Grinding attachment suitable for freely curved face

A surface and grinding technology, applied in the field of free-form surface grinding devices, can solve the problems of long rotating support arm of grinding head, uneven grinding thickness, high management cost, and achieve machining accuracy and surface quality assurance of profile, The machining accuracy is guaranteed and the effect of improving the dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

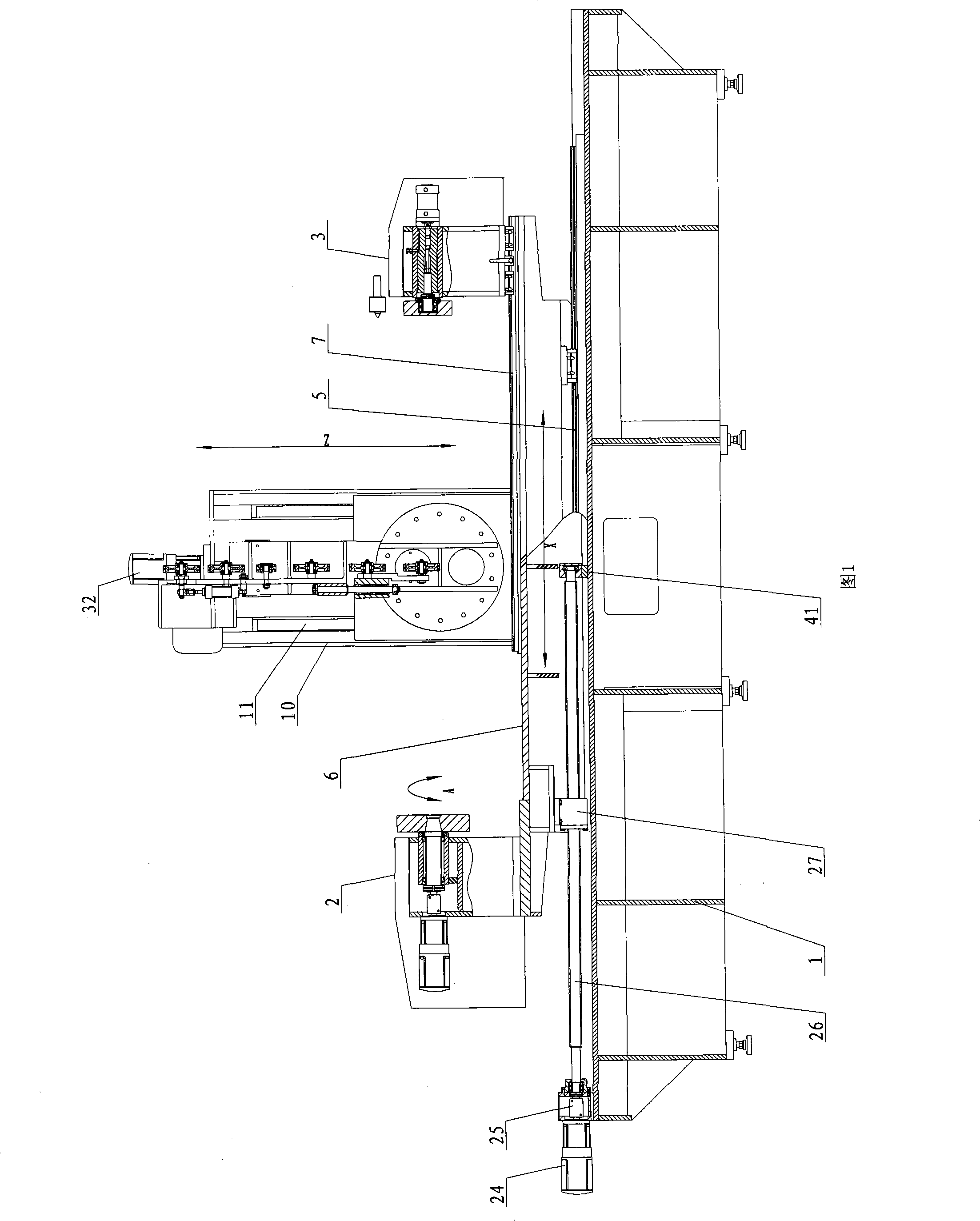

