Patents

Literature

793results about "Coke oven safety devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

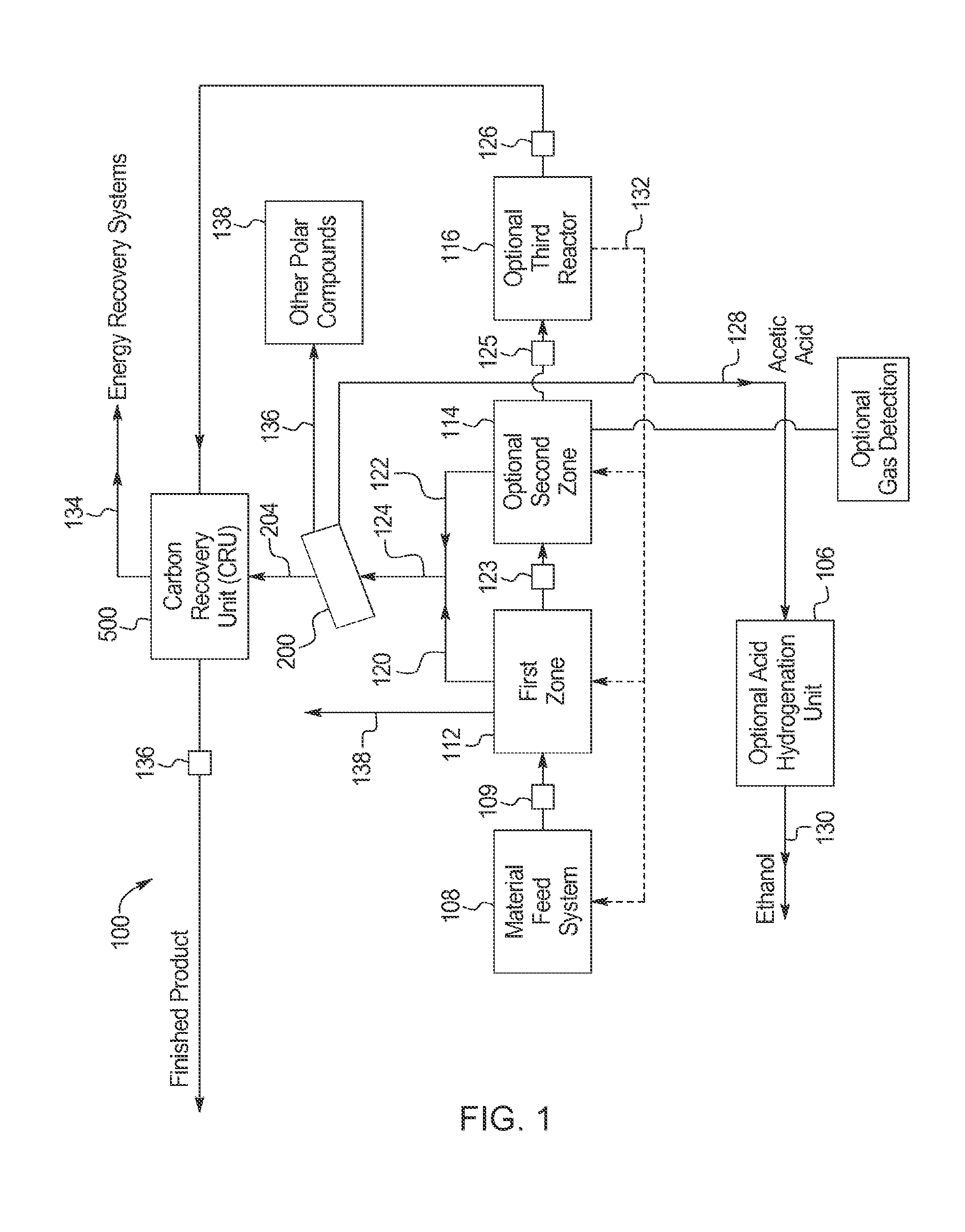

High-carbon biogenic reagents and uses thereof

ActiveUS20120285080A1High carbon contentImprove energy efficiencyCoke quenchingCoke oven safety devicesHigh carbonReagent

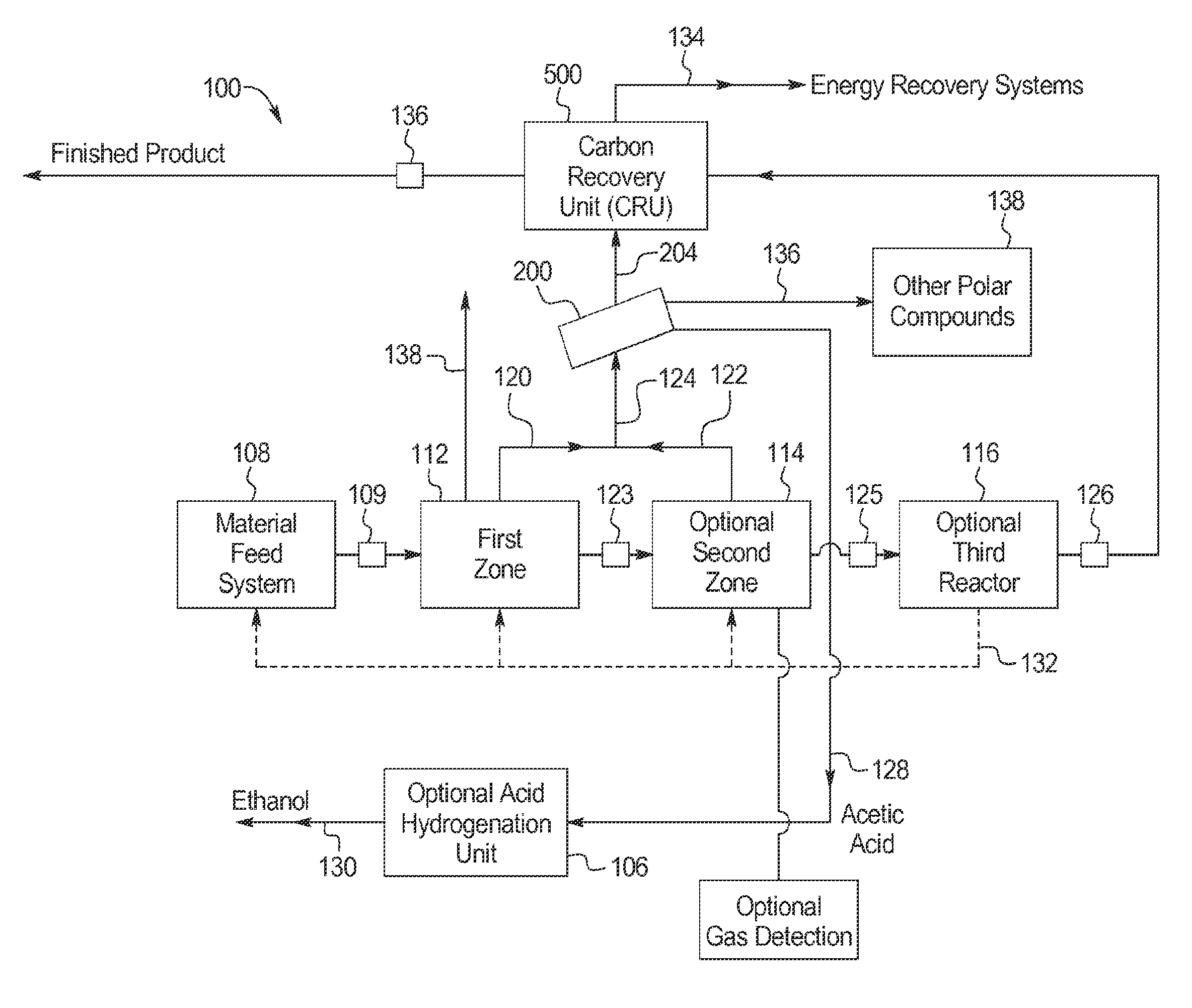

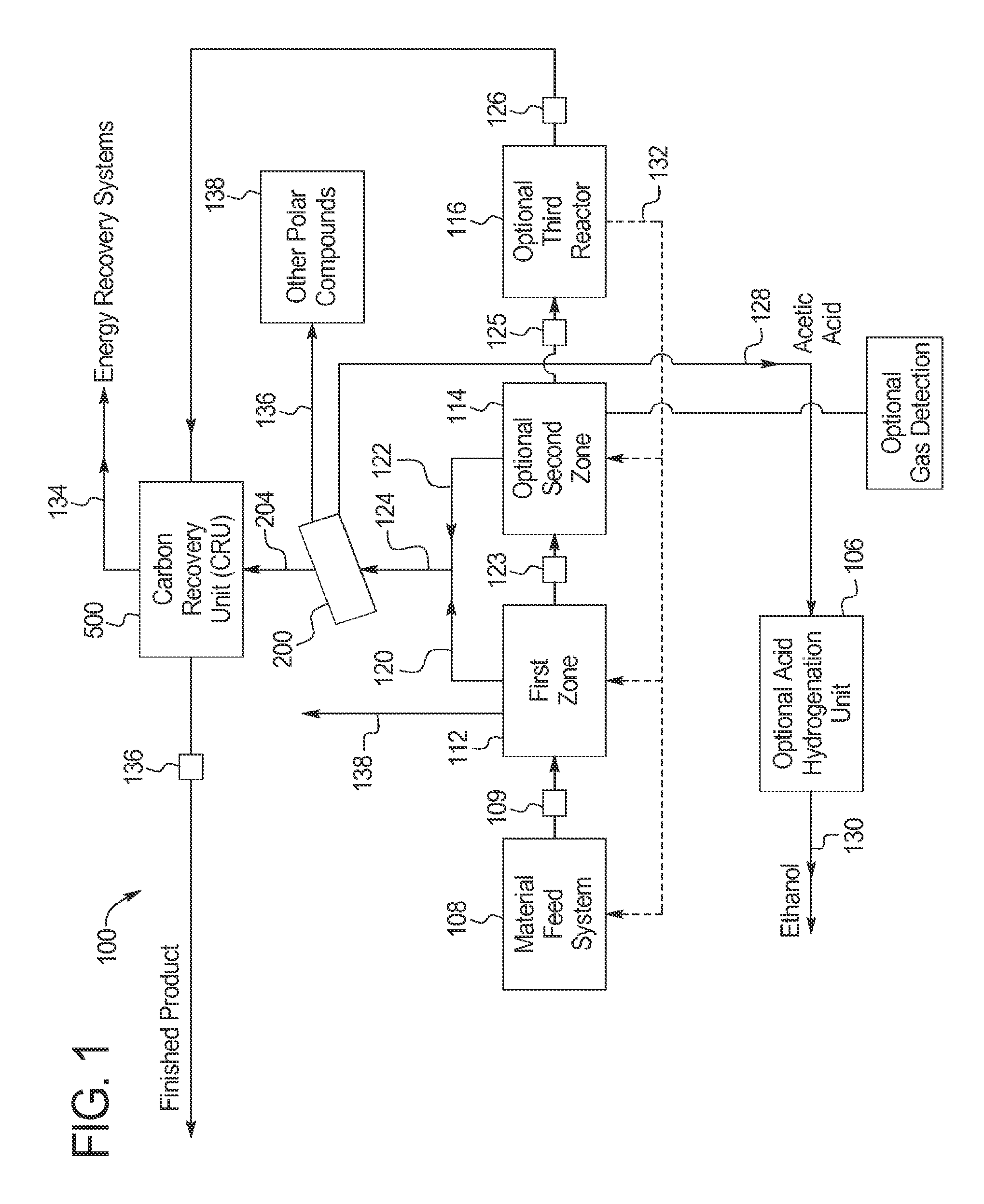

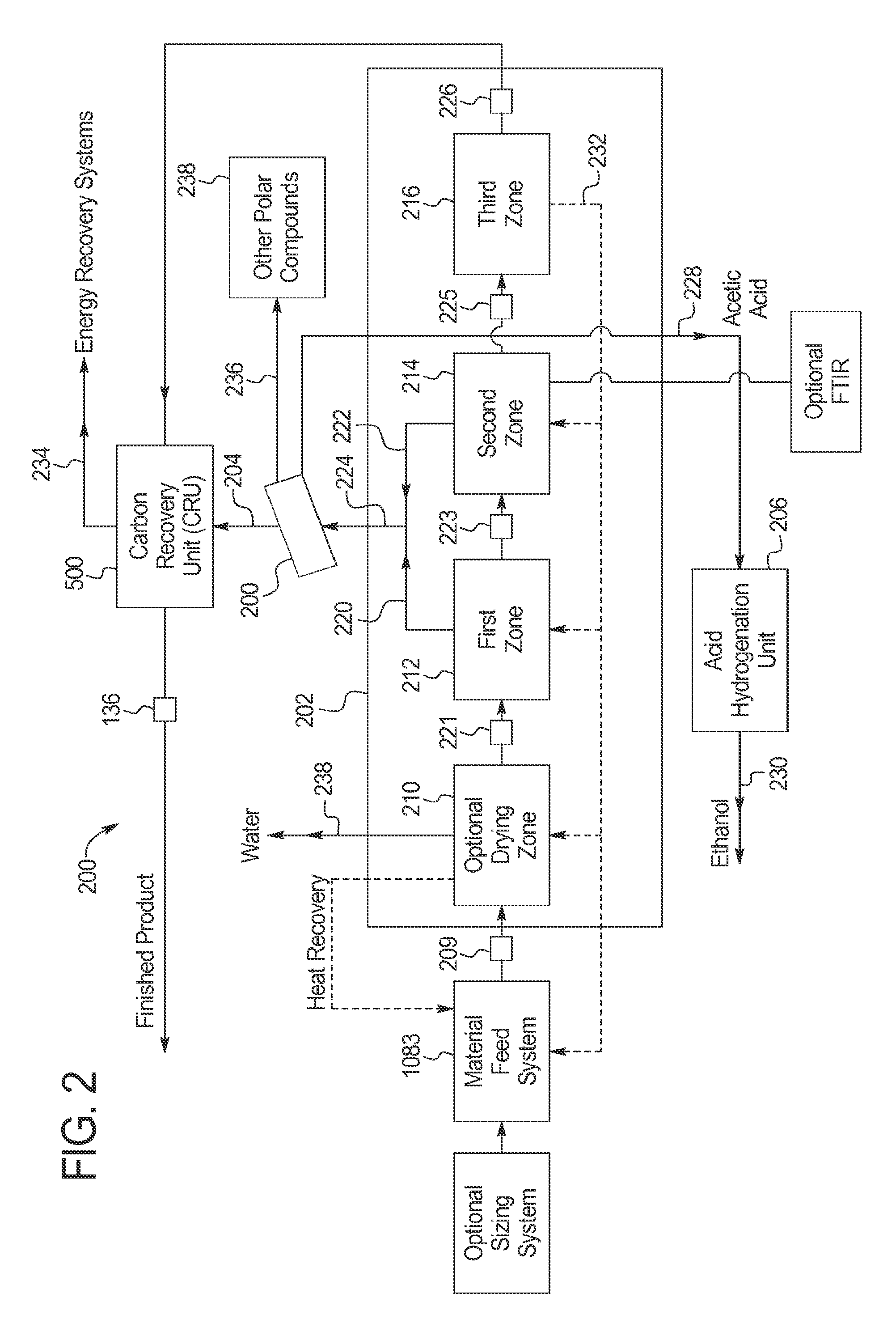

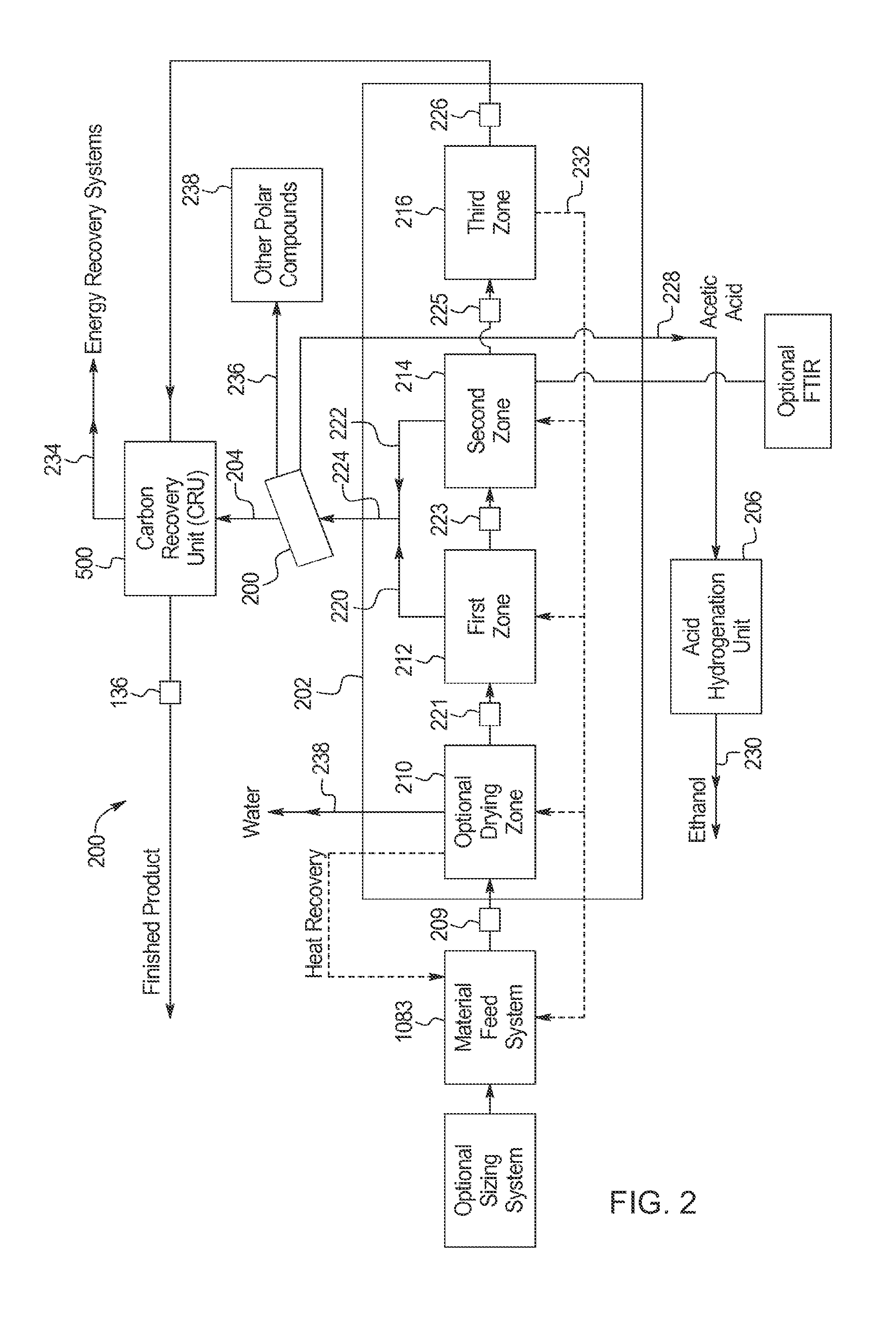

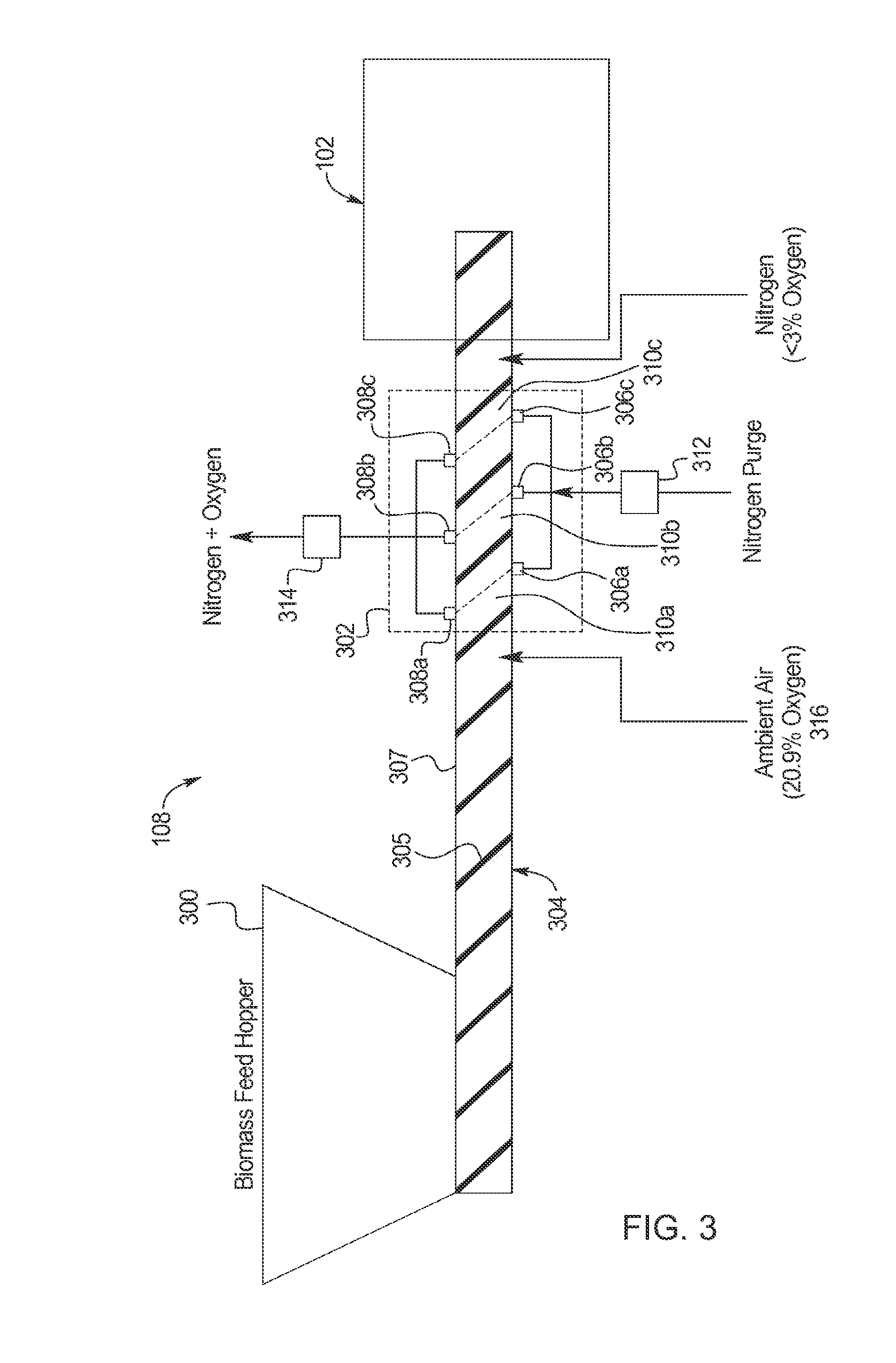

This invention provides processes and systems for converting biomass into high-carbon biogenic reagents that are suitable for a variety of commercial applications. High carbon biogenic reagents are also provided.

Owner:CARBON TECH HLDG LLC

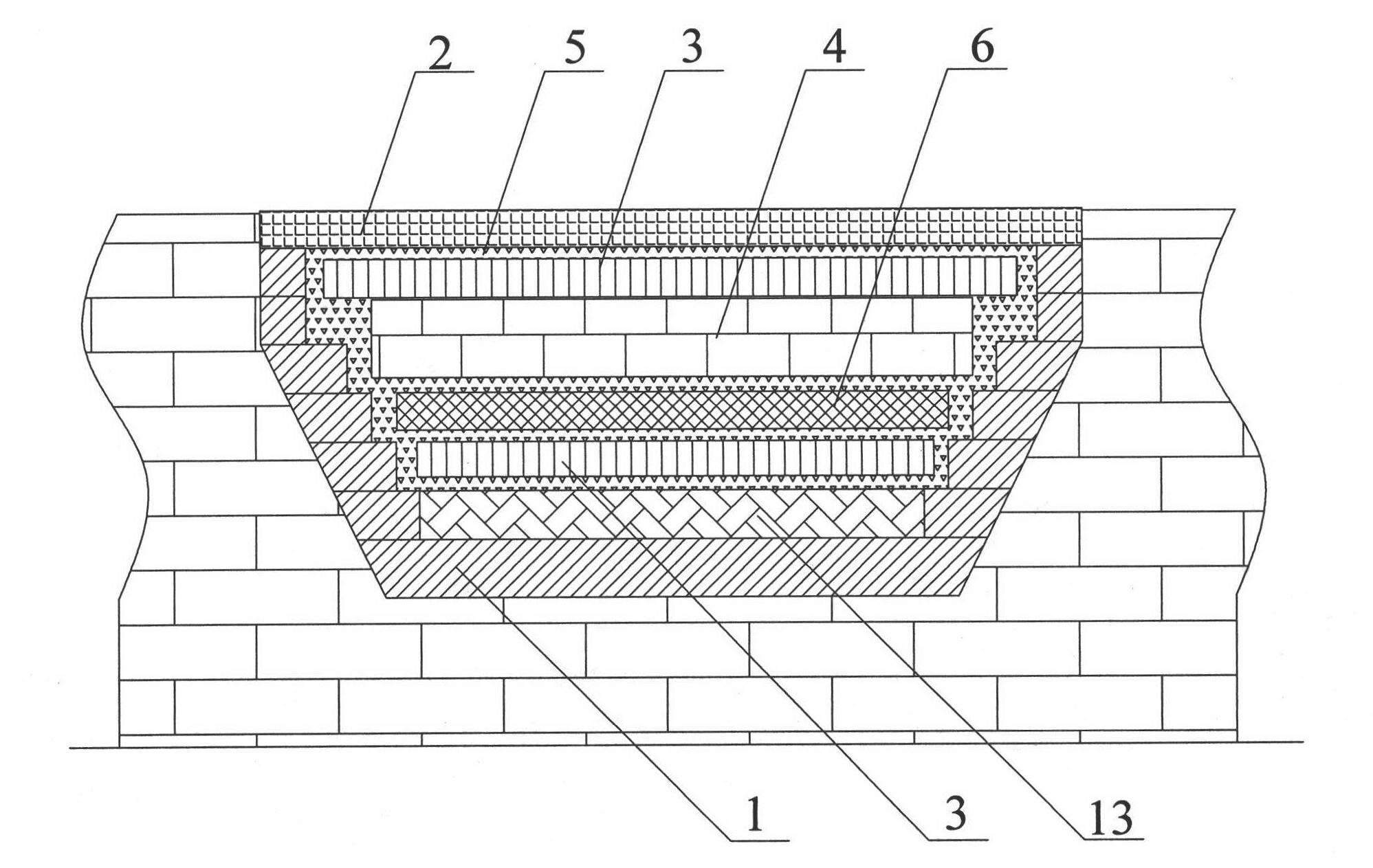

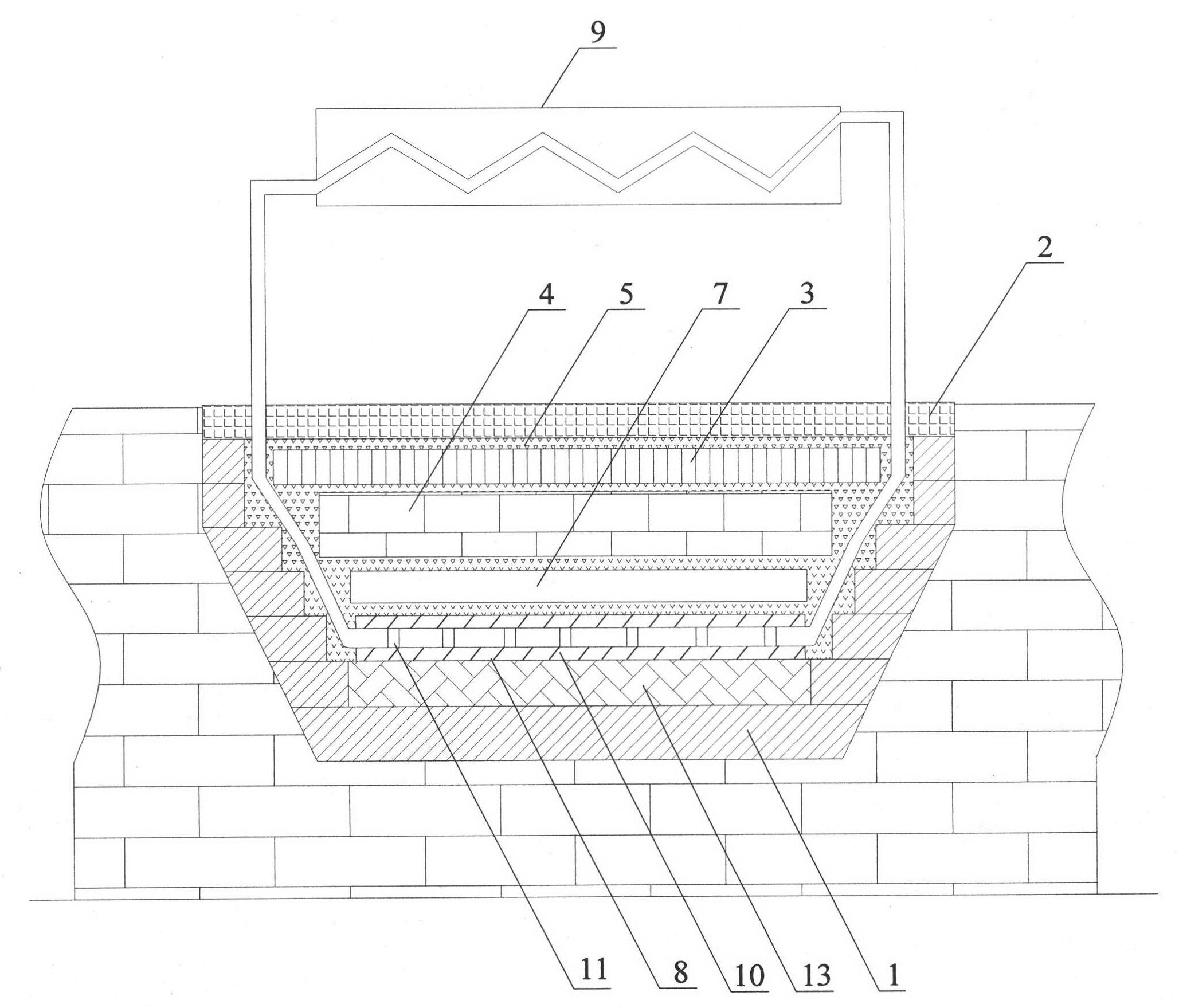

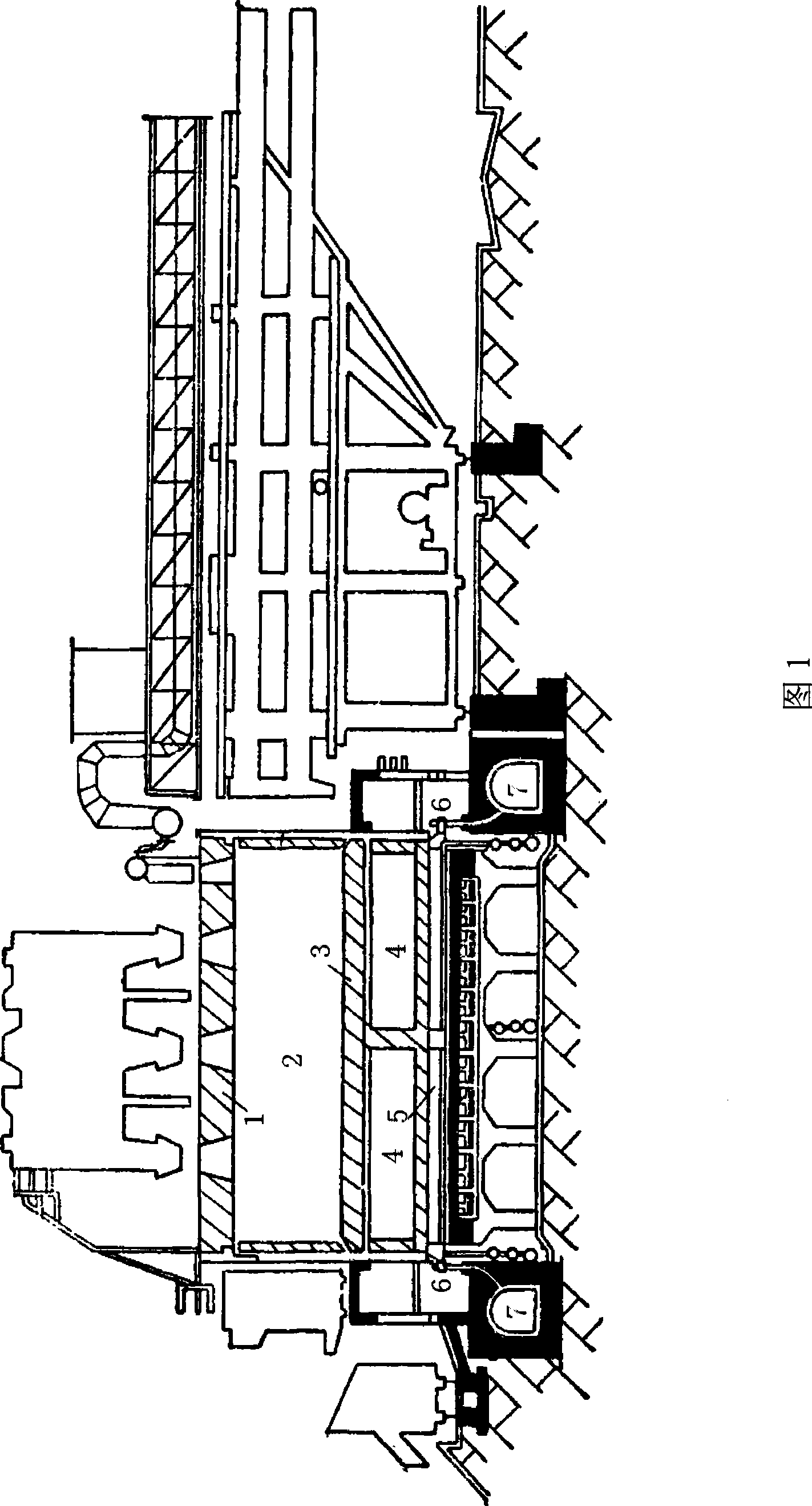

Coke oven top waste heat reclaiming system

InactiveCN102322623AReduce the temperatureImprove insulation effectSteam generation heating methodsCoke oven safety devicesEngineeringCoke oven

The invention discloses a coke oven top waste heat reclaiming system, which mainly consists of a coke oven top large pit (1) and an oven top quarry tile (2) covering the surface of the top of the large pit. The system is characterized in that a poriferous steel plate (3), a thermal baffle layer (4) and a poriferous steel plate (3) are sequentially arranged from bottom to top in the coke oven top large pit (1), and inner gaps of the coke oven top large pit (1) are filled with heat-resisting sealing slurry (5). According to the invention, through the measures that poriferous steel plates and the thermal baffle layer are arranged in the coke oven top large pit (1), the gaps are filled with the heat-resisting sealing slurry and the like, the temperature of the coke oven top surface can be effectively reduced, the heat preservation effect is very obvious, the energy-saving effect is very ideal, and the energy-saving rate can reach 0.4KW / m2.

