted to adjust the pH value of the reaction to 9.0-13.0, 0.2-1.0 wt% of a peroxide initiator of a sulfate is adopted to carry out emulsion polymerization, and an organic amine compound is adopted to adjustthe pH value of the resulting aqueous resin emulsion to 7.0-9.5 at the terminal stage of the reaction. The prepared aqueous resin emulsion has characteristics of particle size of about 100-130 nm, uniform distribution, good appearance, low acid value of 3.5-6.5 mgKOH / g, specific gravity of about 1.07, excellent storage stability, good permeability and easy construction, wherein the specific gravity of the prepared aqueous resin emulsion is slightly larger than the specific gravity of the water. The dry coating film by the emulsion has characteristics of good water resistance, excellent tensile strength and excellent wear resistance.

Owner:CHAMPWARD CHEM IND

Replacement and extrapolation combined navigation method

The invention discloses a replacement and extrapolation combined landing navigation method which is suitable for height and speed navigation in the landing process of an extraterrestrial celestial body of a space detector. The method comprises the following steps of: determining the landing altitude and speed of the detector in a landing preliminary stage by adopting a method in which the inertial navigation and a measuring sensor are in a weighting eclectic manner; and directly determining the landing altitude and speed of the detector by adopting measuring information of the measuring sensor below the specific height of a landing terminal stage, and determining the height and speed in an updating interval of the measuring information by adopting the inertial navigation extrapolation. The method is used, the navigation accuracy of the landing altitude and speed is obviously improved, and the replacement rate and the data smoothing property of navigation data of the detector are guaranteed.

