Eccentric clamping device

An eccentric clamping and eccentric wheel technology, applied in the field of fixtures, can solve the problems of limiting the use of ordinary cam clamping mechanisms, inability to achieve effective clamping, and increased production and processing costs. It achieves simple structure, rapid action, and reduced production. The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

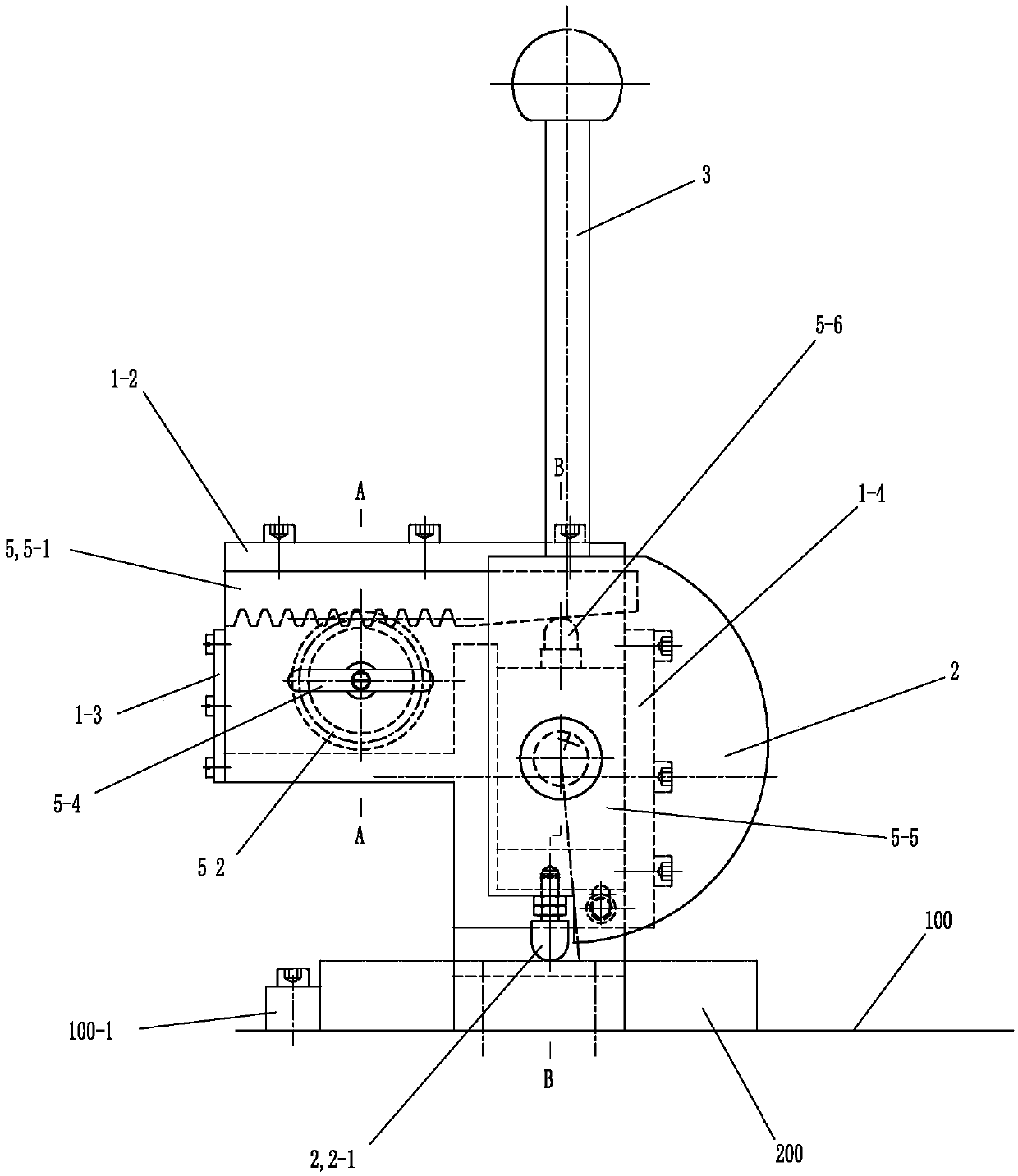

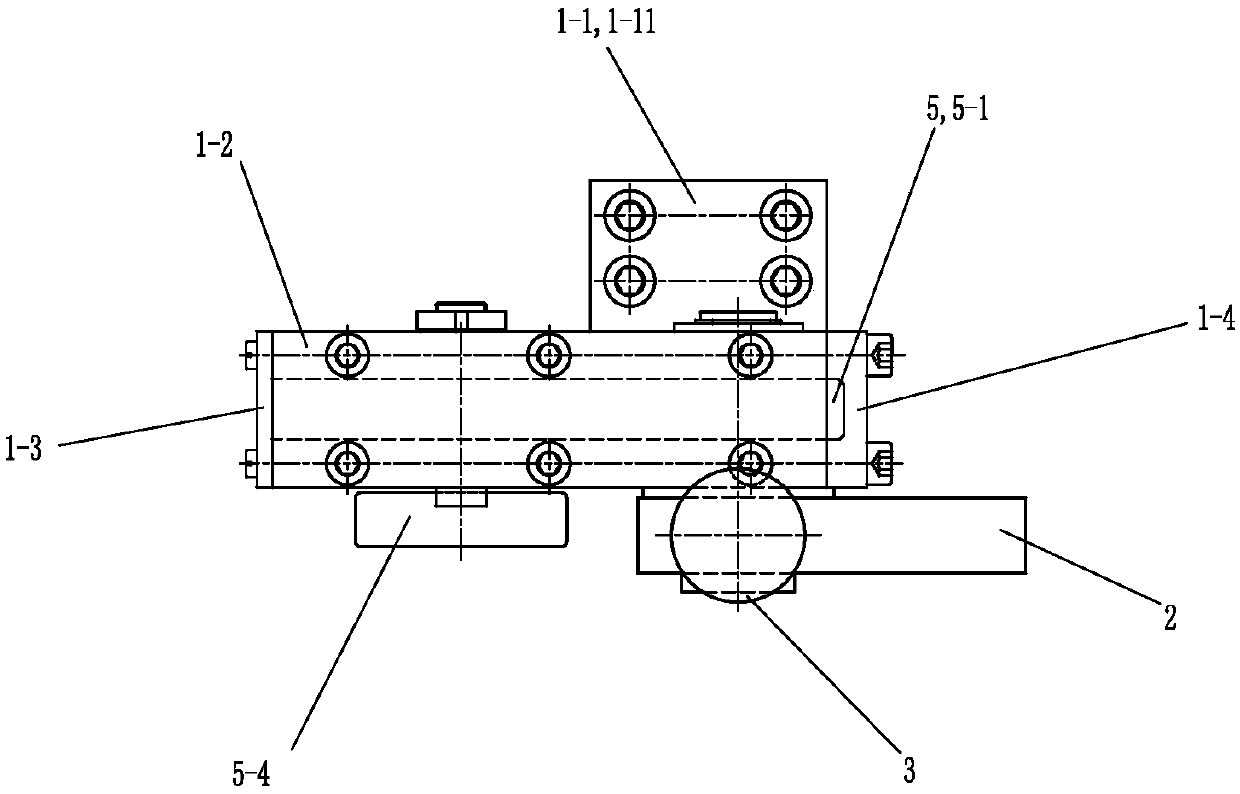

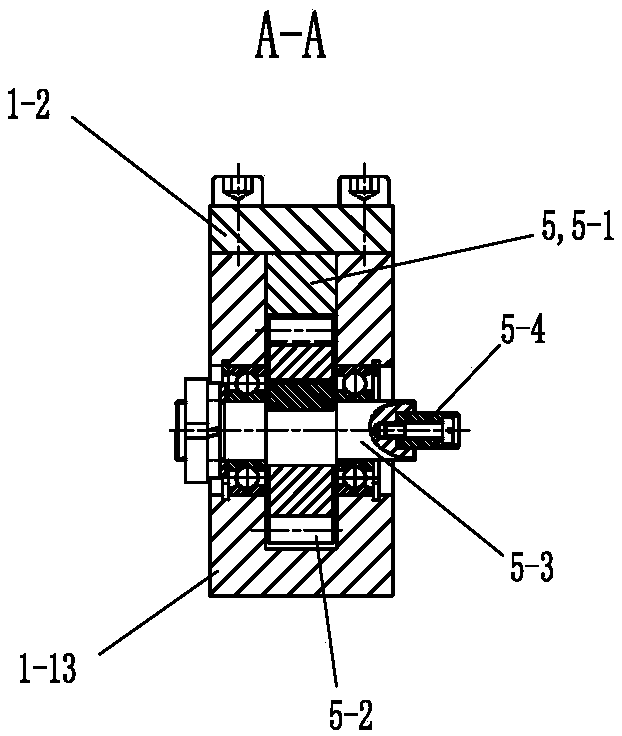

[0027] See Figure 1 to Figure 12 , The eccentric clamping device of the present invention includes a clamp seat, an eccentric cam 2 , a pressing handle 3 , a positioning assembly 4 and an eccentric adjustment assembly 5 .

[0028] See Figure 1 to Figure 7 , The fixture seat includes a fixture body 1-1, an upper cover plate 1-2, a left cover plate 1-3 and a right cover plate 1-4. The clamp body 1-1 is an integral piece made of steel. The clip body 1-1 includes a fixed connection part 1-11 at the lower part, a cam installation part 1-12 at the upper part of the fixed connection part 1-11, and a second installation part 1-13 at the left side of the cam installation part 1-12. The fixed connection portion 1 - 11 of the clamp body 1 - 1 is used for fixedly connecting the clamp body 1 - 1 to the corresponding workbench 100 . The cam mounting part 1-12 is provided with a sliding block mounting groove 1-12-1 opening upwards and to the right. The middle part of the cam mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com