Owner:重庆双腾化工有限公司

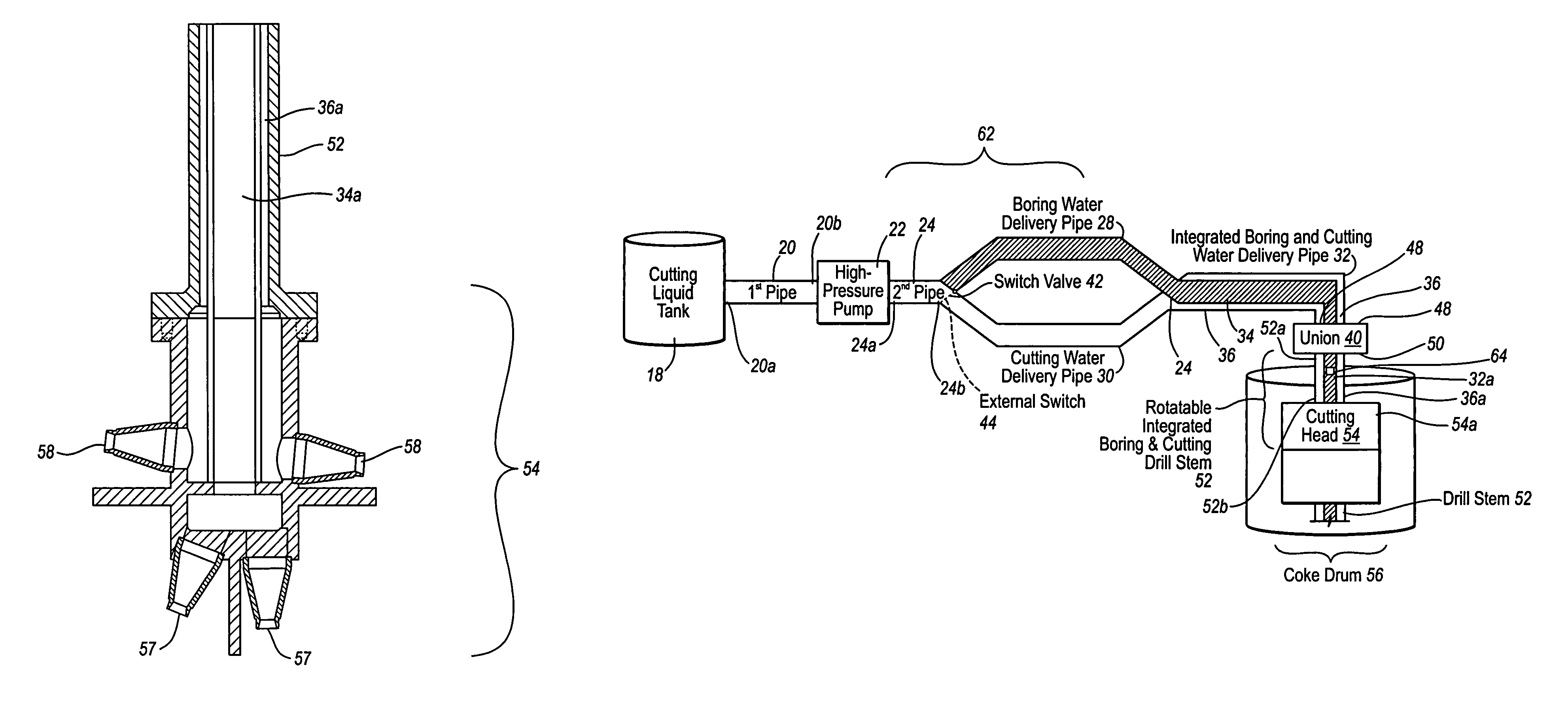

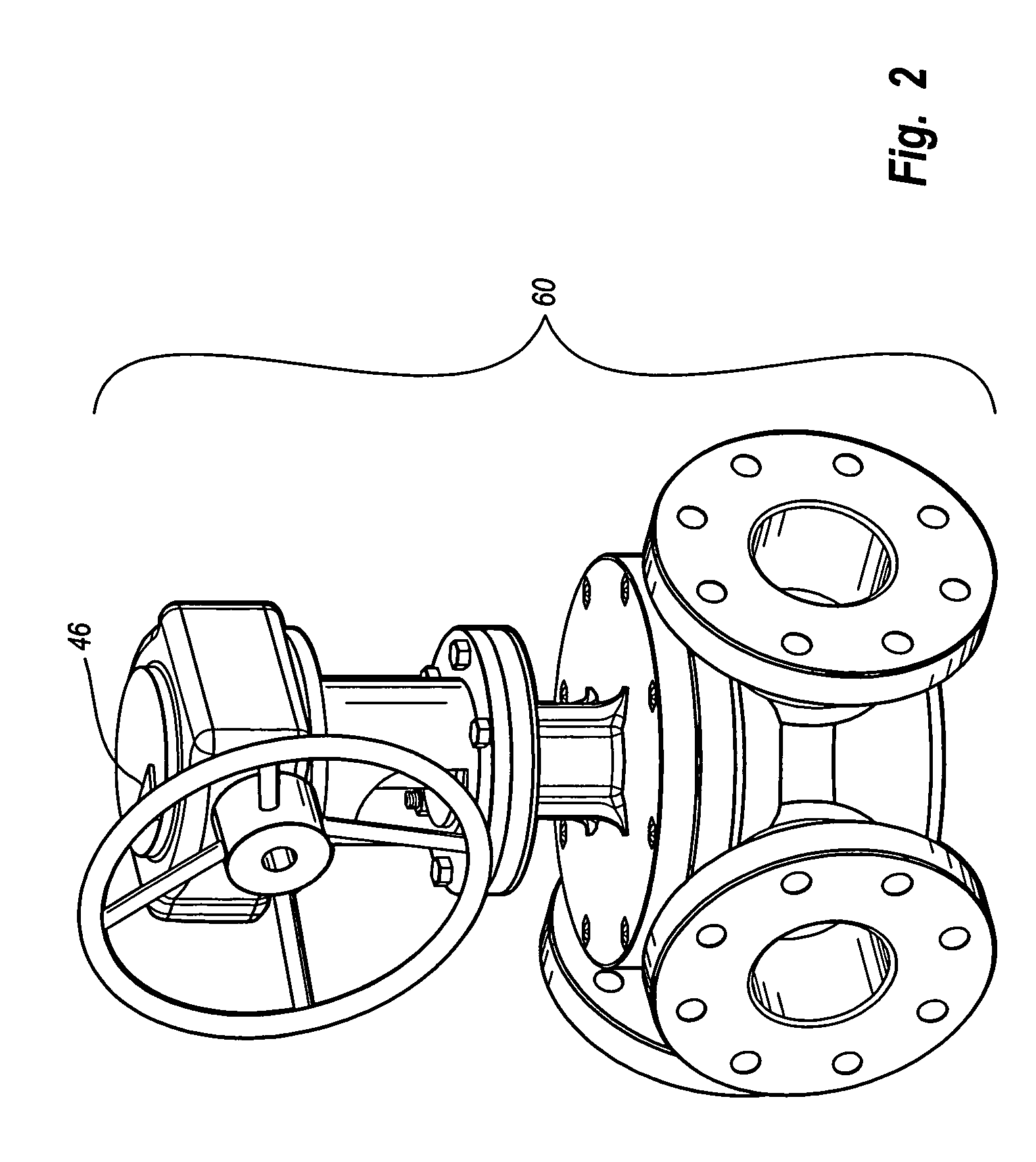

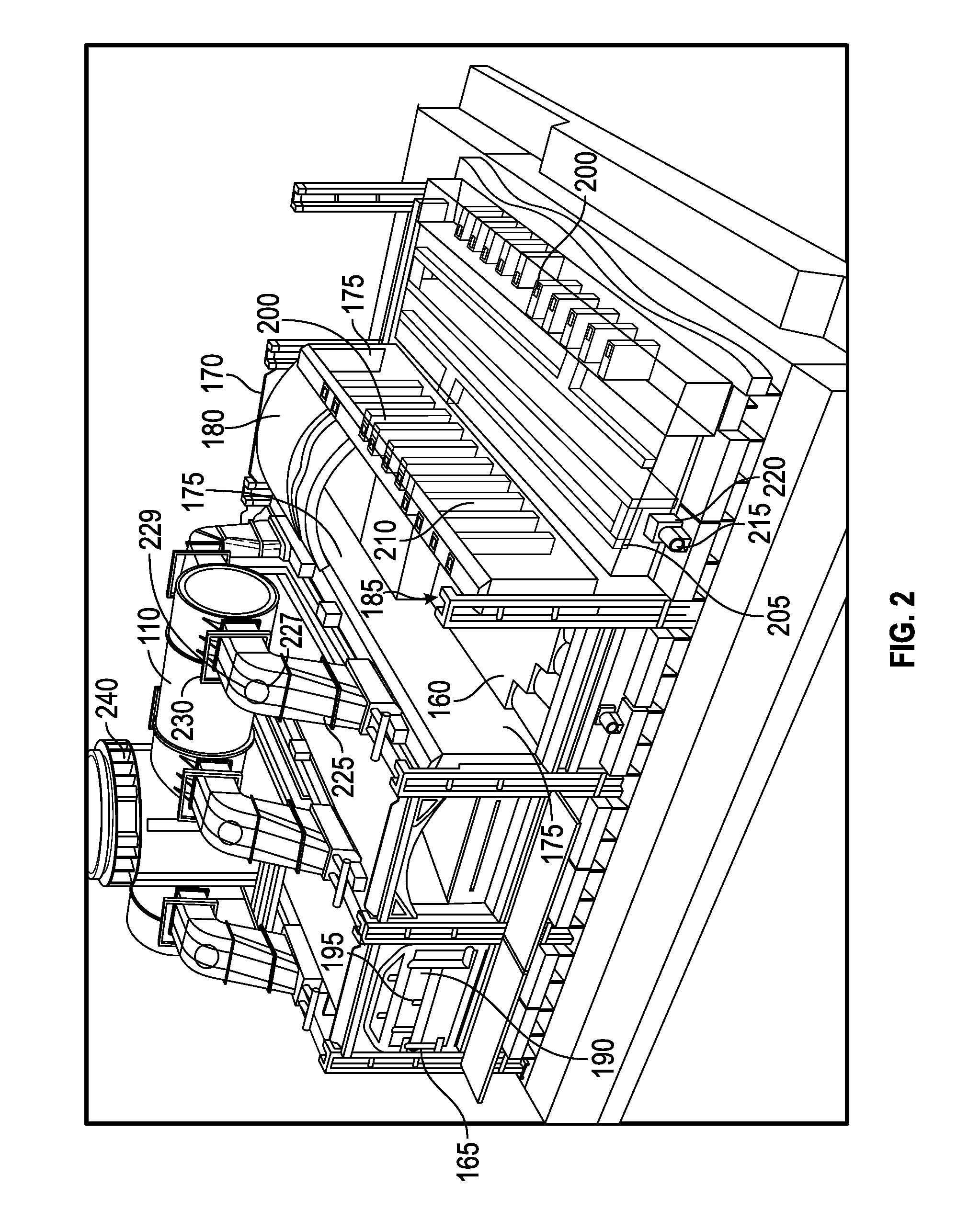

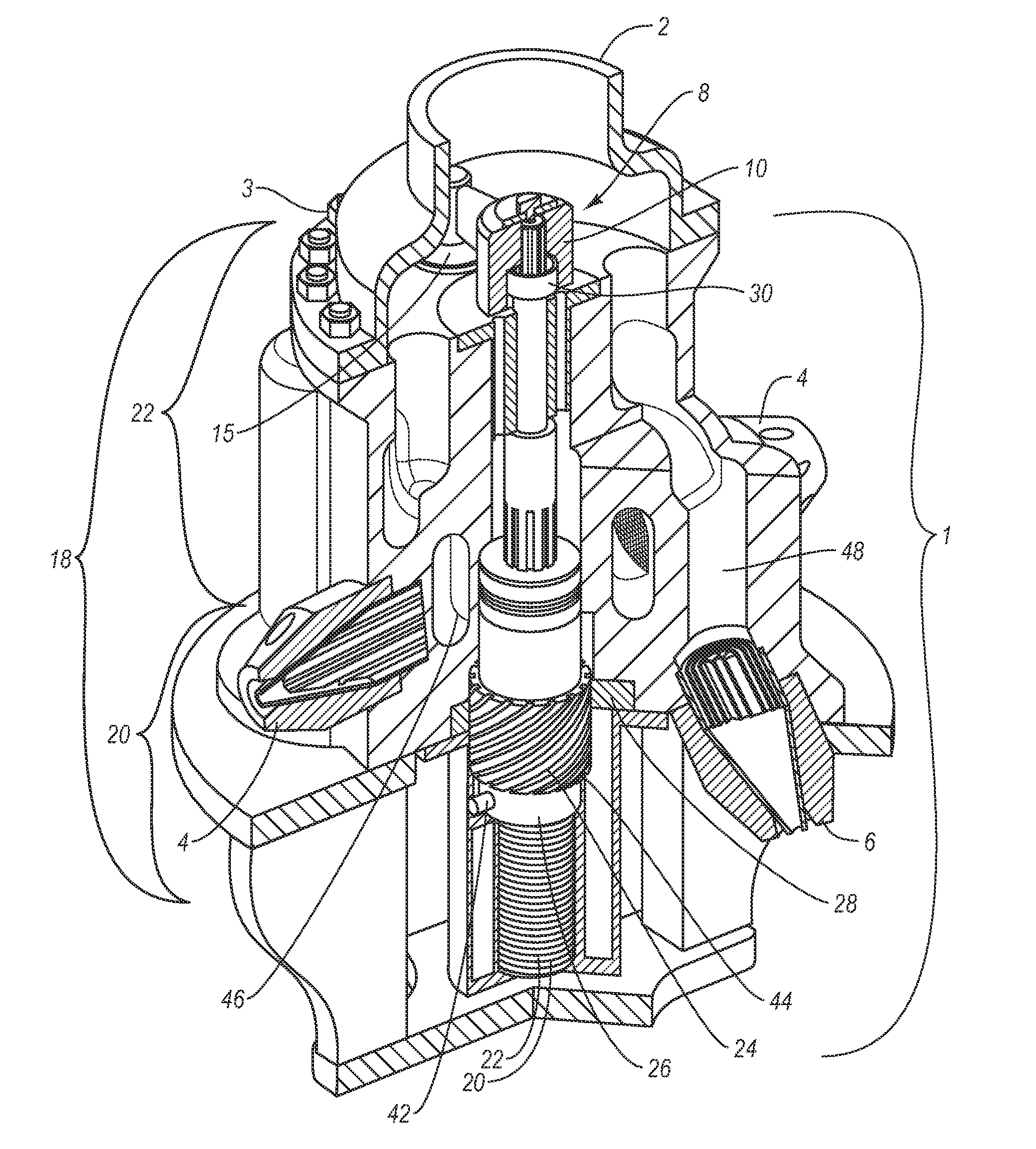

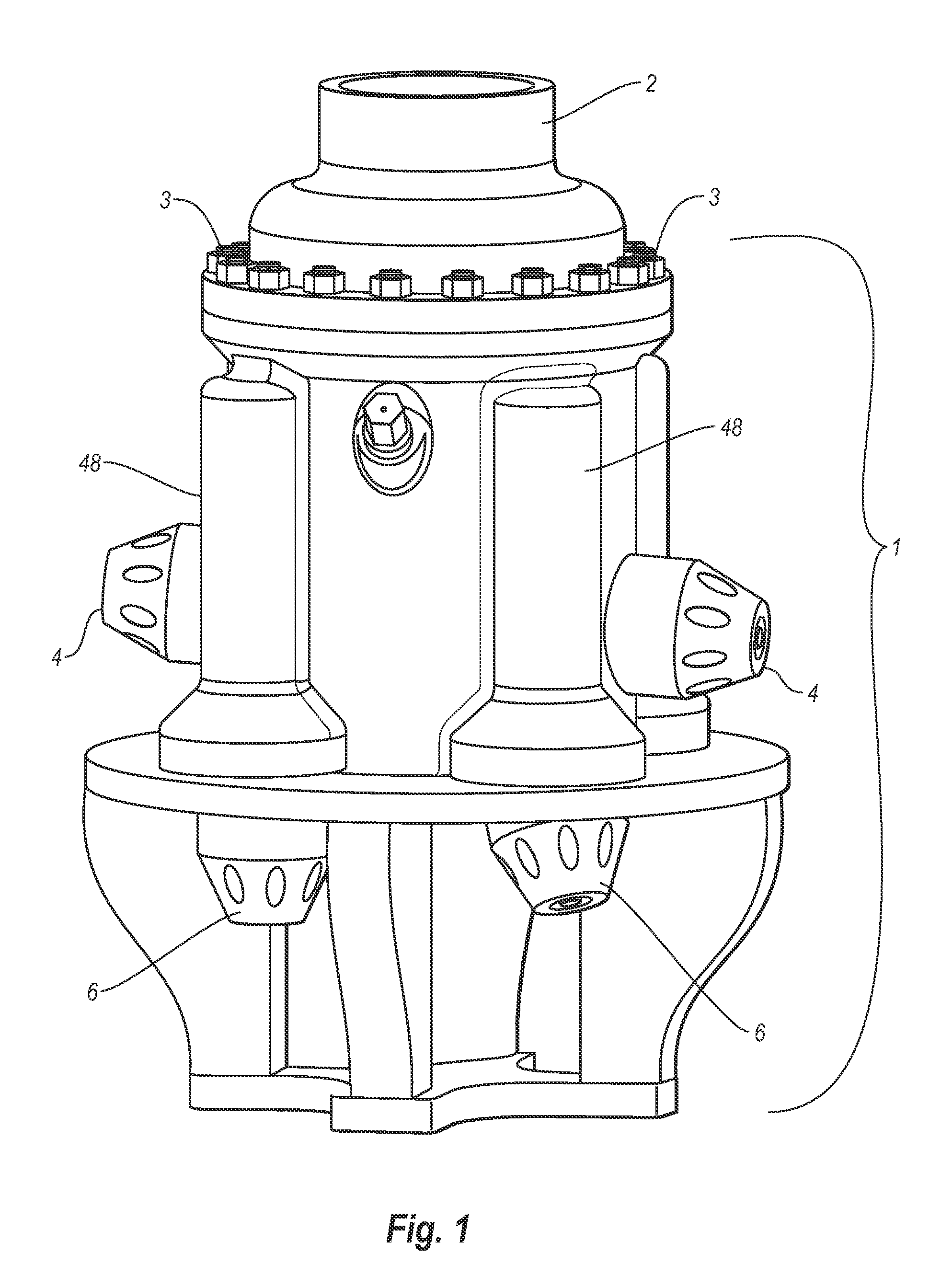

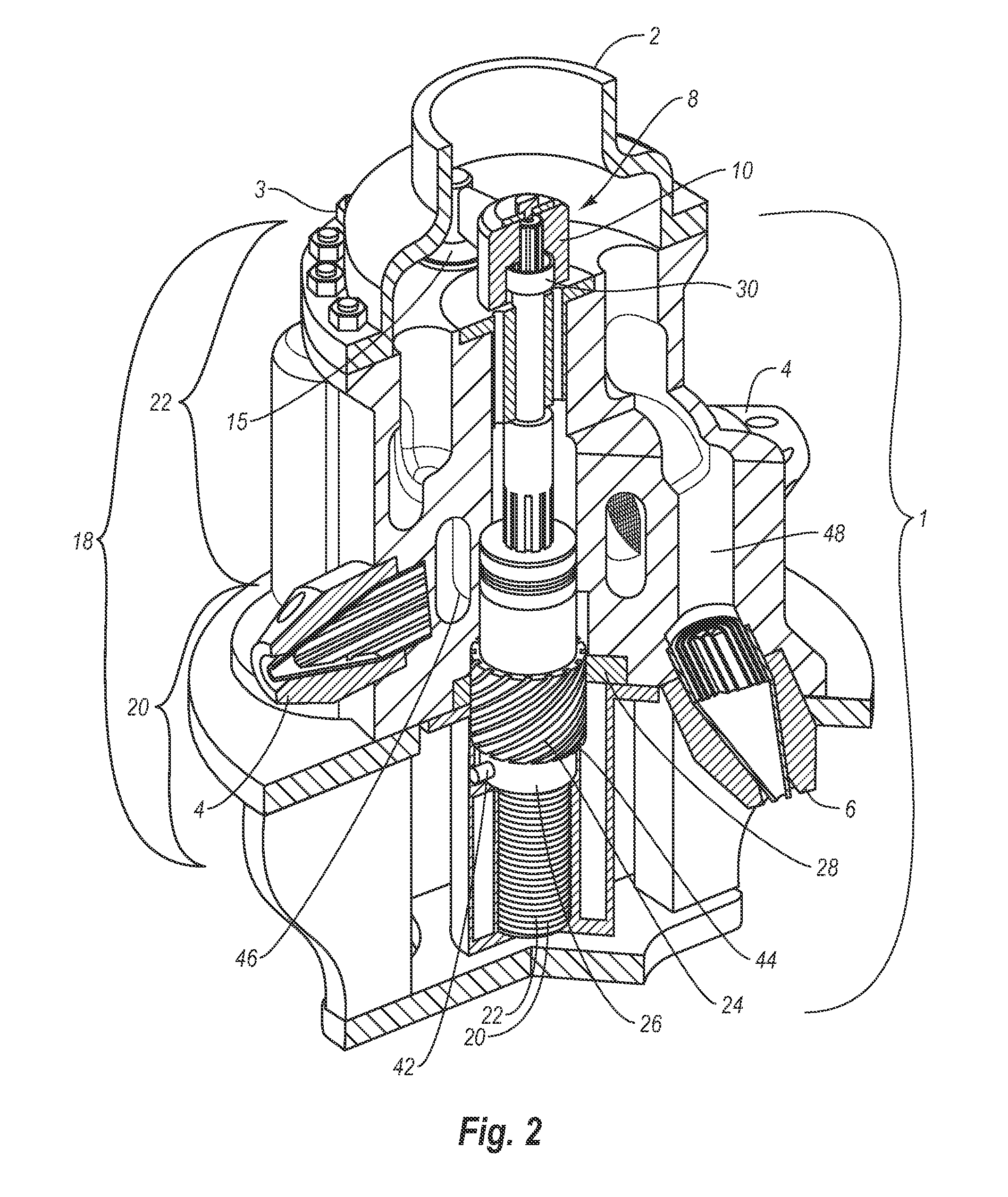

Systems and methods for remotely determining and changing cutting modes during decoking

InactiveUS7117959B2Improve convenienceImprove efficiencyCoke oven safety devicesLiquid/gas jet drillingEngineeringDrill

A decoking system that not only enables an operator to remotely switch the coke-cutting process from boring to cutting mode without removing the drill stem from the coke drum, but also to remotely determine the drill stem's mode so that efficiency, safety and convenience are not compromised, is provided.

Owner:CURTISS WRIGHT FLOW CONTROL CORP

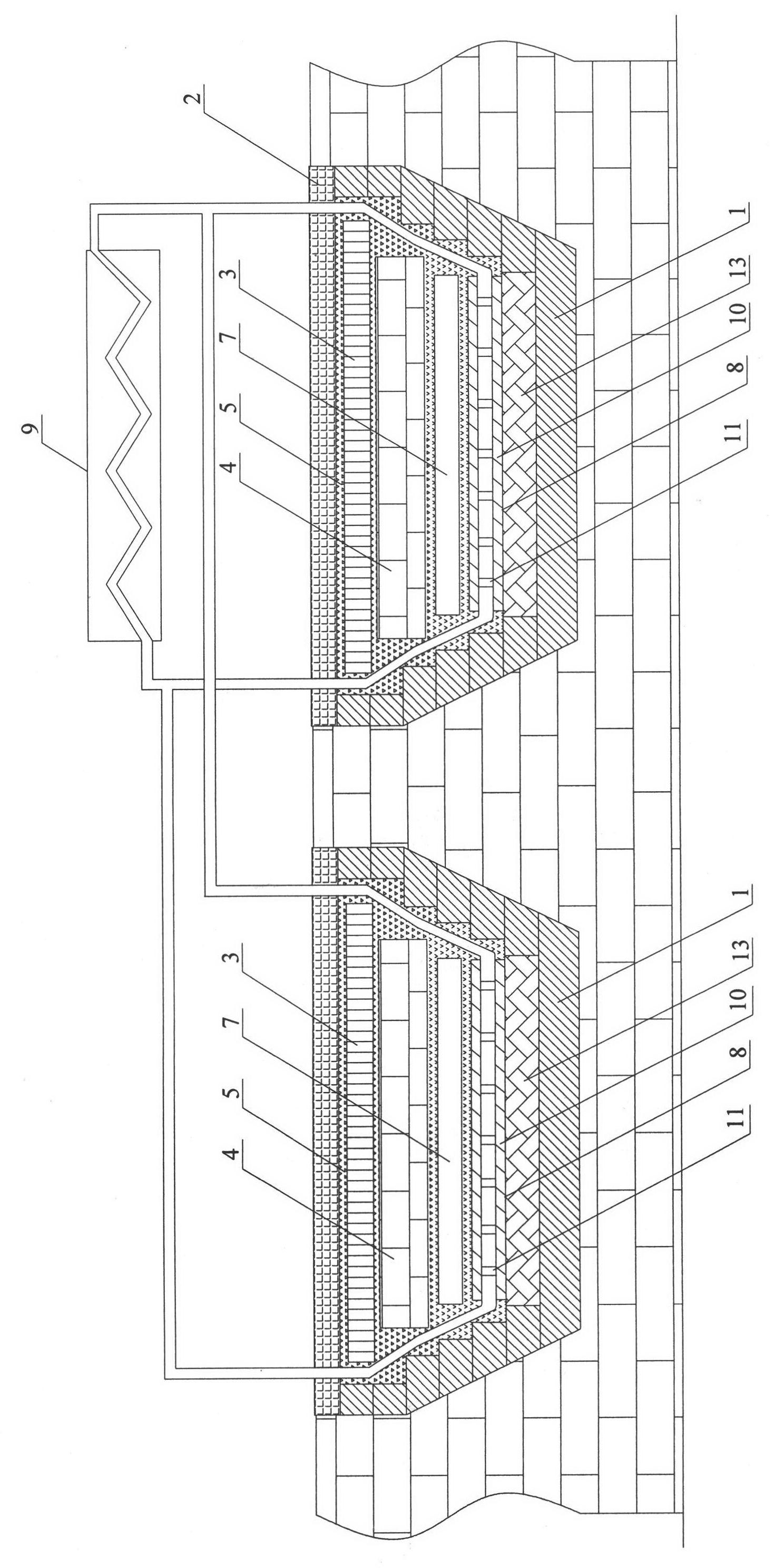

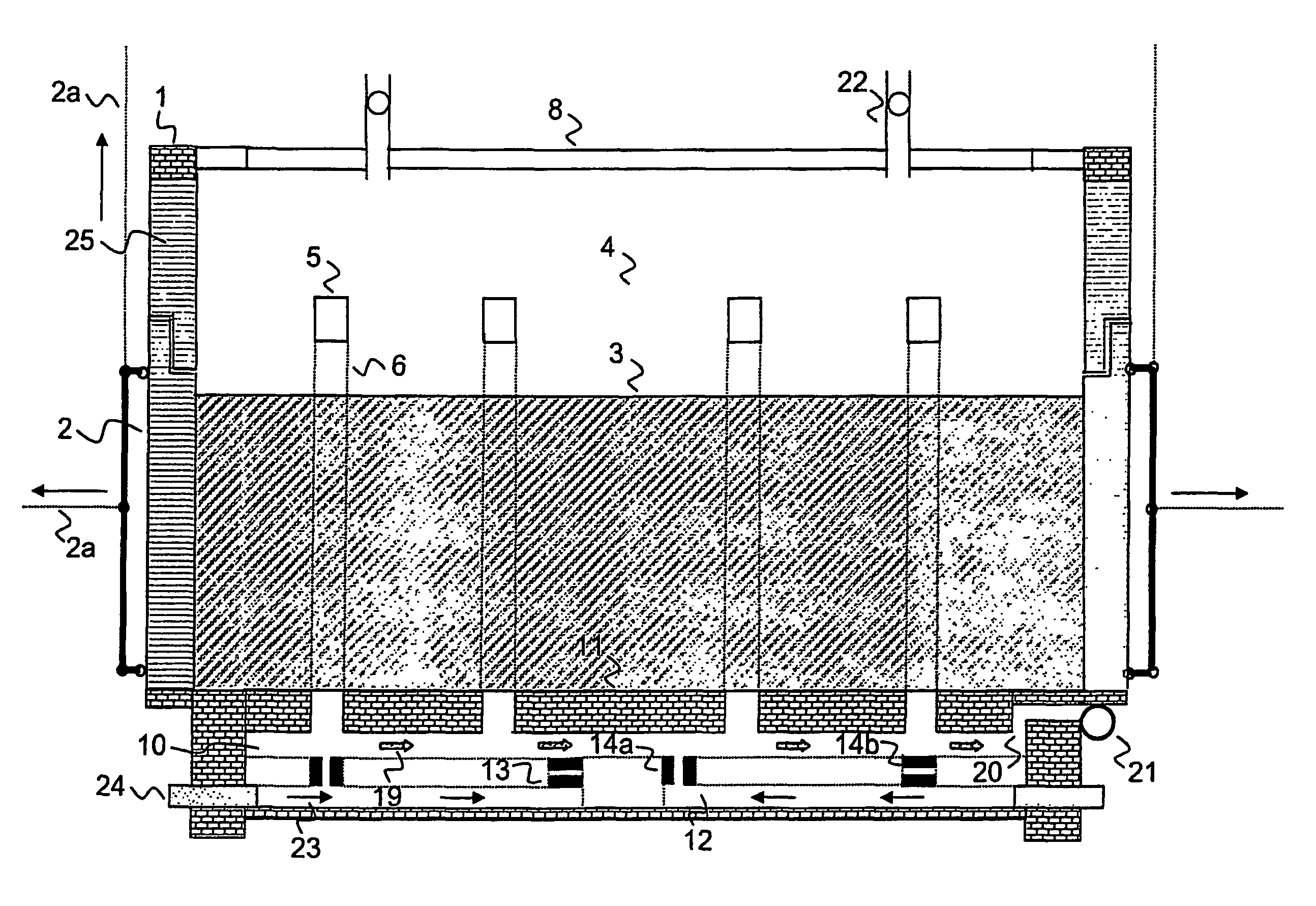

Controllable air ducts for feeding of additional combustion air into the area of flue gas channels of coke oven chambers

ActiveUS9039869B2Reduce carbonizationGood heat distributionCombustible gas coke oven heatingCoke oven safety devicesBrickCombustion

A device for feeding and controlling secondary air from secondary air ducts into flue gas channels of horizontal coke oven chambers is shown. The flue gas channels are located underneath the coke oven chamber floor on which coal carbonization is realized. The flue gas channels serve for combustion of partly burnt coking gases from the coke oven chamber. The partly burnt gases are burnt with secondary air, thus heating the coke cake also from below to ensure even coal carbonization. Secondary air comes from the secondary air ducts connected to atmospheric air and to the flue gas channels. Controlling elements are mounted in the connecting channels between the flue gas channels and secondary air ducts which can precisely control the air flow into the flue gas channels. Thereby, it is possible to achieve a much more regular heating and heat distribution in coke oven chambers. The actual controlling devices in the connecting channels can be formed by turnable pipe sections, wall bricks, or metal flaps. It is particularly advantageous to utilize a hump-like facility (tabouret) which sits in the secondary air ducts and which is comprised of a tabouret plate with a central opening that is slid under the corresponding embranchment to regulate the gas stream. The controlling mechanism can be actuated manually, electrically, or pneumatically. Thereby, the controlling device can also be automated.