Owner:BEIJING INST OF CONTROL ENG

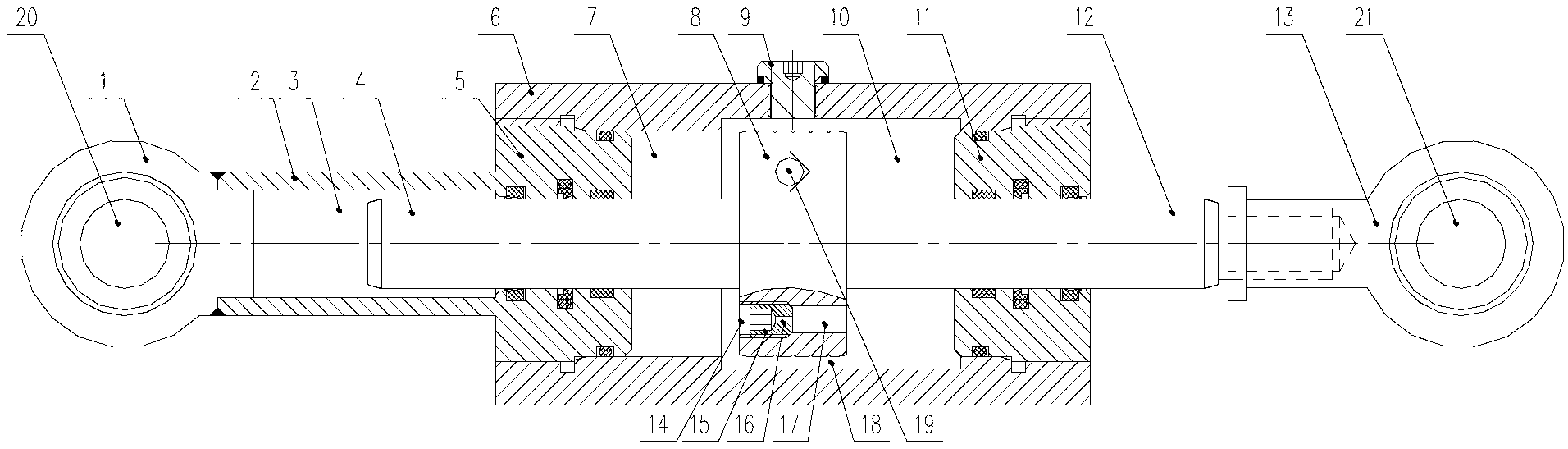

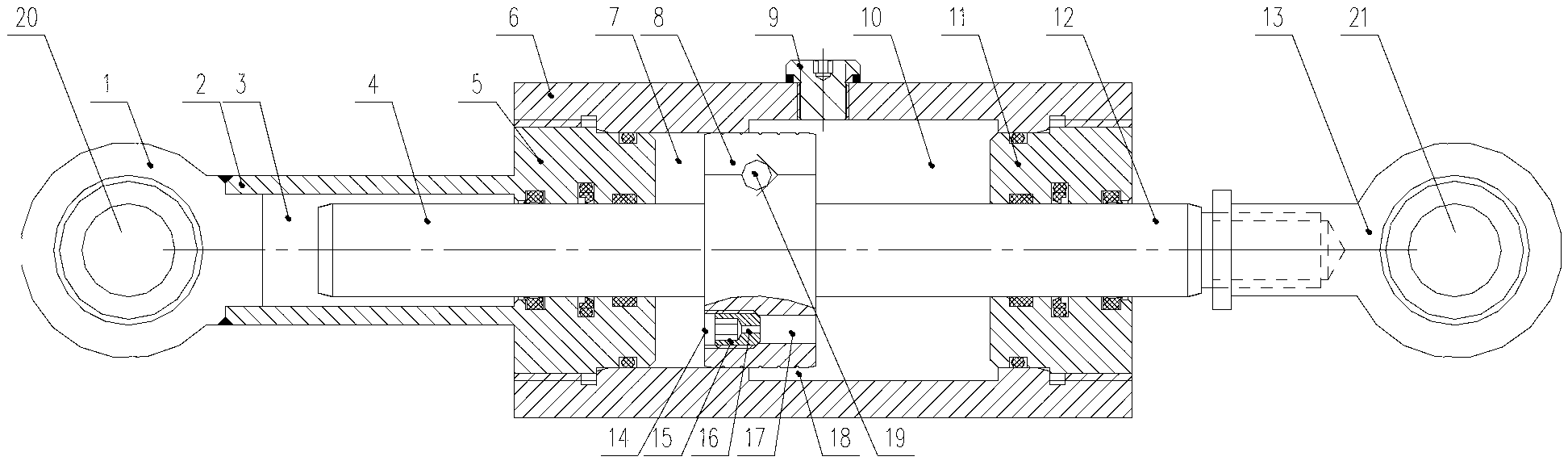

Valve buffer

The invention relates to a valve buffer. By the valve buffer, when a valve is opened or closed, a valve clack rotates to drive a connecting rod to swing, and the connecting rod drives a piston to relatively move in a cylinder; in the initial stage of closing the valve, the valve clack is far away from an adjacent area of a valve seat, the piston moves in a large inner cavity of the cylinder, and when the piston moves left, oil on the right side can flow to the right side and the valve is quickly closed; in the terminal stage of closing the valve, the valve clack is positioned in the adjacent area of the valve seat, oil flows through a damping hole and generates a corresponding damping effect to realize the buffer function, the valve buffer is in a buffer working state, and the valve is slowly closed; in the initial stage of opening the valve, the oil flows to the left side of the piston through a one-way valve and the damping hole, the valve buffer is in a follow-up working state, and the valve can be quickly opened; and in the terminal stage of opening the valve, the valve clack is far away from the adjacent area of the valve seat, the oil flows to the left side of the piston through a large annular channel, the valve buffer is in the follow-up working state, and the valve can be quickly opened.

