Device for transferring a band-shaped weft material

A weft yarn and ribbon-shaped technology, which is applied in the field of devices for introducing components, can solve the problems of damaging the ribbon-shaped weft yarn, troublesome laser mechanical drive, and large structural space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

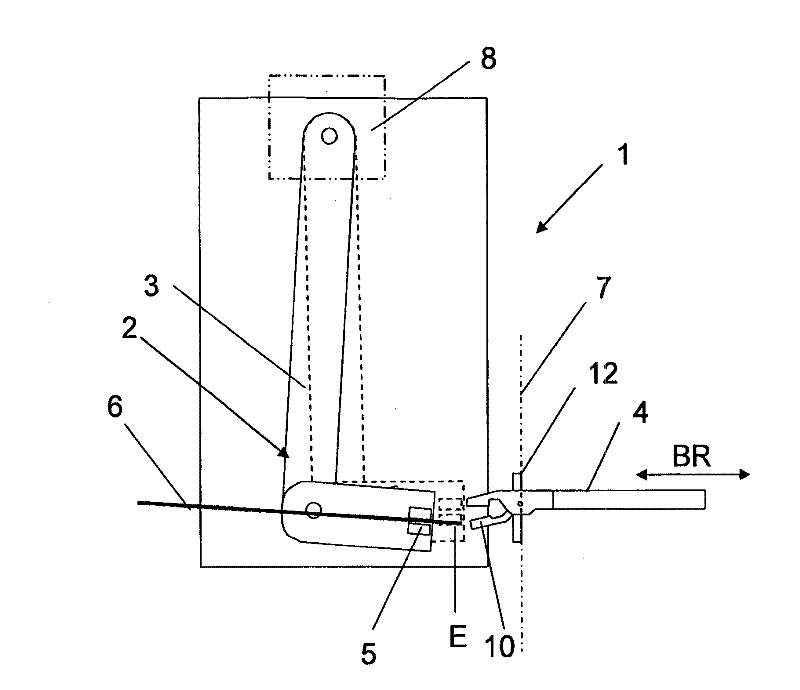

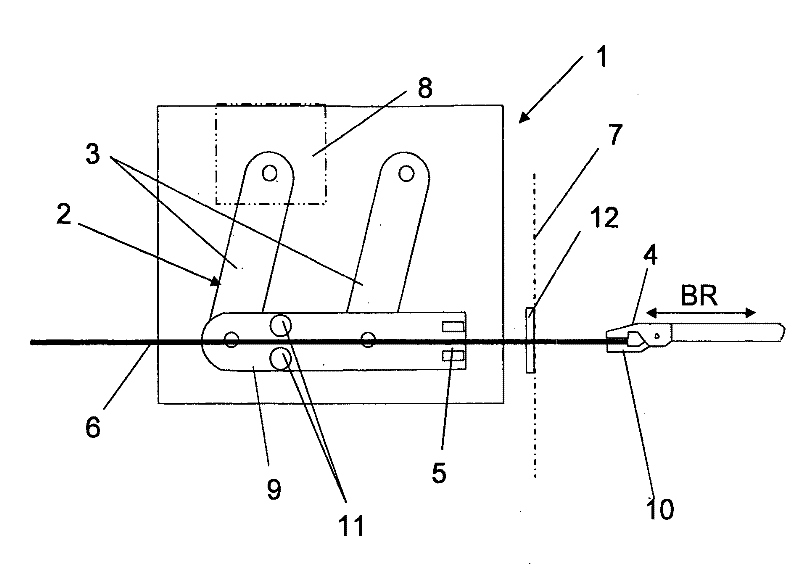

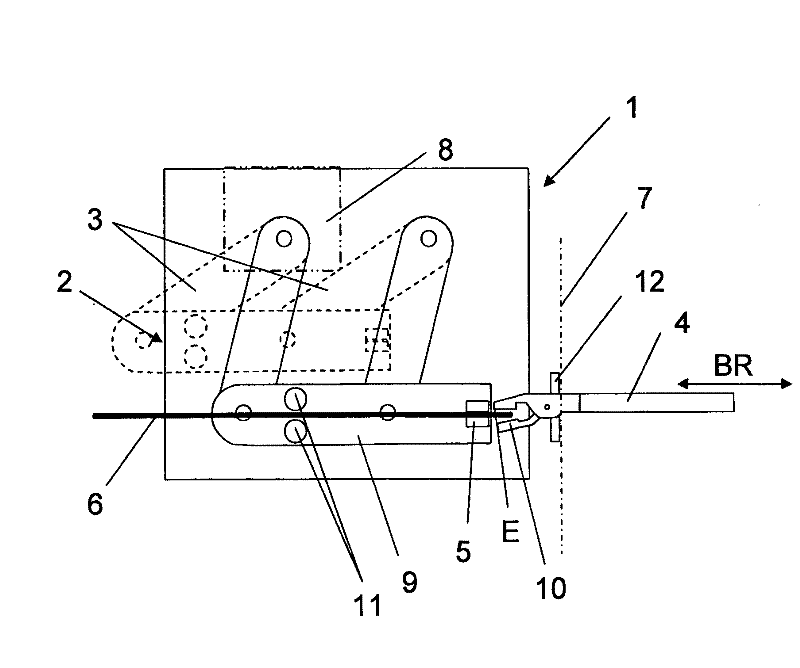

[0035] figure 1 A device 1 according to the prior art is shown for feeding strip-shaped weft threads 6 with a pivot unit 2 having only one pivot arm 3 . The device 1 feeds a weft thread 6 from a delivery unit (not shown here) to the insertion part 4 of the weaving machine. The delivery unit can be formed by storage bobbins, accumulators or pre-bobbins or feeders, which respectively unwind the required weft yarn lengths from bobbins and make them available. The insertion element 4 here is formed by the weft gripper of the weaving machine, but it can likewise be inserted by means of transmitters or other insertion elements. The device 1 comprises a clamping device 5 , which clamps and fixes a weft thread 6 after the weft thread has been inserted and cut for this purpose, for subsequent relaying of the weft thread in front of the insertion element 4 . The insertion element 4 receives the free end of the weft thread 6 on the device-side product edge 7 of the device 1 and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com