Patents

Literature

148results about How to "Reliable cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

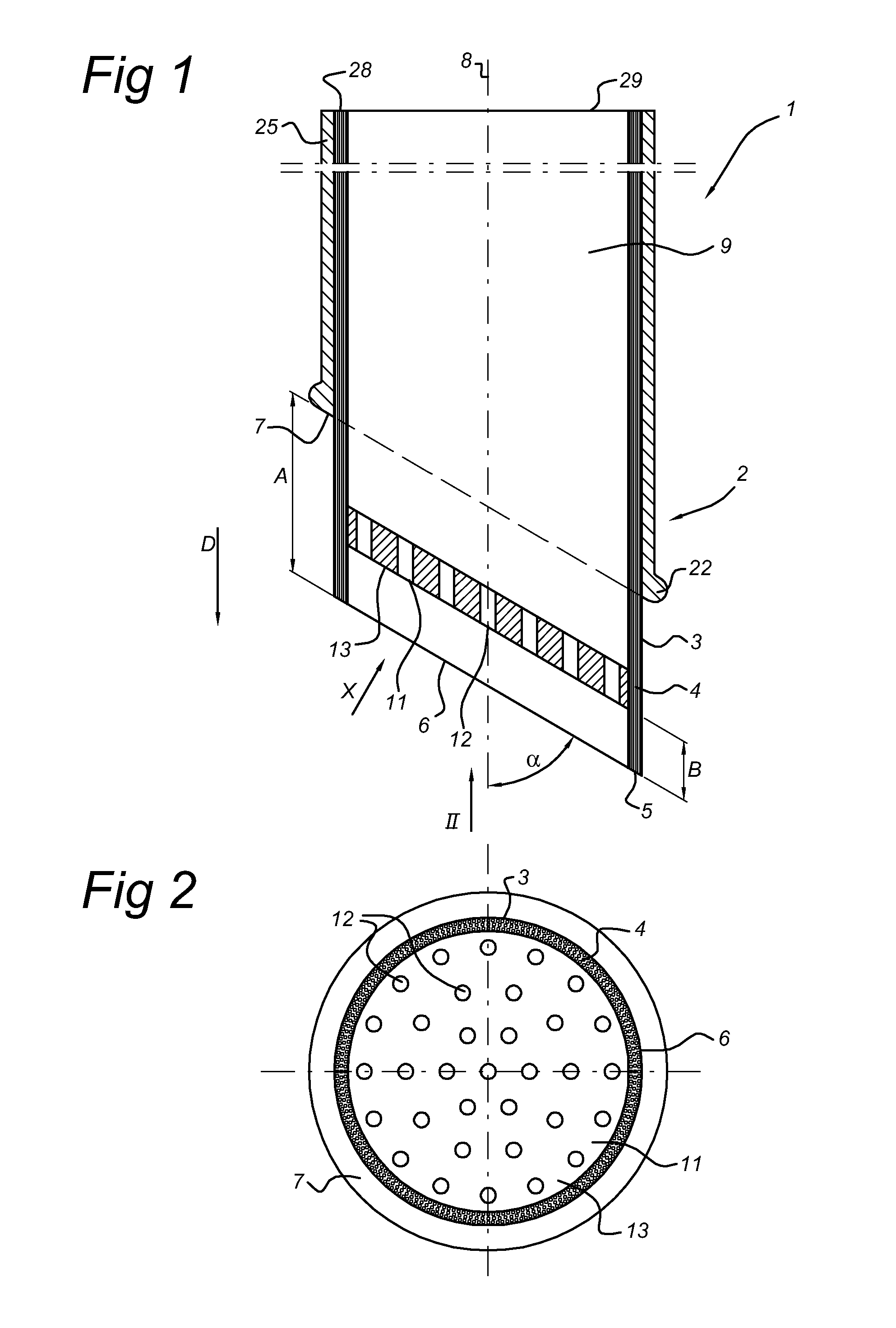

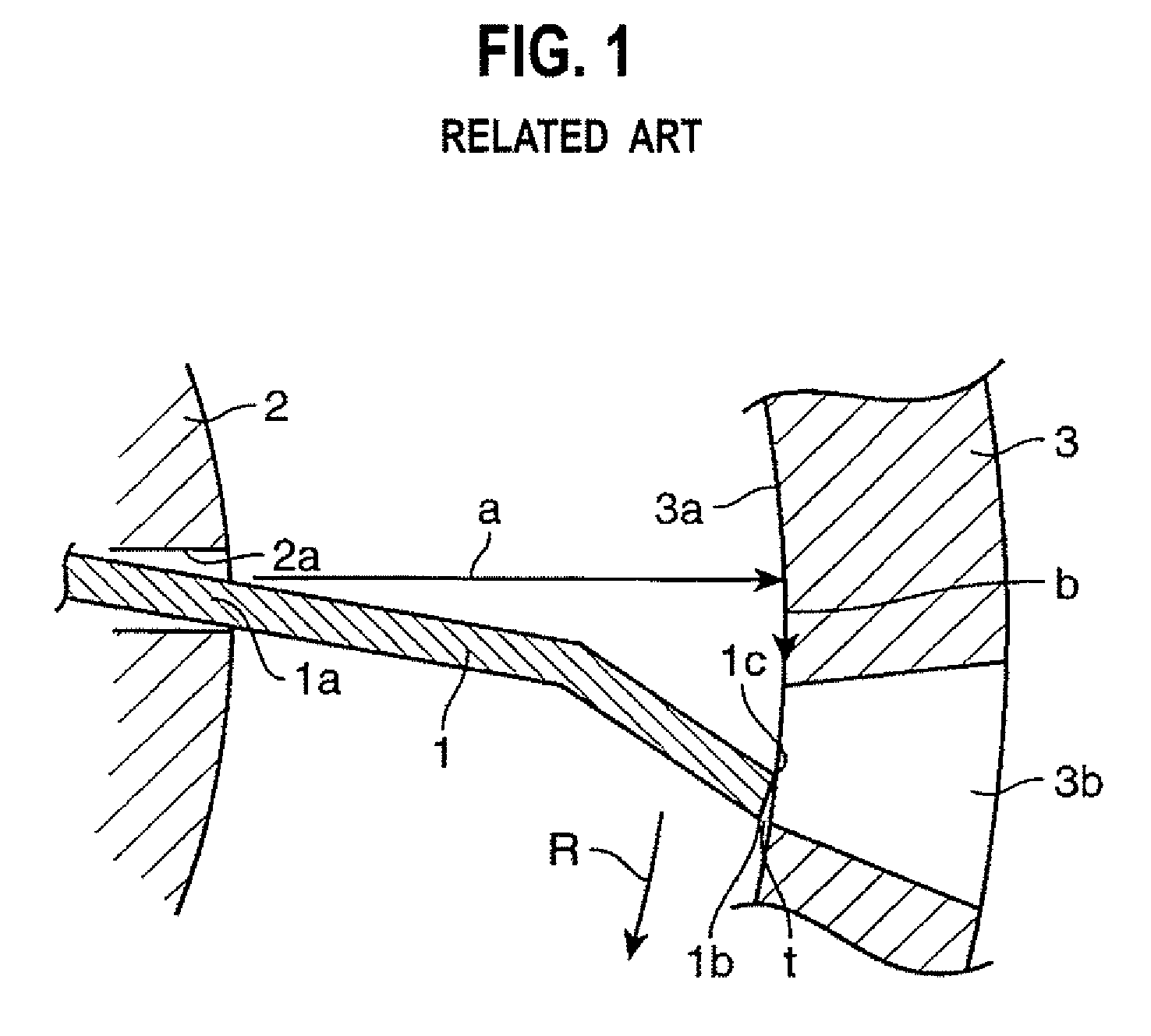

Laser catheter for bypass surgery and assembly comprising said catheter

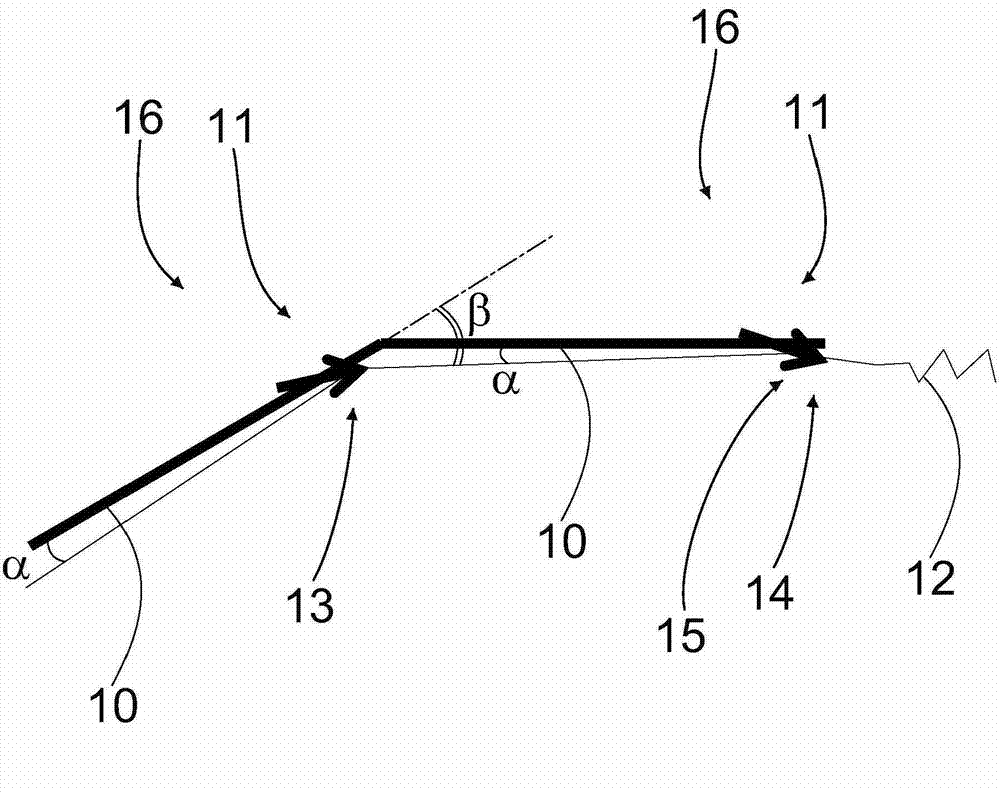

ActiveUS20100331793A1Obstruct passageAvoid leaningCatheterSurgical instrument detailsSlant angleLight beam

The invention is directed to a laser catheter (1) for bypass surgery, wherein the distal part (2) of the catheter (1) is provided with: a tubular arrangement (3) of optical fibres (4) having distal ends (5) defining a ring-shaped light emergence surface (6) for emitting a tubular bundle of light beams in the distal direction (D) of the catheter (1); and a stop surface (7) extending around the tubular arrangement (3) of optical fibres (4) and facing in the distal direction (D), the stop surface (7) being arranged at a distance (A) proximally from the light emergence surface (6). The light emergence surface (6) slants at a slanting angle (α) in the range of [20°, 60°] with respect to the longitudinal axis (8) of the catheter (1). The invention further relates to an assembly comprising such a catheter.

Owner:AMT MEDICAL

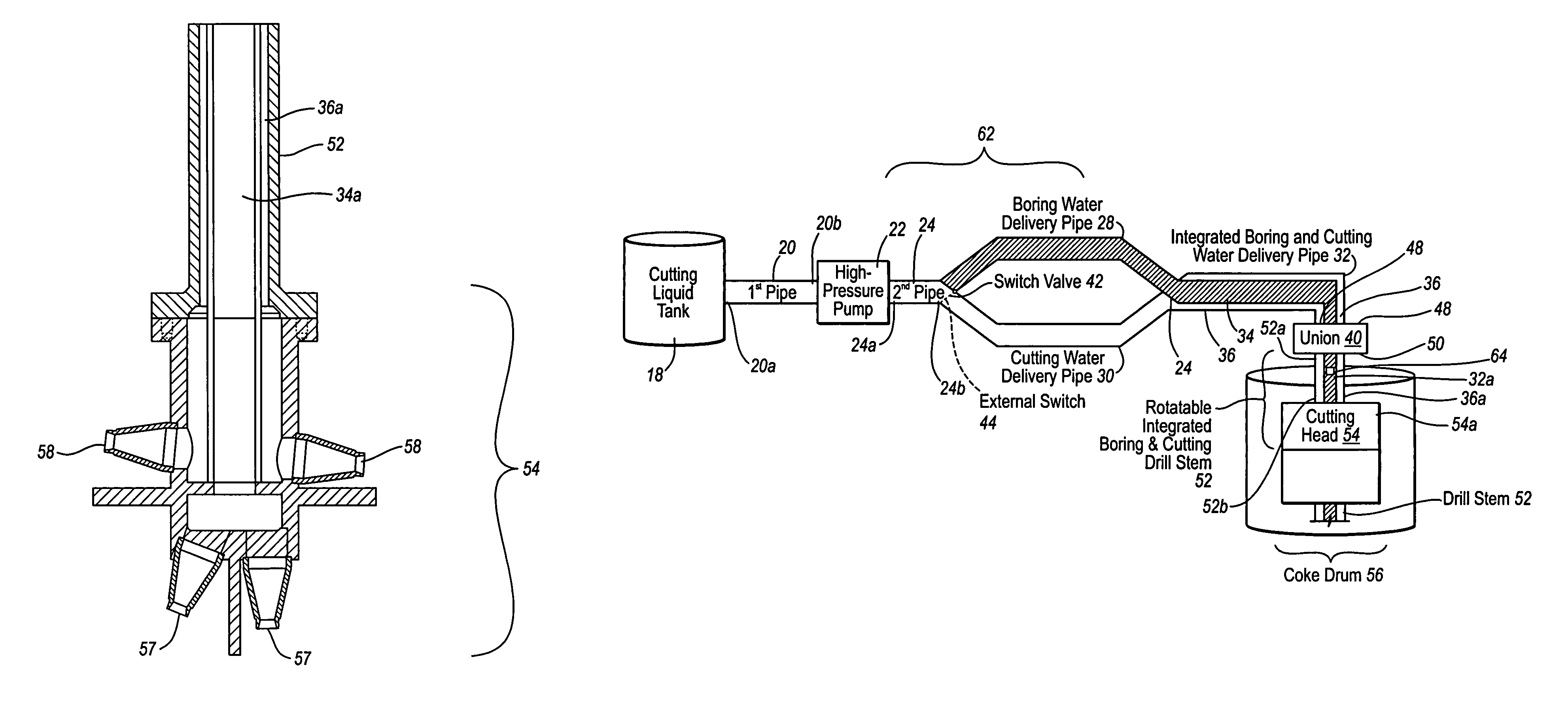

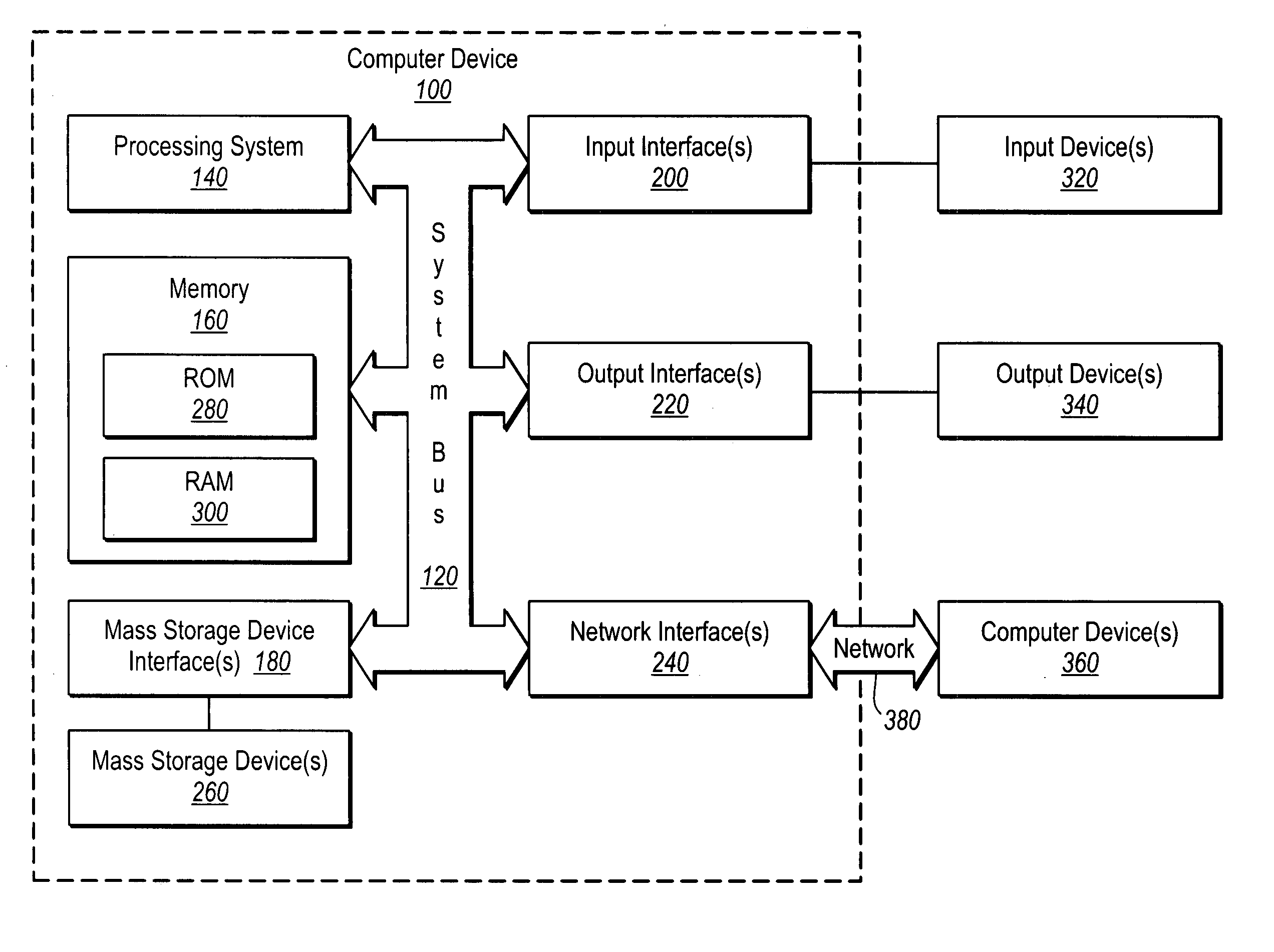

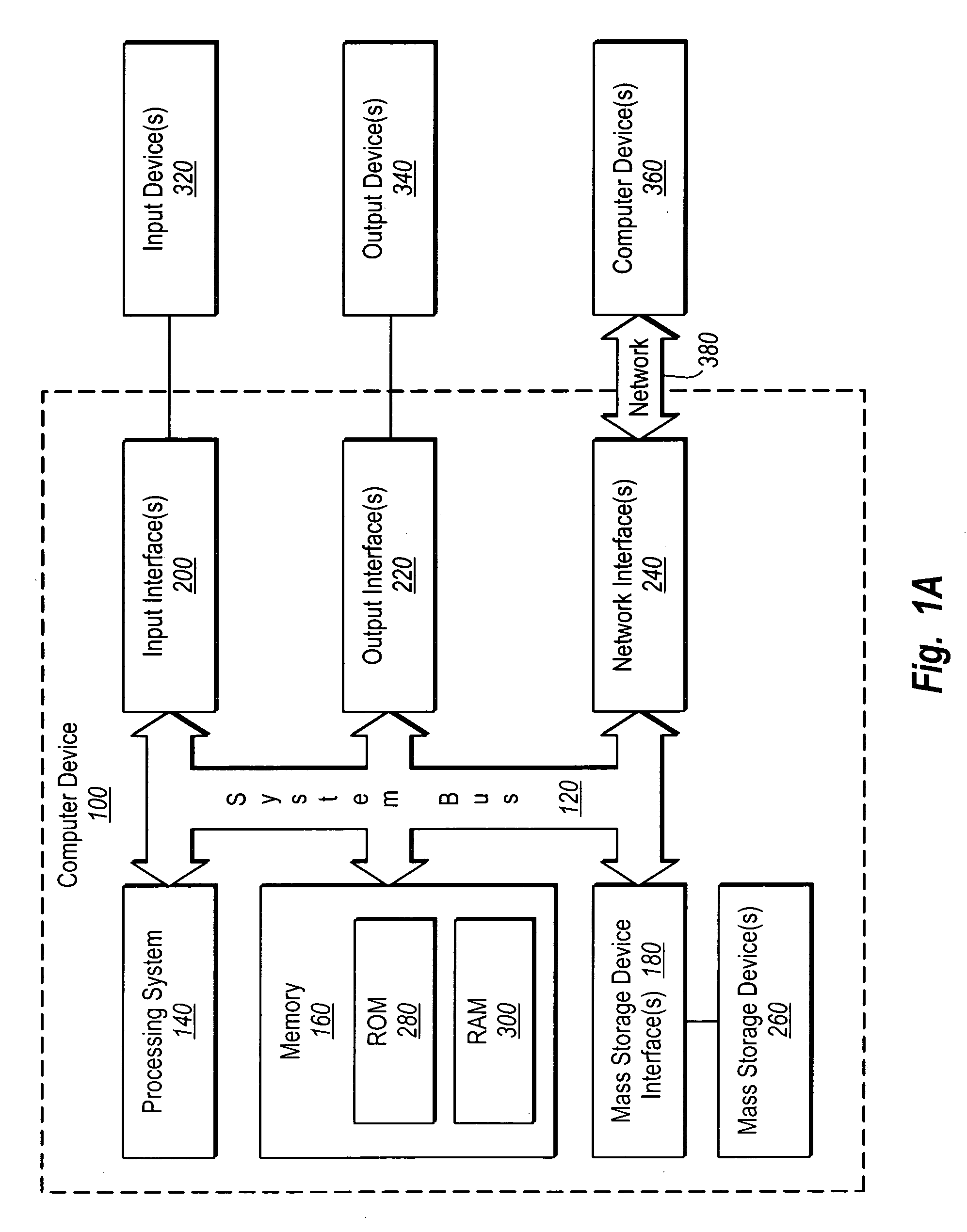

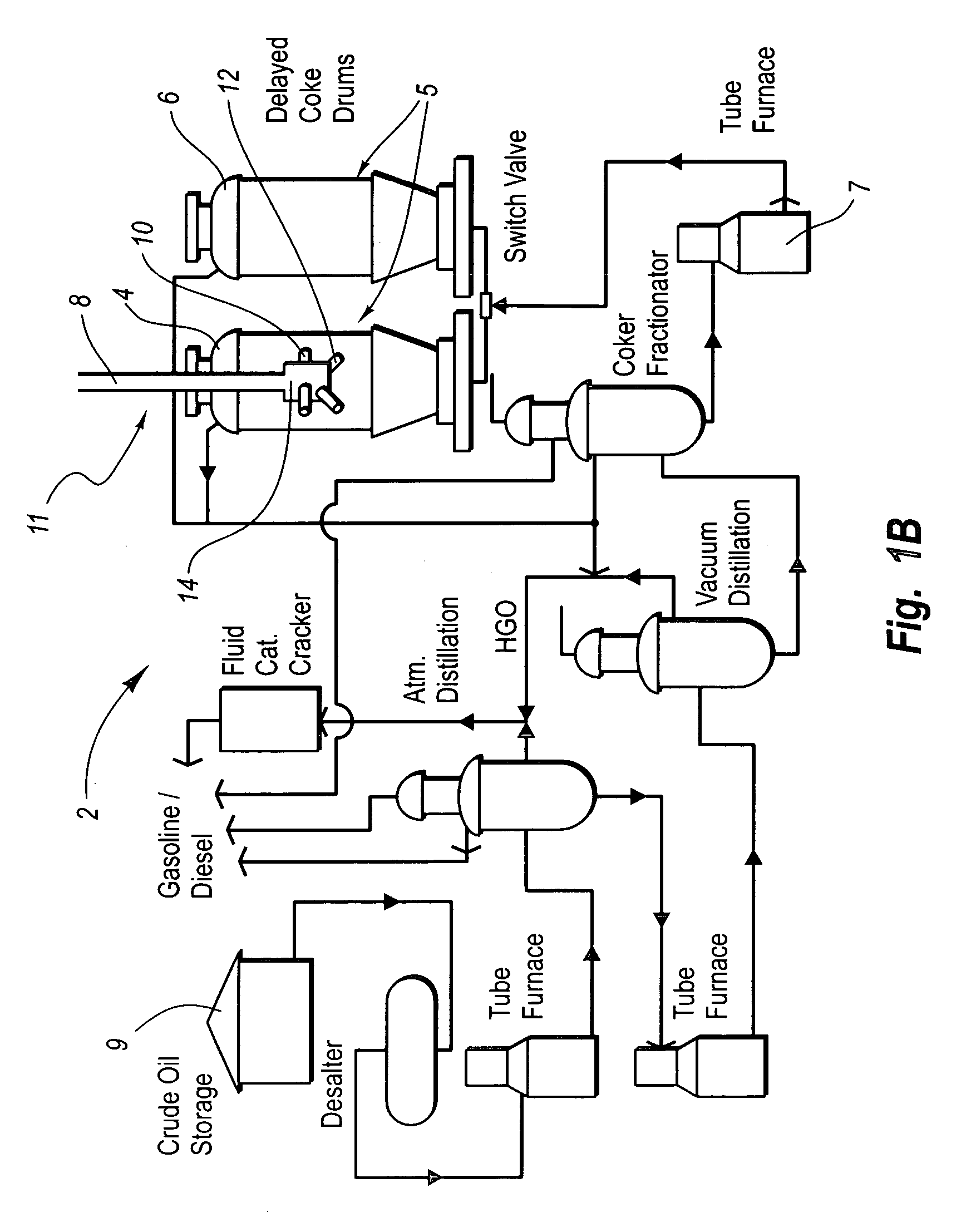

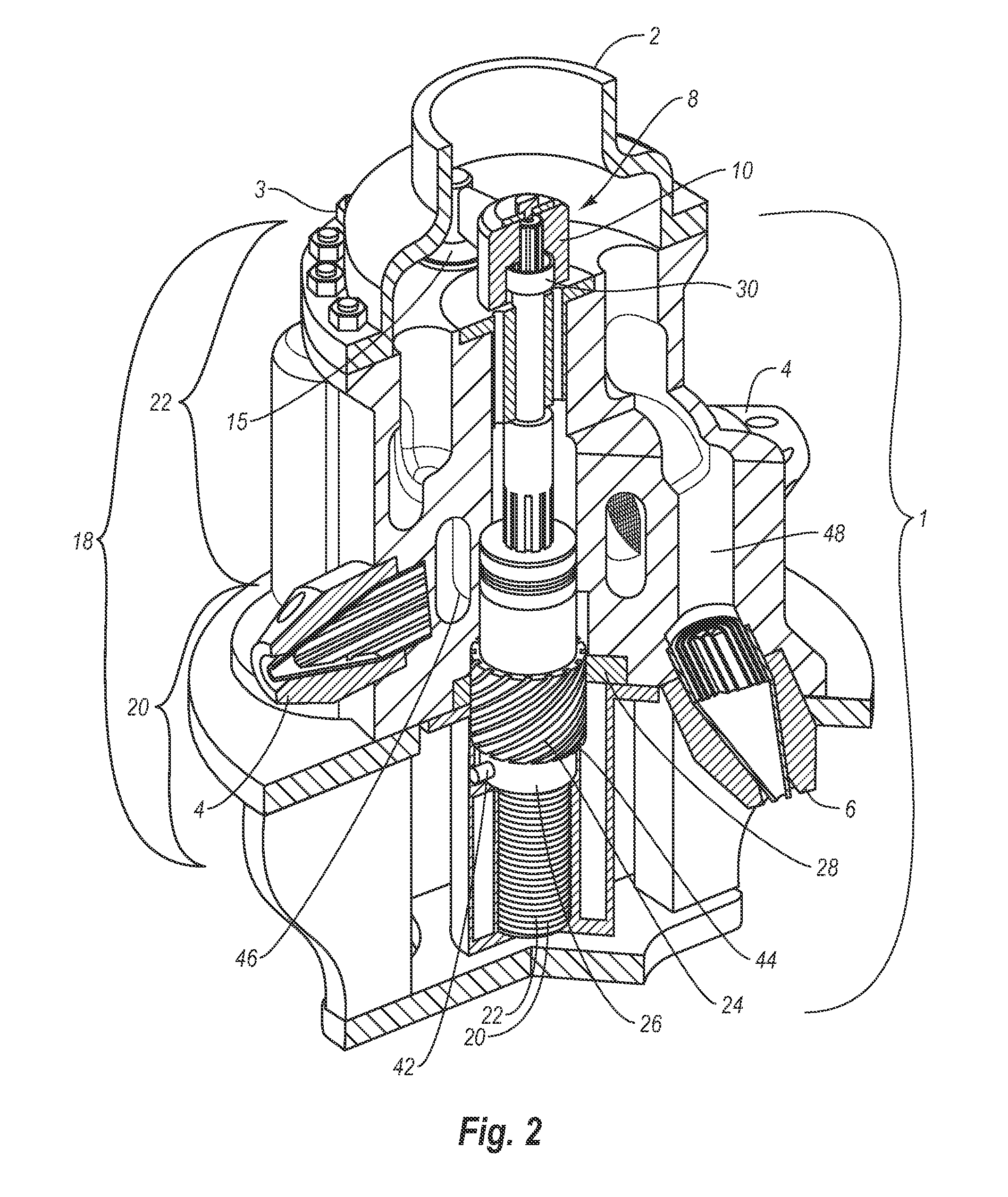

Systems and methods for remotely determining and changing cutting modes during decoking

InactiveUS7117959B2Improve convenienceImprove efficiencyCoke oven safety devicesLiquid/gas jet drillingEngineeringDrill

A decoking system that not only enables an operator to remotely switch the coke-cutting process from boring to cutting mode without removing the drill stem from the coke drum, but also to remotely determine the drill stem's mode so that efficiency, safety and convenience are not compromised, is provided.

