Balance failure recovery method for electric vehicle power source capable of being charged and discharged in fixed capacity mode

A fault recovery, electric vehicle technology, applied in electric vehicles, secondary battery charging/discharging, battery/fuel cell control devices, etc., can solve the problems of battery pack life attenuation, inconsistent internal resistance, and overall capacity reduction of the battery pack, etc. Achieve the effect of eliminating voltage difference, improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

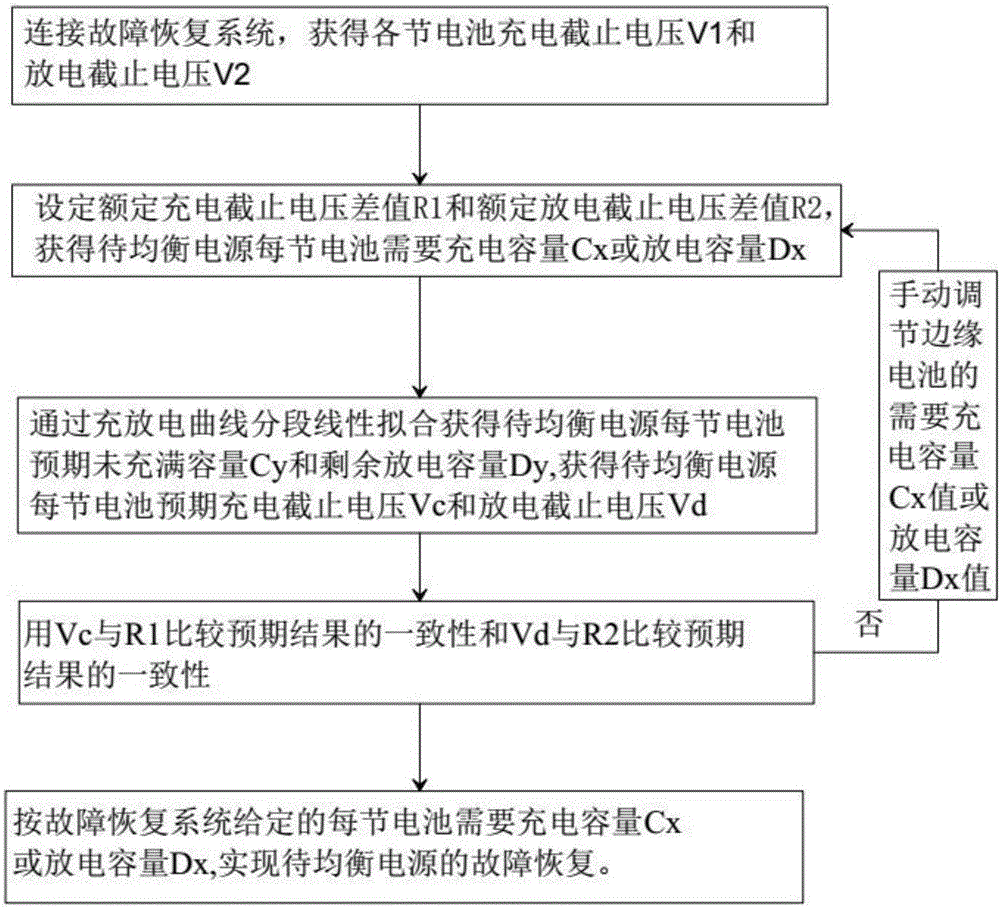

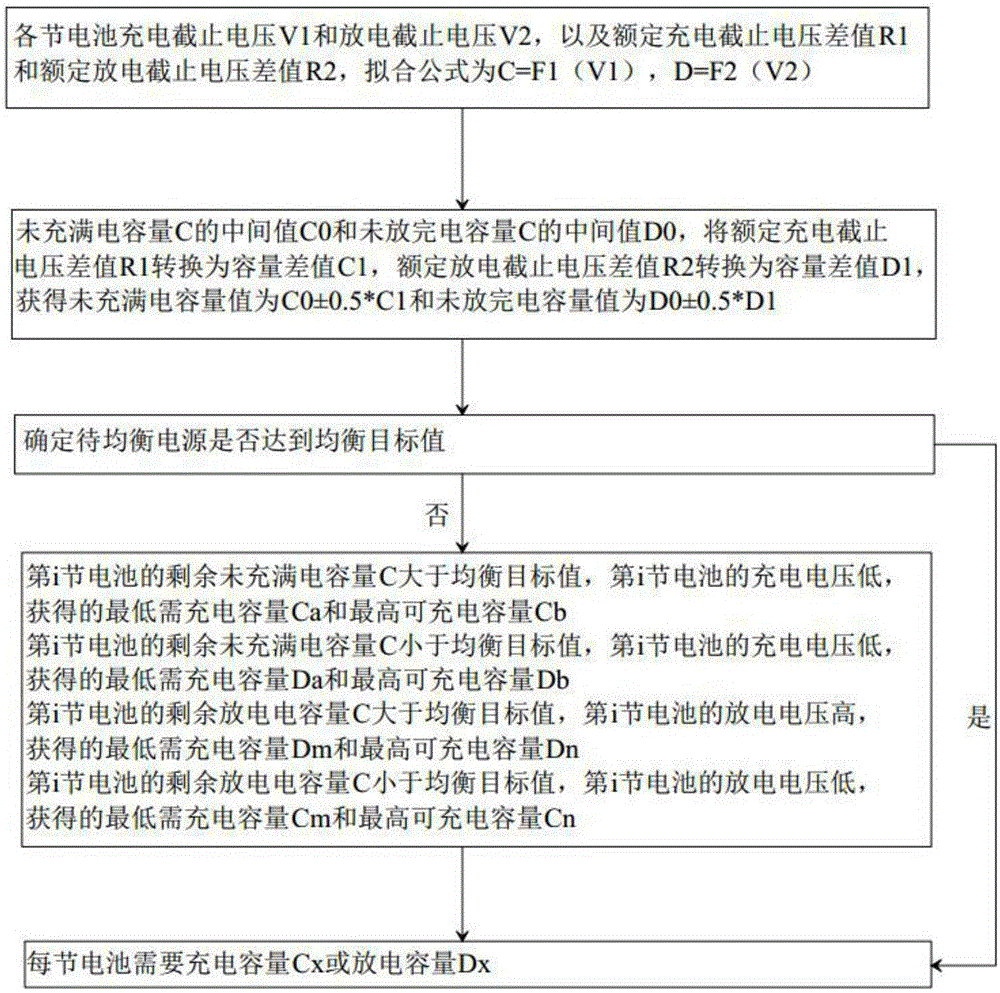

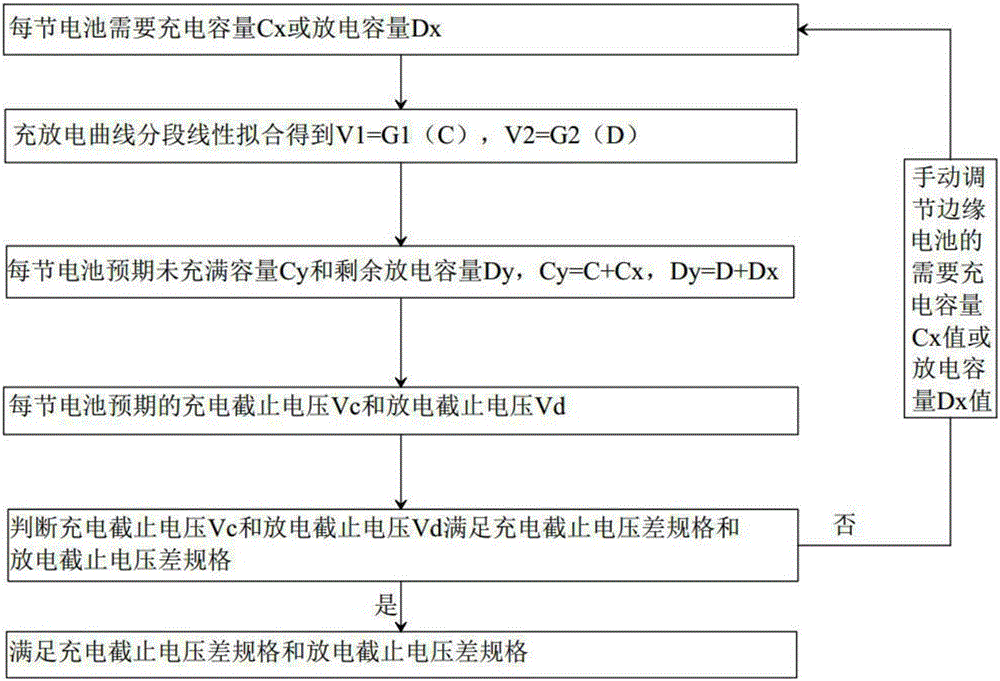

Method used

Image

Examples

specific Embodiment 1

[0031] Take a 92S32P ternary lithium 18650-ion battery pack as an example.

[0032] (a) Charging, the charging cut-off voltage is as Figure 4 shown.

[0033] (b) Discharge, the discharge cut-off voltage is as Figure 5 shown.

[0034] (c) Set equalization target parameters and equalization charge and discharge current:

[0035] The charging cut-off voltage difference specification is <13mV, the discharge cut-off voltage difference specification is <130mV, the balanced charging current is 6A, and the balanced discharging current is 6A. The system automatically calculates the balance charge and discharge time as shown in the table below, some batteries need to be charged, and some batteries need to be discharged.

[0036]

[0037]

[0038] (d) The comparison between the expected charging cut-off voltage after equalization and the actual charging cut-off voltage after equalization Figure 6 shown.

[0039] (e) The comparison between the expected discharge cut-off vol...

specific Embodiment 2

[0043] Increase the balanced charging current and balanced discharging current, set the balanced target parameters and balanced charging and discharging current:

[0044]The charging cut-off voltage difference specification is <13mV, the discharge cut-off voltage difference specification is <130mV, the balanced charging current is 10A, and the balanced discharging current is 10A. The system automatically calculates the balance charge and discharge time as shown in the table below, some batteries need to be charged, and some batteries need to be discharged.

[0045] Rechargeable Battery 6# 11# 80# 85# 86# Charging time (s) 48 16 112 178 48 discharge battery 65# 78# 89# 90# Discharge time (s) 80 14 80 80

[0046] The equalization effect is as follows:

[0047]

[0048] As shown in the table above, after equalization, the charging voltage difference is reduced from 21mV to 13mV, the discharging voltage difference is <130mV, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com