Owner:UHDE GMBH

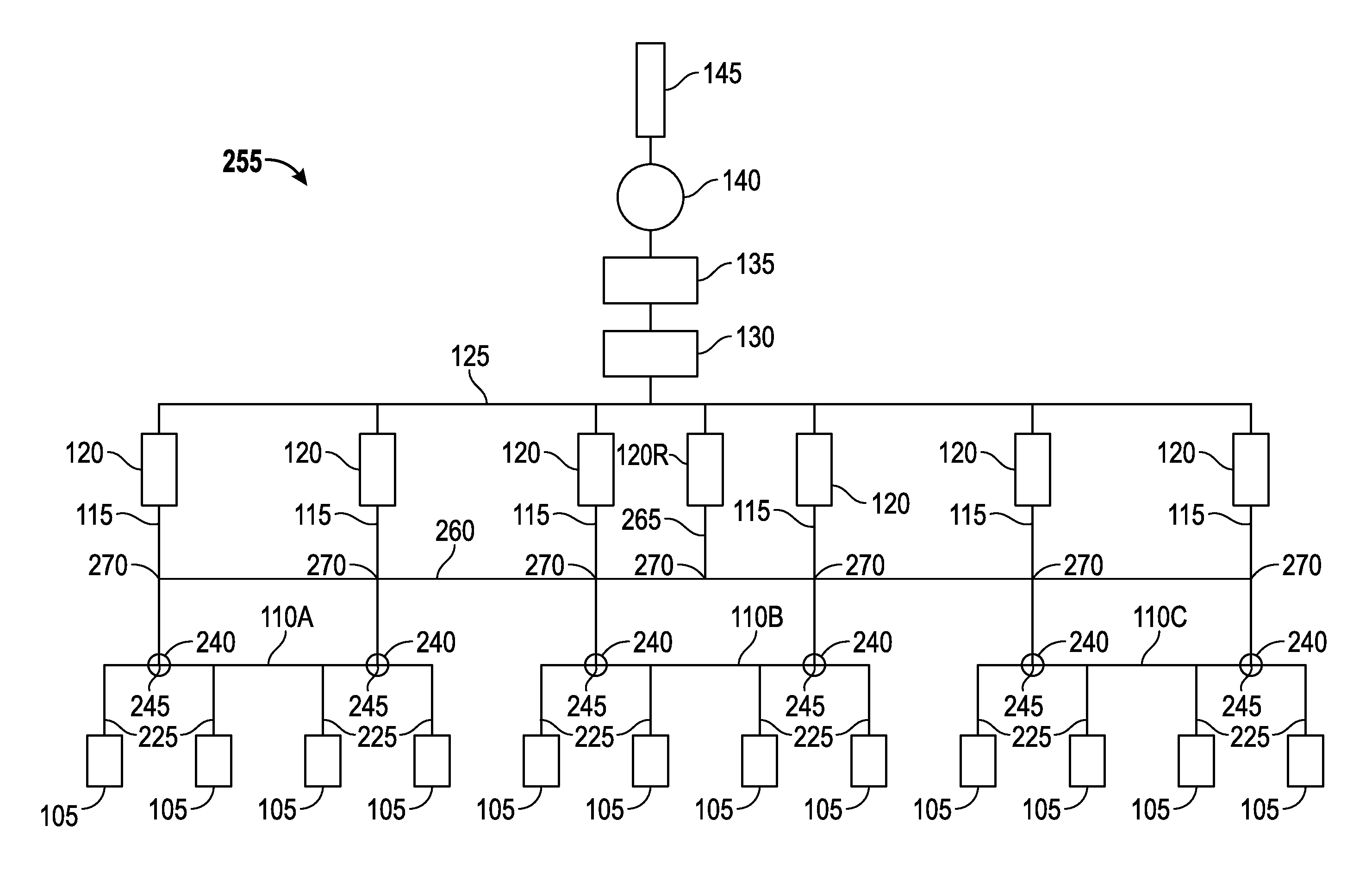

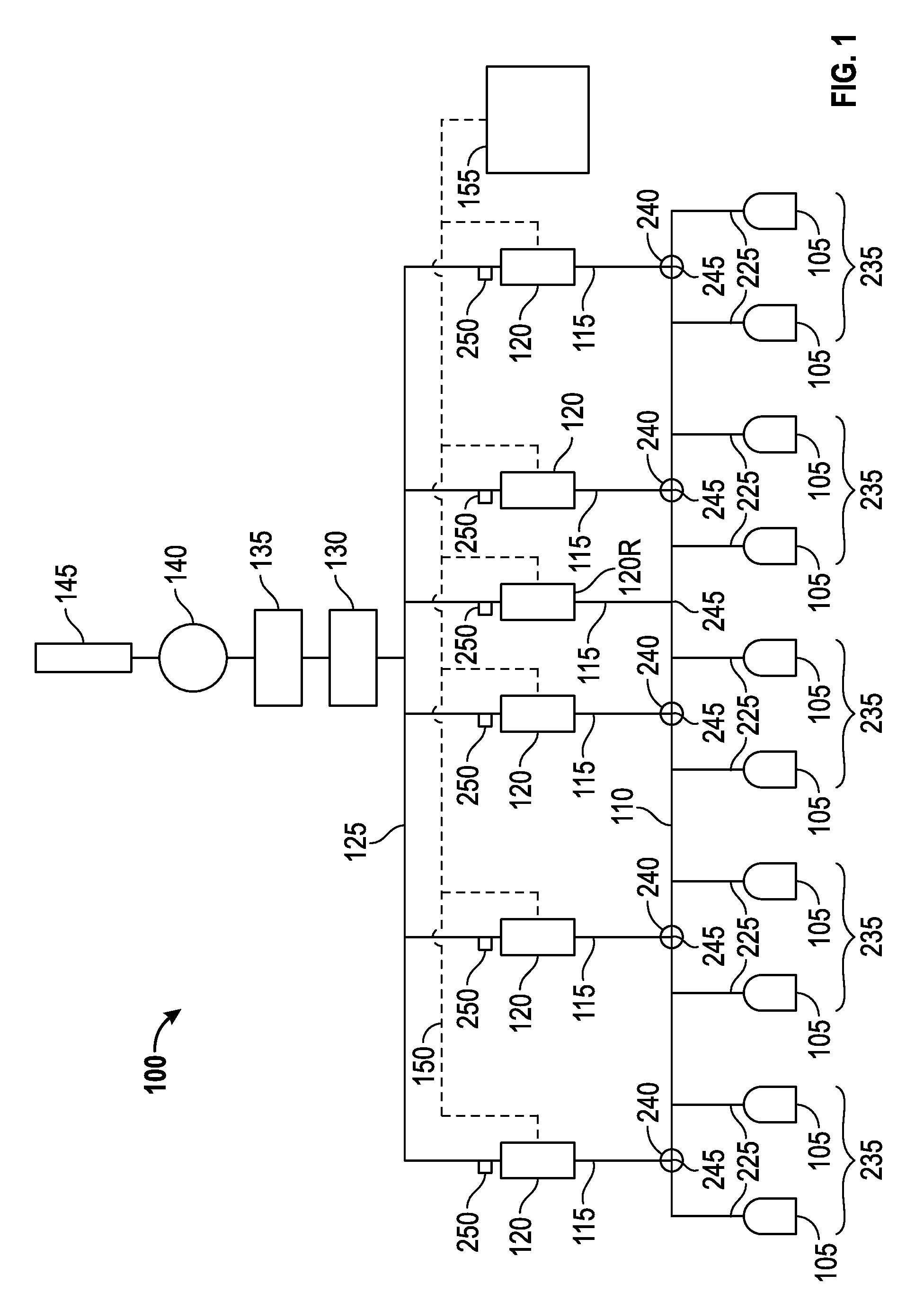

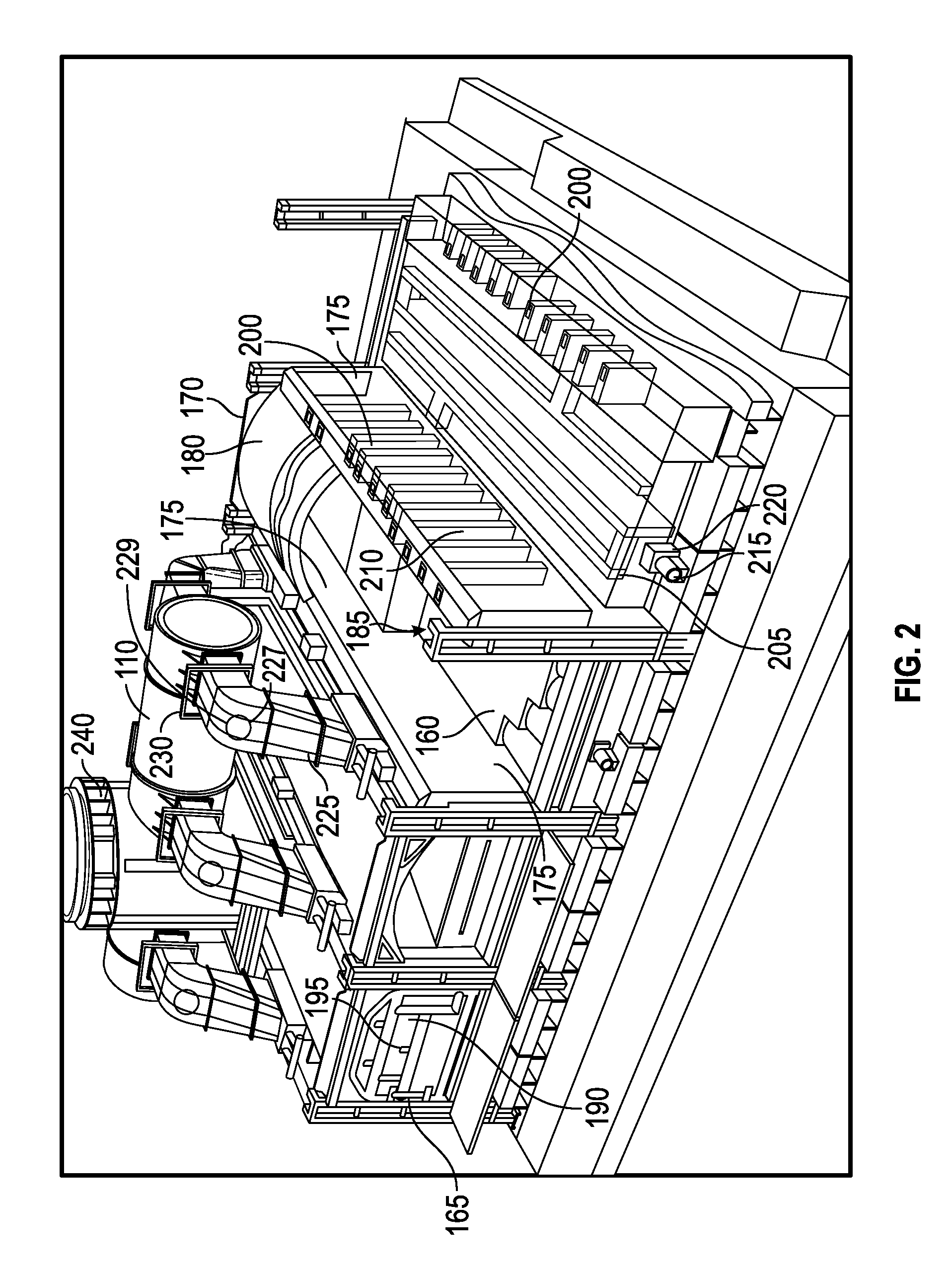

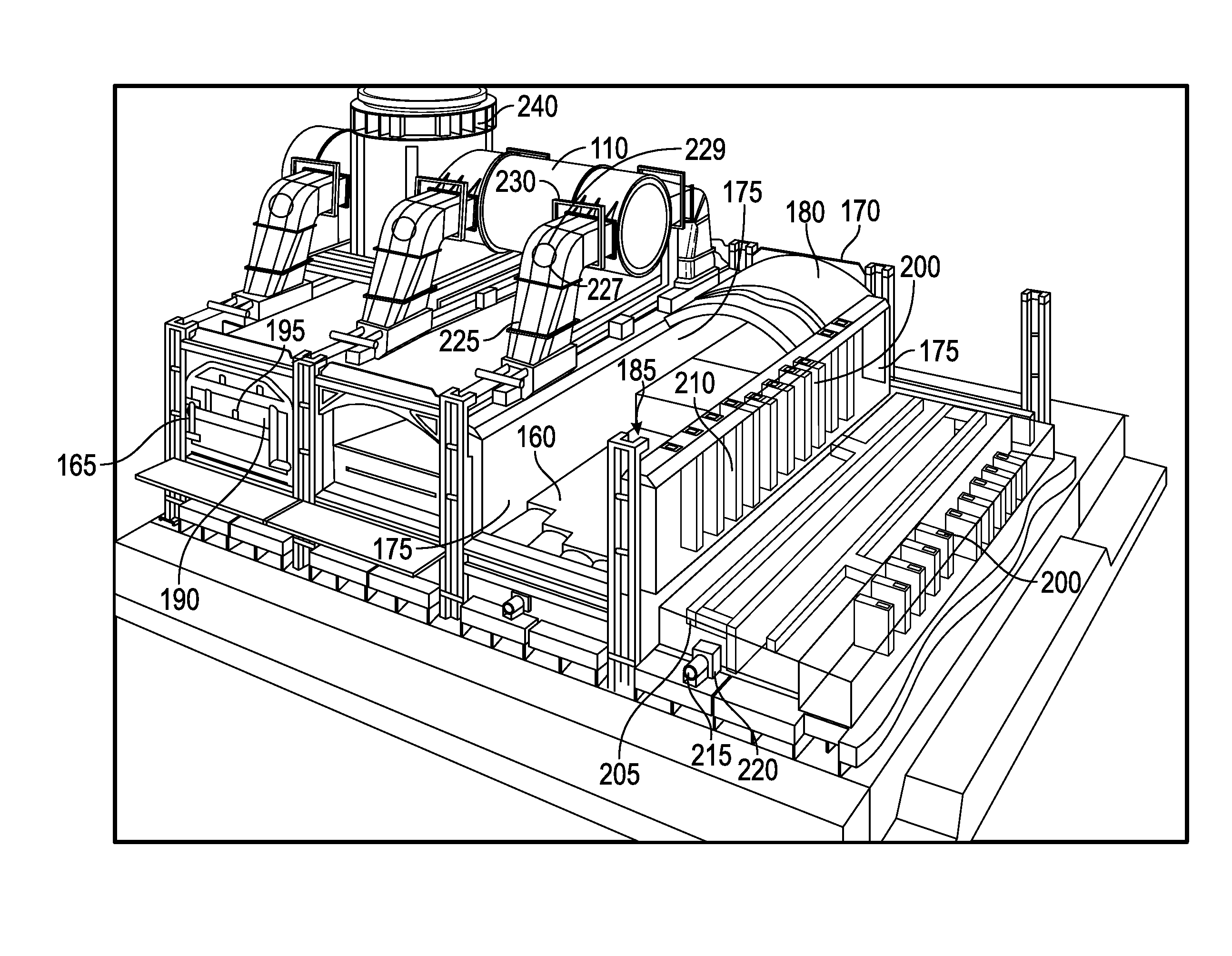

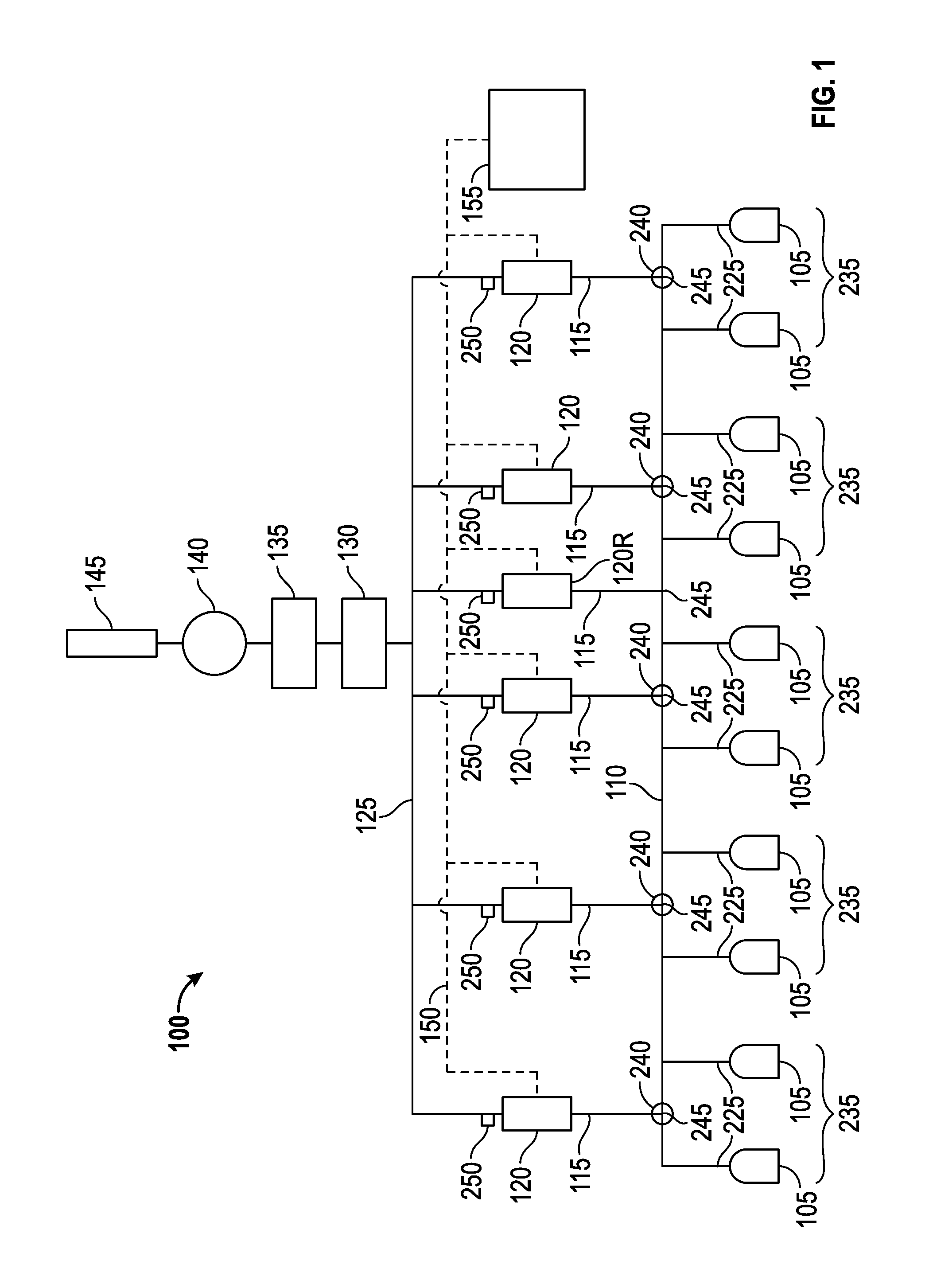

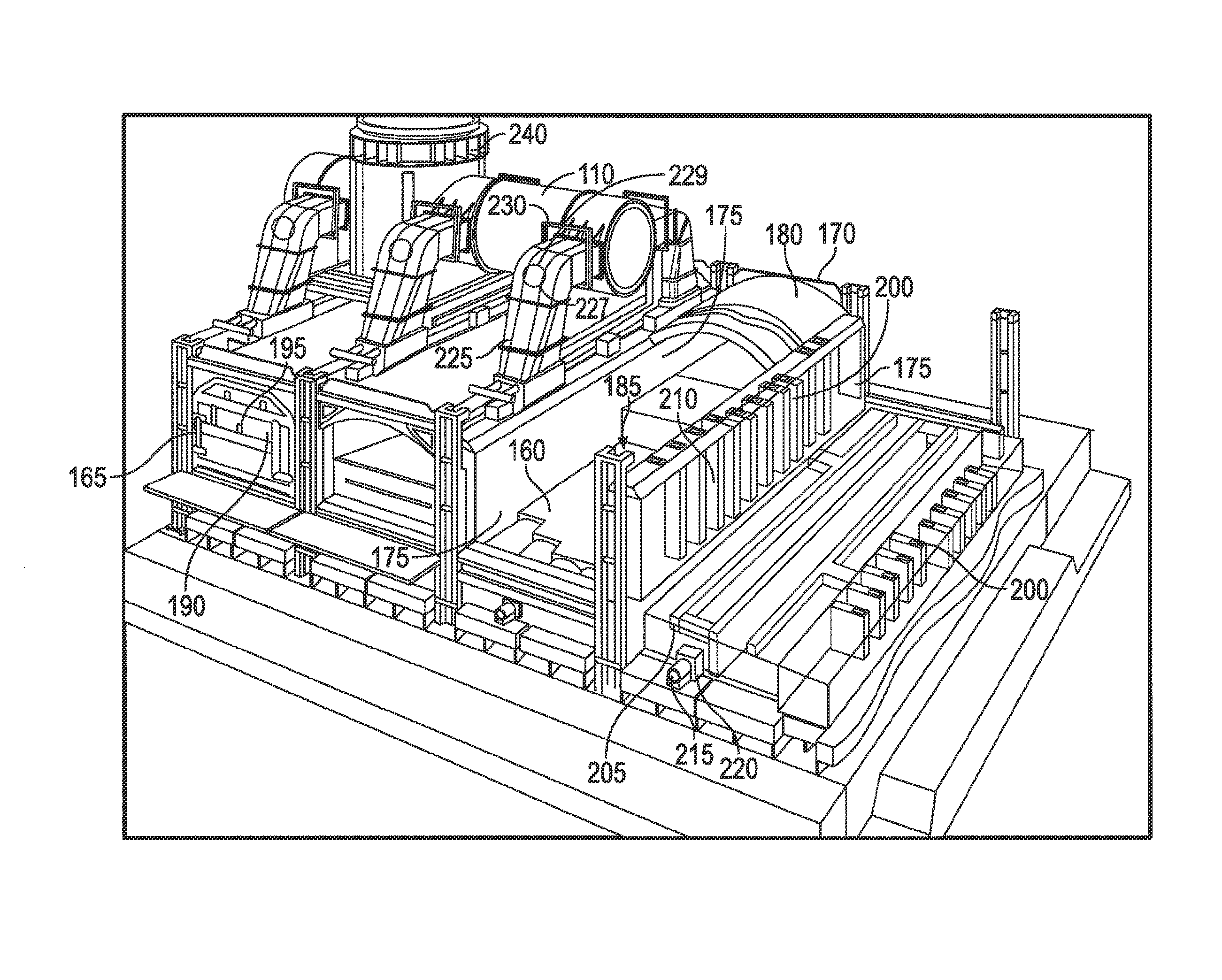

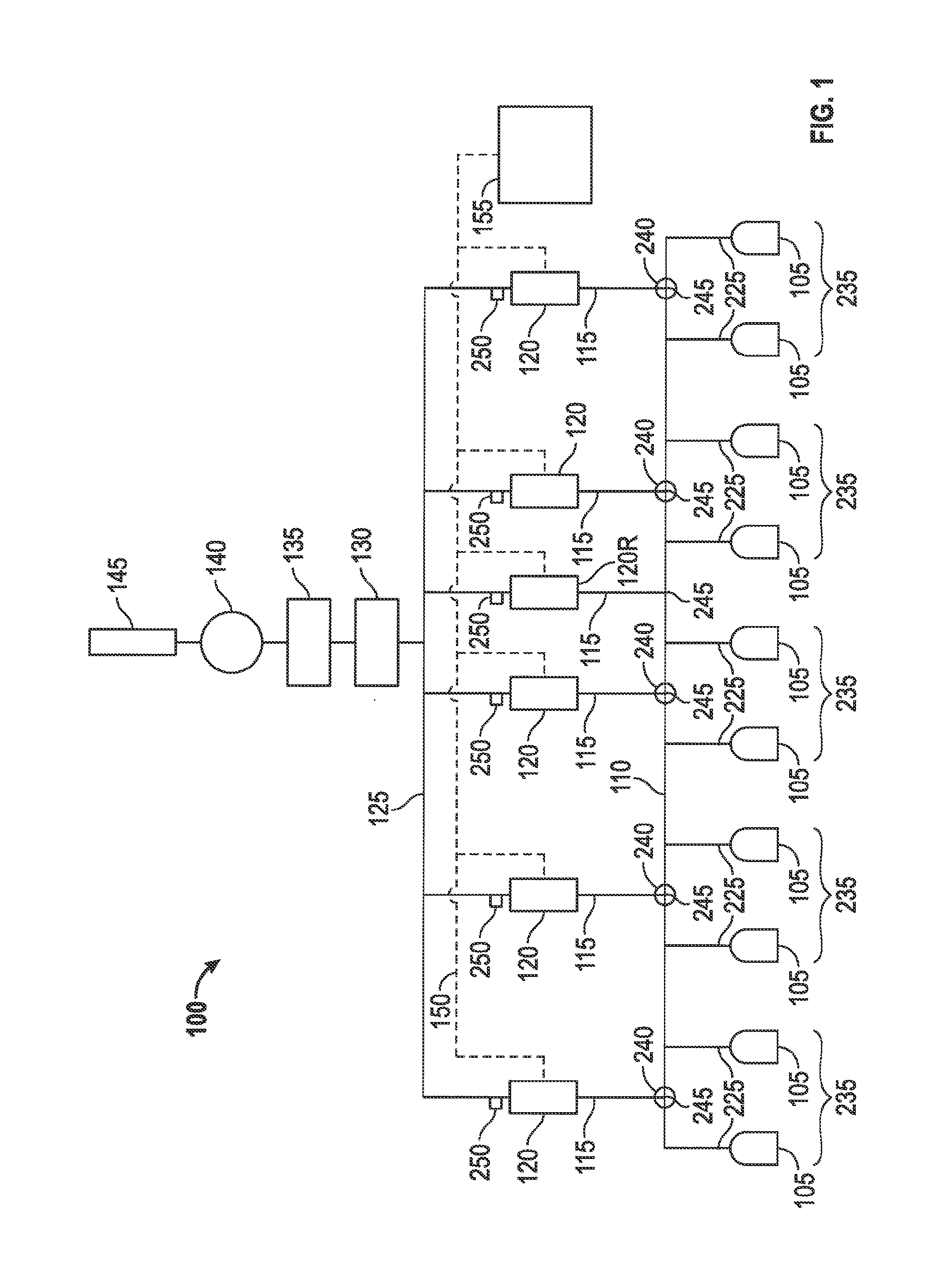

Coke plant including exhaust gas sharing

ActiveUS9243186B2Coke oven safety devicesHorizontal chamber coke ovensExhaust fumesProcess engineering

A coke plant includes multiple coke ovens where each coke oven is adapted to produce exhaust gases, a common tunnel fluidly connected to the plurality of coke ovens and configured to receive the exhaust gases from each of the coke ovens, multiple standard heat recovery steam generators fluidly connected to the common tunnel where the ratio of coke ovens to standard heat recovery steam generators is at least 20:1, and a redundant heat recovery steam generator fluidly connected to the common tunnel where any one of the plurality of standard heat recovery steam generators and the redundant heat recovery steam generator is adapted to receive the exhaust gases from the plurality of ovens and extract heat from the exhaust gases and where the standard heat recovery steam generators and the redundant heat recovery steam generator are all connected in parallel with each other.

Owner:SUNCOKE TECH & DEV LLC

Air proportioning system for secondary air in coke ovens depending on the vault vs. sole temperature ratio

ActiveUS8980063B2Easy to useCombustible gas coke oven heatingCoke oven safety devicesCombustionCoke oven

A device for proportioning of secondary combustion air into the secondary air soles of coke oven chamber ovens is shown. The device is formed by a slide gate or a parallelepiped device or by plates moved by means of a thrust bar, the thrust bar being moved longitudinally in parallel to the coke oven chamber wall so that the plates move away from the secondary air apertures and open or close these. The thrust bar is moved by means of a positioning motor, with the power transmission being effected hydraulically or pneumatically. Via suitable measuring parameters, it is thus possible to optimize secondary heating so that heating is provided evenly from all sides, thus achieving an improvement in coke quality.

Owner:THYSSENKRUPP IND SOLUTIONS AG

Coke plant including exhaust gas sharing

ActiveUS20140048405A1Mechanical conveying coke ovensCoke oven safety devicesCoke ovenProcess engineering

A coke plant includes multiple coke ovens where each coke oven is adapted to produce exhaust gases, a common tunnel fluidly connected to the plurality of coke ovens and configured to receive the exhaust gases from each of the coke ovens, multiple standard heat recovery steam generators fluidly connected to the common tunnel where the ratio of coke ovens to standard heat recovery steam generators is at least 20:1, and a redundant heat recovery steam generator fluidly connected to the common tunnel where any one of the plurality of standard heat recovery steam generators and the redundant heat recovery steam generator is adapted to receive the exhaust gases from the plurality of ovens and extract heat from the exhaust gases and where the standard heat recovery steam generators and the redundant heat recovery steam generator are all connected in parallel with each other.

Owner:SUNCOKE TECH & DEV LLC

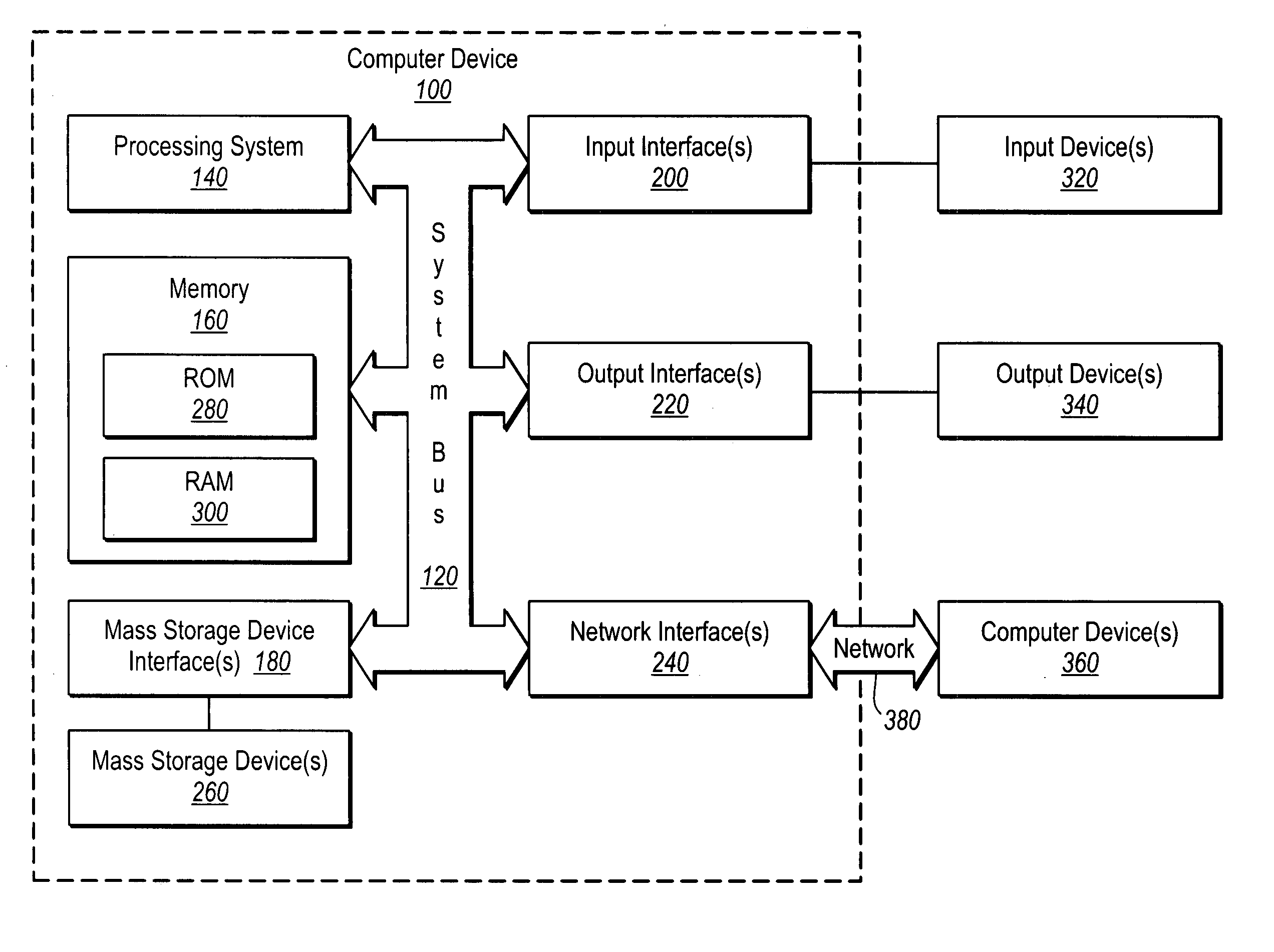

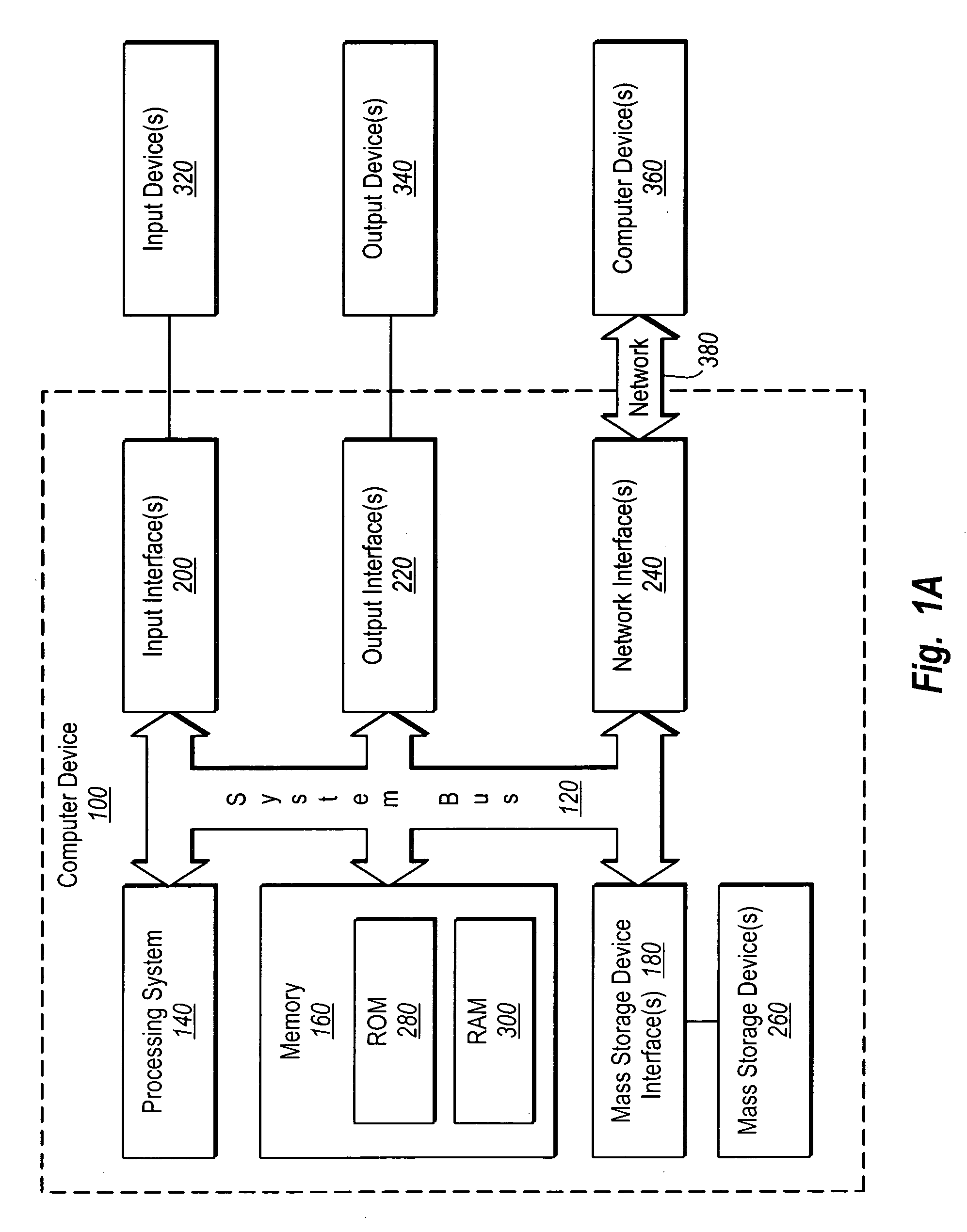

Vibration monitoring

InactiveUS20070038393A1Accurately efficiently preventReliable cuttingVibration measurement in solidsCoke oven safety devicesAccelerometerMonitoring system

Systems, devices, and methods for monitoring the status of a cutting tool during delayed decoker unit operation, and systems for remotely monitoring the level of coke or foam in a drum during the coking process. One or more sensors or accelerometers is coupled to a location in a delayed coking unit operation to read vibrations emanating from the component that the respective accelerometers are located on. Vibrational data is transmitted to a computer system that manipulates the data to provide useful information that an operator of a delayed coking unit operation may view.

Owner:CURTISS WRIGHT FLOW CONTROL CORP

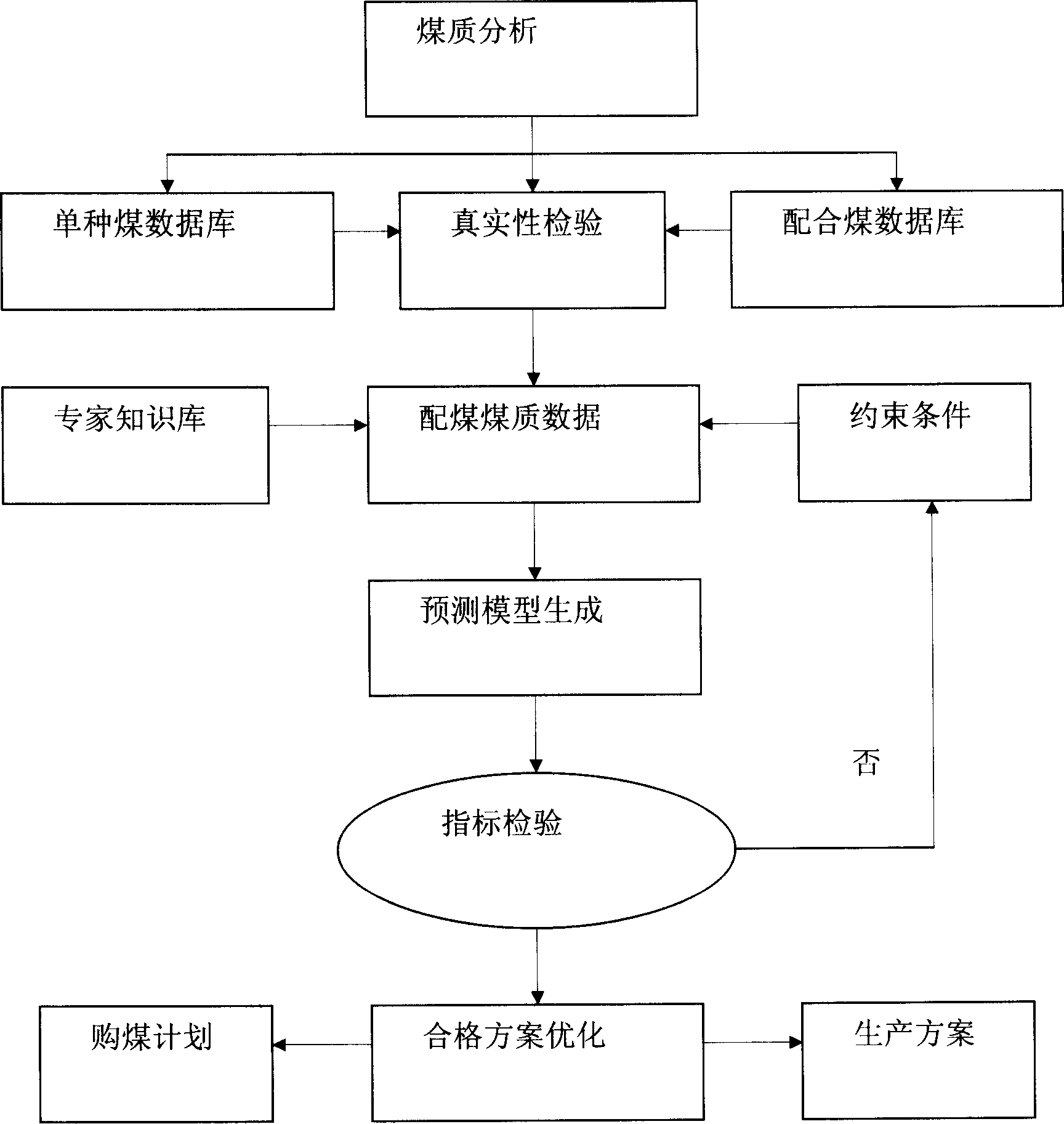

Method for calculating thermal property of coke and control method therefor

This invention relates ti coke heat quality preprocess and control method. First enterprise coal using history is analyzed to get coal resource database information and certain coal caking capacity and evaluation information to coke quality contribution. Expert system knowledge base is built, it relates to coal resource situation, coal blending and coking technique, transportation, coke quality goal, coal blending cost etc. each single coal using constraint condition is ensured according to the knowledge base, optimization coal blending ratio is ensured by using nonlinear planning and simulation evolution algorithm. Coke quality predicted value under optimization match is predicted by coke quality prediction model to produce optimization coal ratio, coal blending slot operation is auto controlled by computer to correct control model according to practical production. This method can solve the problems in coking coal resource effective using, coke heat control and low cost coal blending.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

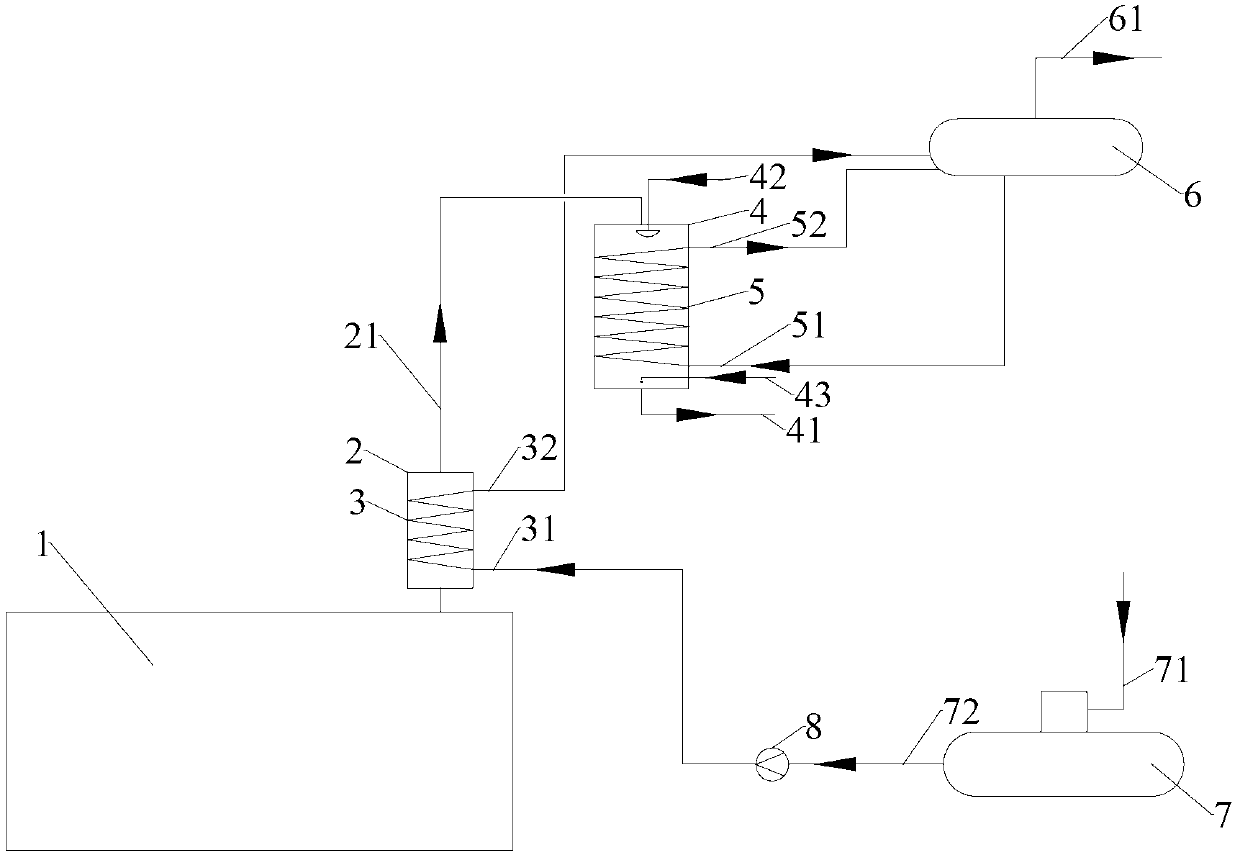

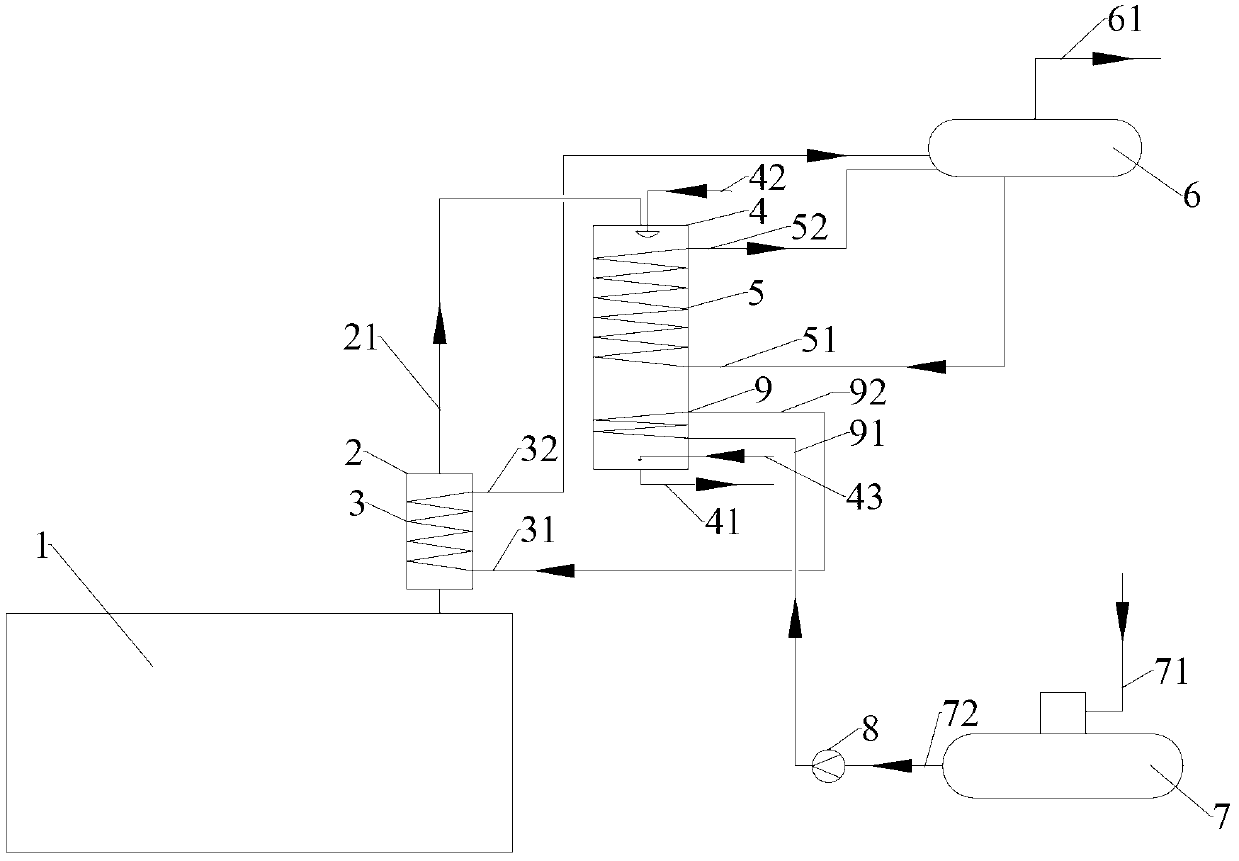

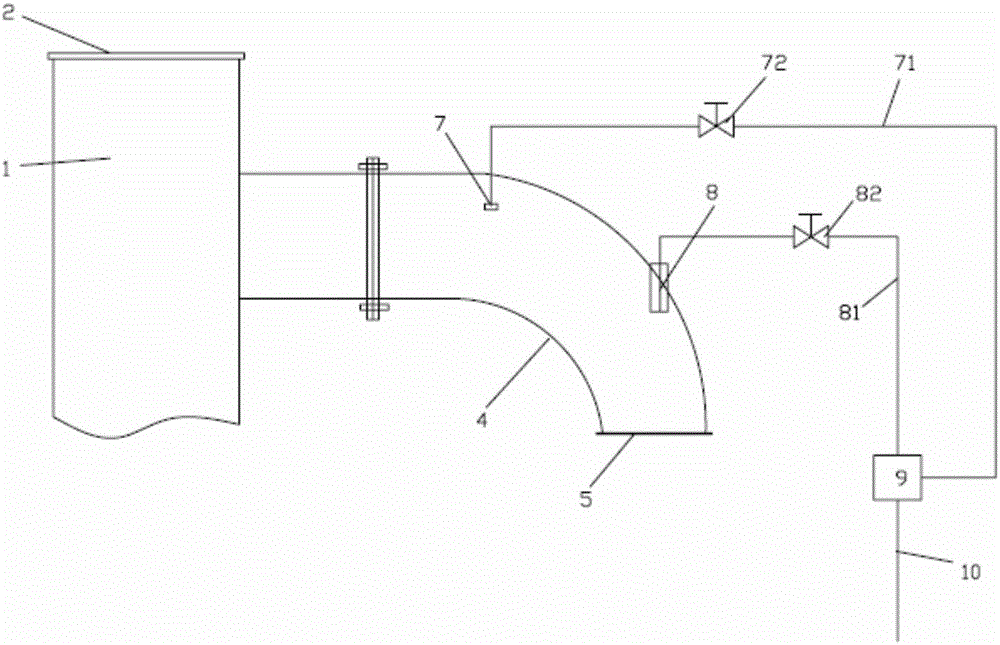

Method for recovering waste heat from coke oven raw gas

ActiveCN103131432AQuality assurancePrevent poppingCoke oven safety devicesEnergy inputWater vaporCoke oven

The invention relates to a method for recovering waste heat from a coke oven raw gas. The method utilizes water as a heat exchange medium, water exchanges heat with the raw gas having a temperature of about 650-750DEG C in a riser heat exchanger, the temperature of the raw gas subjected to the heat exchange decreases to 480-550DEG C, the heat exchange medium forms a vapor-water mixture after heating, and enters a vapor bag, and the vapor-water mixture is separated to form high temperature water and saturated vapor by a vapor-water separator in the vapor bag; the raw gas discharged from the riser heat exchanger undergoes heat exchange in a bridge tube heat exchanger, the temperature of the raw gas subjected to the heat exchange decreases to 280-350DEG C, and the high temperature water obtained after the separation of the vapor-water separator undergoes heat exchange by the bridge tube heat exchanger, enters the vapor bag and generates saturated vapor, wherein the outer wall of the heat exchanger is cleaned through high-pressure ammonia water intermittent spray or water vapor intermittent blow in the bridge tube; and finally the temperature of the raw gas is reduced to 80-85DEG C by adopting ammonia water, and then the raw gas enters a gas collection tube. The method furthest recovers the waste heat of the raw gas and guarantees the continuous normal work of the heat exchangers under a complex condition.