Owner:CURTISS WRIGHT FLOW CONTROL CORP

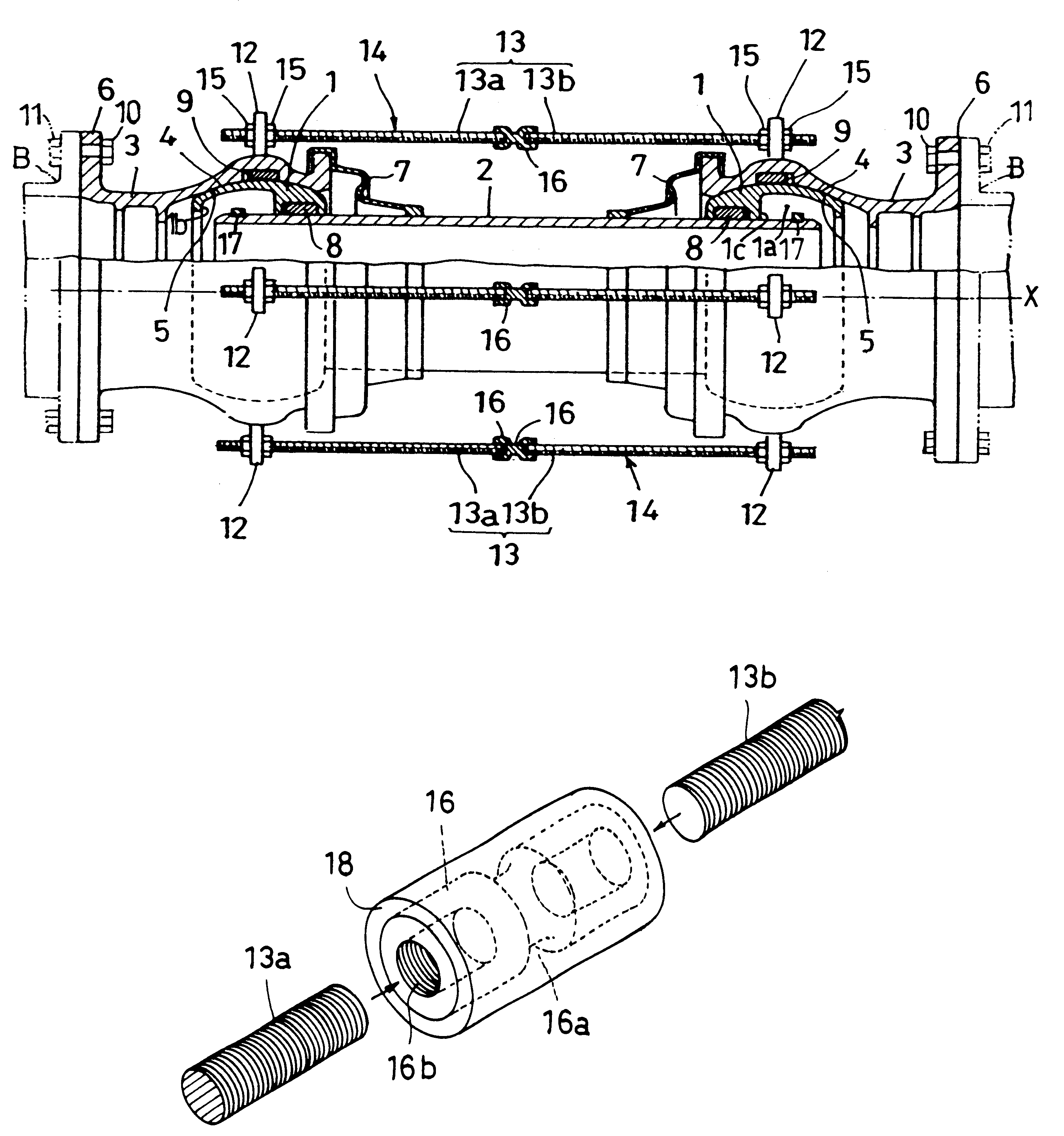

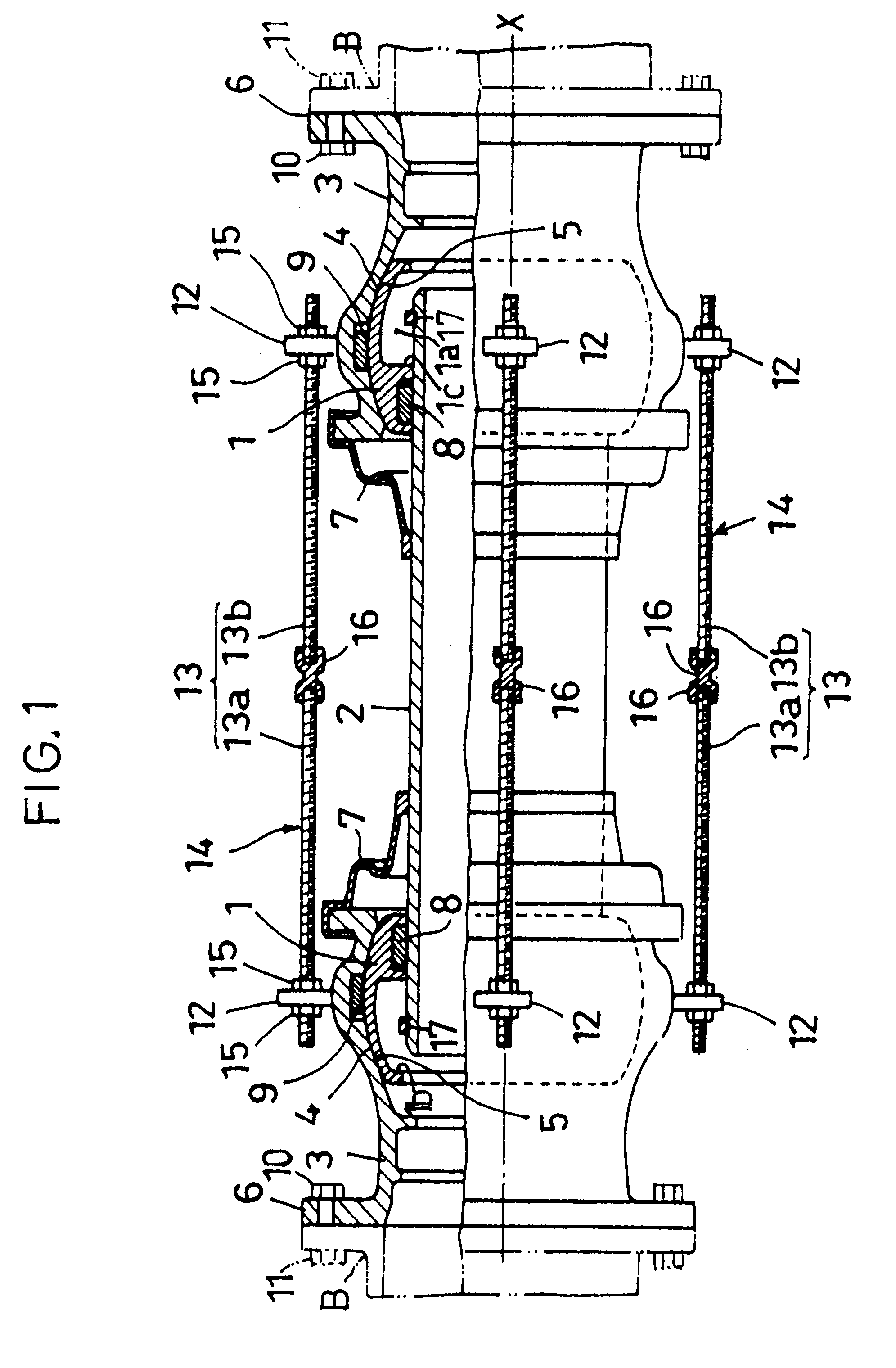

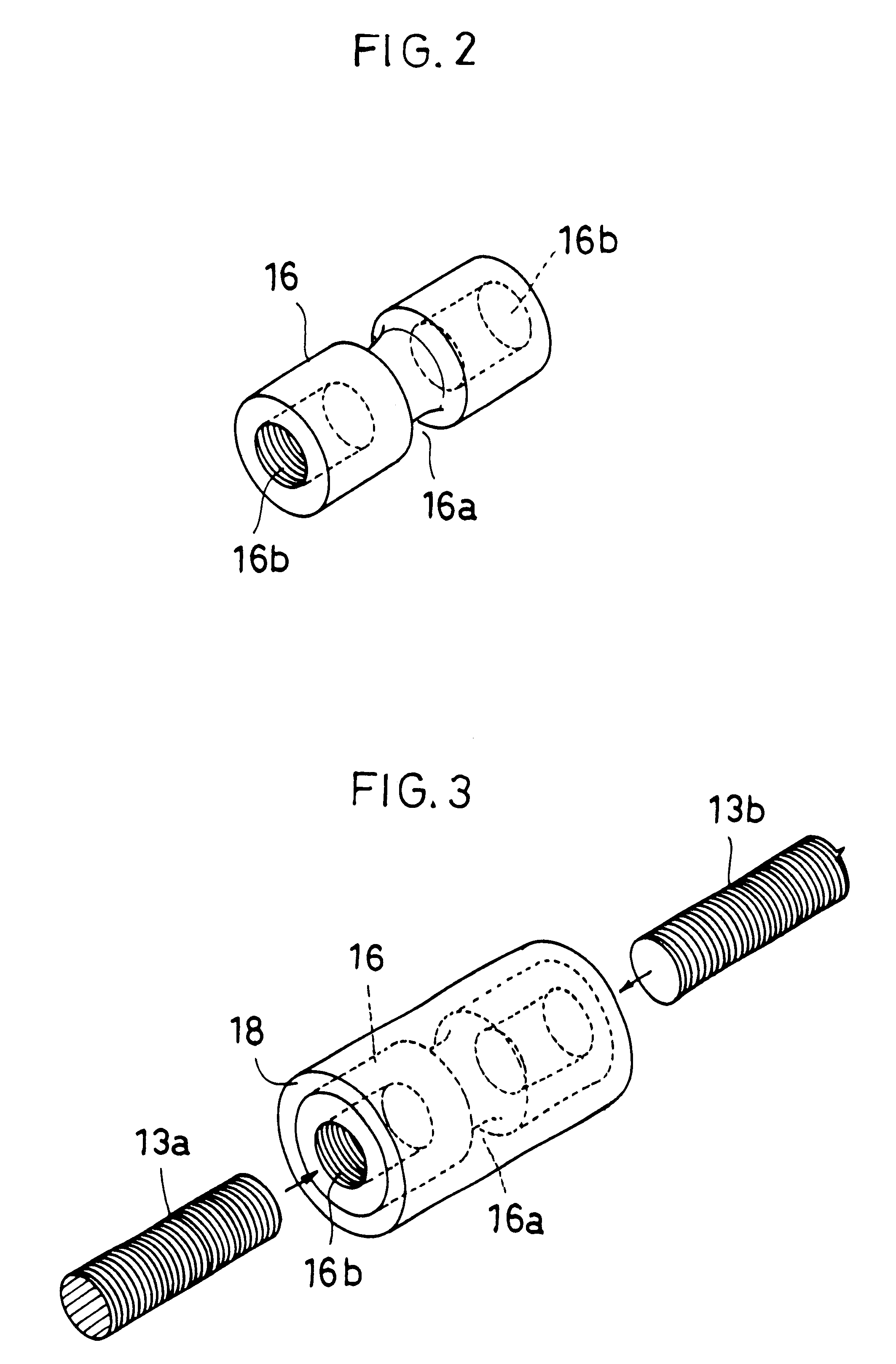

Flexible joint and long nut for flexible joint

InactiveUS6257625B1Easy to moveConveniently determinedLoad modified fastenersNutsEngineeringScrew thread

A flexible joint comprises: first cylindrical bodies comprising a pair of spherical ring members; a second cylindrical body comprising a sleeve relatively movably inserted in the first cylindrical bodies from an axial direction X of the second cylindrical body; third cylindrical bodies comprising a pair of casing tubes which are fitted around outer peripheral surfaces of the first cylindrical bodies and are provided with mutually slidable spherical inner peripheral surfaces, the casings being formed at their opposite ends with connecting portions, and being provided at their outer peripheral surfaces of large diameter portions with projections having through holes; and rods capable of being inserted into the through holes formed in the outer peripheral surfaces of the large diameter portions, each of the rods being provided and fixed between the projections of the pair of third cylindrical bodies for restricting the telescopic movement of the tube joint, wherein the rods comprise a pair of rods connected to each other in the vicinity of a substantially central portion between the opposed projections, the pair of rods being threadedly connected to at least one of bottomed holes opened and formed on opposite ends of a long nut which is provided at its substantially central portion with a notched portion so that when excessive external force is applied, the notched portion is preferentially broken to restore telescopic flexible effect of the tube joint.

Owner:TAISEI KIKO

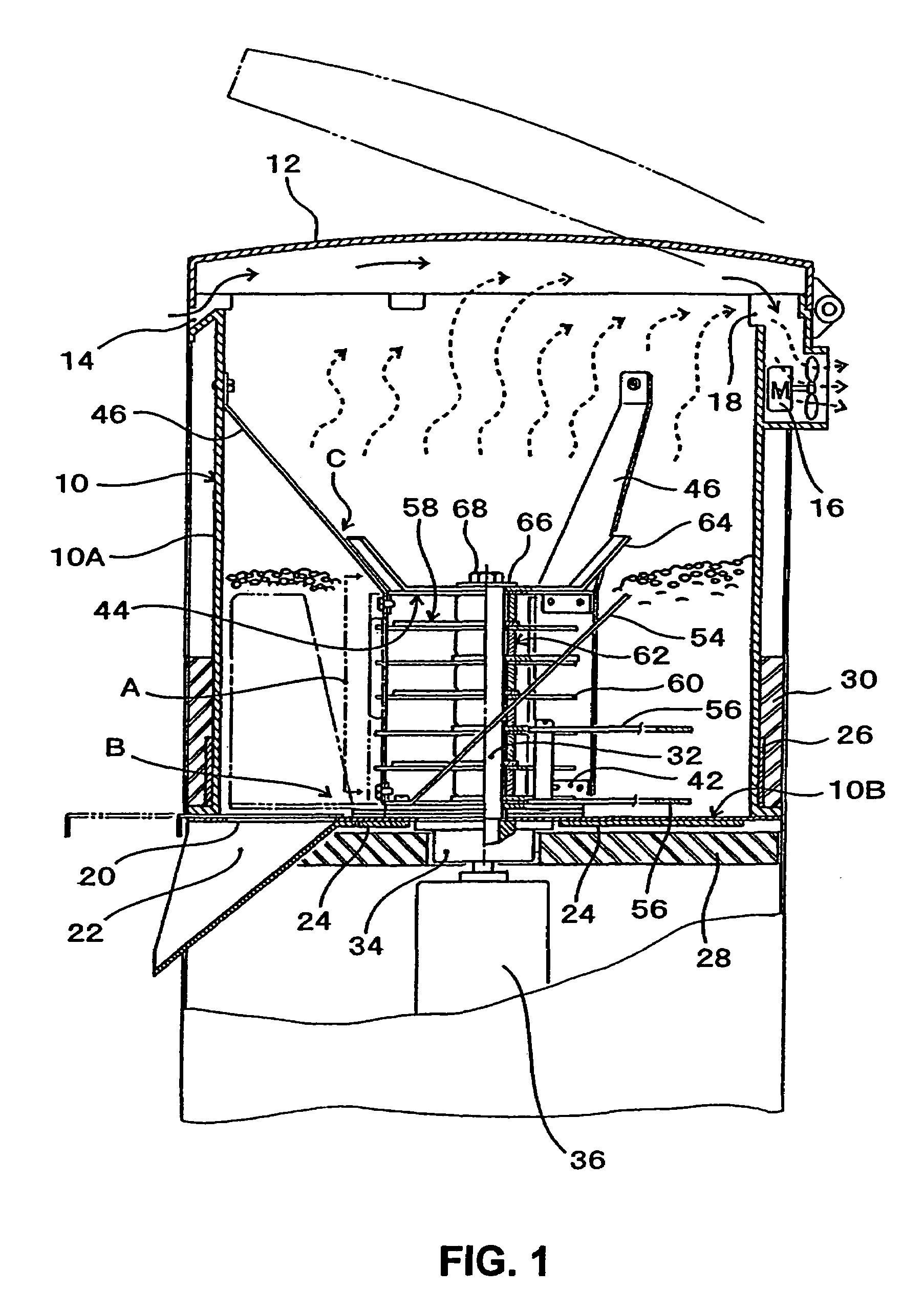

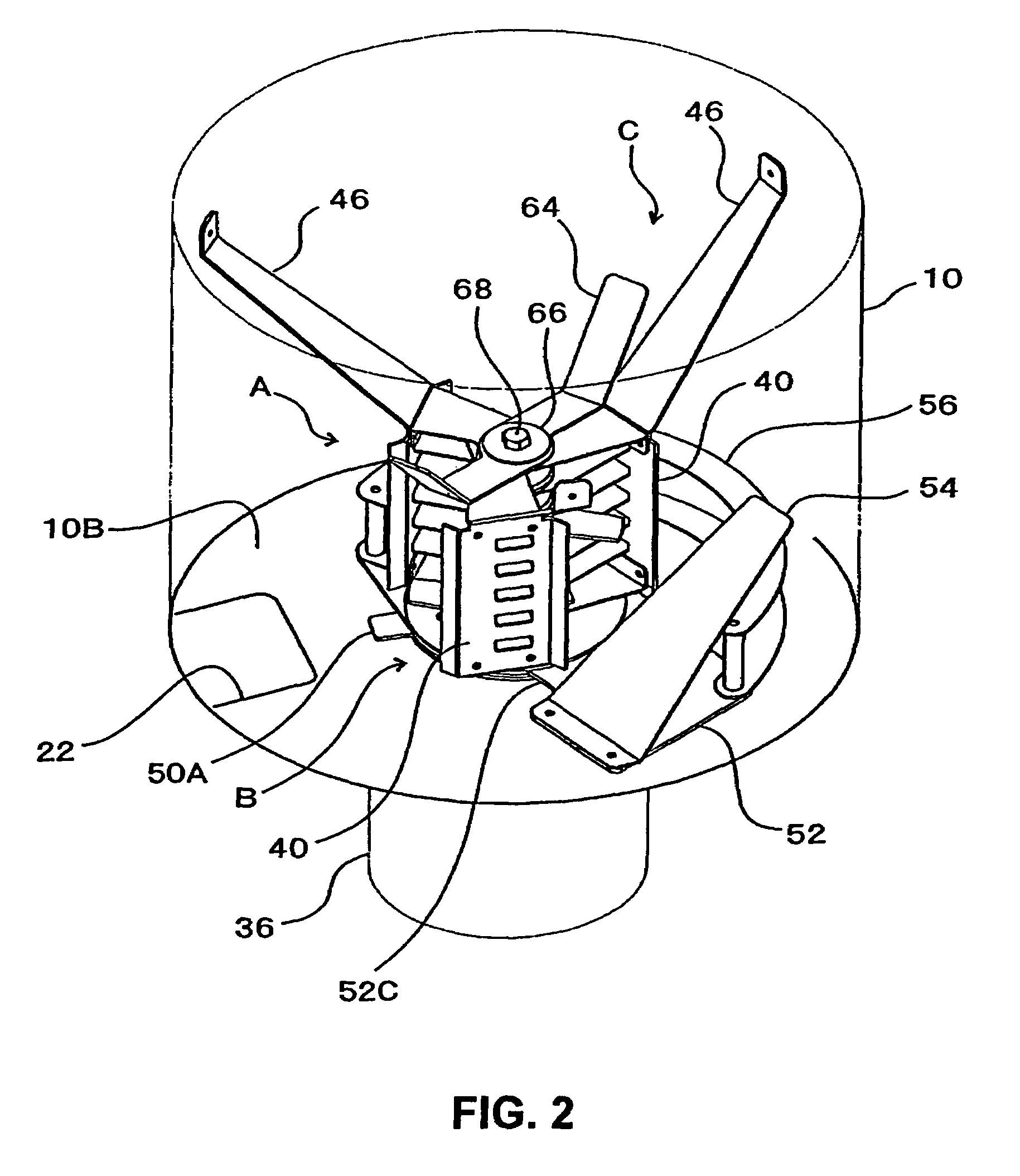

Vibration monitoring

InactiveUS20070038393A1Accurately efficiently preventReliable cuttingVibration measurement in solidsCoke oven safety devicesAccelerometerMonitoring system

Systems, devices, and methods for monitoring the status of a cutting tool during delayed decoker unit operation, and systems for remotely monitoring the level of coke or foam in a drum during the coking process. One or more sensors or accelerometers is coupled to a location in a delayed coking unit operation to read vibrations emanating from the component that the respective accelerometers are located on. Vibrational data is transmitted to a computer system that manipulates the data to provide useful information that an operator of a delayed coking unit operation may view.

Owner:CURTISS WRIGHT FLOW CONTROL CORP

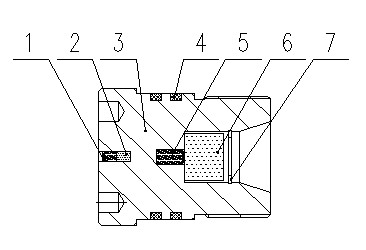

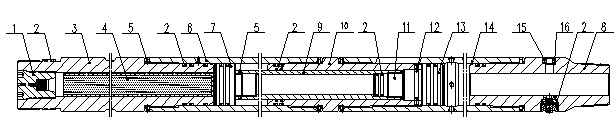

Multi-stage perforation supercharging method

The invention discloses a multi-stage perforation supercharging method. In the technological processes, a supercharging device is connected with the tail of a perforation gun of the upper level, after the perforation gun of the upper level is detonated, the perforation gun transmits detonation waves to the supercharging device, a baffle igniter of the supercharging device is detonated to ignite a supercharging gun powder mechanism, the supercharging gun powder mechanism generates high-pressure gas to push a supercharging piston to move to shear a shear pin of the supercharging device, and to push the piston to extrude a liquid inside an interlayer oil pipe so as to increase the pressure inside the interlayer oil pipe, and the shear pin of the lower-level detonation device is shorn off to detonate a pressure detonation device and a perforation gun of the lower level so as to complete the perforation operation of the lower level. The method can ensure the stability and the controllability of pressure generated due to the combustion of supercharging gun powder in a supercharging cavity, the pressure is then acted on the supercharging piston to ensure that the supercharging piston moves stably, the method can also realize high-precision shearing, can be used in a pressure type multi-stage perforation process, and is suitable for various well conditions.

Owner:CHUANNAN ENERGY TECH CO LTD

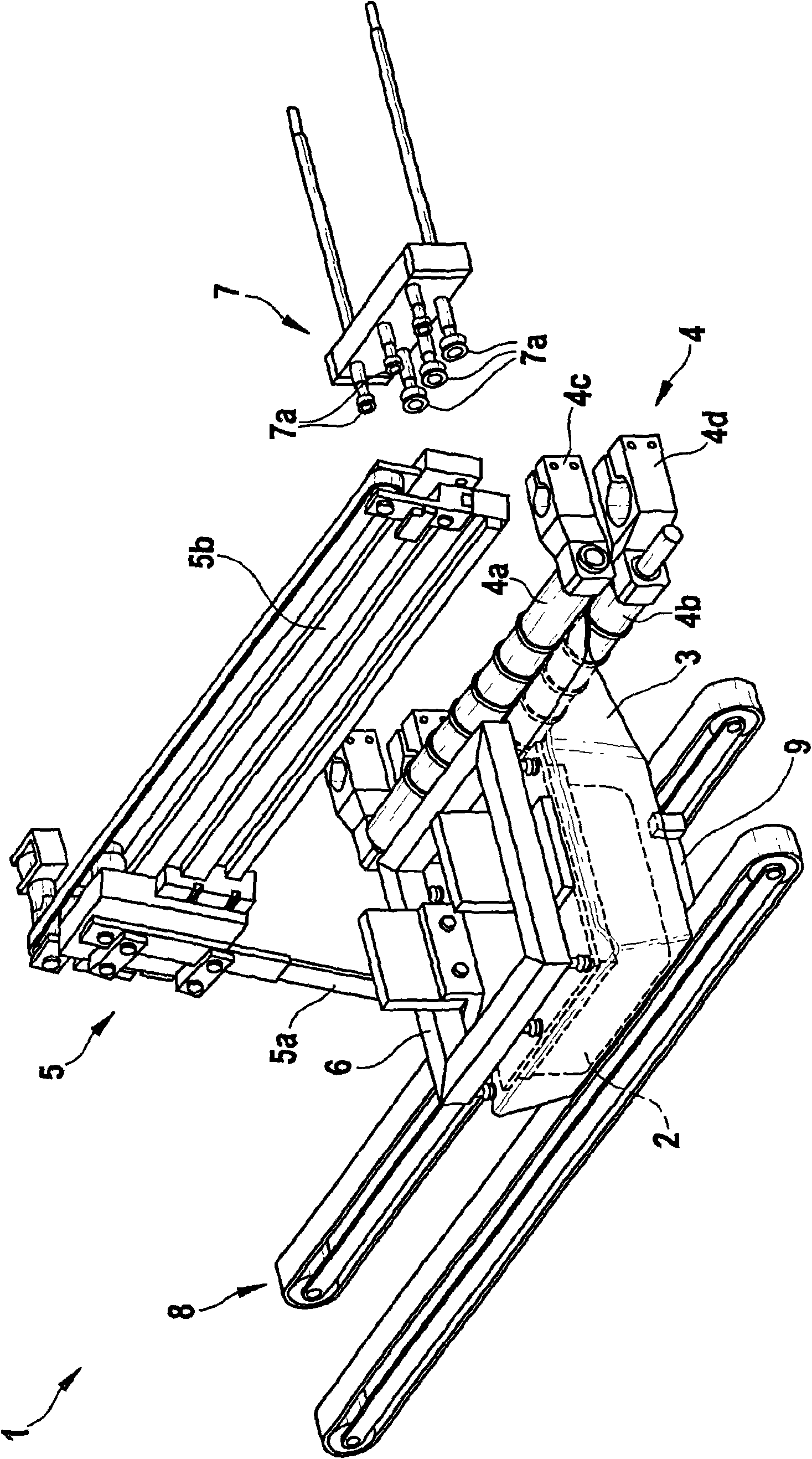

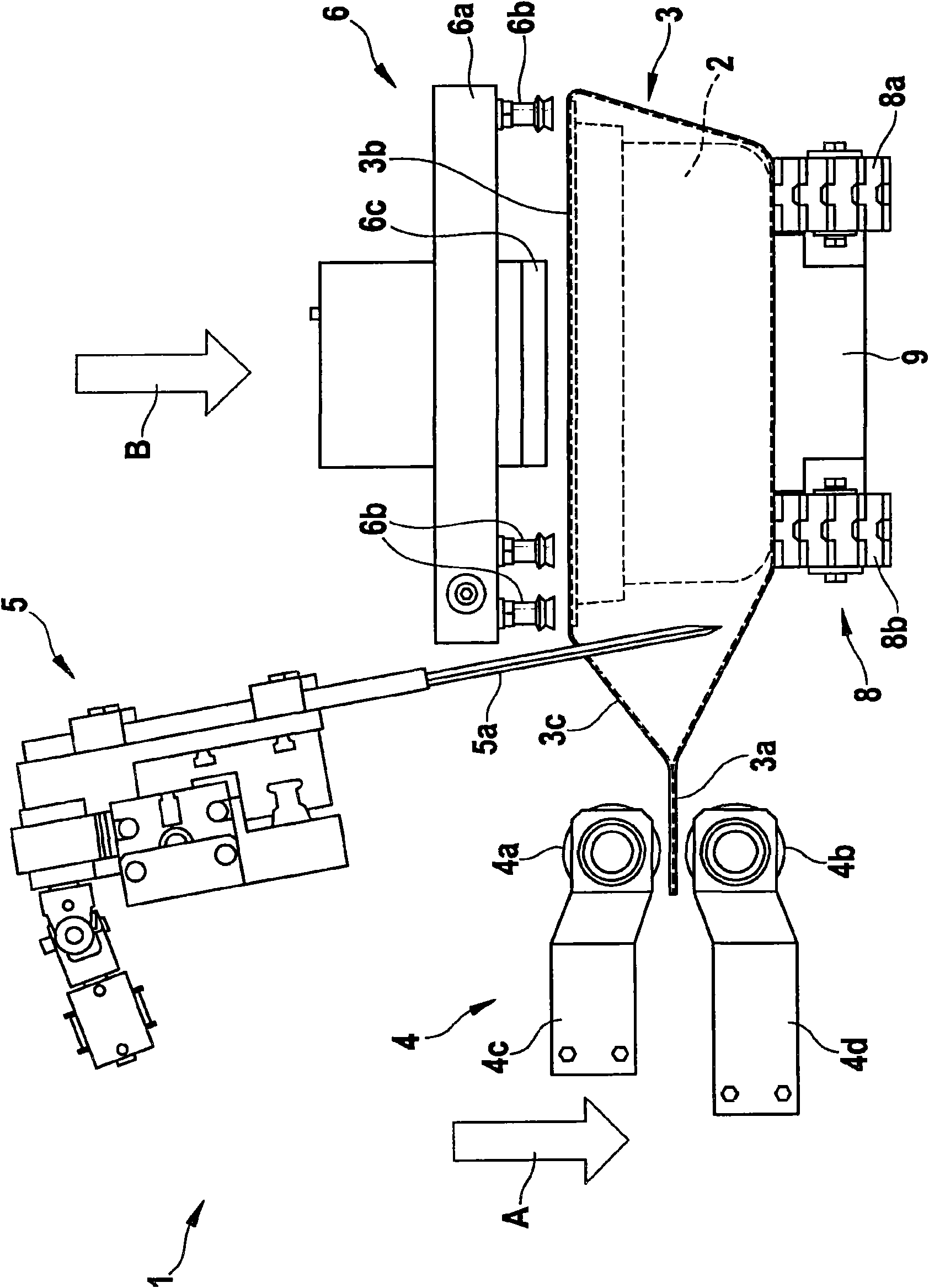

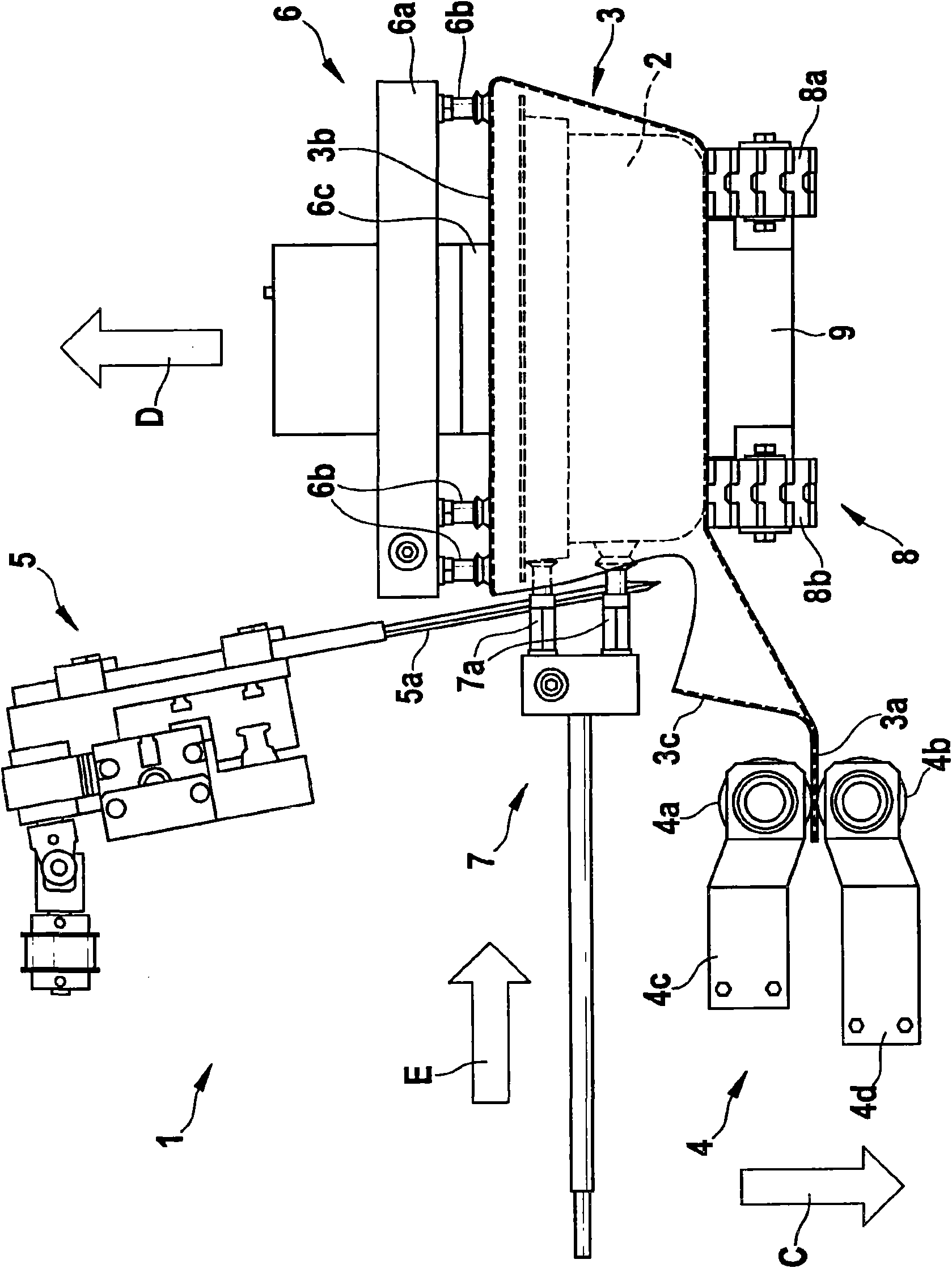

Device and method for removing a sterile object from a sterile packaging

ActiveCN101687559APreferred extension constructFast and reliable clampingBags openingUnpacking by cuttingEngineeringMechanical engineering

The invention relates to a device for removing a sterile object (2) from a sterile packaging (3), having a clamp device (4) which clamps a first subarea (3a) of the sterile packaging (3), a cutting device (5) for cutting the sterile packaging (3) in such a manner that a slit is produced in the sterile packaging (3), a holding device (6) which holds a second subarea (3b) of the sterile packaging (3), and a removal device (7) to remove the object (2) from the sterile packaging (3) through the slit. The invention also relates to a method for removing a sterile object.