Owner:HOHAI UNIV CHANGZHOU

Method for seed selecting and remaining of double-cropping water bamboos in summer

The invention relates to a method for seed selecting and remaining of double-cropping water bamboos in summer. According to the method, at the terminal stage of or after harvest of the water bamboos growing in summer, robust stem tillers in a normal harvest area are selected, piled up under dark conditions after slightly processed, and watered to maintain humidity. Five days later, when the water bamboos can be transplanted into water bamboo fields for autumn, stem tillers without sprouting young leaves are rejected, and stem tillers with young leaves longer than 5cm are transplanted into the large fields. Not only is the output of the water bamboos growing in summer not affected, but also temporary planting in other fields is unnecessary. The selected and remained stem tillers are large in specifications and nutrient amount, and beneficial to sprouting and rapid growth of new-sprouting branch tillers and ensures relatively large output of water bamboos in autumn. Residual stem tillers in water bamboo fields for summer are fully utilized for promoting the use efficiency.

Owner:YANGZHOU UNIV

Round koji making process utilizing soybean and flour as raw materials

The invention discloses a round koji making process utilizing soybean and flour as raw materials. The process comprises the following steps of 1) soaking the soybean; 2) steaming; 3) cooling; 4); inoculating and mixing the flour, namely inoculating koji extract into the cooled ripe soybean, adding the flour and mixing the raw materials to obtain a mixture; 5) feeding, namely inputting the mixture into a koji chamber of a round koji maker; 6), cultivating yeast for making hard liquor, namely cultivating the mixture in the koji chamber of the round koji maker, specifically including the steps of earlier-stage cultivation, primary koji turning after the earlier-stage cultivation, middle-stage cultivation, secondary koji turning after the middle-stage cultivation, later-stage cultivation, tertiary koji turning after the later-stage cultivation, and terminal-stage cultivation in sequence; 7) discharging koji, namely after cultivation of the yeast for making the hard liquor is finished, pumping the yeast for making hard liquor, which is mixed with saline, into an airing tank. The process can be used for solving the problem of hardening during a cultivation process of the yeast for making the hard liquor, improving the quality of the yeast for making the hard liquor and lowering the labor cost; furthermore, the yeast for making the hard liquor, prepared by the process, has the characteristics of less quantity of infectious microbes and high enzyme activity.

Owner:GUANGDONG CHUBANG FOOD

Connection terminal and a connection terminal assembly and method for assembling the connection terminal

InactiveUS7255583B2Low costPrecise positioningIncorrect coupling preventionElectrical connectionEngineering