Owner:BEIJING RISUN TECH CO LTD

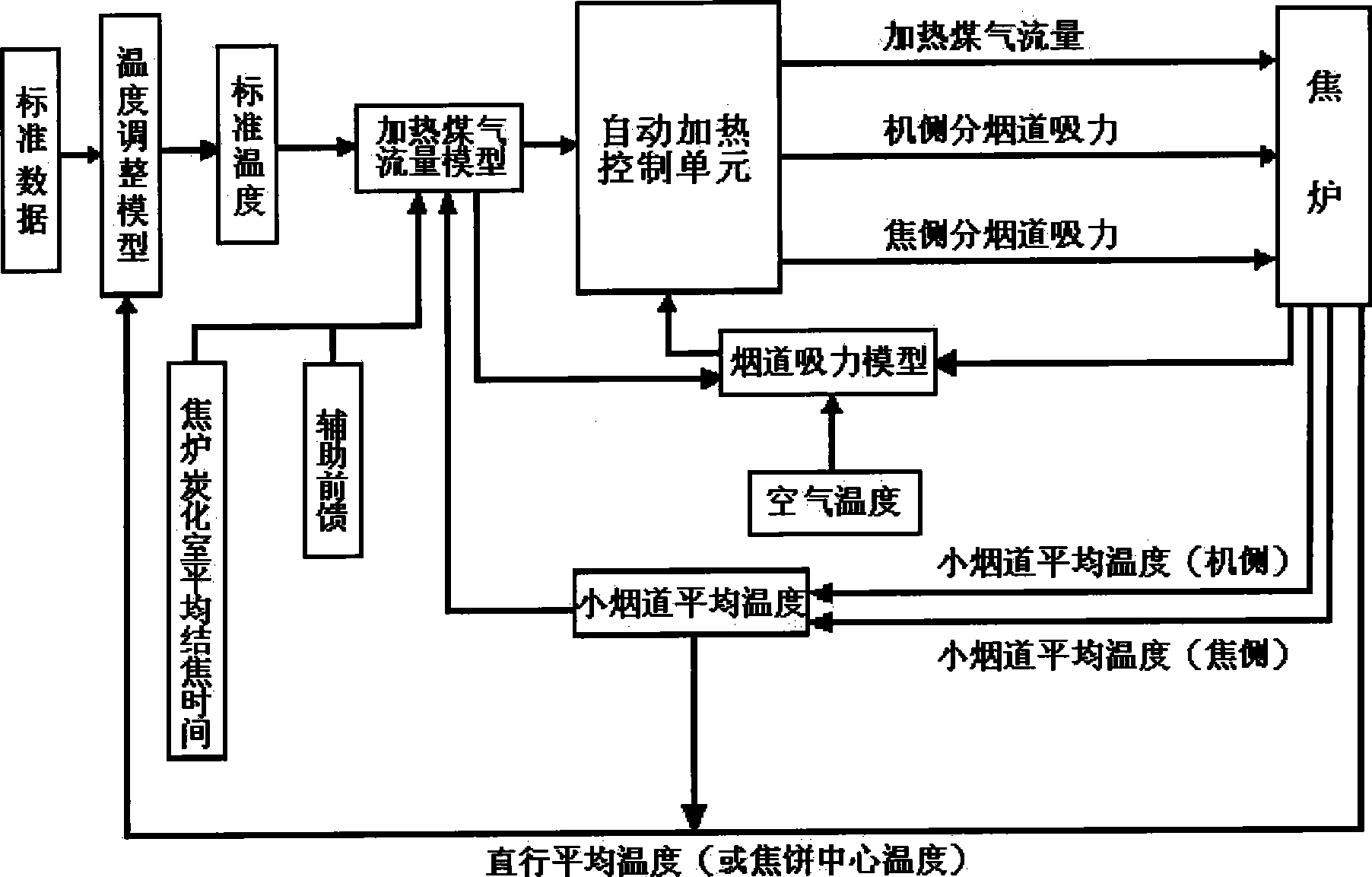

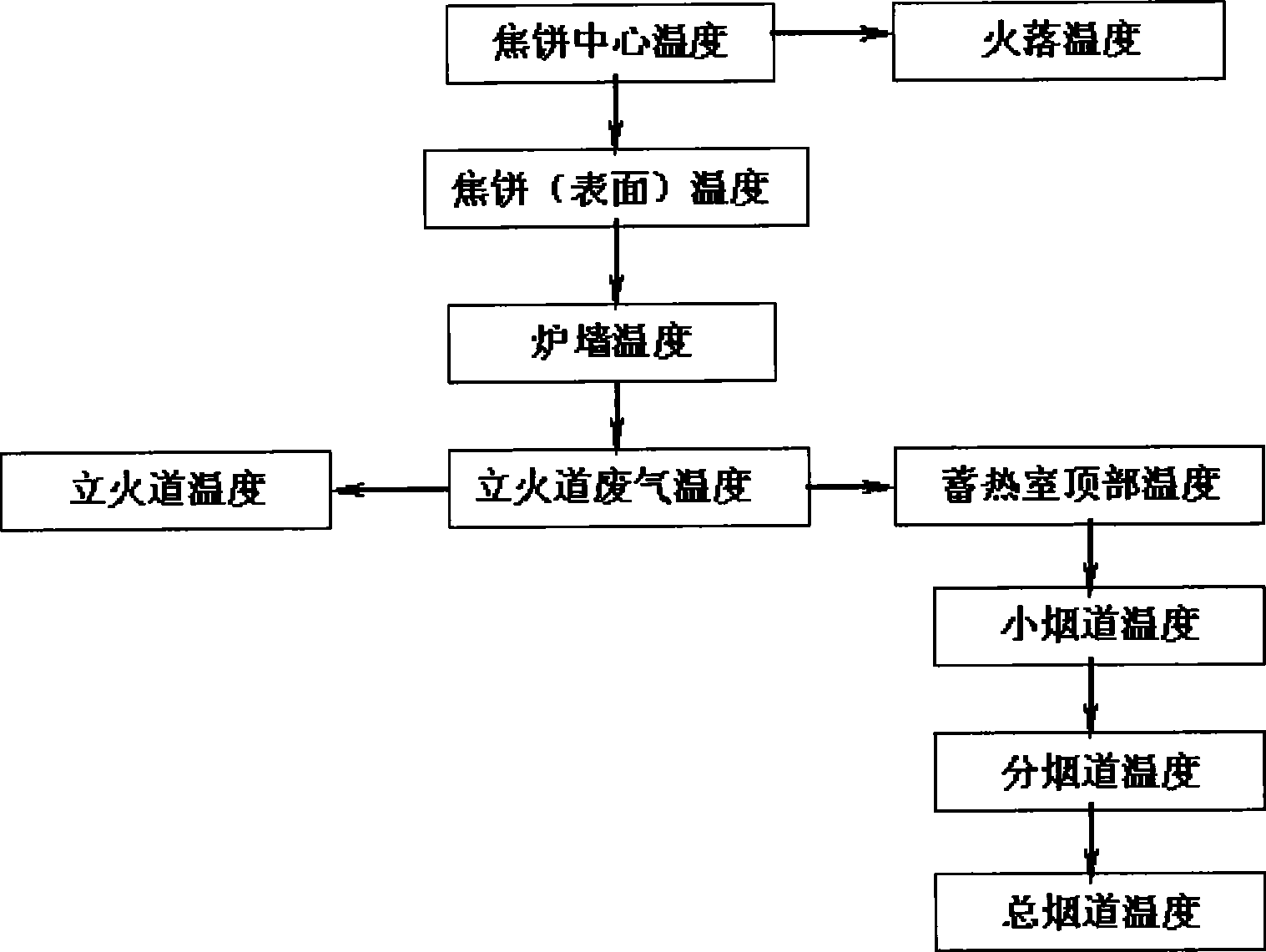

Automation control method for coke oven heating

InactiveCN101372622AGood correlationTemperature controlCombustible gas coke oven heatingCoke oven safety devicesAutomatic controlCoke oven

The invention relates to a coke oven heating automatic control method; in the method, the temperature of a coke oven is measured, a coke oven heating gas flow rate model and a sub-flue suction model are used for calculating heating gas flow rate Q and sub-flue suction a which are respectively controlled to realize the control over the temperature of the coke oven. The method can achieve the purposes of enhancing the control precision of the temperature of the coke oven, improving the quality of coke, maximally reducing the heat consumption in coking and saving energy by mastering and utilizing the change law of the temperature of the coke oven in the coke oven heating automatic control process.

Owner:尚文彬

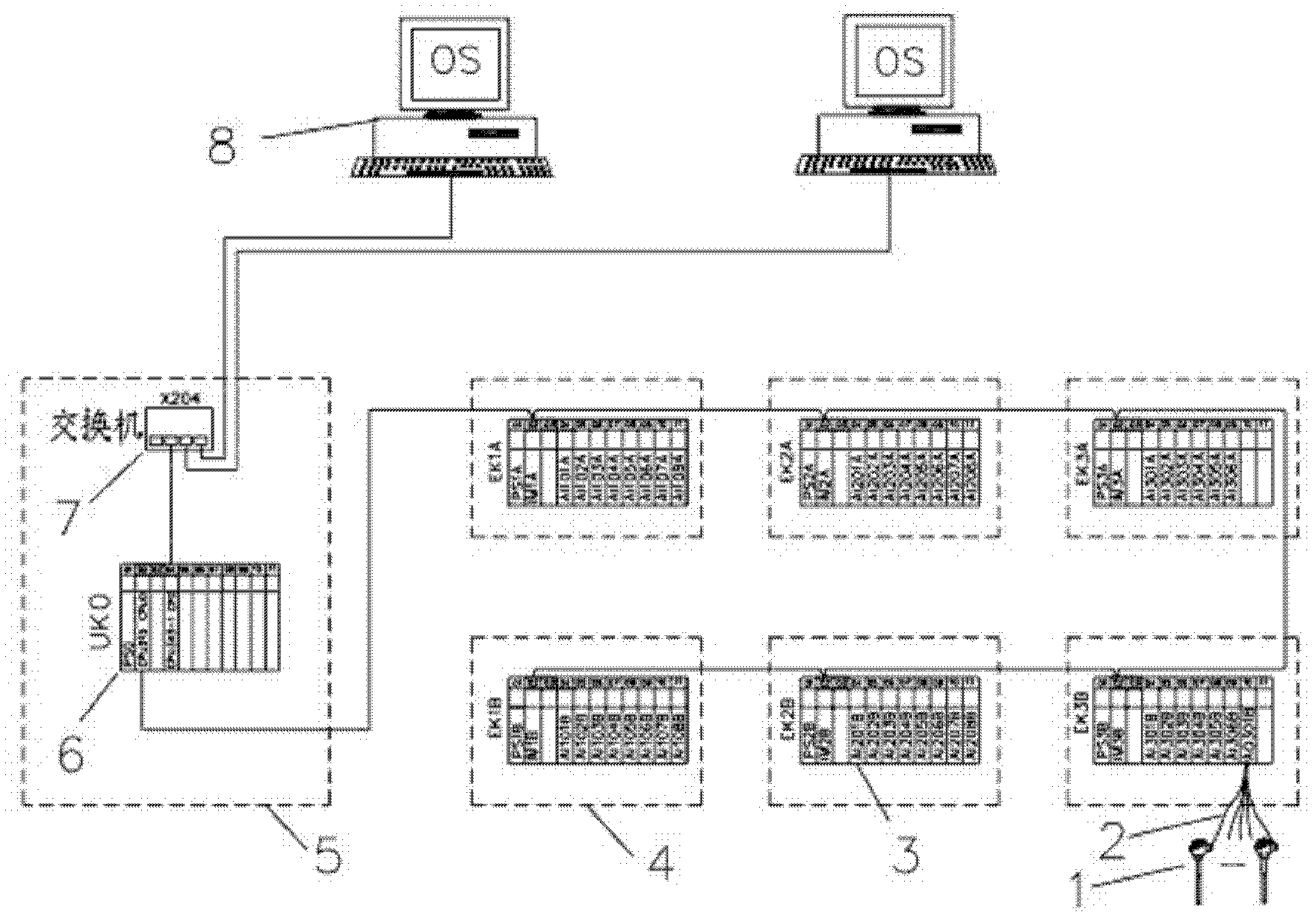

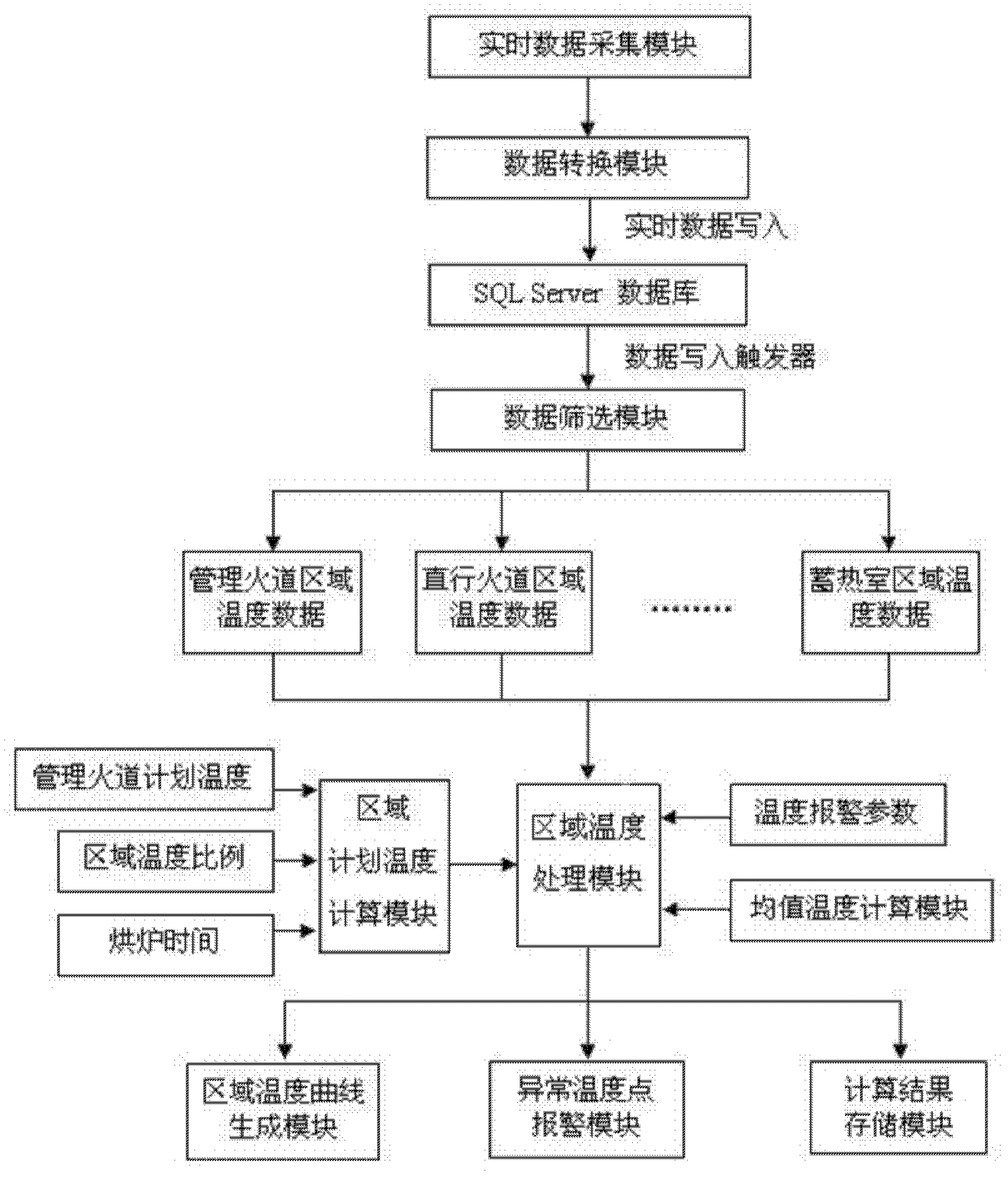

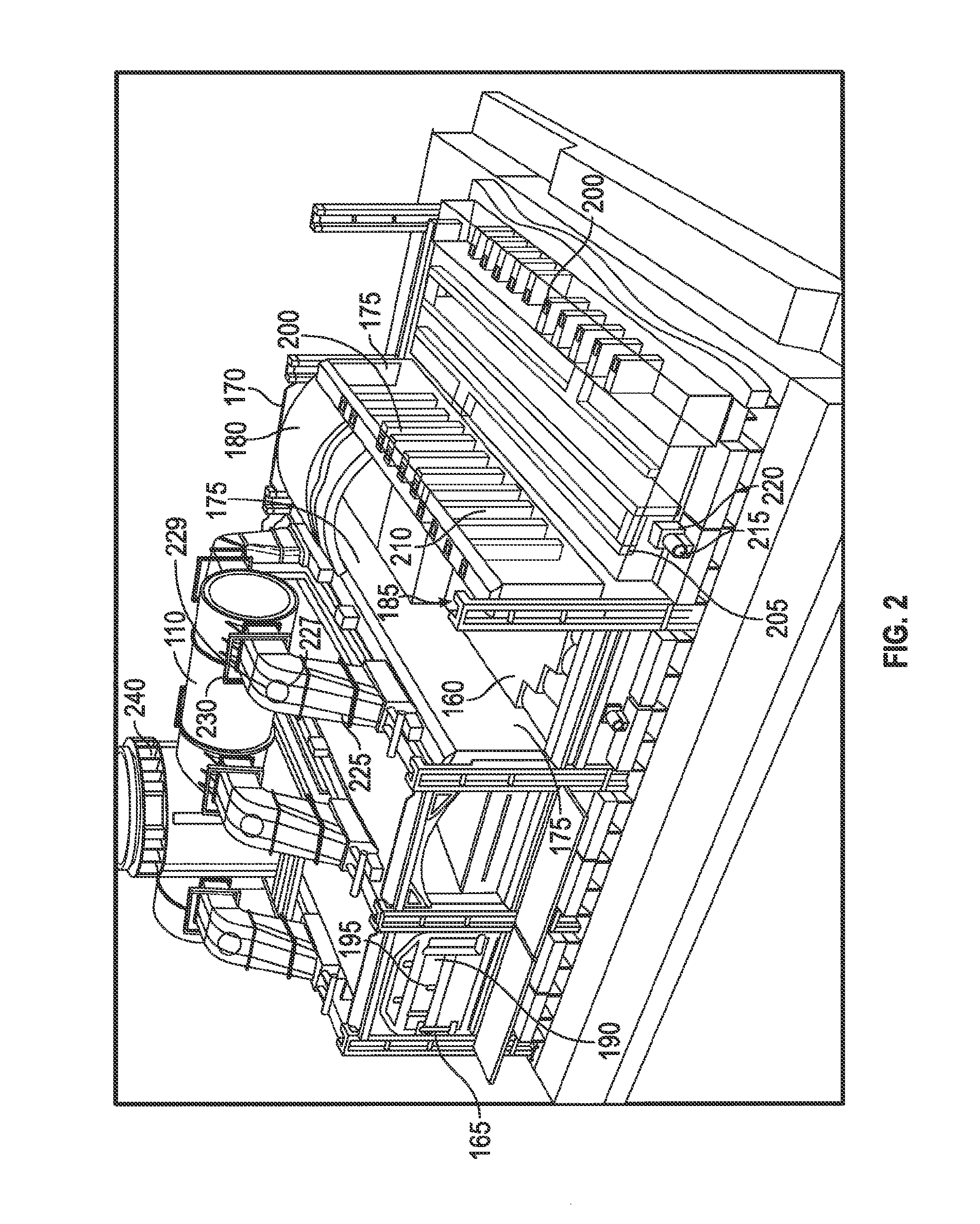

Automatic detection and analysis system for temperatures at multiple points of coke oven baking

InactiveCN102322970AContinuous acquisitionAccurate collectionThermometer detailsCoke oven safety devicesMultiple pointEngineering

The invention relates to the technical field of coke oven baking process, disclosing an automatic detection and analysis system for temperatures at multiple points of coke oven baking. The automatic detection and analysis system comprises a thermoelectric couple, a compensation lead, a lower computer, a switch board and an upper computer, wherein the upper computer comprises an upper computer work station and a redundancy upper computer work station which are respectively connected with the switch board and respectively comprise a database, a real-time data acquisition module, a data conversion module and a data integrated processing module. According to the automatic detection and analysis system disclosed by the invention, the stability and the data analysis capability of the temperature detection and analysis system in the coke oven baking process can be improved; the process maintenance load, the management cost and the fault rate of equipment are reduced; the coke oven baking quality is improved; the function of full-automatic detection and analysis of temperatures at the multiple points of the coke oven baking is achieved; the actual temperature of a furnace body is ensured to be basically matched with a planned temperature curve; the daily expansion ratio of a coke oven building body is controlled within normal range; the smooth implementation of a coke oven process is ensured; and the quality of the coke oven body is improved.

Owner:武汉钢铁有限公司

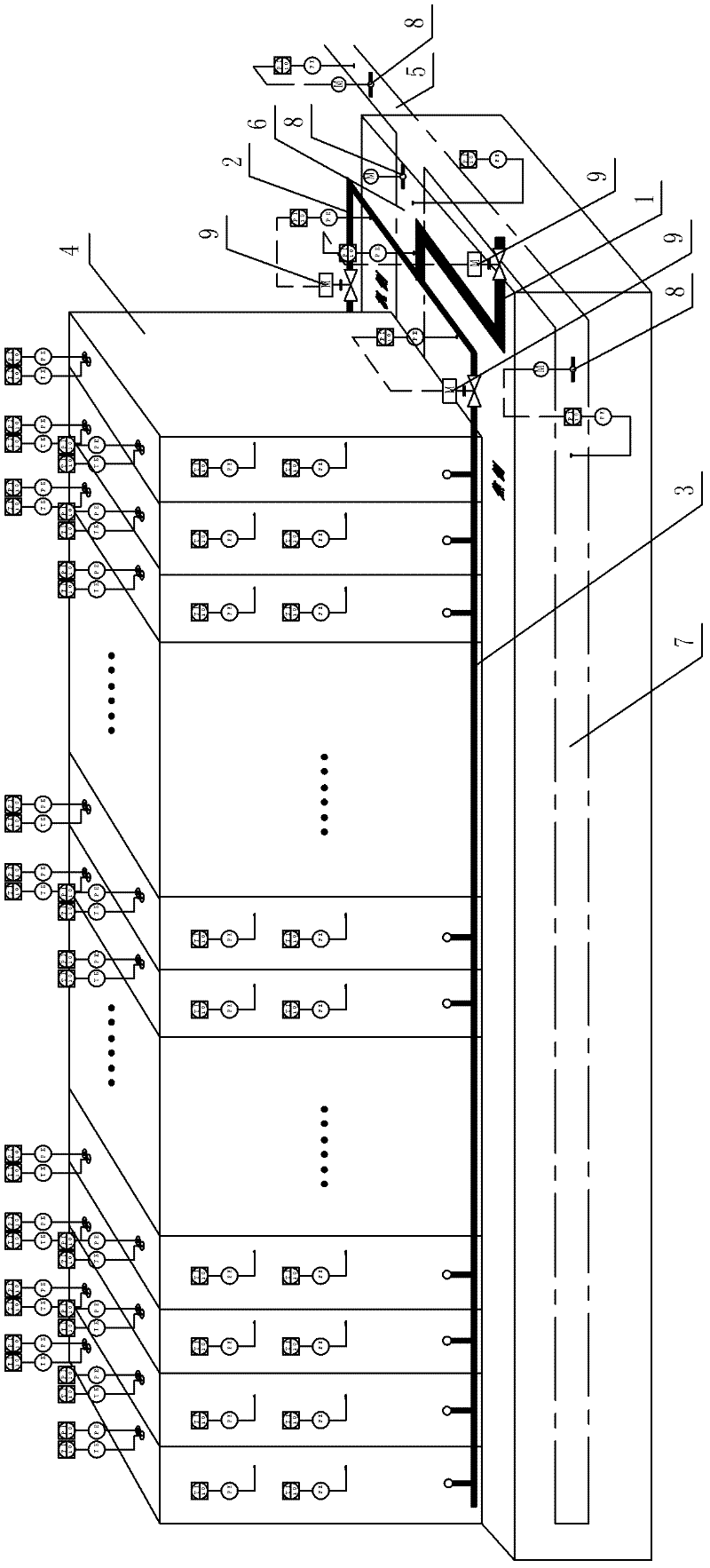

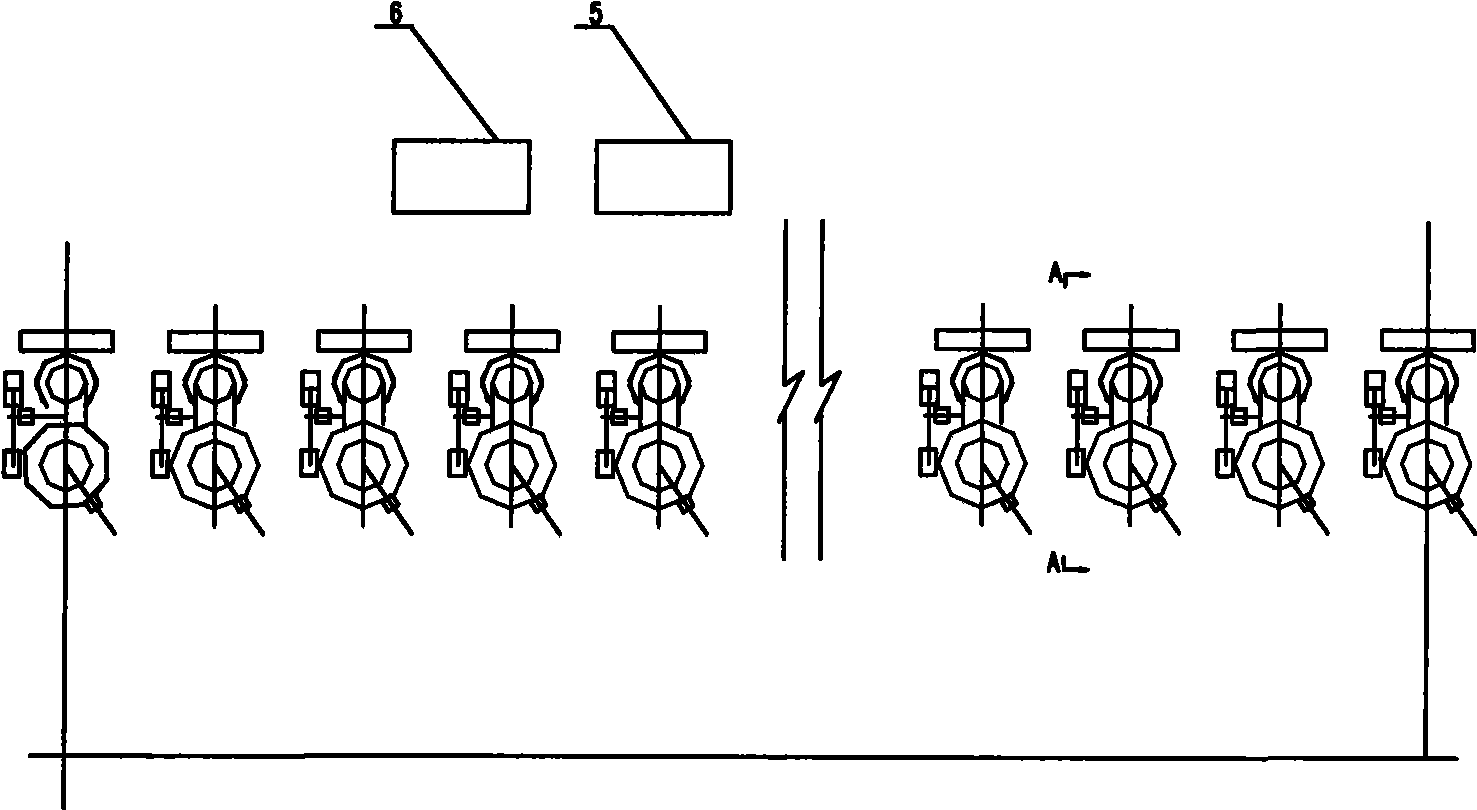

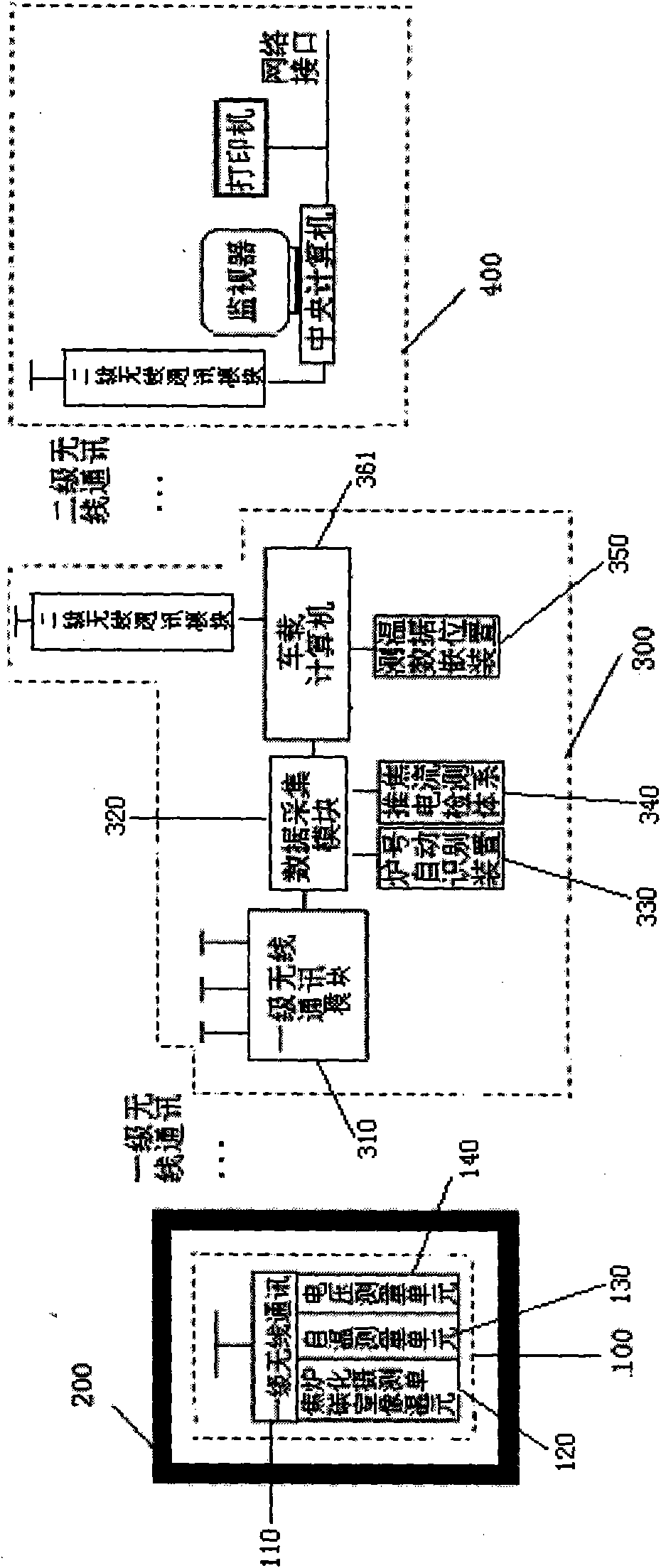

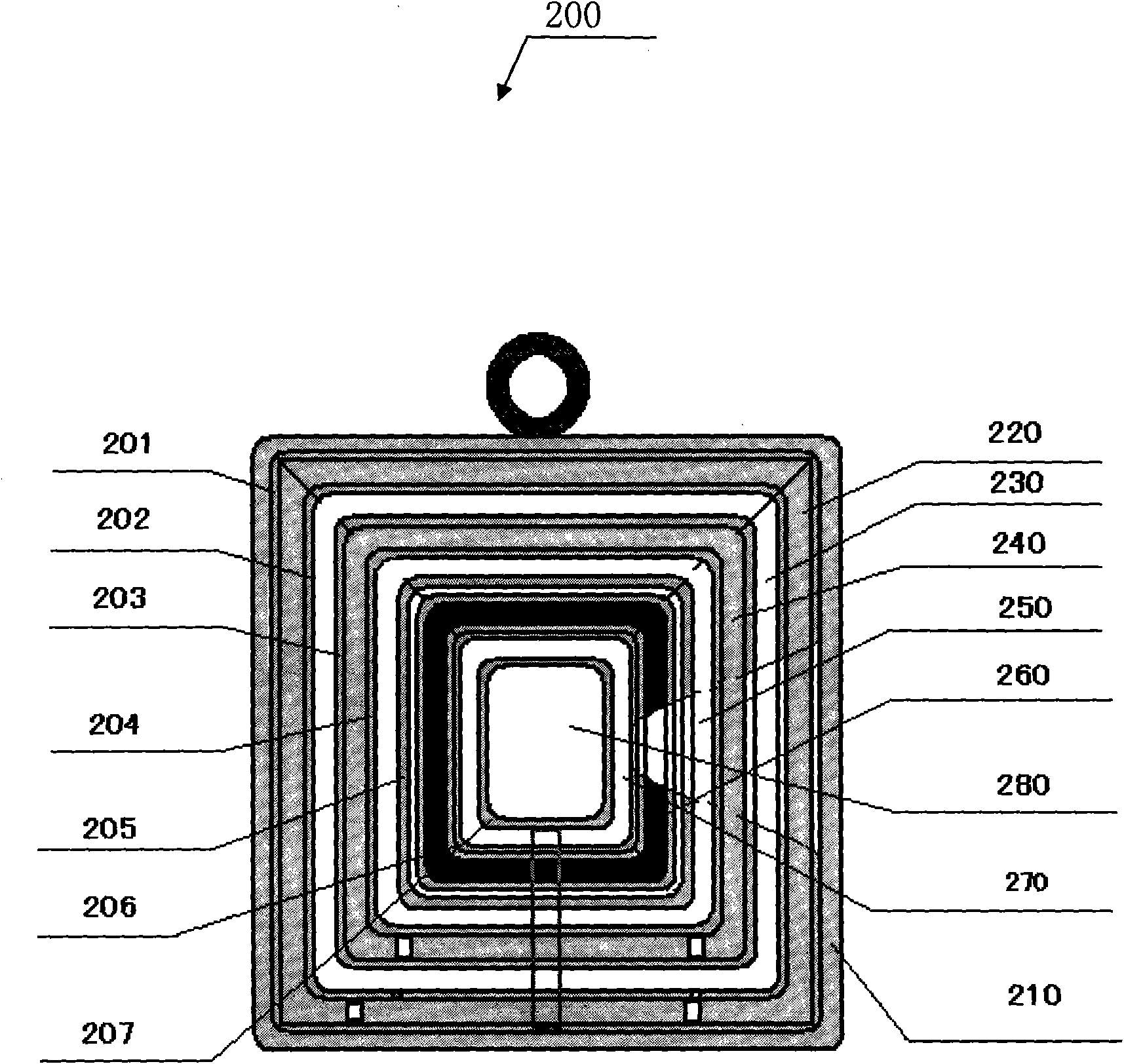

Infrared encoded positioning based automatic operation control system for four machines of cokery

InactiveCN1456635AExtended service lifeReduce labor intensityCoke oven safety devicesInfraredAutomatic train control

An automatic control system based on infrared encoding and locating technique for the coke pusher, coke guide, coke quencher and coal loader of coke oven features that the computer is used for autocontrol and management, the infrared encoding and locating unit is used for position detection, the digital communication hardware platform, PLC and industrial control computer are used for communication, which has 7-layer protocol and master-slave structure, and the low-speed high-torque driver with frequency-charging step speed regulation is used for control running of locomotives. Its advantages are high productivity, high correctness and high reliability.