Owner:SYNTEGON TECHNOLOGY GMBH

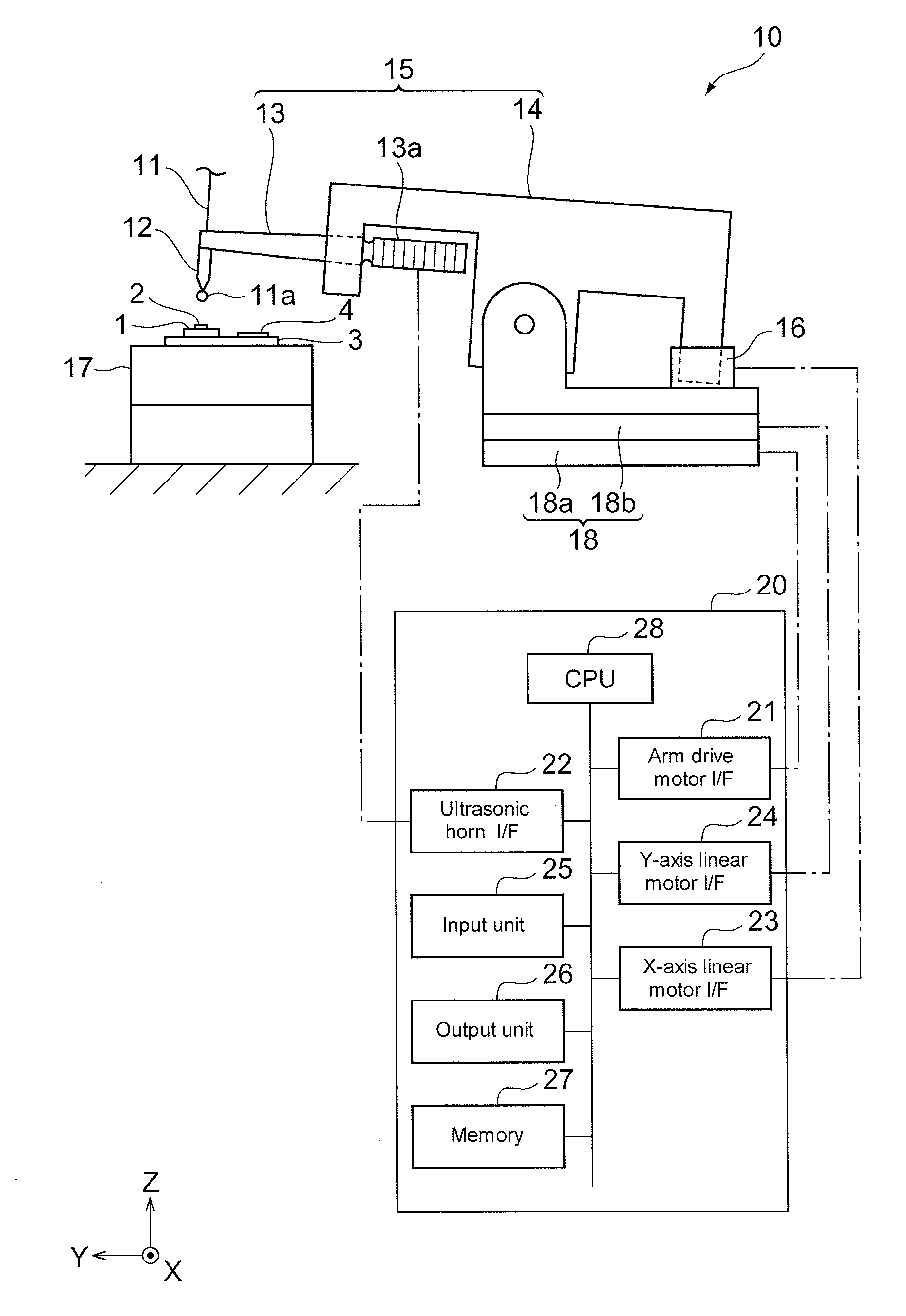

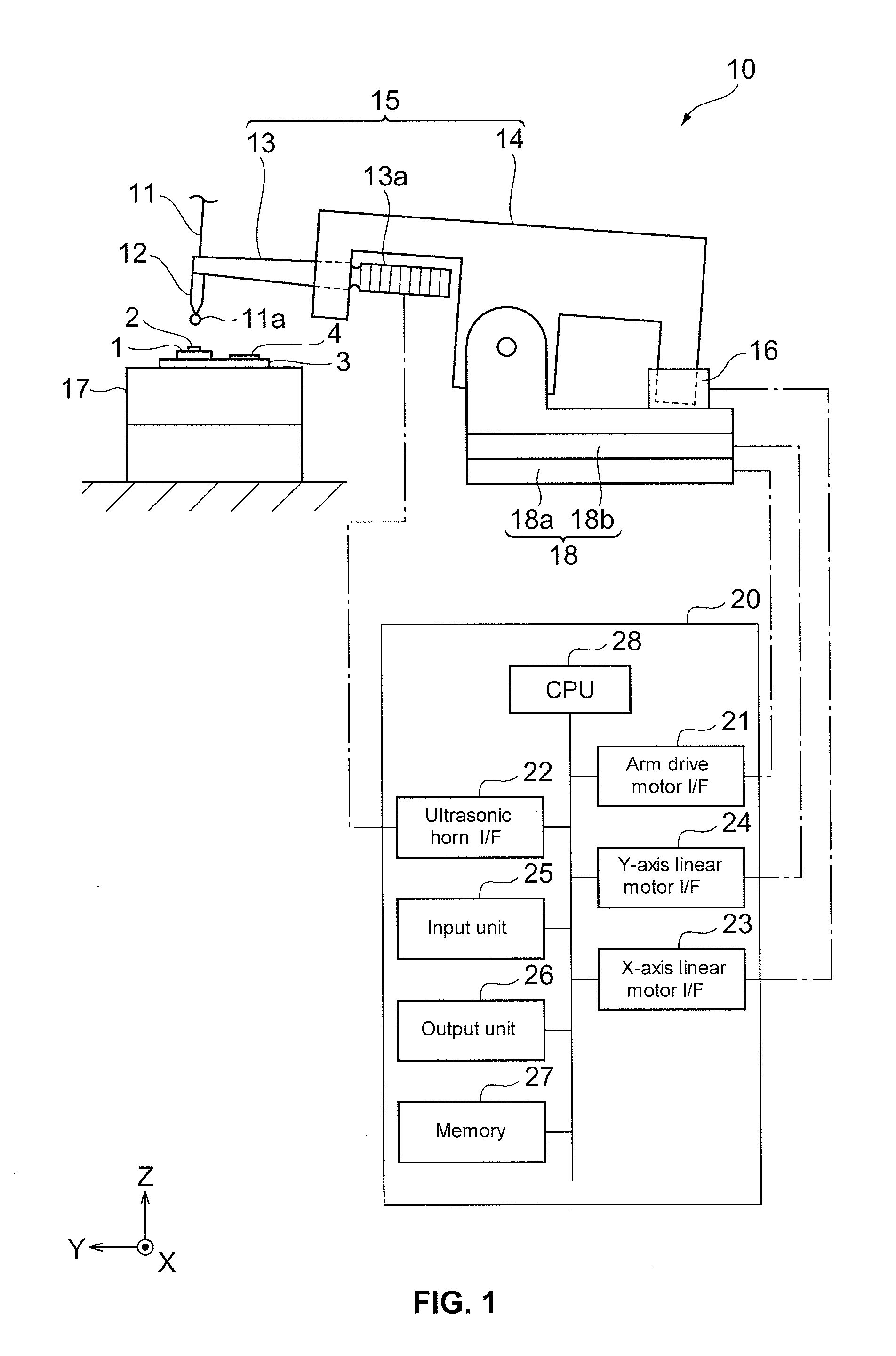

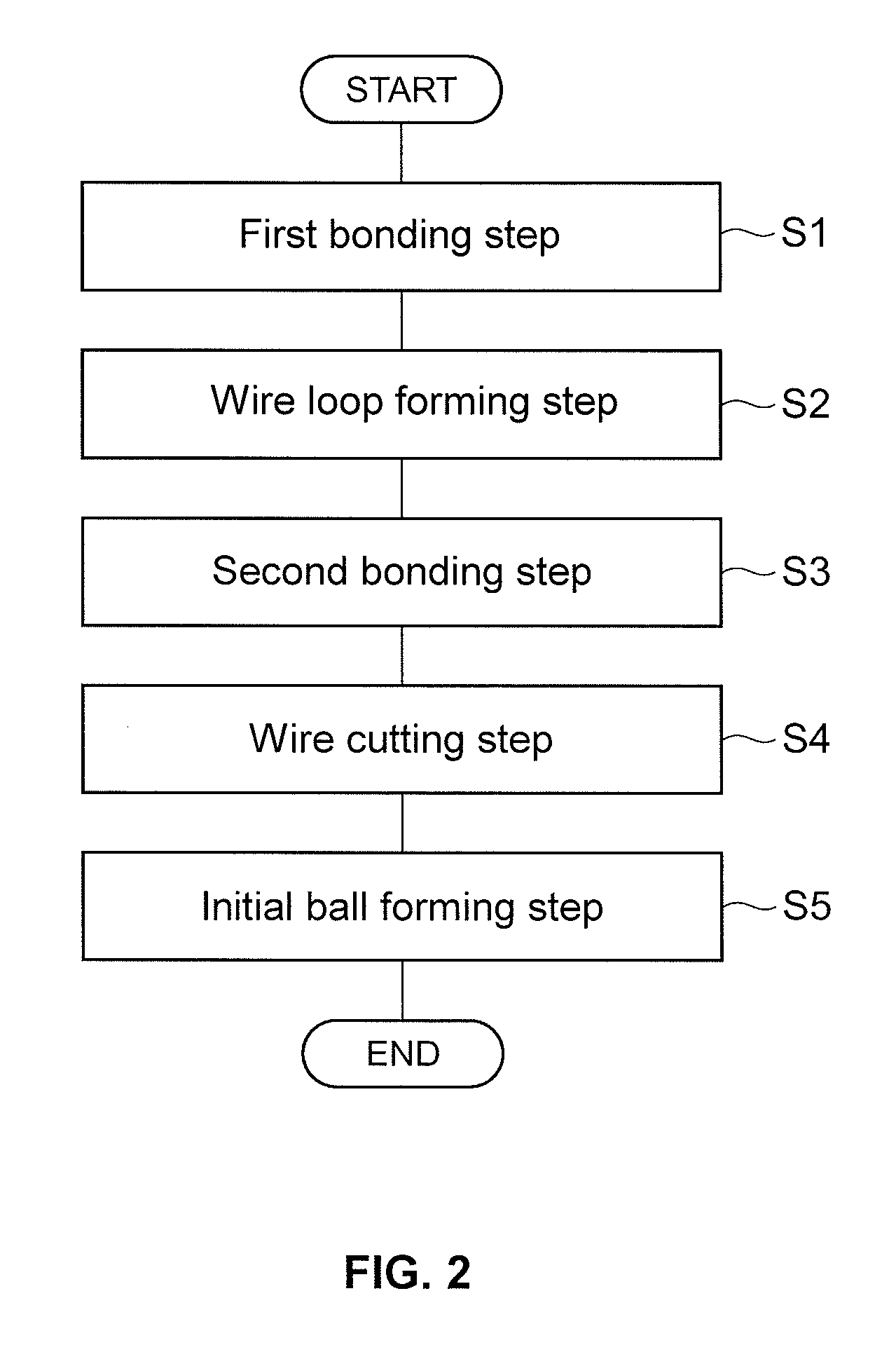

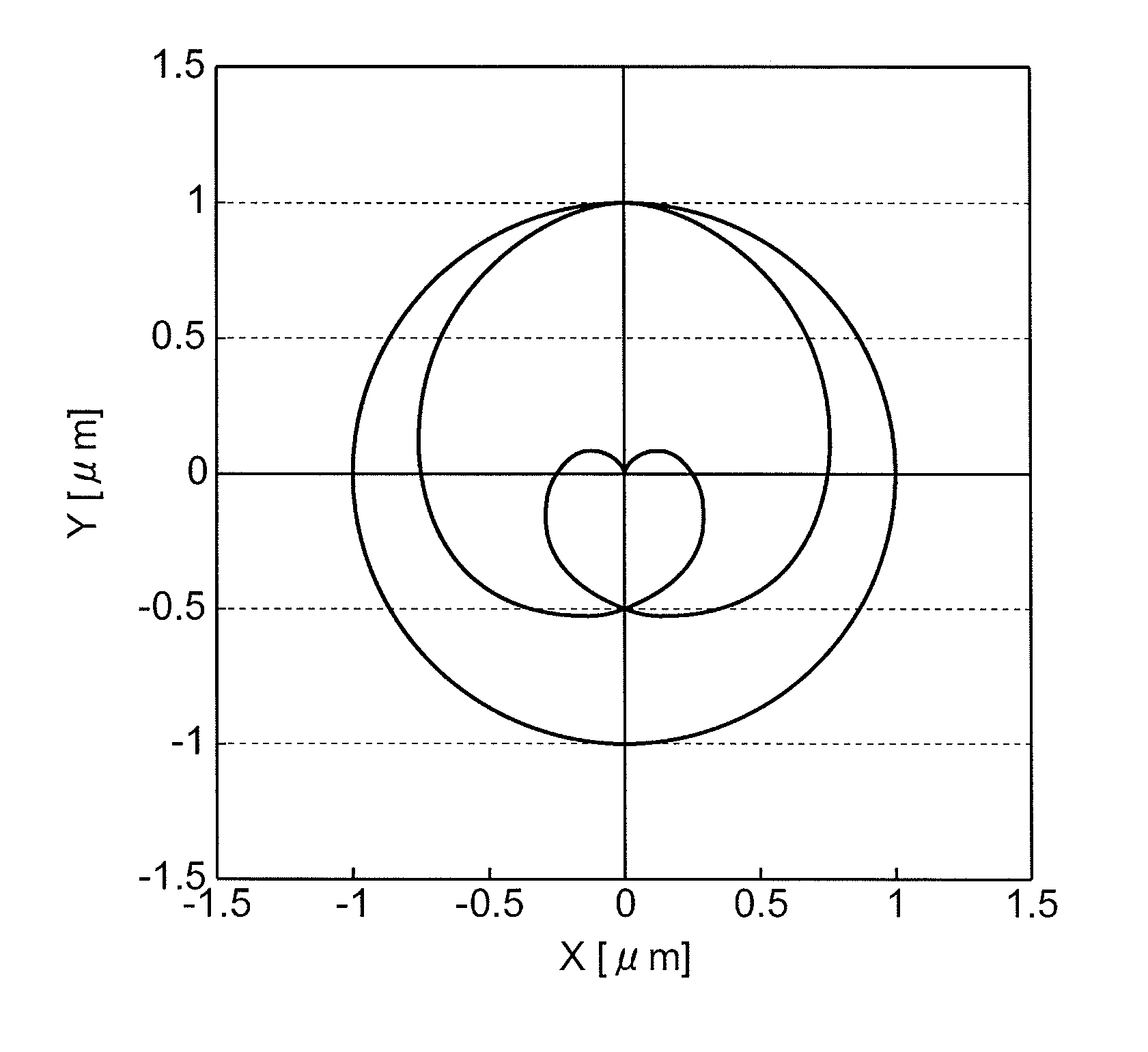

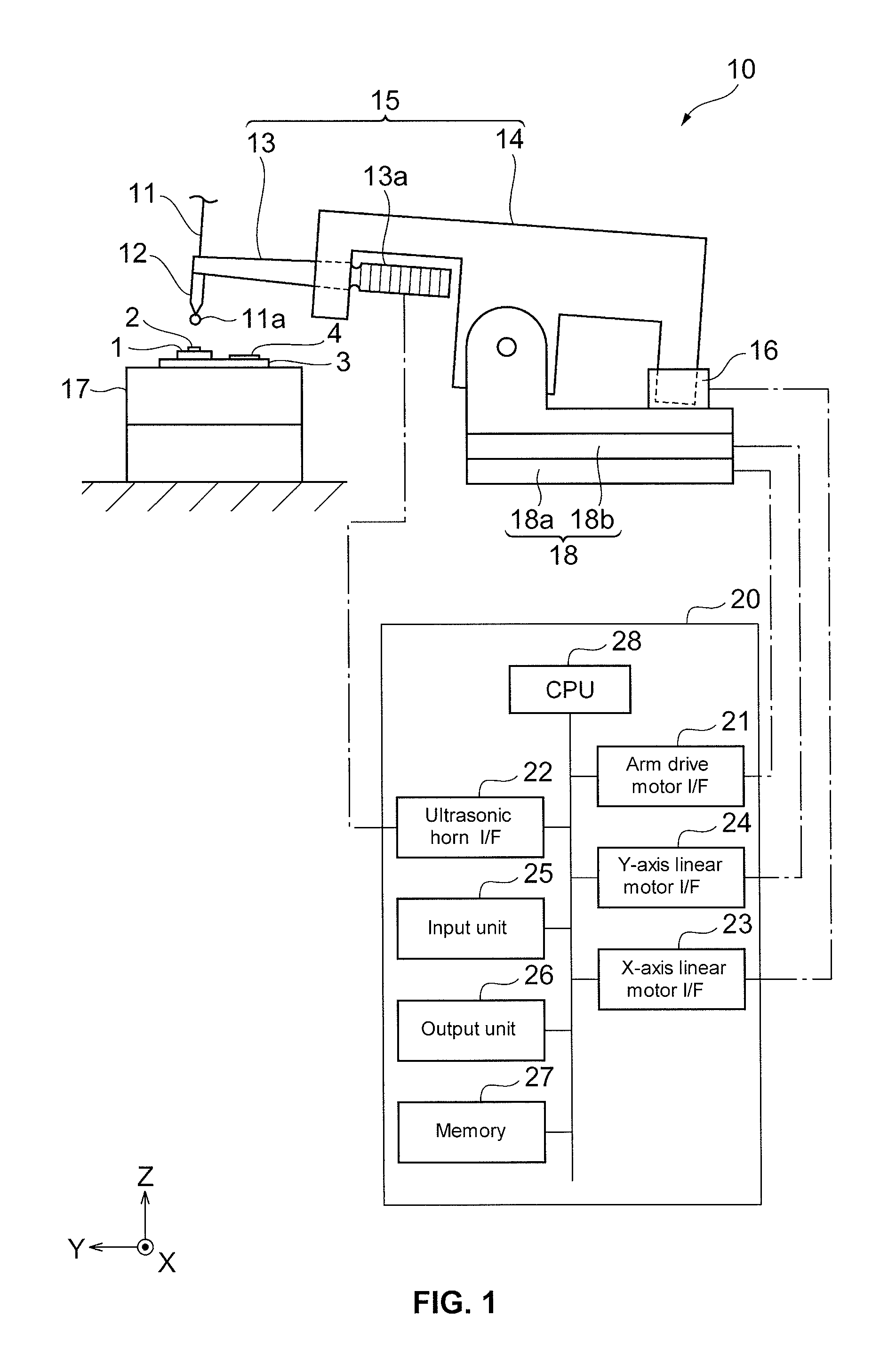

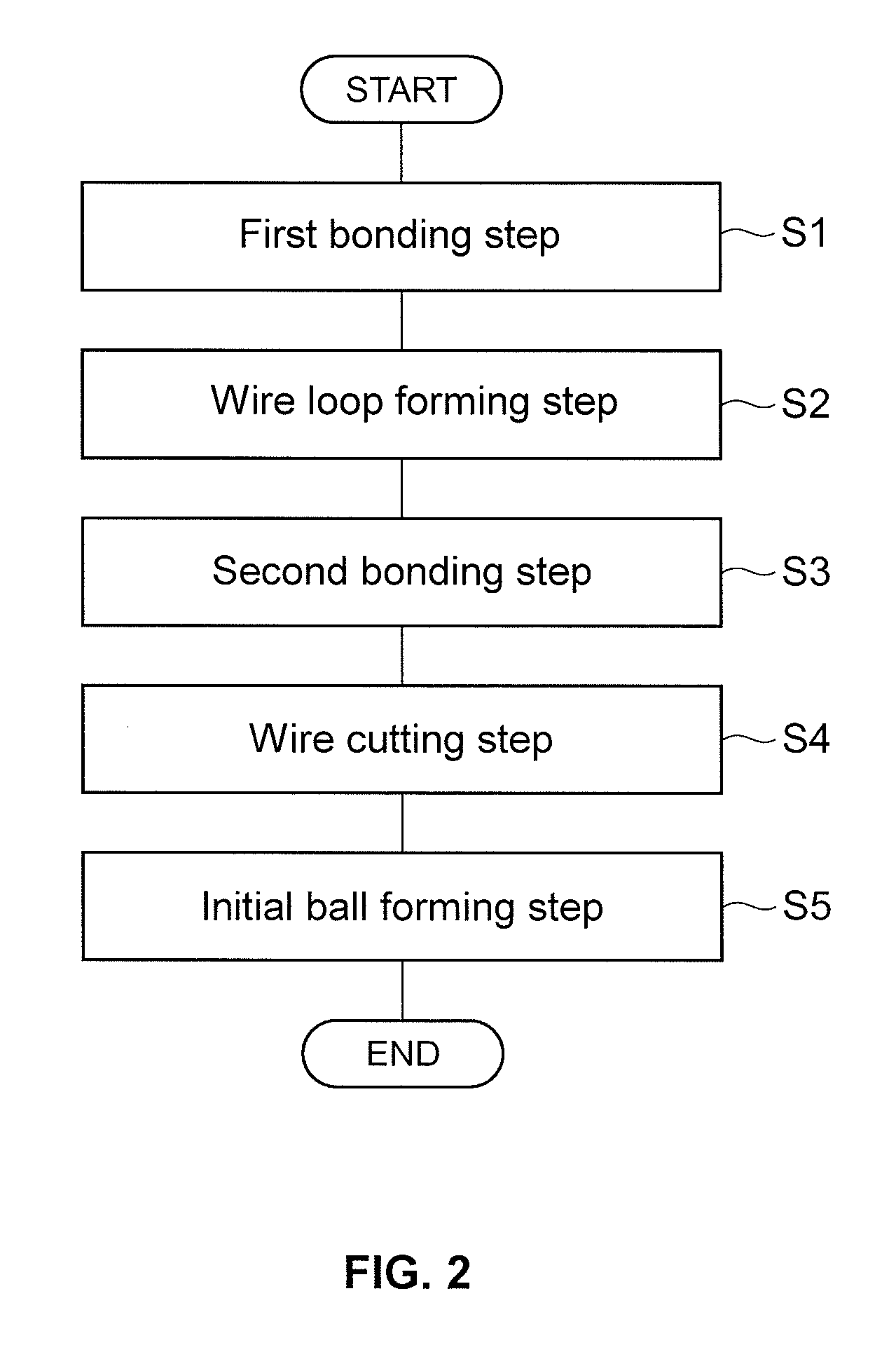

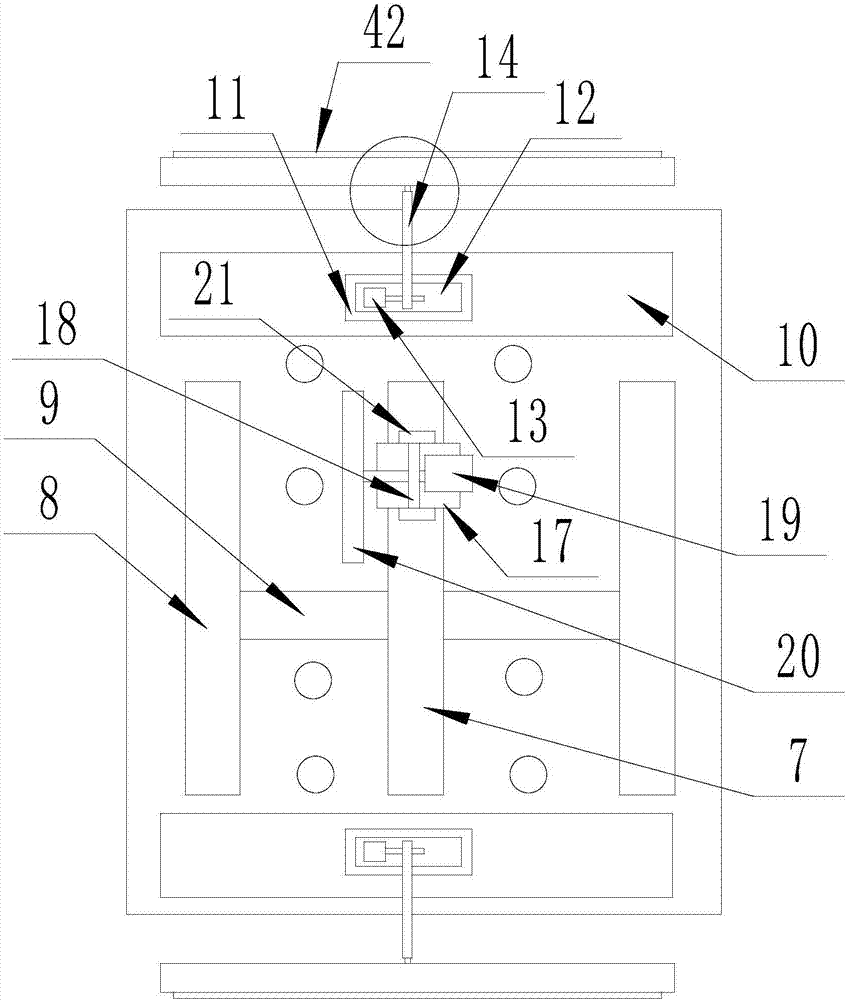

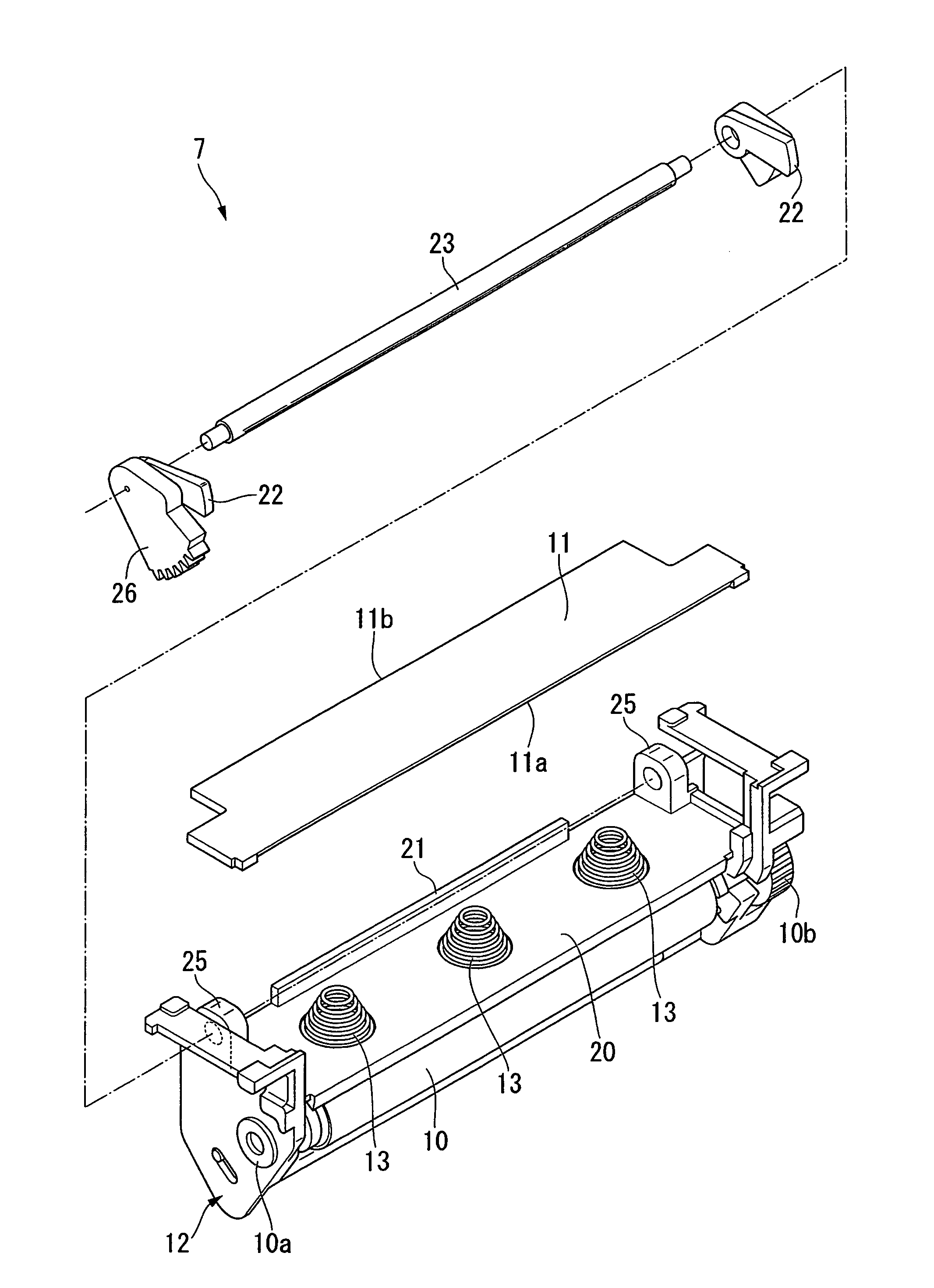

Method of manufacturing semiconductor device, and bonding apparatus

ActiveUS20110315743A1Improve fitting accuracyReduce deformation areaSolid-state devicesWelding/cutting auxillary devicesUltrasonic vibrationEngineering

In a first bonding step of bonding an initial ball to a pad surface, the initial ball is applied by ultrasonic vibration while in pressure contact with the pad surface and a capillary undergoes a scrubbing motion to be rotated spirally. This allows a deformation area of the initial ball to be reduced, whereby the accuracy of bonding can be improved. In a second bonding step of bonding a bonding wire to a lead surface, the capillary and the bonding wire are applied by ultrasonic vibration while in pressure contact with the lead surface and the capillary undergoes a scrubbing motion to be rotated spirally. This allows the bonding wire bonded to the lead surface to be cut reliably.

Owner:SHINKAWA CO LTD

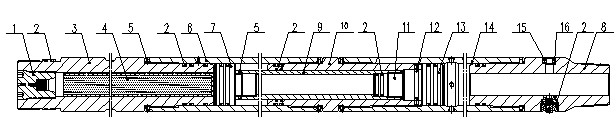

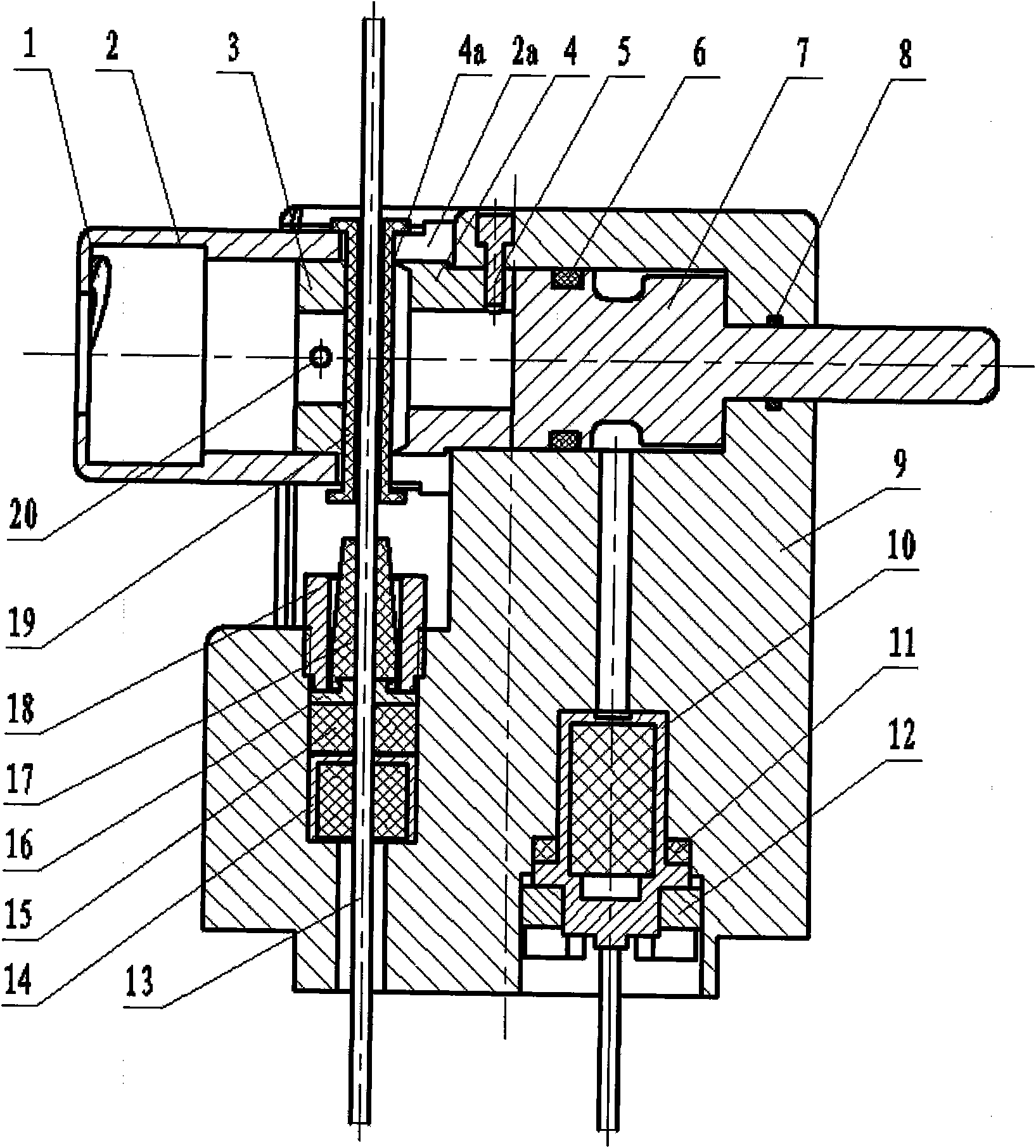

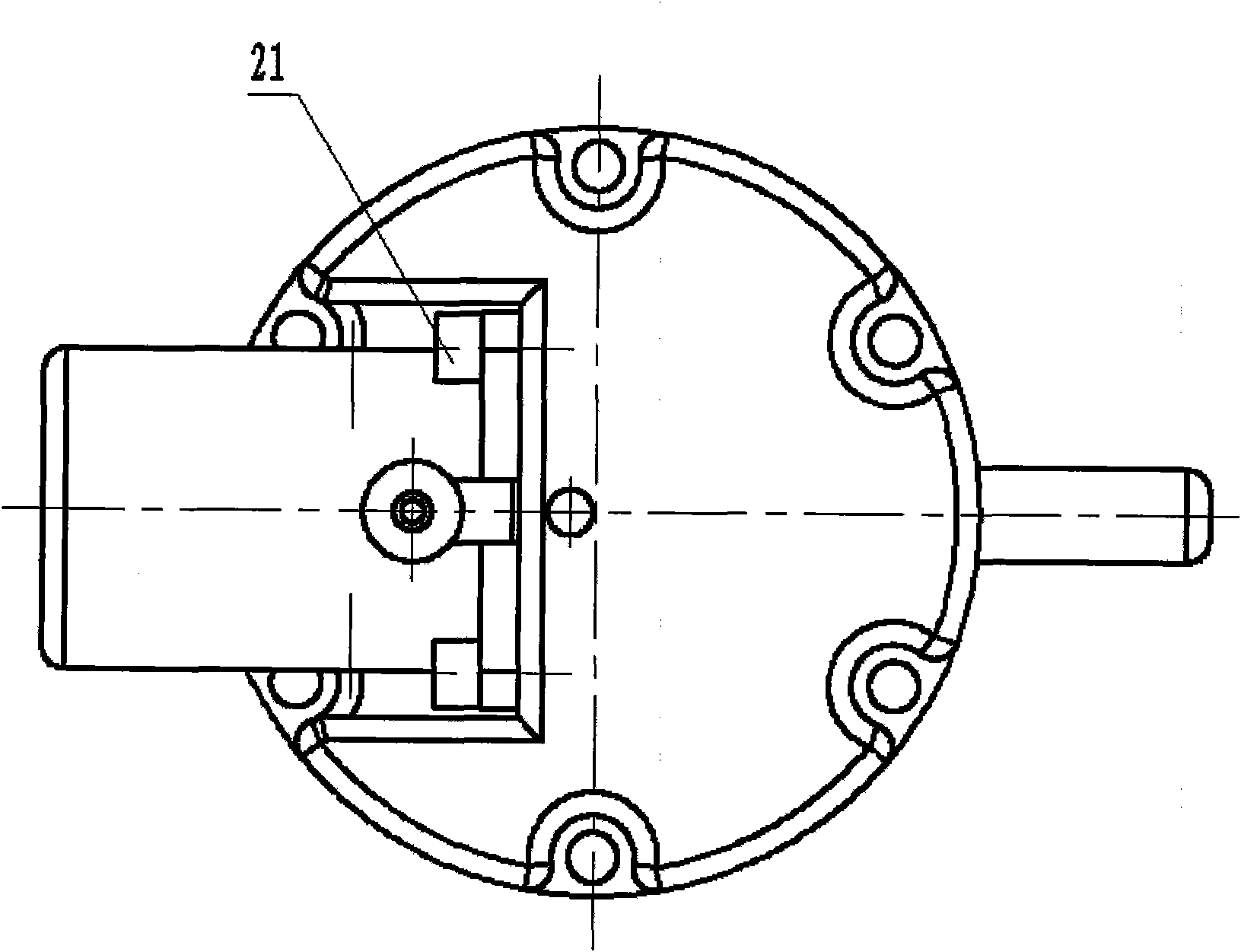

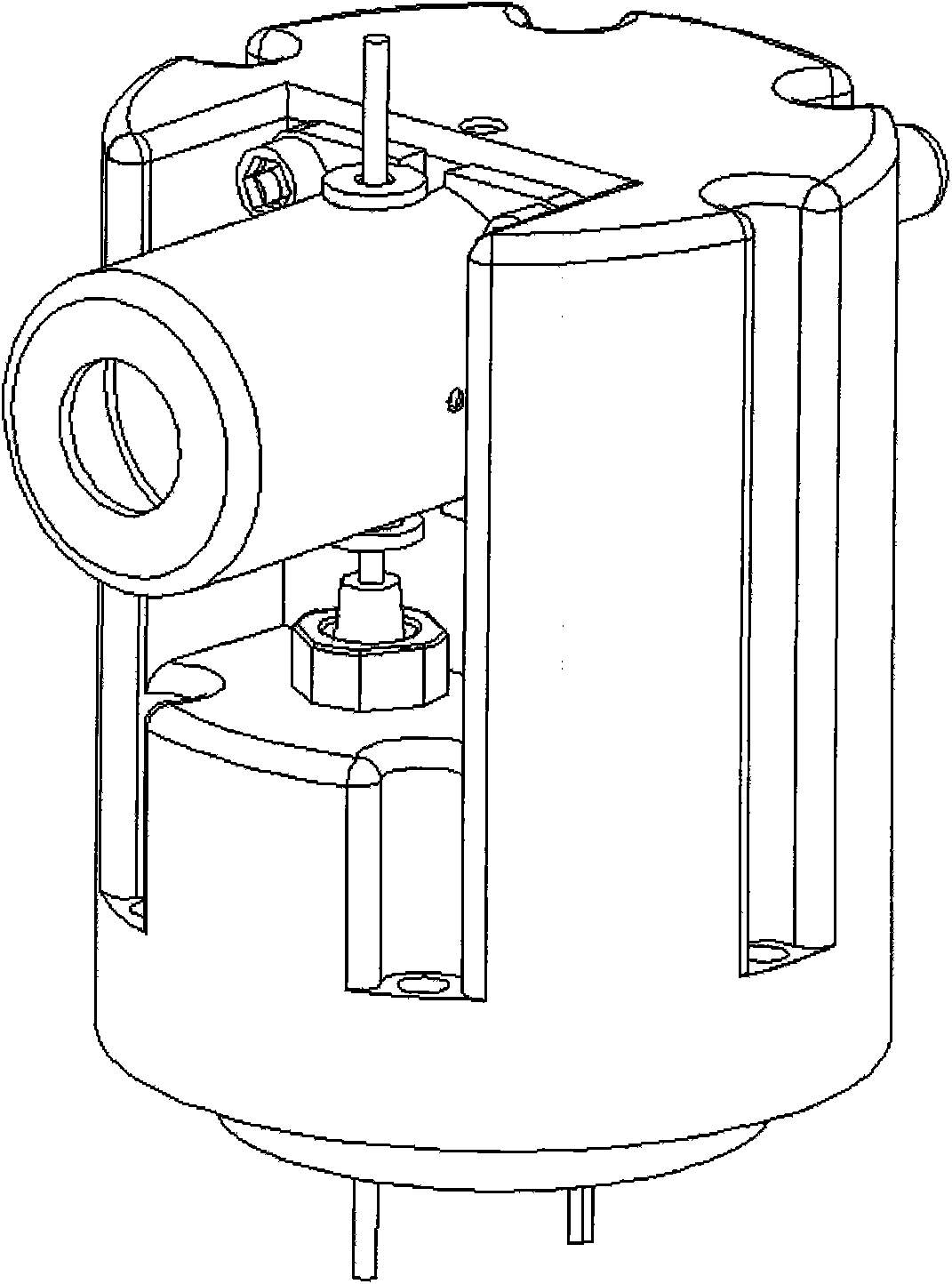

Multi-stage perforating pressurizing device

The invention discloses a multi-stage perforating pressurizing device. The device comprises a power shell and a pressurizing shell positioned on the lower part of the power shell, wherein a power cavity is formed in the power shell; a pressurizing cavity is formed in the pressurizing shell; the power cavity is communicated with the pressurizing cavity; a diaphragm igniter and a pressurizing gunpowder mechanism positioned on the lower part of the diaphragm igniter are arranged in the power cavity; a pressurizing piston driven by power generated by the power cavity is arranged in the pressurizing cavity and is connected with a piston through a push rod; and the piston is fixed on an intermediate joint through a shear pin. The stability and controllability of pressure generated by the combustion of gunpowder in the pressurizing cavity can be ensured; the pressure is applied to the pressurizing piston, so that the pressurizing piston moves stably; pressure increment is generated in an interlayer oil pipe, so that a next stage pressure initiation device and a next stage perforating gun are reliably detonated; and the multi-stage perforating pressurizing device is used for the pressure multi-stage perforating process, is suitable for various well conditions, and particularly can meet the requirements of a high-inclination well and a horizontal well on multi-section, large-distance and negative pressure perforating.