Owner:HITACHI LTD

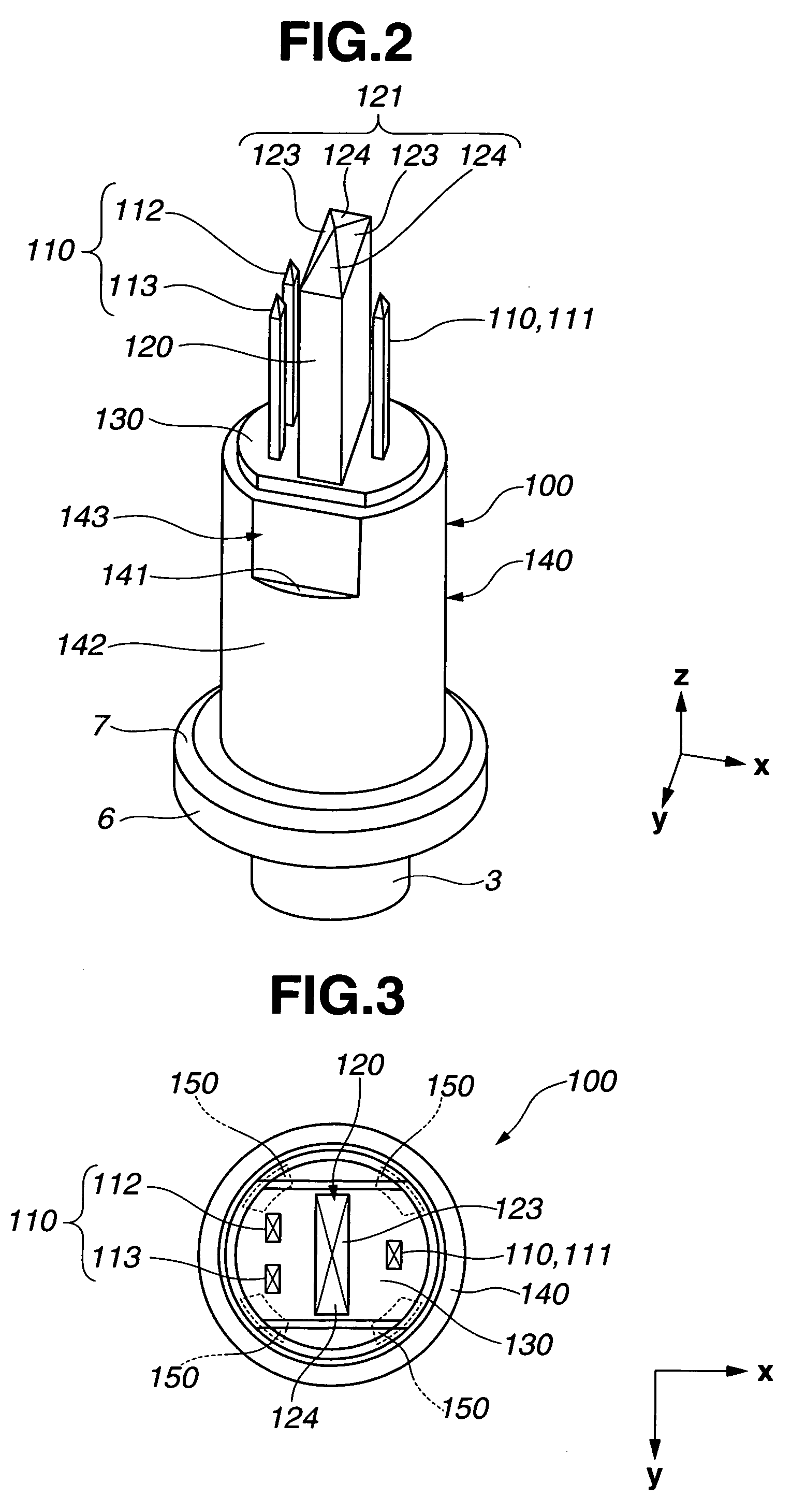

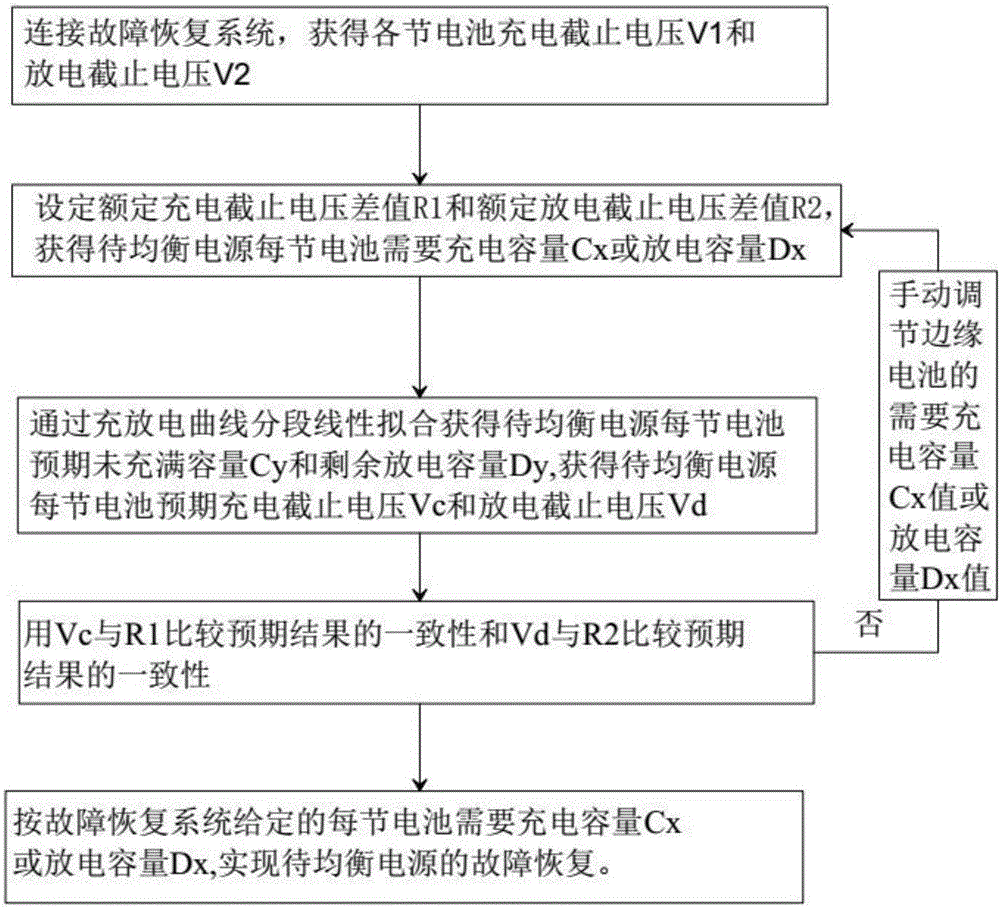

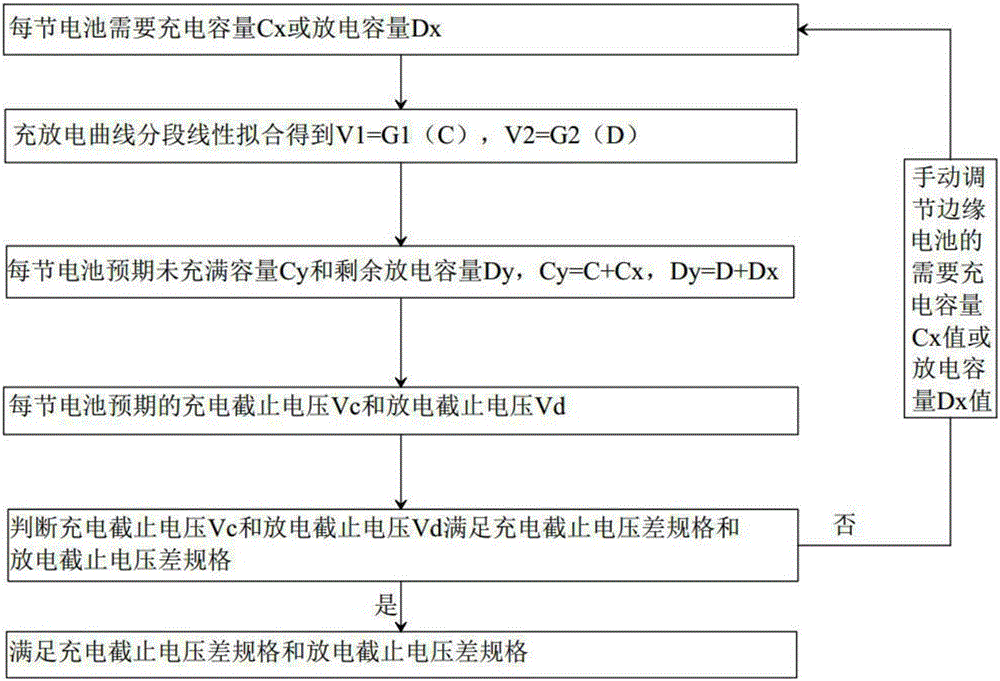

Balance failure recovery method for electric vehicle power source capable of being charged and discharged in fixed capacity mode

ActiveCN106671784AUniform charge and dischargeEliminate voltage differenceElectric devicesSecondary cells charging/dischargingCapacitanceRecovery method