Owner:北京金日新事业技术有限公司

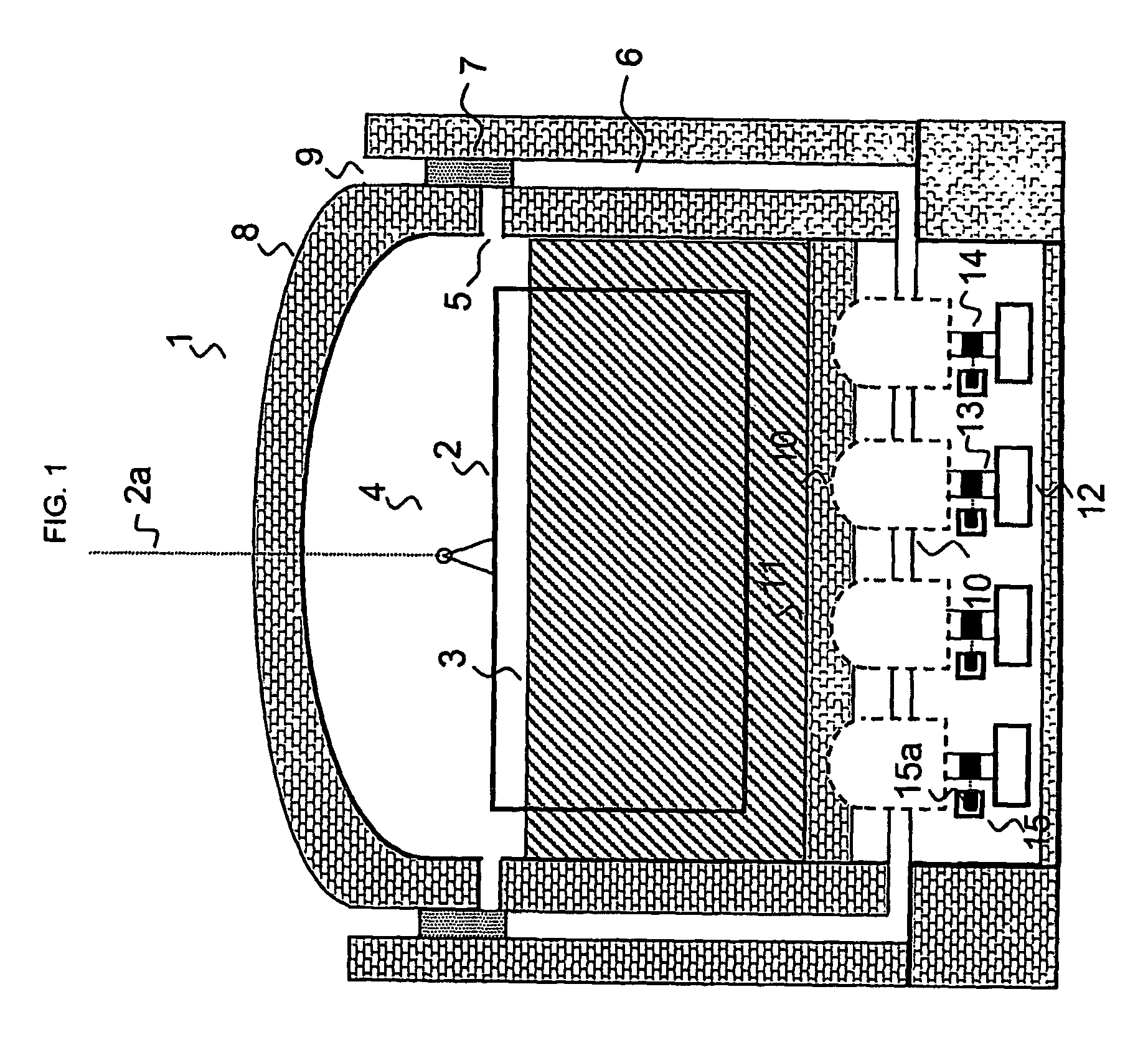

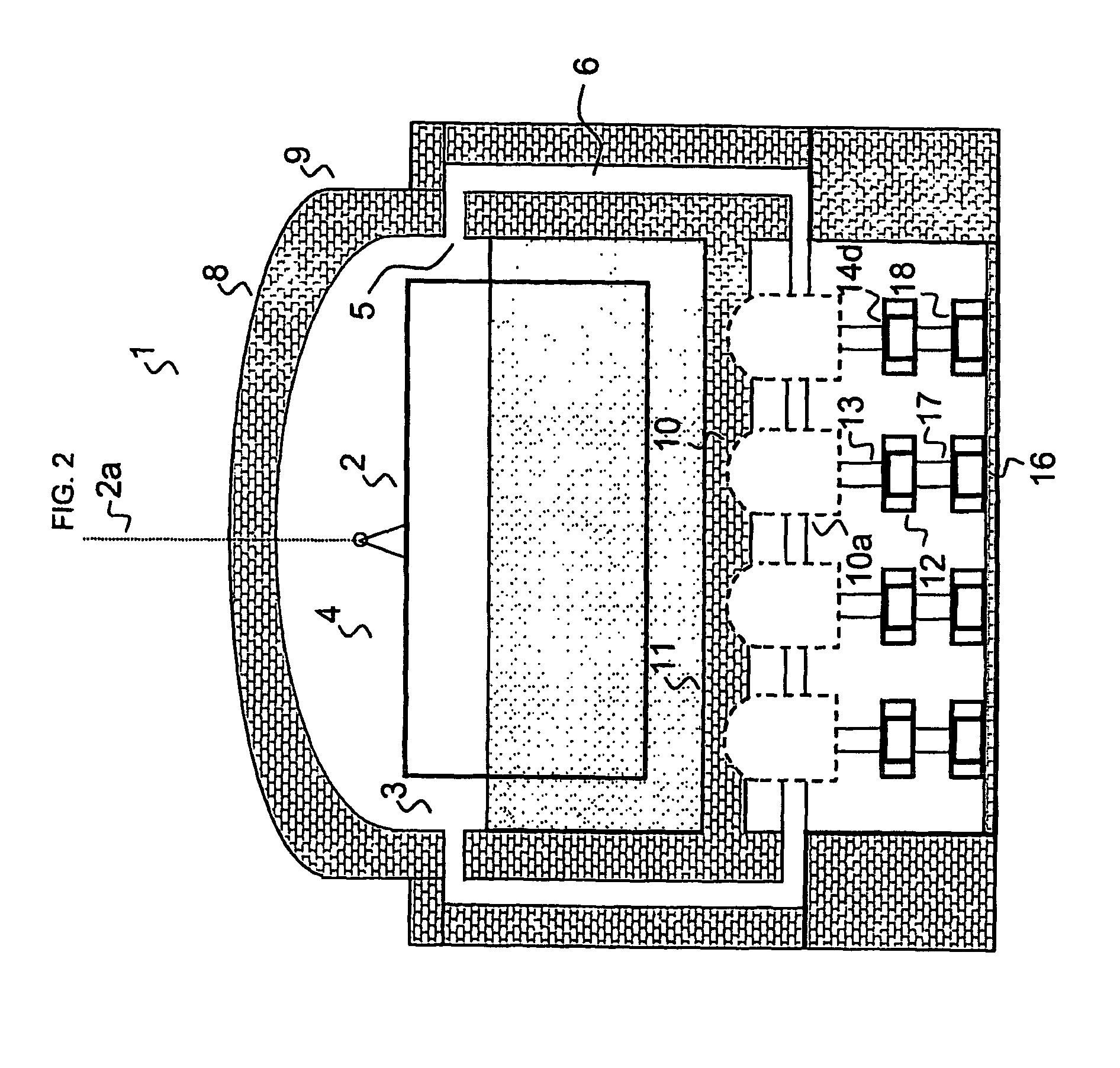

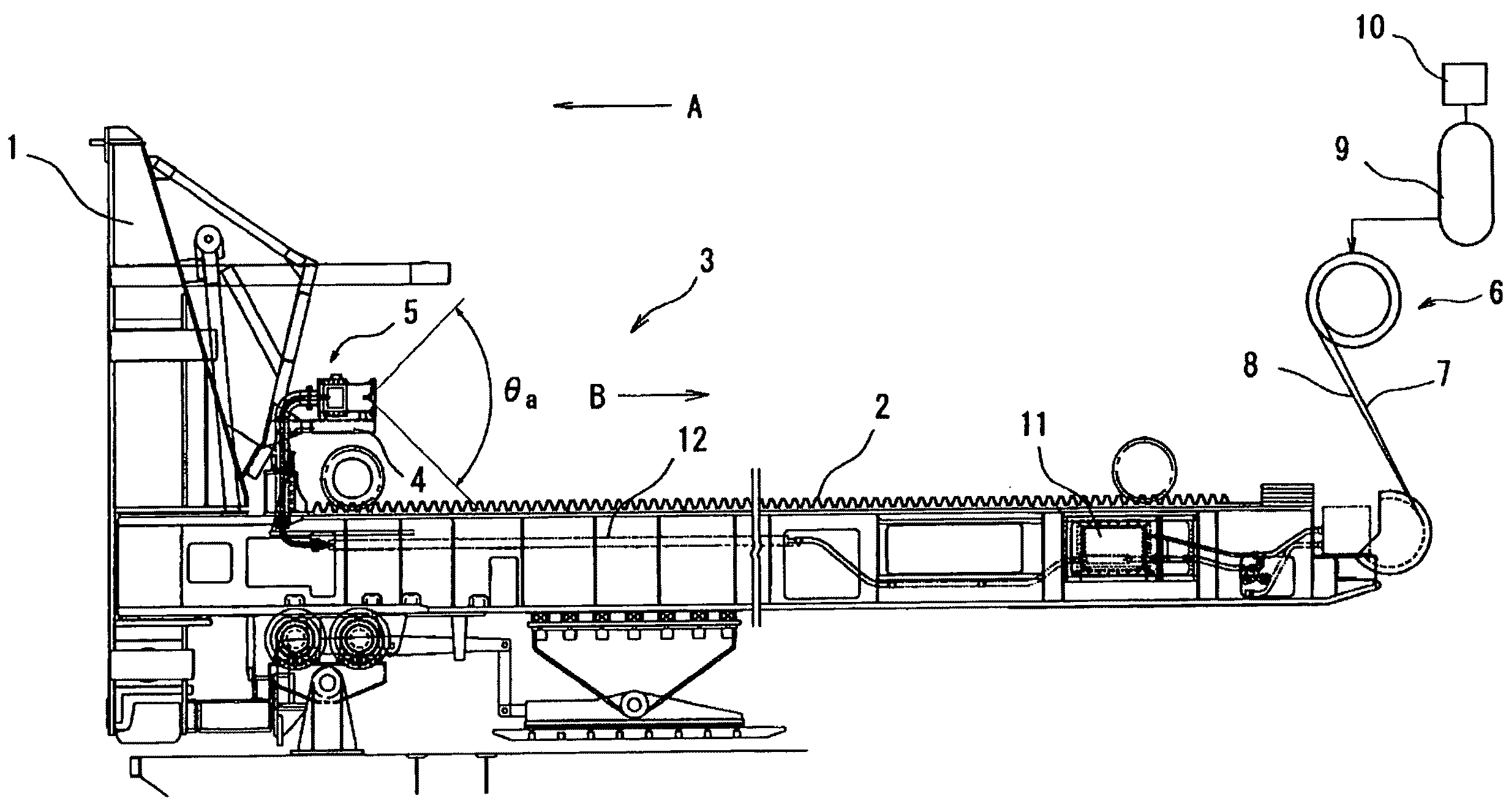

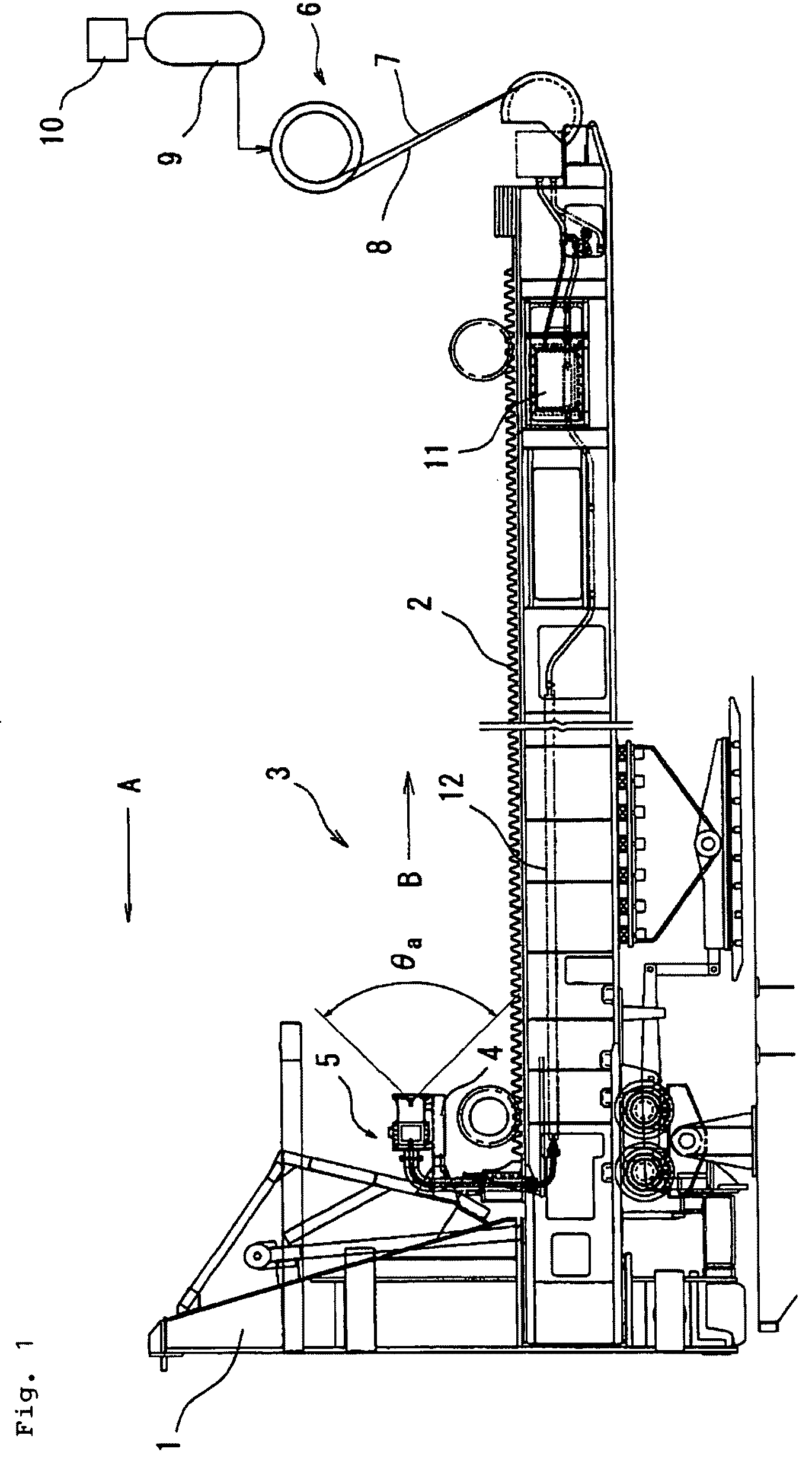

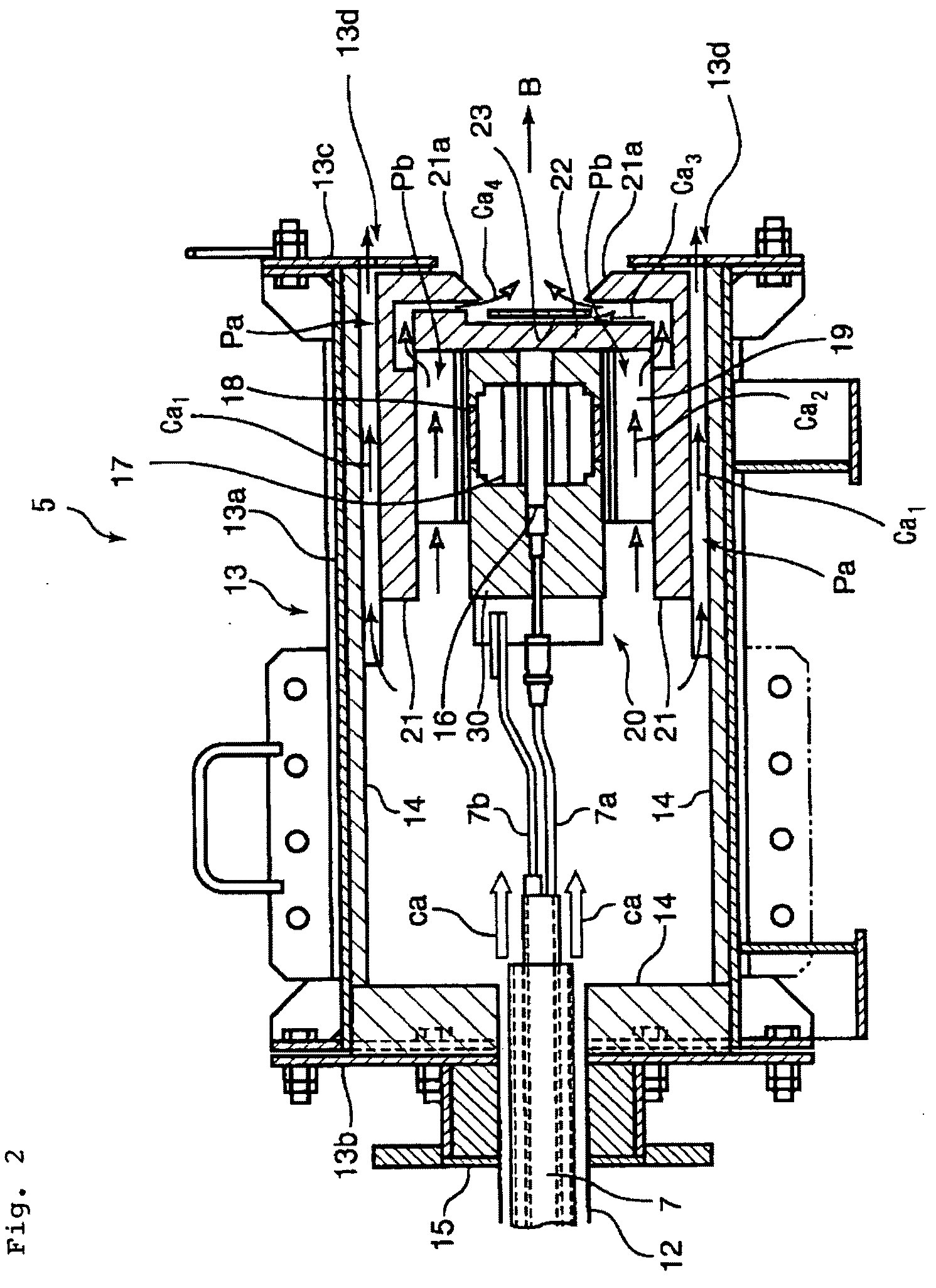

Oven Observing Equipment and Push-Out Ram Having the Same

ActiveUS20090134005A1Improve cooling efficiencyGuaranteed uptimeTelevision system detailsFurnace componentsHeat sinkPush out

An oven observing equipment capable of observing the inside of an oven turned to a high temperature precisely includes: a housing 13 having an intake part for cooling air, and a discharging part for discharging the cooling air after being used for cooling; and an imaging device 20 contained in this housing 13 near the discharge part. This imaging device 20 is composed of integrated combination of an image sensor 16; plate-like thermoelectric cooling elements 18a to 18d arranged in a state that their heat-absorbing faces surround the periphery of a body of the image sensor; thermoconductive blocks 17a to 17d embedded in the gaps between the image sensor body and the thermoelectric cooling elements 18a to 18d; and cooling fins 19a to 19d formed on the heat-radiating faces of the thermoelectric cooling elements 18a to 18d are integrated with each other.

Owner:KANSAI COKE & CHEM

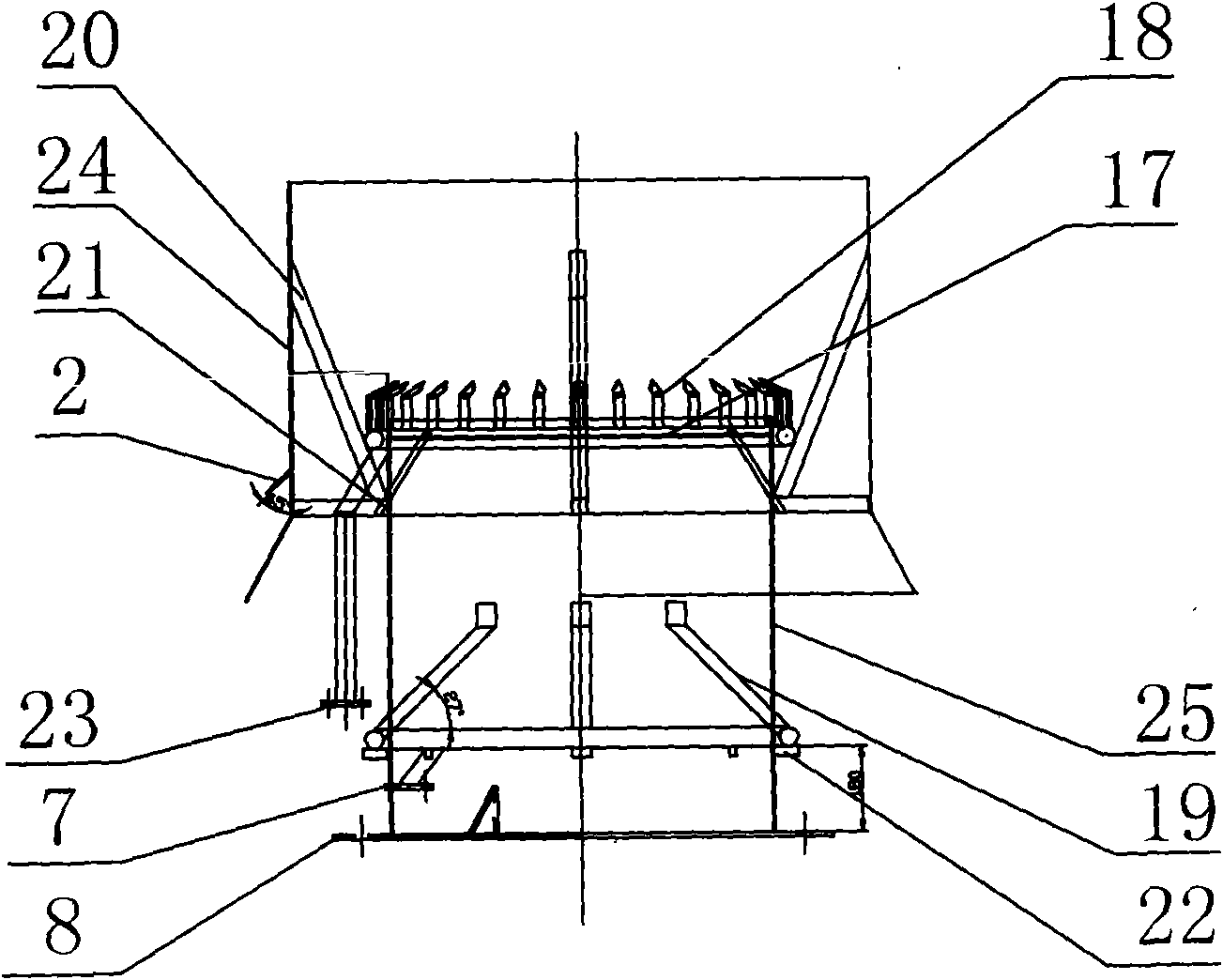

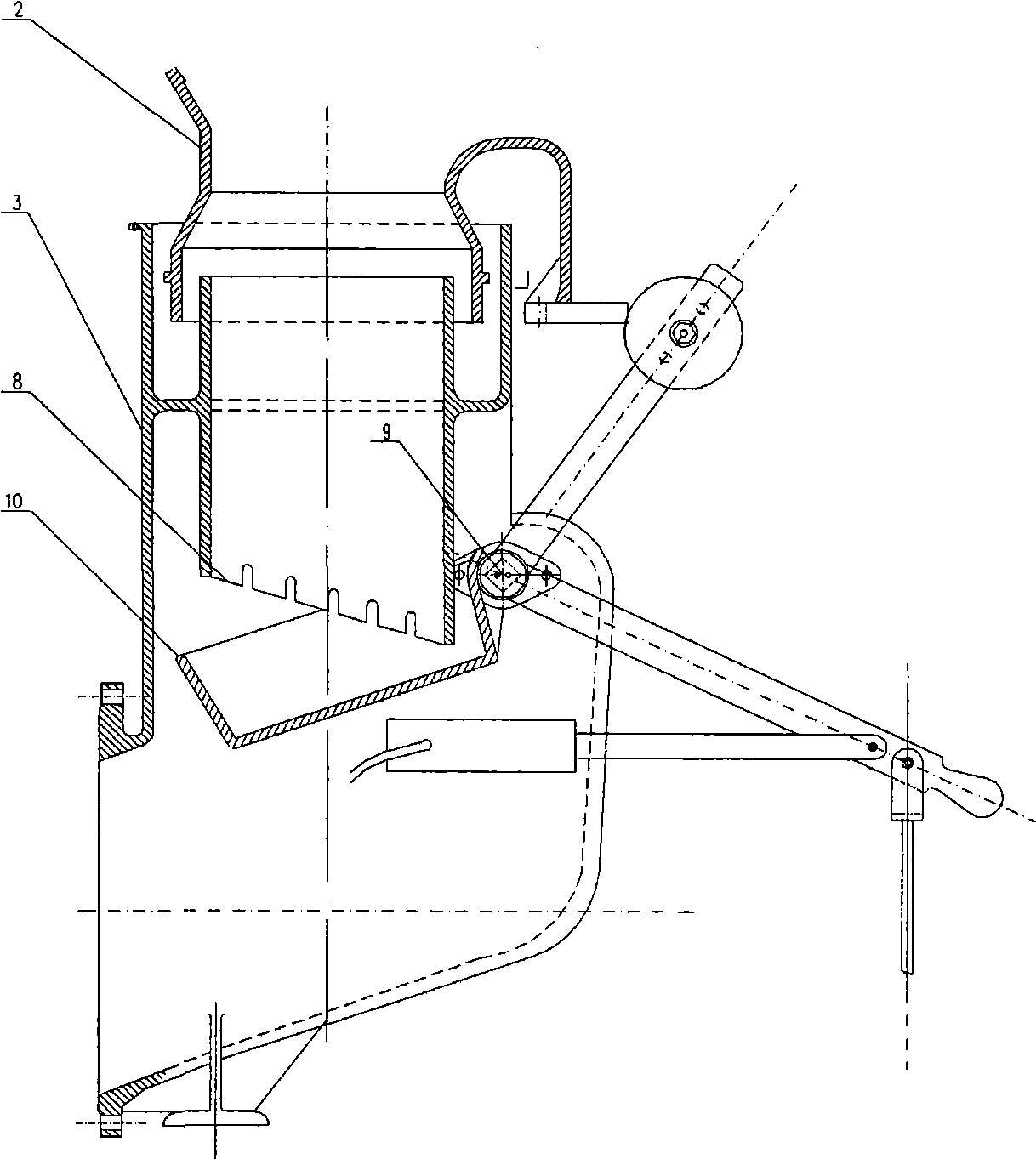

Device and method for pressure regulation of coke oven carbonization chamber

ActiveCN106147803AEasy to implementDoes not take up circulation spaceCoke oven safety devicesControl systemCarbonization

The invention relates to a device and method for pressure regulation of a coke oven carbonization chamber. The regulation device comprises a water-sealed valve and a throttle. The throttle is composed of a casing, an overturning plate, an overflow channel and a rotating shaft. The casing is fixed between an axle tube and a water-sealed valve body. The overturning plate is installed in the casing through the rotating shaft, the rotating shaft is driven by an execution mechanism and can drive the overturning plate to rotate; and the overflow channel is arranged at the bottom of the overturning plate to be used for forming an ammonia water water seal and performing overflow of ammonia water. The axle tube is provided with a pressure measurement device. The pressure measurement device and the execution mechanism are connected with a control system. The structural form of combining the throttle and the water-sealed valve is adopted, the throttle overturning plate is utilized to regulate pressure of the carbonization chamber, the water seal of the water-sealed valve is utilized to cut off raw gas during coke pushing, finally the goals that smoke is prevented from escaping during coal charging into a coke oven and during a coking period, negative pressure of the carbonization chamber during a coking terminal stage is avoided and air is prevented from leaking into the carbonization chamber to damage coke by fire and damage an oven body are achieved. The device is simple in structure, easy to implement and particularly suitable for modification of an existing coke oven gas gathering system.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

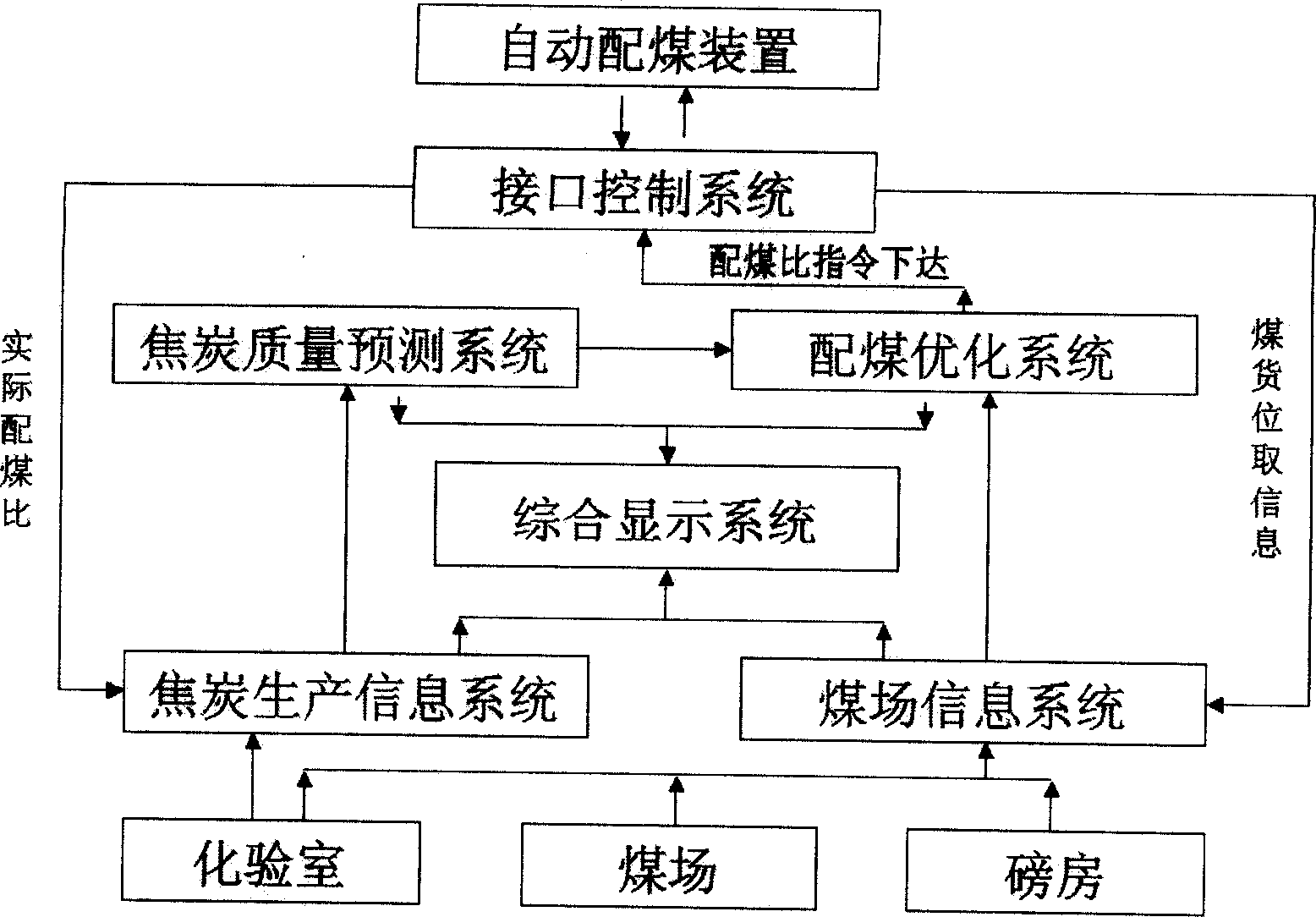

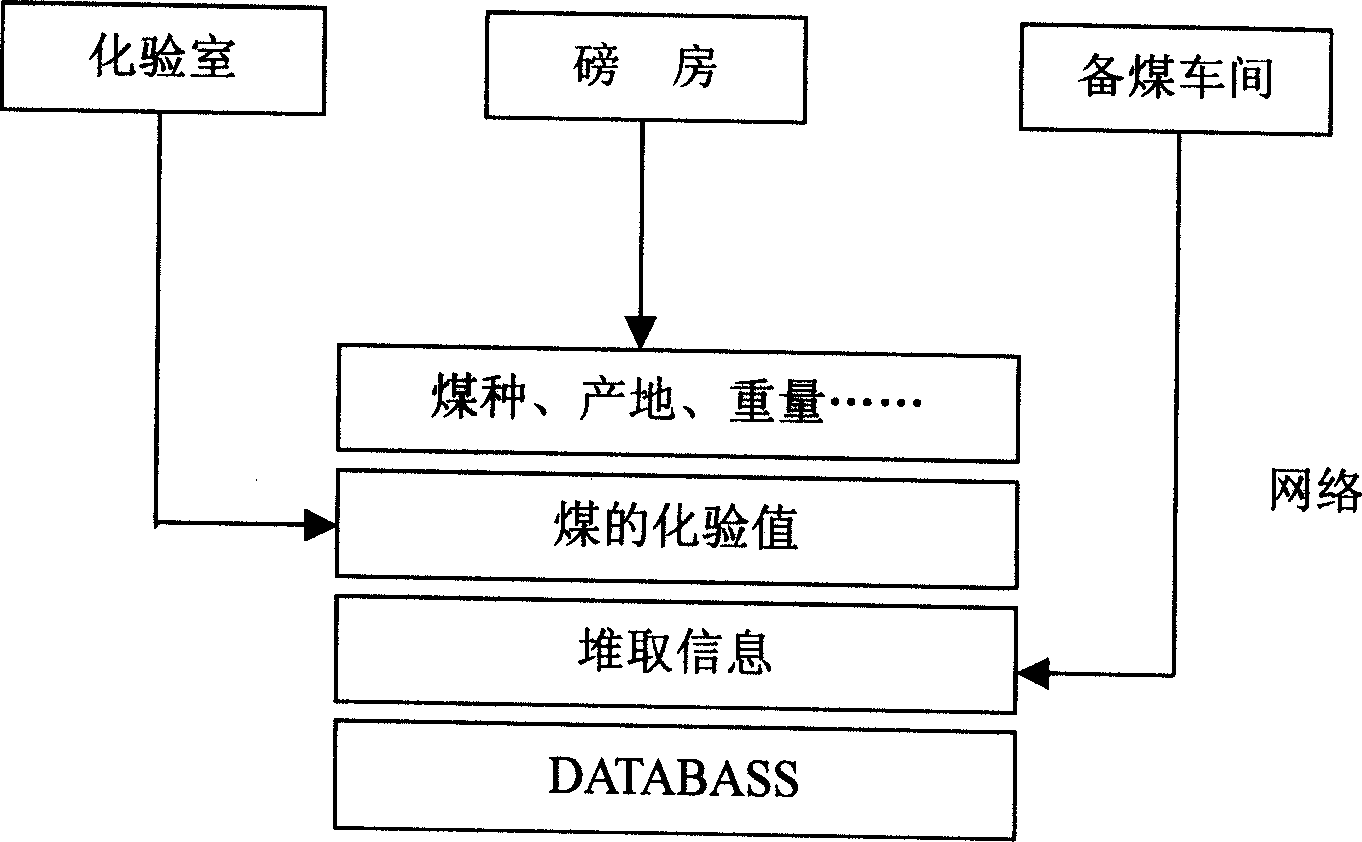

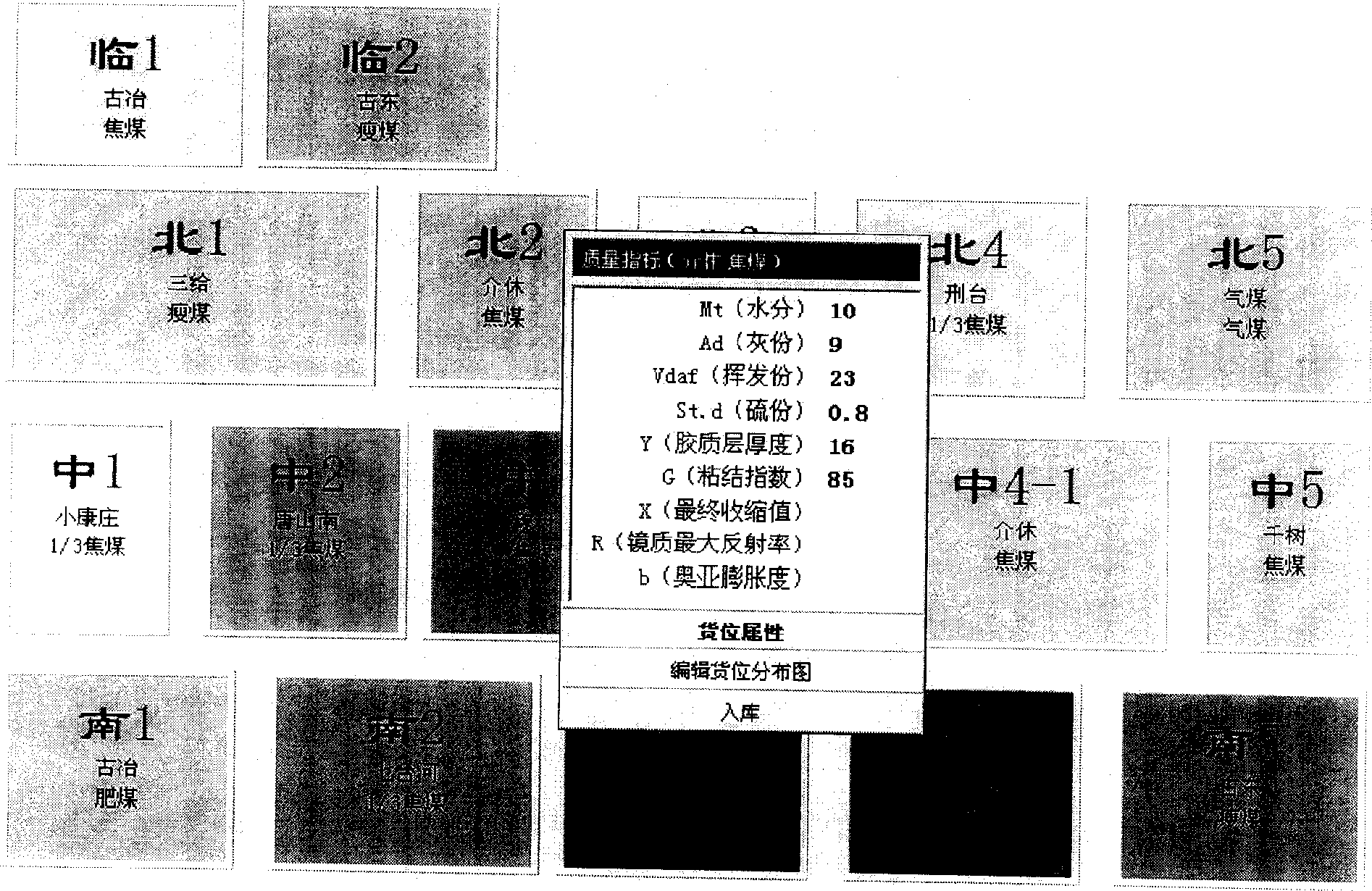

Optimum system for distributing coal of coking controlled by computer

ActiveCN1749358ALow costRealize scientificCoke oven safety devicesComputer controlInformation repositoryControl system

The computer controlled coking-coal distributing optimizing system has a coke producing information system integrating the coal compounding and coke information to form production information database; a coal yard information system integrating the coal information to form coal material database; a coal distribution optimizing system; a coke quality predicting system to ensure coke quality and an interface control system, integrated production control in coke plant. The computer controlled coking-coal distributing optimizing system can ensure the coke quality, and provide coal distributing scheme with minimized cost.

Owner:ACRE AUTOMATION CO LTD MCC

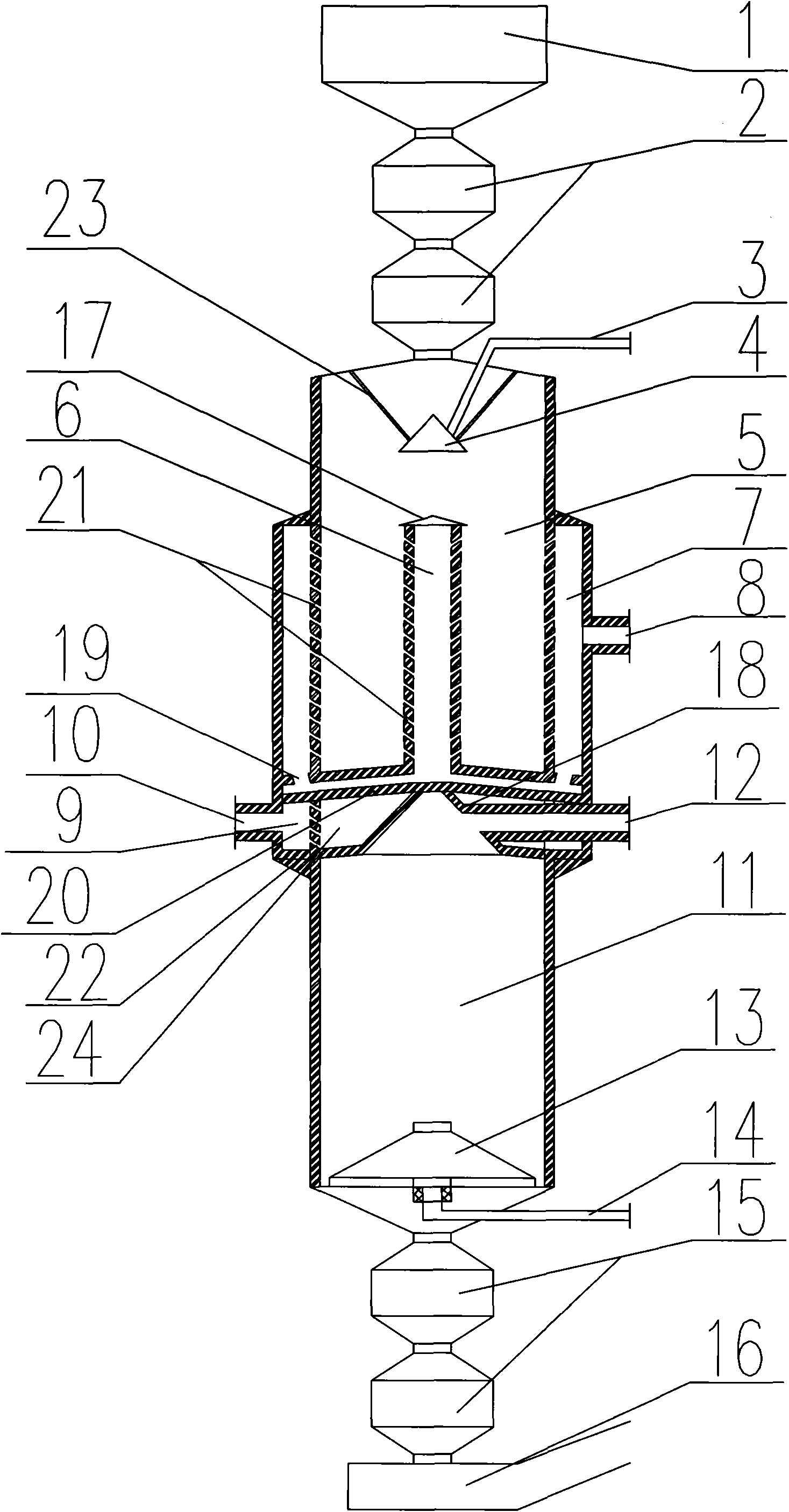

Multilayer gas distribution full circulation carbonization furnace

ActiveCN101928582ASmall spray radiusHeating evenlyCoke oven safety devicesDirect heating destructive distillationHeat carrierSlag

The invention discloses a multilayer gas distribution full circulation carbonization furnace which comprises a furnace body, a discharge system and a slag discharge system, wherein the discharge system is arranged on the top of the furnace body, the slag discharge system is arranged at the bottom of the furnace body, the furnace body is divided into a carbonization section at the upper part and ageneration section at the lower part by an arched leg arranged at the middle part of the furnace body, a carbonization product outlet is arranged at the upper part of the carbonization section, an air supply system is arranged at the lower part of the generation section, a gas seal section which is communicated with a gas-seal gas inlet is arranged between the carbonization section and the generation section, and an annular gas distribution chamber which is communicated with an inner cavity of the carbonization section through a gas distribution hole and also communicated with a circulation gas inlet is arranged outside the carbonization section, a center gas collection cavity is arranged in the carbonization section, the upper end of the center gas collection cavity is closed, the lower end of the center gas collection cavity is communicated with the circulation gas inlet, a gas distribution hole is arranged at the middle part of the center gas collection cavity, and a generation gasoutlet is arranged at the upper part of the generation section. The invention has the advantages of small heat carrier jet radius, more uniform gas distribution and heating, high heating and oil production efficiency, and the like, can fundamentally avoid the oil firing phenomenon, makes up a blank of the kind of carbonization furnaces and is worthy of popularization and application.