Owner:CHINA PETROLEUM LOGGING CO LTD +1

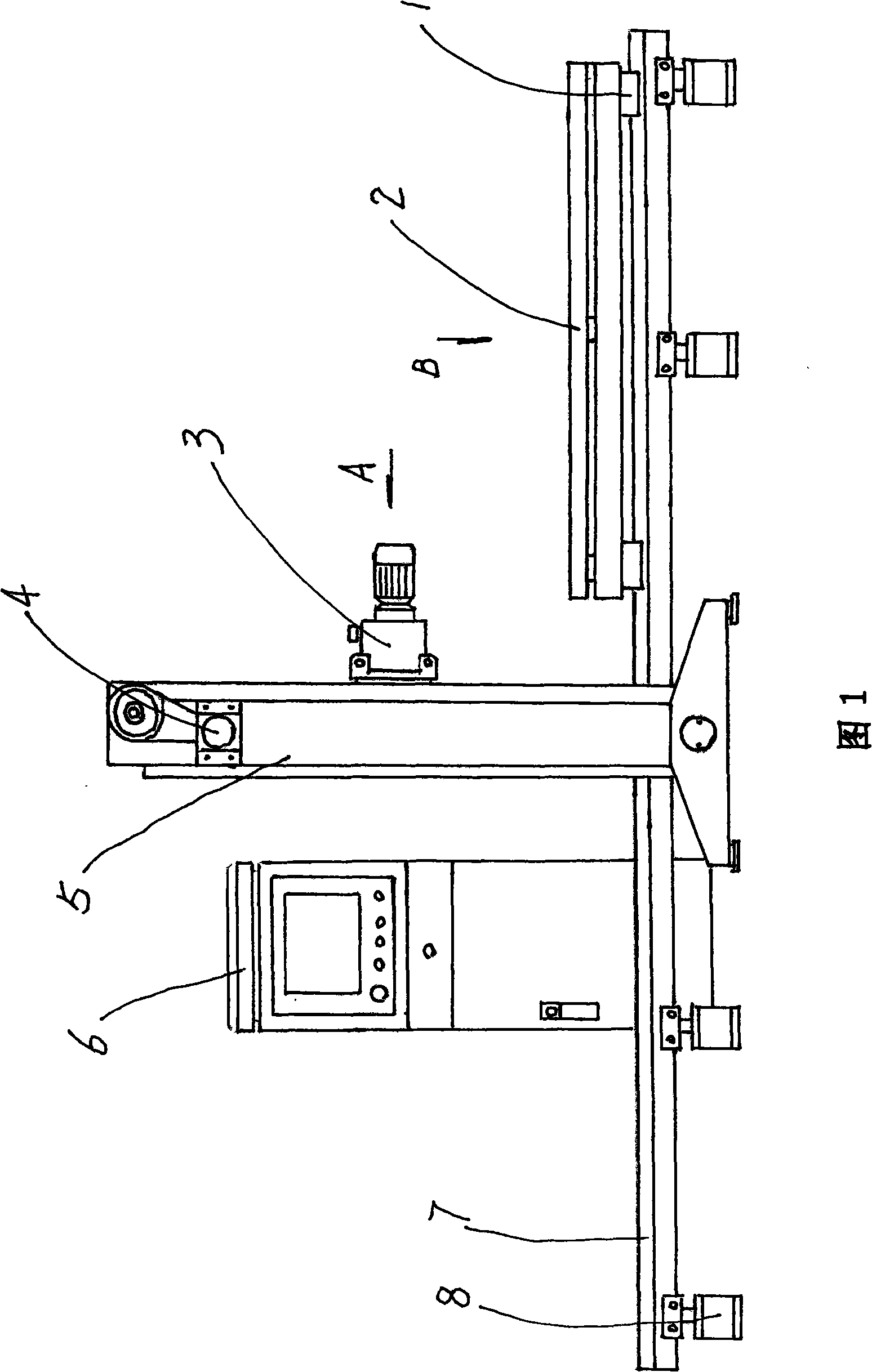

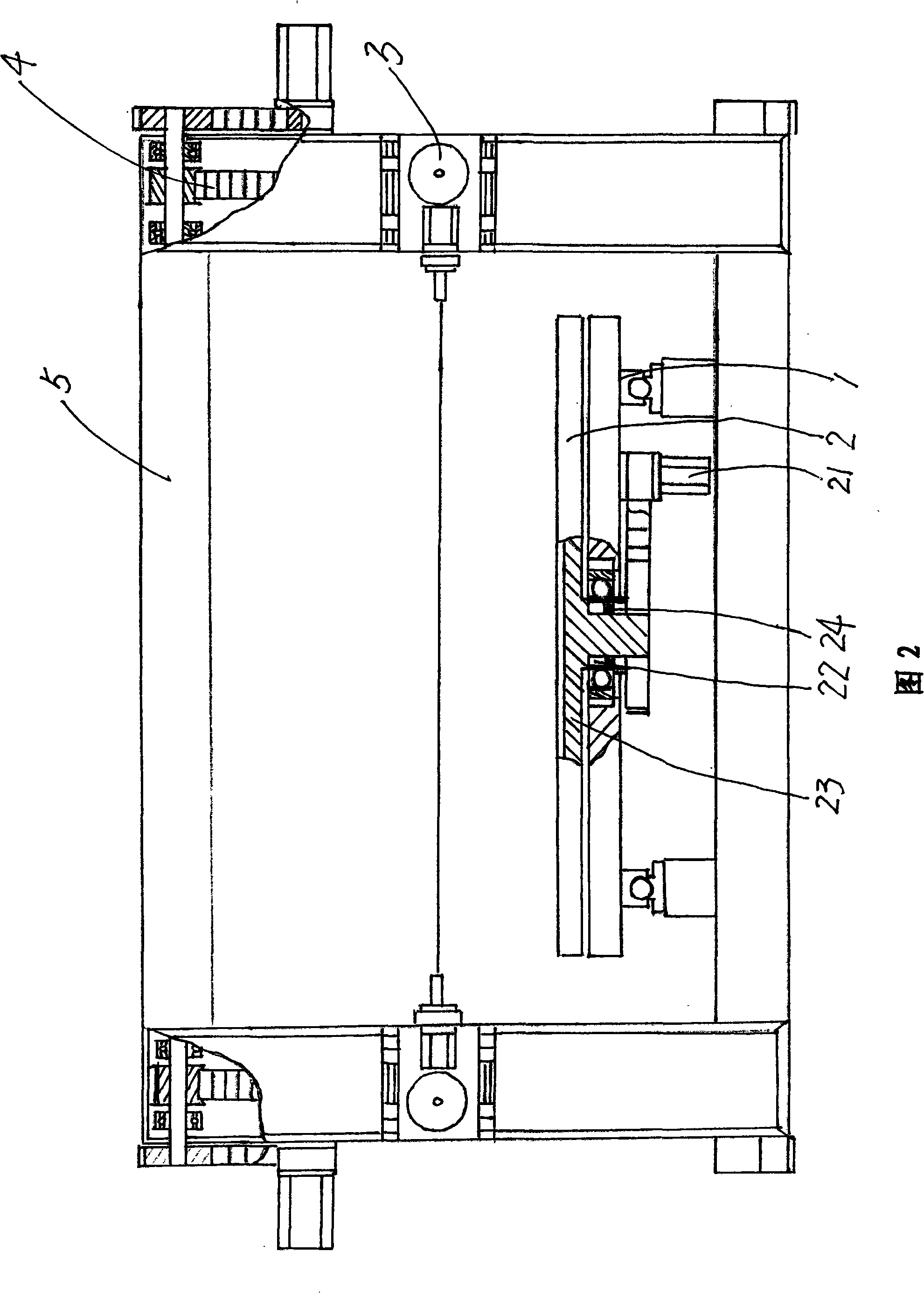

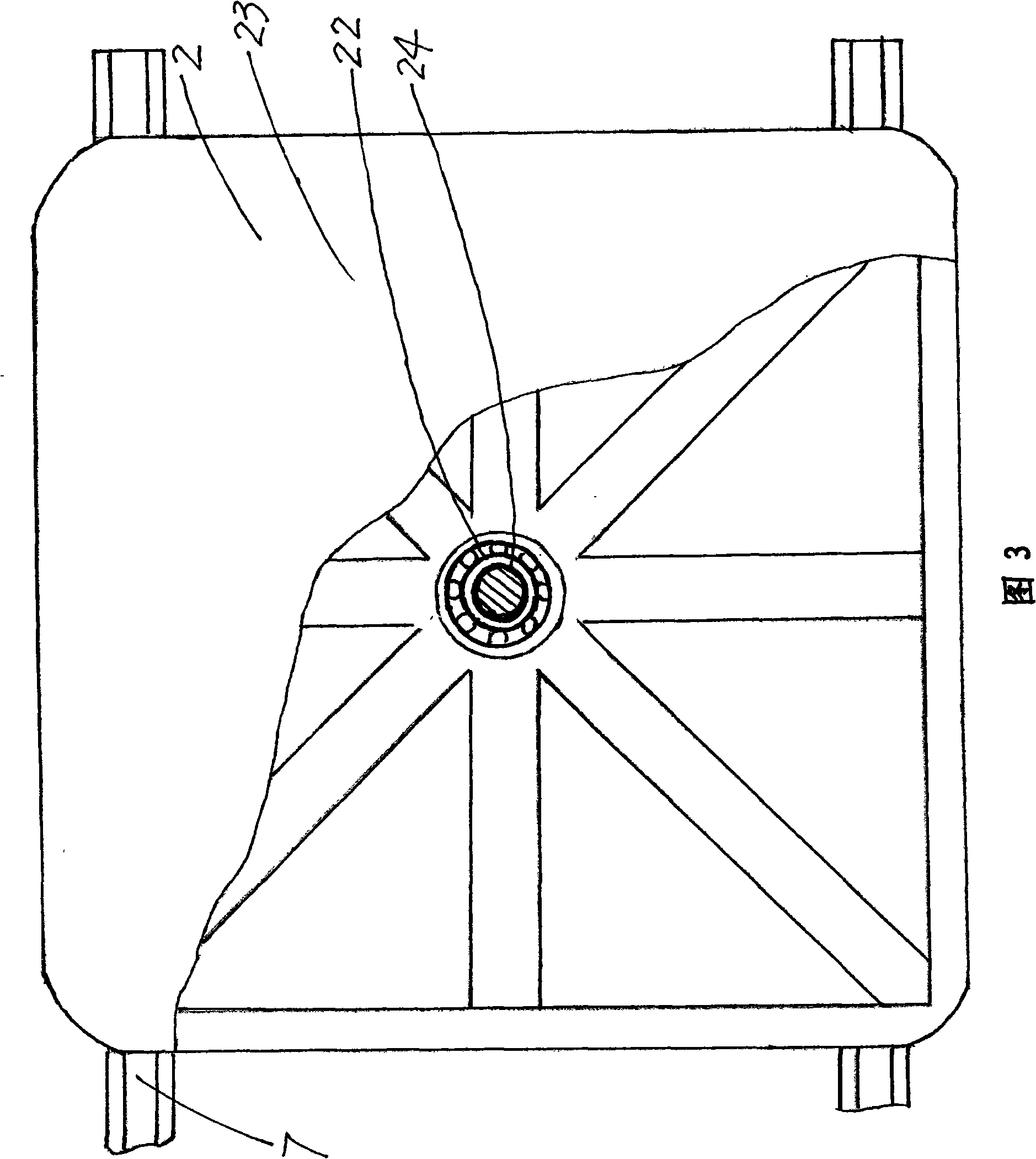

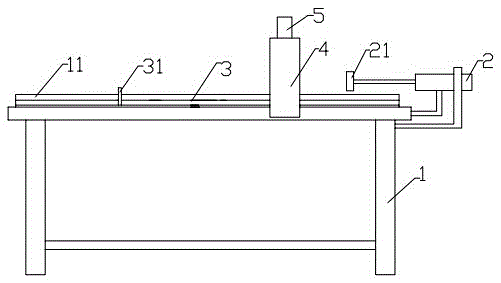

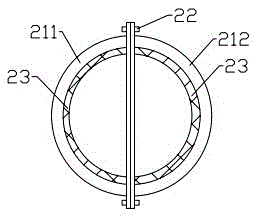

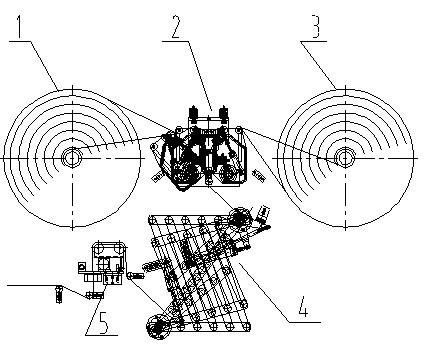

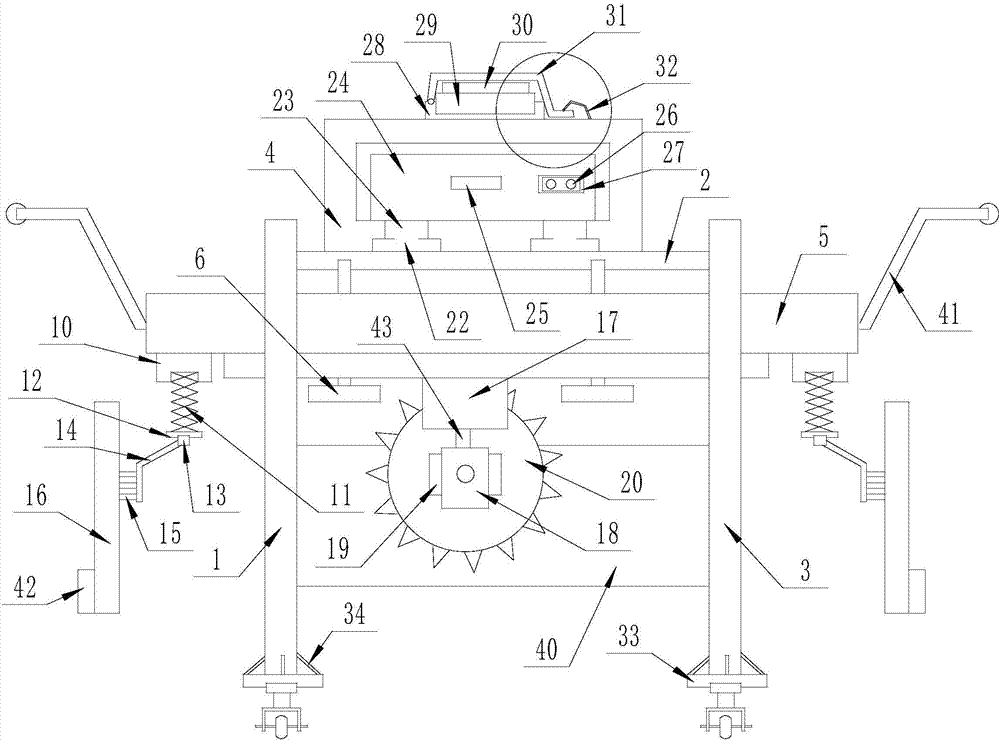

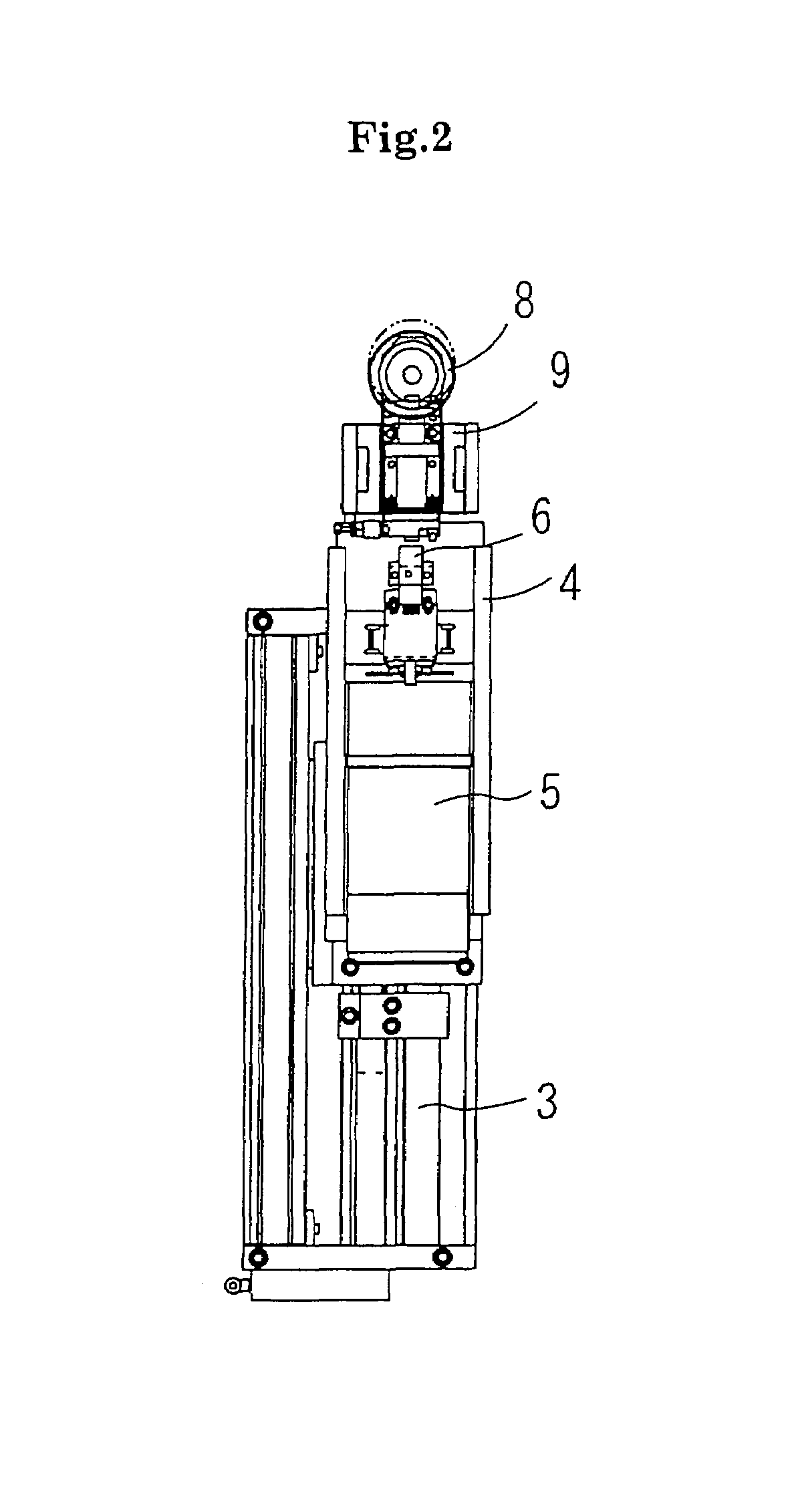

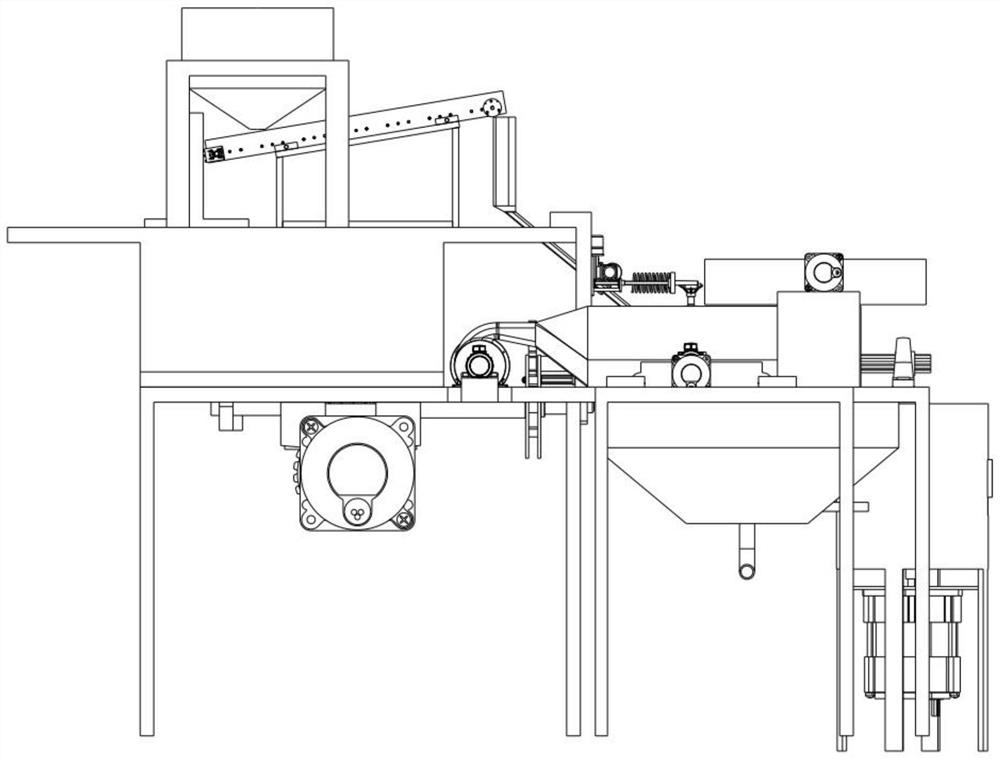

Numerical control sponges cutting machine

ActiveCN101284383AAutomatically adjust the tightnessReliable cuttingMechanical vibrations separationMetal working apparatusControl systemEngineering

The invention relate to a numerical control sponge cutting machine, which comprises a workbench base, a rotary workbench, vibration devices, vertical pulling devices, a gantry, a control part, a horizontal guide rail and a rack. The workbench base is arranged on the horizontal guide rail and the rotary workbench capable of lifting and rotating is arranged on the workbench base; the two vertical pulling devices are arranged on the gantry, and the two vibration devices are respectively arranged on two columns of the gantry; the control part is a numerical control system. Since the two vertical pulling devices are adopted to respectively adjust the height and the position of the two vibration devices, the sponge cutting machine is capable of processing sponge of different heights; since the workbench has a structure capable of lifting and rotating, the sponge cutting machine is capable of processing sponge of various curves; since the combination of adjusting cylinders and dampers is adopted in the vibration devices, the sponge cutting machine has more reliable cutting and the reasonable structure leads to non-environment pollution and high automatization, therefore, the sponge cutting machine is of great utility and popularization value.

Owner:NANTONG MUYE MACHINERY

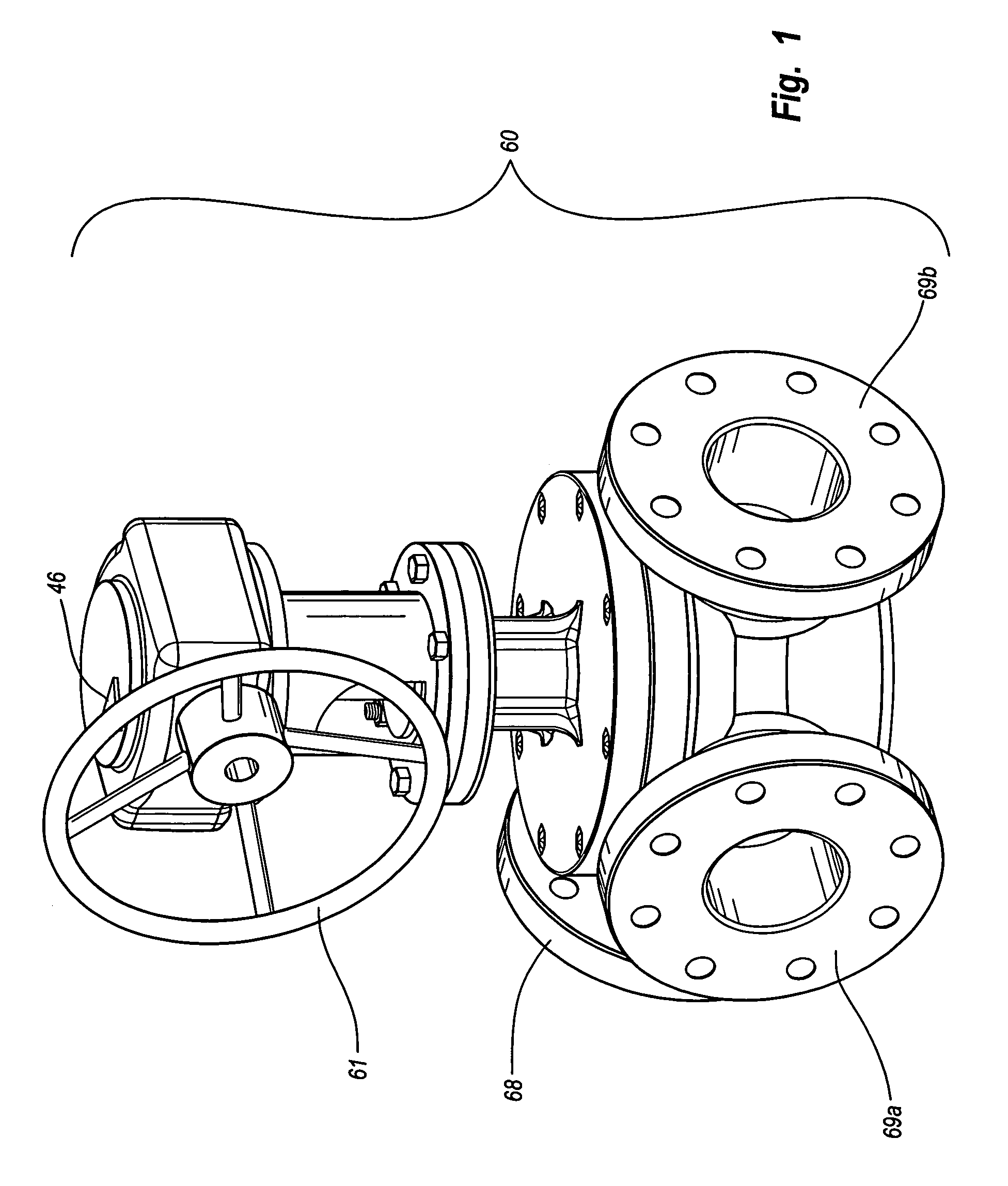

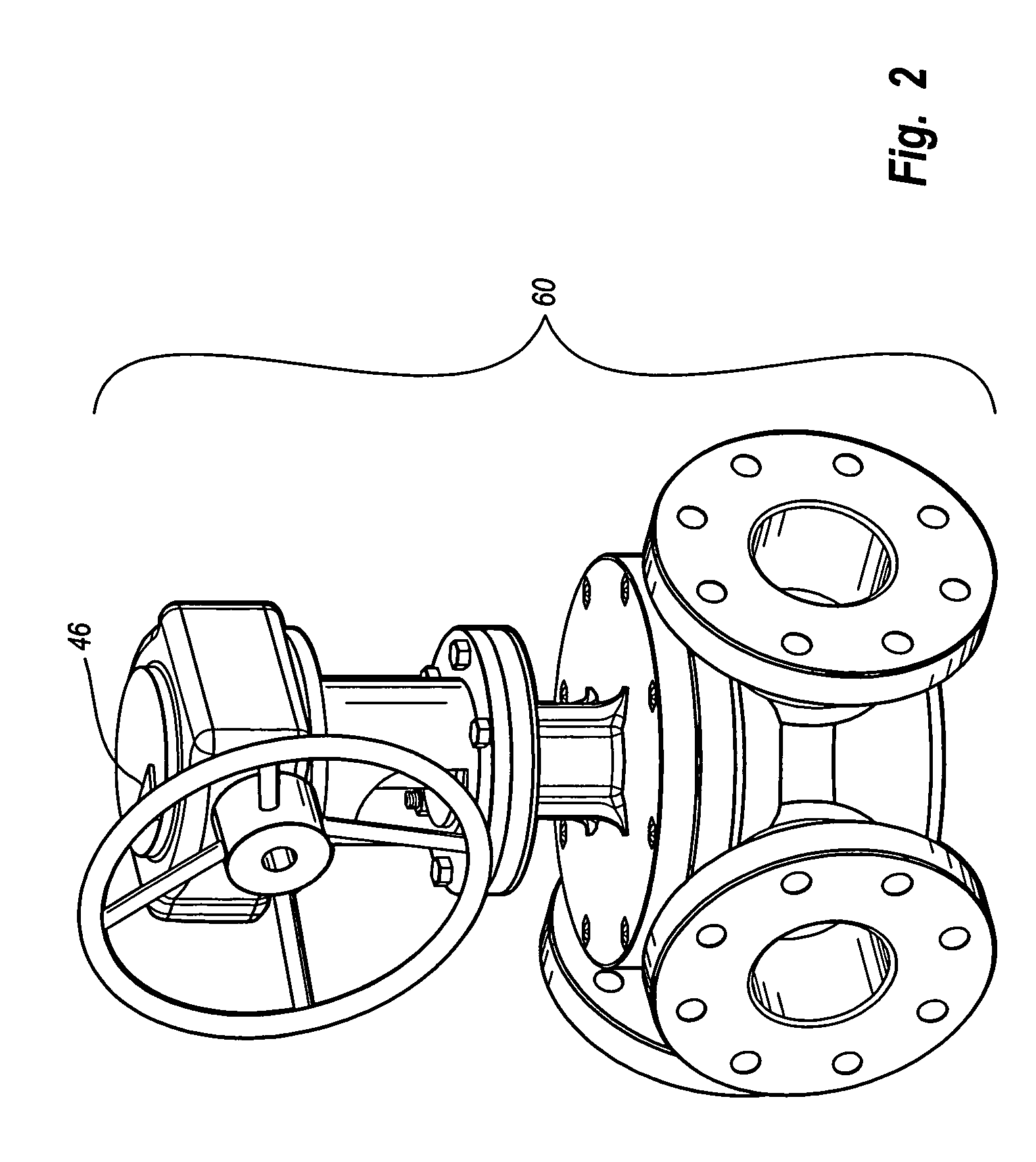

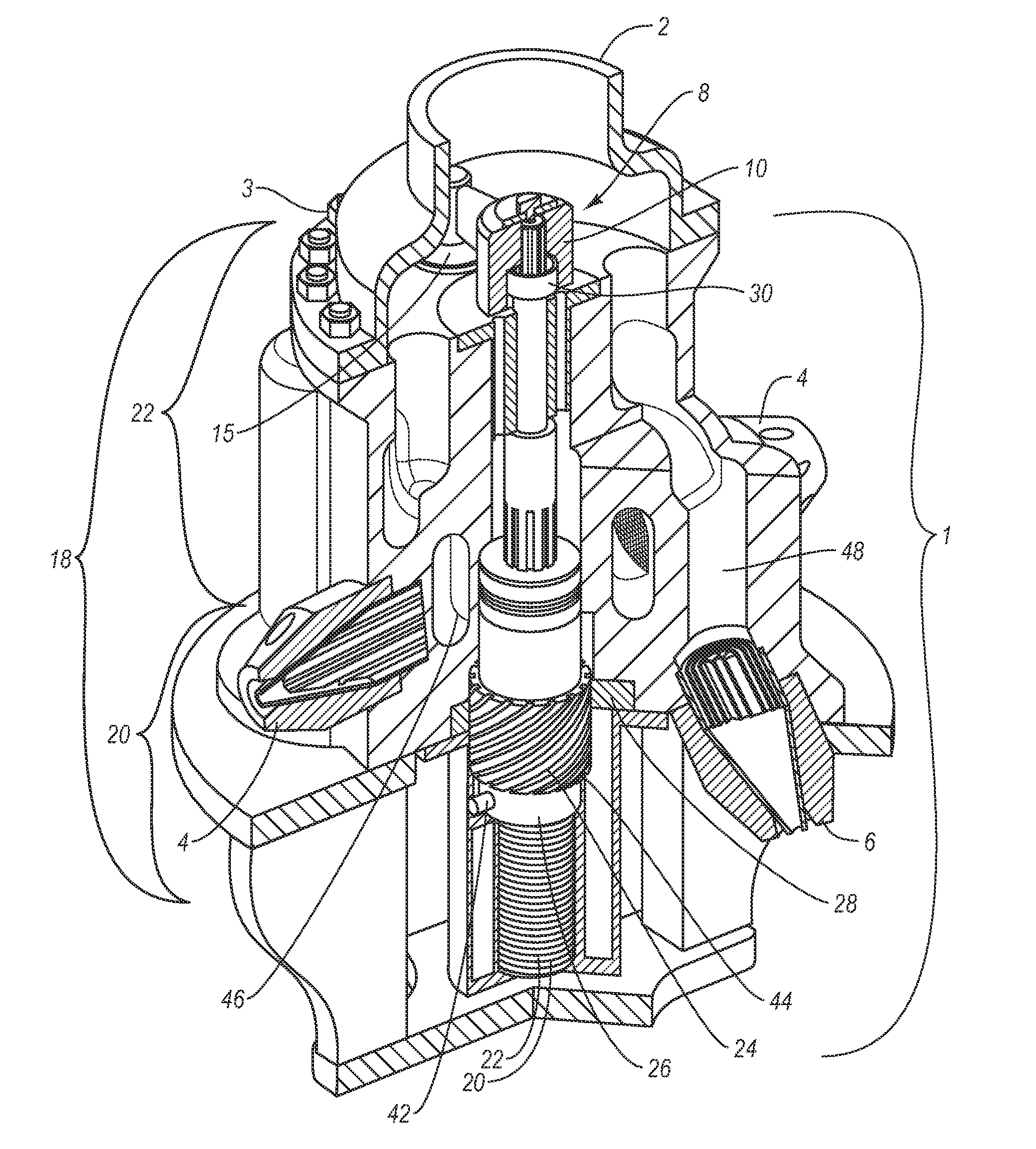

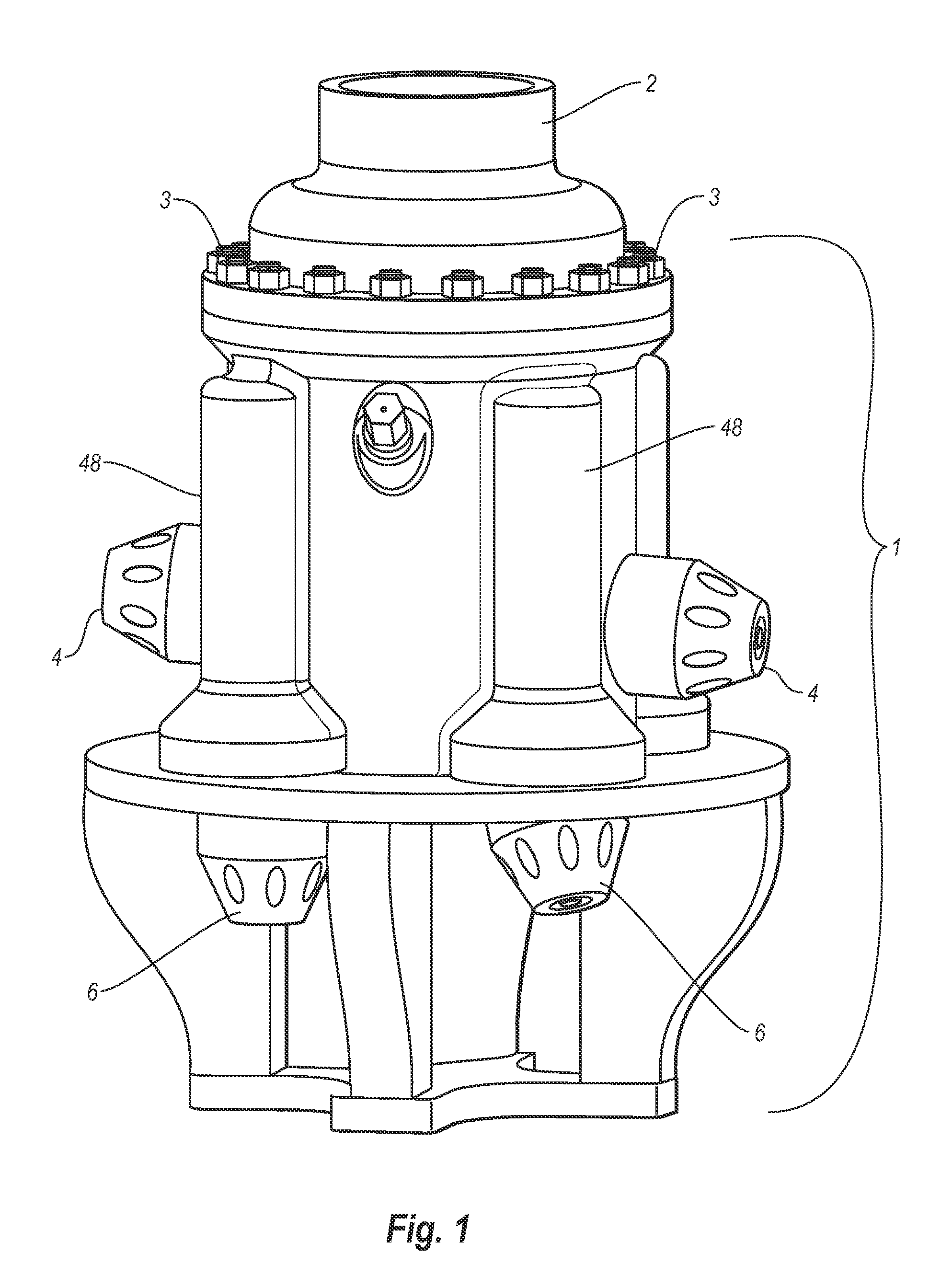

Remotely controlled decoking tool used in coke cutting operations

ActiveUS7473337B2Promote sportsImprove convenienceCoke oven safety devicesCharging-discharging device combinationsEngineeringHigh pressure

The present invention relates to a system that allows an operator to remotely switch between cutting and boring while removing solid carbonaceous residue from large cylindrical vessels called coke drums comprising a cutting head for ejecting high pressure fluids into the coke bed; a flow diversion apparatus; and a shifting apparatus.