The invention relates to a balance failure recovery method for an electric vehicle power source capable of being charged and discharged in a fixed capacity mode. The technical problems that when balancing effects of existing voltage balance modes are influenced by contact internal resistance and the dropout voltage is not high, the electric current for charging and discharging is low, and balancing needs to be conducted for a long time are solved. The balance failure recovery method comprises the steps that (1) the charging cut-off voltage and the discharging cut-off voltage of all batteries are determined; (2) the rated charging and discharging cut-off voltage difference values are set, and the charging capacity and the discharging capacity of each battery are obtained; (3) the expected undercharged capacity, the expected residual discharging capacity, the expected charging cut-off voltage and the expected discharging cut-off voltage of each battery are obtained through charging and discharging curve piecewise linear fitting; and (4) each battery is charged and discharged in a fixed capacity mode, and failure recovery of the to-be-balanced power source is achieved. According to the balance failure recovery method, the batteries are externally charged or discharged in the fixed capacity mode and do not influenced by the contact internal resistance through the certain function relationship between the battery voltage and the battery capacitance in the charging terminal stage and the discharging terminal stage, the balanced current is high, and the time required by balancing is short.

Owner:天津力神新能源科技有限公司

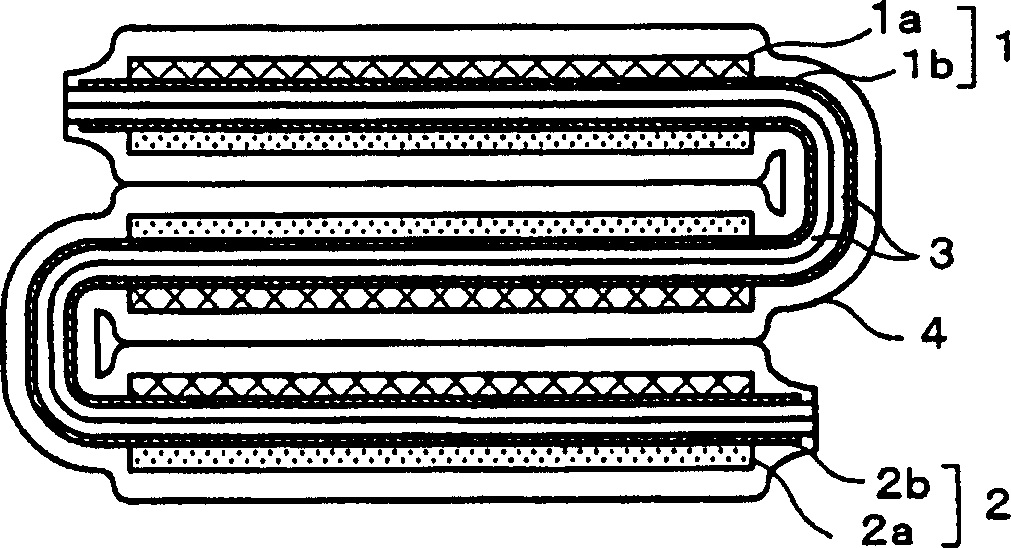

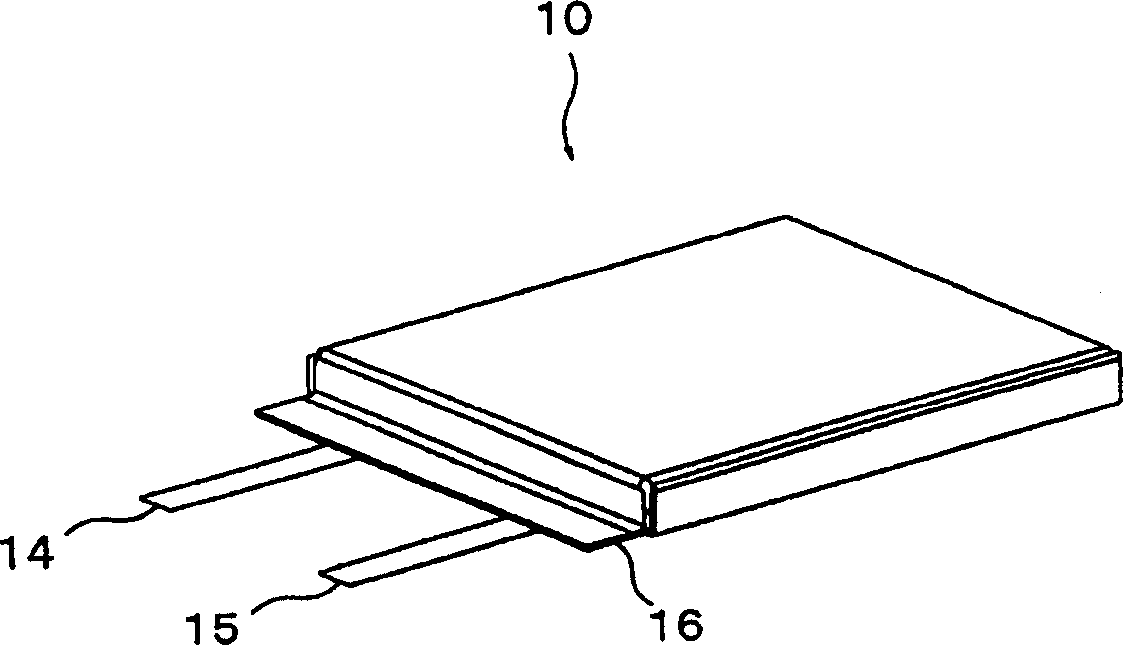

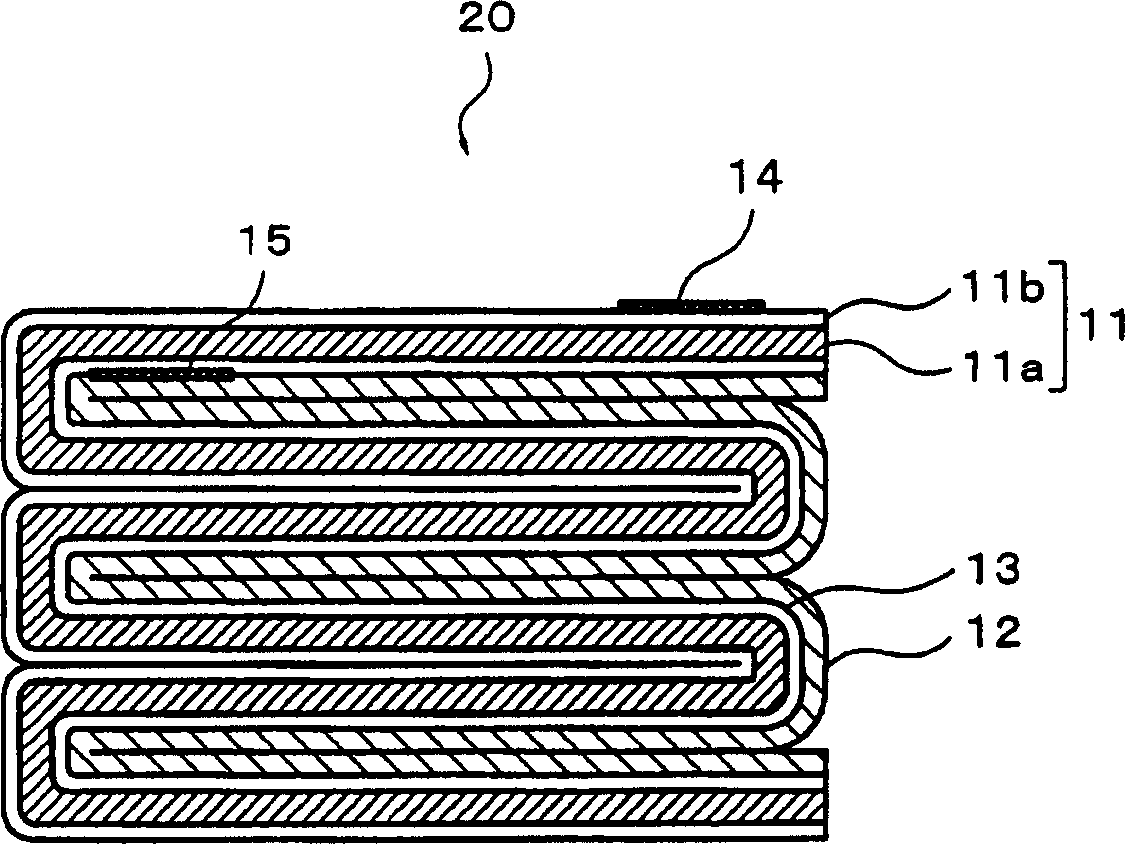

Battery

InactiveCN1776939ALower internal resistanceExcellent battery characteristicsElectrode carriers/collectorsOrganic electrolyte cellsLithiumAlloy

The invention discloses a battery. The battery includes: a positive electrode, wherein the positive electrode active material layer is formed on a positive electrode collection electrode made of strip metal foil; a negative electrode made of metal lithium or metal lithium alloy ; and a separator, wherein in the positive electrode, the positive electrode active material layer is formed only on one surface of the positive electrode collector, and the positive electrode is bent so that the positive electrode active material layers are mutually facing each other, and the negative electrode is disposed in a portion of the positive electrode active material layer facing each other.

Owner:SONY CORP

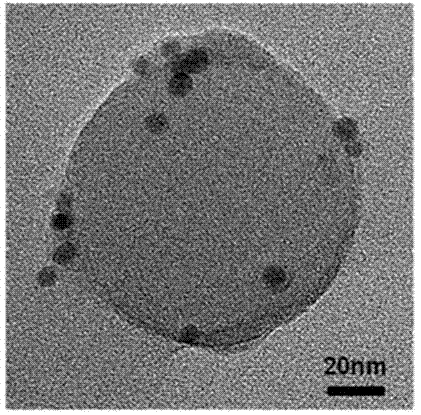

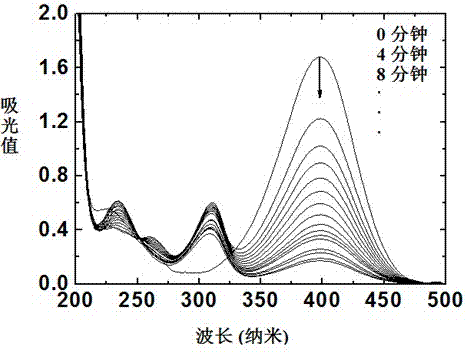

Method for preparing nano nickel by taking nano spherical polyelectrolyte brush as reactor and application of nano nickel