Owner:中国寰球工程有限公司辽宁分公司 +1

Process for producing high-carbon biogenic reagents

ActiveUS20140075834A1Improve energy efficiencyImprove a product attributeCoke quenchingCoke oven safety devicesHigh carbonCombined use

Owner:CARBON TECH HLDG LLC

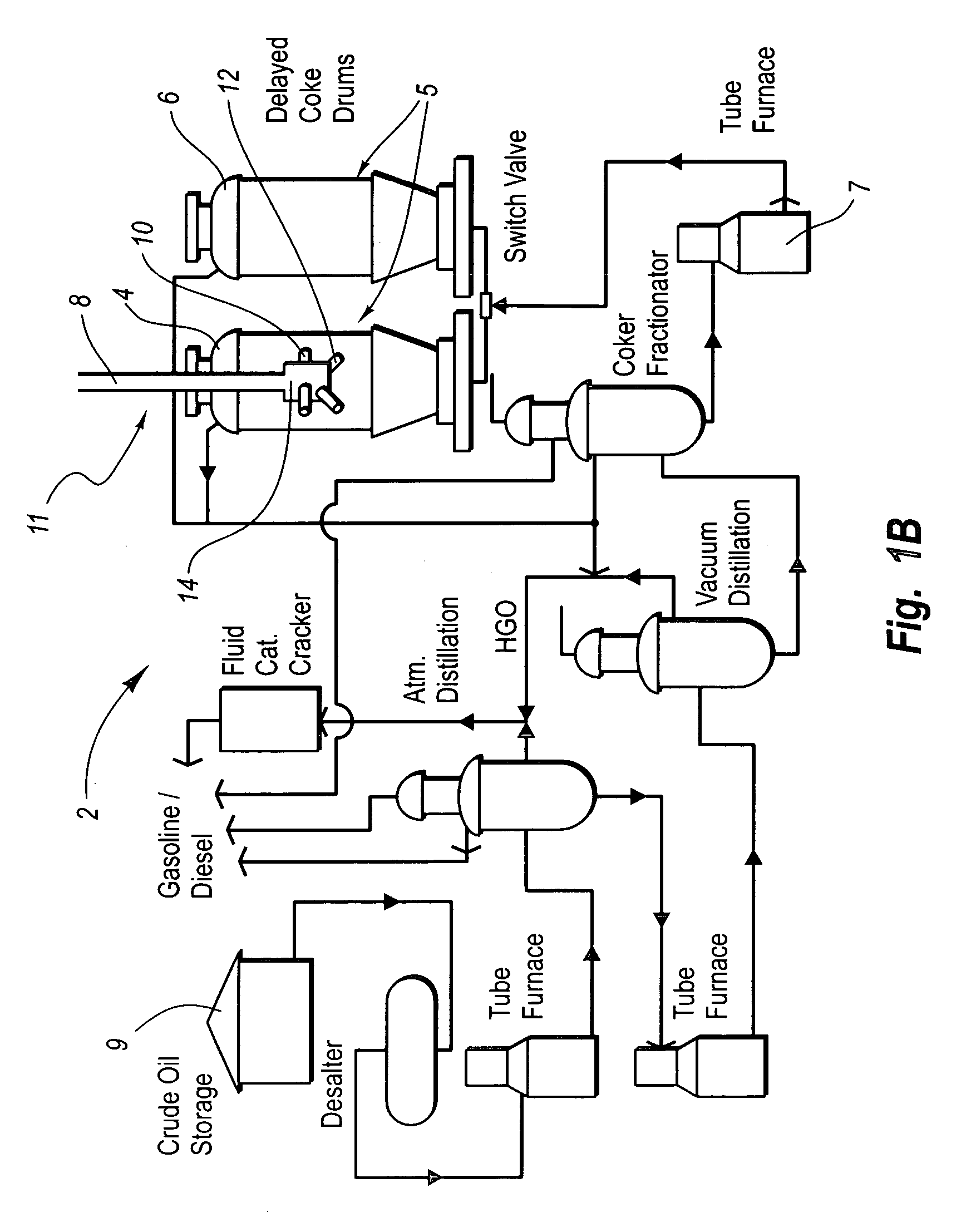

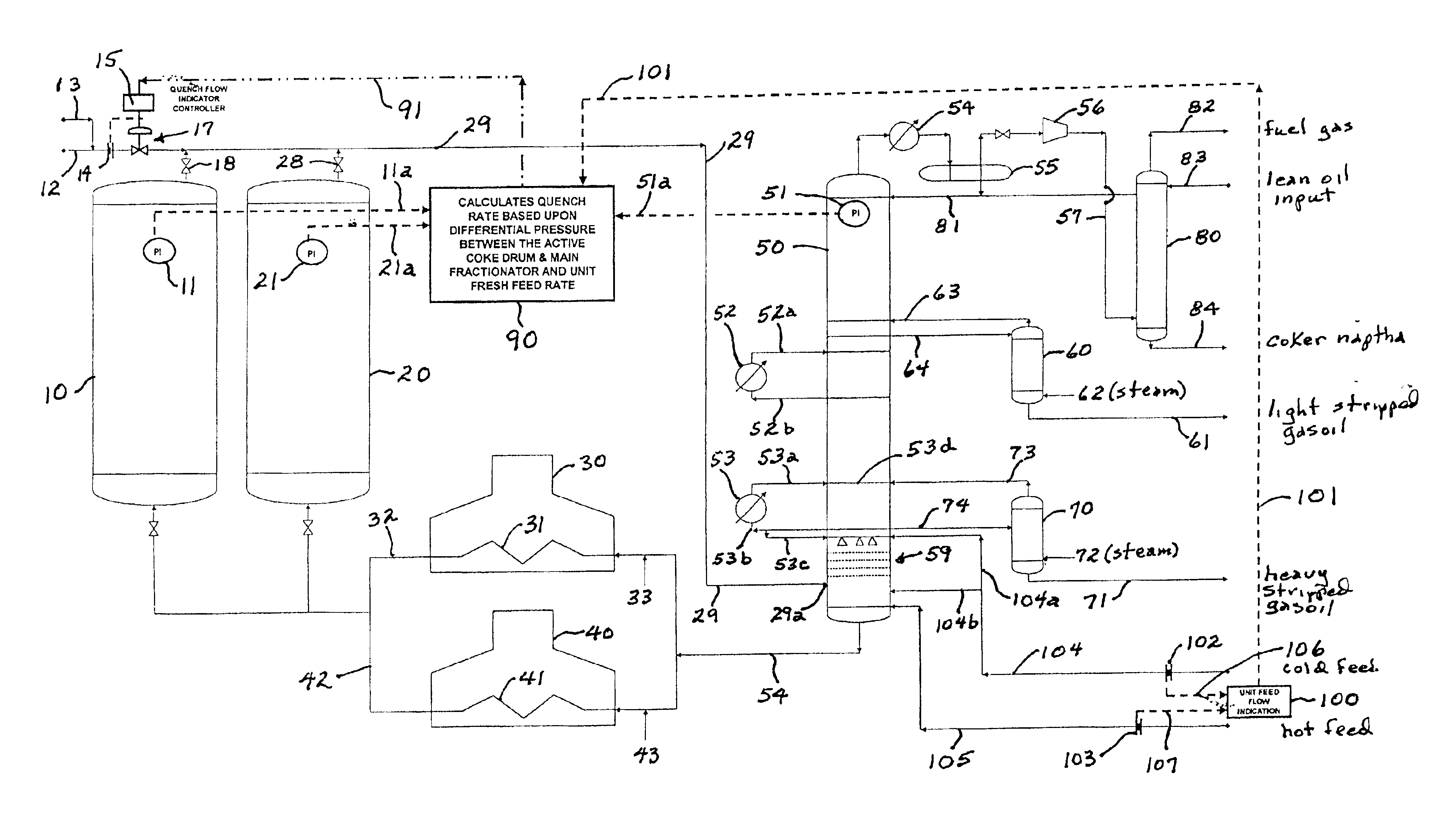

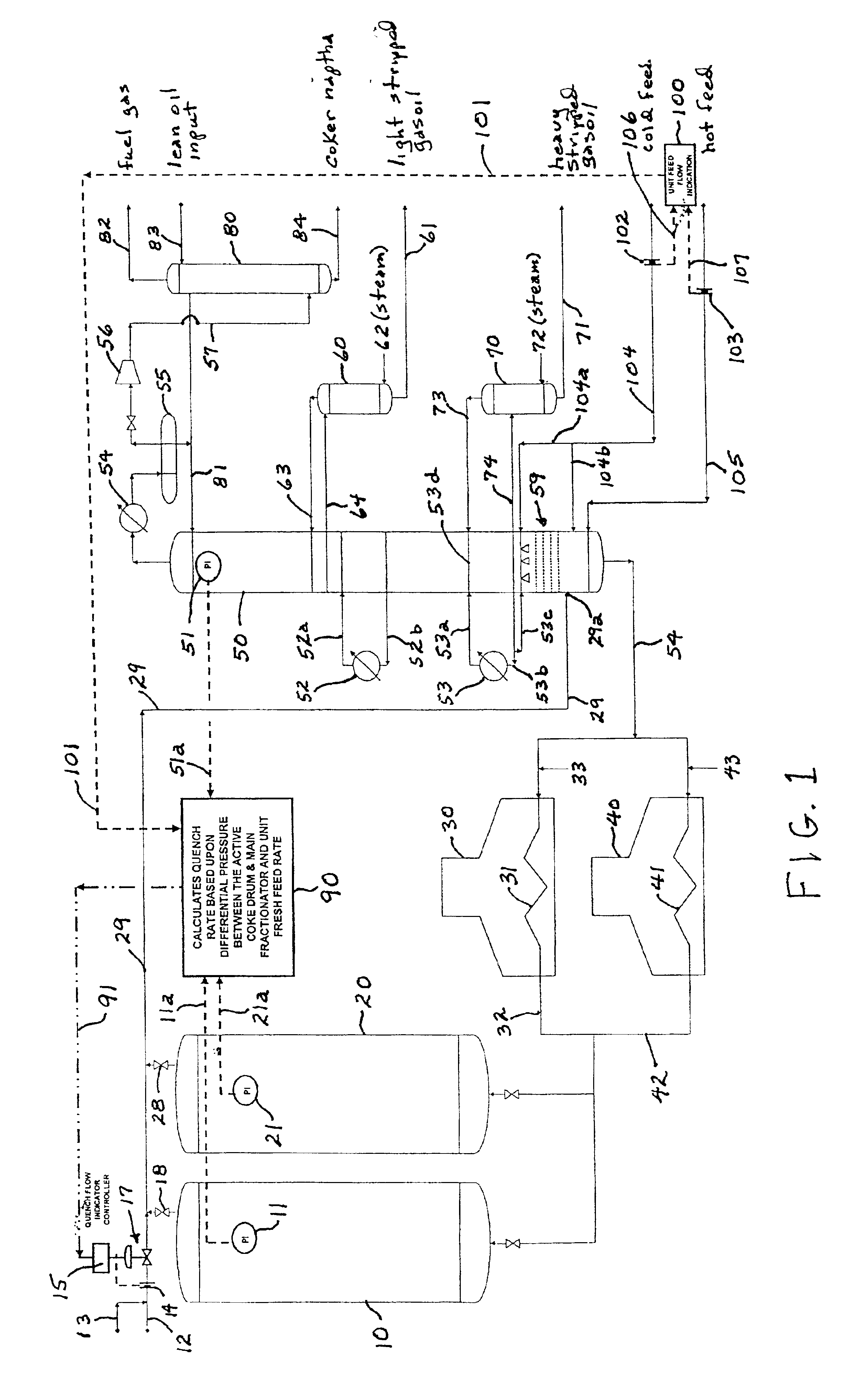

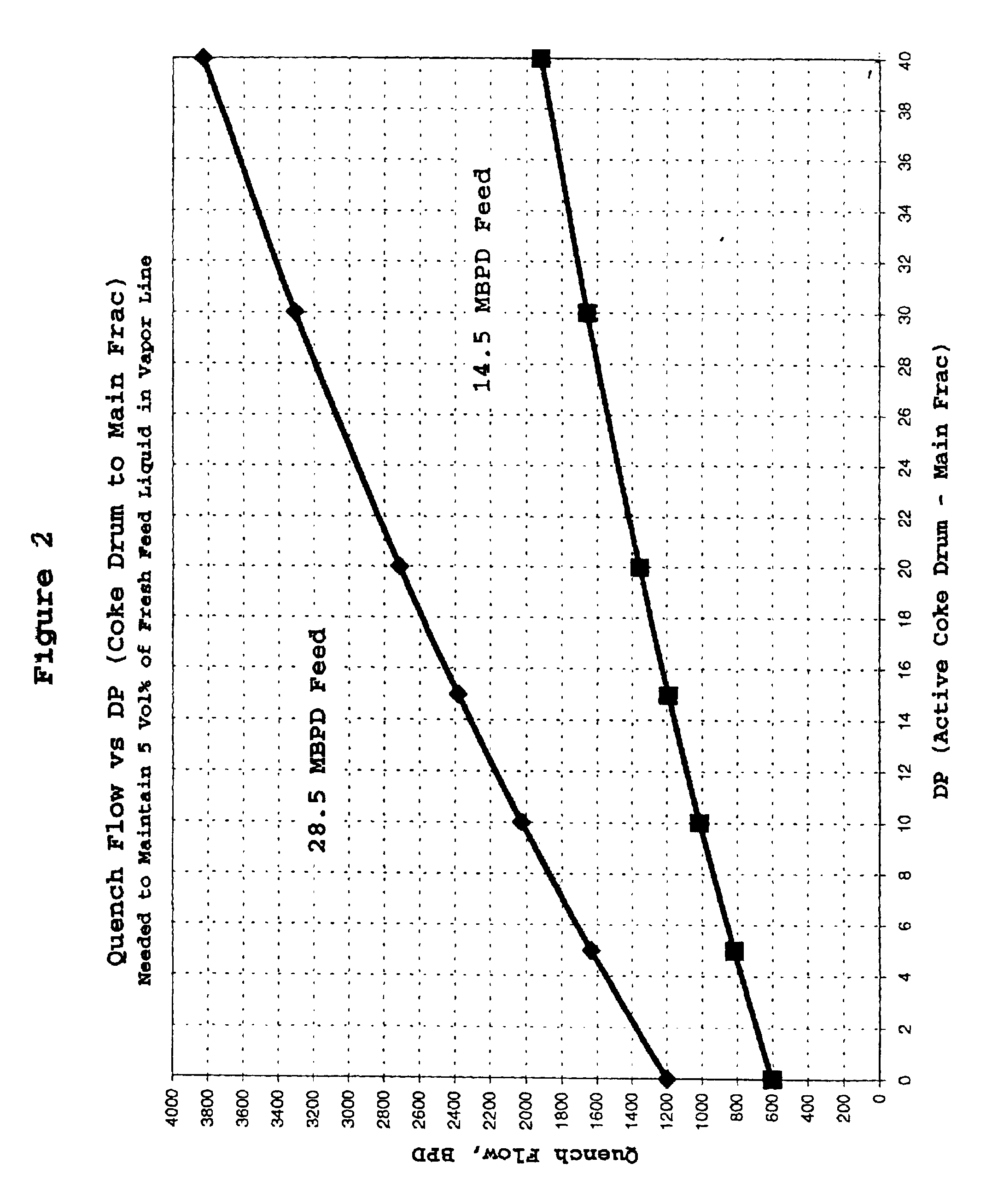

Method and apparatus for quenching the coke drum vapor line in a coker

A method and apparatus for quenching the coke drum vapor line from a coke drum to the main fractionator in a coker unit whereby the volume of quench liquid prevents the drum vapor line from plugging with carbon-based deposits. A differential pressure control technique is utilized to quench the drum vapors being delivered to the fractionator as opposed to a temperature, delta temperature, uninsulated vapor line, or fixed flow rate control as used in the prior art. Vapor line quench control by differential pressure prevents over-quenching of the vapor line during a coke drum switch, unit startup, or slowdown as well as under-quenching during drum warm-ups. It improves the fractionator recovery time from a drum switch and overall liquid product yield during the drum cycle which can be produced by over-quenching. It also prevents the vapor line from drying out at anytime, an under-quenched condition, as long as the quench oil quality and conditions do not vary significantly.

Owner:MOTIVA ENTERPRISES

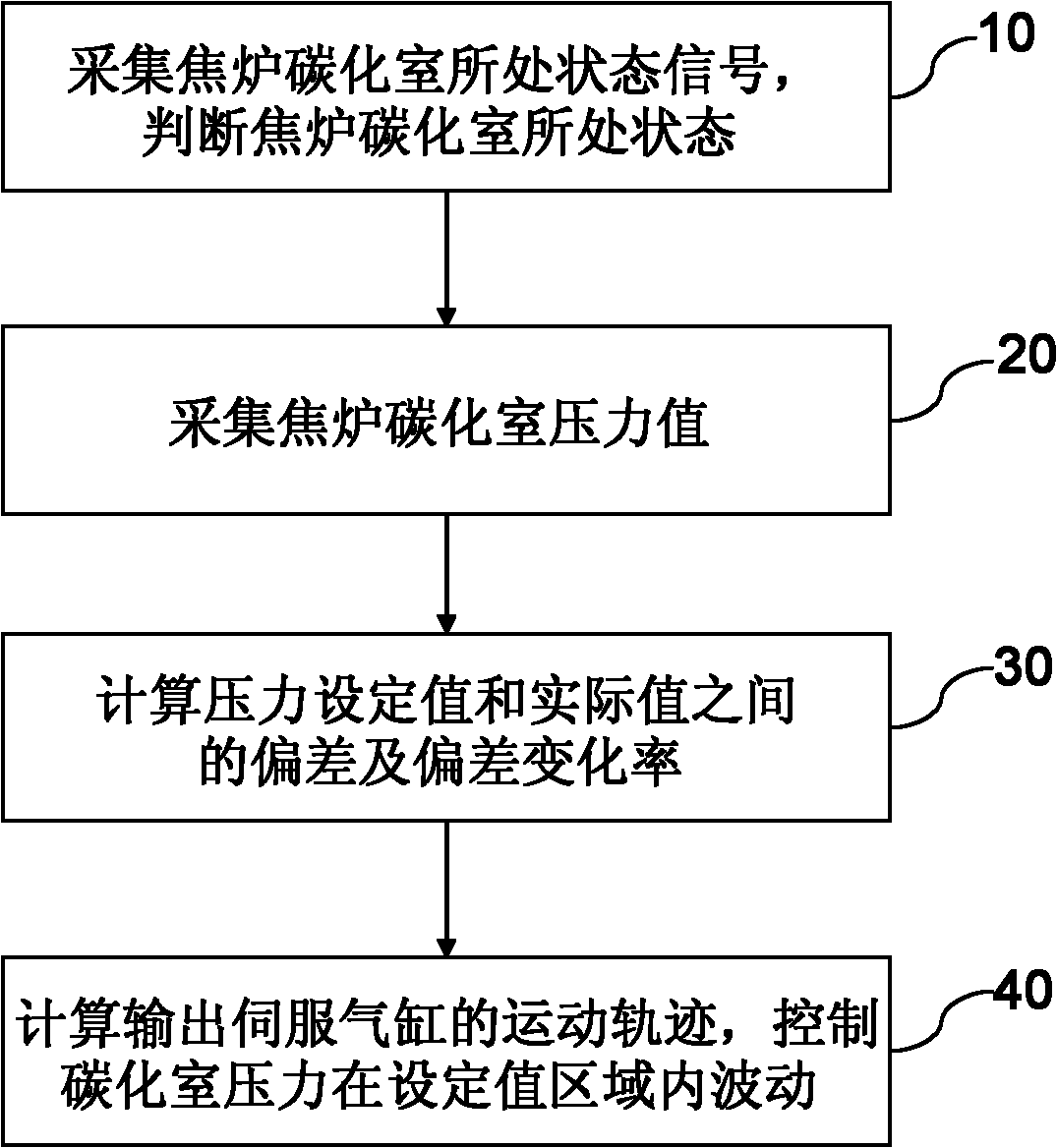

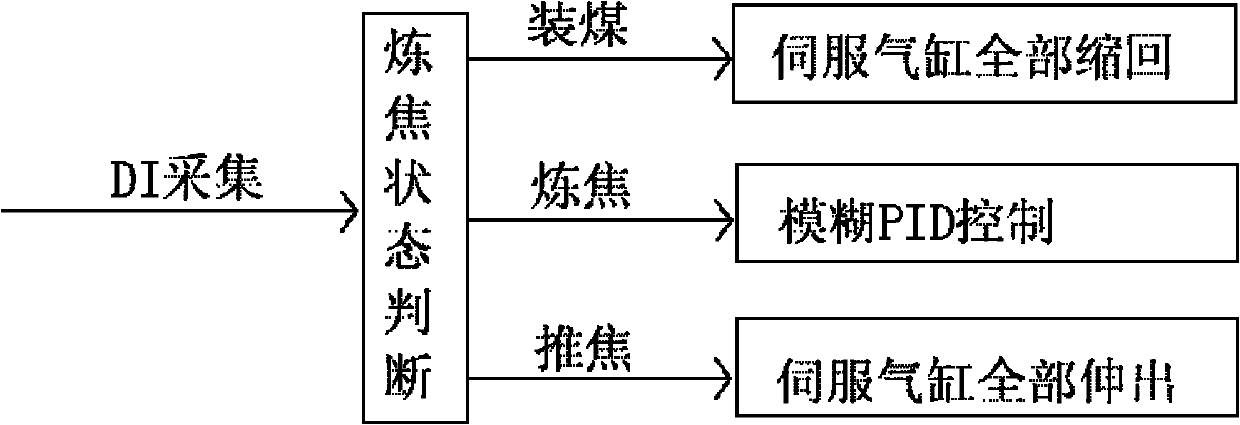

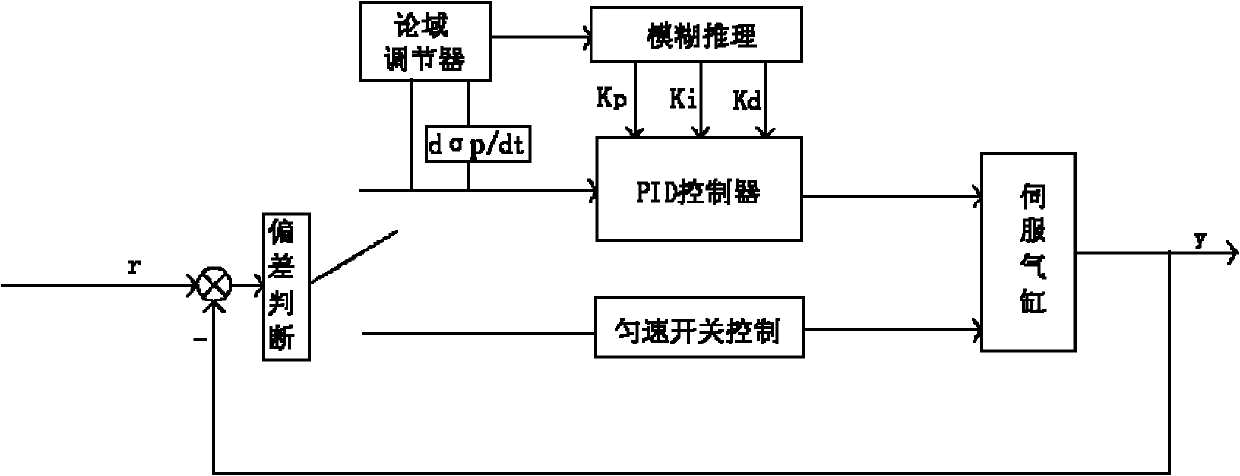

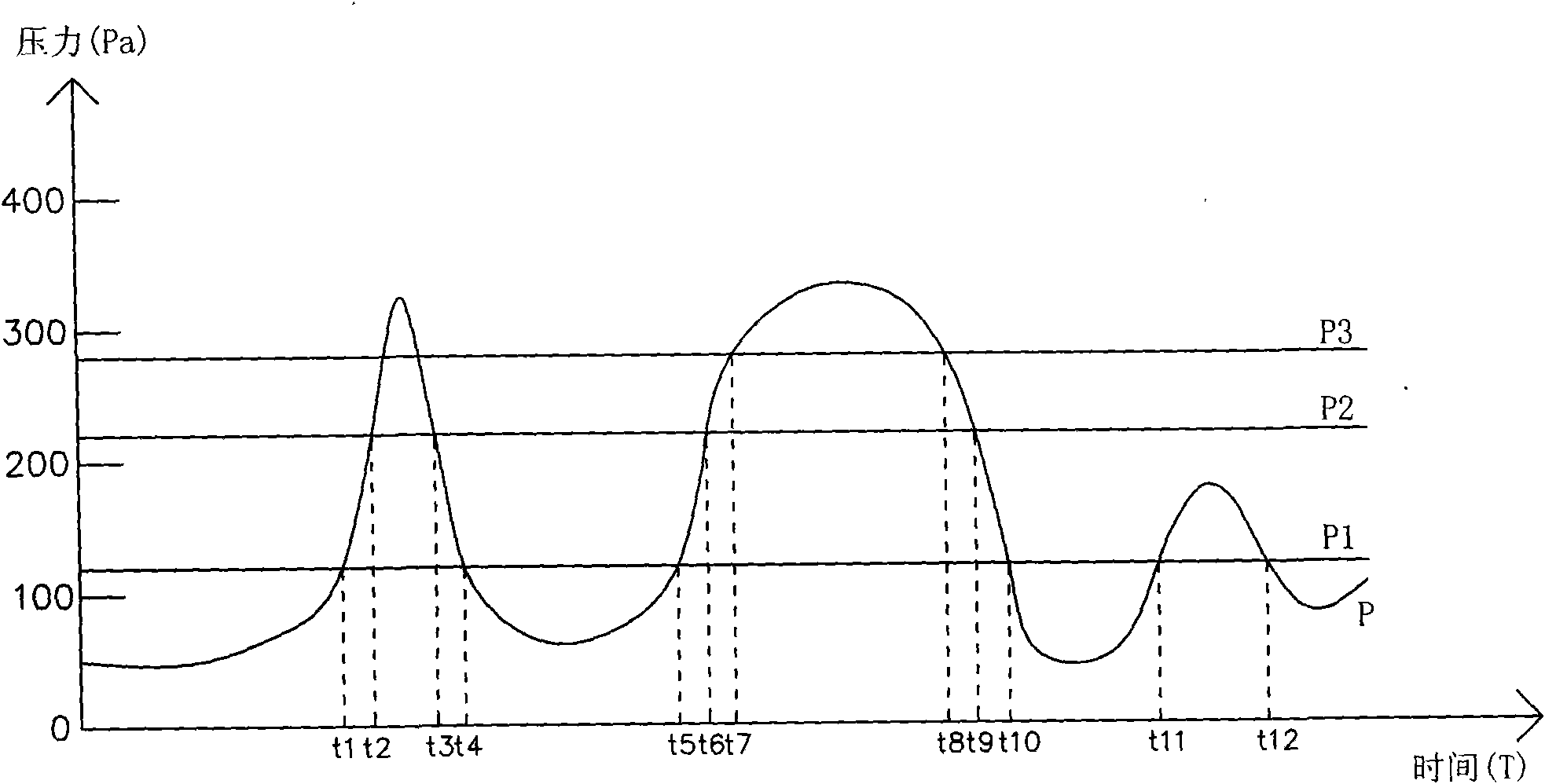

Pressure regulating device for coke oven carbonization chamber and fuzzy control method thereof

ActiveCN102433137AImprove robustnessImprove anti-interference abilityCoke oven safety devicesAdaptive controlCarbonizationCoke oven

The invention discloses a pressure regulating device for a coke oven carbonization chamber and a fuzzy control method thereof. The method comprises the following steps: acquiring a state signal of the coke oven carbonization chamber, and judging the state of the coke oven carbonization chamber; acquiring the pressure value of the coke oven carbonization chamber; calculating deviation between the pressure set value and actual value and the deviation change rate; carrying out fuzzy treatment on the deviation and deviation change rate; and after the fuzzy PID (proportional-integral-derivative) operation, outputting a kinematic trajectory of a servo-cylinder, thereby controlling the pressure of the coke oven carbonization chamber to fluctuate within a small set value range. The fuzzy control method disclosed by the invention overcomes the defect of complex and unstable pressure of the coke oven carbonization chamber, and has the advantages of strong system robustness, quick reaction speed and high antijamming capability.

Owner:BEIJING BESTPOWER INTELCONTROL TECH CO LTD

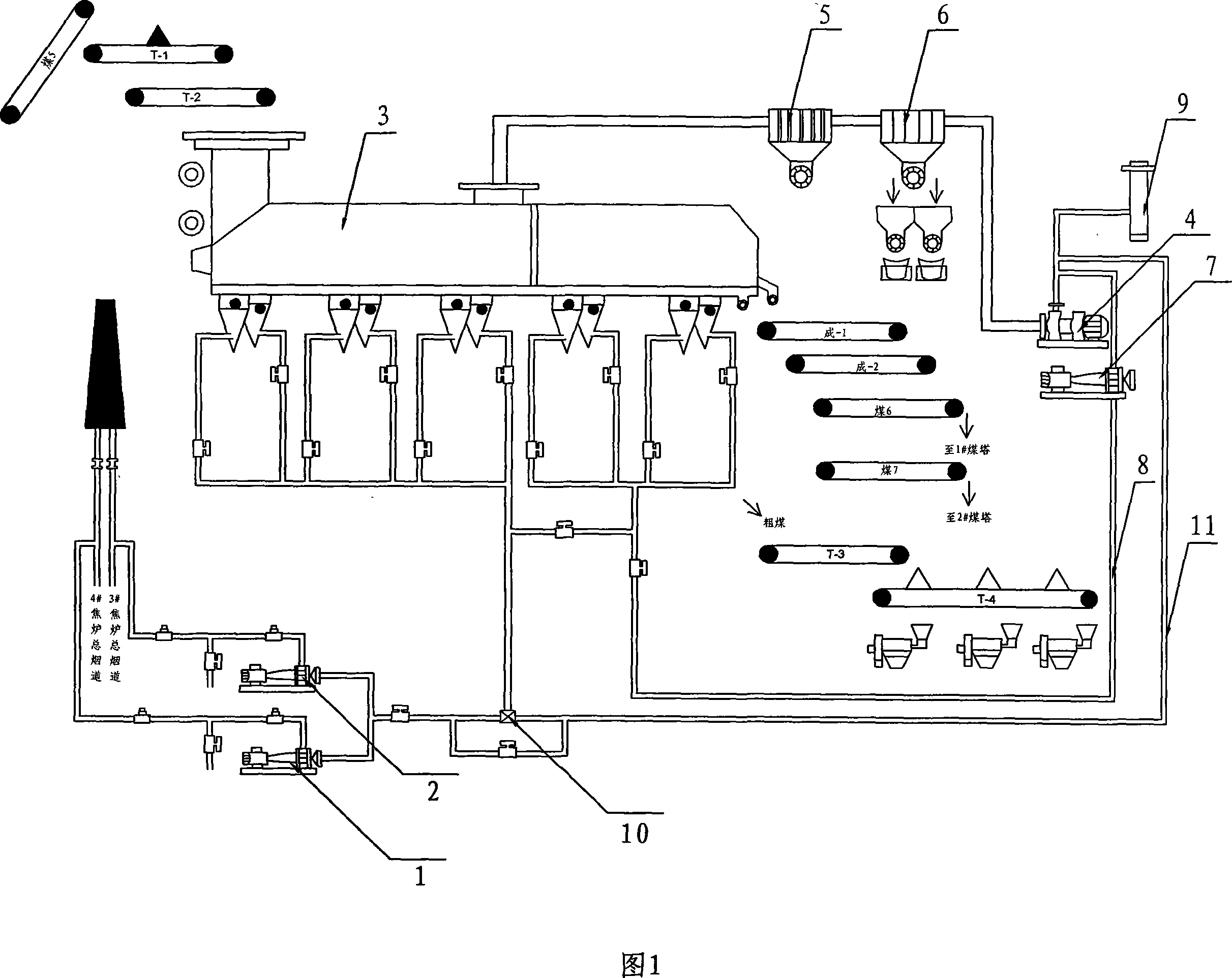

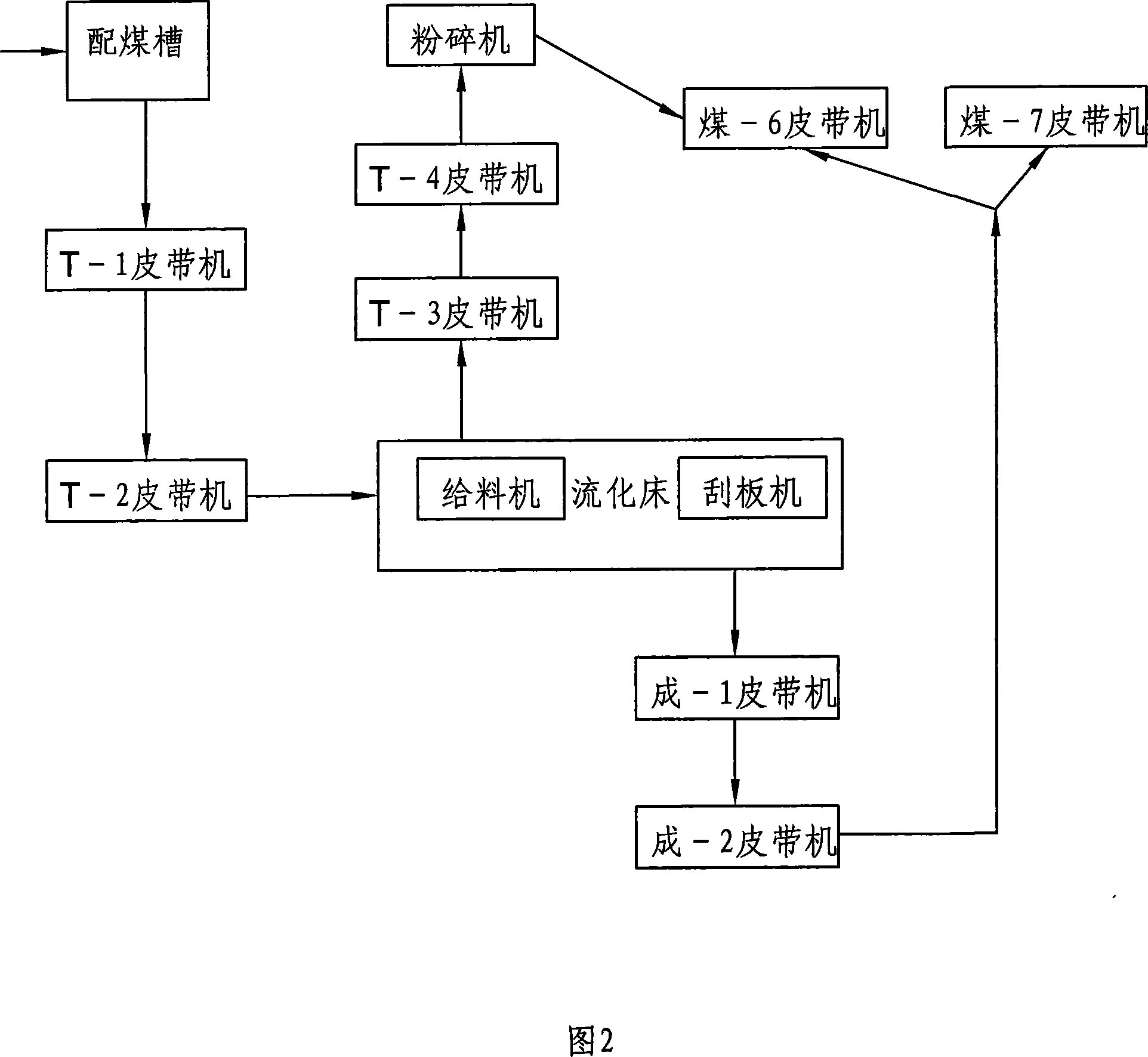

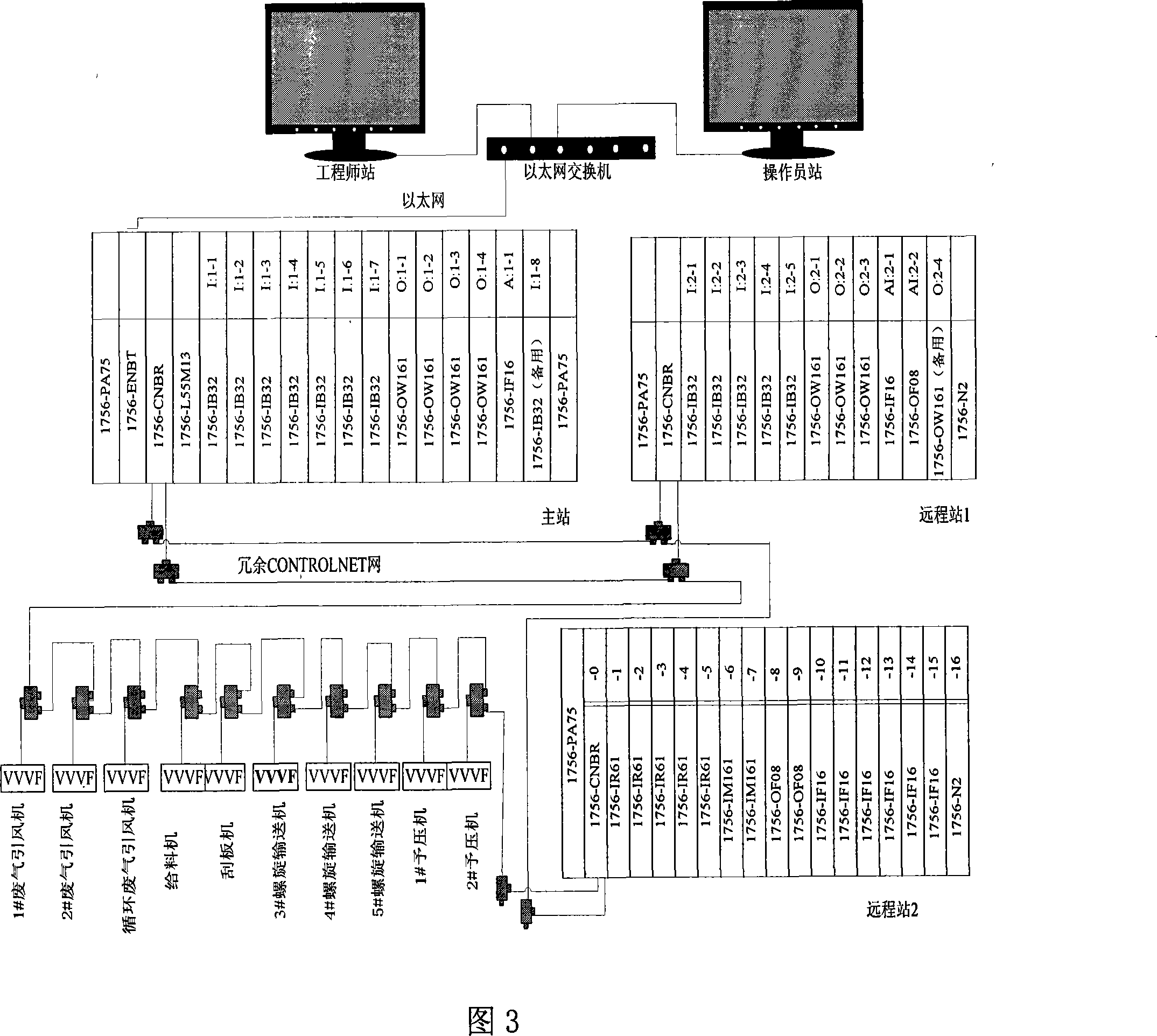

Automatic control method for air current classifying and conditioning technique of coal

InactiveCN101191058AHierarchical implementationStable suctionCoke oven safety devicesProcess systemsAutomatic control

The invention discloses an automatic control method for coal airflow classification and moisture control technology and belongs to the coking industry coal pretreatment automatic control field. The invention integrates frequency conversion technology, network technology, computer technology and control technology into a whole, ensures the movement and fluidization effect of the raw material coal, can control the fluidization time and the dry classification effect, and realizes that three functions-drying, classification and preheating of the mixed coal for coking are integrated into a whole. The technology realizes full-automatic operation of the whole process system flow by flexible and perfect control, and is applied to the control of the coal pretreatment system in the coking industry.

