Pure electric wheelhub drive axle unit

A technology for driving axles and electric wheels, which is applied in the direction of electric power devices, power devices, control devices, etc., and can solve the problems of uneven load, large energy consumption, and high processing and manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

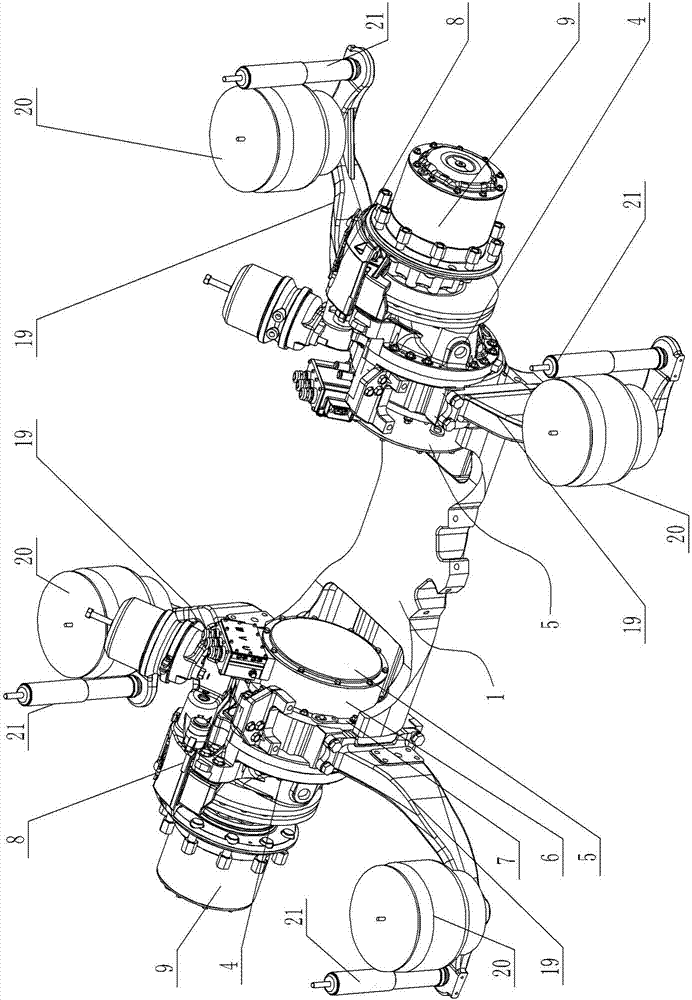

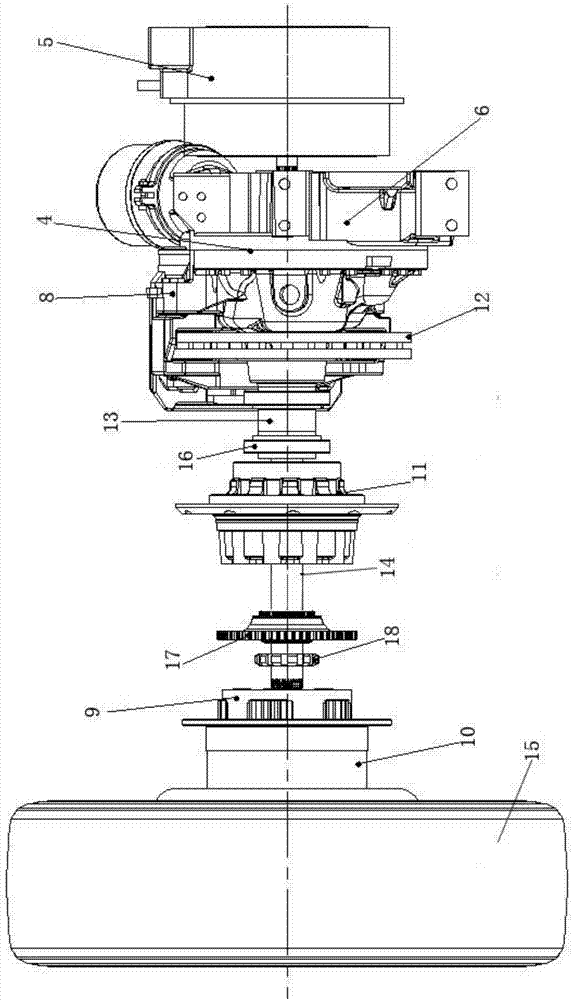

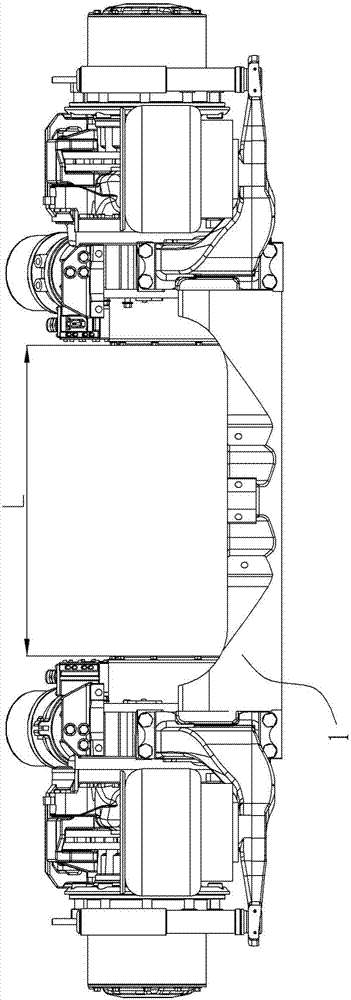

[0018] A pure electric wheel drive axle unit, see figure 1 : It includes a main bridge body 1, the main bridge body 1 is a left-right symmetrical arrangement structure, the two sides of the main bridge body 1 are respectively provided with motor arrangement slots 2, and the two sides of the main bridge body 1 are provided with positioning threaded holes 3, The housings of the wheel-side reducers 4 on both sides are fixedly connected to the positioning threaded holes 3 on the corresponding side end faces by bolts, the driving motor 5 on the corresponding side is located in the motor arrangement groove 2, and the motor seat 6 on the corresponding side of the driving motor 5 is connected to The flange 7 is connected to the inner end surface of the shell of the wheel reducer 4 at the corresponding position, the outer end surface of the shell of the wheel reducer 4 is fixed with a brake assembly 8, and the output end of the wheel reducer 4 is connected to the input of the planetary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com