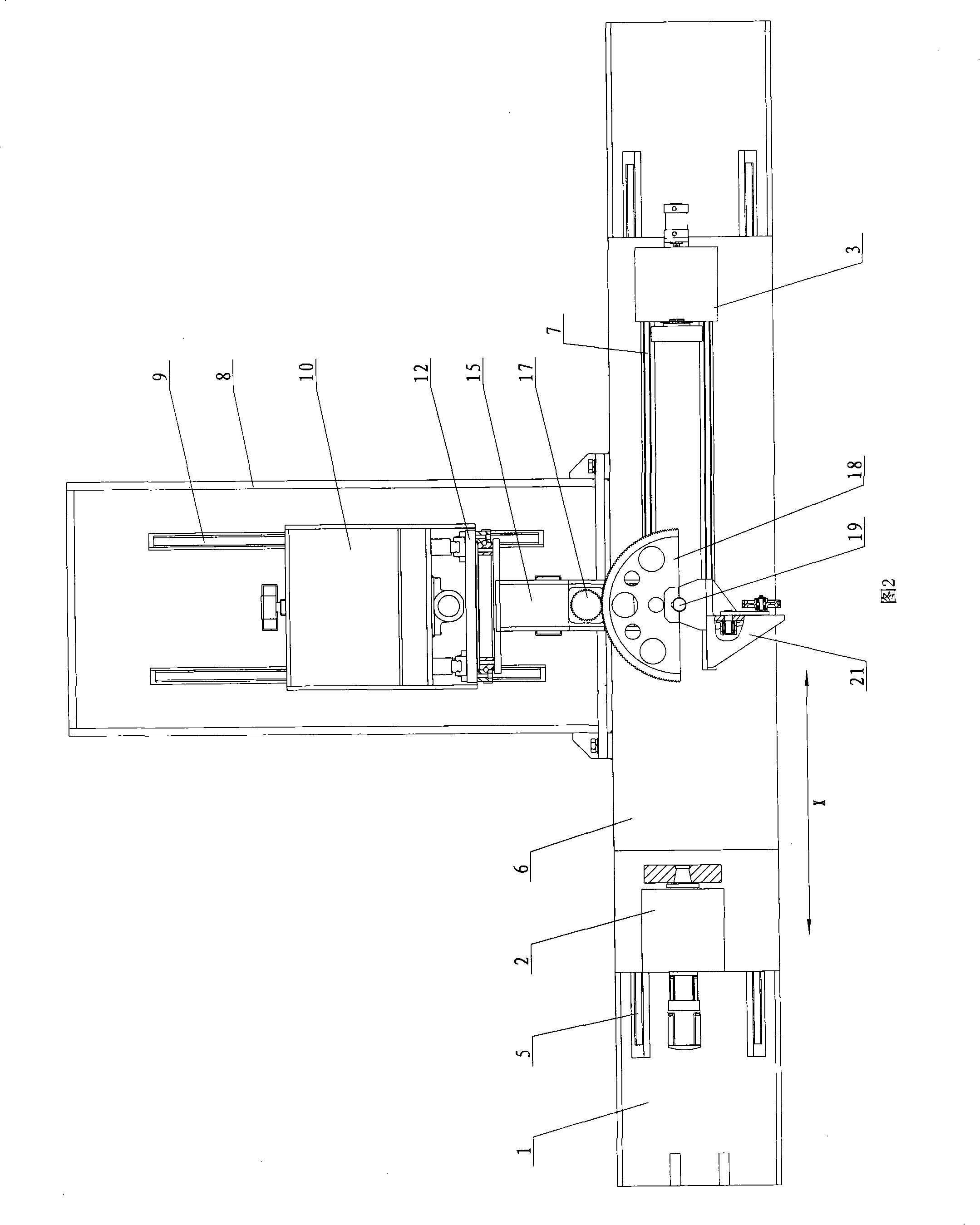

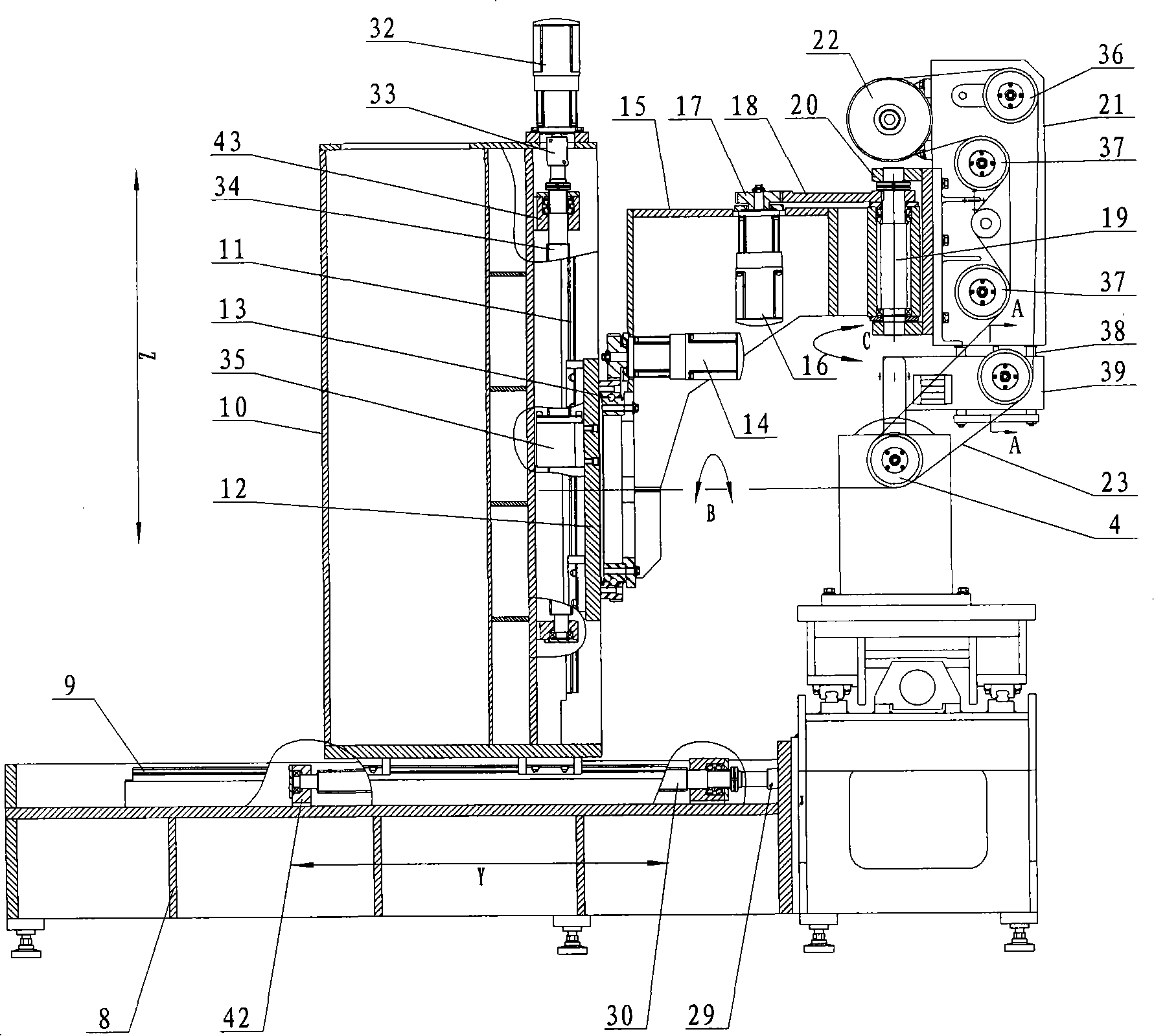

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0029] As shown in Fig. 1, Fig. 2 and Fig. 5, two X-axis guide rails 5 are arranged parallel to the upper surface of the X-axis bed 1 along its length direction, and a workpiece table 6 is supported on the X-axis guide rails 5 . An X-axis servo motor 24 is installed on one end of the upper surface of the X-axis bed 1, and the X-axis servo motor 24 is connected with one end of the X-axis ball screw 26 through a coupling 25, and the X-axis ball screw 26 is supported by two bearings On the corresponding bearing seat 41 , the bearing seat 41 is fixed on the upper surface of the X-axis bed 1 . A screw nut seat 27 is set on the X-axis ball screw 26, and the screw nut seat 27 is fixed on the bottom of the workpiece table 6. When the X-axis servo motor 24 is running, it drives the X-axis ball screw 26 to rotate together, and The screw nut seat 27 matched with the X-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com