Owner:SHANDONG IRON & STEEL CO LTD

Coke plant including exhaust gas sharing

ActiveUS20160160123A1Coke oven safety devicesHorizontal chamber coke ovensCoke ovenProcess engineering

A coke plant includes multiple coke ovens where each coke oven is adapted to produce exhaust gases, a common tunnel fluidly connected to the plurality of coke ovens and configured to receive the exhaust gases from each of the coke ovens, multiple standard heat recovery steam generators fluidly connected to the common tunnel where the ratio of coke ovens to standard heat recovery steam generators is at least 20:1, and a redundant heat recovery steam generator fluidly connected to the common tunnel where any one of the plurality of standard heat recovery steam generators and the redundant heat recovery steam generator is adapted to receive the exhaust gases from the plurality of ovens and extract heat from the exhaust gases and where the standard heat recovery steam generators and the redundant heat recovery steam generator are all connected in parallel with each other.

Owner:SUNCOKE TECH & DEV LLC

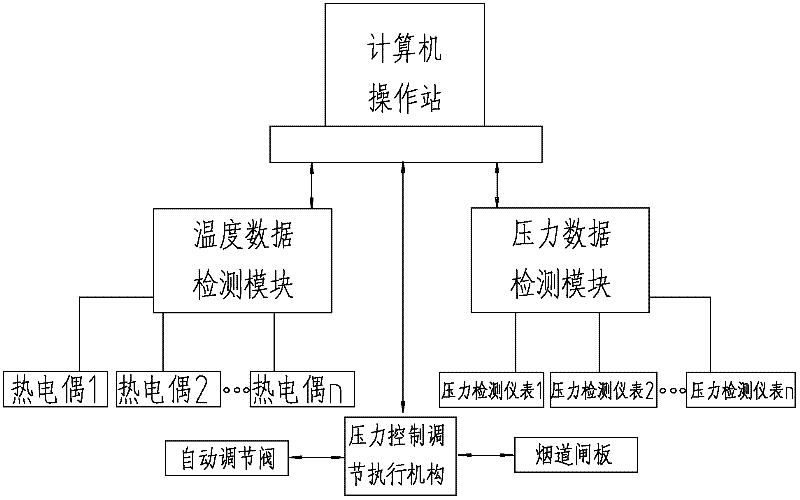

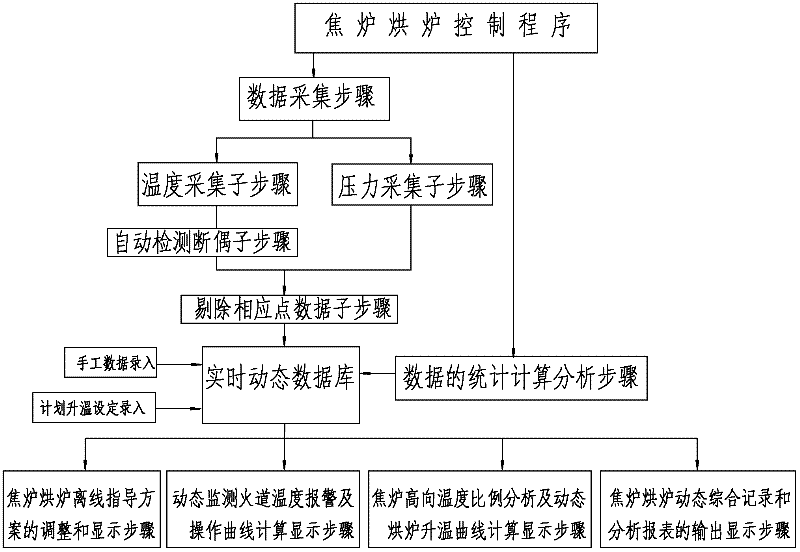

Coke oven temperature and pressure automatic monitoring oven control system

ActiveCN102520747AAutomatic pressure adjustmentQuick searchCoke oven safety devicesCoke oven detailsSuction forcePressure data

The invention relates to the coke oven control technical field, in particular to a coke oven temperature and pressure automatic monitoring oven control system, which is characterized by comprising a temperature data detection module, a pressure data detection module, a computer operation station and a pressure control adjusting execution mechanism, wherein a real-time dynamic database is arranged inside the computer operation station, the computer operation station is respectively connected with the temperature data detection module, the pressure data detection module and the pressure control adjusting execution mechanism, the computer operation station executes a coke oven online instruction control strategy and can automatically control and adjust the coal gas pressure and the flue suction force and can provide an offline instruction adjustment scheme. Compared with the prior art, the coke oven temperature and pressure automatic monitoring oven control system has beneficial effects that: a great amount of coke oven operation personnel can be saved, the labor intensity of the operation personnel can be alleviated, the operation time in the worse environment can be reduced, the operation personnel can concentrate on general control of the coke oven technical process, and an important significance on improving the coke oven quality, the operation efficiency and the operation security can be realized.

Owner:CHINA THIRD METALLURGICAL GRP

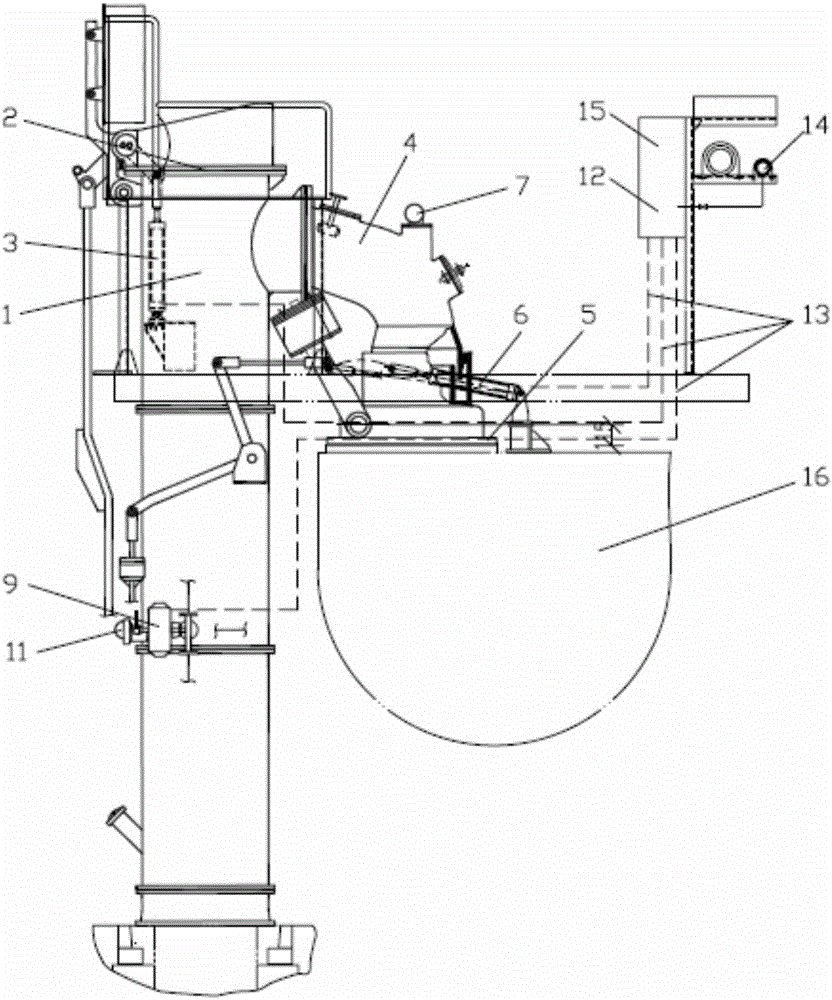

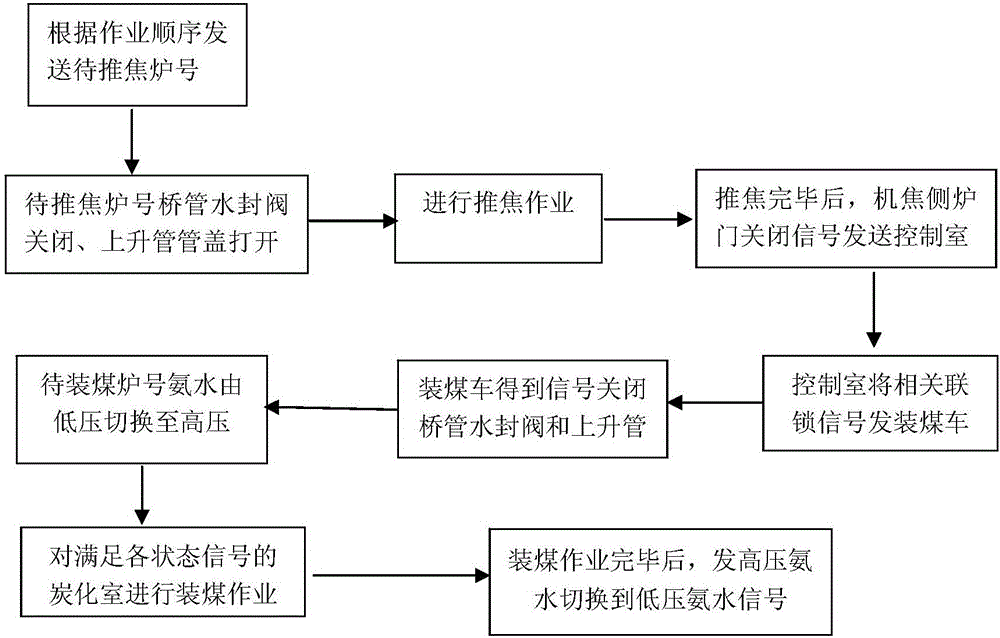

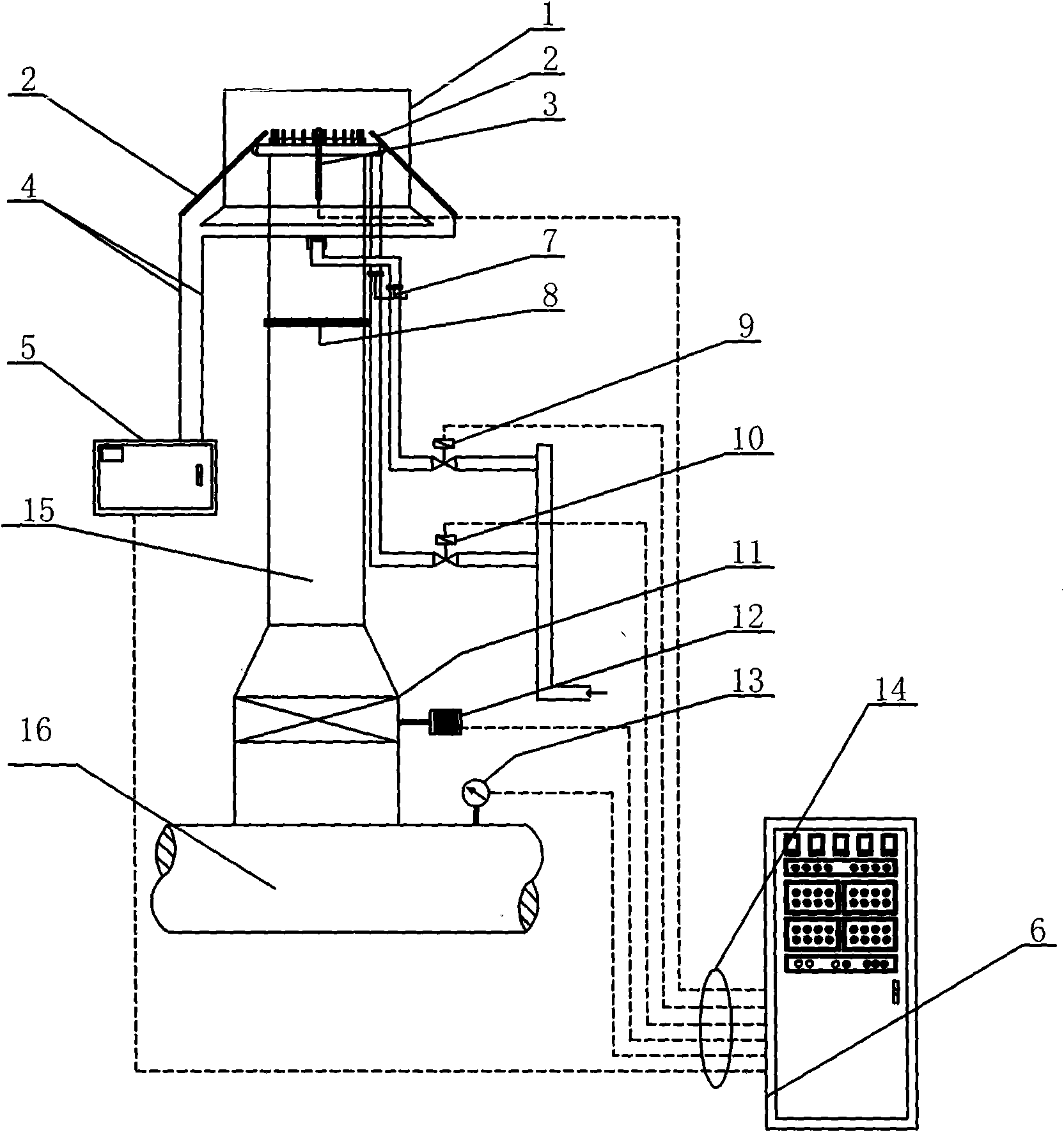

Control method and system for coke oven riser pipe

InactiveCN106753444ARealize safety interlockImprove working accuracyCoke oven safety devicesDistillation gas withdrawalTime deviationAutomatic control

The invention discloses a control method and system for a coke oven riser pipe. The system comprises the riser pipe, a bridge pipe, a low pressure ammonia water spray nozzle, a high pressure ammonia water spray nozzle, a corresponding low pressure ammonia water pipeline, a corresponding high pressure ammonia water pipeline and a programmable controller, wherein a pipe cover capable of being opened and closed and a pipe cover driving cylinder are arranged on the riser pipe; the bridge pipe is connected to an end opening in one side of the riser pipe; a water seal valve and a water seal valve driving cylinder are arranged at the lower end of the bridge pipe; the low pressure ammonia water spray nozzle is arranged at a position, which is close to a riser pipe joint, in the bridge pipe; the high pressure ammonia water spray nozzle is arranged at a position, which is located below the low pressure ammonia water spray nozzle, in the bridge pipe; the low pressure ammonia water pipeline and the high pressure ammonia water pipeline are respectively connected to two end openings of a three-way ball valve; the three-way ball valve is connected with a three-way ball valve driving cylinder or an electromagnetic driving valve; an electromagnetic switching valve or / and the electromagnetic driving valve is / are electrically connected with the controller, and is / are electrically connected with a coke oven control system. According to the control system disclosed by the invention, safe interlocking between all facilities of the riser pipe and work of a coal charging car of the coke oven and a coke pusher is realized; by automatic control and replacement of unmanned work for manual work, the cooperation order of workers and the time deviation of the manual work are eliminated, and the safety and environmental protection risk during work of the coke oven riser pipe is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