Owner:ETHICON ENDO SURGERY INC +1

Full-automatic cutting machine

InactiveCN105459167AWith automatic measurementWith automatic advanceMetal sawing devicesMetal working apparatusControl systemElectric machinery

The invention discloses a full-automatic cutting machine. The full-automatic cutting machine comprises a machine frame, a pushing oil cylinder, a gauge, a cutting machine body and a control system. A guide rail is arranged on the upper portion of the machine frame. An annular pipe frame is connected to the ejecting end of the pushing oil cylinder. The gauge is arranged on the guide rail and extends in the same direction as the guide rail. The cutting machine body is arranged over the machine frame. The control system is electrically connected with the pushing oil cylinder and the cutting machine body. In this way, the full-automatic cutting machine has the automatic measuring function, the automatic cutting function and the automatic pushing function; meanwhile, a motor can be started automatically according to the cutting distance between materials and the cutting machine body, manual operation is not needed, products are cut accurately and reliably, and the product cutting efficiency is effectively improved.

Owner:CHANGSHU SHANG GAO MACHINERY

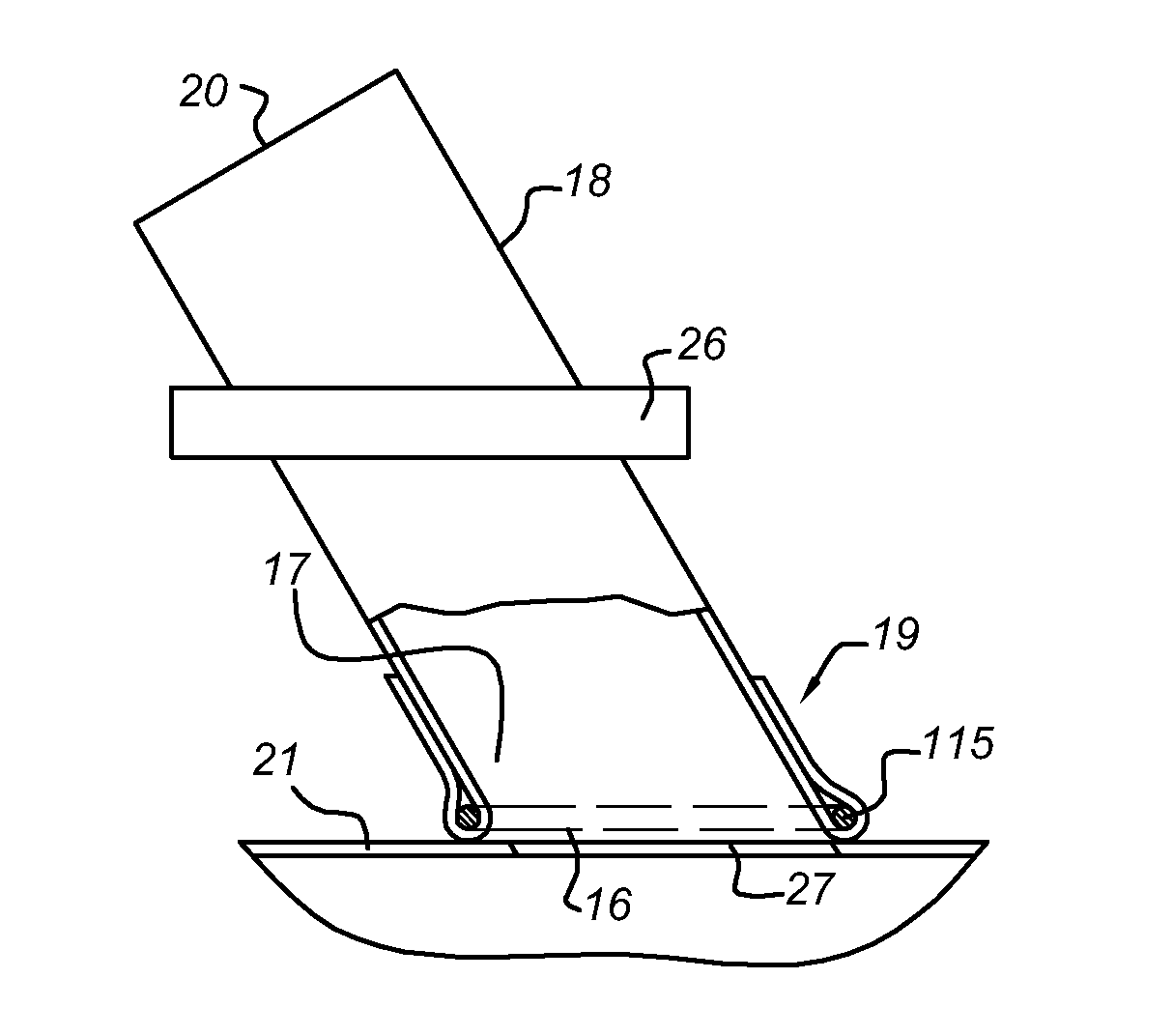

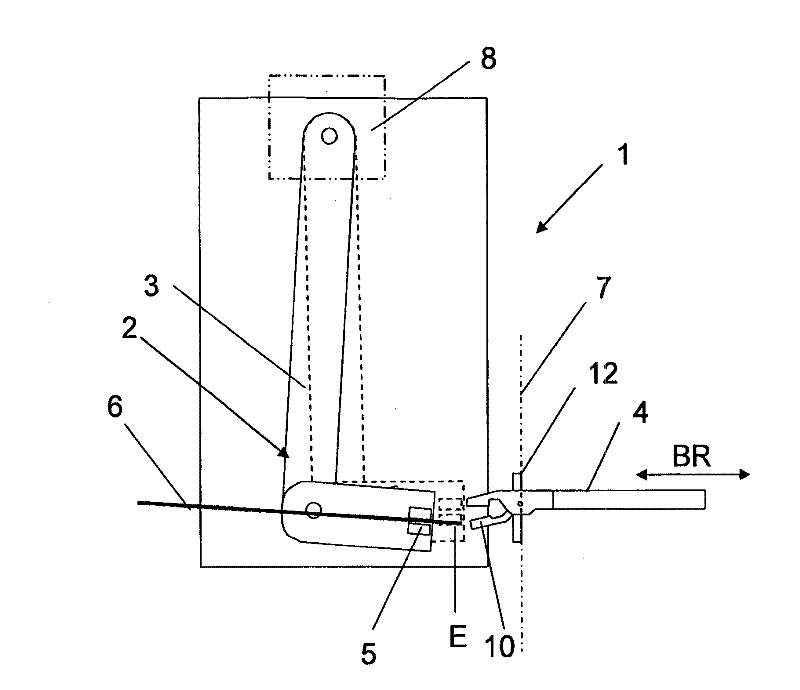

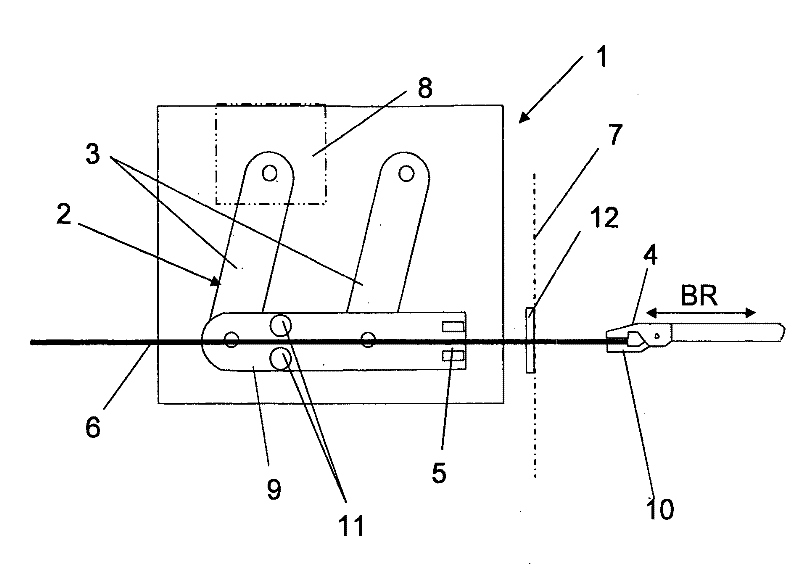

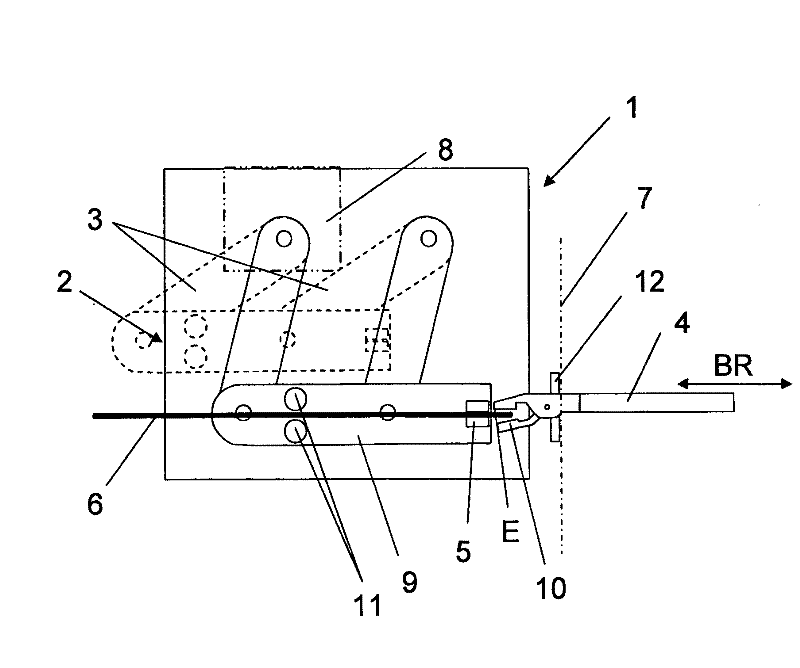

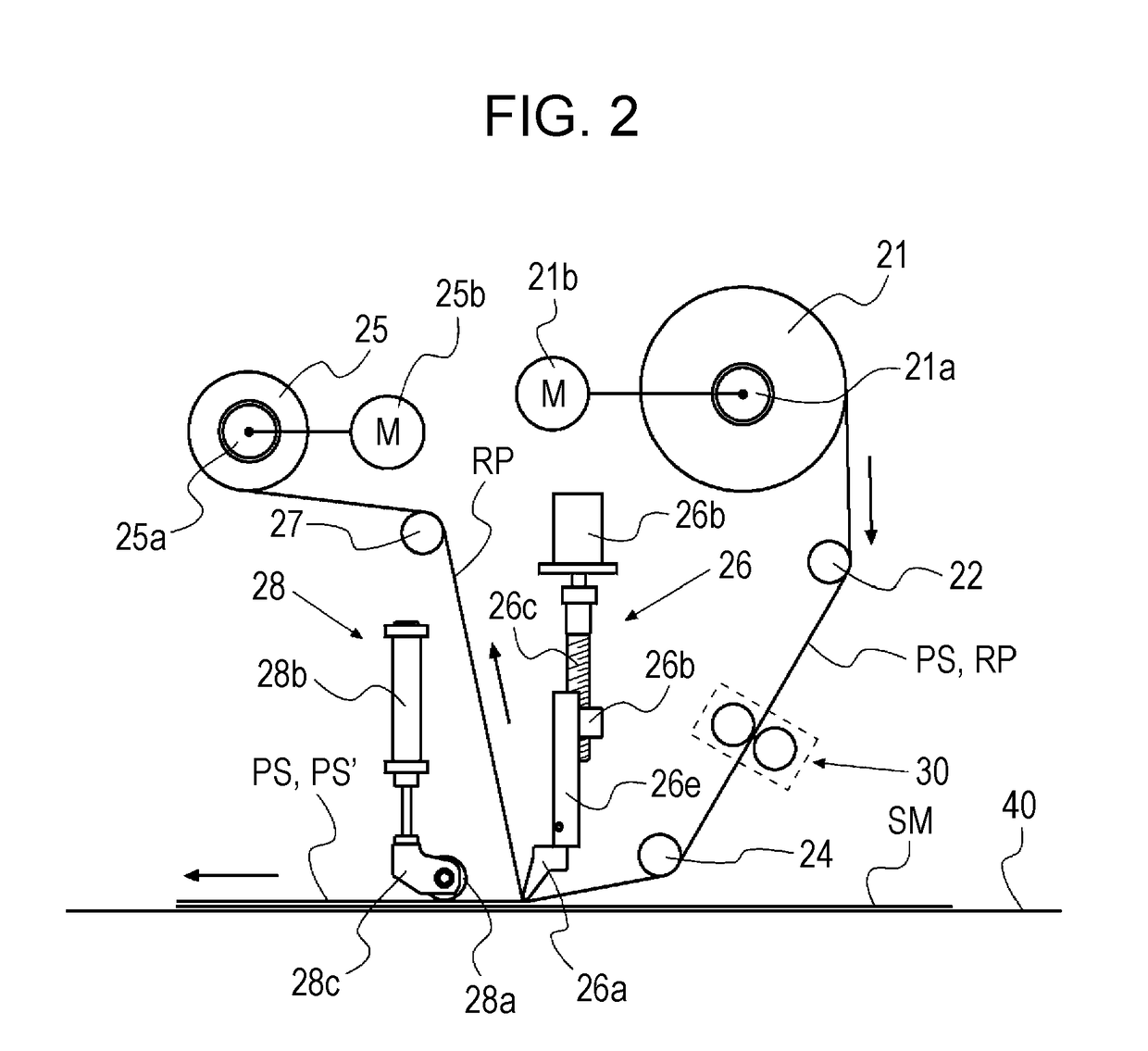

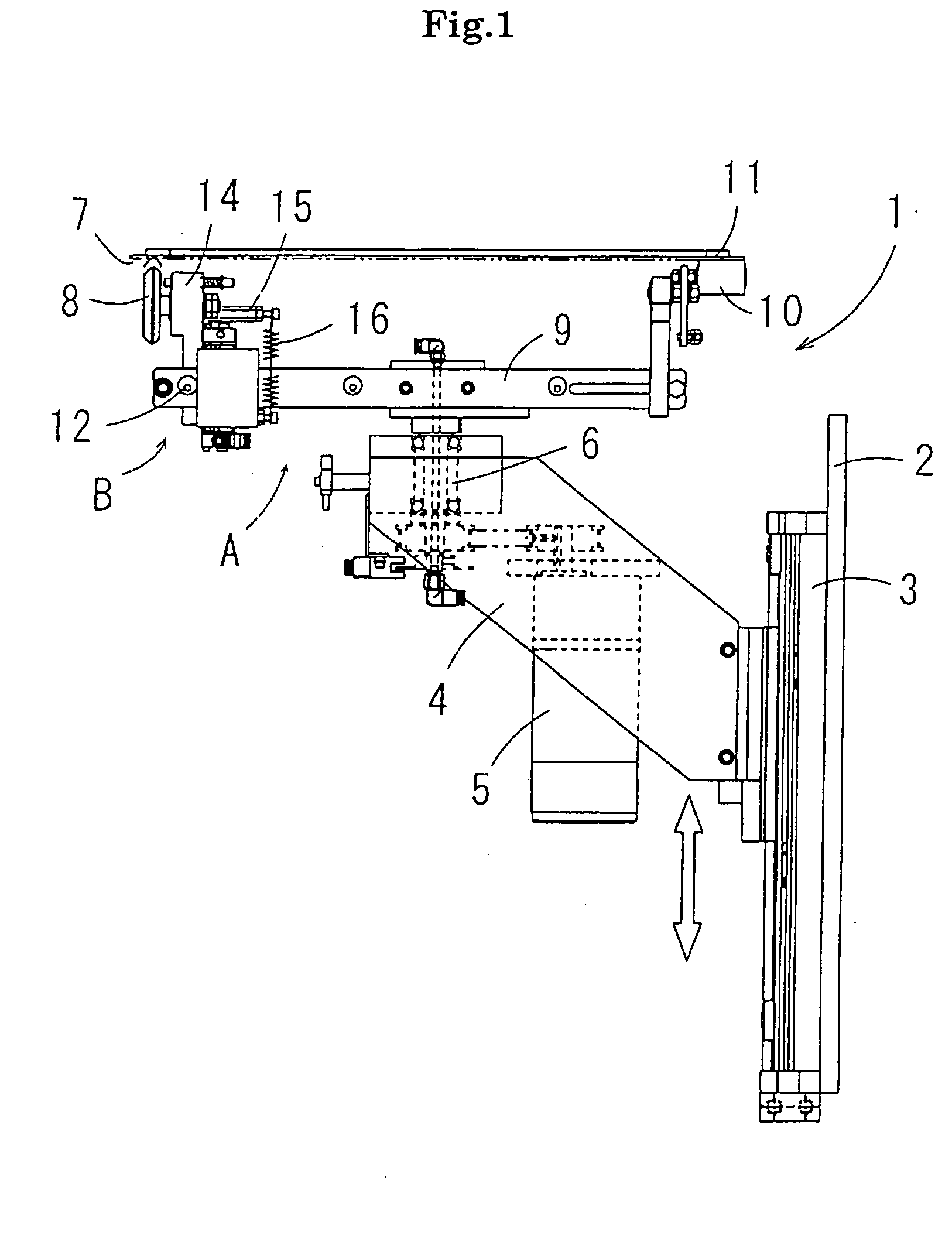

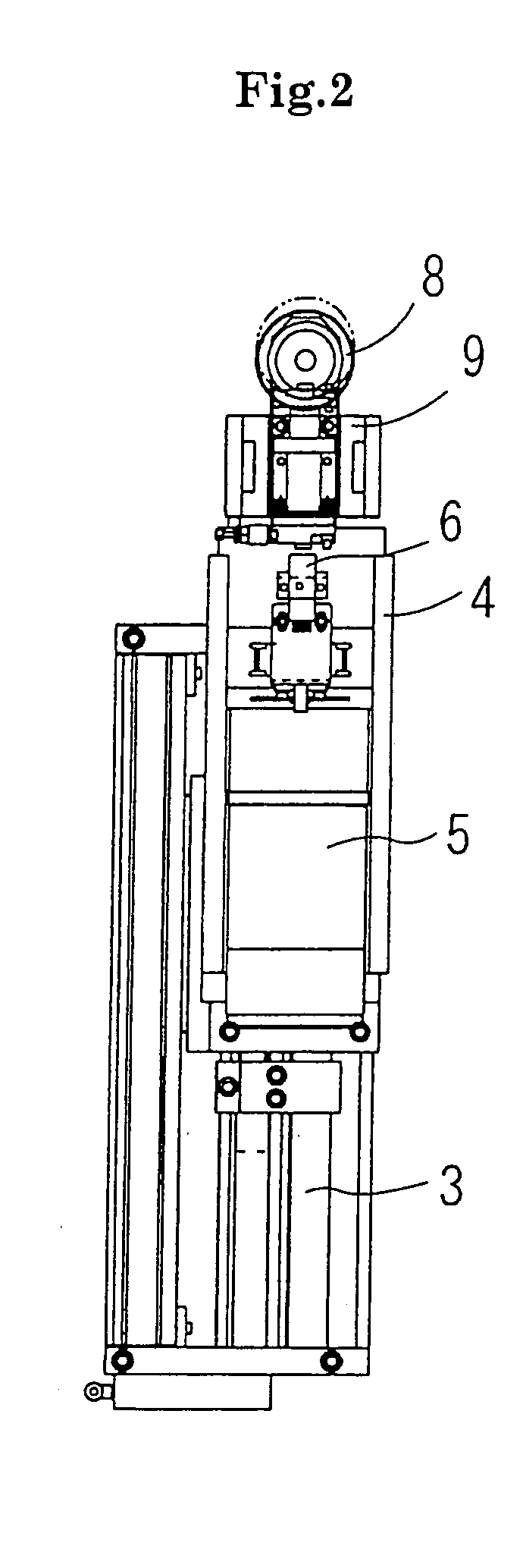

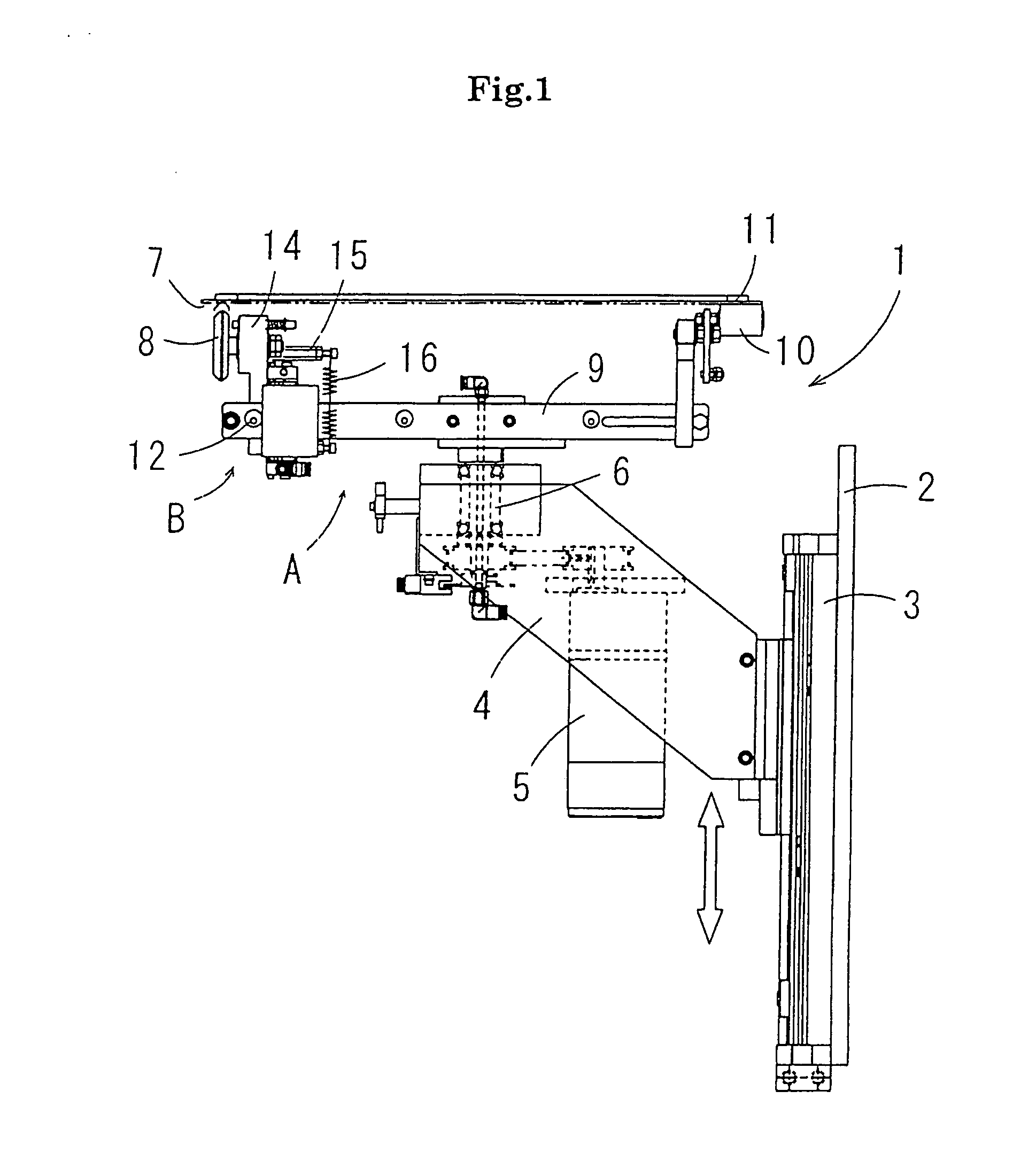

Device for transferring a band-shaped weft material

The invention relates to a device (1) for transferring a preferably band-shaped weft material (6) from a feed unit to an insertion element (4) of a weaving machine, comprising a clamping device (5) for clamping a free end (E) of the weft material (6). The clamping device (6) can be moved substantially in the direction (BR) of motion of the insertion element (4) between at least two different operating positions. The device (1) contains a drive (8) for moving the clamping device (5). In a method for transferring a preferably band-shaped weft material (6) from a coil or a feed unit to an insertion element (4) of a weaving machine, a free end (E) of the weft material (6) is clamped in a clamping device (5), the free end (E) is transferred to the insertion element (4), then the clamping device (5) is opened, and the weft material is inserted. The clamping device (5) is moved substantially in the direction of motion of the insertion element (4) between at least two different operating positions by means of a drive (8).