InactiveCN102240816AGood dispersionImprove catalytic performanceMaterial nanotechnologyOrganic compound preparationPolyelectrolyte brushesNano catalyst

The invention discloses a method for preparing nano nickel by taking a nano spherical polyelectrolyte brush as a microreactor and an application of the nano nickel. The method comprises the following steps of: preparing polymer microspheres with the particle size of 80-140nm by adopting emulsion polymerization initiated by an oxidation-reduction system; adding a photoinitiator in the terminal stage of the emulsion polymerization, coating the photoinitiator on the surfaces of the polymer microspheres to form a photoinitiator layer, then utilizing an ultraviolet lamp to initiate polyelectrolytemonomers to be polymerized so as to obtain a spherical electrolyte brush with the particle size of 10-400nm; then adding sodium hydroxide to dissociate carboxyl on an electrolyte chain; treating the dissociated spherical polyelectrolyte brush by use of a nickel chloride aqueous solution, thus nickel ions exchange sodium ions and enters into the polyelectrolyte brush; and adding sodium borohydrideto reduce the nickel ions into nano nickel in situ, thus finally obtaining controllable nano nickel which are uniformly distributed inside the nano spherical polyelectrolyte brush and have the particle size of 1-14nm. The nano nickel loaded on the spherical polyelectrolyte brush is an ideal efficient nano catalyst.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com