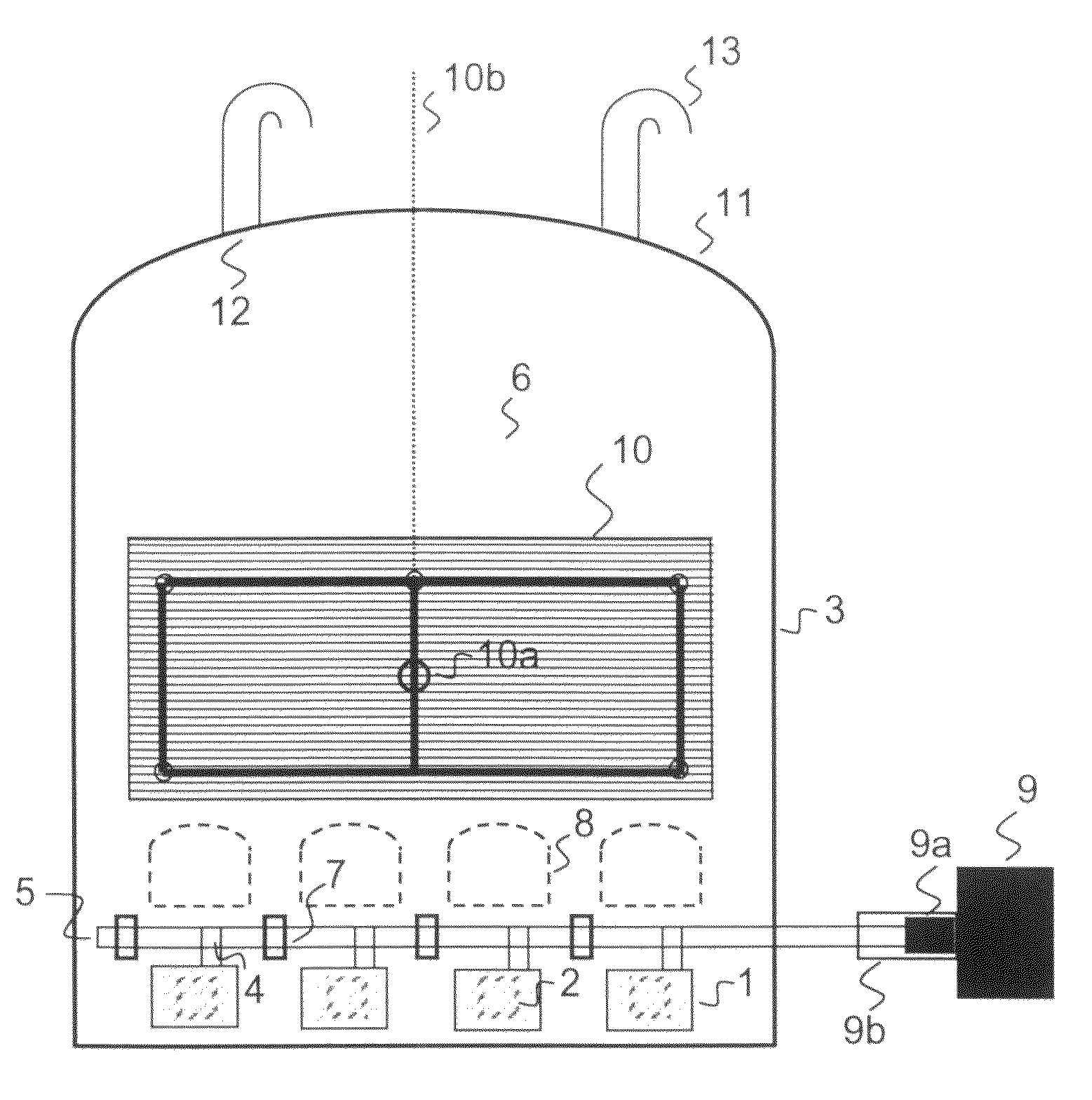

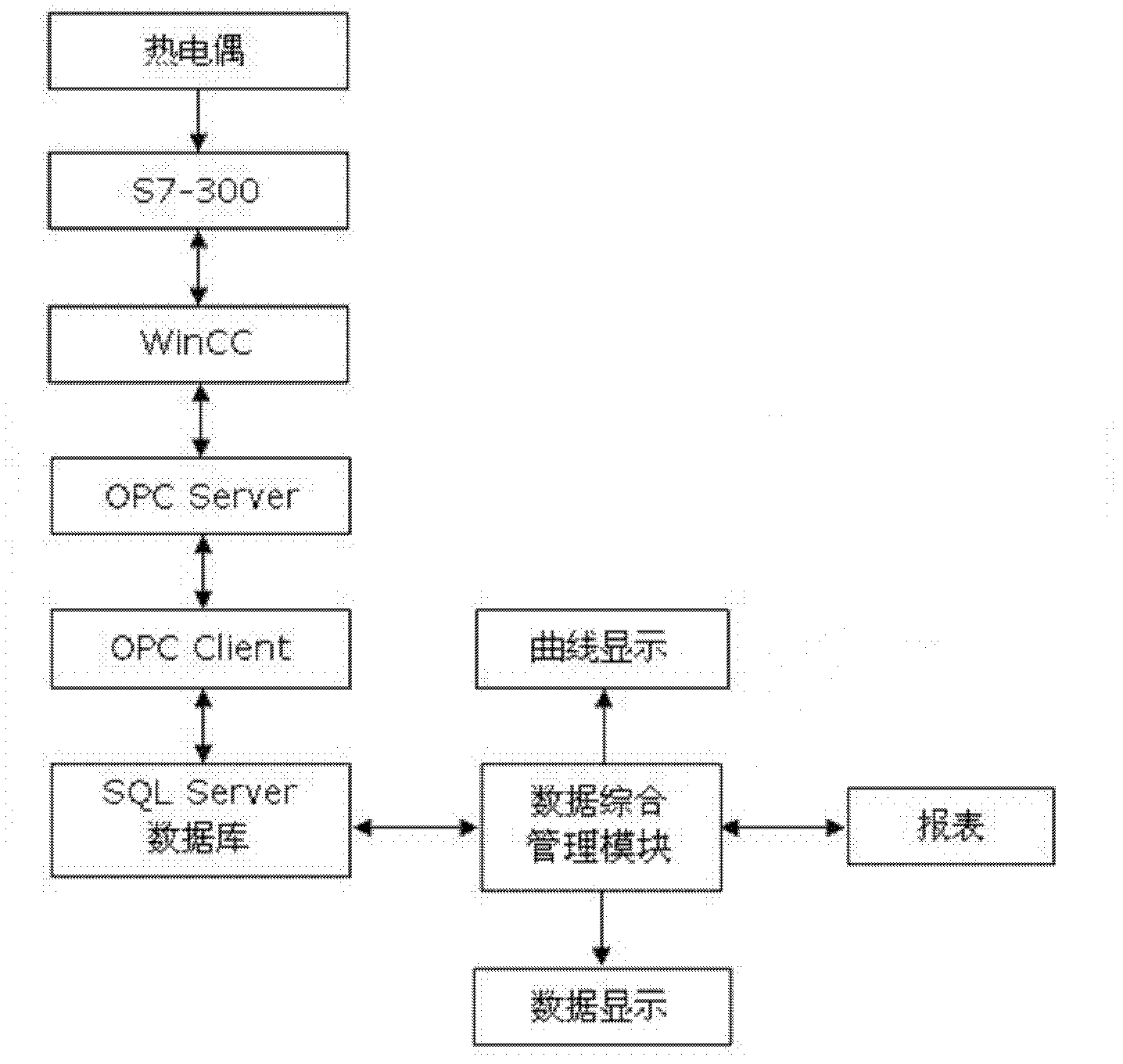

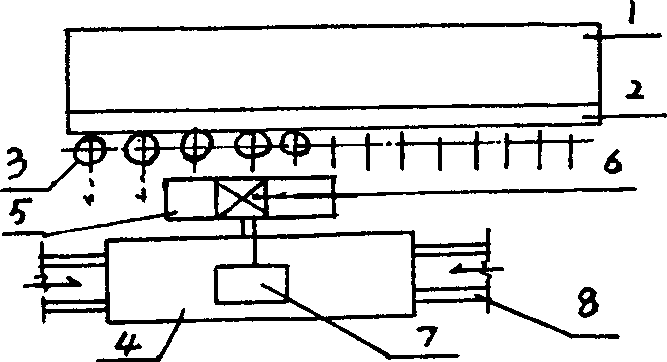

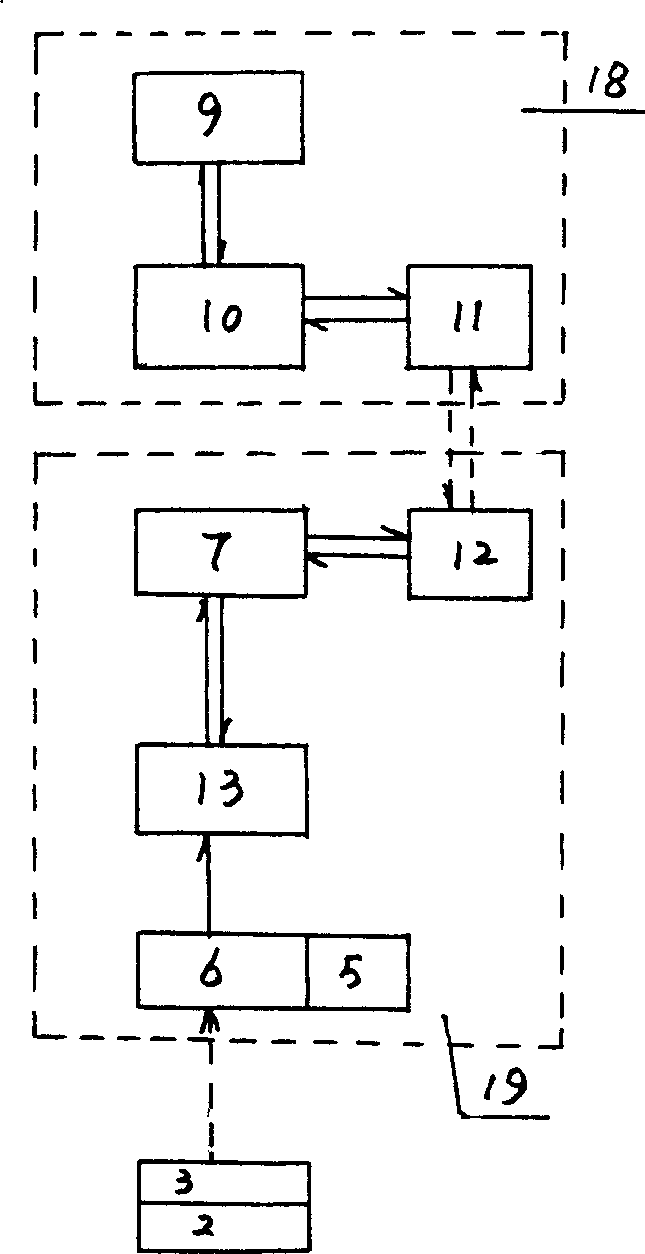

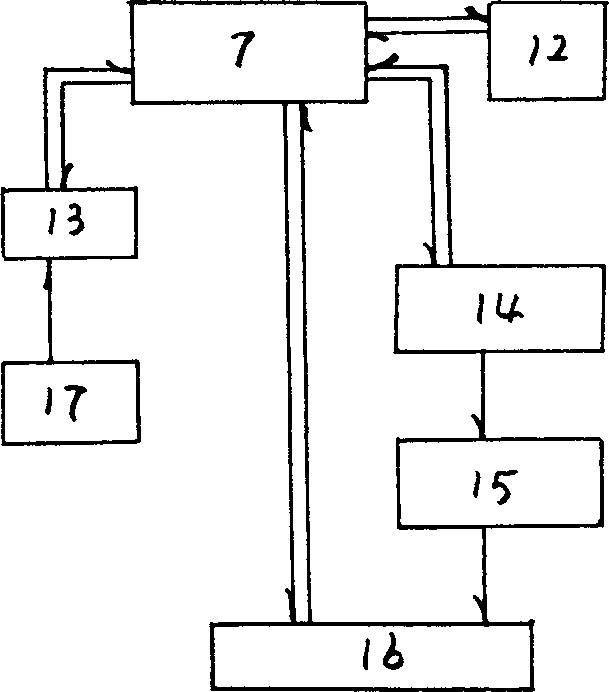

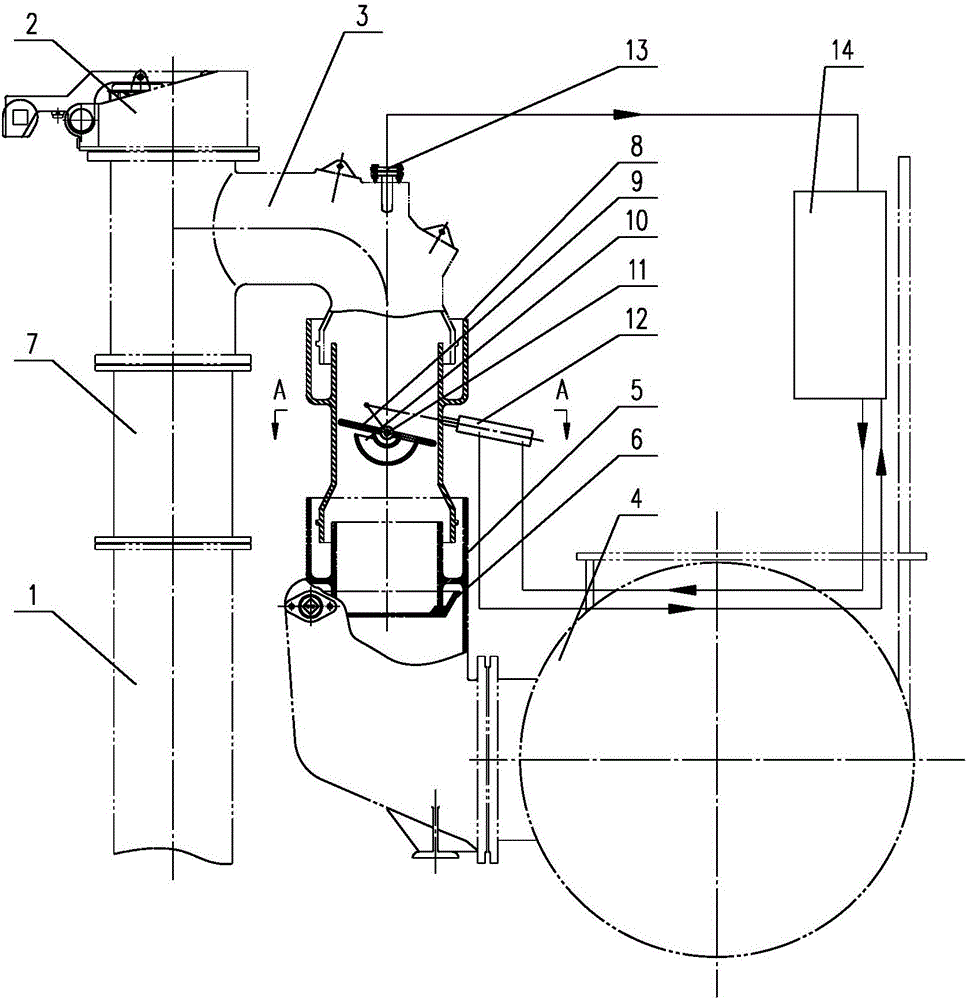

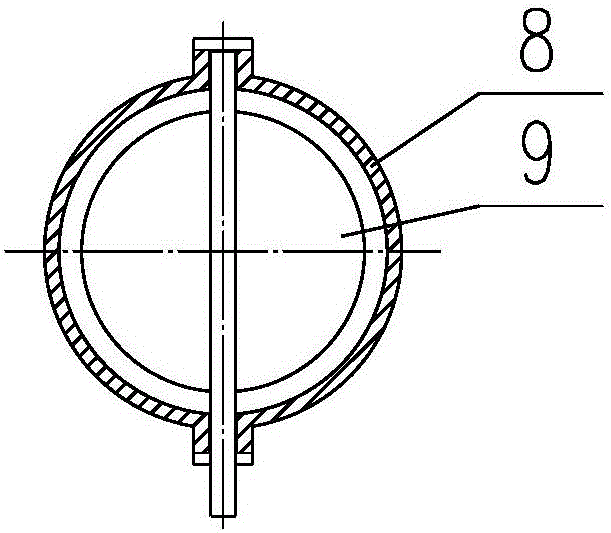

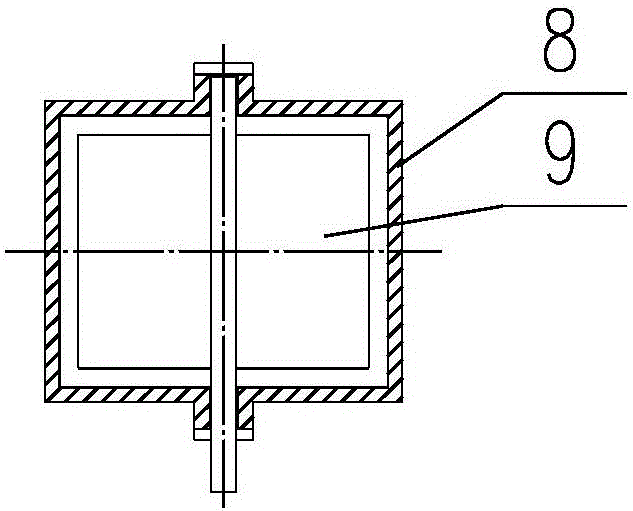

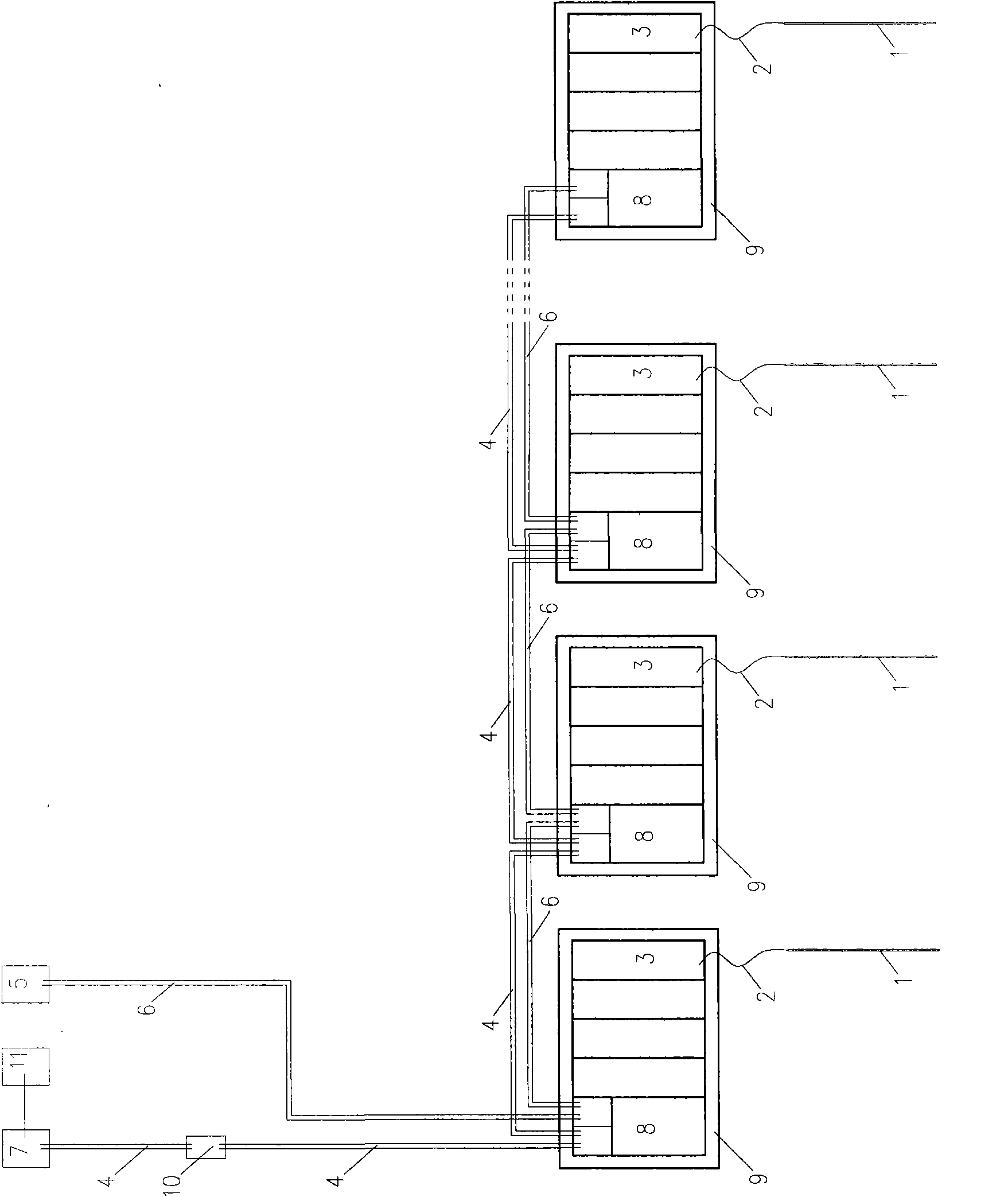

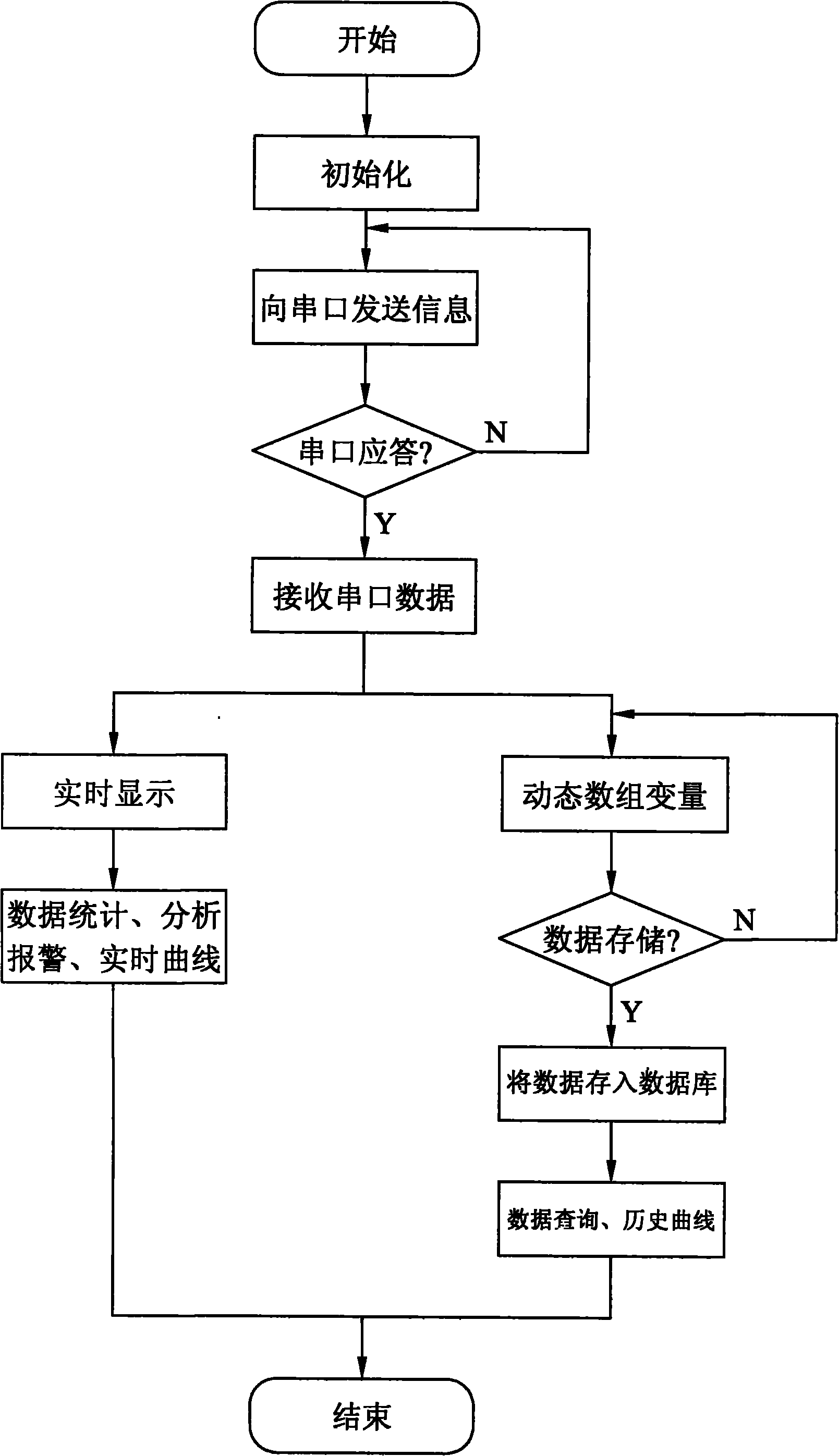

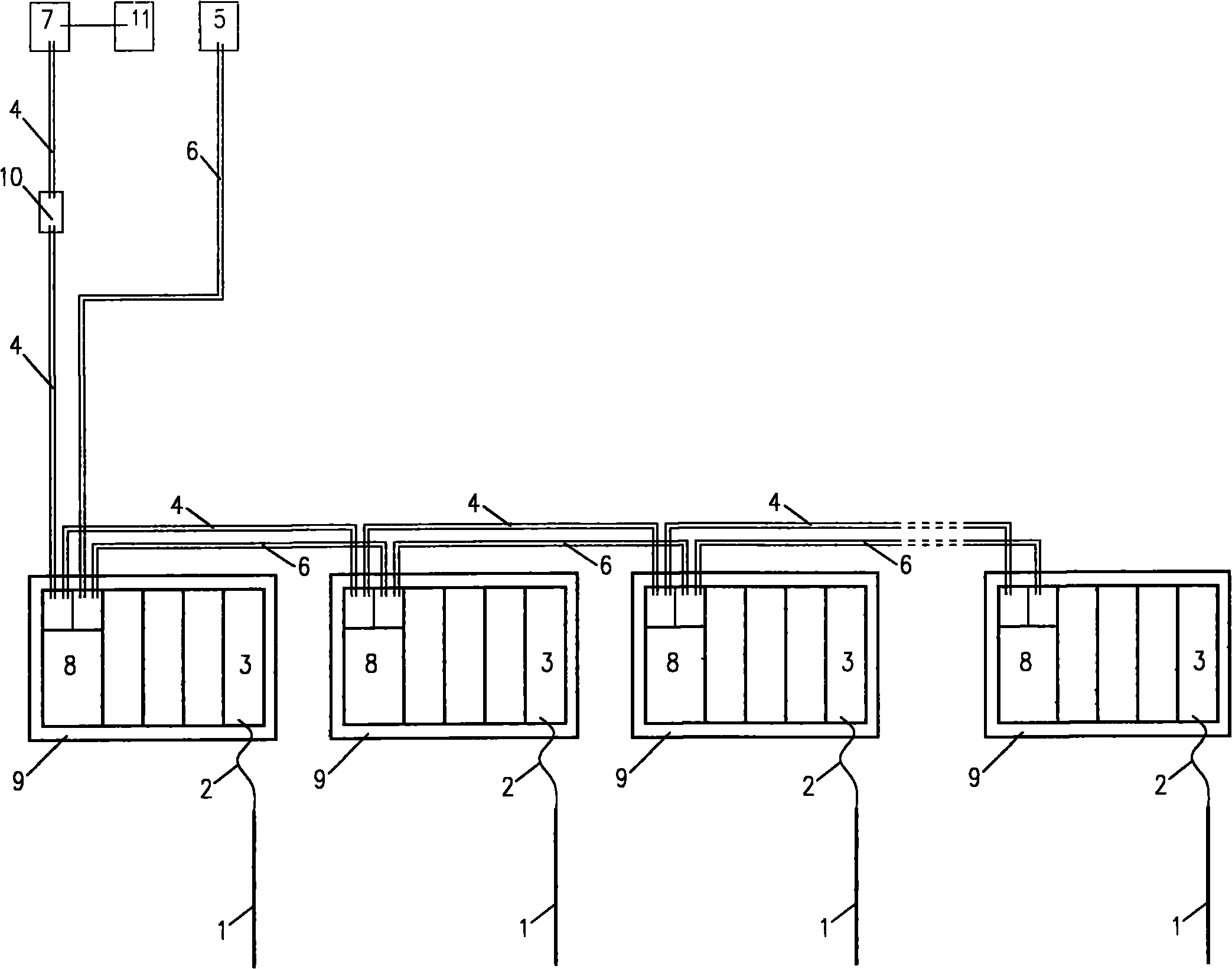

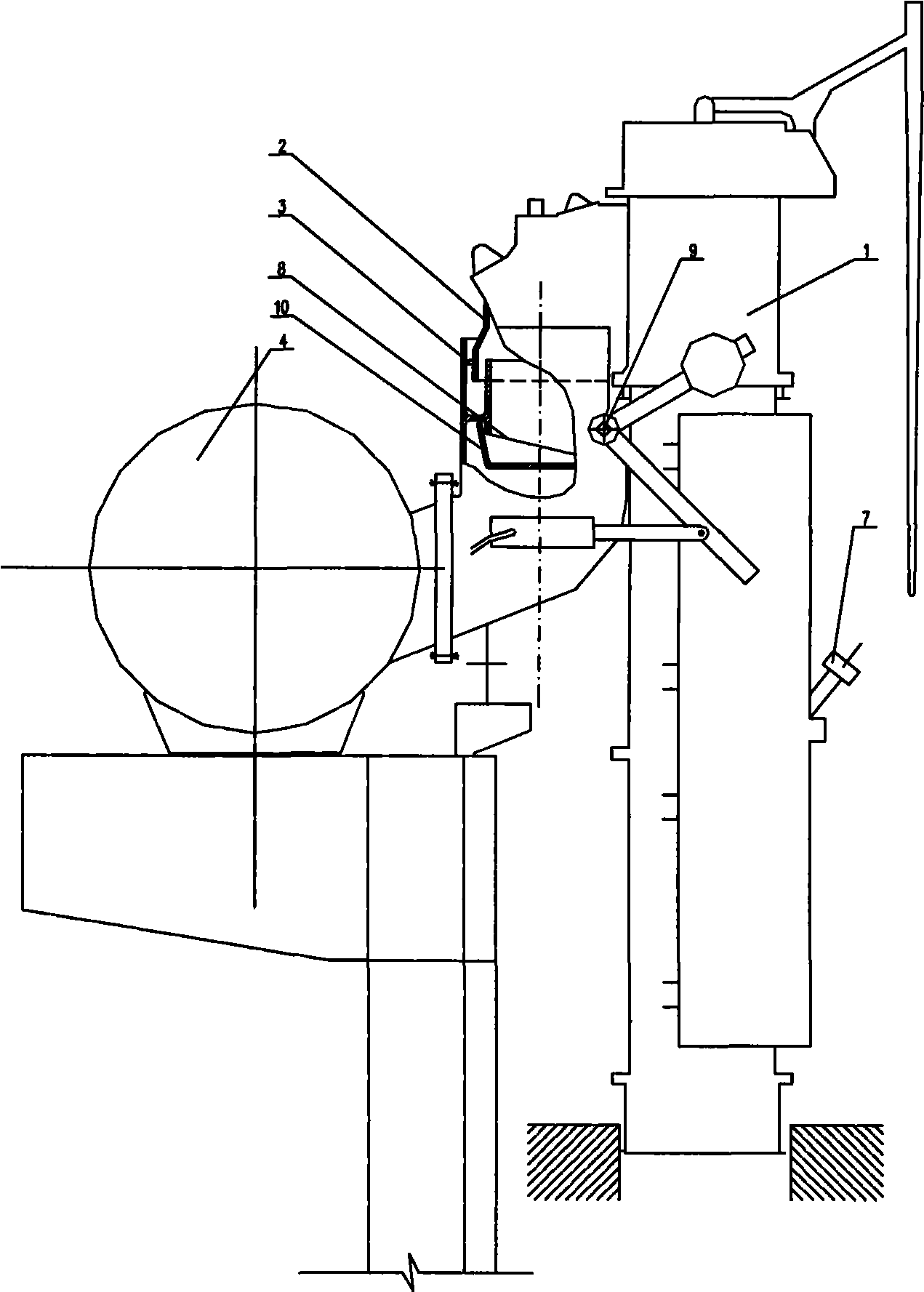

Automatic monitoring system for oven drying temperature of coke oven

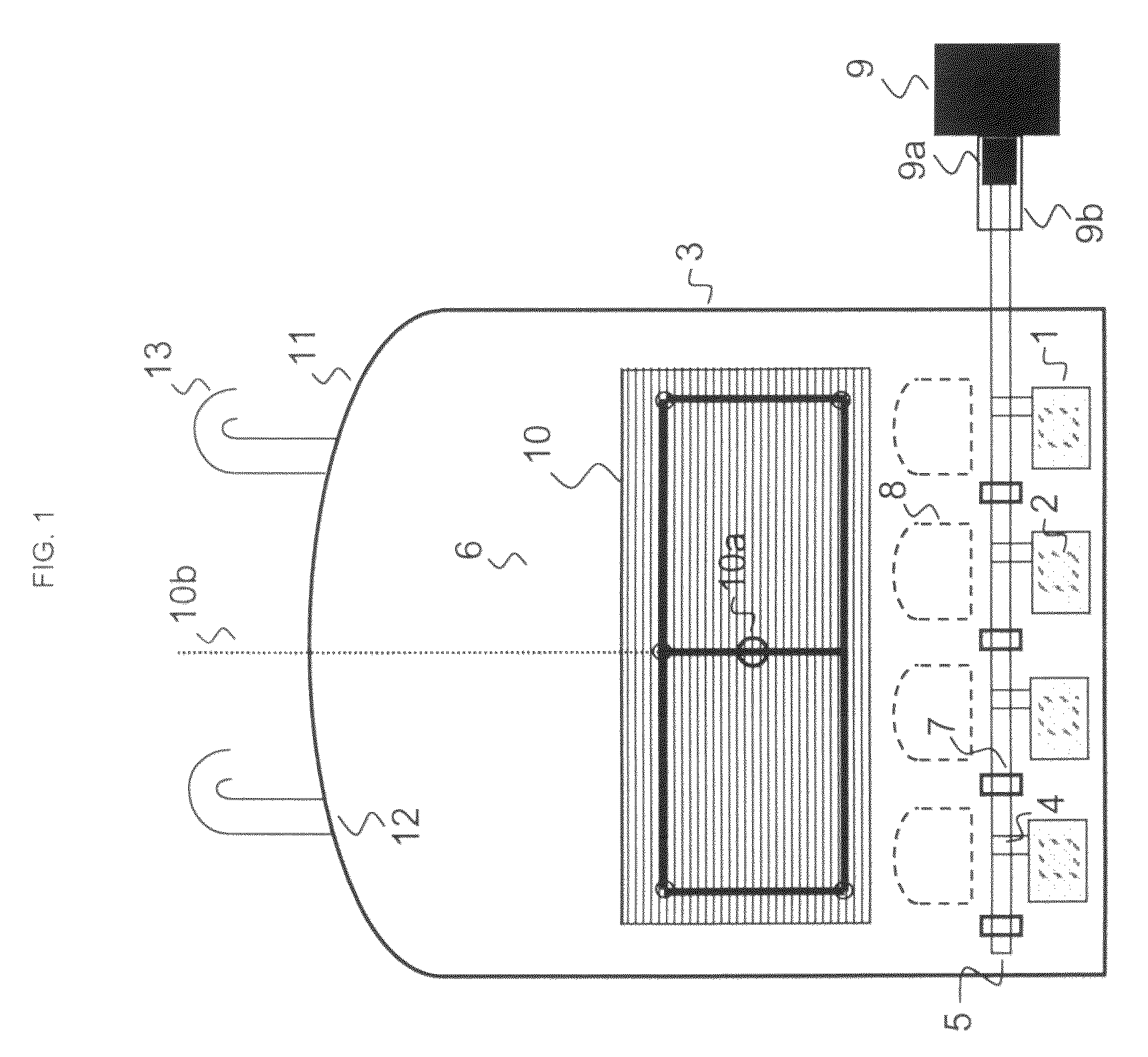

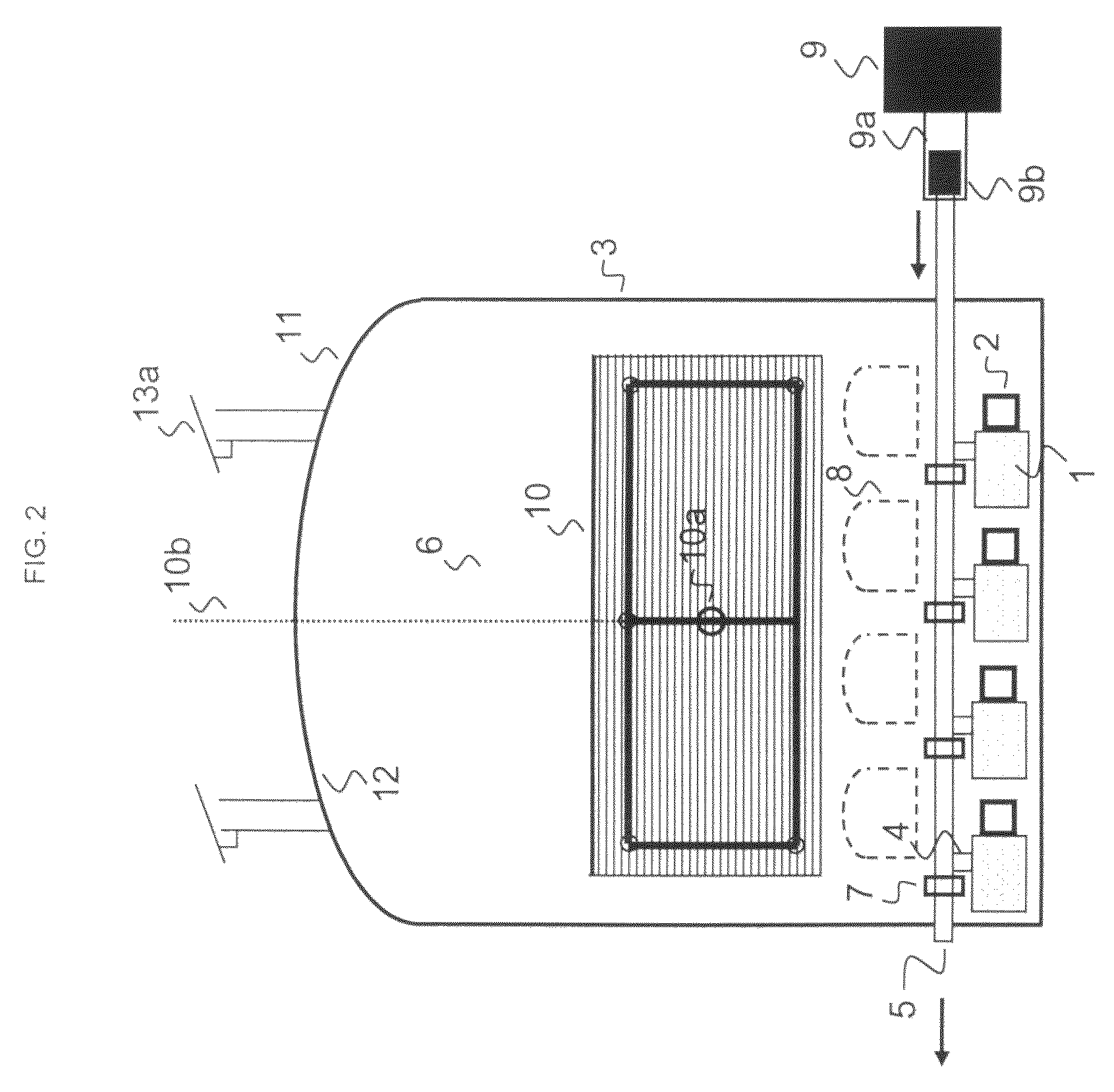

ActiveCN101781574ACoherentComparableCoke oven safety devicesThermometers using electric/magnetic elementsMonitoring systemTemperature monitoring

The invention relates to the technical field of temperature measurement devices using thermoelectric elements, in particular to an automatic monitoring system for the oven drying temperature of a coke oven. The automatic monitoring system comprises a thermocouple (1), a compensating lead wire (2), a temperature acquisition module (3), a shielding data line (4), an industrial power supply (5), a power supply conducting wire (6) and an upper computer (7). The invention is characterized in that the automatic monitoring system additionally comprises a base (8) and an acquisition box (9), the thermocouple (1) is connected with the temperature acquisition module (3) inserted on the base (8) through the compensating lead wire (2), the shielding data line (4) is connected with the acquisition box (9), a converter (10) and the upper computer (7), the acquisition box (9) is connected with a power supply interface through the power supply conducting wire (6), the acquisition box (9) is connected with the upper computer (7) and the industrial power supply (5), and a temperature monitoring control program is resided in the upper computer (7). The invention has the advantages that the detection precision is high and the oven drying quality is improved.

Owner:MCC5 GROUP CORP SHANGHAI

Device and method for controlling diffusion of gas collecting pipe

The invention relates to a device and a method for controlling the diffusion of a gas collecting pipe. The device comprises a burner, a diffusion pipe, an igniter cabinet, a control cabinet, a diffusion valve, a diffusion valve executing mechanism, a fire collection valve, a fire extinguishing valve and a pressure transmitter, wherein the burner is positioned at the upper part of the diffusion pipe, the igniter cabinet is connected with the burning torch on the burner through a cable, the fire collection valve is connected with the fire collection pipe of the burner, and the fire extinguishing valve is connected with the fire extinguishing pipe of the burner; the diffusion valve is positioned at the joint of the diffusion pipe and the gas collecting pipe and connected with the diffusion valve executing mechanism, and the pressure transmitter is arranged on the gas collecting pipe at the inlet of the diffusion pipe; and the motion of the diffusion valve executing mechanism of the gas collecting pipe is controlled through the continuous monitoring of the pressure of the gas collecting pipe, the fluctuation of the pressure is maintained within a reliable range, the sequential motions of the associated ignition device, the steam fire collection and smoke abatement valve and the steam fire extinguishing valve are synchronously controlled to achieve the optimal scheme. The invention has the advantages of rapid response, safety and reliability, good burning effect and environmental protection.

Owner:ACRE AUTOMATION CO LTD MCC

Automatic pressure regulating method and device for coke oven chamber

InactiveCN101519596AAvoid negative pressureAchieving non-spillCoke oven safety devicesPipe waterCoke oven

The invention relates to an automatic pressure regulating method and a device for a coke oven chamber, which is characterized in that the lower end of a cylinder of a bridge pipe water sealing valve device is an inclined surface, the inclined surface is formed by inclining downwards towards the nearest (farthest) end from the farthest (nearest) end of a water sealing valve disc shaft of the bridge pipe water sealing valve device in a mode of oblique lines with same slope or broken lines and curve contours with different slopes, rotation of the water sealing valve disc shaft enables one end of the water sealing valve disc shaft closing to the inclined surface to firstly sink into a water sealing valve disc, a gas channel is formed between the upper end of the inclined surface and the water sealing valve disc, and size of gas flow is controlled by the opening size of the water sealing valve disc. The device is used for controlling the pressure of single coke oven chamber, realizes no overflow of soot when coals are charged in a coke oven and in coking period, avoids negative pressure occurring in the coking chamber in coking terminal, and prevents air from leaking into the coking chamber to burn coke and damage the oven body; the equipment has simple structure, low manufacture cost and low operation and maintenance requirement, and is easy to manufacture.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

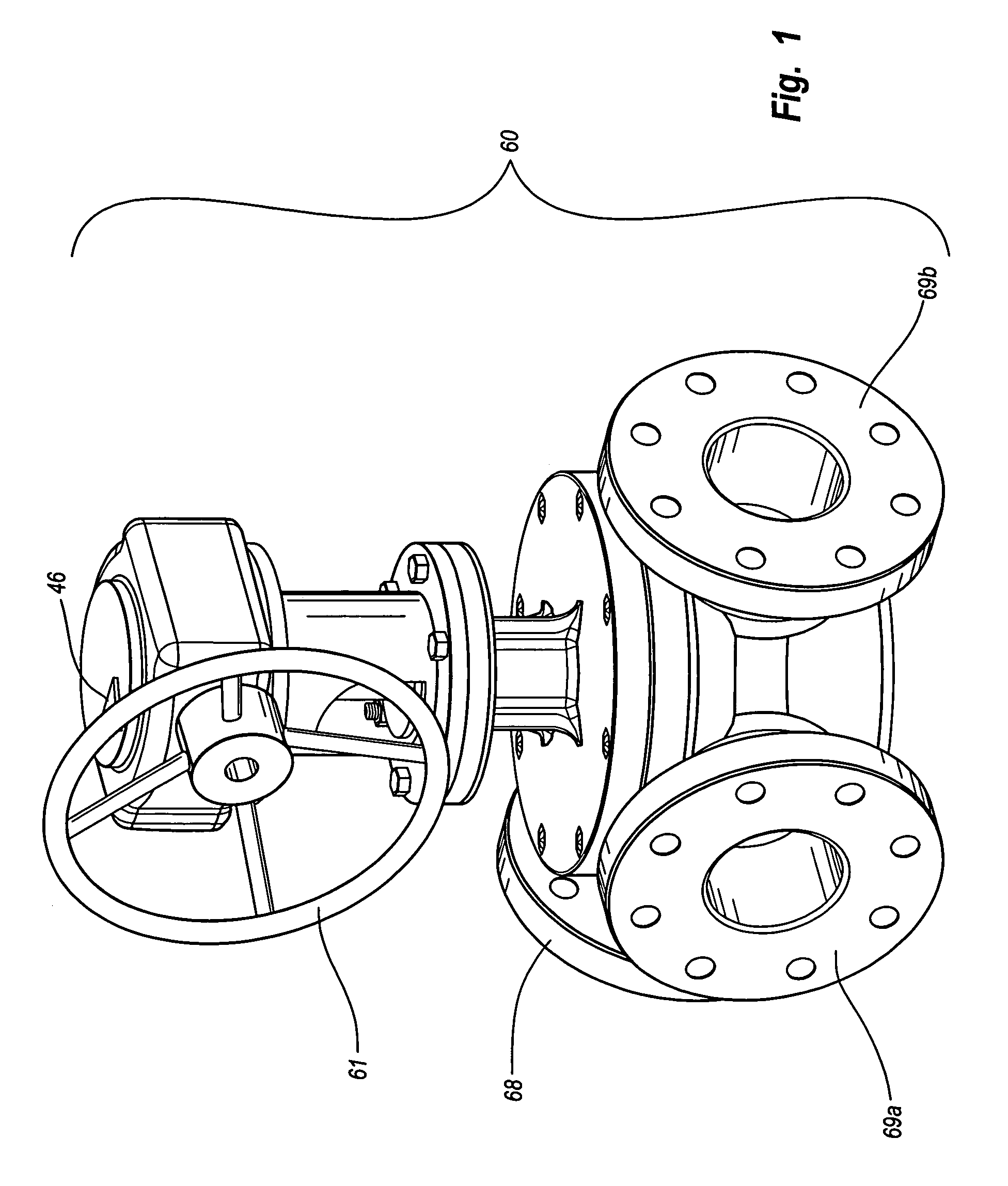

Remotely controlled decoking tool used in coke cutting operations

ActiveUS7473337B2Promote sportsImprove convenienceCoke oven safety devicesCharging-discharging device combinationsEngineeringHigh pressure

The present invention relates to a system that allows an operator to remotely switch between cutting and boring while removing solid carbonaceous residue from large cylindrical vessels called coke drums comprising a cutting head for ejecting high pressure fluids into the coke bed; a flow diversion apparatus; and a shifting apparatus.

Owner:ETHICON ENDO SURGERY INC +1

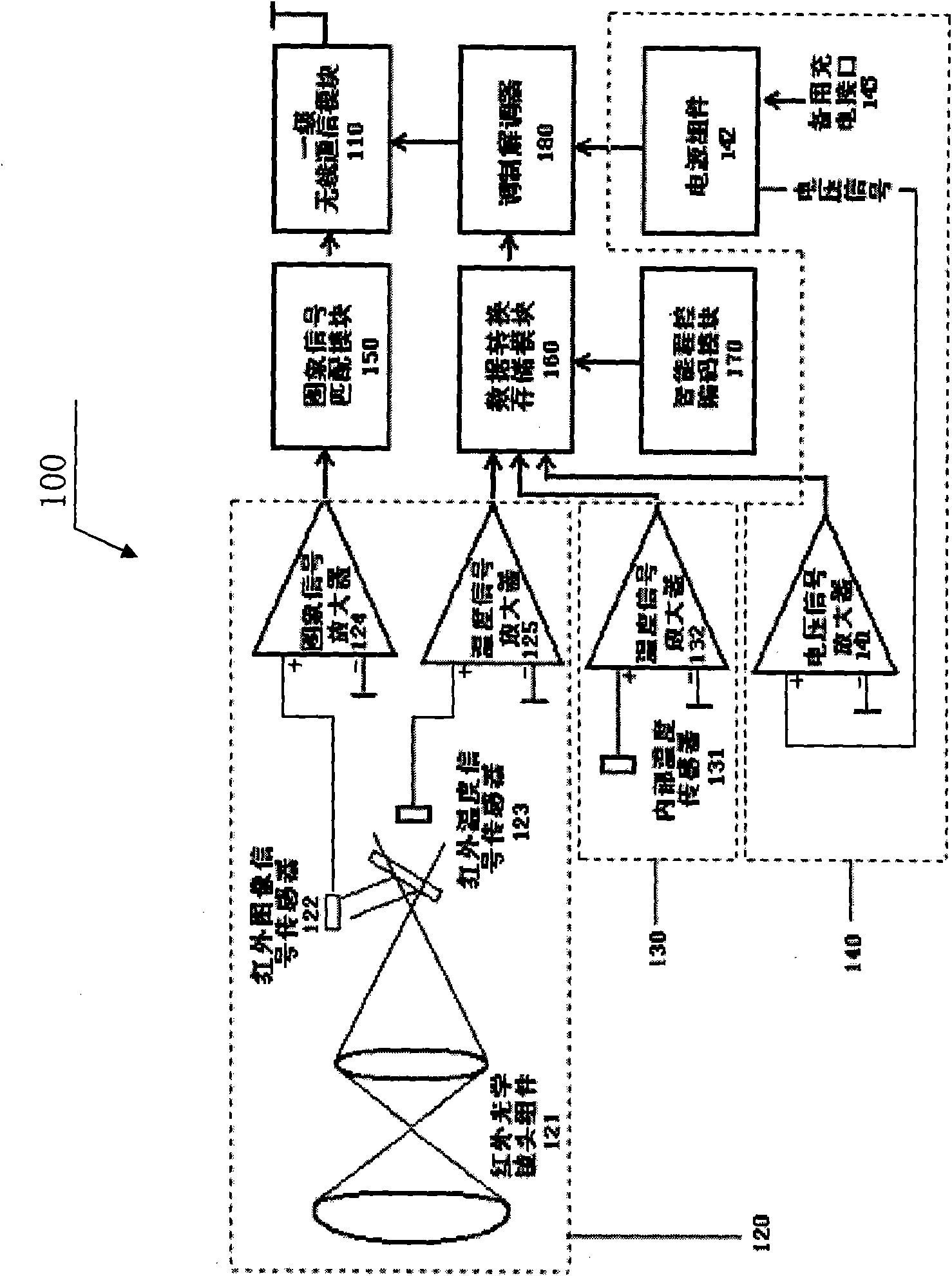

Internal wireless self-cooled continuous automatic temperature measurement method in coke oven and spectrogram device thereof

InactiveCN101598600AWith self-protection functionSo as not to damageRadiation pyrometryCoke oven safety devicesWireless dataEngineering

The invention relates to a novel device aiming at solving the problem of internal temperature measurement of a coke oven. The device comprises the following parts: an intelligent wireless data collection and transmission device, a bionic high-temperature-resistant protection device, a car-mounted computer workstation and a base central computer workstation, wherein the outside of the intelligent wireless data collection and transmission device is provided with the bionic high-temperature-resistant protection device. The intelligent wireless data collection and transmission device carries out mutual contact and information transmission with the car-mounted computer workstation by first-grade wireless communication. The car-mounted computer workstation carries out mutual contact and information transmission with the base central computer workstation by second-grade wireless communication. The device can substitute an original indirect temperature measurement device to carry out wide-angle multi-directional entire direct temperature measurement. A set of temperature measurement devices can be continuously and repeatedly used, has no interchangeable error, can carry out periodical common measurement to tens of thousands of important temperature measurement points of the coke oven, and has accurate measurement data, easy management, easy maintenance and very high direct economic benefits.

Owner:上海隆缔电子设备有限公司

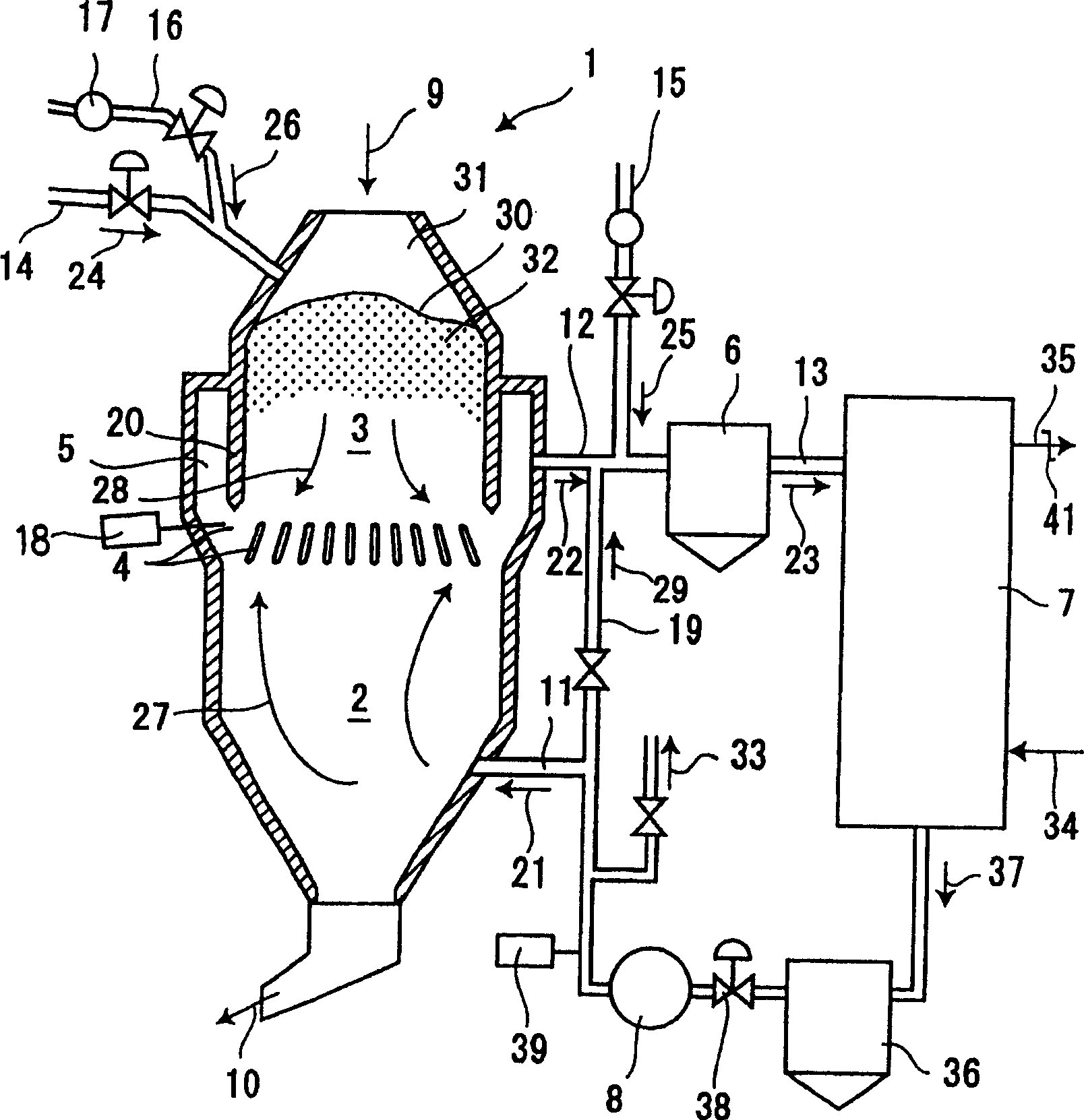

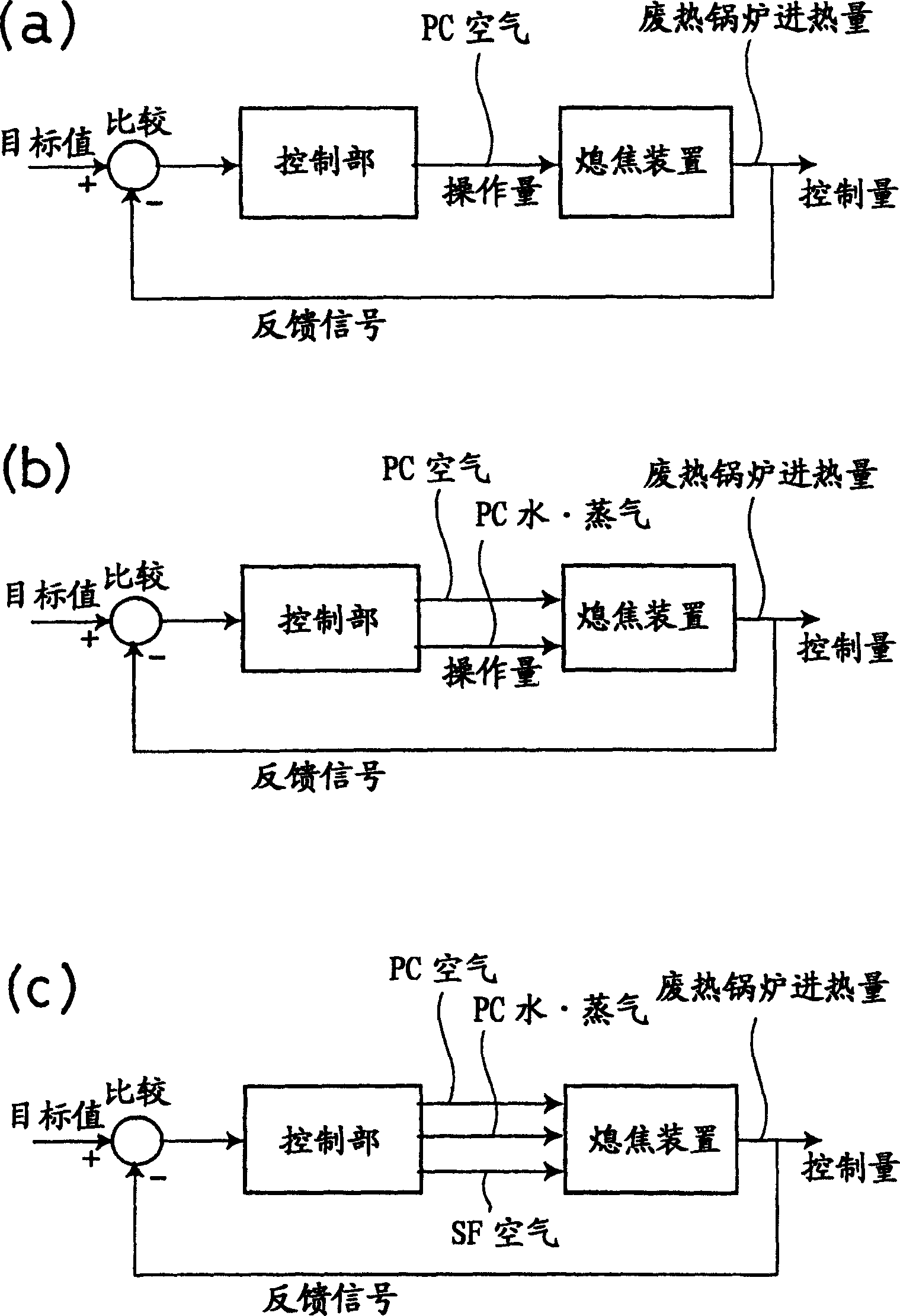

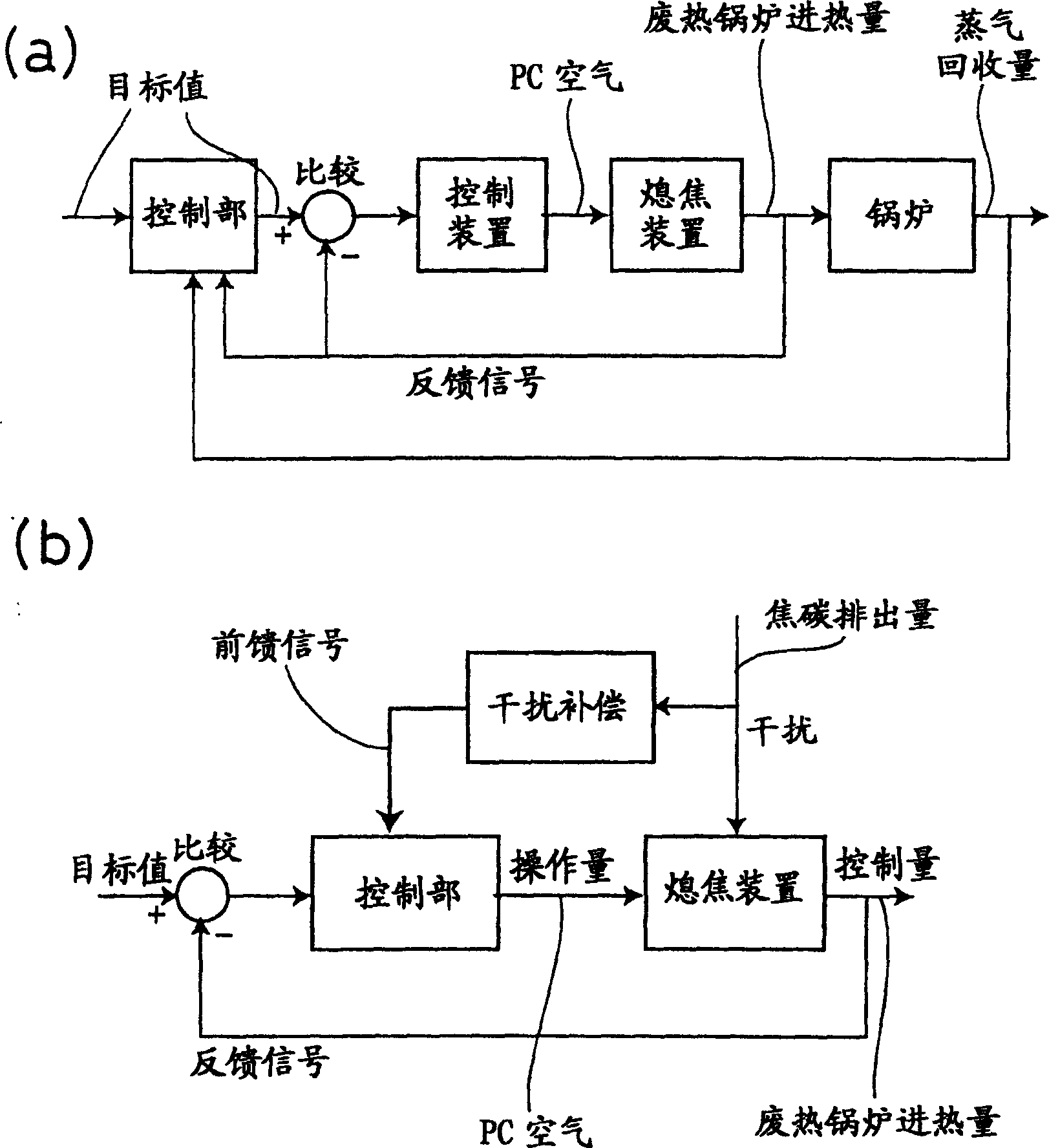

Coke dry quenching method and system

A coke dry quenching method for recovering heat in the form of steam in a waste heat boiler using a quenching column comprising a cooling chamber and a prechamber located above by loading red heat coke from above the prechamber, blowing air and / or water or steam into the prechamber, and exchanging sensible heat of the red heat coke in the cooling chamber using an inert gas as a medium. The quantity of steam being recovered is kept at a constant level by regulating the quantity of air and / or water or steam being blown into the prechamber such that the quantity of heat entering the waste heat boiler has a target level, the quantity of combustible gas component and oxygen component in the circulation gas is kept at a minimum level, adhesion of foreign matters to the sloping flue section is prevented, a heat recovery efficiency is prevented from lowering while protecting the boiler tubes against thermal damage, and the quantity of sensible heat being recovered is maximized while preventing increase of circulation gas ventilation resistance and protecting the boiler tubes against damage due to wear.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com