Owner:LINDAUER DORNIER GMBH

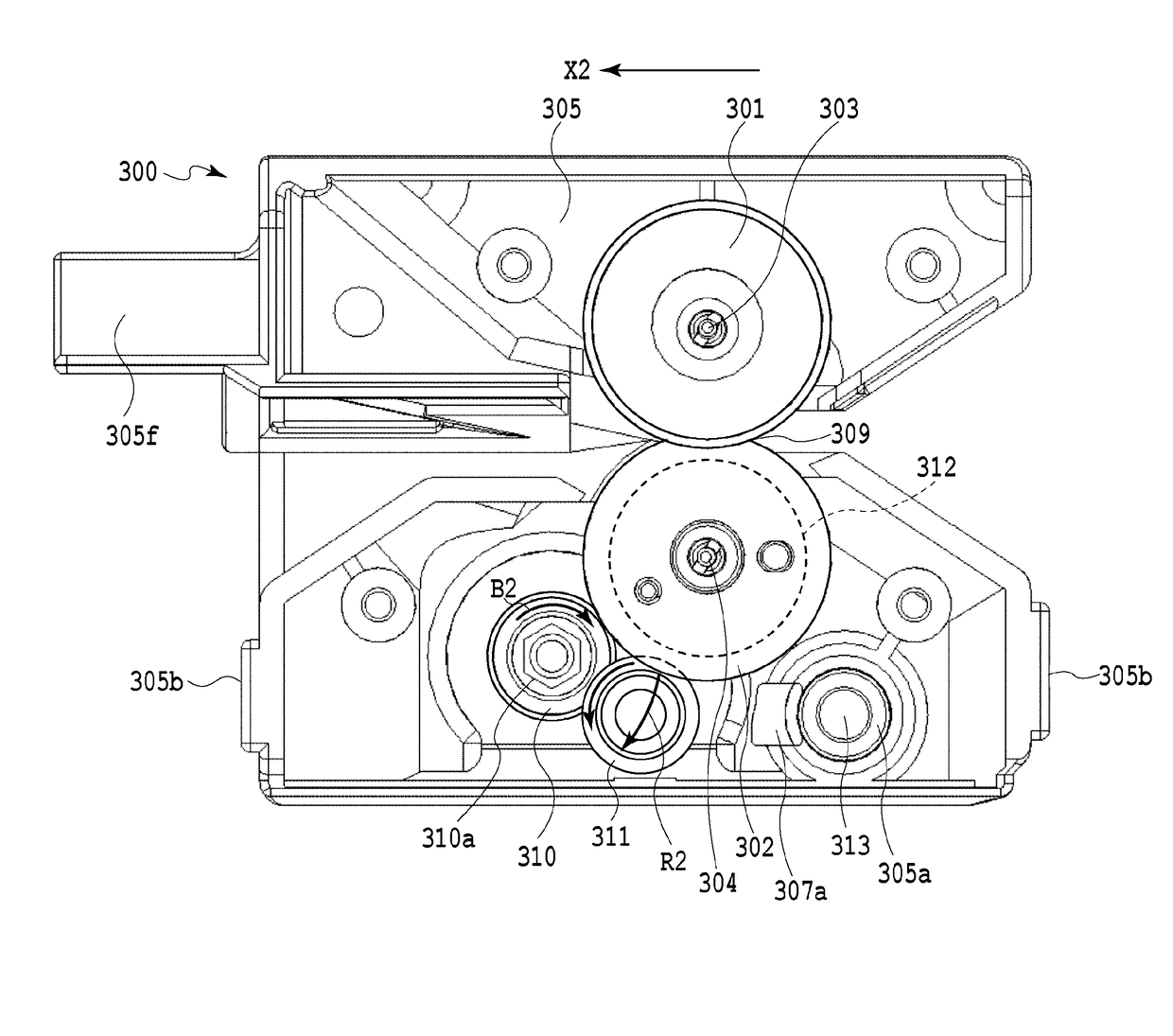

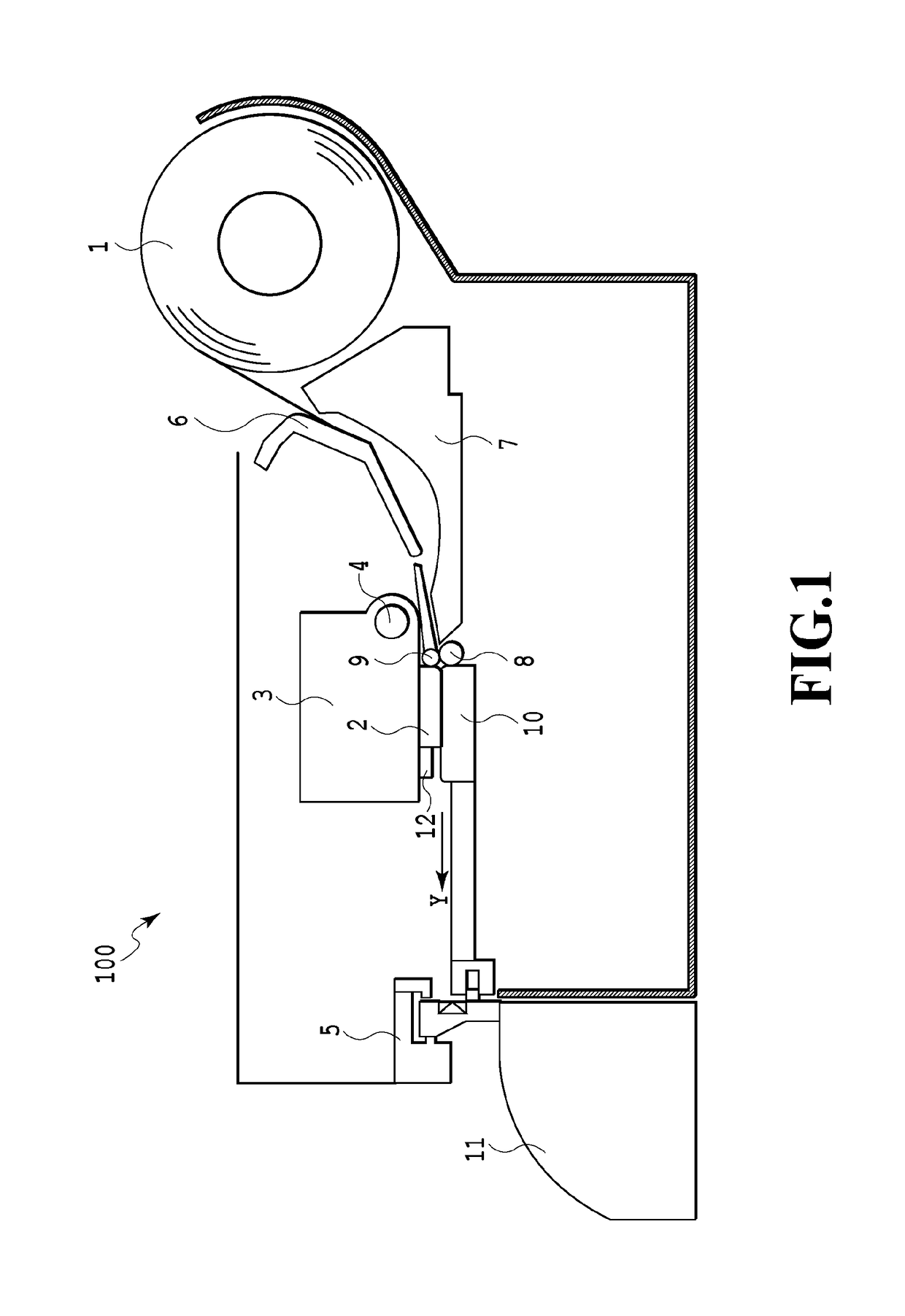

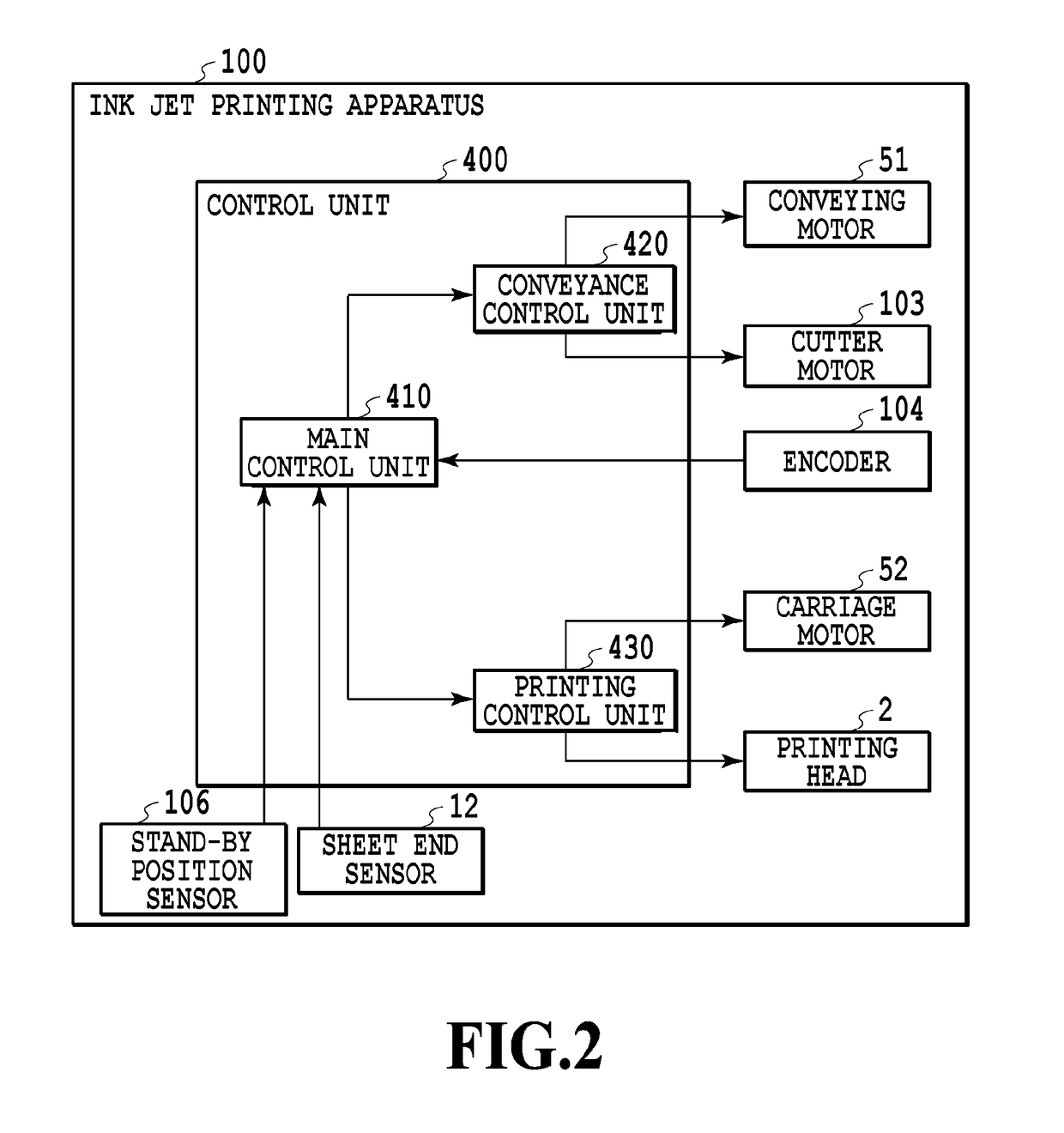

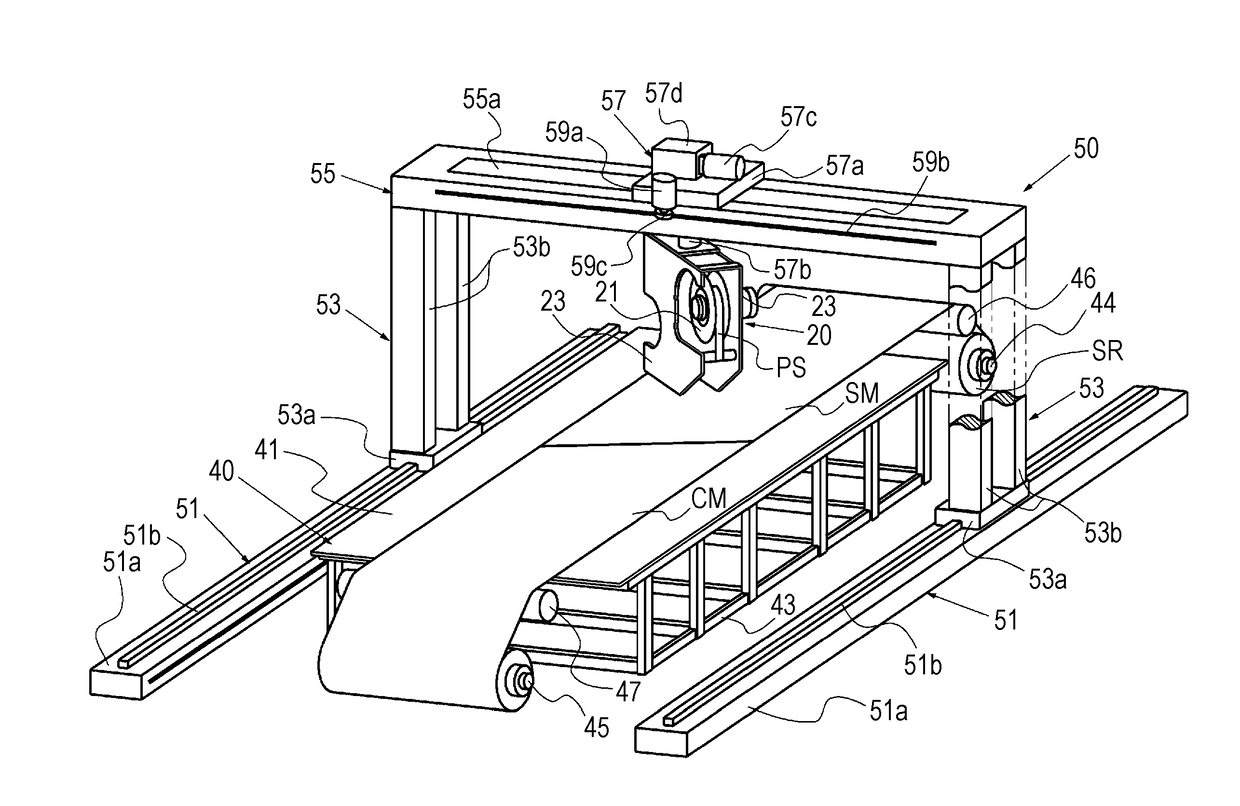

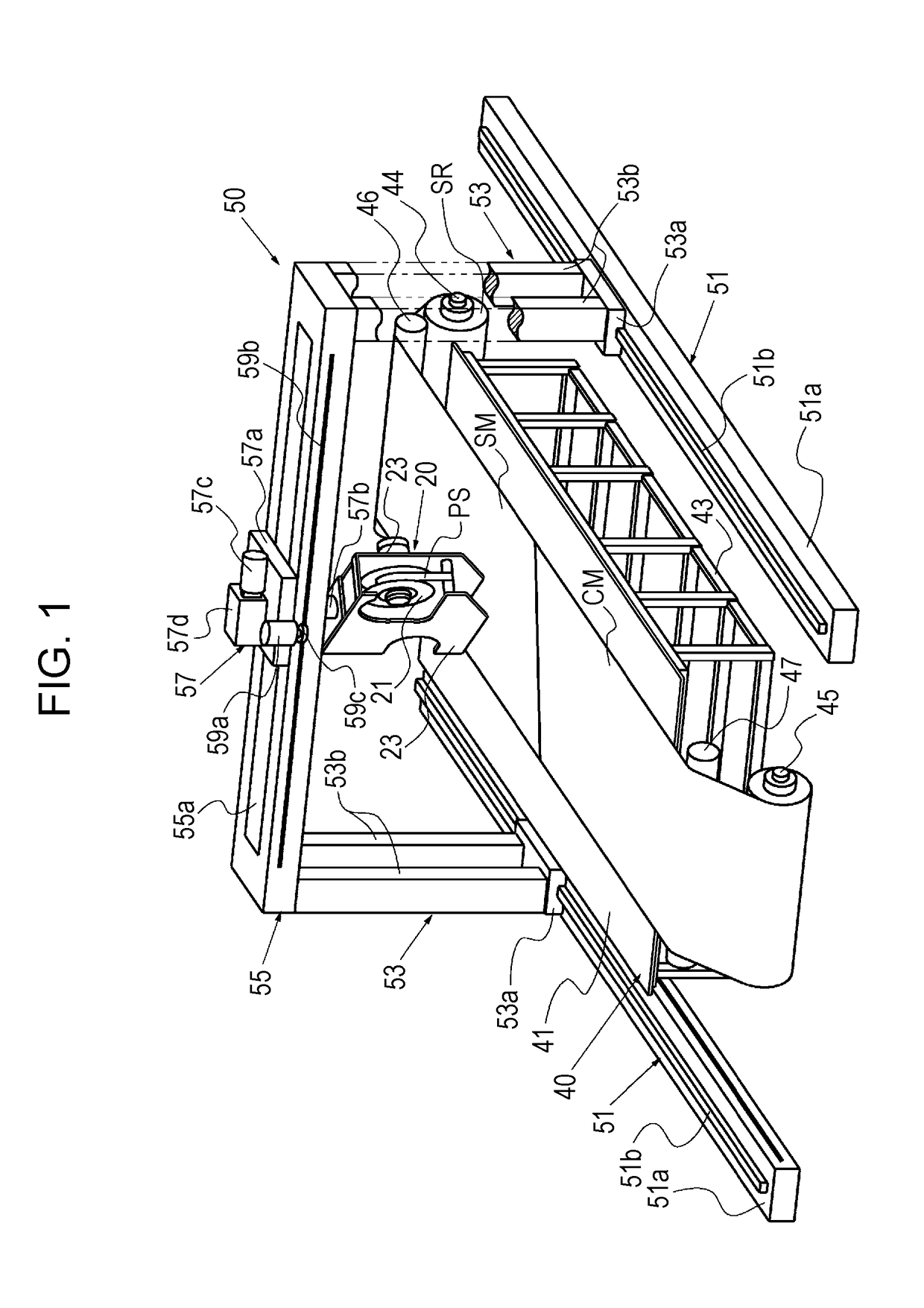

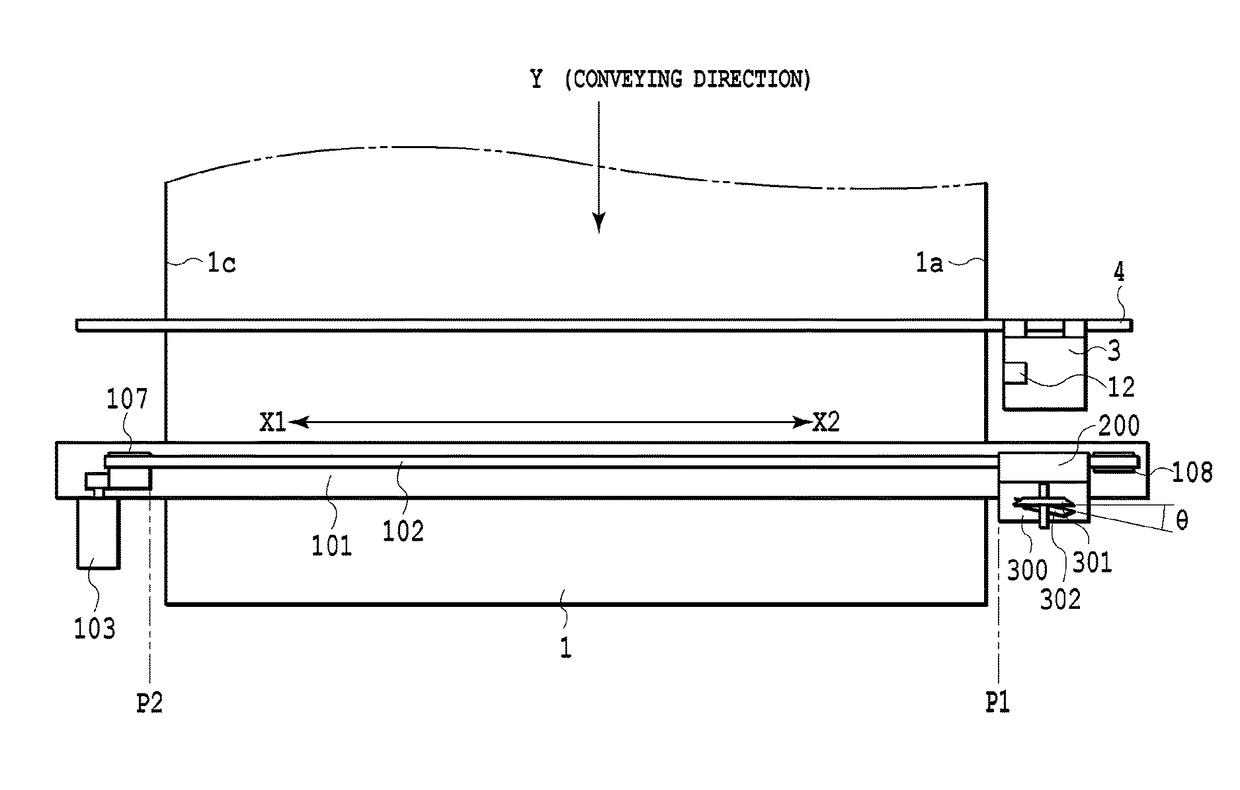

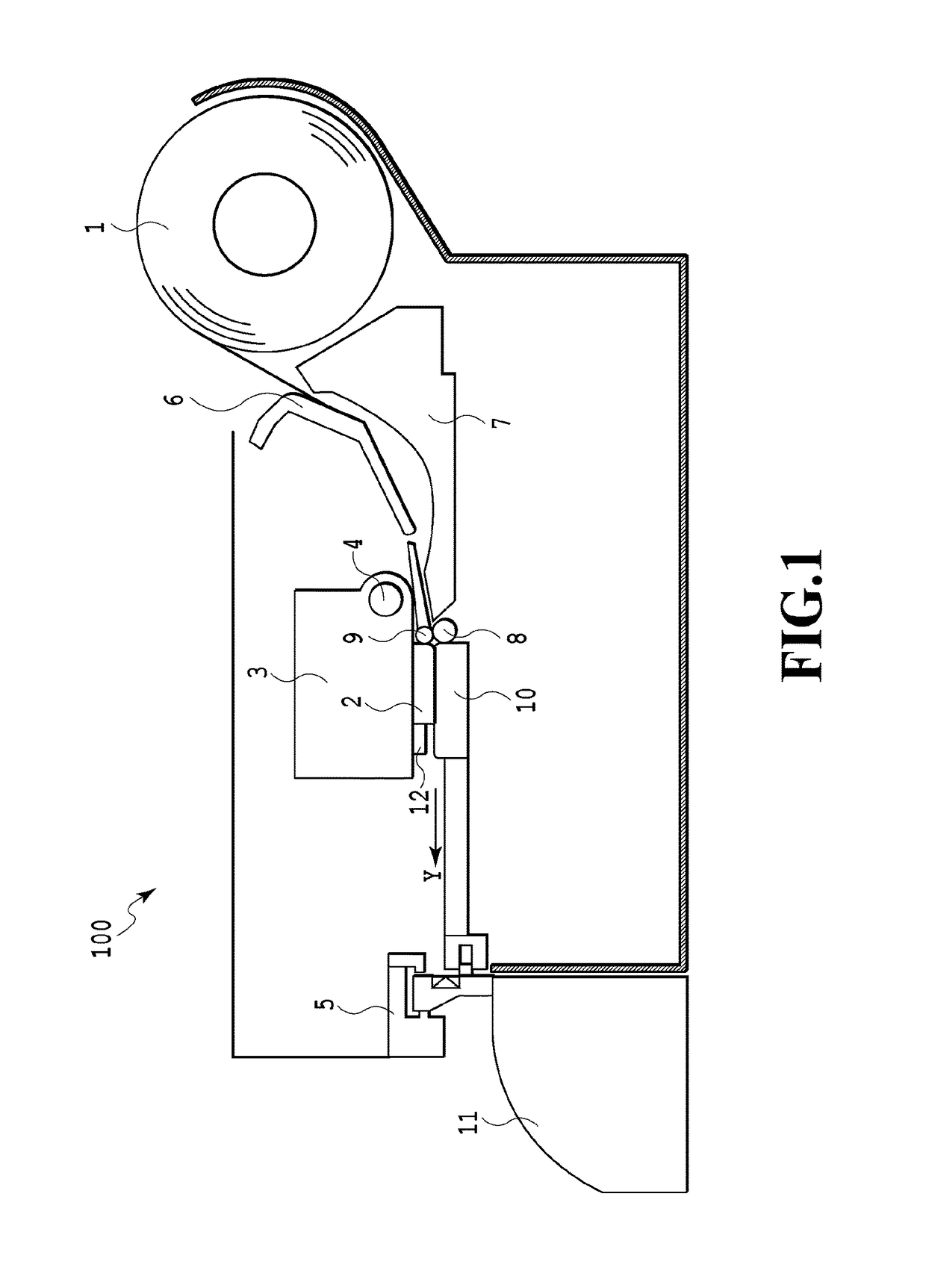

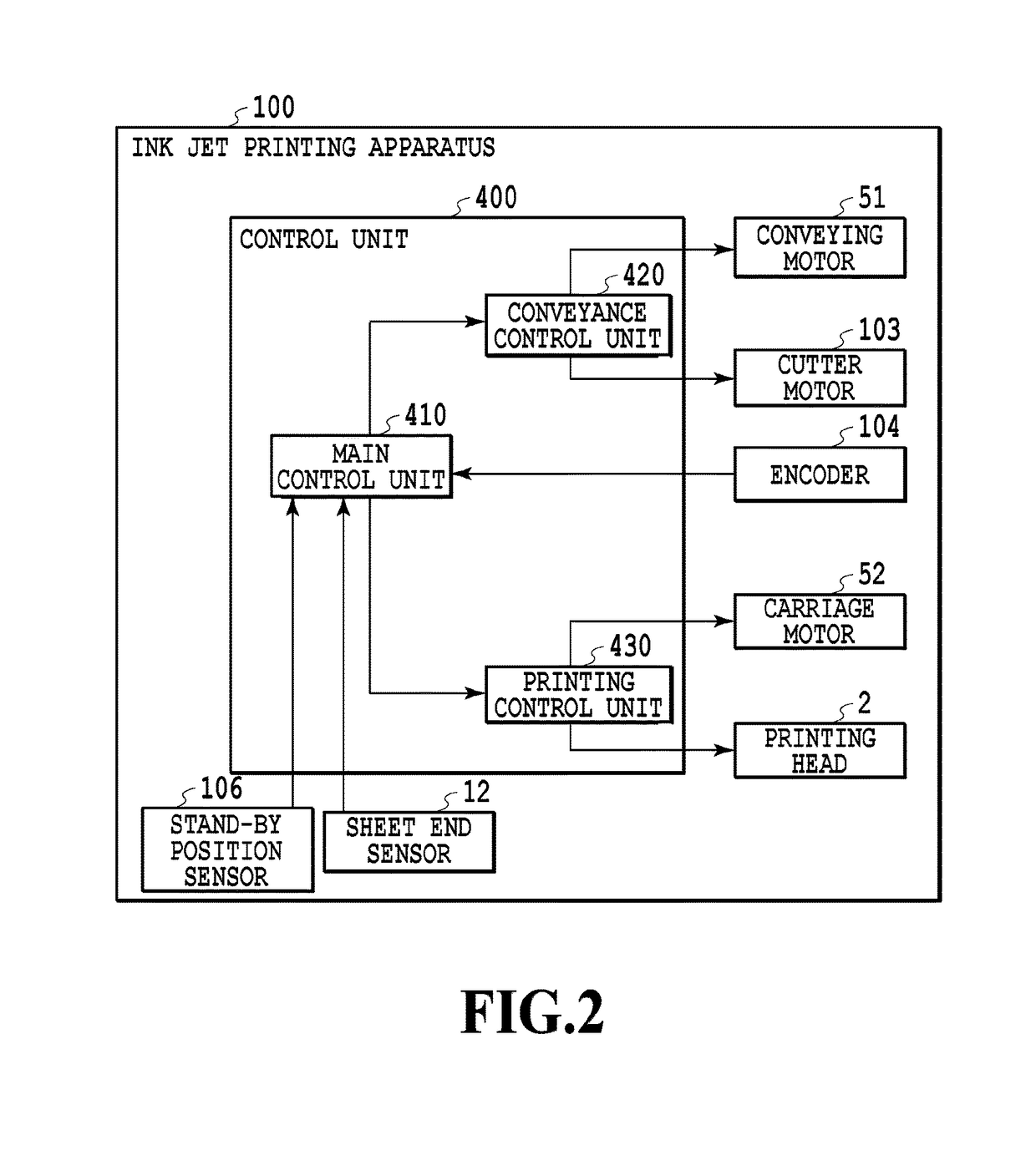

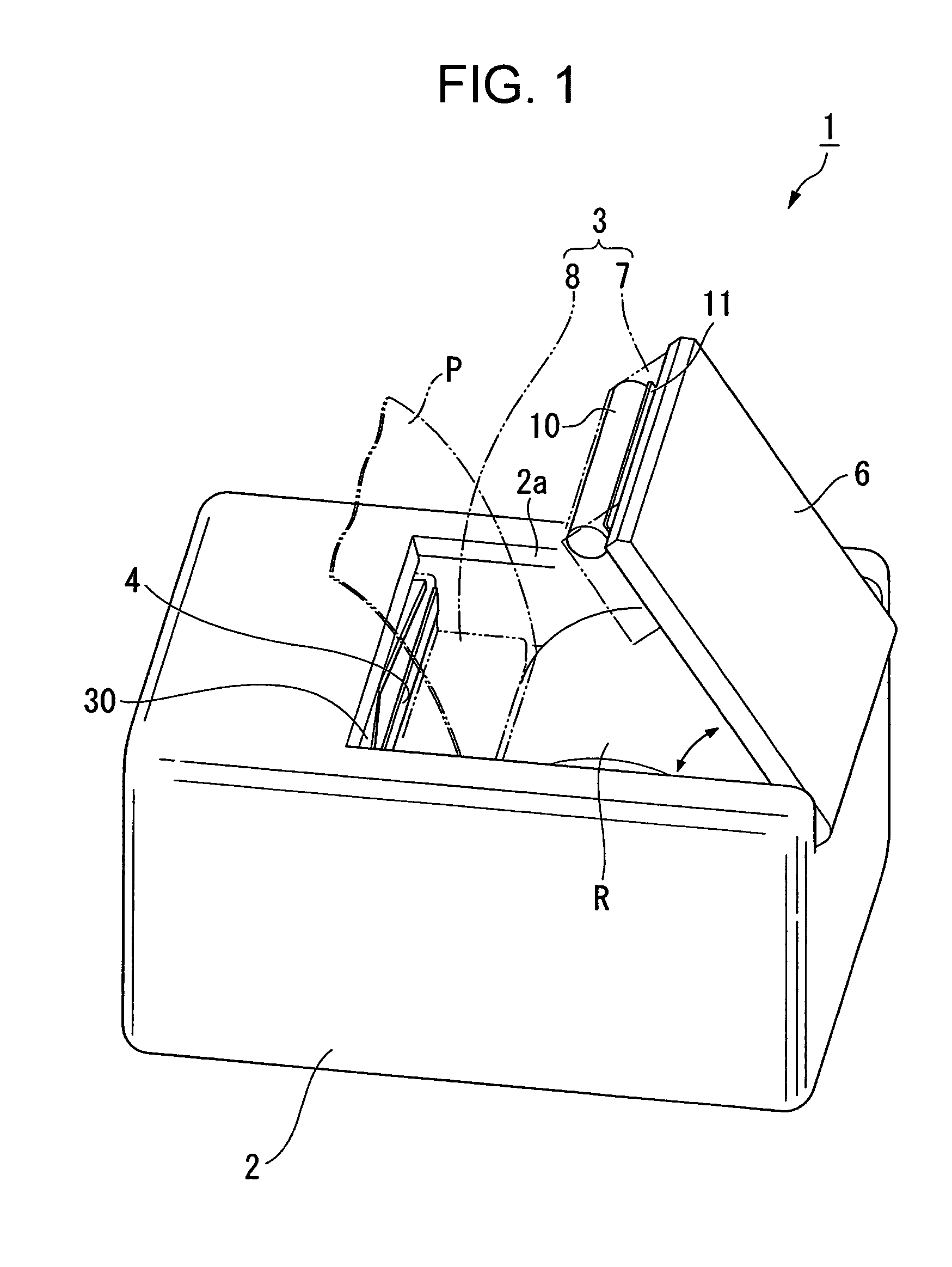

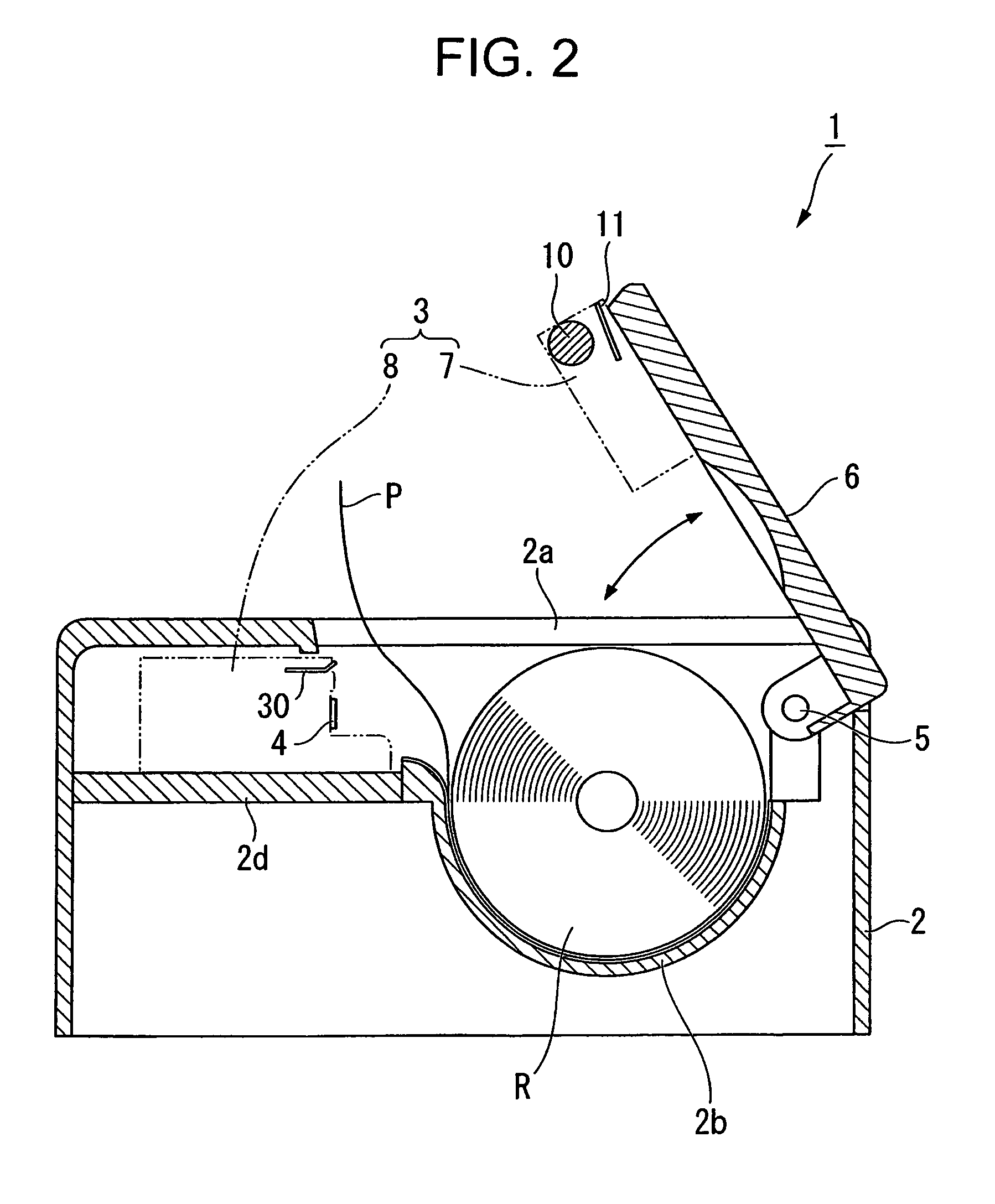

Cutting apparatus and printing apparatus

ActiveUS20170087889A1Reliably cut a sheetReduce cutting timeOther printing apparatusMetal working apparatusEngineeringMechanical engineering

Owner:CANON KK

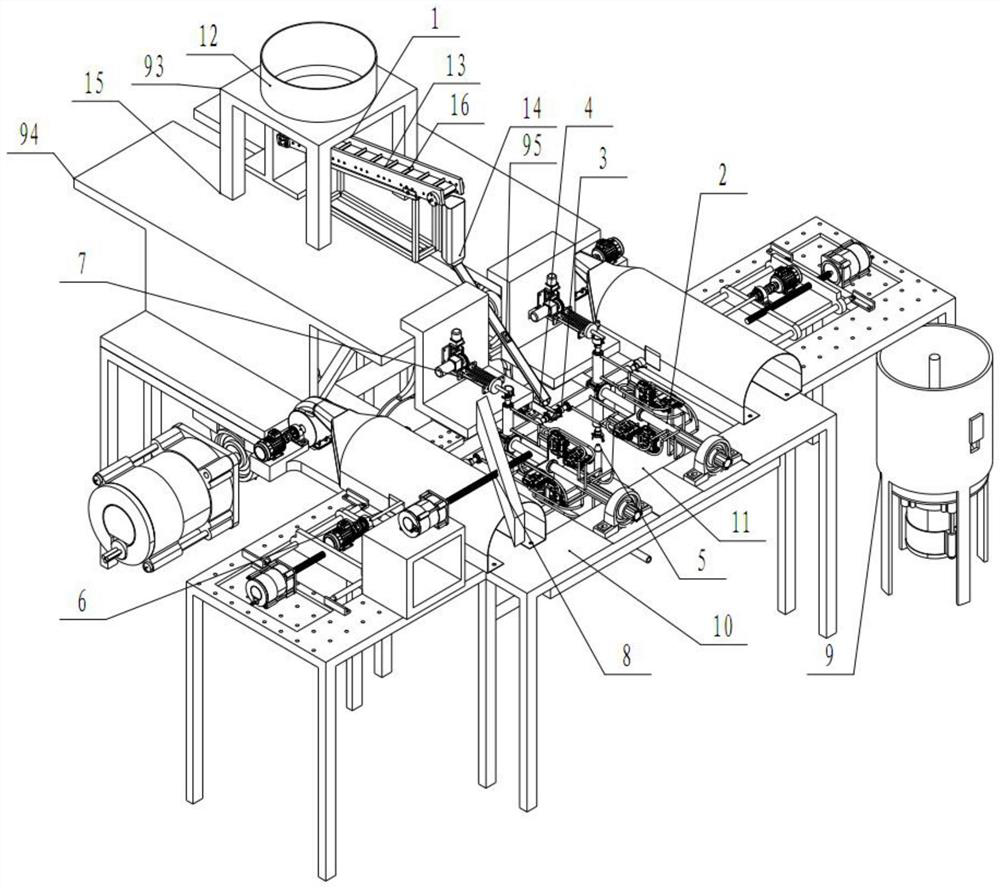

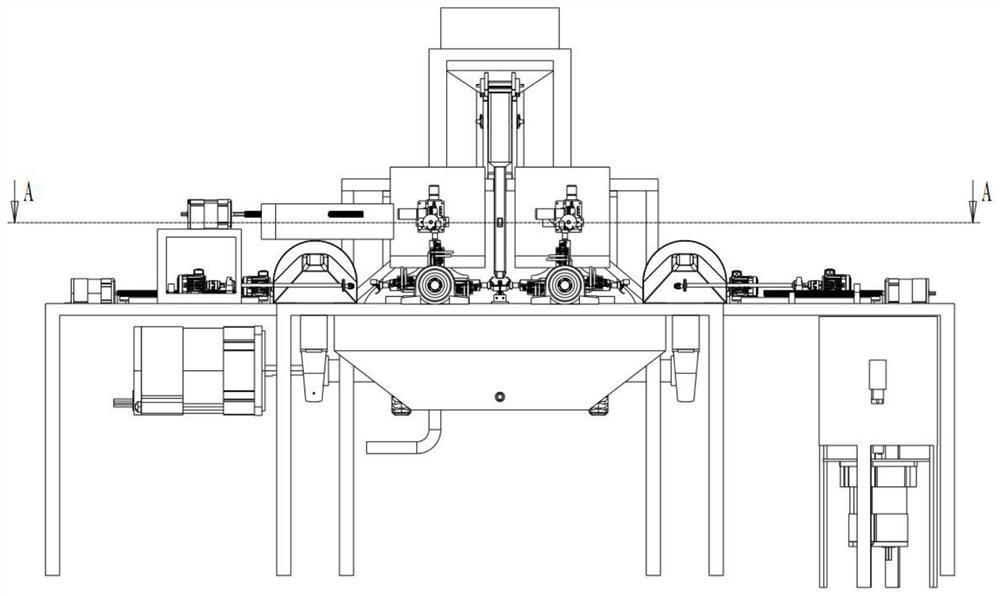

Feed device for reinforcing fiber material and method for cutting reinforcing fiber material by using the feed device

A cutting mechanism includes a cutter roll and a rotational driving mechanism for rotationally driving the cutter roll. The cutter roll has a roll body and a blade portion protruding from a peripheral surface of the roll body. The blade portion is formed at a same position on a circumference of the roll body and extends in an axial direction of the roll body. The cutter roll is arranged so that the axial direction is at a predetermined angle with respect to a pull-out direction of the reinforcing fiber material. The cutting mechanism further includes a slide mechanism that displaces cutter roll in the axial direction toward a side in the pull-out direction of the reinforcing fiber material at least when the reinforcing fiber material is cut.

