Device and method for removing a sterile object from a sterile packaging

An object and cutting device technology, which is applied in the directions of unsealing, packaging, transportation and packaging of packaging objects, can solve the problems of failure, removal, and inability to take out the conveying container in the take-out facility, and achieves the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

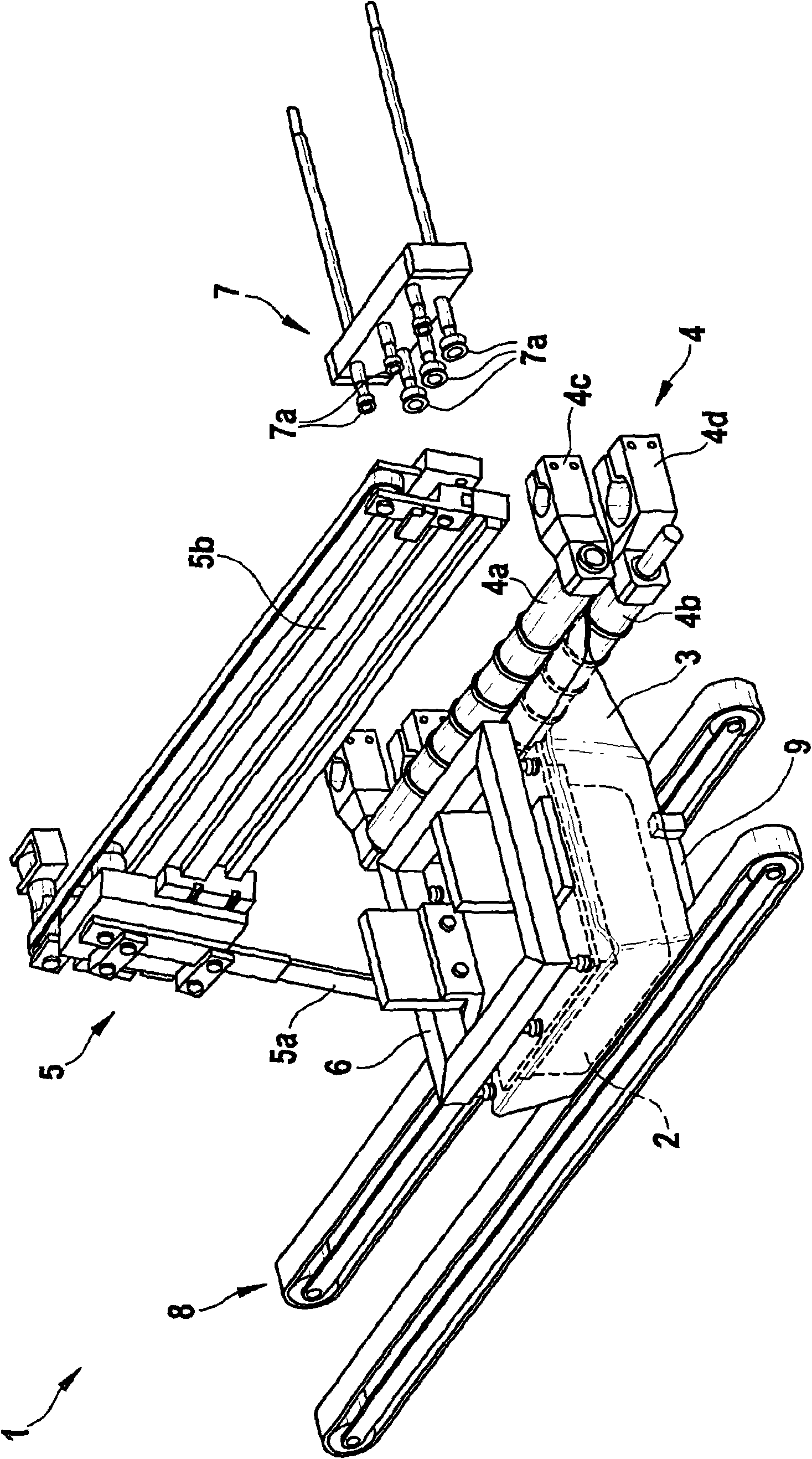

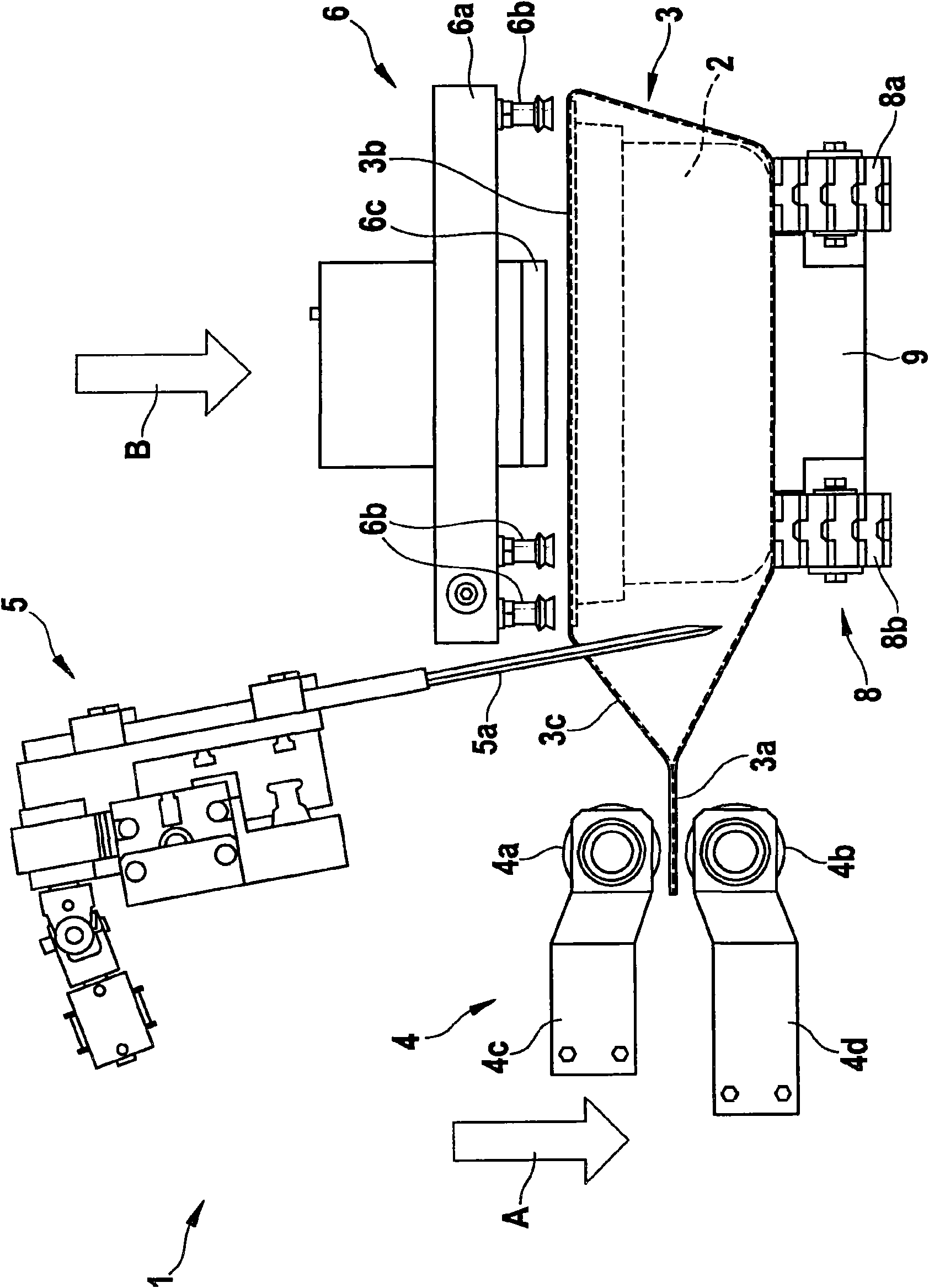

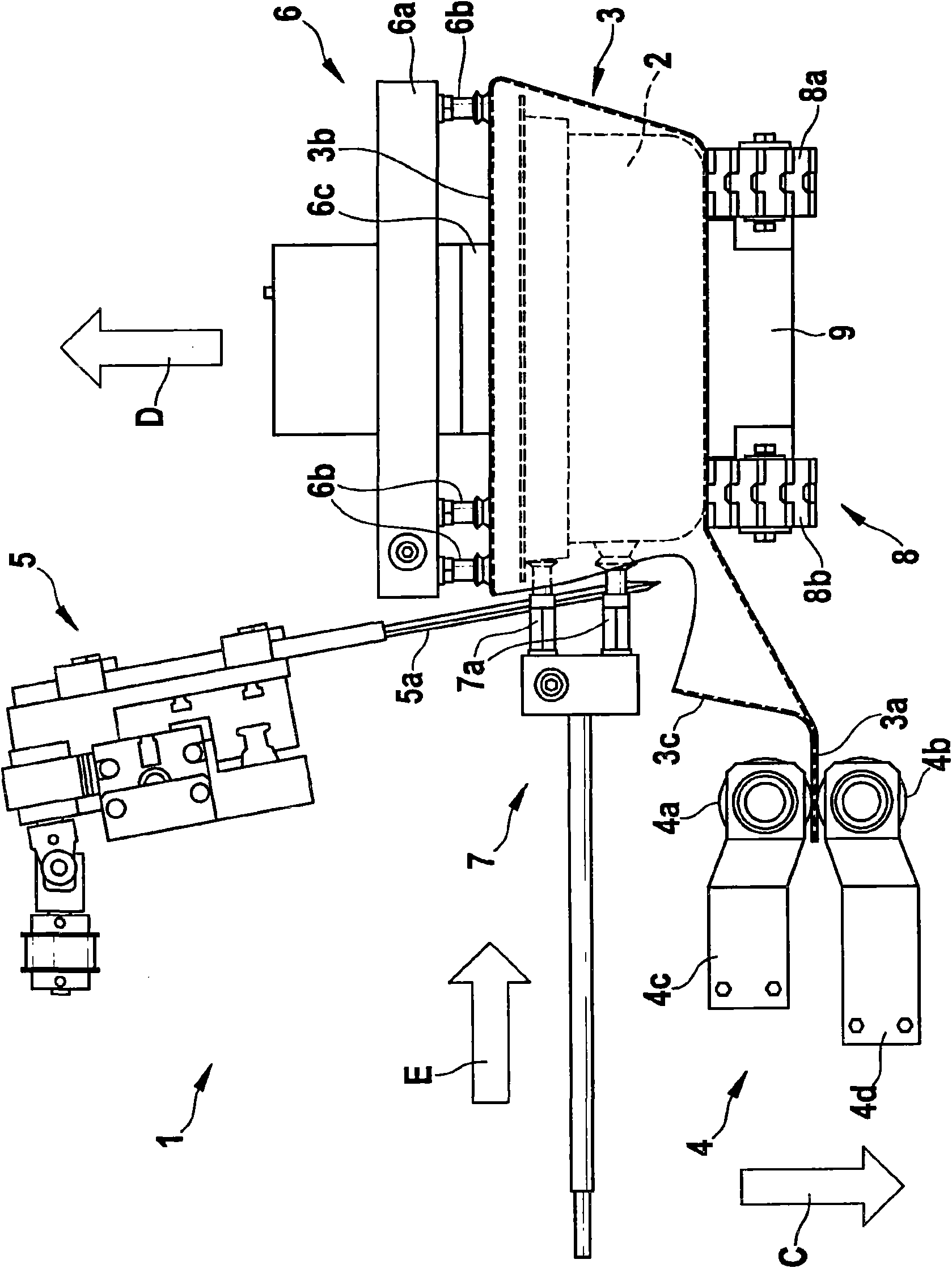

[0023] Refer below Figures 1 to 5 A device 1 for removing sterile objects 2 from sterile packaging 3 is described in detail. The sterile packaging 3 is here a plastic film.

[0024] as in figure 1 As shown in , the device 1 for removing sterile objects 2 includes a clamping device 4 , a cutting device 5 , a holding device 6 and a removal device 7 . The clamping device 4 clamps the first partial area 3 a of the sterile packaging 3 . as from figure 2 It can be seen that the first subregion 3 a is an outwardly protruding web of the foil packaging. The web extends over the entire width of the film packaging. The clamping facility 4 comprises a first clamping roller 4a and a second clamping roller 4b. The first clamping roller 4a is supported on a first support arm 4c and the second clamping roller 4b is supported on a second support arm 4d. Such as figure 2 As indicated by arrow A in , the first support arm 4c can move relative to the second support arm 4d. The two cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com