Owner:TSUDAKOMA KOGYO KK

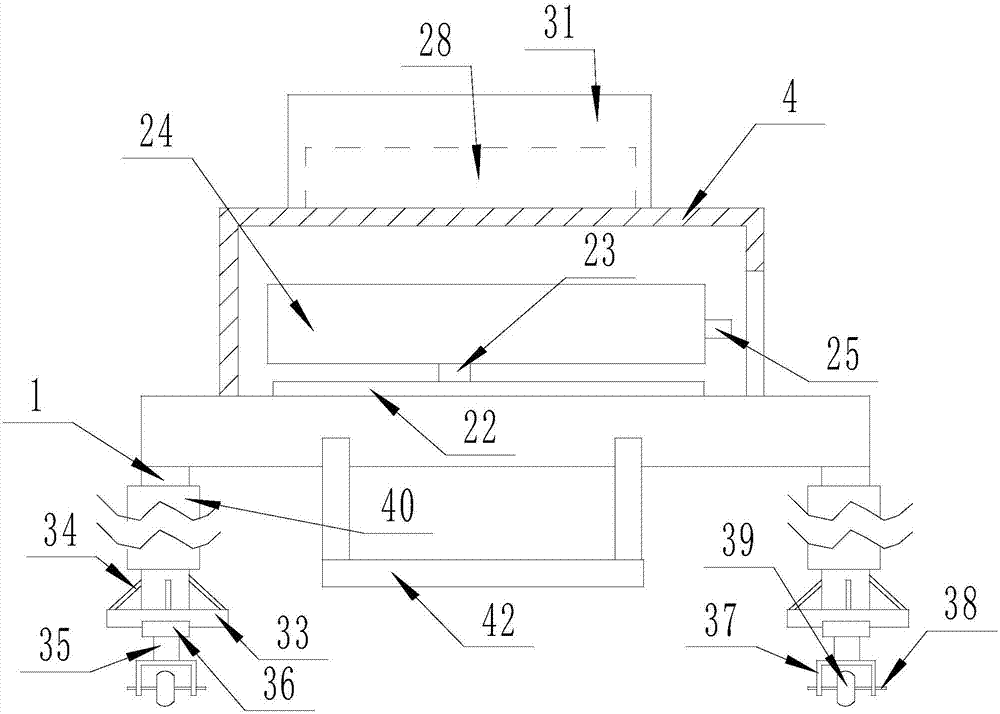

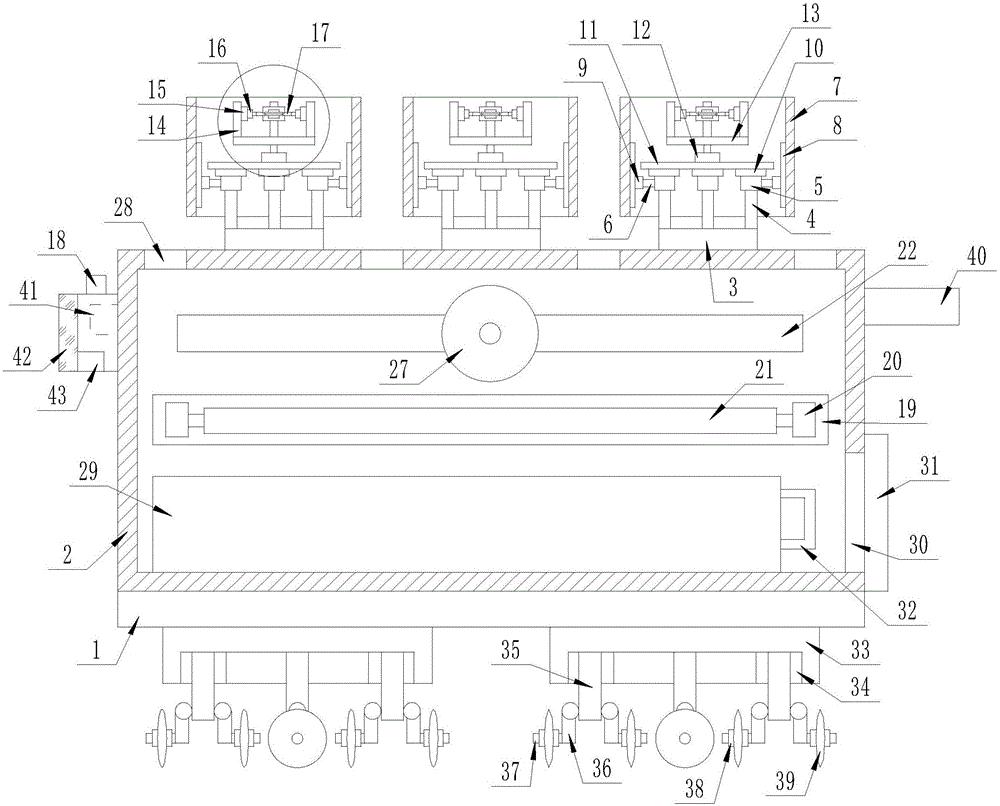

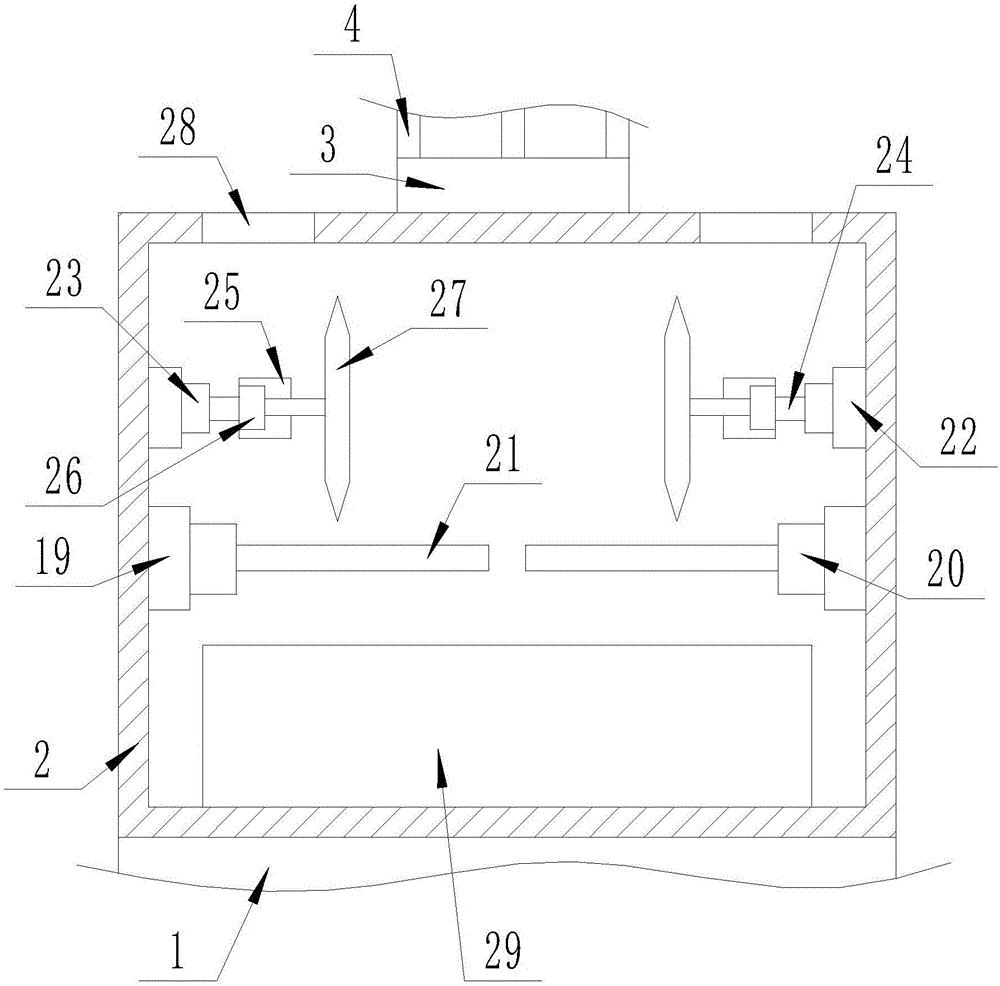

Cutting machine for automatically slitting long tube stock into short tubes

ActiveCN102528159AReduce pollutionReduce labor intensityMetal sawing devicesMetal sawing accessoriesEngineeringTube diameter

The invention relates to the technical field related to tube stock cutting devices, in particular to a cutting machine for automatically slitting a long tube stock into short tubes, comprising a rack, and a lifting mechanism and a cutting mechanism arranged on the rack. The cutting mechanism is arranged on the left side of the lifting mechanism, a tube feeding mechanism is arranged on the lifting mechanism, a support mechanism is arranged above the feeding mechanism and the cutting mechanism, a tube rotating mechanism is arranged above the support mechanism, a gap for containing the tube stock is arranged between the support mechanism and the tube rotating mechanism, the support mechanism comprises a V-shaped bracket and two support rotating sleeves which are respectively arranged on two arms of the V-shaped bracket. In the invention, a dust collector on a machine starts to work while tube cutting is performed, so that the dust pollution is reduced, and the labor protection is strengthened. The cutting machine has a simple structure, is reliable in cutting and can cut tube stocks with high thickness and large tube diameter specification range, and is suitable for various specifications of tube diameters when in clamping.

Owner:GUANGDONG LIANSU MACHINERY MFG

Linear shaped charge

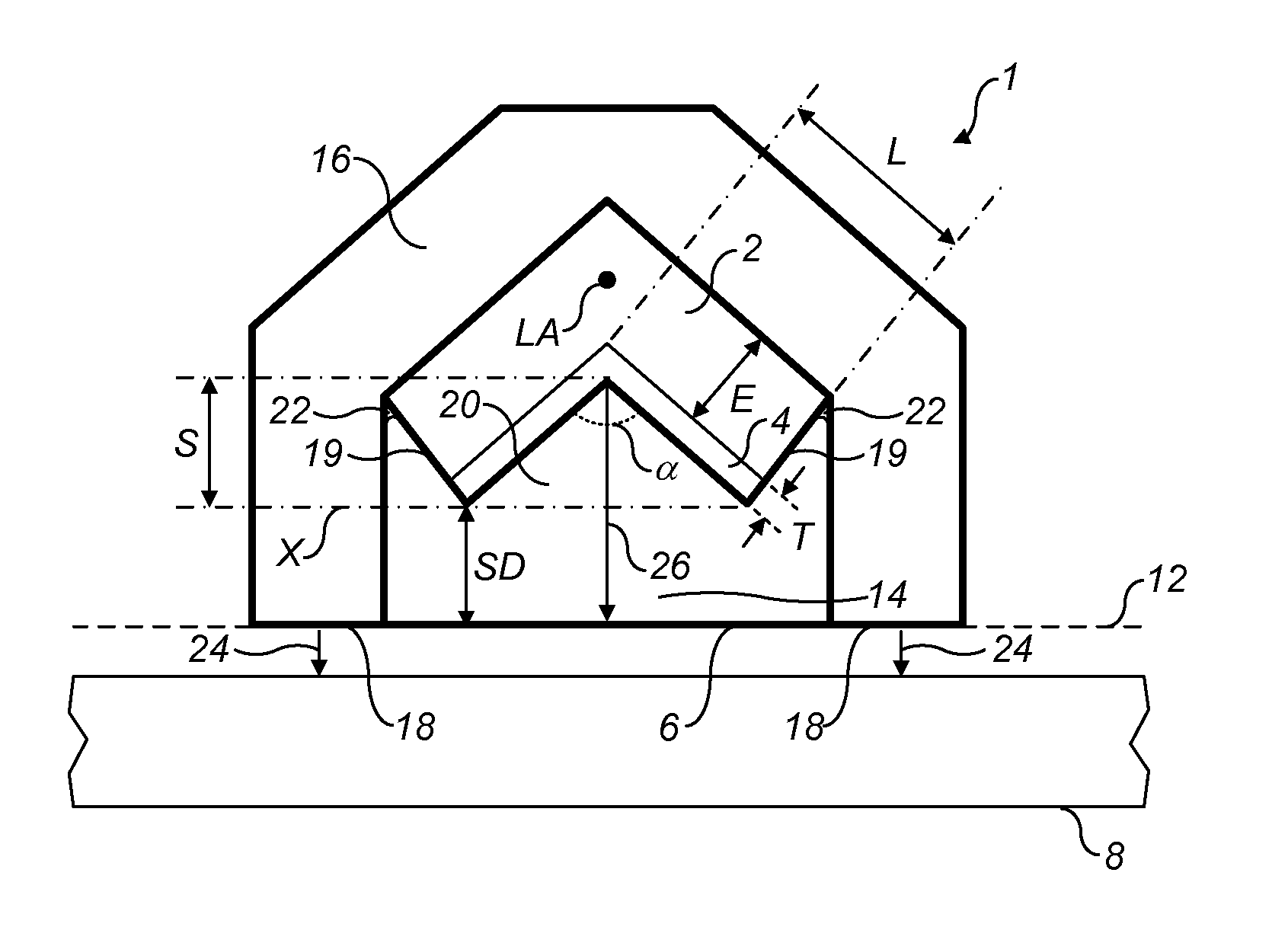

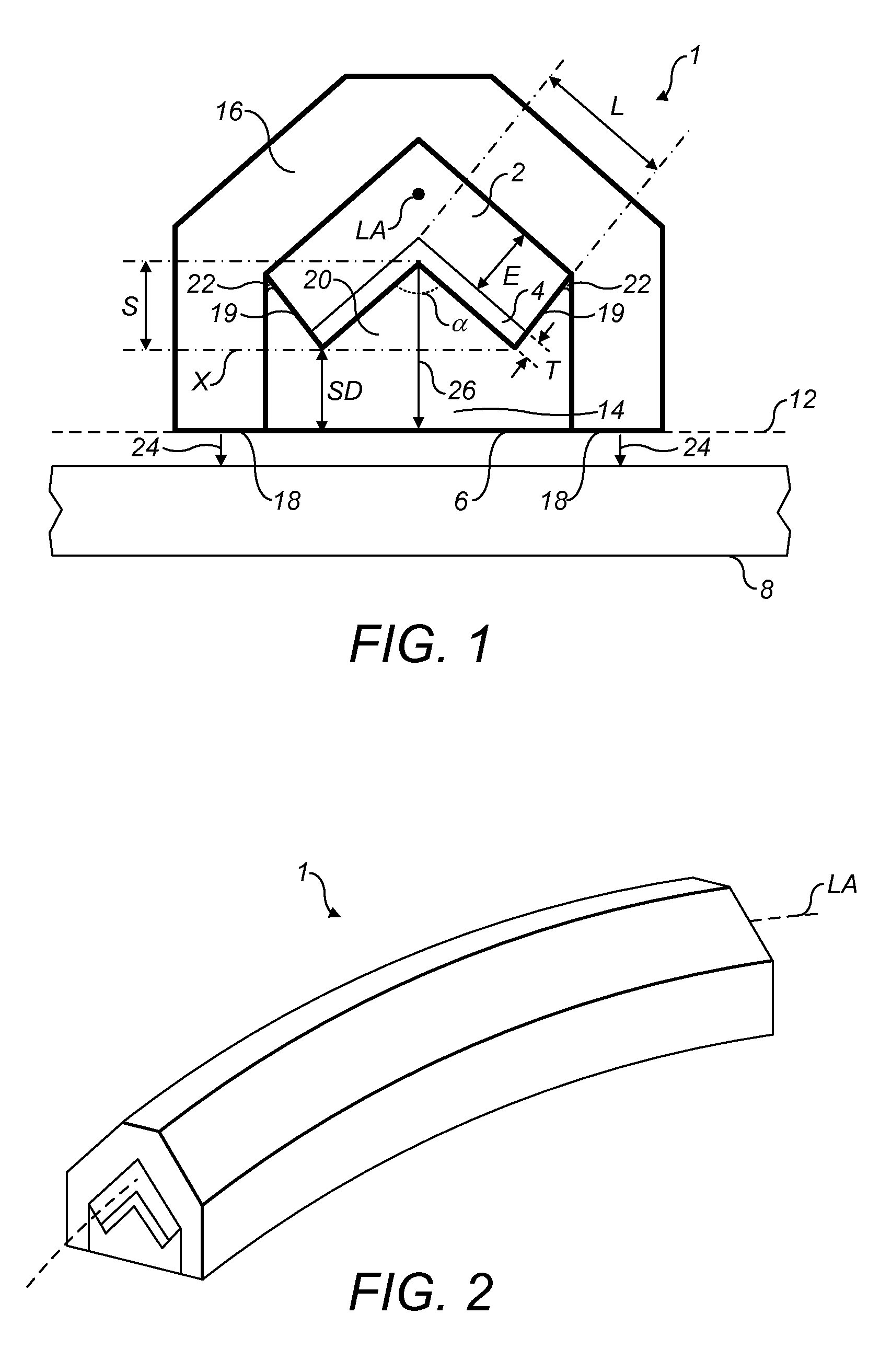

ActiveUS9045692B2Efficient and effectiveEffective and reliableExplosive chargesDirect heating destructive distillationShaped chargeEngineering

One or more aspects of the present invention relate to a linear shaped charge comprising an explosive element, a liner, a face for application to a target object and a space between the liner and the face, the liner being arranged for projection through the space, towards the face, when the explosive element is detonated, and the explosive element and the liner having a V-shaped cross section, the liner lying in a groove of the V-shaped cross section of the explosive element, the liner having a length L of a side furthest from the face and the liner having a thickness T taken perpendicular to said length L, wherein an angle α of an apex of the liner nearest the face is 101.5 to 106.5 degrees, and a stand-off distance SD between the face and a point of the liner nearest the face is 0.99 S to 1.21 S, S being a distance, parallel the stand-off distance SD, between the point of the liner nearest the face and the apex of the liner nearest the face.

Owner:JET PHYSICS

Automatic compression joint material breaking and material changing mechanism for hygienic product coiled material and material breakage method

The invention relates to an automatic compression joint material breaking and material changing mechanism for a hygienic product coiled material. The mechanism comprises a left unwinding mechanism, a right unwinding mechanism, a compression joint material breakage mechanism, a tension control mechanism, a deviation correcting mechanism and a programmable logic controller (PLC); positive rotation or negative rotation of left and right motor shafts is controlled by the PLC; the compression joint surfaces of compression joint plates in a compression assembly are opposite, and the compression joint plates are connected with pistons of two compression joint cylinders respectively; two sets of cutting assemblies have the same structure and are distributed opposite, transition wheels in the cutting assemblies are connected with the upper parts of an inner swing arm and an outer swing arm through transition wheel axles, and the lower ends of the inner swing arm and the outer swing arm are connected with a main shaft through a bearing respectively and can be outwards turned, opened and reset; two ends of a serrated cutter are positioned on the shaft seats of the inner swing arm and the outer swing arm and positioned below the transition wheels; one end of a cutting cylinder is sleeved on a positioning rod, and the other end of the cutting cylinder is hinged with a cutter shaft through a connector and drives the serrated cutter to extend or reset; a compression plate is positioned above the transition wheels and connected with the piston of a compression cylinder through a top plate; and the compression cylinder drives the compression plate to extend or reset.

Owner:湖州唯可新材料科技有限公司

Method of manufacturing semiconductor device, and bonding apparatus

ActiveUS8292160B2Improve fitting accuracyReduce areaWelding/cutting auxillary devicesSolid-state devicesUltrasonic vibrationSemiconductor

In a first bonding step of bonding an initial ball to a pad surface, the initial ball is applied by ultrasonic vibration while in pressure contact with the pad surface and a capillary undergoes a scrubbing motion to be rotated spirally. This allows a deformation area of the initial ball to be reduced, whereby the accuracy of bonding can be improved. In a second bonding step of bonding a bonding wire to a lead surface, the capillary and the bonding wire are applied by ultrasonic vibration while in pressure contact with the lead surface and the capillary undergoes a scrubbing motion to be rotated spirally. This allows the bonding wire bonded to the lead surface to be cut reliably.

Owner:SHINKAWA CO LTD

Movable device for long cutting of cement surface

The invention discloses a movable device for long cutting of a cement surface. The movable device comprises a first N-shaped frame, a set of horizontal fixing rods are embedded at the two ends of the side surface of a beam of the first N-shaped frame, and the set of horizontal fixing rods are sleeved with a second N-shaped frame matched with the first N-shaped frame; and a fixed-length cutting mechanism and a movable mechanism are arranged on the lower surfaces of the first N-shaped frame and the second N-shaped frame, an electricity storage box body is arranged on the upper surfaces of the set of horizontal fixing rods, an electricity storage mechanism is arranged in the electricity storage box body, and a manipulating mechanism is arranged on the upper surface of the electricity storage box body. The movable device for long cutting of the cement surface has the beneficial effects that cutting is reliable, the cutting length can be limited according to the circumstances, it is ensured that excessive cutting is avoided in cutting, it is ensured that the cutting surface is tidy and clean, operation is easy, using is convenient, and controlling is convenient.

Owner:中源宏宇建设集团有限公司

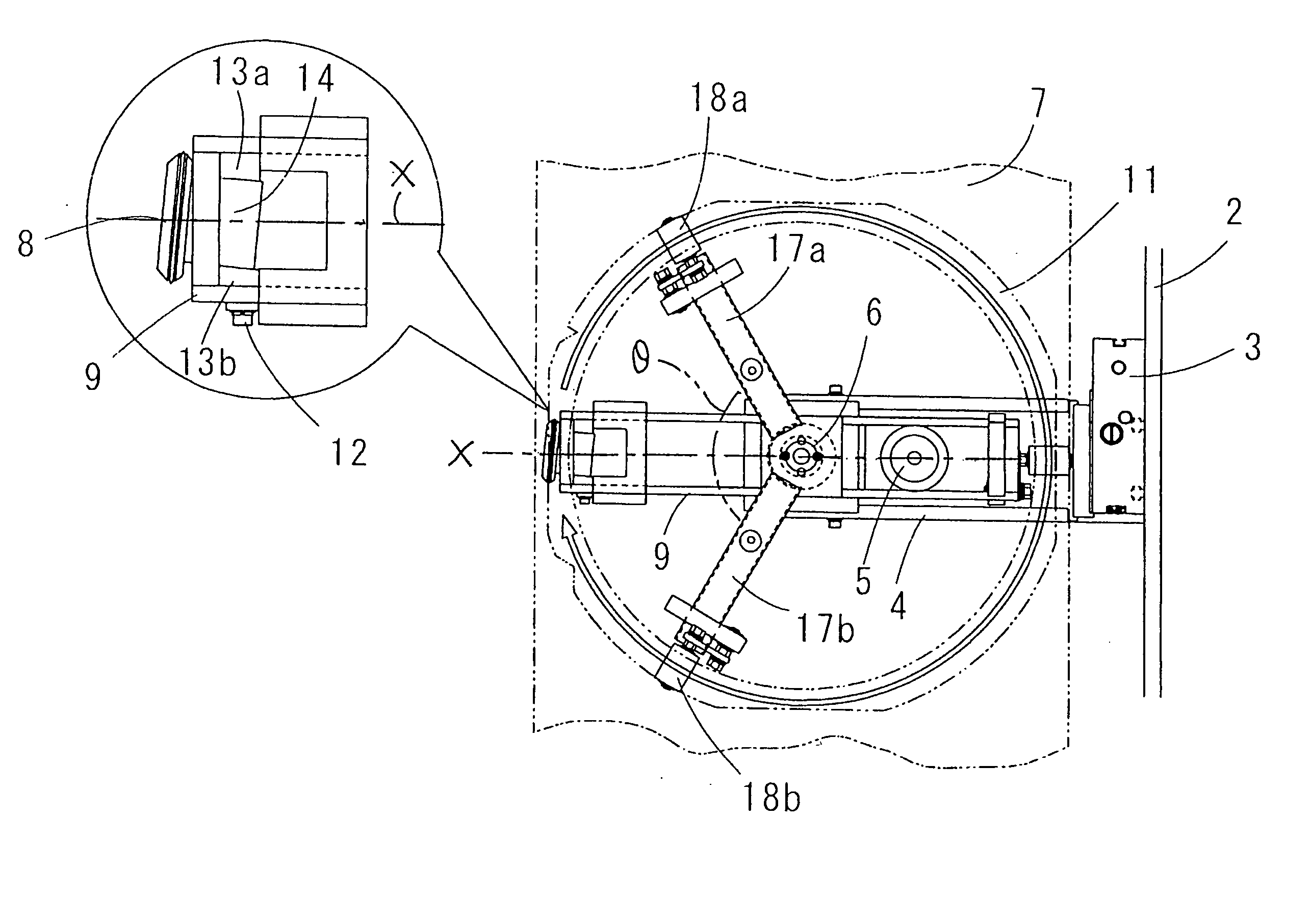

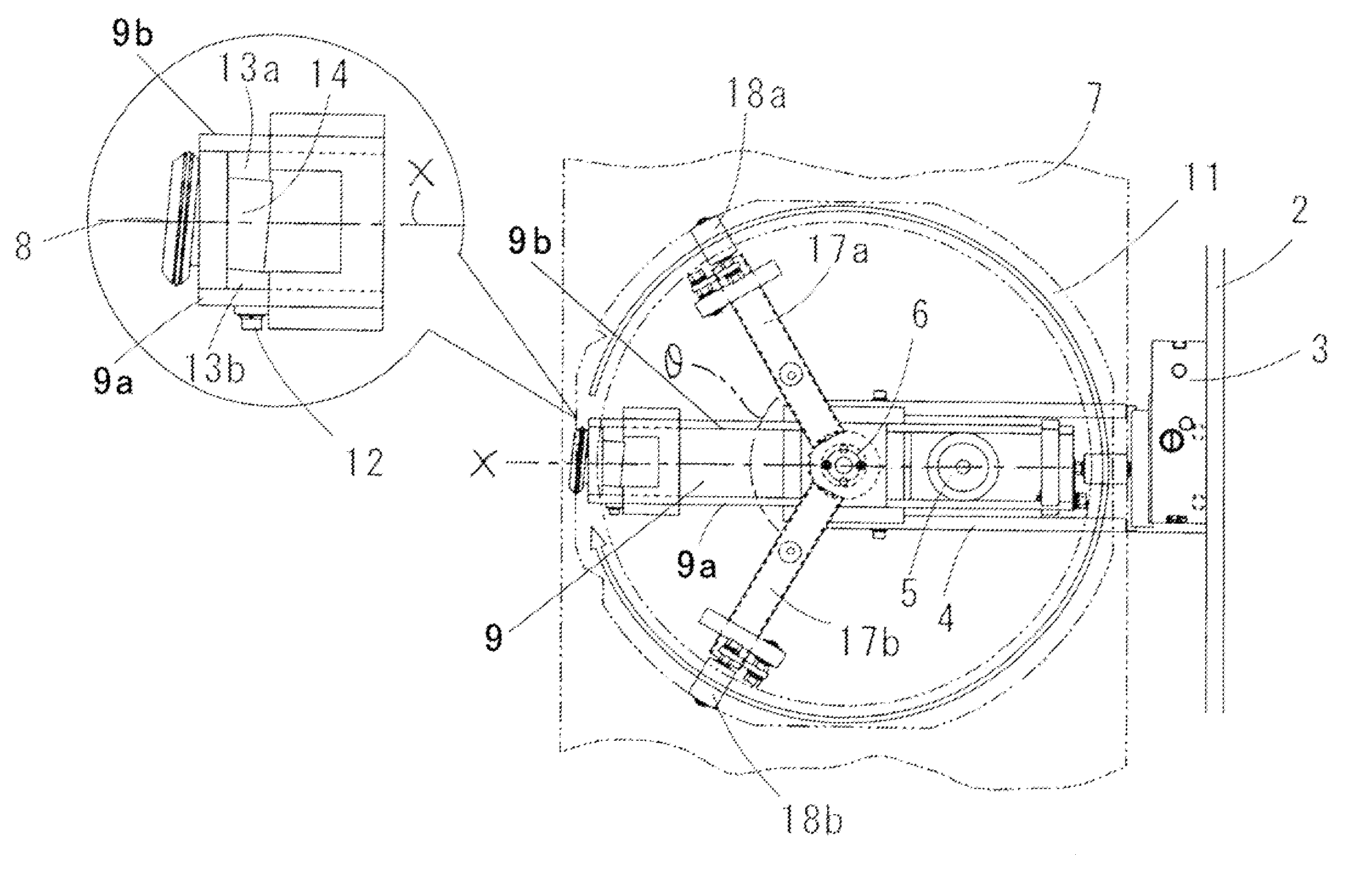

Method and apparatus for cutting adhesive tape

InactiveUS20050115666A1Reliable supportGood precisionLamination ancillary operationsLaminationEngineeringMechanical engineering

In a method of making a cutter revolve along a circumference of a circle having an optional size to cut an adhesive tape into a circular shape of a predetermined size, the cutter is made revolve while being tilted to an inner circumferential side in the revolving direction of the circumference, and a cutting start point and a cutting end point in a cutting path of the cutter are made coincide with each other.

Owner:NITTO DENKO CORP

Apparatus for cutting adhesive tape

InactiveUS7430950B2Reliable supportGood precisionLamination ancillary operationsLaminationAdhesive beltEngineering

In a method of making a cutter revolve along a circumference of a circle having an optional size to cut an adhesive tape into a circular shape of a predetermined size, the cutter is made revolve while being tilted to an inner circumferential side in the revolving direction of the circumference, and a cutting start point and a cutting end point in a cutting path of the cutter are made coincide with each other.

Owner:NITTO DENKO CORP

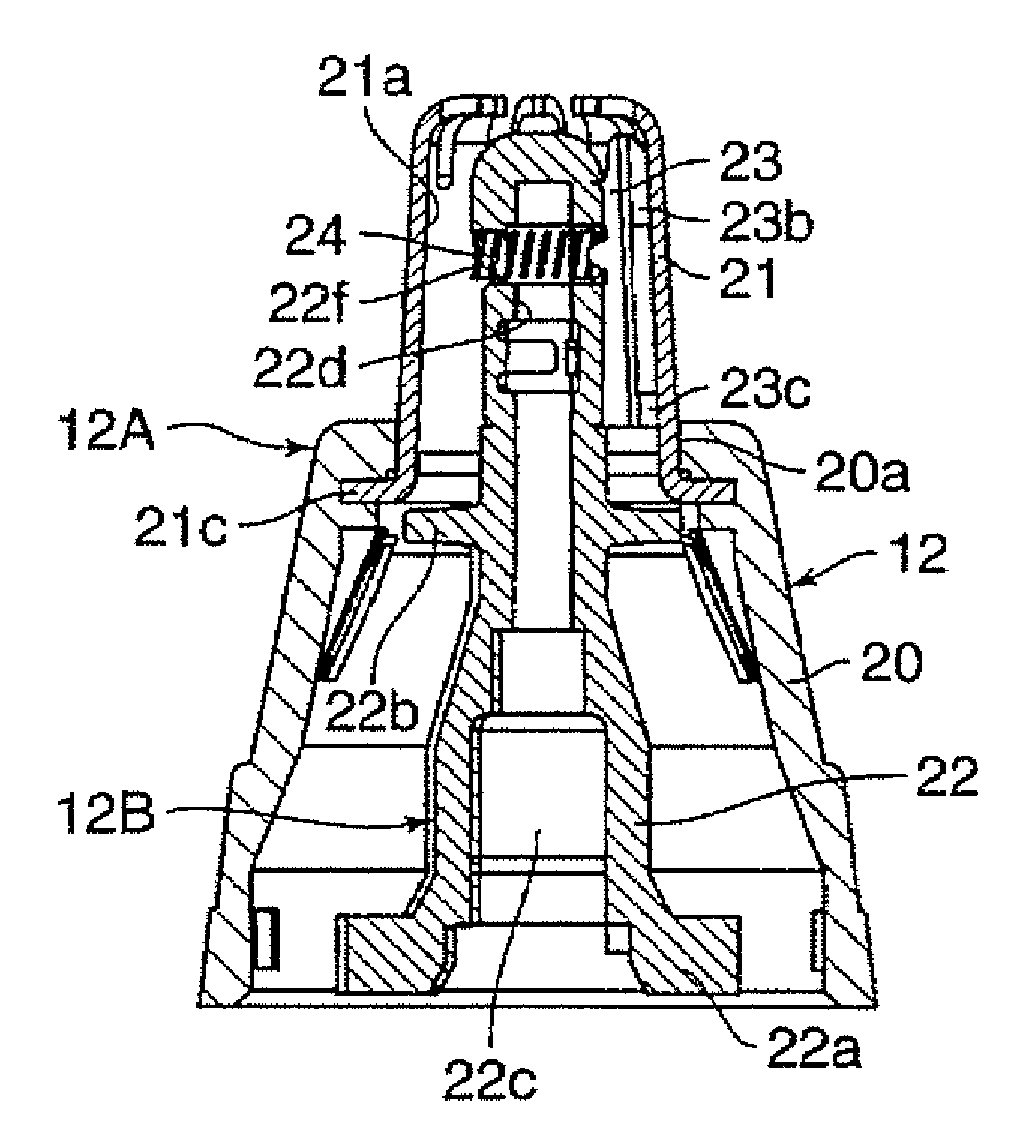

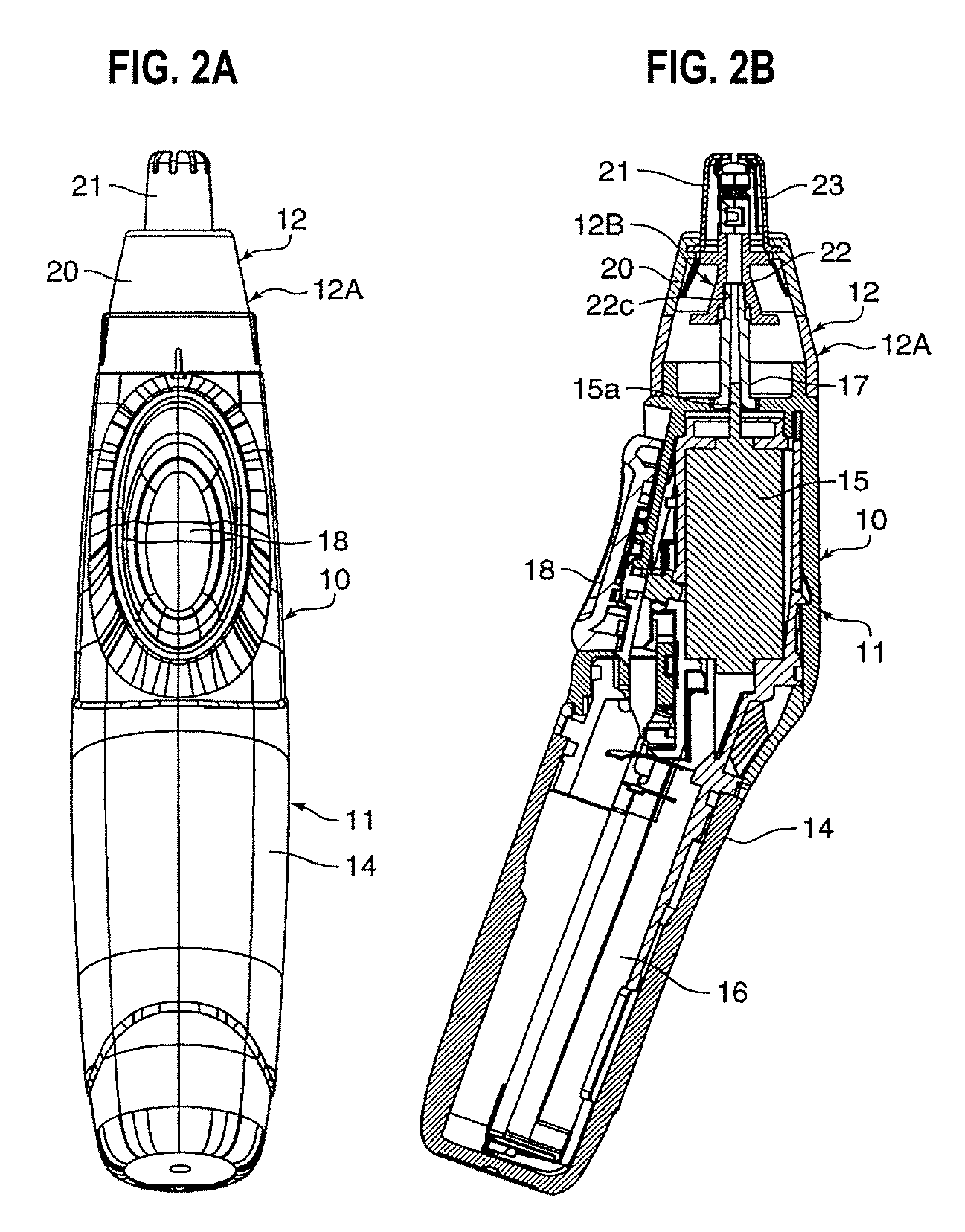

Nose hair cutter

A main body of an inner blade is inserted into an inner blade insertion hole of an inner blade frame such that the main body can extend and retreat, a tip end cutting edge is pushed by a spring such that it comes into contact with an inner peripheral surface of a slit outer blade, the main body of the inner blade projecting outward from the inner blade insertion hole is bent rearward in a rotational direction, and the cutting edge of the inner blade is located rearward of the main body in the inner blade insertion hole in the rotational direction. With this configuration, the cutting edge does not fall forward in the rotational direction, and no gap is generated between the cutting edge and the inner peripheral surface of the slit outer blade.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Device cutting and shredding cabbage skin automatically

InactiveCN106579503ASimple structureEasy to operateFeeding-stuffGrain treatmentsMechanical engineering

The invention discloses a device cutting and shredding cabbage skin automatically. The device includes a strip-shaped bearing board. A strip-shaped working box is fixedly connected to the upper surface of the strip-shaped bearing board. A skin cutting mechanism is arranged on the upper surface of the strip-shaped working box. A bearing mechanism in overlapping connection with the skin cutting mechanism is arranged in the strip-shaped working box. A moving mechanism is arranged on the lower surface of the strip-shaped bearing board. A smashing mechanism is arranged in the strip-shaped working box and disposed above the bearing mechanism. A controller is arranged on the side face of the strip-shaped working box. The device provided by the invention has beneficial effects of simple structure and high practicability.

Owner:孙瑞秀

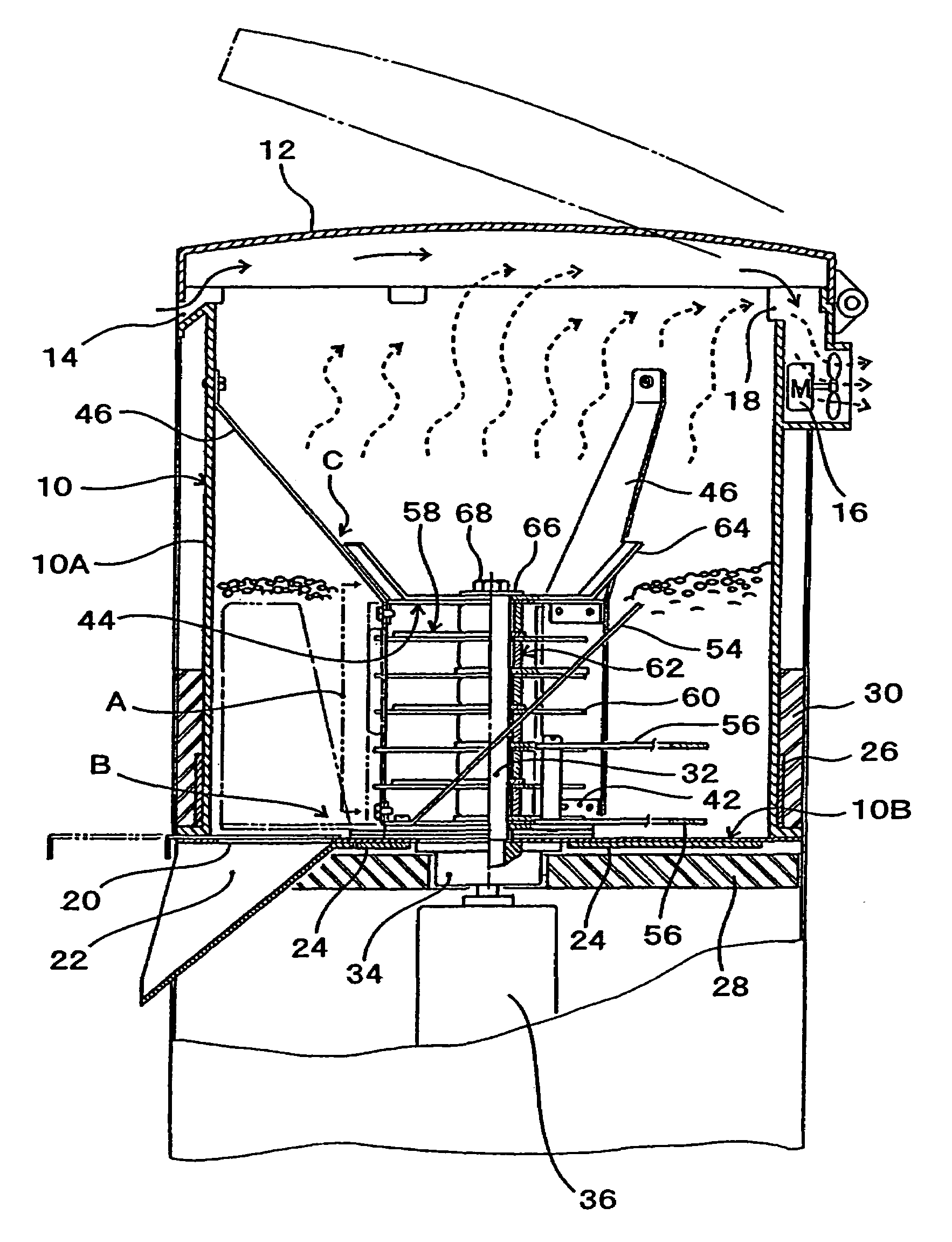

Raw garbage treatment apparatus and a cutter thereof

InactiveUS7011260B2Many of characteristicAvoid large fluctuationsGrain huskingGrain polishingEngineeringMechanical engineering

A raw garbage treatment apparatus including a treatment tank 10, a rotating shaft 32 which rises in an upright attitude from the center of the bottom of the treatment tank, a motor 36 which rotates the rotating shaft from beneath the treatment tank, a plurality of rotating blades 58 which have cutting vanes 58A that extend outward with the rotating shaft as the center and which are provided on the rotating shaft at intervals from each other, a plurality of fixed blades 60 through which the rotating shaft rotatably passes and which form a main cutter A together with the rotating blades, and a supporting frame 38 which has vertical plates 40 that hold the outer end portions of the fixed blades and whose upper end is fastened to the upper portion of the inside of the treatment tank.

Owner:IZUMI PROD CO

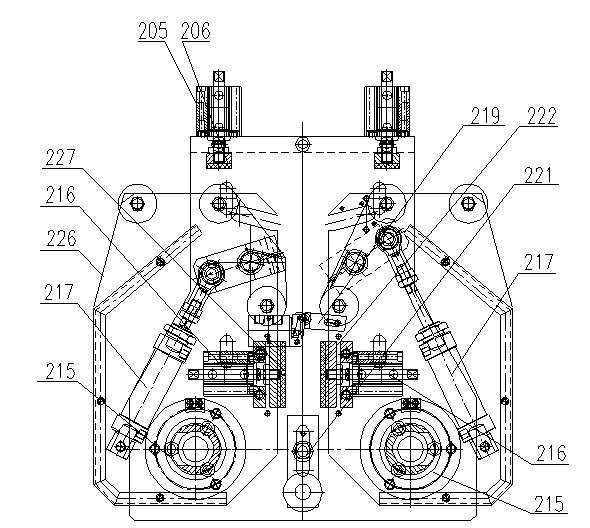

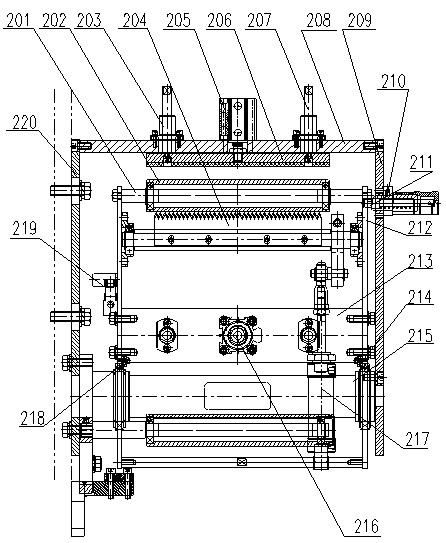

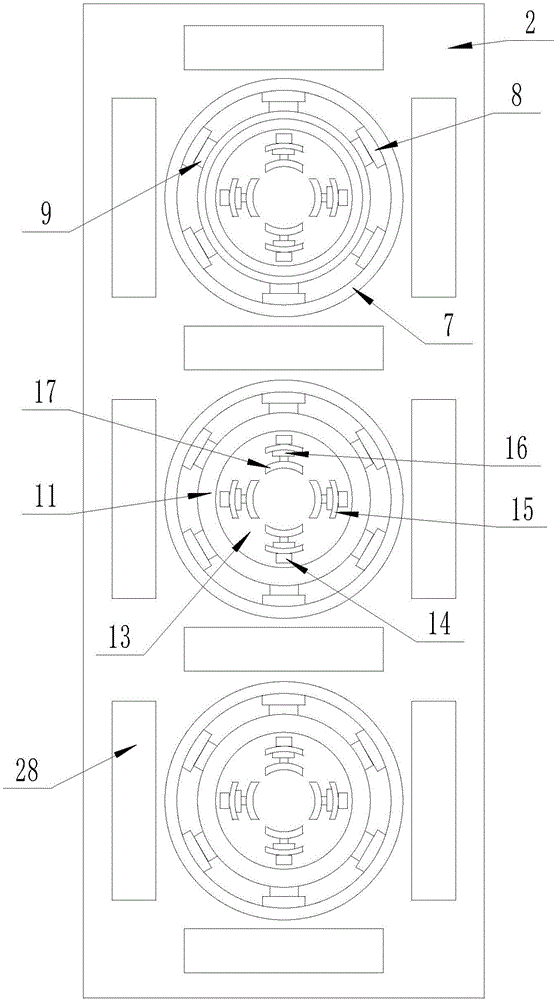

Multistage juice and peel separating device for passion fruits

The invention discloses a multistage juice and peel separating device for passion fruits. The separating device includes a feeding mechanism, main shaft power mechanisms, grab bucket mechanisms, a linear cutting mechanism, juice separation mechanisms, spongy layer separation mechanisms, popup mechanisms, a push-in roller mechanism and a peel separation mechanism; the feeding mechanism is installedat the upper part on the rear side of a supporting platform; the two main shaft power mechanisms are symmetrically arranged on the supporting platform; four grab bucket mechanisms in circumferentialuniform distribution are installed on each main shaft power mechanism in a radial direction; the grab bucket mechanisms are provided with openings corresponding to the supporting platform; the linearcutting mechanism is installed on the rear side of the supporting platform; the two juice separation mechanisms are symmetrically installed at the lower parts of the openings; the two spongy layer separation mechanisms are symmetrically installed on the two sides of the supporting platform; the popup mechanisms are installed at the rear parts of the grab bucket mechanisms; the push-in roller mechanism is installed in front of the grab bucket mechanisms; and the peel separation mechanism is installed at the lower part of the discharging port of the push-in roller mechanism. Thus, the multistageprocessing of the juice and peels of the passion fruits can be realized, processing can be automated, so that the separating device is time saving and labor saving.

Owner:GUIZHOU UNIV

Cutting apparatus and printing apparatus

ActiveUS10124609B2Reliably cut a sheetReduce cutting timeOther printing apparatusMetal working apparatusStructural engineeringIndustrial engineering

Owner:CANON KK

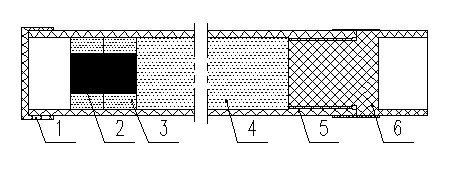

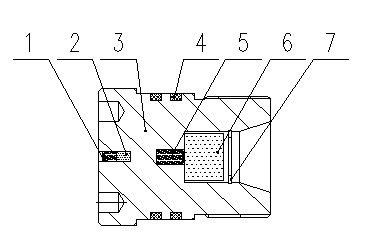

Underwater cutting releasing mechanism

The invention discloses an underwater cutting releasing mechanism which mainly comprises a guide sheet, a cutting knife cavity, a baffle ring, a cutting knife, breakable pins, a piston-type pull pin, a basal body, an igniter, pressure rings, a communication cable, a watertight joint, a sealing cushion, a gasket, protective sleeves, a screw, a communication floater, and the like. The underwater cutting releasing mechanism is characterized in that the appearance is in a cylindrical structure with a smooth surface; one side of the basal body is provided with a TT-shaped groove, a hole in the vertical surface of the TT-shaped groove is sequentially provided with the piston-type pull pin, the cutting knife, the protective sleeve, the communication cable, the baffle ring, the cutting knife cavity and relative sealing rings, and a hole in the horizontal surface of the TT-shaped groove is sequentially provided with the watertight joint, a sealing ring, the gasket, the protective sleeves and the pressure rings; and a passage structure is formed at the bottom edge of the basal body from a gas passage start in the mounting position of the igniter to a gas passage end in the position of the piston-type pull pin.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

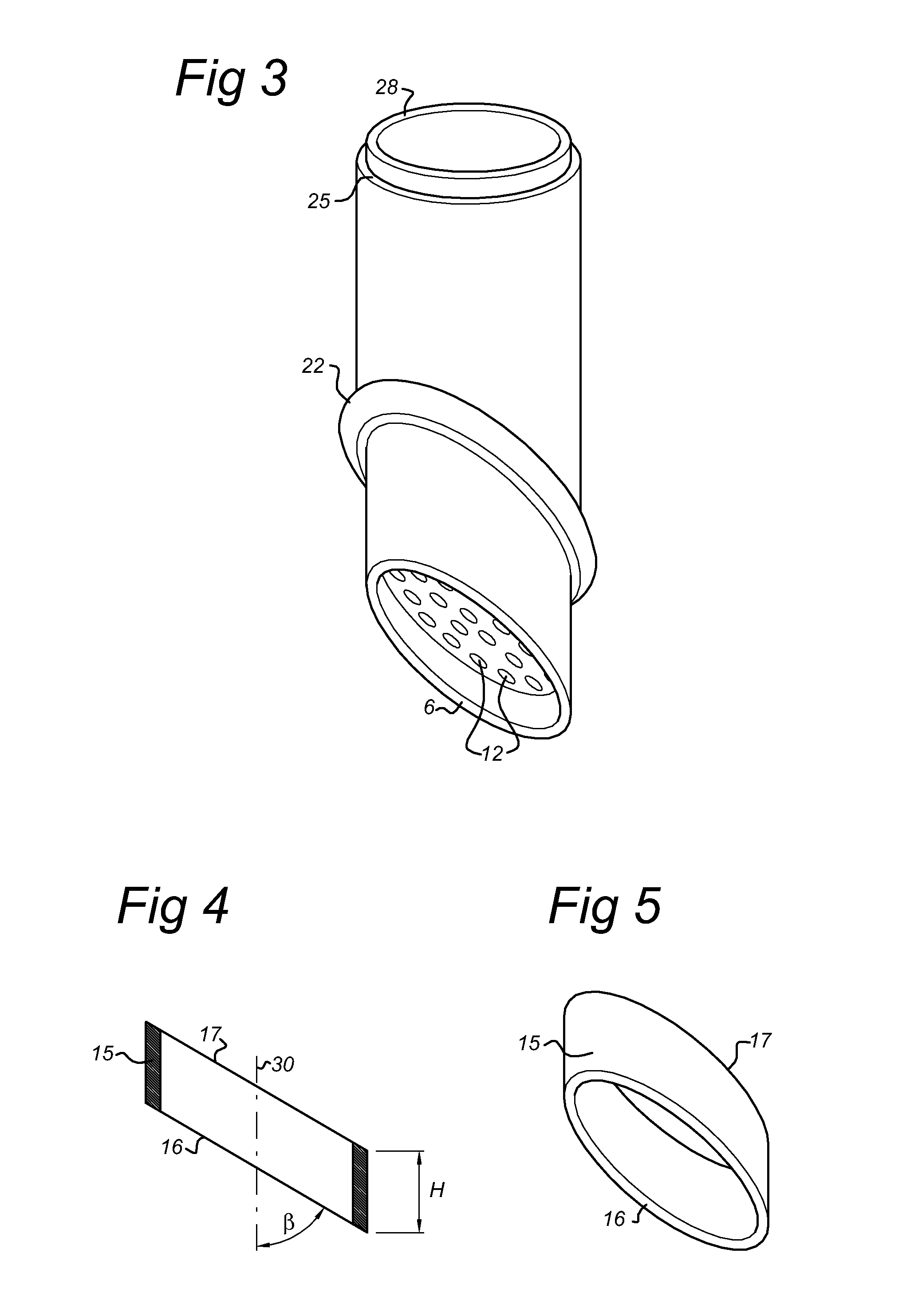

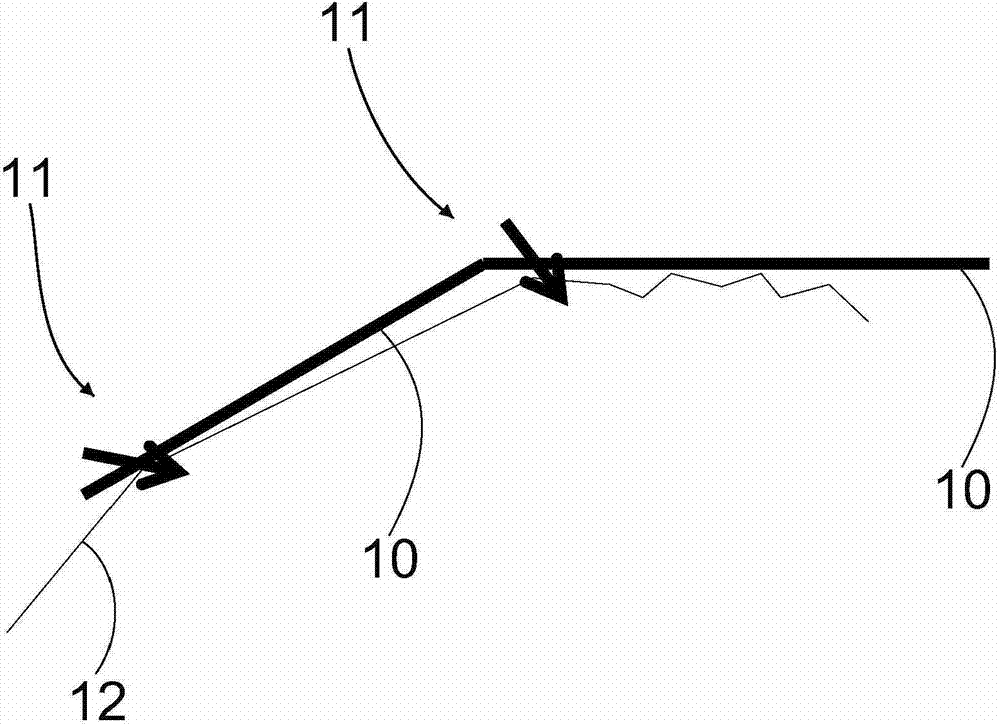

Web guiding device and guiding belt separation device used for fibrous web machine and

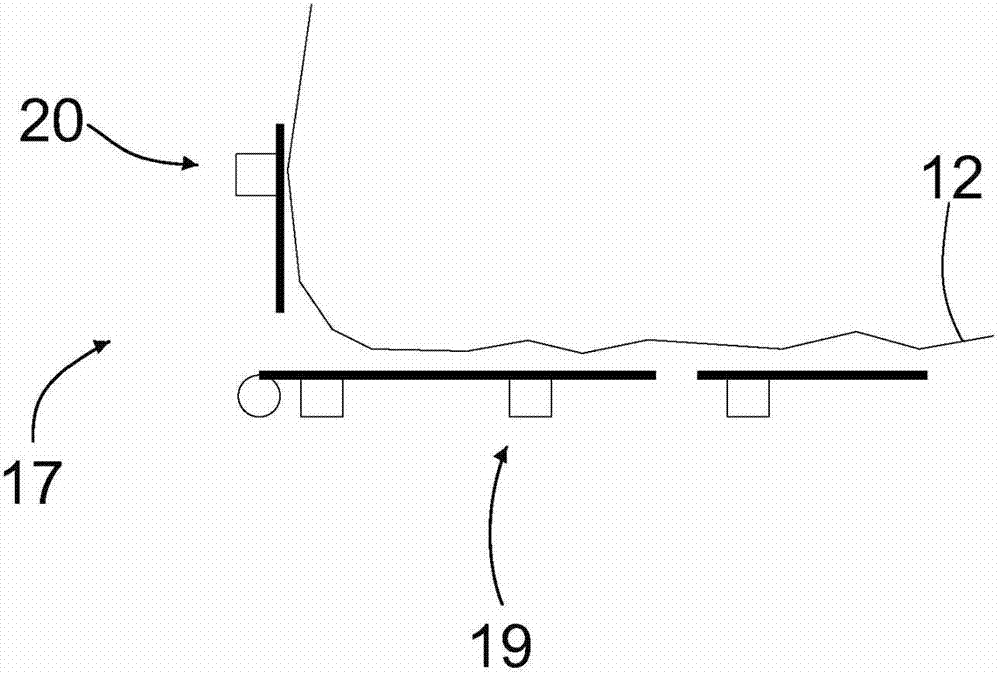

ActiveCN102817275AEasy to cutReliable cuttingMachine wet endPress sectionMechanical engineeringDeflection angle

The invention relates to a web guiding device for a fiber web machine. The web guiding device is provided with a guiding surface (10), and each guiding blowing device (11) used for conveying a guiding belt (12) is aligned with the guide surface (10). The device is arranged to be, between two mutually succeeding guiding blowing devices (11), the deflection angle beta between guiding belt moving directions defined by a stop position (15) formed via a second blowing position (14) and the average moving direction of the guiding belt (12) on a first blowing position (13) of the guiding belt (12) is 10DEG -70 DEG, preferably 30 DEG -60 DEG. The invention also relates to a guiding belt separation device for a fibrous web machine.

Owner:VALMET TECH OY

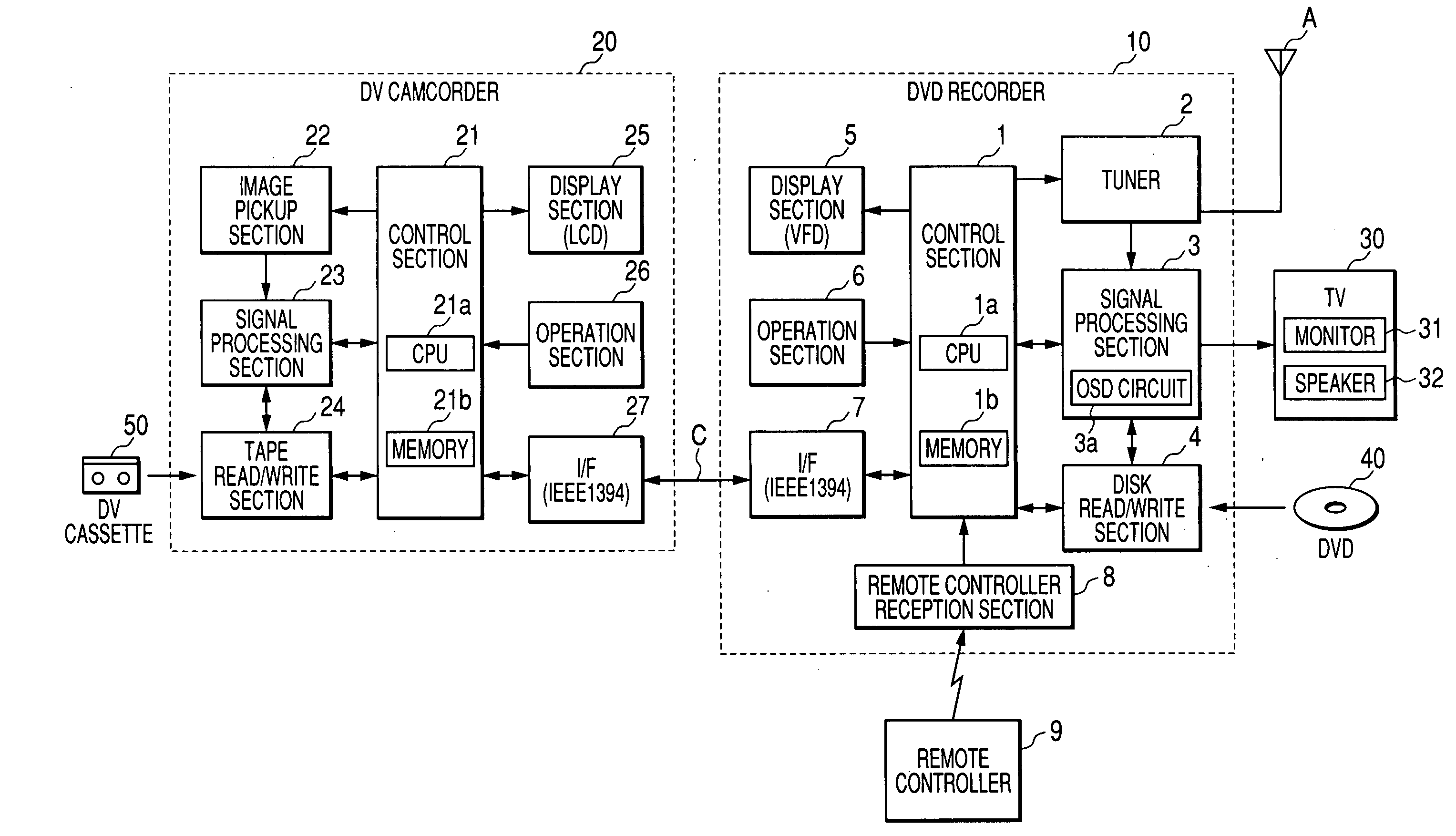

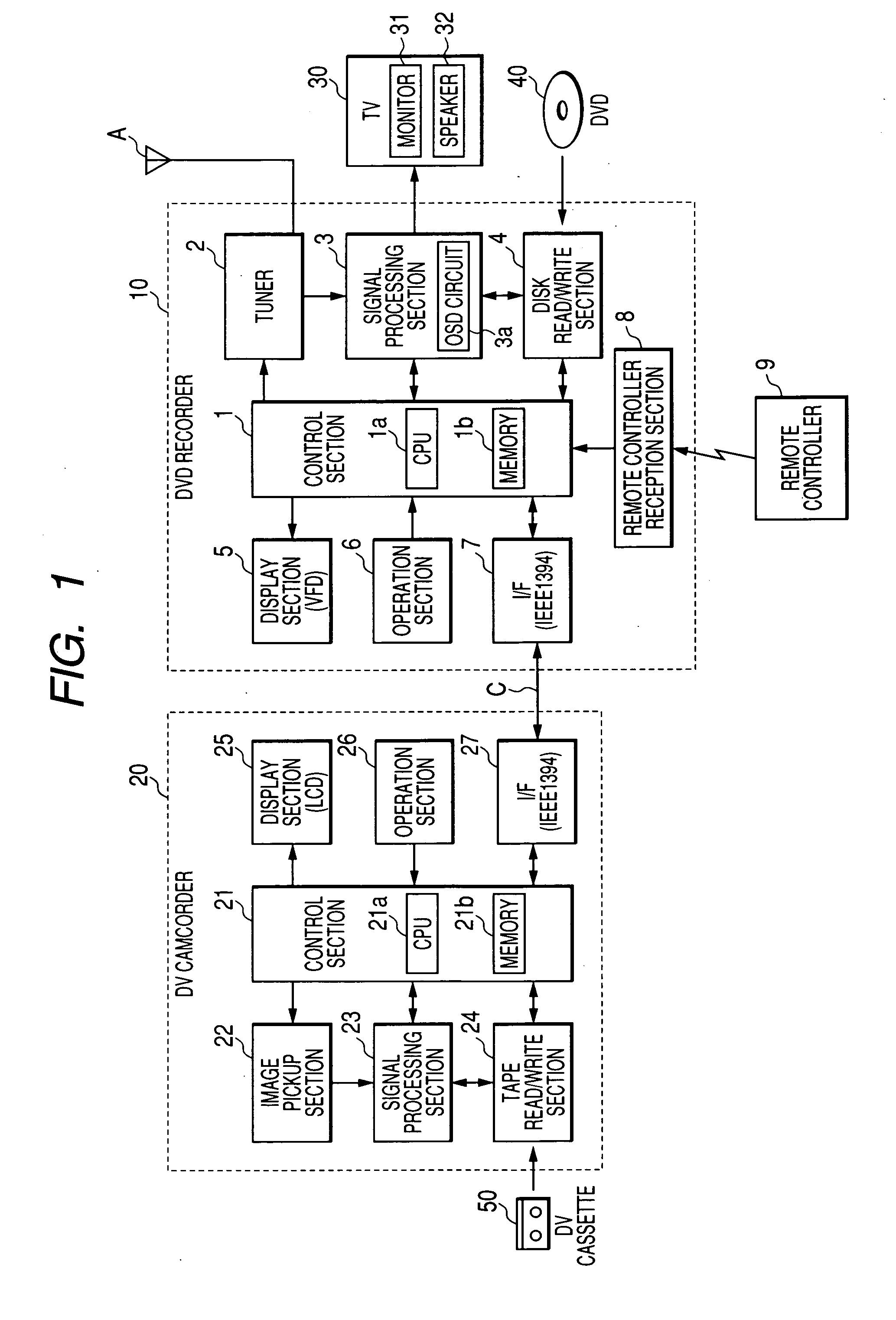

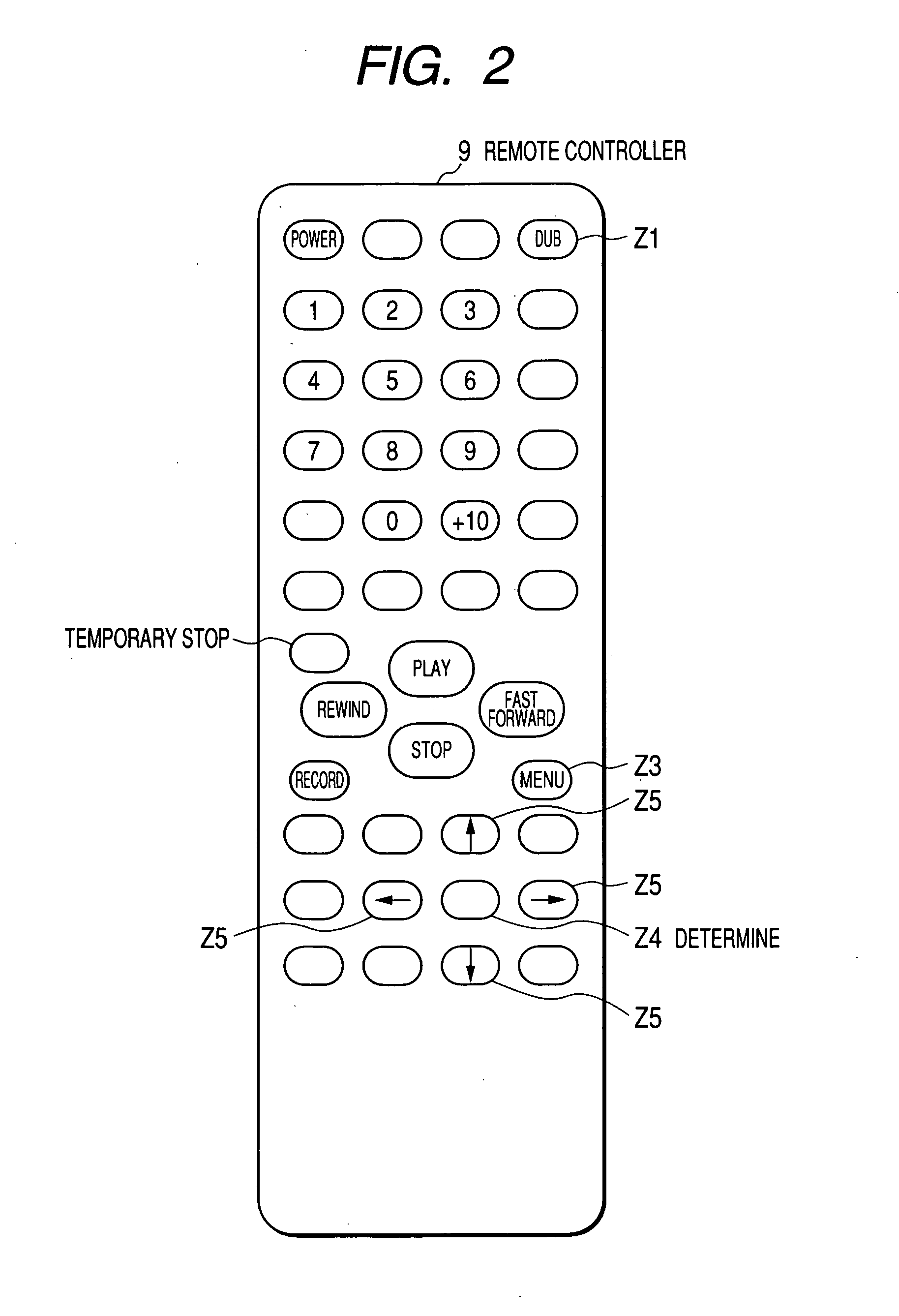

Video record apparatus

InactiveUS20050259975A1Reliable cuttingTelevision system detailsElectronic editing digitised analogue information signalsVideo recordDVD recorder

When a video is input from a DV camcorder connected through an IEEE 1394 interface, a DVD recorder displays the input video in a dubbing screen displayed on a monitor of a television and starts dubbing the input video on a DVD. Subsequently, the DVD recorder displays a DV scene cut key for entering a temporary stop command of dubbing the input video on the monitor together with the input video. When the user operates the DV scene cut key with a remote controller, the DVD recorder temporarily stops dubbing the input video on the DVD. Accordingly, it is made possible to dub in a short time while the user reliably cuts the unnecessary scene of the input video being dubbed by properly operating the DV scene cut key just after display of the unnecessary scene is started on the monitor.

Owner:FUNAI ELECTRIC CO LTD

Cutter mechanism and printer with a cutter

ActiveUS8506190B2High swinging propertyReliable cuttingTypewritersOther printing apparatusKnife bladesEngineering

A cutter mechanism has a fixed blade and slidable blade which cooperates with the fixed blade to cut a recording sheet. The fixed blade is biased in a direction away from a base portion by a biasing member. A holder supports the fixed blade away from the base portion to cause a cutting edge of the fixed blade to swing up and down and permit opposite ends of the fixed blade to be pushed down at least in the direction of the base portion. The fixed blade holder has a wall portion positioning the fixed blade in a sliding direction of the slidable blade, a first regulating member that regulates lifting of the fixed blade cutting edge, and a second regulating member that regulates lifting of the fixed blade root portion in a state in which a gap is formed between the base portion and the root portion.

Owner:SEIKO INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com